Page 1

Technical Note

English

HBM public

GEN series 1 kV Input

Cards GN610 and GN611

Isolation and Type

Testing

Page 2

GN610, GN611 Isolation and type testing

1 International standards for test equipment safety

1.1

Measurement categories

l

The international standards for test equipment safety are the IEC 61010-1

and the IEC 61010-2-030.

l

IEC 61010-1 defines three overvoltage categories (CAT II, CAT III, and

CAT IV) on the power supply side of an instrument.

l

IEC 61010-2-030 defines three measurement categories (CAT II, CAT III,

and CAT IV) on the measurement input side of an instrument, for

measurement inputs which can be directly connected to mains.

l All measurement inputs, which are not specified to be connected to mains,

have no CAT rating and are referred to as O (like

Categories according to IEC 61010-2-030:2010

Electrical equipment, specifically measurement tools can according to IEC

61010-2-030:2010 be assigned into 4 categories. These measurement

categories are indicated with the terms O (previously CAT I), CAT II, CAT III

and

CAT IV. Originally these categories are used to indicate the overvoltage or

surge voltage that is likely to occur and can be sustained by the equipment.

Actually the category indicates the amount of energy that can be released in

the event of a short circuit. A higher category number indicates a higher energy

level that can occur and can be sustained by the equipment.

O (Other) (previously referred to as CAT I): This category is for measurements

not directly connected to mains. Think of measurement of: signal levels,

regulated low voltage circuits or protected secondary circuits. For this category

there are no standard over voltage or surge impulse levels defined.

Others).

CAT II: This category is for measurements directly connected to low-voltage

mains. Think of measurement of: mains sockets in household applications or

portable tools. This category is expecting to have a minimum of three levels of

over current protection between the transformer and connection point of the

measurement. (See Figure 1.1).

CAT III: This category is for measurements directly connected to the distribution

part of a low-voltage mains installation. Think of measurement of: circuit

breakers, wiring, junction boxes etc. This category is expecting to have a

minimum of two levels of over current protection between the transformer and

connection point of the measurement. (See Figure 1.1).

2 HBM public

Page 3

GN610, GN611 Isolation and type testing

CAT IV:

a low-voltage mains installation. Think of measurement of: over current

protection devices, ripple control units etc. This category is expecting to have

a minimum of one level of over current protection between the transformer and

connection point of the measurement circuit. (See Figure 1.1).

Figure 1.1: Category indication according to IEC 61010-2-030:2010

This category is for measurements directly connected to the source of

Example:

voltage 1000 V DC.

