Page 1

User Manual

English

FS42

Portable BraggMETER

Page 2

Hottinger Baldwin Messtechnik GmbH

Im Tiefen See 45

D-64239 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

info@hbm.com

www.hbm.com

HBM FiberSensing, S.A.

Optical Business

Rua Vasconcelos Costa, 277

4470-640 Maia

Portugal

Tel. +351 229 613 010

Fax +351 229 613 020

fibersensing@hbm.com

www.hbm.com/fs

Mat.: 7-2002.4250

DVS: A4250-5.0 HBM: public

07.2017

Interrogator version: v3.2

SW version: v5.5

E Hottinger Baldwin Messtechnik GmbH.

Subject to modifications.

All product descriptions are for general information only.

They are not to be understood as a guarantee of quality or

durability.

Page 3

English

1 General Details 5...........................................

1.1 General Information 5........................................

1.2 System Components 5.......................................

1.3 Technical Data 6............................................

2 Hard Disk Image Recovery 9.................................

2.1 System Recovery 9..........................................

3 Regulatory and Certification Considerations 13................

3.1 Environment Considerations 13.................................

3.1.1 Disposal of your old Appliance 13...............................

3.2 Laser Safety 14..............................................

3.2.1 Symbols 14..................................................

3.2.2 Class 1 Laser 14..............................................

3.2.3 General Precautions Considerations 15..........................

3.2.4 Certification 16...............................................

4 Operation 17................................................

4.1 Connectors 17................................................

4.2 Status Indicators 18...........................................

4.3 Protection and Carrying Bag (optional) 19........................

4.4 Power Supply 19.............................................

4.5 Battery Pack 20..............................................

4.5.1 Removing the Battery Pack 21..................................

4.5.2 Connecting the Battery Pack 25................................

4.6 Switching ON 26..............................................

4.7 Switching OFF 26.............................................

4.8 Touch Screen Calibration 28...................................

5 Measuring Examples 32......................................

5.1 Measuring in 5 Steps 32.......................................

5.2 Typical Configuration 32.......................................

FS42 A4250-5.0 HBM: public 3

Page 4

5.2.1 HBM FS Wavelengths 34......................................

5.3 Definitions and Operation Methods 35...........................

5.3.1 Wavelength 35...............................................

5.3.2 Power 36....................................................

5.3.3 Threshold 37.................................................

5.4 Common Measuring Difficulties 39..............................

5.4.1 Dirty Connector 39............................................

5.4.2 Broken Connector 41..........................................

5.4.3 Reflective Fiber Ending 42.....................................

5.4.4 Cut Fiber 43.................................................

6 iLog Software 45............................................

6.1 General Details 45............................................

6.1.1 Software Version 45...........................................

6.1.2 Software Update 45...........................................

6.2 Graphical User Interface 46....................................

6.2.1 General and Management Controls 46...........................

6.2.2 Graphical View 47............................................

6.2.3 Data View 52.................................................

6.2.4 Configuration 53..............................................

6.2.5 Spectral View 66..............................................

6.2.6 Alarms 71...................................................

4 A4250-5.0 HBM: public FS42

Page 5

1 General Details

1.1 General Information

The HBM FiberSensing Portable BraggMETER is a con

tinuous swept laser scanning interrogator designed to

interrogate Fiber Bragg Grating (FBG) sensors.

The interrogator includes a NIST traceable wavelength

reference that provides continuous calibration to ensure

system accuracy over long term operation. The high

dynamic range and high output power allows high resolu

tion to be attained even for long fiber leads and lossy

connections.

Its high dynamic range and broadband tuning range com

bined with the available 4 optical channels makes this

interrogator particularly suitable for large scale sensing

networks, acquiring a large number of sensors, providing

an acquisition rate of 1S/s with 1 pm resolution.

General Details

This Manual applies to the following equipment:

K-FS42-01-010-420 FS42 - Portable BraggMETER Quad channel

K-FS42-03-010-420 FS42 - Portable BraggMETER Quad channel

1.2 System Components

The Portable BraggMETER set includes:

S Interrogator

S Support CD

S AC/DC Adapter

S Power cord

FS42 A4250-5.0 HBM: public 5

Page 6

General Details

S Power adapter

S Protection and carrying bag (optional)

S Battery pack (2 batteries)

S Connector protection caps

S Touch screen pen

S User manual

S Calibration certificate

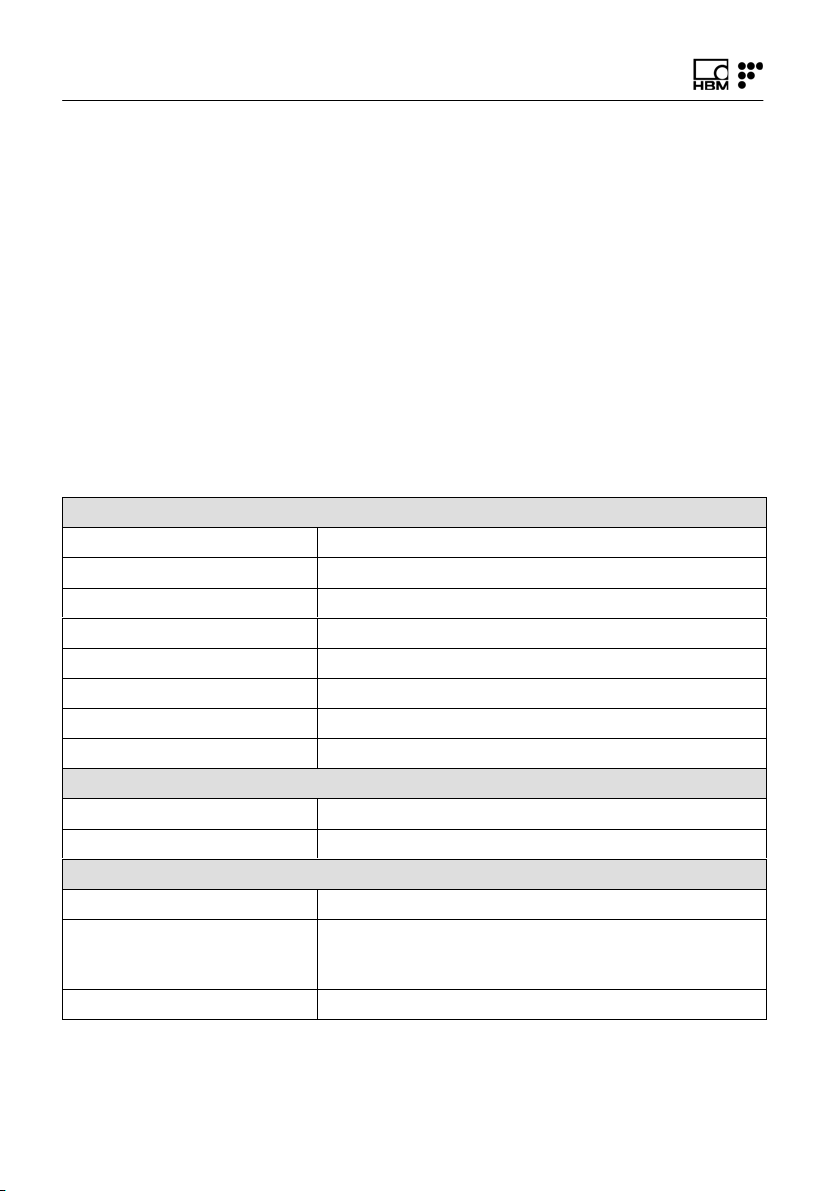

1.3 Technical Data

Wavelength Measurement

Range 100 nm (1500 to 1600 nm)

Resolution

Absolute accuracy

Sensors per channel 25 (maximum recommended)

Optical channels

Sample rate 1 S/s

Optical detection Logarithmic

Dynamic range

Laser Source

Optical output power

Line width < 500 MHz

Connectors

Optical FC/APC or SC/APC

Electrical 2.5 x 5.5 DC Socket panel mount

Communication RJ45 Ethernet; USB

1)

2)

4)

5)

6)

1.0 pm

±2.0 pm

4 (in parallel)

> 50 dB

-3 dBm

supplied with 100-230 V power adapter and Type F

plug cable

7)

3)

