Page 1

User Manual

English

FS22 DI

Industrial BraggMETER DI

Page 2

Hottinger Baldwin Messtechnik GmbH

Im Tiefen See 45

D-64239 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

info@hbm.com

www.hbm.com

HBM FiberSensing, S.A.

Optical Business

Rua Vasconcelos Costa, 277

4470-640 Maia

Portugal

Tel. +351 229 613 010

Fax +351 229 613 020

fibersensing@hbm.com

www.hbm.com/fs

Mat.: 7-2002.4248

DVS: A4248-6.0 HBM: public

10.2017

Interrogator version: v2.0

SW version: v1.7

E Hottinger Baldwin Messtechnik GmbH.

Subject to modifications.

All product descriptions are for general information only.

They are not to be understood as a guarantee of quality or

durability.

Page 3

English

1 Technical Details 6.........................................

1.1 General Information 6........................................

1.2 System Components 7.......................................

1.3 Technical Data 8............................................

2 Regulatory and Certification Considerations 10................

2.1 Environment Considerations 10.................................

2.1.1 Disposal of your Old Appliance 10...............................

2.2 Laser Safety 11..............................................

2.2.1 Symbols 11..................................................

2.2.2 Class 1 Laser 11..............................................

2.2.3 General Precautions Considerations 12..........................

2.2.4 Certification 13...............................................

3 Operation 14................................................

3.1 Connectors 14................................................

3.1.1 Standard 14..................................................

3.1.2 Rack-Mountable 15...........................................

3.2 Setting Up 16................................................

3.2.1 Power Supply 16.............................................

3.2.2 Optical Connectors 16.........................................

3.2.3 Ethernet Connection 17........................................

3.3 Switching On 17..............................................

3.4 Switching Off 18..............................................

3.5 Operating the Interrogator 19...................................

3.5.1 Network Properties 19.........................................

3.5.2 Interrogator IP Address 23.....................................

3.5.3 Synchronization 24............................................

3.5.4 Operation 27.................................................

4 Measuring Examples 34......................................

4.1 Typical Configuration 34.......................................

FS22 DI A4248-6.0 HBM: public 3

Page 4

4.1.1 HBM FS Wavelengths 36......................................

4.2 Definitions and Operation Methods 37...........................

4.2.1 Wavelength 37...............................................

4.2.2 Power 38....................................................

4.2.3 Gain 39.....................................................

4.2.4 Threshold 40.................................................

4.3 Common Measuring Difficulties 41..............................

4.3.1 Dirty Connector 41............................................

4.3.2 Broken Connector 43..........................................

4.3.3 Reflective Fiber Ending 43.....................................

4.3.4 Cut Fiber 44.................................................

4.3.5 Fuse Failure 46...............................................

5 Remote Communications 48..................................

5.1 Communication Protocol Syntax 48.............................

5.1.1 Command Syntax 48..........................................

5.1.2 Common Commands 50.......................................

5.1.3 System Commands 51........................................

5.1.4 Acquisition Commands 54.....................................

6 BraggMONITOR DI Software Details 63........................

6.1 Software Version 63...........................................

6.2 Install and Uninstall Software 63................................

6.2.1 System Requirements 63......................................

6.2.2 Software Installation 64........................................

6.2.3 Software Uninstall 65..........................................

6.3 Running the Software 65.......................................

6.3.1 Network Properties 65.........................................

6.3.2 Run as Administrator 66.......................................

7 BraggMONITOR DI User Interface 68..........................

7.1 General Bar 69...............................................

7.1.1 Acquisition 70................................................

4 A4248-6.0 HBM: public FS22 DI

Page 5

7.1.2 Software and Interrogator Information 75.........................

7.1.3 Exit Application 75............................................

7.2 Graphical Area 75............................................

7.2.1 Graphical View 76............................................

7.2.2 Numerical View 77............................................

7.2.3 Spectral View 78..............................................

7.2.4 FFT View 80.................................................

7.2.5 Configuration 81..............................................

7.2.6 SCPI Interface 89.............................................

FS22 DI A4248-6.0 HBM: public 5

Page 6

Technical Details

1 Technical Details

1.1 General Information

The Industrial BraggMETER DI is a continuous swept

laser scanning interrogator for fiber Bragg grating (FBG)

sensors. It includes a traceable wavelength reference

that provides continuous calibration to ensure system

accuracy over long term operation. The high dynamic

range and high output power allow high resolution to be

attained even for long fiber leads and lossy connections.

Multiple sensors can be connected in series in each opti

cal fiber, which in combination with the eight optical chan

nels with parallel acquisition for the FS22 - Industrial

BraggMETER DI, makes it particularly suitable for large

scale sensing networks, acquiring a large number of sen

sors simultaneously, providing 1000 S/s acquisition rates

with sub picometer resolution.

The BraggMETER is available in Standard and Rackmountable format. This Manual applies to the following

equipment:

Standard

K-FS22-01-500-120 FS22 – Industrial BraggMETER DI Single channel

K-FS22-03-500-120 FS22 – Industrial BraggMETER DI Single channel

K-FS22-01-500-420 FS22 – Industrial BraggMETER DI Quad channel

K-FS22-03-500-420 FS22 – Industrial BraggMETER DI Quad channel

K-FS22-01-500-820 FS22 – Industrial BraggMETER DI Octo channel

K-FS22-03-500-820 FS22 – Industrial BraggMETER DI Octo channel

6 A4248-6.0 HBM: public FS22 DI

Page 7

Technical Details

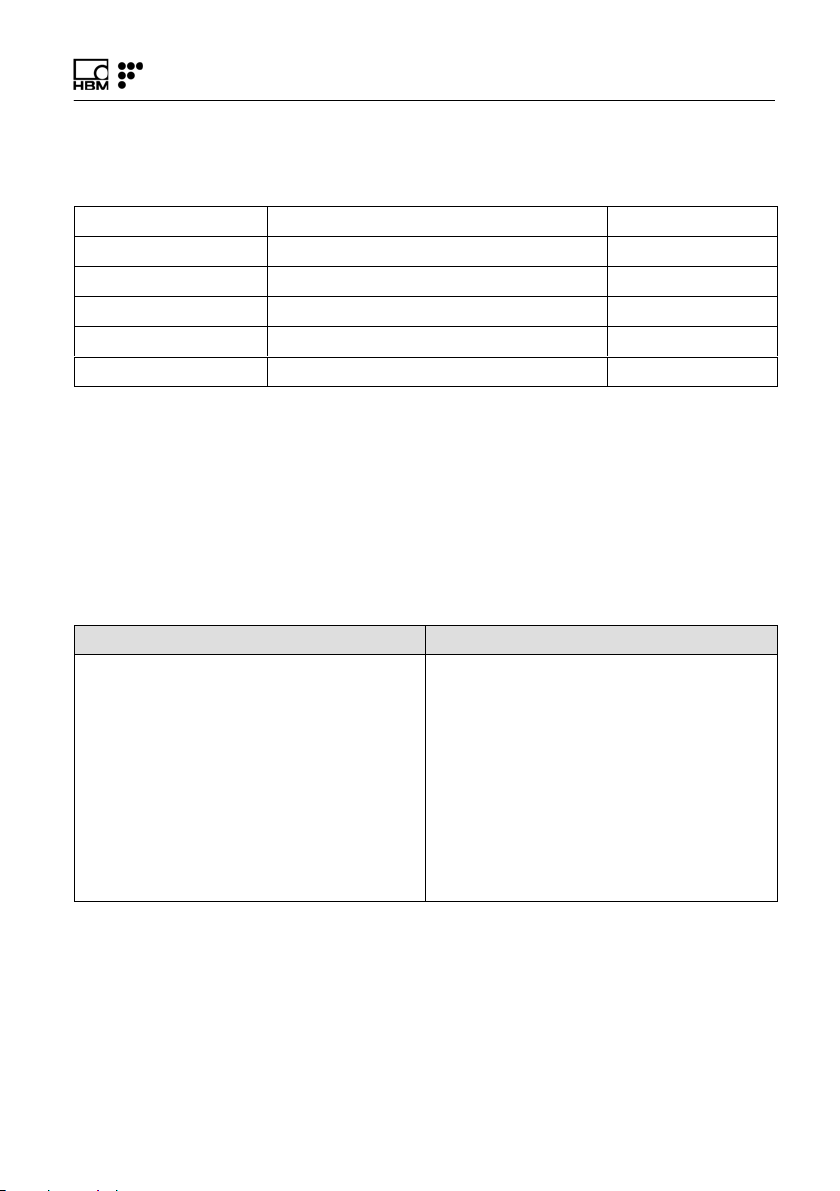

Rack-Mountable

K-FS22-11-500-120 FS22 – Industrial BraggMETER DI Single channel

K-FS22-13-500-120 FS22 – Industrial BraggMETER DI Single channel

K-FS22-11-500-420 FS22 – Industrial BraggMETER DI Quad channel

K-FS22-13-500-420 FS22 – Industrial BraggMETER DI Quad channel

K-FS22-11-500-820 FS22 – Industrial BraggMETER DI Octo channel

K-FS22-13-500-820 FS22 – Industrial BraggMETER DI Octo channel

HBM FiberSensing interrogators are compatible with

catman® software, a powerful tool for data acquisition

and processing.

1.2 System Components

The Industrial BraggMETER DI set includes:

Standard format Rack-mountable format

- Interrogator

- Power cord

- Power adapter

- Ethernet cable (L ~2 m)

- Mounting blocks with M6 screws

- Connector protection caps

- Quick guide

- Digital support material

- Calibration certificate

- Interrogator

- Power cord

- Ethernet cable (L ~2 m)