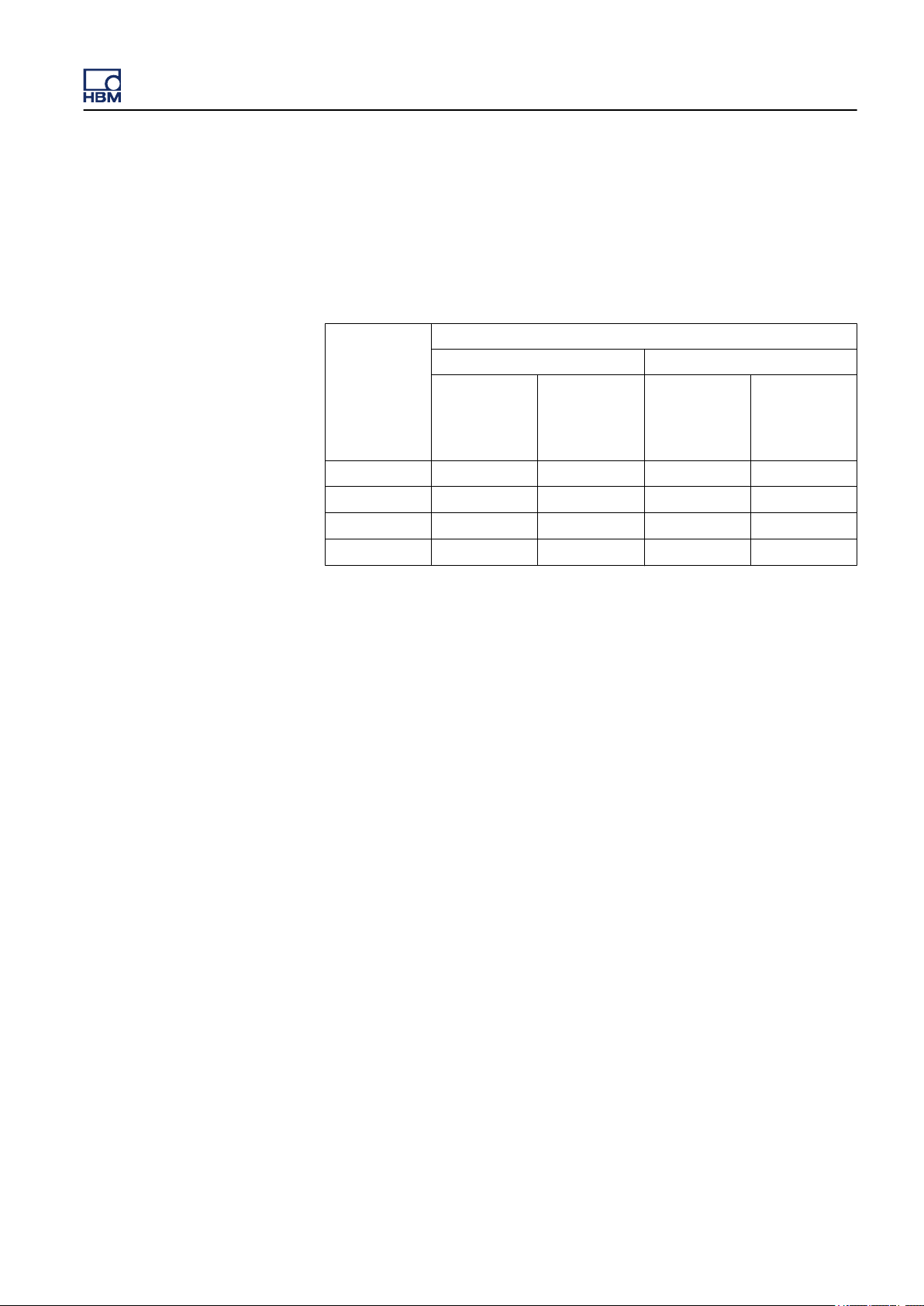

Table 1.1: Insulation test voltages according to IEC 61010

Nominal Voltage

(V RMS or V DC)

≤ 150

> 150 ≤ 300

> 300 ≤ 600

> 600 ≤ 1 000

Using the above table one can deduct that this specification informs the user

the device passed the insulation tests;

4.000 V. The maximum operating input voltage is 1000 V DC. This device is to

be used to measure CAT II circuitry up to 600 V.

A measurement device is specified as 600 V CAT II, maximum input

-2-

030:2010

IEC 61010-2-030:2010

5 sec. AC test (V RMS) Impulse test (V)

CAT II CAT III CAT IV CAT II CAT III CAT IV

840 1.390 2.210 1.550 2.500 4.000

1.390 2.210 3.310 2.500 4.000 6.000

2.210 3.310 4.260 4.000 6.000 8.000

3.310 4.260 6.600 6.000 8.000 12.000

5 sec at 2.210 V RMS and impulse

HBM public 3

Page 4

GN610, GN611 Isolation and type testing

WARNING

Measurement inputs of this instrument should not be used to measure

high-energy signals of measurement categories

CAT IV (IEC 61010-2-30:2010) (e.g. mains measurements) , unless

specifically stated for the specific input.

CAT II, CAT III or

4 HBM public

Page 5

GN610, GN611 Isolation and type testing

1.2 Basic versus reinforced insulation

For reference below one can find the basic insulation and supplementary

insulation as well as the reinforced insulation test values for CATII.