6 A4250-5.0 HBM: public FS42

Page 7

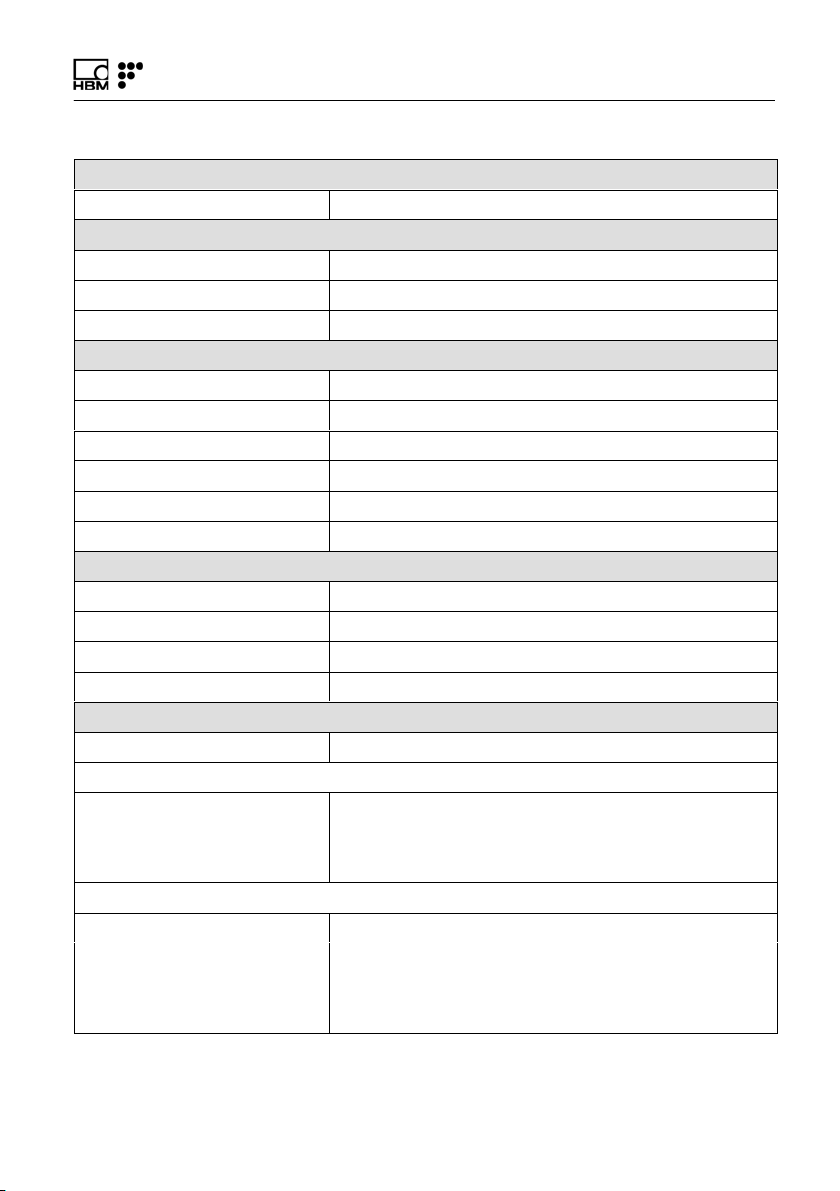

General Details

Control

Interface 12" touchscreen GUI, Ethernet (TCP/IP), USB

Features

8)

OSA trace Continuous

Functions Sampling; archiving

Data format MySQL database; Excel™ compatible files

Environmental

Operation temperature 10 to 40 ºC

Operation humidity < 90% at 40 ºC

Storage temperature -20 to 70 ºC

Storage humidity <95% (non-condensing)

Shock resistance Class 2 (EN 60068-2-27)

Vibration resistance9) Class 2 (EN 60068-2-6)

Mechanical

Dimensions (w x h x d) 360 x 280 x 105.5 mm

Mounting Available with handle and transportation bag

Enclosure Aluminum (IP20)

Weight 7.3 kg

Power

Voltage 18-20 VDC

Nominal consumption10)

Charging, not running 45 W

Charging, running 90 W

Not charging, running 45 W

Battery pack

Number of batteries 2

Battery model pcga-bp2nx

Battery capacity 4400 mAh

Battery voltage 14.8 V

(wavelength, absolute power)

FS42 A4250-5.0 HBM: public 7

Page 8

General Details

Battery technology Li-ion

Autonomy

1)

σ value from an error histogram with +0.25M samples

2)

± (|xc|+2σ) value from an error histogram with +8.4M samples obtained over full temperature

range

3)

Considering sensor wavelengths equally spaced over the operating range and maximum

measurement range of ±2 nm per sensor

4)

With simultaneous acquisition

5)

Considered as the ratio between the optical power emitted at an optical channel and the minimum

detectable optical power reflected by a fiber Bragg grating

6)

Typical values

7)

Different plug format can be added upon request

8)

Full spectrum trace with 20001 points acquired over the 100 nm range (sampled every 5 pm)

9)

Sinusoidal vibration

10)

Peak consumption may reach 90 W

6)

3 hours

8 A4250-5.0 HBM: public FS42

Page 9

2 Hard Disk Image Recovery

The Portable BraggMETER has a functionality to recover

all hard disk factory contents, restoring the default set

tings and original configurations of the interrogator.

Important

System recovery will erase all the data stored in the hard

disk.

2.1 System Recovery

To apply the recovery process, follow the instructions as

explained:

1. Turn off the device

2. Connect the keyboard and mouse to the device

Hard Disk Image Recovery

3. Turn on the device

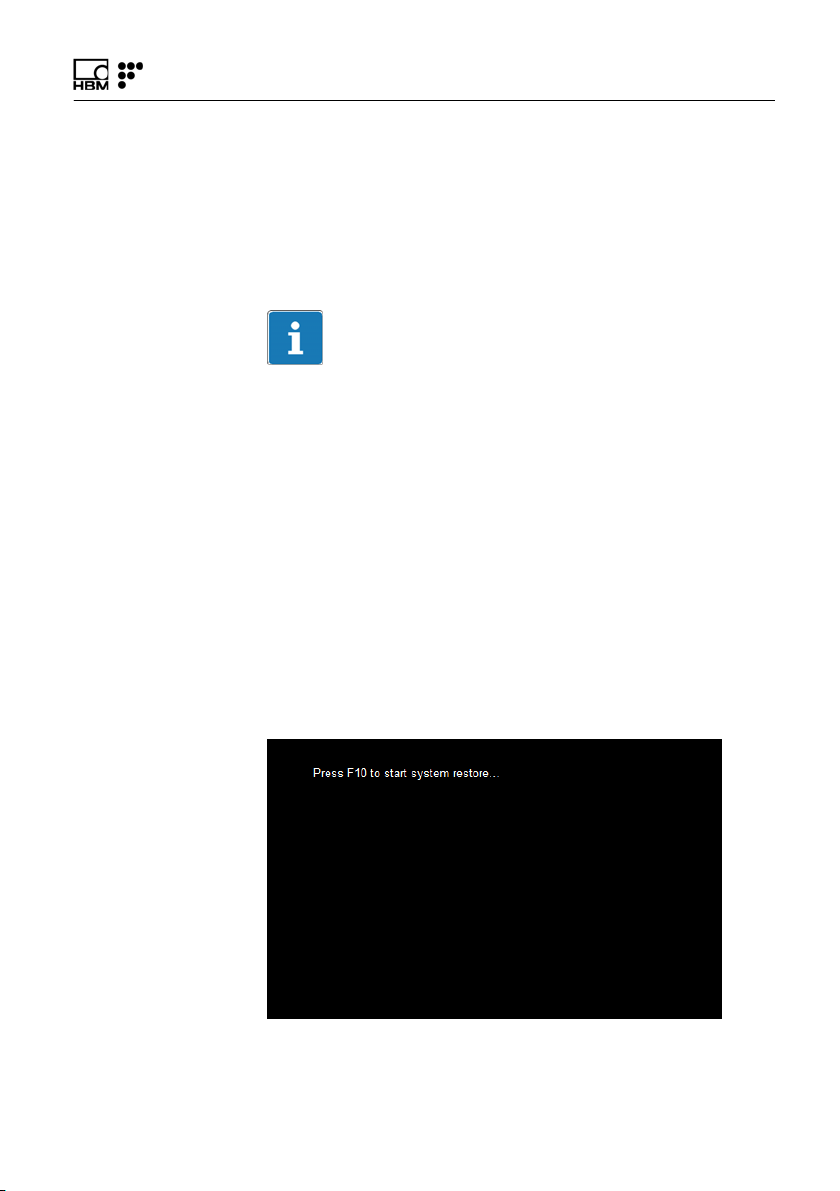

4. When the splash screen (Fig. 2.1) appears press F10

Fig. 2.1

FS42 A4250-5.0 HBM: public 9

Page 10

Hard Disk Image Recovery

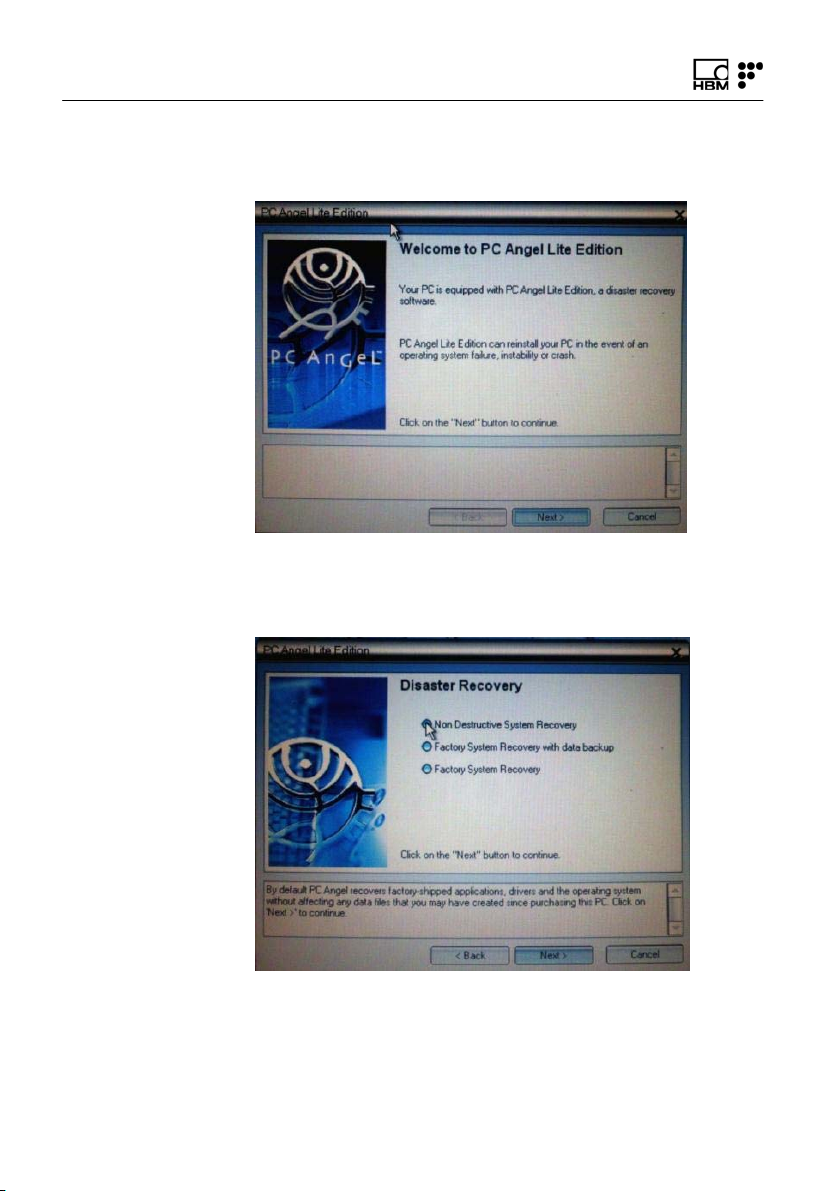

5. Press Next button (Fig. 2.2)

Fig. 2.2

6. Select Non Destructive System Recovery (Fig. 2.3)

Fig. 2.3

10 A4250-5.0 HBM: public FS42

Page 11

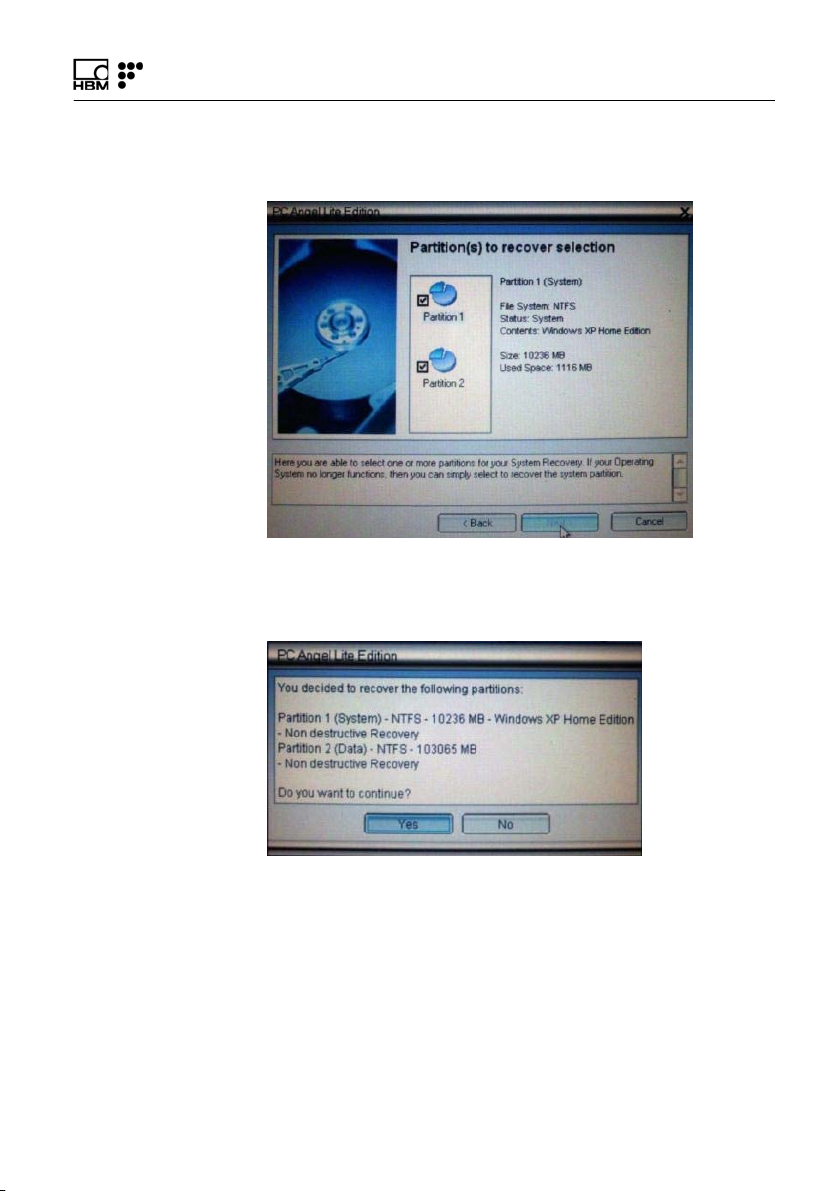

7. Press Next (Fig. 2.4)

Fig. 2.4

8. Press Yes (Fig. 2.5)

Hard Disk Image Recovery

Fig. 2.5

FS42 A4250-5.0 HBM: public 11

Page 12

Hard Disk Image Recovery

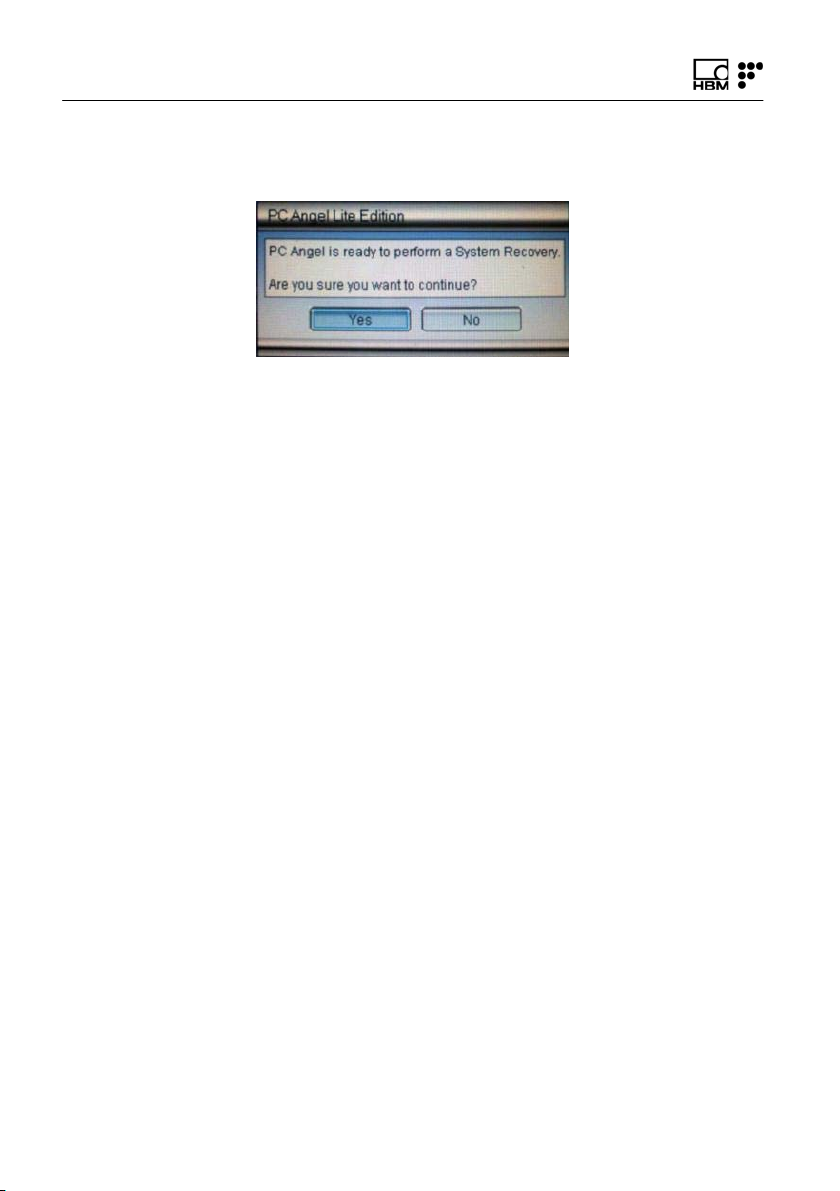

9. Press Yes (Fig. 2.6)

Fig. 2.6

10.Allow approximately 10 minutes for the recovery

process to complete. Reboot the PC into Windows

Embedded™.

12 A4250-5.0 HBM: public FS42

Page 13

Regulatory and Certification Considerations

3 Regulatory and Certification Considerations

3.1 Environment Considerations

3.1.1 Disposal of your old Appliance

When the attached symbol combination - crossed-out

wheeled bin and solid bar symbol is attached to a product

it means the product is covered by the European Direc

tive 2002/96/EC and is applicable in the European Union

and other countries with separate collection systems.

All electrical and electronic products should be disposed

of separately from the municipal waste stream or house

hold via designated collection facilities appointed by the

government or the local authorities. The correct disposal

of your old appliance will help prevent potential negative

consequences for the environment and human health.

For more detailed information about disposal of your old

appliance, please contact your city office, waste disposal

service or distributor that purchased the product.

HBM FiberSensing, S.A. is a manufacturer registered in

the ANREEE - "Associação Nacional para o Registo de

Equipamentos Eléctricos e Electrónicos" under number

PT001434. HBM FiberSensing celebrated a "Utente"

type contract with Amb3E - "Associação Portuguesa de

Gestão de Resíduos de Equipamentos Eléctricos e Elec

trónicos", which ensures the transfer of Electrical and

Electronic appliance waste management, i.e. placing

Electronic and Electrical appliances in the Portuguese

market, from the manufacturer HBM FiberSensing to

Amb3E.