- Connector protection caps

- Quick guide

- Digital support material

- Calibration certificate

FS22 DI A4248-6.0 HBM: public 7

Page 8

Technical Details

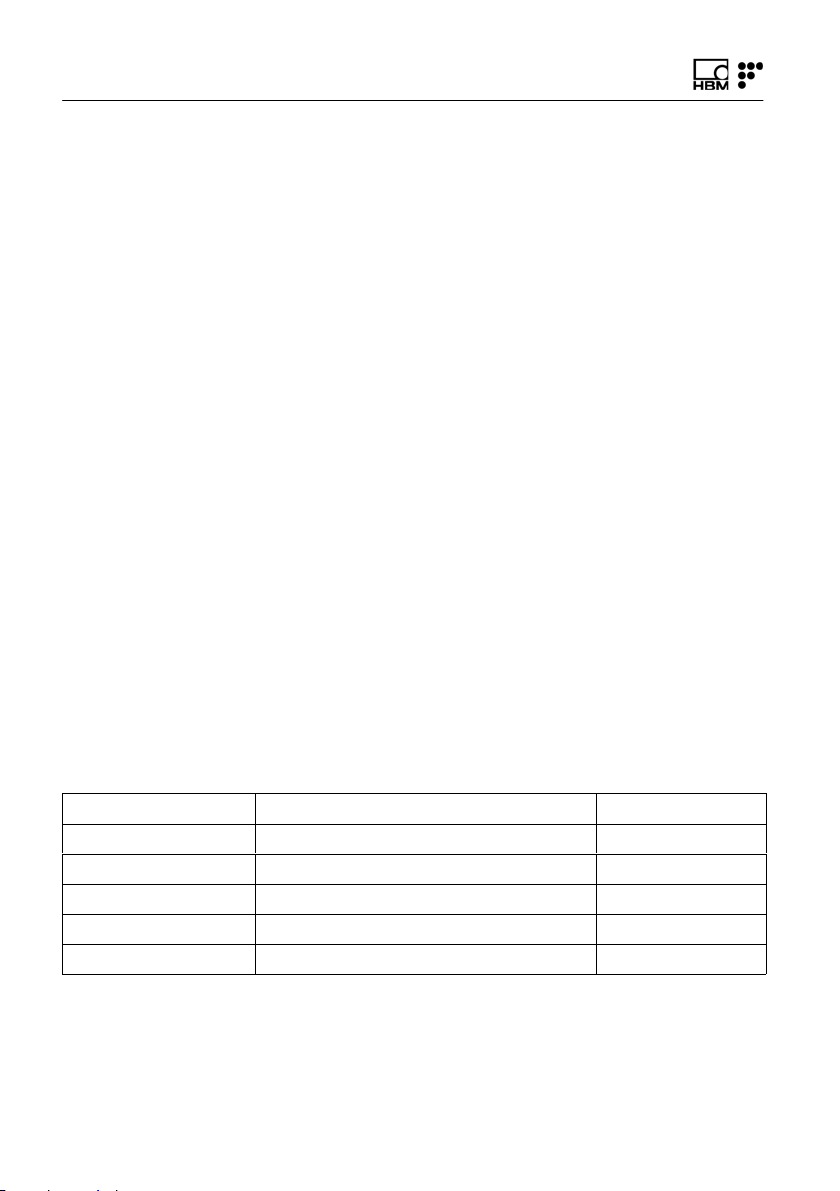

1.3 Technical Data

Wavelength Measurement

Range 100 nm (1500 to 1600 nm)

Resolution/Repeatability1)<1 pm

Stability/Reproducibility

Optical channels

Sample rate All available, user selectable

Possible values (S/s) 1000 500 200 100 50

Max. sensors/OC 31 63 127 127 127

Max. sensors total 48 96 200 400 600

Optical detection Linear (selectable gain steps)

Dynamic range

Laser Source

Optical output power

Single 0 dBm

Quad -3 dBm

Octo -6 dBm

Linewidth < 500 MHz

Connectors

Optical FC/APC or SC/APC

Electrical Standard: Weidmüller Terminal Block

Communication RJ45 Ethernet

Synchronization NTP

Control

Interface Ethernet (TCP/IP)

Commands SCPI (ASCII textual strings)

Features

OSA trace Continuous (1 S/s)

1)

5 pm

2)

3)

4)

1, 4 or 8

> 25 dB

SLDF 5.08 2-way supplied with 100-230V power adapter

and Type F plug cable

5)

Rack-Mountable: C14 (IEC/EN 60320-1) supplied with

Type F plug cable

(Wavelength, absolute power)

5)

6)

7)

8 A4248-6.0 HBM: public FS22 DI

Page 9

Technical Details

Environmental

Operation temperature 0 to 50 ºC

Storage temperature -20 to 70 °C

Operation humidity < 90% at 40 ºC

Storage humidity < 95% (non-condensing)

Shock resistance 20 g; 11 ms (EN60068-2-27)

Vibration resistance

Mechanical

Dimensions (w x h x d) Standard: 155 x 125 x 275 mm

Mounting Standard: 6 screws M6

Weight Standard: 4.5 kg (w/o mounting brackets)

Enclosure Aluminum (IP20)

Power

Voltage Standard: 11-36 VDC

Consumption

Nominal

9)

Stand by 2 W

1)

As described in HBM FiberSensing Technical Note "Definitions for Measurement Quality".

2)

With simultaneous acquisition.

3)

Considered as the ratio between the optical power emitted at an optical channel and the minimum

detectable optical power reflected by a fiber Bragg grating.

4)

Typical values.

5)

Different plug format can be added upon request.

6)

Standard Commands for Programmable Instruments.

7)

Full spectrum trace with 7050 points acquired over the 100 nm range.

8)

Sinusoidal vibration.

9)

Peak consumption may reach 50 W (during startup).

8)

2.5 g (EN60068-2-6)

Rack-Mountable: 483 x 88 x 400 mm

Rack-Mountable: 19" rack mountable (2U)

Rack-Mountable: 7 kg

Rack-Mountable: 100-240 VAC 50-60 Hz

4)

22.5 W

FS22 DI A4248-6.0 HBM: public 9

Page 10

Regulatory and Certification Considerations

2 Regulatory and Certification Considerations

2.1 Environment Considerations

2.1.1 Disposal of your Old Appliance

When the attached symbol combination - crossed-out

wheeled bin and solid bar symbol is attached to a product

it means the product is covered by the European Direc

tive 2002/96/EC and is applicable in the European Union

and other countries with separate collection systems.

All electrical and electronic products should be disposed

of separately from the municipal waste stream or house

hold via designated collection facilities appointed by the

government or the local authorities. The correct disposal

of your old appliance will help prevent potential negative

consequences for the environment and human health.

For more detailed information about disposal of your old

appliance, please contact your city office, waste disposal

service or distributor that purchased the product.

HBM FiberSensing is a manufacturer registered in the

ANREEE - "Associação Nacional para o Registo de

Equipamentos Eléctricos e Electrónicos" under number

PT001434. HBM FiberSensing celebrated a "Utente"

type contract with Amb3E - "Associação Portuguesa de

Gestão de Resíduos de Equipamentos Eléctricos e Elec

trónicos", which ensures the transfer of Electrical and

Electronic appliance waste management, i.e. placing

Electronic and Electrical appliances in the Portuguese

market, from the manufacturer HBM FiberSensing to

Amb3E.

10 A4248-6.0 HBM: public FS22 DI

Page 11

Regulatory and Certification Considerations

2.2 Laser Safety

The FS22 - Industrial BraggMETER DI interrogator con

tains a laser in its core. A laser is a light source that can

be dangerous to people exposed to it. Even low power

lasers can be hazardous to a person's eyesight. The

coherence and low divergence of laser light means that it

can be focused by the eye into an extremely small spot

on the retina, resulting in localized burning and perma

nent damage.

The lasers are classified by wavelength and maximum

output power into the several safety classes: Class 1,

Class 1M, Class 2, Class 2M, Class 3R and Class 4.

2.2.1 Symbols

Warning symbol Class 1 Laser symbol

2.2.2 Class 1 Laser

The FS22 - Industrial BraggMETER DI is a class 1 laser

product:

«Any laser or laser system containing a laser that cannot

emit laser radiation at levels that are known to cause eye

or skin injury during normal operation.»

FS22 DI A4248-6.0 HBM: public 11

Page 12

Regulatory and Certification Considerations

It is safe under all conditions of normal use. No safety

requirements are needed to use Class 1 laser devices.

This product contains a laser within an enclosure that

prevents exposure to the radiation and that cannot be

opened without shutting down the laser.