Table 1.2: Test voltages for testing electric strength of solid insulation in

measuring circuits of measurement category II (IEC 61010

-2-

30:2010)

Nominal

voltage line to

neutral a.c

r.m.s. or d.c. of

MAINS being

measured. (V)

≤ 150

> 150 ≤ 300

> 300 ≤ 600

> 600 ≤ 1000

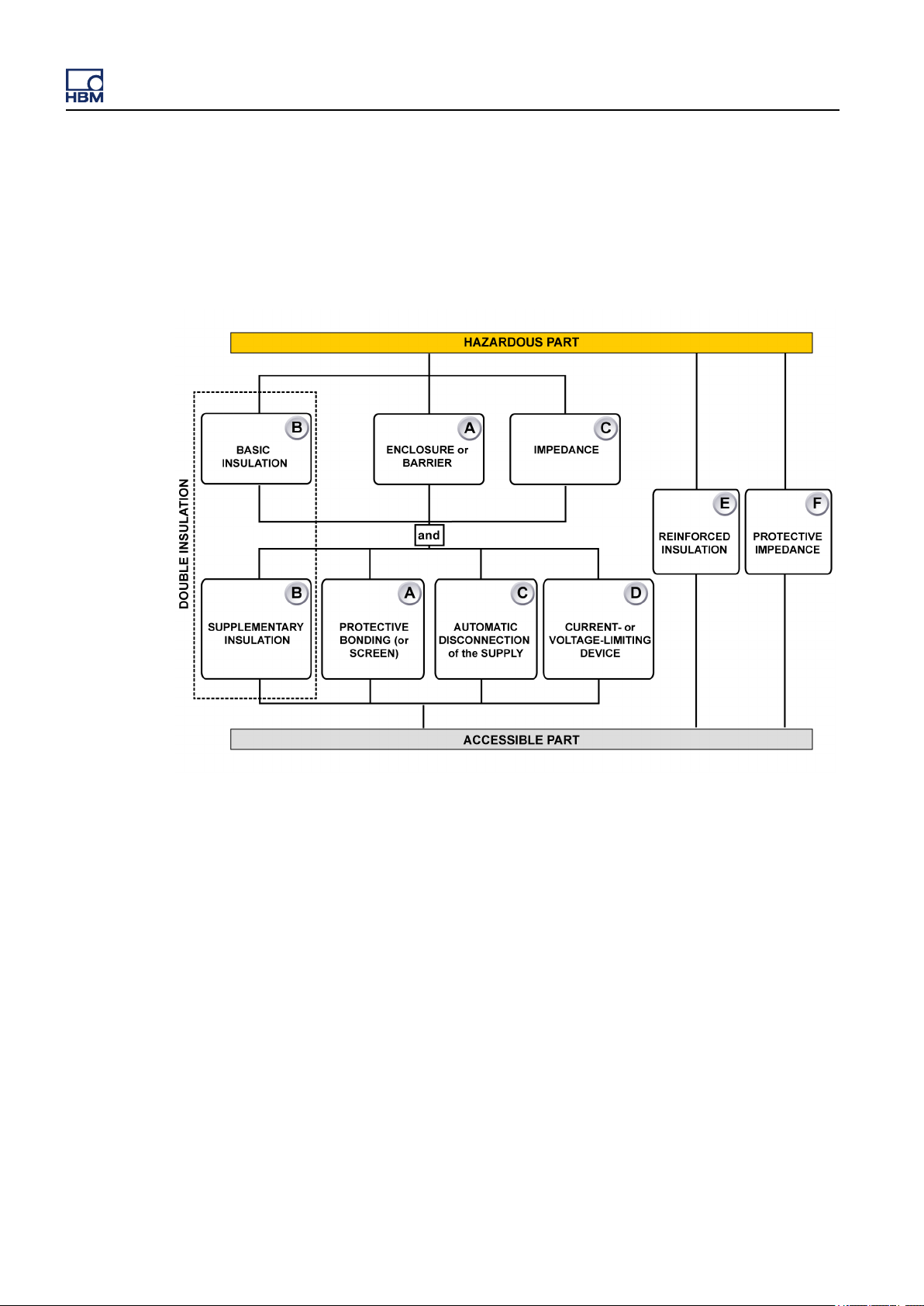

To protect a user from hazardous voltages there are several means of

protection possible. As one can see below basic insulation + supplementary

insulation is a possibility but also reinforced isolation is a means of protection.

The test voltages are different per means as can be found in the above table.

