Page 1

Installation Guide

English

FS65

Accelerometer

Page 2

Hottinger Baldwin Messtechnik GmbH

Im Tiefen See 45

D-64239 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

info@hbm.com

www.hbm.com

HBM FiberSensing, S.A.

Optical Business

Rua Vasconcelos Costa, 277

4470-640 Maia

Portugal

Tel. +351 229 613 010

Fax +351 229 613 020

fibersensing@hbm.com

www.hbm.com/fs

Mat.: 7-2002.4265

DVS: A4265-2.3 HBM: public

05.2015

Sensor Design Version: v1.0

E Hottinger Baldwin Messtechnik GmbH.

Subject to modifications.

All product descriptions are for general information only.

They are not to be understood as a guarantee of quality or

durability.

Page 3

English

1 Technical Details 4.........................................

1.1 General Information 4........................................

1.1.1 Overview 4.................................................

1.1.2 Characteristics 4.............................................

1.1.3 Applications 5...............................................

1.1.4 Quality 6...................................................

1.1.5 Accessories 6...............................................

1.2 General Specifications 7......................................

2 Sensor Installation 8........................................

2.1 Accelerometer 8.............................................

2.1.1 List of Materials 8............................................

2.1.2 Placing the Sensor 9.........................................

2.1.3 Fixing the Sensor 10..........................................

2.1.4 Protecting the Sensor 10.......................................

2.2 Bi or Triaxial Accelerometer 11.................................

2.2.1 List of Materials 11............................................

2.2.2 Assembling the Sensors 12....................................

2.2.3 Fixing the Assembly 20........................................

2.2.4 Protecting the Sensors 20......................................

3 Sensor Configuration 22.....................................

3.1 Sensor Calibration Sheet 22....................................

3.1.1 General nformation 23.........................................

3.1.2 Calibration Data 23...........................................

3.1.3 Acceleration Computation 23...................................

FS65 A4265-2.3 HBM: public 3

Page 4

Technical Details

1 Technical Details

1.1 General Information

This installation guide applies to the following products:

Part Number Description

K-FS65-30-11-302 FS65 - Accelerometer • Outdoor • FC/APC

K-FS65-30-13-302 FS65 - Accelerometer • Outdoor • SC/APC

K-FS65-30-10-302 FS65 - Accelerometer • Outdoor • NC

1.1.1 Overview

The FS65 - Accelerometer is a Fiber Bragg Grating

(FBG) based sensor, suitable for a large range of appli

cations where low frequency and small amplitude vibra

tions are present.

1.1.2 Characteristics

: Robustness

Long-term reliability ensured by innovative sensor

design, careful selection of materials and IP68 packag

ing.

: Completely passive

Inherent immunity to all electromagnetic effects (EMI,

RFI, sparks, etc.) and safe operation in hazardous envi

ronments.

4 A4265-2.3 HBM: public FS65

Page 5

Technical Details

: High multiplexing capability

Connection of a large number of sensors to a single opti

cal fiber, reducing network and installation complexity.

: Remote sensing

Large distance between sensors and interrogator (sev

eral kilometers).

: Compatible with most interrogators

Provided with calibration sheet, allowing easy and accu

rate configuration.

: Self-referenced

Based on the measurement of an absolute parameter the Bragg wavelength - independent of power fluctua

tions.

1.1.3 Applications

HBM FiberSensing accelerometer can be used in a large

range of monitoring applications, including measuring

ambient induced vibration of civil structures.

: Civil Engineering

: Energy

: R&D

FS65 A4265-2.3 HBM: public 5

Page 6

Technical Details

1.1.4 Quality

All HBM FiberSensing's processes are strictly controlled

from development to production. Each product is sub

jected to high standard performance and endurance

tests, individually calibrated and checked before ship

ping.

HBM FiberSensing, S.A. concentrates all optical sensing

activity of HBM and is an ISO 9001:2008 certified com

pany.

1.1.5 Accessories

The implementation of complex sensing networks in large

structures is made simpler with HBM FiberSensing

accessories. These include cables especially designed to

resist harsh environments as in civil engineering, not only

during construction, but also during the lifetime of the

structure (humidity, corrosion, etc.).