2.2.3 General Precautions Considerations

Everyone who uses a laser equipment should be aware

of the risks.

The laser radiation is not visible to the human eye but it

can damage user's eyesight.

The laser is enabled when the interrogator is turned on.

Users should never put their eyes at the level of the hori

zontal plane of the optical adapters of the interrogator or

uncovered optical connectors.

Adequate eye protection should always be required if

there is a significant risk for eye injury.

When an optical channel is not in use (no optical connec

tor plugged to the interrogator), a proper connector cap

must be used.

The optical connectors are subjected to maintenance

and/or inspection. Please refer to section 4.3.1 for main

tenance procedure.

Do not attempt to open or repair a malfunction interroga

tor. It must be returned to HBM FiberSensing for repair

and calibration.

12 A4248-6.0 HBM: public FS22 DI

Page 13

Regulatory and Certification Considerations

2.2.4 Certification

This product carries the CE marking and complies with

the applicable international requirements for product

safety and electromagnetic compatibility, according to the

following Directives:

S Low Voltage Directive (LVD) 2014/35/EU - Electrical

Safety

S Electromagnetic Compatibility (EMC) Directive

2014/30/EU

It is in compliance with the EN61326/EN55011 Emission

Radiated Test Class A, under the Electromagnetic Com

patibility Standard.

The corresponding Declaration of Conformity is available

upon request.

FS22 DI A4248-6.0 HBM: public 13

Page 14

Operation

3 Operation

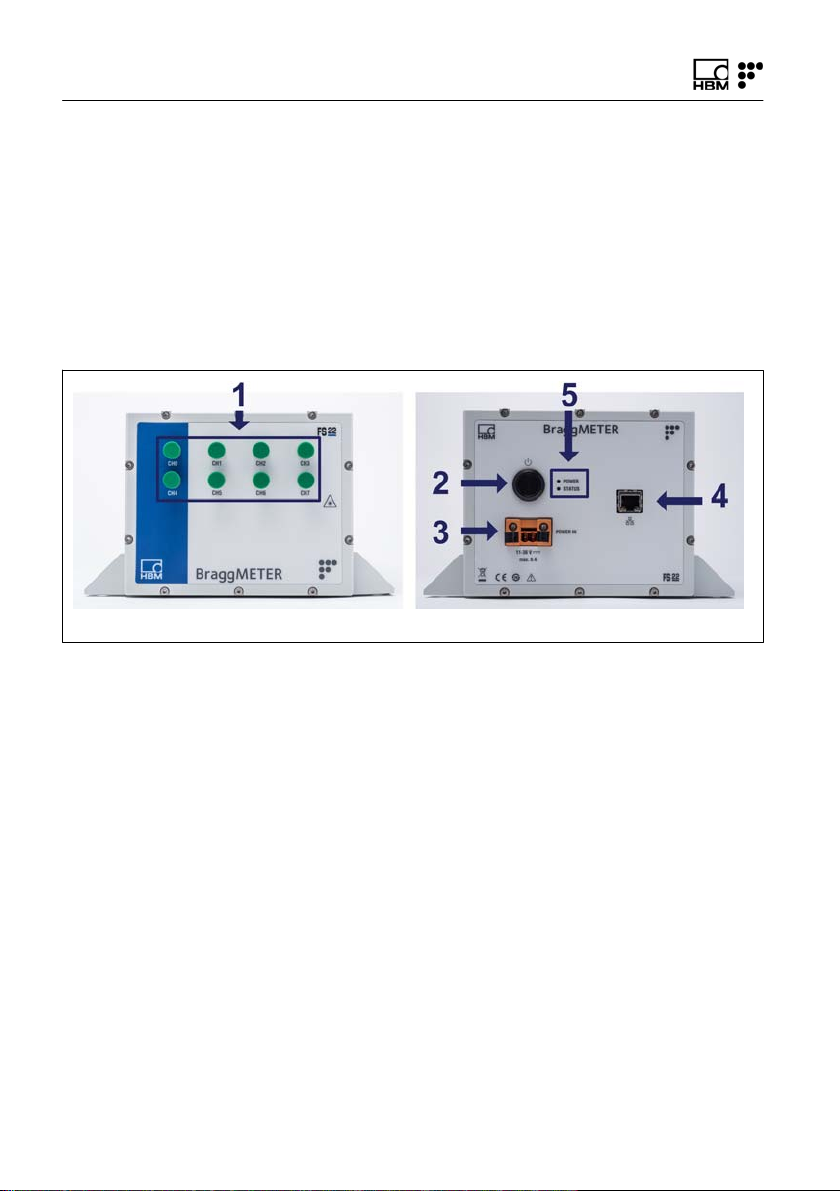

Front view Back view

3.1 Connectors

3.1.1 Standard

Fig. 3.1

The connectors and buttons in Fig. 3.1 are:

1 Optical Output Connectors (FC/APC)

2 ON/OFF Button

3 Power Connector

4 Ethernet Connector

5 POWER and STATUS LEDs

14 A4248-6.0 HBM: public FS22 DI

Page 15

3.1.2 Rack-Mountable

Front view

Back view

Fig. 3.2

Operation

The connectors and buttons in Fig. 3.2 are:

1 ON/OFF Button

2 POWER and STATUS LEDs

3 Optical Output Connectors

4 Power Connector

5 Electric Fuse

6 Safety Power Button

7 Fans

8 Ethernet Connector

FS22 DI A4248-6.0 HBM: public 15

Page 16

Operation

3.2 Setting Up

3.2.1 Power Supply

To start the Industrial BraggMETER DI Standard inter

rogator connect the supplied power adaptor to a 100 240 V power line, or an 11-36 VDC power line directly, to

the interrogator power connector (number 3 in Fig. 3.1).

To start the Industrial BraggMETER DI Rack-Mountable

interrogator connect the supplied power cable from a

100 - 240 V power line to the interrogator (number 4 in

Fig. 3.2) and turn on the safety power button (number 6

in Fig. 3.2).

The interrogator must be used with a dedicated power

supply source and not shared with other equipment.