FS42 A4250-5.0 HBM: public 13

Page 14

Regulatory and Certification Considerations

3.2 Laser Safety

The FS42 - Portable BraggMETER interrogator contains

a laser in its core. A laser is a light source that can be

dangerous to people exposed to it. Even low power

lasers can be hazardous to a person's eyesight. The

coherence and low divergence of laser light means that it

can be focused by the eye into an extremely small spot

on the retina, resulting in localized burning and perma

nent damage.

The lasers are classified by wavelength and maximum

output power into the several safety classes: Class 1,

Class 1M, Class 2, Class 2M, Class 3R and Class 4.

3.2.1 Symbols

Warning symbol Class 1 Laser symbol

3.2.2 Class 1 Laser

The FS22 - Portable BraggMETER is a class 1 laser

product:

«Any laser or laser system containing a laser that cannot

emit laser radiation at levels that are known to cause eye

or skin injury during normal operation.»

14 A4250-5.0 HBM: public FS42

Page 15

Regulatory and Certification Considerations

It is safe under all conditions of normal use. No safety

requirements are needed to use Class 1 laser devices.

This product contains a laser within an enclosure that

prevents exposure to the radiation and that cannot be

opened without shutting down the laser.

3.2.3 General Precautions Considerations

Everyone who uses a laser equipment should be aware

of the risks.

The laser radiation is not visible to the human eye but it

can damage user's eyesight.

The laser is enabled when the interrogator is turned on.

Users should never put their eyes at the level of the hori

zontal plane of the optical adapters of the interrogator or

uncovered optical connectors.

Adequate eye protection should always be required if

there is a significant risk for eye injury.

When an optical channel is not in use (no optical connec

tor plugged to the interrogator), a proper connector cap

must be used.

The optical connectors are subjected to maintenance

and/or inspection.

Do not attempt to open or repair a malfunction interroga

tor. It must be returned to HBM FiberSensing for repair

and calibration.

FS42 A4250-5.0 HBM: public 15

Page 16

Regulatory and Certification Considerations

3.2.4 Certification

This product carries the CE marking and complies with

the applicable international requirements for product

safety and electromagnetic compatibility, according to the

following Directives:

S Low Voltage Directive (LVD) 2014/35/EU - Electrical

Safety

S Electromagnetic Compatibility (EMC) Directive

2014/30/EU

It is in compliance with the EN61326/EN55011 Emission

Radiated Test Class A, under the Electromagnetic Com

patibility Standard.

The corresponding Declaration of Conformity is available

upon request.

16 A4250-5.0 HBM: public FS42

Page 17

4 Operation

Operation

4.1 Connectors

Left view Right view

Fig. 4.1

The connectors and buttons in Fig. 4.1 are:

1 VGA Connector

2 LAN Connector

3 USB Connector (2x)

4 Fan

5 Power Connector

6 ON/OFF button

7 Optical Channel Connectors (FC/APC or SC/APC)

FS42 A4250-5.0 HBM: public 17

Page 18

Operation

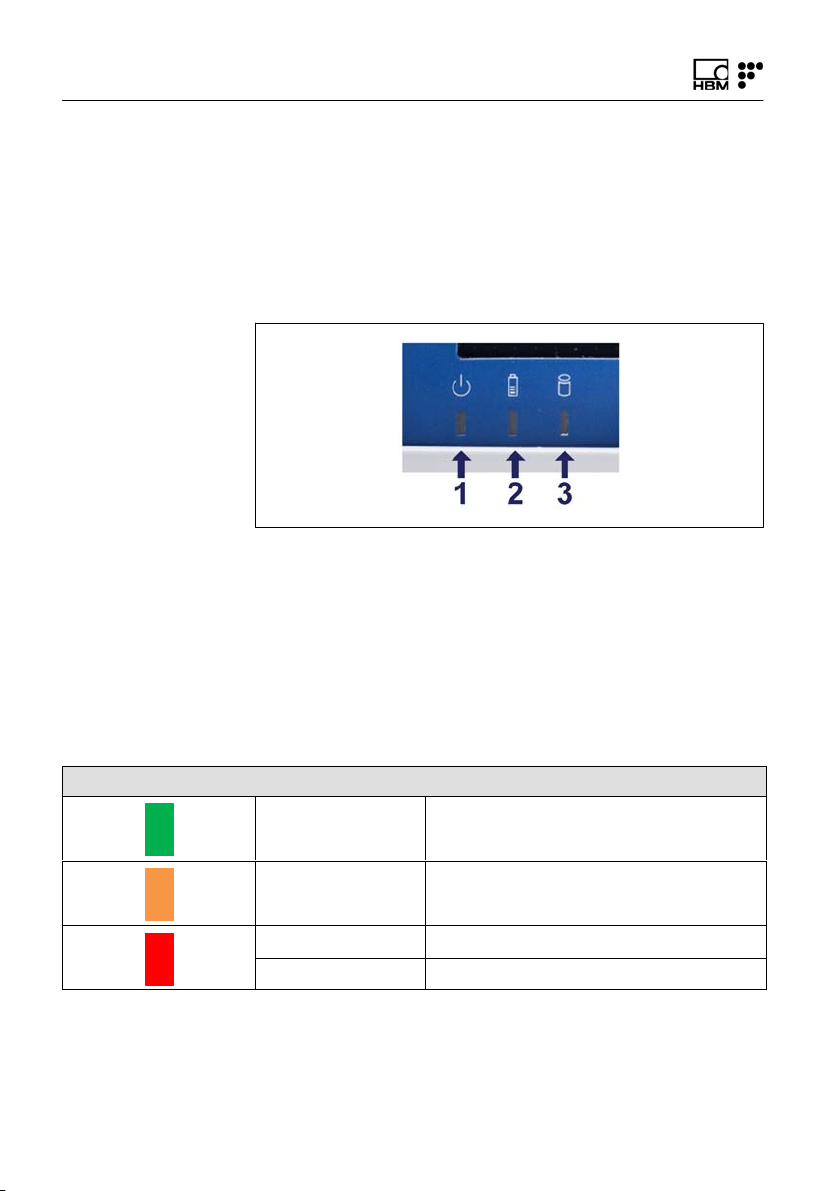

4.2 Status Indicators

On the bottom of the screen panel the user can find three

indicators. Number 1 on Fig. 4.2 refers to the power sta

tus of the equipment, number 2 refers to the battery sta

tus and number 3 refers to disk writing.

Fig. 4.2

Number 1 and number 3 in Fig. 4.2 can only assume one

color. When led 1 is green the interrogator is powered on

and when led 3 is yellow the hard disk is being written.

The battery status (Led number 2 in Fig. 4.2) assumes

different colors depending on charge level, according to

the following table.

Battery LED

Steady green Charge level > 60%

Steady orange 60% > Charge level > 35%

Steady red 35% > Charge level > 20%

Blinking red Charge level < 20%

18 A4250-5.0 HBM: public FS42

Page 19

Operation

Important

Battery with less than 20% of maximum charge will com

promise the correct startup of the interrogator.

4.3 Protection and Carrying Bag (optional)

To place or remove the protection and carrying bag, pro

ceed as follows:

S Remove the handle fixation protection cover;

S With a Torx screw driver 20 unscrew the handle;

S Remove the handle;

S Place/Remove the bag from the interrogator;

S Put back the handle on its place respecting its orienta

tion;

S Screw the handle.

S Place back the handle fixation protection cover

4.4 Power Supply

The interrogator must be used with a dedicated power

supply source and not shared with other equipment,

when powering with a direct source and not with the

power adapter.