Test voltage

5 s a.c. test V a.c. r.m.s. Impulse test V peak

Basic

insulation and

supplementary

insulation

840 1390 1550 2500

1390 2210 2500 4000

2210 3510 4000 6400

3310 5400 6000 9600

Reinforced

insulation

Basic

insulation and

suplementary

insulation

Reinforced

insulation

HBM public 5

Page 6

GN610, GN611 Isolation and type testing

Additional means of protection in case of single fault conditions

Accessible parts shall be prevented from becoming HAZARDOUS LIVE IN

SINGLE FAULT CONDITION. The primary means of protection (see

Figure 1.2) shall be supplemented by one of A, B, C or D. Alternatively one of

the single means of protection E or F shall be used. See Figure 1.2

.

Figure 1.2: Acceptable

Example: A measurement device is specified as 600 V CAT II reinforced

insulation, maximum input voltage 1000 V DC.

Using the above information one can deduct that this specification informs the

user that the measurement device is tested on input to chassis ground 5 s at

3.510 V RMS and impulse 6.400 V. The maximum operating input voltage is

1000 V DC. This device is to be used to measure CAT II circuitry up to 600 V.

6 HBM public

arrangement of protective means against electric shock

Page 7

GN610, GN611 Isolation and type testing

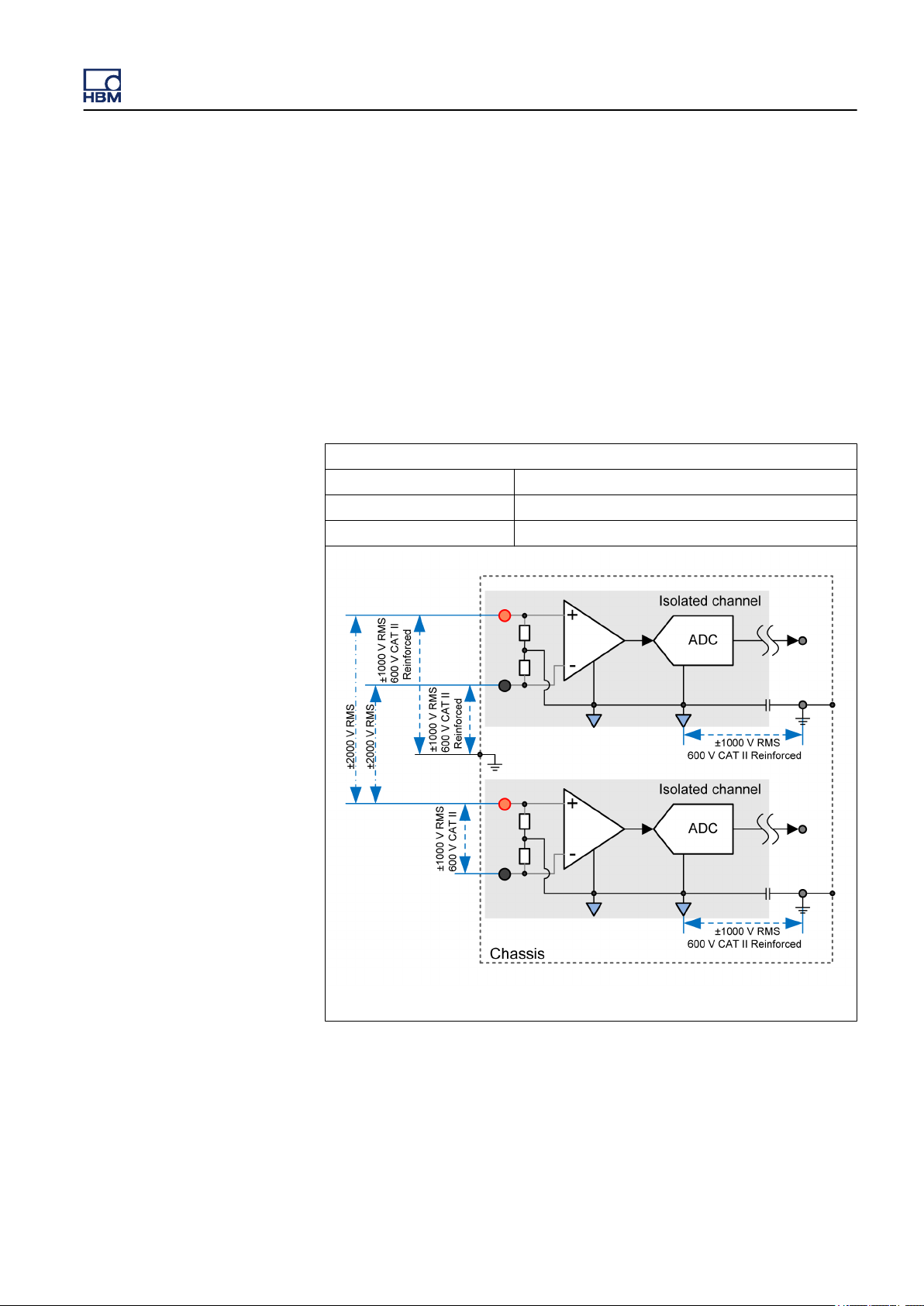

2 GEN series 1 kV input cards GN610, GN611

2.1

Isolation and input of the GN610, GN611

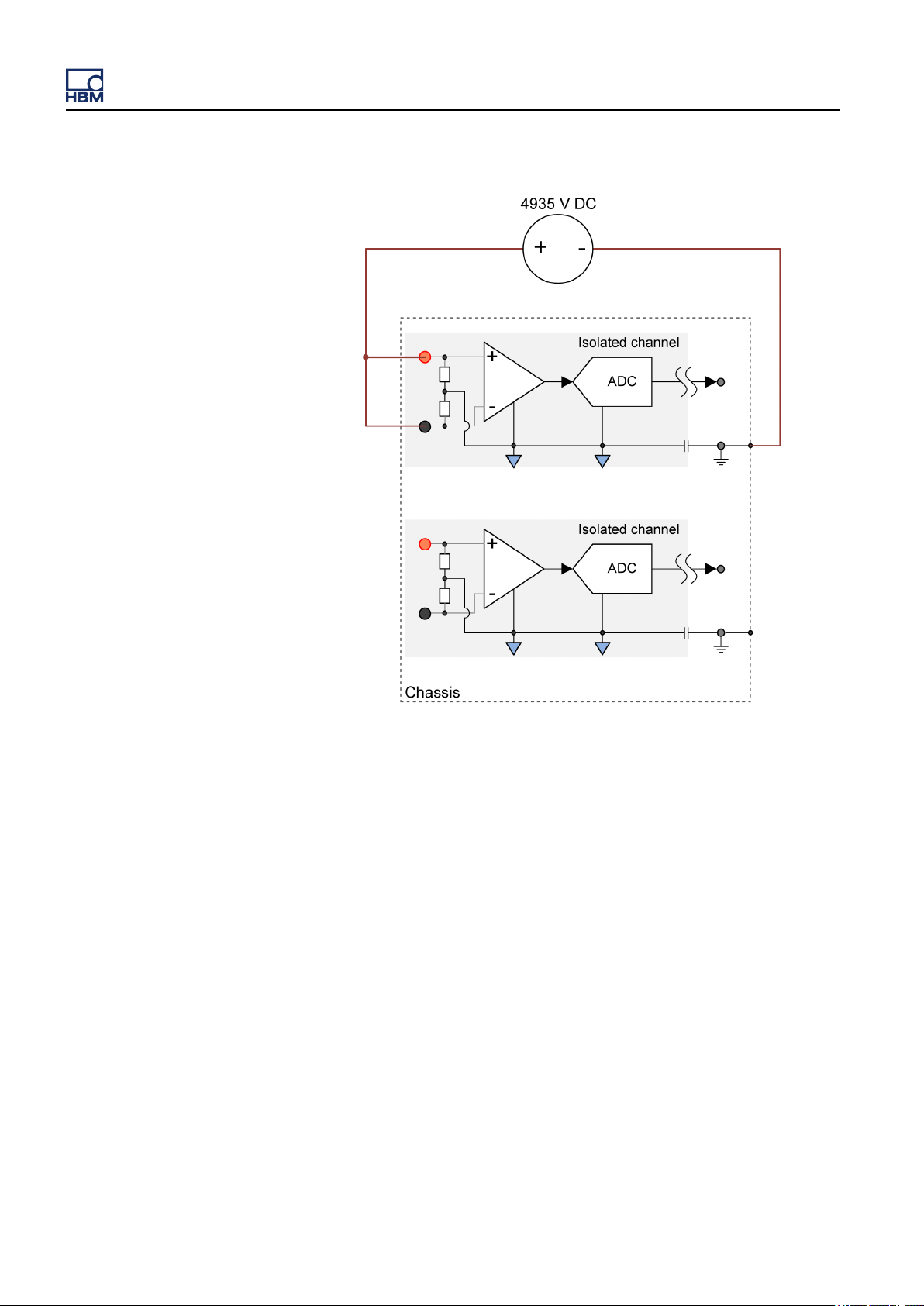

An overview of the GN610, GN611 card isolation and input is given below (see

Figure 2.1). The isolation of the channel to chassis is 1000 V RMS and is also

qualified as 600 V CAT II (or 300 V CAT III). The common mode of the