3.2.2 Optical Connectors

The Industrial BraggMETER DI can be purchased either

with FC/APC, or SC/APC optical connectors. Number 1

in Fig. 3.1 and number 3 in Fig. 3.2 exemplifies FC/APC

connectors.

Attention should be paid to the cleaning of the optical

connectors. A dirty connector can compromise the mea

surement and will degrade the performance of the inter

rogator. It is advisable to frequently clean the connectors

using appropriate tools.

FS22 - Industrial BraggMETER DI can have one, four or

eight optical channels in parallel.

16 A4248-6.0 HBM: public FS22 DI

Page 17

Operation

3.2.3 Ethernet Connection

Connect the Ethernet RJ45 connector directly to a PC

using a Ethernet cross-over cable, or to a network con

nector using a direct Ethernet cable (in this case, the

Industrial BraggMETER DI must be in the same subnet

as your Local Network).

Important

The interrogator default network configuration is

"10.0.0.150:255.0.0.0:0.0.0.0".

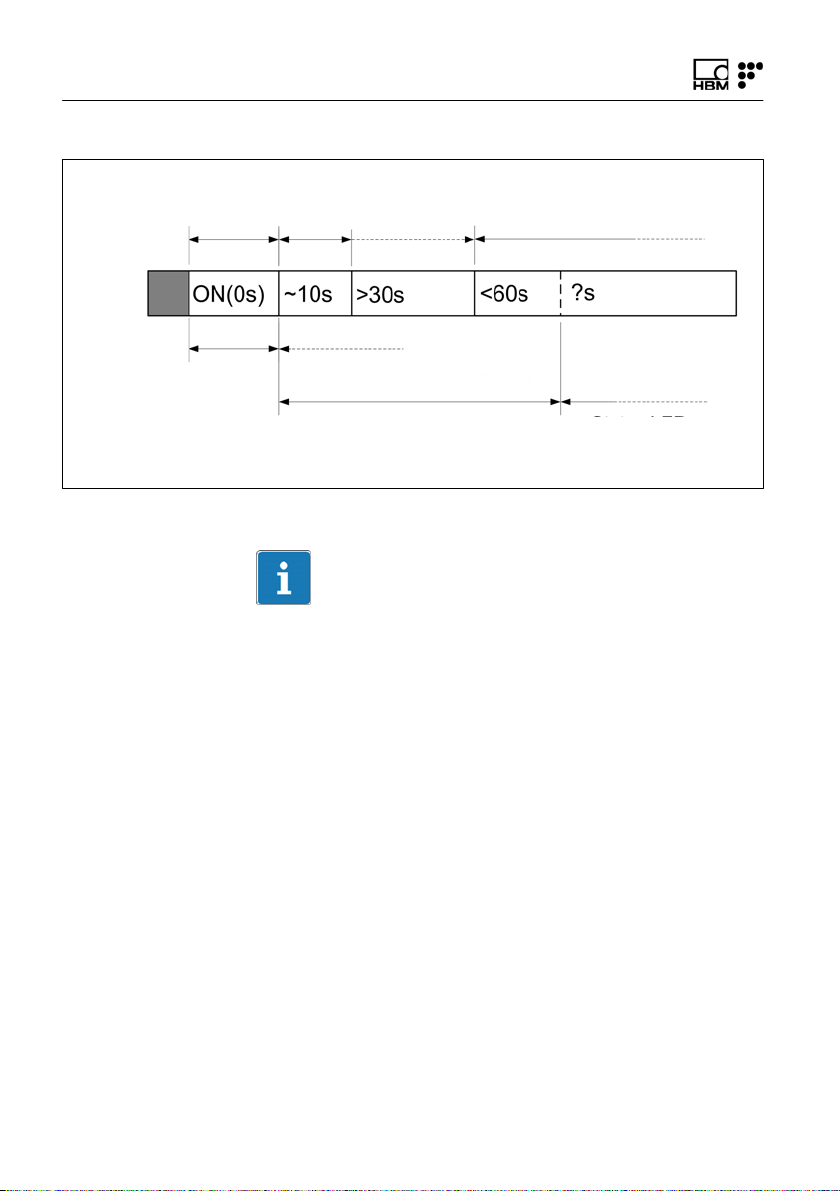

3.3 Switching On

Pressing the “ON/OFF" button (number 2 in Fig. 3.1 or

number 1 in Fig. 3.2) will start the interrogator. The STA

TUS LED (number 5 in Fig. 3.1 or number 2 in Fig. 3.2)

will start blinking at 2 Hz. After approximately 10 seconds

it will start blinking at 1 Hz. This means that the inter

rogator is already on and responsive, but the optoelec

tronic module is still warming up. After approximately

60 seconds it should stay on permanently. This means

that the interrogator is able to measure.

FS22 DI A4248-6.0 HBM: public 17

Page 18

Operation

CorrectWrong

Status LED

Blinking 2 Hz

Status LED

Blinking 2 Hz

Status LED

Blinking 1 Hz

Status LED

Blinking 5 Hz

(initialization issues)

Status LED

Blinking 1 Hz

Status LED

On

Status LED

Blinking 5 Hz

(measurement issues)

Fig. 3.3

Information

If the interrogator does not start correctly, the STATUS

LED will blink faster. If this happens, please contact HBM

FiberSensing technical support.