HBM FiberSensing also provides accessories for com

pact in series mounting of two or three accelerometers in

transversal directions, allowing the simultaneous mea

surement of vibration along multiple axis.

6 A4265-2.3 HBM: public FS65

Page 7

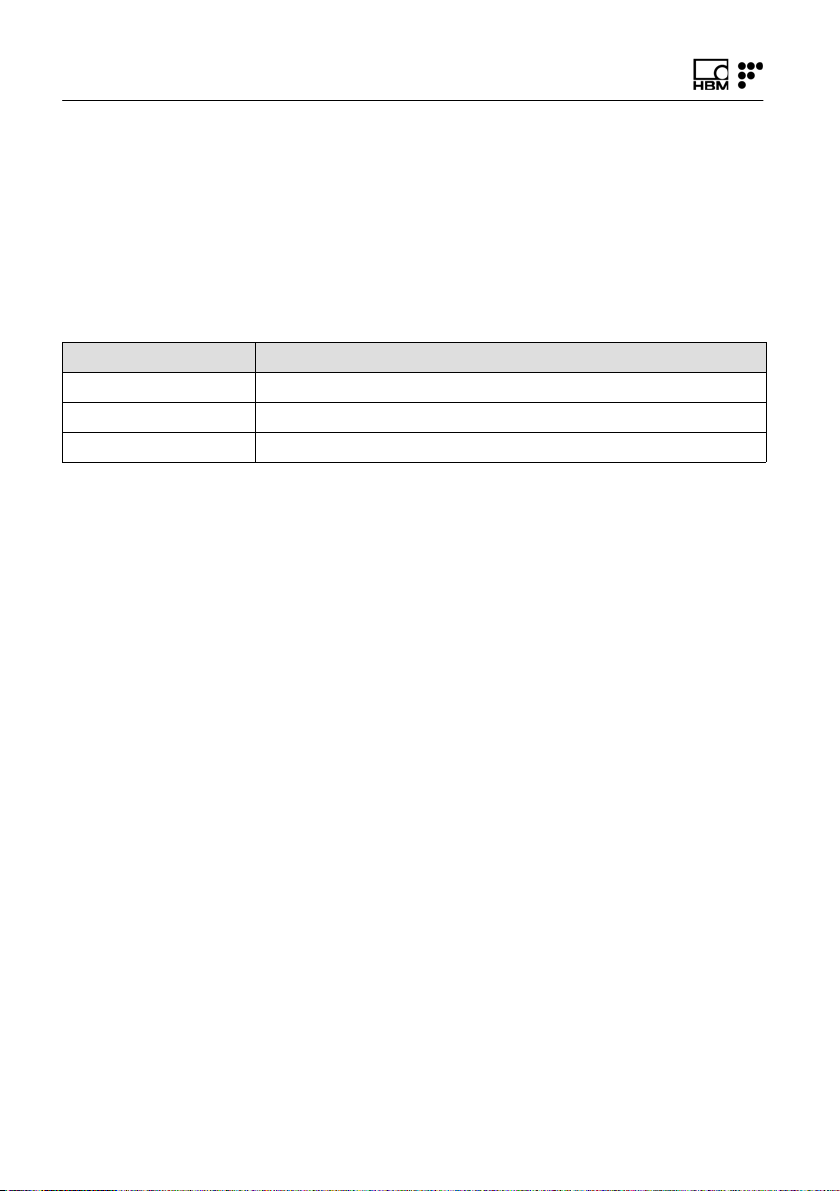

1.2 General Specifications

Sensor

Sensitivity

Measurement range ±10 g

Frequency range 0 to 50 Hz

Resonance frequency

Flatness < 2%

Resolution

Maximum calib. error ±0.1 g @ 40 Hz

Transverse sensitivity < 0.1%

Optical

Central wavelength 1500 to 1600 nm

Spectral width (FWHM) < 0.2 nm

Reflectivity > 65%

Side lobe suppression > 10 dB

Inputs / Outputs

Cable type Ø 3 mm outdoor (armor)

Cable length 2 m each side (±5 cm)

Connectors FC/APC

Environmental

Operation temperature -20 to 80 ºC

Protection class IP68

Mechanical

Materials Aluminum

Dimensions 73 x Ø 53 mm

Weight 250 g

1)

Typical values

2)

For 1 pm resolution in wavelength measurement

1)

1)

2)

75 pm/g @ 40 Hz

430 Hz

12.5 μg/ǠHz

SC/APC

NC (No Connectors)

Technical Details

FS65 A4265-2.3 HBM: public 7

Page 8

Sensor Installation

2 Sensor Installation

2.1 Accelerometer

2.1.1 List of Materials

Included Material

Accelerometer

List of Needed Equipment

The needed tools to install the FS65 - Accelerometer

depend on the structure the sensor is to be installed on.