FS42 A4250-5.0 HBM: public 19

Page 20

Operation

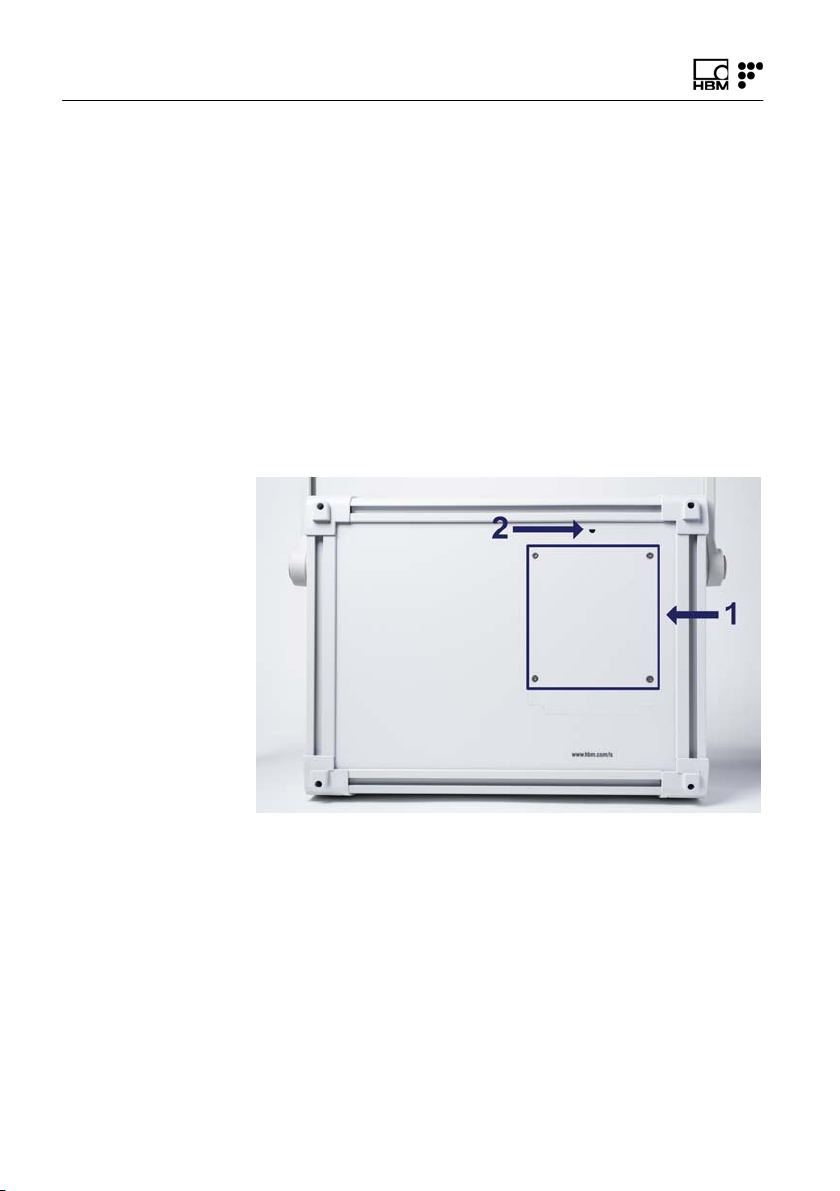

4.5 Battery Pack

Portable BraggMETER is supplied with a replaceable

battery pack located in the back panel of the equipment,

identified with a blue rectangle in Fig. 4.3. The battery

pack is a pair of two commercially available battery mod

ules (model: pcga-bp2nx), see chapter 1.3

“Technical Data”, on page 6 for battery details.

The numbers in Fig. 4.3 refer to:

1 4 Hexalobular Csk screws M3x6

2 Hole for opening

Fig. 4.3

Before turning on the Portable BraggMETER for the first

time, the batteries should be fully charged. Connect the

Portable BraggMETER directly to 100~240 V power line

using the provided 20 V AC adapter. Once the interroga

tor starts charging, the left sided fan (see Fig. 4.1) will

start working.

20 A4250-5.0 HBM: public FS42

Page 21

Operation

The replaceable battery pack has two independent bat

teries. To avoid lifetime reduction of the batteries this

device manages charge-discharge cycles, as result of

this process some charge cycles will not reach the maxi

mum charge level of 100%. The estimated time to fully

charge the battery pack is about 4 hours.

Important

It is advisable to fully recharge and remove the battery

pack before periods of inactivity longer than 4 weeks, see

chapter 4.5.1 “Removing the Battery Pack”.

4.5.1 Removing the Battery Pack

Changing batteries is a simple process that must be per

formed following the procedure here described, since

irreversible damage can be caused due to incorrect use.

Important

Take the necessary precautions to avoid Electro Static

Discharge (ESD).

To change the batteries proceed as follows:

1. Shut down the interrogator and wait until the power

LED is off.

2. Unplug the power supply cable if connected to the

interrogator.

3. Unscrew Csk M4x8 screws, number 1 in Fig. 4.3.

FS42 A4250-5.0 HBM: public 21

Page 22

Operation

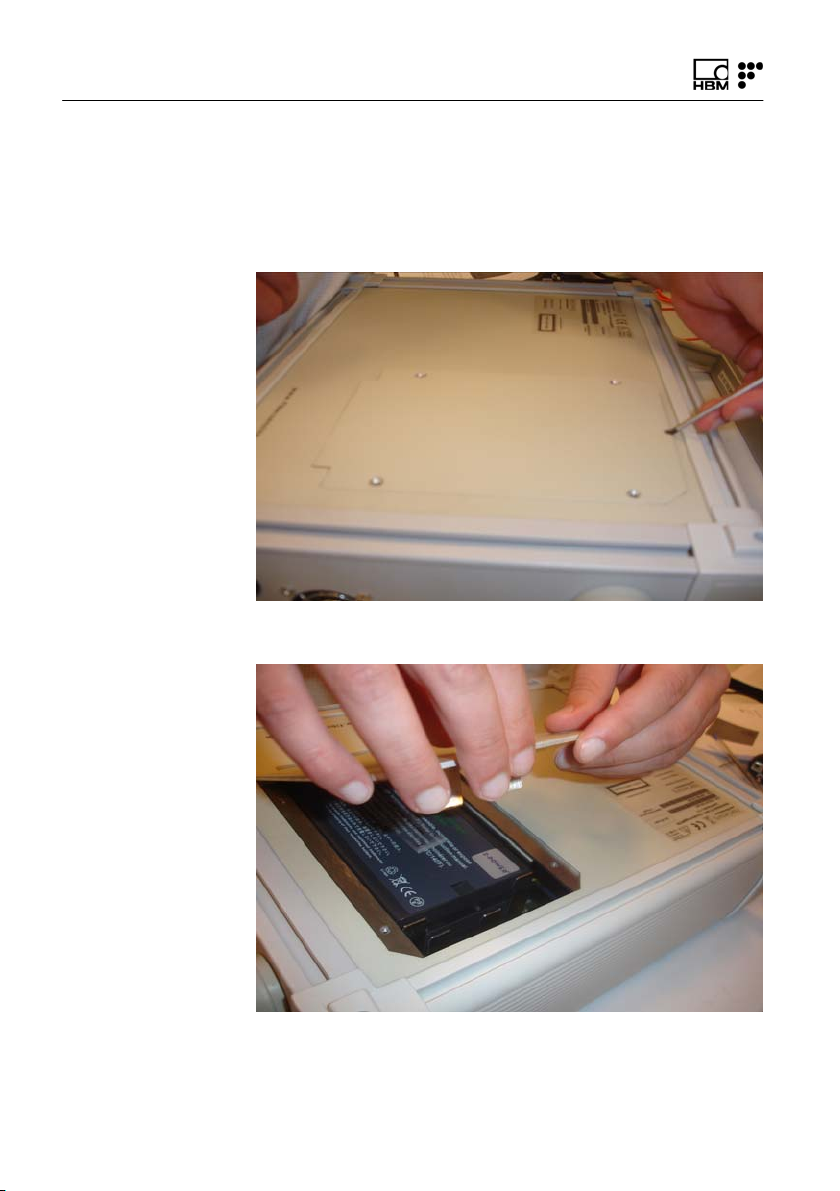

4. Pull the battery cover rotating on the bottom edge and

then remove it. To lift-up the pack, use a screwdriver

as shown in Fig. 4.4. Do not insert the screw driver

more than few millimeters.

Fig. 4.4

Fig. 4.5

22 A4250-5.0 HBM: public FS42

Page 23

Operation

5. Pull the edge of the battery vertically, number 1

in Fig. 4.6.

6. Remove the battery by sliding it horizontally,

number 2 in Fig. 4.6.

7. Repeat the process for the second battery, see

Fig. 4.7.

Fig. 4.6

FS42 A4250-5.0 HBM: public 23

Page 24

Operation

Fig. 4.7

24 A4250-5.0 HBM: public FS42

Page 25

Operation

4.5.2 Connecting the Battery Pack

Important

Make sure the interrogator is switched off before placing

the batteries.

To connect a battery pack, proceed as follows:

1. Align the Battery Pack in the Back Panel slot, as in

Fig. 4.8. Take particular attention not to damage the

pins of the connection, blue rectangle in Fig. 4.8.

Fig. 4.8

2. Slide the battery horizontally, number 1 in Fig. 4.8,

until the battery is connected on the blue rectangle

(blue rectangle in Fig. 4.8).

3. Lower the edge of the Battery down, number 2 in

Fig. 4.8.

4. Repeat the process for the second battery and screw

the cover.

FS42 A4250-5.0 HBM: public 25

Page 26

Operation

4.6 Switching ON

Pressing the “ON/OFF" button (see in Fig. 4.1 on

page 17) will start the engine. The interrogator software

will be automatically launched.

Once the interrogator is turned on both fans (see in

Fig. 4.1 on page 17) will start working.

To connect fiber Bragg grating based sensors to the Por

table BraggMETER FC/APC or SC/APC connectors must

be used (see in Fig. 4.1 on page 17). Attention should be

paid to the cleaning of the connector. A dirty connector

can compromise the measurement and will degrade the

interrogator. It is advisable to frequently clean the con

nectors using appropriate tools.

4.7 Switching OFF

To switch off the interrogator proceed in one of the fol

lowing ways:

1. While running the iLog software:

- Press the Exit button (see Fig. 4.9). If for the active

configuration the settings are set to “shut down on

exit", the interrogator will shut down directly. If not,

the software is active and steps described in 2

should be performed. Refer to section 6

“iLog Software”, on page 45, for further details.

26 A4250-5.0 HBM: public FS42

Page 27

Fig. 4.9

- Press and release the ON/OFF button (see

Fig. 4.10) for ~250 milliseconds. A pop-up will

appear to confirm the action.

Operation

Fig. 4.10

2. While at Windows™ environment:

- Select the start button and press shutdown.

- Press and release the ON/OFF button for

~250 milliseconds. A pop-up will appear to confirm

the action.

FS42 A4250-5.0 HBM: public 27

Page 28

Operation

4.8 Touch Screen Calibration

If a cover is applied on the touch screen for protection, it

might be necessary to repeat the screen configuration.

To perform the screen configuration proceed as follows:

1. Go to Start and press My Computer.

2. Open the file C:\Program Files\UPDD\TBCALIB

(Fig. 4.11).

3. The screen will become white and a cross will appear

on the top left corner. Use the screen pen to click on

the center of this and on the following crosses

(Fig. 4.12).