differential input channel (isolated GND) can be 1000 V RMS with respect to

the chassis. If one channel has common mode at +1000 V and one at

-1000 V (with respect to chassis), the voltage between the two channels is

2000 V. The standards at which the card is certified is IEC61010-1:2010 and

IEC61010-2-30:2010.

Isolation

Input signal to chassis 1000 V RMS, 600 V CAT II (REINFORCED)

Channel to chassis 1000 V RMS, 600 V CAT II (REINFORCED)

Channel to channel 2000 V RMS, (BASIC)

Figure 2.1: Isolation 1kV card overview

l The isolation between channel and chassis is classified as

REINFORCED. This can be seen as double isolation, which is necessary

because the chassis might be accessible (conductive parts can be touched)

to users (personal safety).

HBM public 7

Page 8

GN610, GN611 Isolation and type testing

l Isolation between channels is BASIC, since a channel is not accessible

and there is therefore no direct risk for a user (product safety).

l REINFORCED or DOUBLE isolation has higher test values than BASIC

isolation.

8 HBM public

Page 9

3 Type testing

GN610, GN611 Isolation and type testing

3.1

Channel to chassis isolation test

To qualify the isolation as 1000 V RMS and 600 V CAT II (REINFORCED),

certain tests are performed on some cards during the engineering design

qualification phase. These tests are known as type tests. These tests are

described in the IEC61010-1:2010 and IEC61010-2-30:2010 standards. The

principle of the tests is given below.

For the isolation barrier test, both the DC and AC tests below (see Figure 3.1

and Figure 3.2) are used with DC voltage √2 higher than the AC voltage. The