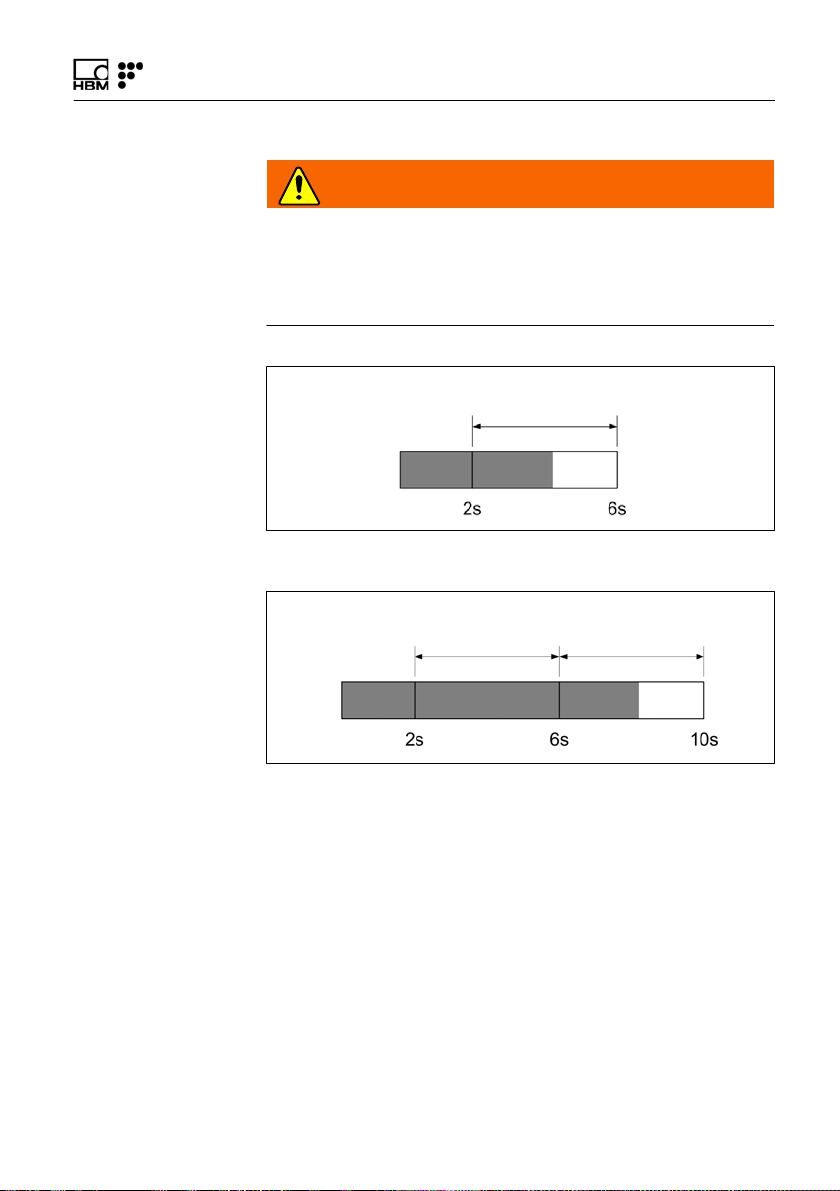

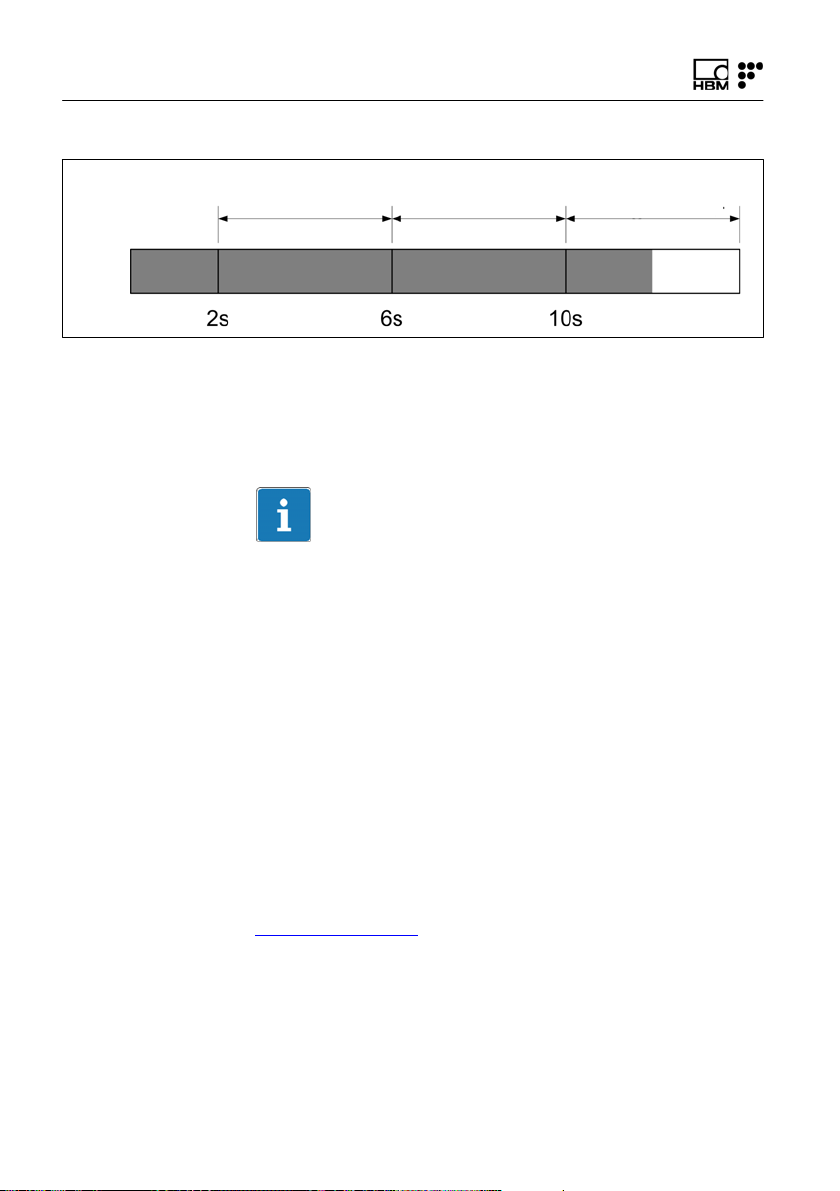

3.4 Switching Off

To avoid accidental shut-down of the interrogator, press

the "ON/OFF" button (number 2 in Fig. 3.1 or number 1

in Fig. 3.2) between 2 and 6 seconds (Fig. 3.4).

If for some reason the 6 seconds are exceeded and the

button is released before 10 seconds are over, the inter

rogator will remain ON (Fig. 3.5).

18 A4248-6.0 HBM: public FS22 DI

Page 19

Operation

WARNING

If the “ON/OFF” button is pressed more than 10 seconds,

changes on the interrogator configuration are performed

and connection might be lost. See section 3.5.2, under

Resetting IP to Default, for further details.