4. Press the Confirm button (Fig. 4.13).

28 A4250-5.0 HBM: public FS42

Page 29

Operation

Fig. 4.11

FS42 A4250-5.0 HBM: public 29

Page 30

Operation

Fig. 4.12

30 A4250-5.0 HBM: public FS42

Page 31

Operation

Fig. 4.13

FS42 A4250-5.0 HBM: public 31

Page 32

Measuring Examples

5 Measuring Examples

5.1 Measuring in 5 Steps

To start making an acquisition it takes no more than five

easy steps.

1. Charge the batteries;

2. Turn on the Portable BraggMETER interrogator;

3. Connect one sensor to an Optical Channel;

4. Click Auto Scan Button on the Configuration tab;

5. Hit the Run Button on the Graphical View or Spectral

View tabs.

5.2 Typical Configuration

Typically, a fiber Bragg grating sensing network is divided

into branches of sensors connected in series. In Fig. 5.1

there is a scheme of a usual FBG sensing branch.

FS62 Strain

FS63 Temperature

Fig. 5.1

FS64 Tilt

32 A4250-5.0 HBM: public FS42

Page 33

Measuring Examples

A branch can accommodate sensors with wavelengths

corresponding to all standard HBM FS wavelengths. The

number of sensors in a channel can vary if there is previ

ous knowledge about the spectral range the sensors will

cover. The major concern is the overlap of adjacent sen

sors. The available optical channels have simultaneous

acquisition, meaning that the sensing network can have a

large number of fiber Bragg grating sensors interrogated

at the same time.

The employed technology allows a multi-functionality

meaning that on the same branch it is possible to mea

sure Strain, Temperature, Displacement, Pressure,

Acceleration, etc…

The sensing network can be up to 10 km away from the

interrogator for there are no EM/RF interferences or sig

nificant losses of light in the optical fiber.

Each FBG sensor has a characteristic central wavelength

(λ0) that depends only on the measurand. This means

that with this technology there is no need for recalibra

tions every time the system is shut down.

The Portable BraggMETER is a portable interrogator

designed to be autonomous (uses battery) and easy to

carry (small size and reduced weight) to be plainly used

in different projects.

FS42 A4250-5.0 HBM: public 33

Page 34

Measuring Examples

5.2.1 HBM FS Wavelengths

The HBM FiberSensing standard wavelengths are:

FS Line

Central wavelength (nm)

N - 1503.3 1520

O - 1509.7 1525

K - 1516.1 1530

L - 1522.5 1535

A - 1528.9 1540

B - 1535.1 1545

C - 1541.5 1550

D - 1547.9 1555

E - 1554.3 1560

F - 1560.8 1565

G - 1567.2 1570

H - 1573.8 1575

I - 1580.2

J - 1586.6

OP Line

Central wavelength (nm)

34 A4250-5.0 HBM: public FS42

Page 35

Measuring Examples

5.3 Definitions and Operation Methods

The following definitions are applicable to this equipment

only.

5.3.1 Wavelength

The wavelength value corresponds to the wavelength at

the peak of the fiber Bragg grating reflection spectrum,

commonly referred as Bragg wavelength (Fig. 5.2).

Fig. 5.2

FS42 A4250-5.0 HBM: public 35

Page 36

Measuring Examples

5.3.2 Power

The Power value corresponds to the optical power

reflected by the fiber Bragg grating at the peak wave

length (Fig. 5.3). It is a relative value from 0 to 4095.

Fig. 5.3

36 A4250-5.0 HBM: public FS42

Page 37

Measuring Examples

5.3.3 Threshold

The threshold value corresponds to the considered

power level for the FBG peak computation and can be

used to disregard side lobes and ground noise.

In its linear representation, it is measured bottom-up from

the 0 (zero) power value.

Fig. 5.4

In its logarithm representation, it is a value in dB from the

maximum peak power of the channel.

FS42 A4250-5.0 HBM: public 37

Page 38

Measuring Examples

Fig. 5.5

Threshold is a value between:

-minimum: 23dB (corresponding to 0.005 in linear scale)

-maximum: 0.1 dB (corresponding to 0.95 in linear scale)

38 A4250-5.0 HBM: public FS42

Page 39

Measuring Examples

5.4 Common Measuring Difficulties

There may be the possibility of having measuring mal

functions due to several problems in the sensing network

or optical connections. A list of some of the usual prob

lems is described below with the explanation for its

occurrence and correction.

5.4.1 Dirty Connector

When an interrogator is repeatedly being plugged in and

out with optical connectors, it is very important that the

connectors are cleaned prior to any connection. Other

wise, dust and moister can be deposited in the interroga

tor adaptor and this will compromise measurements. In

Fig. 5.6 a picture of a magnified connector is presented.

The dark gray circle corresponds to the fiber cladding

and the small light gray circle is the core of the fiber. One

picture for a clean connector and one picture for a dirty

connector are presented.

Clean connector Dirty connector

Fig. 5.6

The most common effect of dirt on the connections is a

large amount of broad band light being reflected at the

connection, in both directions, meaning that the dynamic

range for measurements becomes smaller.

FS42 A4250-5.0 HBM: public 39

Page 40

Measuring Examples

Fig. 5.7

To clean an optical interrogator adapter, use an appropri

ate cotton swab (there are several cleaning swabs in the

market frequently used for telecom) embedded in iso

propyl alcohol. Insert it in the optical adapter, as in

Fig. 5.8, and rotate the swab always in the same direc

tion.

40 A4250-5.0 HBM: public FS42

Page 41

Measuring Examples

Fig. 5.8

5.4.2 Broken Connector

It may also occur that the interrogator adapter ferrule

breaks. In this case, when an optical connector is

inserted it does not get proper alignment and measure

ments are compromised. A broken ferrule will look as

shown in Fig. 5.9.

Fig. 5.9

To solve this problem you should contact HBM

FiberSensing.

FS42 A4250-5.0 HBM: public 41

Page 42

Measuring Examples

Tip

A connector is more prone to degradation in applications

where you are constantly connecting and disconnecting

sensors. To avoid early degradation and protect the inter

rogator connector use a small patch cable and an

adapter.

5.4.3 Reflective Fiber Ending

Even when all connections have been performed cor

rectly, it may occur that the interrogator does not find any

sensor on the array. One of the reasons may be the

excess of reflected light saturating the detectors.

When a fiber is perfectly cut (Fig. 5.10 on the left) a large

amount of light is reflected right back to the fiber core in

the right direction, heading to the interrogator detectors.

When this occurs, an index matching gel or an angled

termination must be used. If these are unavailable, the tip

of the fiber can be smashed with a metallic tool. This will

destroy the perfect geometry (Fig. 5.10 on the right) and

the light that is reflected will take random directions end

ing up outside of the core.

42 A4250-5.0 HBM: public FS42

Page 43

Measuring Examples

Reflective Fiber Ending

Fig. 5.10

5.4.4 Cut Fiber

When the fiber, for any reason, is broken between sen

sors in a series, the sensors that are after the fault may

disappear from the optical spectrum and will not be

detected.

There may also be the case that the fiber is cut, but not

completely spread apart (e.g. the fiber is damaged in an

area covered with glue). This will cause a Fabry-Pérot

effect – the light will suffer multiple reflections inside the

cavity creating sinusoidal background reflection. Fig. 5.11

shows a schematic representation of the reflected spec

trum for these three presented cases.

Refractive Fiber Ending

FS42 A4250-5.0 HBM: public 43

Page 44

Measuring Examples

Fig. 5.11

44 A4250-5.0 HBM: public FS42

Page 45

6 iLog Software

6.1 General Details

6.1.1 Software Version

This document refers to HBM FiberSensing interrogator

software version v5.4.

6.1.2 Software Update

The interrogator software can be updated. Whenever the

software is updated, changes will also be performed in

the internal Database.

iLog Software

Information

To ensure no configuration losses, please make sure you

have properly backed up your sensor configurations.

To see the current software version use "info" (number 7

in Fig. 6.2) functionality.

FS42 A4250-5.0 HBM: public 45

Page 46

Graphical User Interface

6.2 Graphical User Interface

The Front Panel of the iLog software is divided in two

functional areas. The bottom toolbar contains the con

trols that are always available. The upper main area has

several menus separated with tabs.

6.2.1 General and Management Controls

The controls that are always available are the following:

Fig. 6.1

1 General Information Bar – Displays information on the

current status or instructions.

2 Alarm Led – If blinking red or yellow, this led indicates

that an alarm has been reported (see section 6.2.6,

page 71). It will turn green again, once the alarm is

acknowledged.

3 Battery Status – For interrogators where there is a

battery, this icon has three different states regarding

the actual power situation: Charging, Battery OK or

Battery Low. For interrogators plugged in, this icon will

be on with a figure of a plug.

4 Battery Charge – Displays percentage of remaining

battery charge.

46 A4250-5.0 HBM: public FS42

Page 47

Graphical User Interface

Information

S When the battery level reaches 10%, a popup

appears informing the user of that situation.

S When the battery level reaches 7%, the interrogator

shuts down.

S When the battery level reaches 5%, it is not possible

to power up the interrogator.

5 Eject External devices – Using this button USB flash

drive or other external devices can be safely removed.

6 Run/Stop – Starts and stops data acquisition.

7 Exit – Shuts down the interrogator or exits the appli

cation (see number 2 in Fig. 6.10, on page 56).

8 Current date and time.

6.2.2 Graphical View

Within the Graphical View tab, real time measurements

can be monitored.