test value meets the requirements for 600 V CAT II REINFORCED, the test

value for 1000 V RMS is lower and therefore also covered with this test. Tests

are conducted for one minute, see IEC61010 for details.

Figure 3.1: AC Type test Channel to Chassis

HBM public 9

Page 10

GN610, GN611 Isolation and type testing

Figure 3.2: DC Type test Channel to Chassis

10 HBM public

Page 11

GN610, GN611 Isolation and type testing

3.2 Channel to channel isolation test

For the channel to channel test, both the DC and AC tests below (see

Figure 3.3 and

voltage. The test value meets the requirements for 600 V CAT II REINFORCED,

the value for 2000 V RMS BASIC is lower and therefore also covered with this

test. Tests are conducted for one minute, see IEC61010-1 for details.

Figure 3.4) are used with DC voltage √2 higher than the AC

Figure 3.3: DC Type test Channel to Channel

HBM public 11

Page 12

GN610, GN611 Isolation and type testing

Figure 3.4: AC Type test Channel to Channel

12 HBM public

Page 13

GN610, GN611 Isolation and type testing

4 Production tests

4.1

High potential test

The type tests are performed on a selection of cards to prove the design. Every

produced card will undergo a production test, to verify the correct construction

and safety of the card. The tests called “hipot” (high potential) tests (see

Figure 4.1 and Figure 4.2).

The test are performed in two steps to make sure the channels that are side by

side on the card can with stand the high potential voltages.

1 The inputs of channel 1, 3 and 5 are tested using a 1500 V RMS common

mode signal with ground attached to chassis ground and the inputs of

channel 2, 4 and 6 all connected to chassis ground.