In many cases, mounting parts may need to be designed

in order to adapt the sensor to the spot where it is going

to be installed.

The installation solution should be carefully designed in

order to meet the sensor measuring direction and the

structure characteristics.

8 A4265-2.3 HBM: public FS65

Page 9

Sensor Installation

2.1.2 Placing the Sensor

The FS65 - Accelerometers can be placed headed up,

headed down or towards the side (Fig. 2.1).

Fig. 2.1

Information

This will only alter the sensor's DC output. Dynamically, it

will still have the same behavior.

Its position must be set according to its measuring direc

tion.

FS65 A4265-2.3 HBM: public 9

Page 10

Sensor Installation

measuring

direction

Fig. 2.2

2.1.3 Fixing the Sensor

The Accelerometer has a M5 hole on its basis to be

screwed to the surface.

2.1.4 Protecting the Sensor

Accelerometer is IP68 rated, meaning that no protection

is needed. Nevertheless, it can be protected with a box

or other protection methods.

10 A4265-2.3 HBM: public FS65

Page 11

Sensor Installation

2.2 Bi or Triaxial Accelerometer

2.2.1 List of Materials

Included Material

S Accelerometers

S Mounting Plate:

- 1x Plate

- 1x Positioning Block

- 4x Cable Guide

- 8x M3x6

- 2x M5x8

- 4x M5x12

- 4x M6x20

S Protection Cover (optional):

- 1x Cover

- 8x M6x20

List of Needed Equipment

The needed tools to install the FS65 - Accelerometer

depend on the structure the sensor will be installed. In

many cases, mounting parts may need to be designed in

order to adapt the sensor to the spot where it is going to

be installed.

The installation solution should be carefully designed in

order to meet the sensor measuring direction and the

structure characteristics.

FS65 A4265-2.3 HBM: public 11

Page 12

Sensor Installation

2.2.2 Assembling the Sensors

The Bi or Triaxial Accelerometer is assembled on a

mounting base using two or three accelerometers.

Its position must be set according to its measuring direc

tion. On Fig. 2.3 an example of the possible two measur

ing directions is presented and on Fig. 2.4 a Triaxial

assembly is presented.

measuring

directions

Fig. 2.3

measuring

directions

Fig. 2.4

12 A4265-2.3 HBM: public FS65

Page 13

Sensor Installation

Preparing the Mounting Plate

Mechanical parts of the mounting plate are delivered

separately.

Start by screwing the position block to the mounting plate

using 3 of the provided M5x12 screws. These screws

should be threaded from the backside as shown on

Fig. 2.5.

Mounting plate

M5x12

Fig. 2.5

Position block

Fig. 2.6

FS65 A4265-2.3 HBM: public 13

Page 14

Sensor Installation

Fixing the Sensors

On the horizontal axis, use the provided M5x8 screws to

fix the accelerometer to the positioning block.

Ensure that the fibers are oriented at approximately 30º,

with the fibers that will be exiting the protection cover at

the lower position (see Fig. 2.7 and Fig. 2.8).

M5x8

Fig. 2.7

Approx. 30°

Fig. 2.8

Fig. 2.9

14 A4265-2.3 HBM: public FS65

Page 15

Sensor Installation

For the vertical axis sensor, use the remaining M5x12

screw.

Place the vertical sensor with the fibers oriented at 45º

(Fig. 2.12).

M5x12

Fig. 2.10

Fig. 2.11

45°

Fig. 2.12

FS65 A4265-2.3 HBM: public 15

Page 16

Sensor Installation

Arranging Cables

Use the provided Cable Guides (Fig. 2.13) and M3x6

screws to place and fix the cable guides on the mounting

plate (Fig. 2.14).