FS42 A4250-5.0 HBM: public 47

Page 48

Graphical User Interface

Fig. 6.2

Data is both displayed in values format (number 1 in

Fig. 6.2) and graphs format (number 2 in Fig. 6.2).

Graph and Plot

The two vertical scales of the graph can be changed. To

change one side of the scales, click on the label near the

edge. A popup window will appear where the new maxi

mum or minimum value can be written (Fig. 6.3). The

Zoom Fit button (number 4 in Fig. 6.2) can be used to

change the vertical scales limits in order to visualize the

full data range.

48 A4250-5.0 HBM: public FS42

Page 49

Graphical User Interface

Fig. 6.3

The time scale can also be altered by pressing on the

horizontal axis. The time scale window will pop up

(Fig. 6.4).

Fig. 6.4

The Collapse button (number 5 in Fig. 6.2) zeros graphi

cal values. While this function is ON the button is pre

sented in dark gray. Once it is pressed again, the graphi

cal zero function is turned off and actual values are

displayed.

Important

The saved values on the recorded data will be the origi

nal ones despite the graphical representation.

FS42 A4250-5.0 HBM: public 49

Page 50

Graphical User Interface

The maximum number of sensors that can be plotted

is 16. Sensor order of appearance and plot color is

defined on the Configuration tab (see section “Sensor",

page 59).

Saving Data

The first action to perform before starting an acquisition

is defining sensors. This procedure is explained on sec

tion 6.2.4 “Configuration”, page 53.

The Run/Stop button (see Fig. 6.1 on section 6.2.1

“General and Management Controls”, page 46) will start

the acquisition process.

While the acquisition is running, the Run/Stop button

changes into its stop status (Fig. 6.5).

Fig. 6.5

Data can be saved by pressing the Save button (num

ber 3 in Fig. 6.2). A popup window will ask for the dataset

name. Saved data consists on a table containing the

timestamp for each measurement and corresponding

values for the active sensors. Other relevant information

relative to active sensors and interrogator configuration is

also saved.

Important

Saving data is impossible when the available database

space is lower than 5%.

50 A4250-5.0 HBM: public FS42

Page 51

Graphical User Interface

To stop recording, acquisition must be stopped and then

the save button should be pressed. This data can be

consulted and transferred under the tab Data View (fur

ther details are presented on section 6.2.3 “Data View”,

page 52).

Info and Help button

Pressing the Information button (number 7 in Fig. 6.2) an

information box on the software version will appear.

On the Help button (number 6 in Fig. 6.2), the .pdf of this

document can be found.

FS42 A4250-5.0 HBM: public 51

Page 52

Graphical User Interface

6.2.3 Data View

With several functionalities, this tab is suitable for viewing

datasets that have previously been saved, getting addi

tional information on the available database space and

transferring data.

Fig. 6.6

Displaying Saved Datasets

Select the dataset on the datasets dropdown box (num

ber 1 in Fig. 6.6).

To display data, select the View Data button (number 2 in

Fig. 6.6). While data is being loaded into the Data Graph

(number 3 in Fig. 6.6) the View Data button is replaced

by a Stop button that can be used to stop data loading.

52 A4250-5.0 HBM: public FS42

Page 53

Graphical User Interface

Fig. 6.7

The displayed data can be zoomed in using the Zoom In

button (number 4 in Fig. 6.6). While the button is active,

the area to zoom in can be selected. When pressed

back, the displayed data will be zoomed out.

Copying Saved Datasets

Data can be readily saved as a .txt file to an external

USB flash drive by pressing the Export button (number 5

in Fig. 6.6). The saved data corresponds to the data that

is displayed on the Data Graph.

Deleting Saved Datasets

The Available Database Space is displayed on a specific

box (number 6 in Fig. 6.6). Pressing the Delete button

(number 7 in Fig. 6.6) will remove the selected dataset.

Note that saving new data is impossible when Available

Data Base Space is lower than 5%.

6.2.4 Configuration

Under the Configuration tab it is possible to configure the

sensors and branches to be measured by the device.

Sensors in iLog Software are organized in a tree. Its ele

ments are Configurations, Branches and Sensors. The

configuration is the parent tree node and has one branch

FS42 A4250-5.0 HBM: public 53

Page 54

Graphical User Interface

per each available optical channel. In its turn, branches

group up sensors.

Fig. 6.8

The Configuration is divided in four major sections: The

Tree Configuration layout (number 1 in Fig. 6.8); a tool

bar with buttons that perform actions to the tree elements

(number 2 in Fig. 6.8); element properties box (number 3

in Fig. 6.8); and an area that changes accordingly to the

tree level that is selected (number 4 in Fig. 6.8). If the

selected element is Configuration or Branch, clicking on

the area will prompt a Windows Explorer window in order

to choose any picture or drawing to associate to that spe

cific Configuration or Branch. If the selected element is a

54 A4250-5.0 HBM: public FS42

Page 55

Graphical User Interface

Sensor, then a testing graph will appear (see section

“Sensor", page 59).

Creating Tree Elements

There are two distinct ways to create sensors:

1. The Autoscan button (number 10 in Fig. 6.10) auto

matically searches for Fiber Bragg Sensors creating a

configuration with branches that correspond to the

optical channels. Using the auto scan action the main

sensor characteristics will be filled. A popup window

will appear for the channel selection (Fig. 6.9) when

the Autoscan button is pressed.

Fig. 6.9

2. The New Configuration button (number 1 in Fig. 6.10)

creates a new configuration from scratch. This means

that there is the need to define a new branch selecting

New Branch button (number 9 in Fig. 6.10) and then

creating a new sensor using the New Sensor button

FS42 A4250-5.0 HBM: public 55

Page 56

Graphical User Interface

Configuring Tree Elements

Most of the operations that can be performed to the con

figuration elements are similar. The user can create new,

delete, rename, zero and set active any element of the

configuration simply by selecting it on the tree menu and

pressing the respective button.

Configuration

Fig. 6.10

and filling in the sensor characteristics (see section

“Sensor", page 59).

1 Create New configuration.

2 Edit configuration – The iLog supports multiple config

urations and each configuration can have its own

properties.

3 Delete configuration.

4 Rename configuration.

5 Zero configuration – Introduces an offset on all the

sensors in the configuration.

6 Set configuration Active – Sets active every element

of the selected configuration.

7 Save configuration – Saves the configuration selected

on the tree menu to a .srs file.

56 A4250-5.0 HBM: public FS42

Page 57

Graphical User Interface

8 Open configuration – Loads a configuration from a

.srs file.

9 Create New branch (see section “Branch", page 58)

10 AutoScan – Searches for connected sensors creating

an automatic configuration.

The editable characteristics of the configuration are:

Fig. 6.11

1 Acquisition (number 1 in Fig. 6.11) – When “ON” upon

start-up, the interrogator immediately starts to acquire

data.

2 Logging (number 2 in Fig. 6.11) – When “ON” upon

start-up, the interrogator immediately starts to acquire

and save data.

3 Shutdown on Exit (number 3 in Fig. 6.11) – When the

user selects the exit button, the interrogator checks

this setting on the active configuration to determine

whether to shutdown the interrogator or just the iLog

application.

FS42 A4250-5.0 HBM: public 57

Page 58

Graphical User Interface

Branch

Fig. 6.12

1 Edit branch.

2 Delete branch.

3 Rename branch.

4 Zero branch.

5 Set branch Active.

6 Create New sensor - Selecting the new sensor, the

sensor window for defining its characteristics is called.

The menu is the same as the Edit sensor (see num

ber 6 from section “Sensor”, page 59).

The branch characteristic that can be edited for every

sensor of a branch at once is the Threshold (number 2

in Fig. 6.13) to the selected Optical Channel (number 1

in Fig. 6.13).

Information

For more information on Threshold see section 5.3.3 on

page 37.

58 A4250-5.0 HBM: public FS42

Page 59

Fig. 6.13

Sensor

Graphical User Interface

Fig. 6.14

1 Edit sensor.

2 Delete sensor.

3 Rename sensor.

4 Zero sensor.

5 Set sensor Active.

6 Test sensor – Pressing the Test sensor button, the

sensor value will be displayed on the graph area.

Sensor characteristics can be edited (Fig. 6.15).

FS42 A4250-5.0 HBM: public 59

Page 60

Graphical User Interface

Fig. 6.15

1 Sensor Category defines whether the sensor is an

Optical Sensor or a Virtual Sensor.

2 For all sensors the Name is a compulsory field.

3 CWL Central Wavelength (λ0) is the wavelength value

to which wavelength shift (Δλ) is calculated. In some

sensors, for absolute values, this should be the stated

wavelength on the calibration sheet. For zeroed mea

surements, this should be the sensors wavelength on

the zero instant.

4 The Ranges are defined as safety bands to avoid

crosstalk between sensors meaning that each sensor

60 A4250-5.0 HBM: public FS42

Page 61

Graphical User Interface

has its own operation range. It is not possible to con

figure sensors with overlapping operation ranges.

Nevertheless, since these ranges are dynamic, they

will follow the measured wavelength (λ). If a range

from a neighbor sensor overlaps the sensor's range,

measurement errors will occur.

Important

Dynamic ranges should be carefully selected in order to

avoid overlap during measurement. If this happens, read

ing errors will occur.

5 The Formula box allows the definition of the calcula

tions to be performed on the measured value of wave

length shift (x=Δλ=λ-λ0) (x=Measured WL-CWL). Here

it is possible to set a formula manually. To do so, click

on the formula box and a formula window will appear

(Fig. 6.16).