2 The inputs of channel 2, 4 and 6 are tested using a 1500 V RMS common

mode signal with ground attached to chassis ground and the inputs of

channel 1, 3 and 5 all connected to chassis ground.

Figure 4.1: Hipot testing channels 1, 3 and 5

HBM public 13

Page 14

GN610, GN611 Isolation and type testing

Figure 4.2: Hipot testing channels 2, 4 and 6

14 HBM public

Page 15

GN610, GN611 Isolation and type testing

5 Engineering tests

5.1

Overview

Besides the type tests and the production tests, HBM has also performed

several engineering tests to verify the robustness of the design during the

engineering design qualification phase.

Component tests

Every component crossing the isolation barrier is tested and/or examined to

make sure it will pass the type test. The test voltage used is the same high

voltage

up to 6 kV, using a 1.2 μs rise time and an amplitude reduction to 50 % of the

maximum peak voltage in 50 μs after the peak has been reached.

DC as used for the type tests as well as an additional impulse voltage

Figure 5.1: Example of 1.2/50 µs impulse

HBM public 15

Page 16

GN610, GN611 Isolation and type testing

Active input switch test

To guarantee the stability of the channels, the input relays are tested with the

maximum

switched from isolated GND to DC by the input relay, resulting in the 1000 V

being applied to the input as a step pulse.

This test is done with the highest input range (± 1000 V) and also repeated with

the lowest input range (± 20 mV), both with an input voltage of 1000 V and

repeated for over 1000 times. These tests all passed successfully.

input voltage (1000 V) applied. The inputs of the channels have been

Figure 5.2: Engineering test input switching

16 HBM public

Page 17

GN610, GN611 Isolation and type testing

6 GN610, GN611 Protection mechanisms

6.1

Overview

Overvoltage and current protection

All signal inputs are protected against voltage overload. This is specified at

± 1000 V for all ranges except for the ± 1000 V range that is limited to

± 1250 V. Exceeding these limits can damage the input card.

GN610 and GN611 input overload protection

The input section has several methods to protect against voltage overload on

the input.

Every selected input range allows a 200 % overload without any change of input

resistance or auto ranging. This 200 % overrange is designed to allow for

smaller voltage overloads without effecting the measurement. Within this

200 % overload the amplifier is also able to respond with normal rise/fall times

to signal being restored within the standard selected range.

When exceeding the 200 % overload condition, the input impedance might start

to increase. The impedance increase will lower the input current with the

positive effect of lowering the dissipated heat. It is the excessive heat

dissipation that typically damages the input channel.

The first action of the system will be to add an additional current load on the

input signal to create an extra voltage drop on the input series resistance. The

actual additional current depends on several factors and is therefore not

predictable. A negative side effect of this additional current is the extra power

dissipated in the input section which in turn results in additional heat dissipation.

Secondly, within the lower ranges of the amplifier (≤ ± 5 V ranges) the input

section will start switching to disconnect from the input signal to reduce the

power dissipated.

HBM public 17

Page 18

GN610, GN611 Isolation and type testing

Figure 6.1: Input Overload protection - Schematic diagram

Thermal monitor of the input channels

Any overload condition has the same end result: extra heat generated within

the

channel. Not only because of the extra current through the input resistance,

but also because internal amplifier sections will be driving their local output to

maximum levels creating excessive heating within the amplifier.

As a third protective mechanism every input is equipped with a thermal sensor

to monitor the local temperature. When the local temperature reaches

maximum levels the system will automatically start changing the user selected

input range to reduce the dissipated heat. As the heat dissipation will not

immediately start the auto ranging, short overloads will not results in auto

ranging. Longer overload conditions will lead to higher local temperature and

this will start the auto ranging process.

Whenever an overload condition pushes local temperature to above the

maximum level, the input range will be adapted to a factor 10 less sensitive

range. E.g. User selected ± 40 mV range, when required the system will change

the range to ± 400 mV. As this might not be enough due to an even higher

overvoltage, the system keeps on monitoring the local temperature. If the local

temperature doesn’t reduce within the expected response time, the system will

automatically increase the input range with a factor of 10 for a second, third or

how many times required to reach a safe condition not to increase local

temperature anymore.