Cable Guide

M3x6

Fig. 2.13

Fig. 2.14

Considering the triaxial configuration and the defined

directions as represented on Fig. 2.15, sensor connec

tion should be performed as on Fig. 2.16:

16 A4265-2.3 HBM: public FS65

Page 17

Sensor Installation

A

B

y

Fig. 2.15

A

z

x

AB

B

A

Sensor x

B

A

Sensor z

B

A

Sensor y

B

Fig. 2.16

Standard Accelerometers are delivered with 2 m length

cables on each side. This is not an optimized length for

the Bi or Triaxial configuration, but connections can be

performed. Fig. 2.17 shows an assembly of sensors with

FS65 A4265-2.3 HBM: public 17

Page 18

Sensor Installation

the standard cable lengths. In Fig. 2.18, an assembly of

sensors with an optimized cable length is presented.

Fig. 2.17

Fig. 2.18

Start by taking the cable B (Fig. 2.15) of the sensor on

the x axis and place it around the assembly as on

Fig. 2.19.

Then, take cable A of the sensor on the z axis and place

it around the assembly as on Fig. 2.20. Use an Optical

Adapter and attach both connectors.

18 A4265-2.3 HBM: public FS65

Page 19

Sensor Installation

Ç

Ç

Fig. 2.19

Fig. 2.21

Fig. 2.20

Fig. 2.22

Proceed in a similar way with cable B of the z axis

accelerometer (Fig. 2.21) and cable A of the y axis

accelerometer (Fig. 2.22). Use clumps to fix cabling and

connections.

FS65 A4265-2.3 HBM: public 19

Page 20

Sensor Installation

2.2.3 Fixing the Assembly

The Bi or Triaxial assembly is now ready to be fixed to

the structure. The mounting base has 4 M6 holes for that

purpose. Four M6x20 screws are provided, but these can

be or not be suited for fixing the base to the structure.

The fixing method should be carefully defined.

2.2.4 Protecting the Sensors

Although the accelerometer is IP68 rated, the performed

connections on the assembly are not. This means that

for outdoor usage of the assembly arranged as above

should have the connectors protected against moisture

and dust. HBM FiberSensing suggests the use of a vul

canizing tape around the connectors and adapter

(Fig. 2.23).

Fig. 2.23

For mechanical protection and external cover of the Bi or

Triaxial Assembly, HBM FiberSensing has a specially

designed cover.

It is prepared to be screwed to the surface with 8 M6x20

screws and has two holes for cable exiting.

20 A4265-2.3 HBM: public FS65

Page 21

Fig. 2.24

Sensor Installation

FS65 A4265-2.3 HBM: public 21

Page 22

Sensor Configuration

3 Sensor Configuration

3.1 Sensor Calibration Sheet

Every HBM FiberSensing sensor is provided with a cali

bration sheet. The layout of this document is the same

for all accelerometers.

Fig. 3.1

22 A4265-2.3 HBM: public FS65

Page 23

Sensor Configuration

3.1.1 General nformation

Number 1 in Fig. 3.1 shows the general information on

the particular sensor, such as its type, the sensor part

number, its serial number and the production tracking

number, the FBG ID.

3.1.2 Calibration Data

The most important information related to the accelerom

eter sensor – the two central wavelengths at room tem

perature and sensitivity - is shown in the Calibration Data

table (number 2 in Fig. 3.1). These values should be

used for acceleration computation.

3.1.3 Acceleration Computation

Number 3 in Fig. 3.1 exemplifies the calculations that

should be performed for wavelength measurement to

acceleration conversion. The acceleration variation of an

Accelerometer, under a reference frequency, is given by

the quotient of wavelength shift from the zero moment by

the sensor's sensitivity.

acceleration + xńS ´ acceleration

+ (WL * CWL)ńS

Fig. 3.2

Where

S x is the wavelength shift in nm

S S is the given sensitivity in nm/g

S CWL is the central wavelength of the sensor at the

zero moment in nm

S WL is the measured wavelength in nm.

FS65 A4265-2.3 HBM: public 23

Page 24

HBM Test and Measurement

Tel. +49 6151 803-0

Fax +49 6151 803-9100

info@hbm.com

measure and predict with confidence

www.hbm.com

A4265-2.3 7-2002.4265 HBM: public

Loading...

Loading...