Fig. 6.16

Formulas can be inserted using Excel syntax on the for

mula area (number 1 in Fig. 6.16).

FS42 A4250-5.0 HBM: public 61

Page 62

Graphical User Interface

It is possible to copy and paste formulas from other loca

tions.

Additionally, it is possible to save formulas and use them

as a pre-set formula (Fig. 6.17) by pressing the button

Create Formula (number 2 in Fig. 6.16).

To select previously saved formulas use the box num

ber 3 in Fig. 6.16. Selected Formulas can be deleted

(number 4 in Fig. 6.16).

Information

Fig. 6.17

Name the formula (number 1 in Fig. 6.17), write its

expression (number 2 in Fig. 6.17) and select the unit

type (number 3 in Fig. 6.17) for that formula.

6 On the Offset box an offset to the wavelength (in nm)

can be defined.

7 Type dropdown box can be changed according to the

sensors type.

62 A4250-5.0 HBM: public FS42

Page 63

Graphical User Interface

8 Unit can be changed according to the sensor's output

unit.

9 The Active dropdown box defines whether the sensor

is active, hence plotted and saved. A sensor that is

not active will not be plotted nor saved on the dataset.

10 The Plot dropdown box activates the plotting of the

sensor and prompts the user to choose a color for the

sensor (number 11 in Fig. 6.15).

11 Changes the plot color.

12 The Scale option defines if the graphical representa

tion is to be referred to the left or to the right scales.

13 Temperature compensation - activates or deactivates

the computation of temperature compensation. Sen

sors can be automatically compensated for tempera

ture effects. Clicking on the edit button that appears

when temperature compensation is checked, the for

mula window will be displayed (Fig. 6.18).

Fig. 6.18

FS42 A4250-5.0 HBM: public 63

Page 64

Graphical User Interface

The correction can be performed using a preset tempera

ture gradient (number 1 in Fig. 6.18) or by collecting tem

perature data from a sensor in runtime (number 2 in

Fig. 6.18).

The sensor from which data will be collected for tempera

ture compensation must be defined as a Temperature

Sensor Type (number 8 in Fig. 6.15).

The Temperature Compensated Value will be calculated

using the Sensor measurement, minus the influence of a

temperature change in the sensor's output:

Important

FMLAS1[lS1* offsetS1* l

] * TCS [FMLAS1(lS2* offsetS2* l

0 S1

0 S2

) * T

REF

]

Where:

S S1 is the sensor to be compensated;

S S2 is the temperature sensor to be used as a refer

ence;

S FMLASk is the formula defined for the sensor Sk

(see Fig. 6.16);

S λSk is the measured wavelength for sensor Sk;

S offsetSk is the defined offset for sensor Sk (see num

ber 7 in Fig. 6.15);

S λ

is the central wavelength defined for sensor Sk;

0 Sk

S TCS is the sensor's Temperature Cross Sensitivity

(see number 4 in Fig. 6.18);

S T

is the user defined temperature (number 3 in

REF

Fig. 6.18) that should correspond to the temperature

64 A4250-5.0 HBM: public FS42

Page 65

Graphical User Interface

sensor measurement on the instant the user wishes

to define as “zero".

Tip

Start acquisition of the temperature sensor to define

T

.

REF

Important

The temperature compensation does not consider the

effect of the temperature gradient on the structure.

Sensor Categories

Optical Sensor

An Optical Sensor is a real Fiber Bragg Grating to which

a certain central wavelength corresponds.

Virtual Sensor

The Virtual Sensor is a sensor that is defined as a func

tion of one or more Optical Sensors.

To set the Virtual Sensor formula select the sensor cate

gory as virtual (number 1 in Fig. 6.15) and click in the

Formula button (number 5 in Fig. 6.15, page 60).

FS42 A4250-5.0 HBM: public 65

Page 66

Graphical User Interface

Fig. 6.19

The formula can be entered on the Formula box (num

ber 1 in Fig. 6.19) using the Sensor List dropdown (num

ber 2 in Fig. 6.19) and the Virtual Keyboard (number 3 in

Fig. 6.19).

6.2.5 Spectral View

The main purpose of the Spectral View tab is to provide

graphical information on some characteristics of the Fiber

Bragg Grating Sensors Spectrum from each Optical

Channel.

66 A4250-5.0 HBM: public FS42

Page 67

Fig. 6.20

Graphical User Interface

On the Spectral View graph (number 1 in Fig. 6.20) the

normalized power spectral distribution of each Optical

Channel is displayed. The Optical Channel that is repre

sented can be chosen using the Optical Channel Drop

down Box (number 2 in Fig. 6.20). Information on peak

wavelength values as well as on their normalized ampli

tudes (number 3 in Fig. 6.20) can also be found on the

Spectral View tab.

Information

The amplitudes are normalized to the highest reflection

peak.

FS42 A4250-5.0 HBM: public 67

Page 68

Graphical User Interface

The normalized threshold value for each Optical Channel

can be inserted on the Threshold box (number 4 in

Fig. 6.20) and can be shown graphically in the OSA

graph (number 5 in Fig. 6.20). This is an important

parameter, and must be set so that all FBG spectrum

peaks are above the line and that only one peak per FBG

sensor appears over the line. For definition please refer

to section 5.3.3, on page 37.

Graphic Tools

Tools to manage the graphical representation are avail

able on the buttons above the graph (number 6 in

Fig. 6.20).

Fig. 6.21

1 Zoom out - The Spectrum graph can be zoomed in or

out. The Zoom In tool is ready every time the cursor is

on the graph area. Zooming In is only possible on the

horizontal axis. By pressing the Zoom Out button

(number 1 in Fig. 6.21) the graph will zoom out to dis

play the entire optical spectrum range.

2 Linear/log - the vertical scale can be changed from

linear to logarithmic by pressing the Scale button.

With this selection the spectrum is represented in log

arithmic scale (number 1 in Fig. 6.22) and the normal

ized threshold value is converted to match Optical

Power units regarding maximum peak acquired value.

68 A4250-5.0 HBM: public FS42

Page 69

Graphical User Interface

The label will change to match the scale option that is

selected, linear or logarithmic."

Fig. 6.22

If the user chooses Logarithmic peak detection mode in

Configuration tab (see number 2 in Fig. 6.21, page 68)

the OSA graph will be showed in logarithmic mode after

starting acquisition.

Information on peak wavelength values as well as on

their amplitudes (number 2 in Fig. 6.22) can also be

found on the Spectral View tab.

FS42 A4250-5.0 HBM: public 69

Page 70

Graphical User Interface

The connector output optical power reference is specified

on the interrogator User Manual.

3 Add reference - the tracing tools allow the displaying

4 Manage - to display or rename a previously saved

Information

of an additional trace on the Spectrum Graph. These

can be previously saved wavelength graphs or user

defined traces.

Pressing the Add button, the software will save the

wavelength graph naming the file with the instant date

and time (DD.MM.YYYY_hh:mm:ss.dat).

OSA trace, the Manage OSA Trace button should be

pressed (number 4 in Fig. 6.21). A selection window

will appear (Fig. 6.23) and the OSA Reference file can

be chosen (number 1 in Fig. 6.23).

Fig. 6.23

To rename the reference file, press the button num

ber 2 in Fig. 6.23.

To turn off an active OSA Reference choose “----“ on

OSA references drop list, (number 1 in Fig. 6.23).

70 A4250-5.0 HBM: public FS42

Page 71

Graphical User Interface

5 Save as Table - the Spectrum can be saved as a

table to a USB flash drive. Naming is automatic: OSADD-MM-YYY-hh-mm-ss.xls.

6 Save as Picture - the Spectrum can be saved as a

bitmap file to a USB flash drive. Naming is automatic:

OSA-DD-MM-YYY-hh-mm-ss.bmp.

6.2.6 Alarms

This tab is mainly used for gathering information on the

generated alarms and events. Alarms are system created

events. Events correspond to every action that the user

performs.

Fig. 6.24

FS42 A4250-5.0 HBM: public 71

Page 72

Graphical User Interface

All alarm and events messages are displayed in a table

(number 1 in Fig. 6.24).

Every time the iLog software starts up, events and

alarms with more than 30 days are deleted.

The only actions that can be performed under this tab

are:

1. Cleaning tables by pressing the Clear button (num

2. Displaying the last 30 day events and alarms that

The Alarm LED on the general management controls

(number 2 in Fig. 6.1) can be in three different colors:

Information

ber 2 in Fig. 6.24)

have occurred during handling and usage of the inter

rogator (number 4 in Fig. 6.24) and export them (num

ber 3 in Fig. 6.24)

System Alarms

Blinking red

Blinking yellow

Steady green No alarm.

NaN measurement or communication error/failure at a

rate of more than 10 events per minute.

NaN measurement or communication error/failure at a

rate of less than 10 events per minute.

72 A4250-5.0 HBM: public FS42

Page 73

Sensor Alarms

Graphical User Interface

Blinking yellow

Steady green

More than 10 “sensor out of range" notification per

minute.

No alarm or less than 10 “sensor out of range" notifi

cation per minute

FS42 A4250-5.0 HBM: public 73

Page 74

Graphical User Interface

74 A4250-5.0 HBM: public FS42

Page 75

Graphical User Interface

FS42 A4250-5.0 HBM: public 75

Page 76

HBM Test and Measurement

Tel. +49 6151 803-0

Fax +49 6151 803-9100

info@hbm.com

measure and predict with confidence

www.hbm.com

A4250-5.0 7-2002.4250 HBM: public

Loading...

Loading...