18 HBM public

Page 19

GN610, GN611 Isolation and type testing

Every one of the automatic range changes will be identified within the

measurement data. Not only will the measured input be scaled correctly with

the adapted input range, but also the exact moment the automatic range

change happens is identified within Perception software.

the highest selectable range is ± 1 kV the ultimate protection for the system

As

will be to disconnect the input from the external signal source. This step will

only be executed if the system is in the ± 1 kV range and local temperature is

still outside maximum operating limits. Disconnecting from the external signal

source is done by grounding the input. When inputs are grounded, the only

connections to the external signal are the input connectors and the input pin of

the ground relay.

Thermal shutdown in critical conditions

This protective scheme allows for any overload condition the input would be

confronted with during normal operation. For any other failure condition that

would result in excessive heat dissipation, the GEN series mainframe has a last

protective stage built in. When local temperatures reach a critical condition the

system will turn-off the mains power automatically to prevent damage to the

system or other systems near the GEN series system. Maximum and critical

temperature conditions are defined as such that it is very unlikely the system

will ever reach this critical condition when operating within its specified

conditions.

HBM public 19

Page 20

GN610, GN611 Isolation and type testing

Figure 6.2: Automatic thermal overload response

Automatic restore of user selected range

As the GEN series system is designed to measure 24 hours per day, 7 days

per week, the automatic ranges switching has the negative side effect of

reduced sensitivity of the amplifier. During the actual overload condition the

channel will not be able to measure the input signal anyhow, so no extra

negative side effects are introduced. If the overload condition disappears and

the system is running unattended, the automatic selected input range will not

be the best measurement range. Therefore the amplifier will remember the

original selected user range and restore this user selection as soon as regular

thermal conditions are restored. Temporary large overload conditions will then

only result in temporary adjusted input sensitivity.

It is expected that the thermal conditions might only be restored because of the

automatic range adaption of the input channel. So the actual overload condition

might not have disappeared yet. If this would be the case, the thermal increase

would re-trigger the automatic range adaption process and the overload is

handled exactly the same way as before.

20 HBM public

Page 21

GN610, GN611 Isolation and type testing

In case the overload condition is permanent, the system keeps on automatic

ranging to reduce the dissipated heat, then restores the user selected range

with the effect of overheating again therefore restarting the automatic ranging

process again. This cycle will repeat forever until the overload condition

disappears.

HBM public 21

Page 22

Index

B

GN610, GN611 Isolation and type testing

Basic versus reinforced insulation

C

Categories according to IEC 61010-2-030:2010 .... 2

Channel to channel isolation test ......................... 11

Channel to chassis isolation test ............................ 9

G

GN610 and GN611 Input Overload protection ..... 17

GN610, GN611 Protection mechanisms

Overvoltage and current protection ................. 17

H

High potential test ................................................. 13

I

Isolation and input of the GN610, GN611 .............. 7

.......................... 5

M

Measurement categories ........................................ 2

22 HBM public

Page 23

Page 24

Head Office

HBM

Im Tiefen See 45

64293 Darmstadt

Germany

Tel: +49 6151 8030

Email: info@hbm.com

France

HBM France SAS

46 rue du Champoreux

BP76

91542 Mennecy Cedex

Tél:+33 (0)1 69 90 63 70

Fax: +33 (0) 1 69 90 63 80

Email: info@fr.hbm.com

UK

HBM United Kingdom

1 Churchill Court, 58 Station Road

North Harrow, Middlesex, HA2 7SA

Tel: +44 (0) 208 515 6100

Email: info@uk.hbm.com

USA

HBM, Inc.

19 Bartlett Street

Marlborough, MA 01752, USA

Tel : +1 (800) 578-4260

Email: info@usa.hbm.com

PR China

HBM Sales Office

Room 2912, Jing Guang Centre

Beijing, China 100020

Tel: +86 10 6597 4006

Email: hbmchina@hbm.com.cn

© Hottinger Baldwin Messtechnik GmbH. All rights reserved.

All details describe our products in general form only.

They are not to be understood as express warranty and do

not constitute any liability whatsoever.

measure and predict with confidence

HBM public

Loading...

Loading...