POWER LED

blinking at 1 Hz

Fig. 3.4

POWER LED

blinking at 1 Hz

Fig. 3.5

POWER LED

ON

3.5 Operating the Interrogator

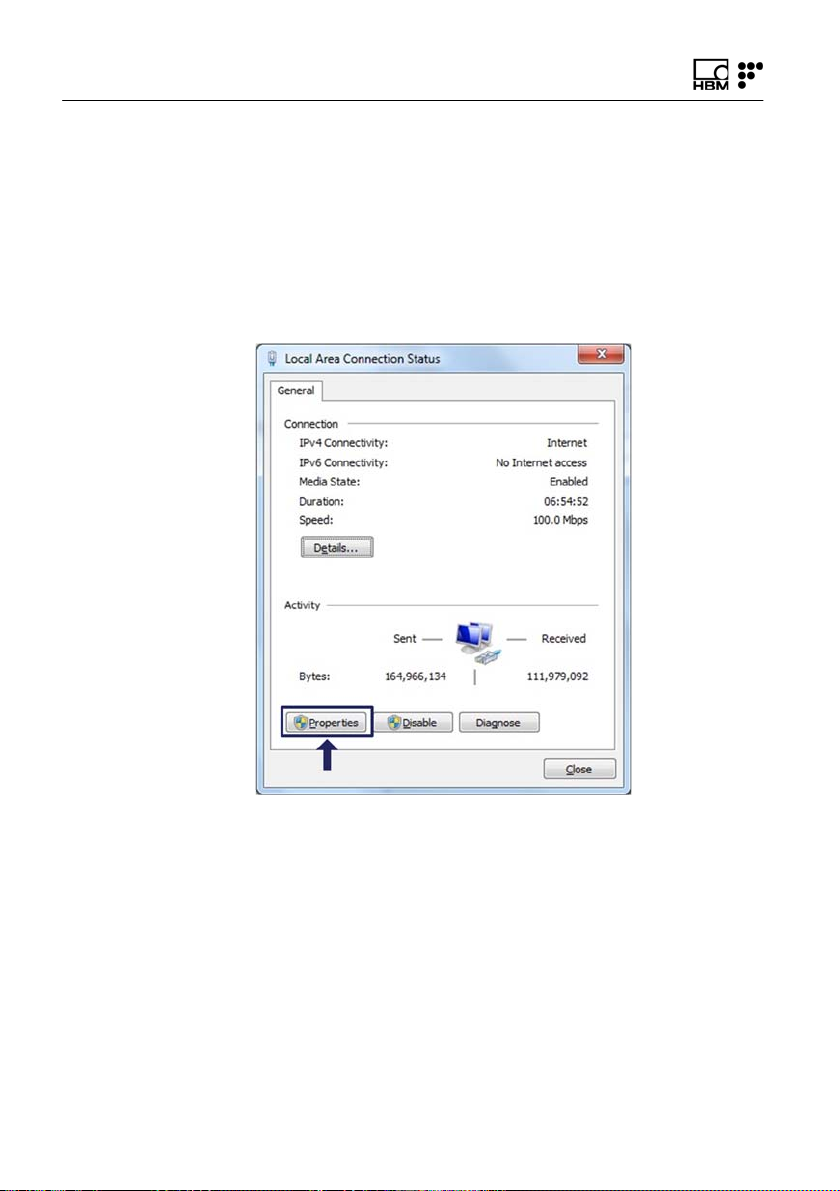

3.5.1 Network Properties

To operate the FS22 - Industrial BraggMETER DI from a

personal computer, the PC network properties should be

set so that both elements are configured in the same

subnet.

FS22 DI A4248-6.0 HBM: public 19

Page 20

Operation

To configure your personal computer so that it is on the

same subnet as the default for the interrogator, proceed

as follows:

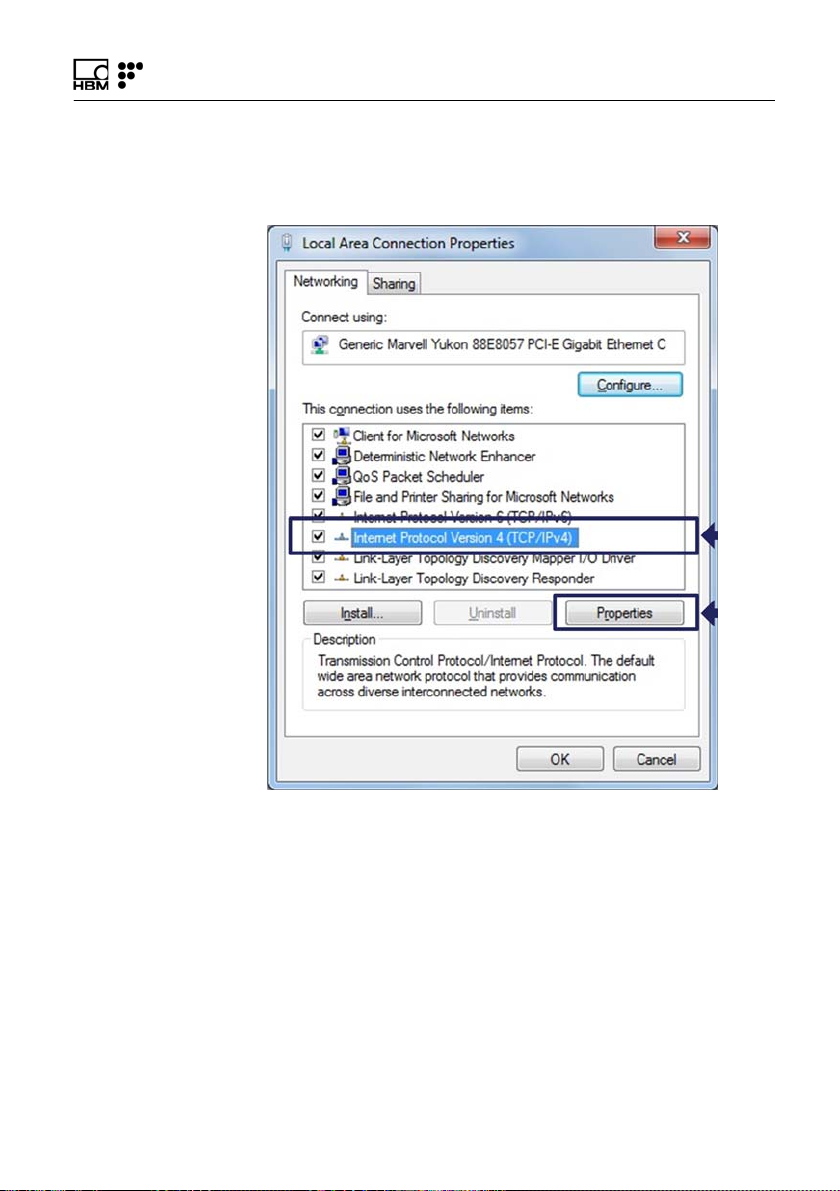

► On the control panel choose Network Connections

► Select the LAN connection. The window displayed in

Fig. 3.6 will appear. Click on Properties.

Fig. 3.6

20 A4248-6.0 HBM: public FS22 DI

Page 21

Operation

► Select the Internet Protocol (TCP/IP) and click on the

Properties button (Fig. 3.7).

Fig. 3.7

FS22 DI A4248-6.0 HBM: public 21

Page 22

Operation

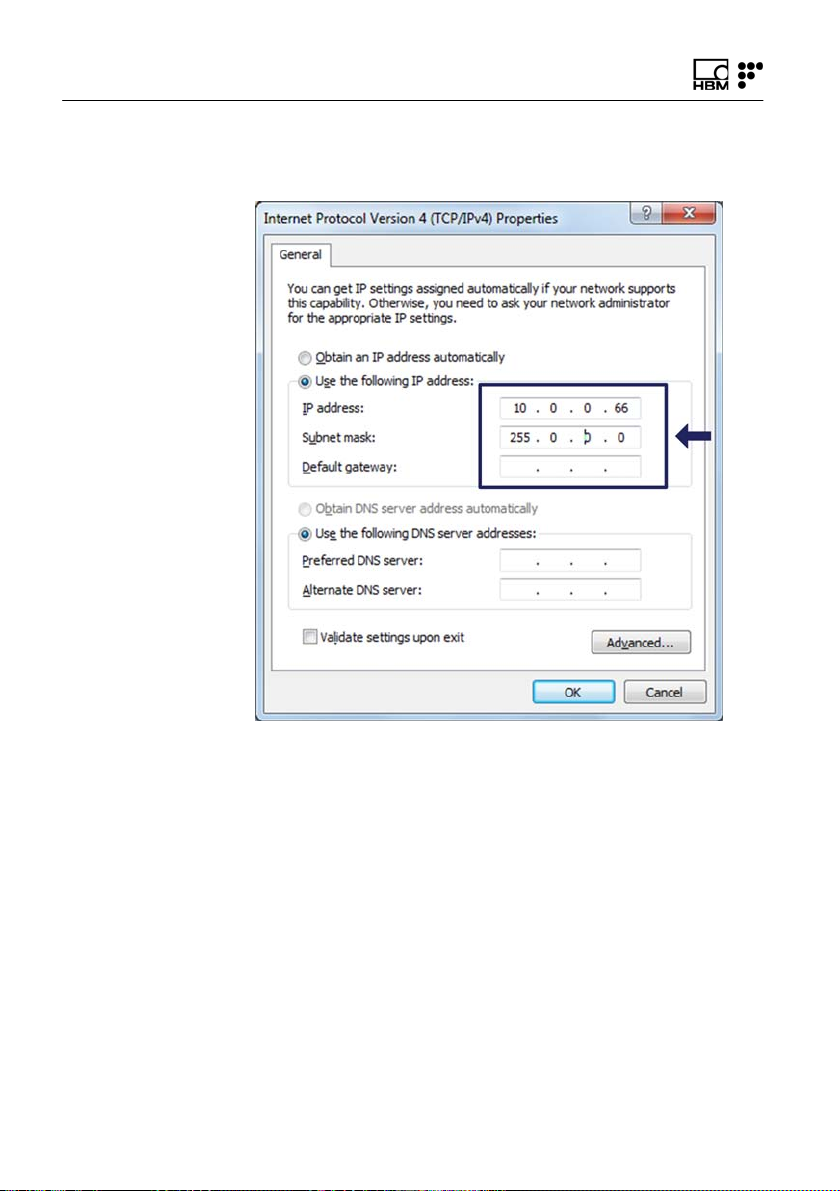

► Set the IP address and the Subnet mask (Fig. 3.8).

Fig. 3.8

► Press OK.

22 A4248-6.0 HBM: public FS22 DI

Page 23

Operation

3.5.2 Interrogator IP Address

Changing IP

The interrogator default network properties are

10.0.0.150:255.0.0.0:0.0.0.0. These can be changed

using the SCPI commands.

The interrogator proceeds with a change of these proper

ties when :SYST:IPAD:N.N.N.N:N.N.N.N:N.N.N.N com

mand is sent. See section 5.1.3 “System commands”

under IP Address for further details.

Information

The definition of the network properties shall comprise

three digits to define each number – e.g.,

010.000.000.150:255.000.000.000:000.000.000.000 –.

Default IP Address

The default network properties of the interrogator are

"10.0.0.150:255.0.0.0:0.0.0.0". These default network

properties cannot be changed.

Resetting IP to Default

If by any chance there is the need to physically change

the IP address of the interrogator, press the "ON/OFF"

button for more than 10 seconds to reset the interrogator.

When the button is being pressed for 10 seconds the

POWER LED blinks 3 times and goes OFF. The "ON/

OFF" button can then be released and the IP Address

will be reset.

This procedure will restart the interrogator automatically.

FS22 DI A4248-6.0 HBM: public 23

Page 24

Operation

POWER LED

blinking at 1 Hz

Fig. 3.9

POWER LED ON POWER LED blinks

3 times and goes OFF

This procedure resets the interrogator changing its IP

address to the default and its measuring settings to the

last ones stored.

Information

The interrogator default network properties are

"10.0.0.150:255.0.0.0:0.0.0.0".

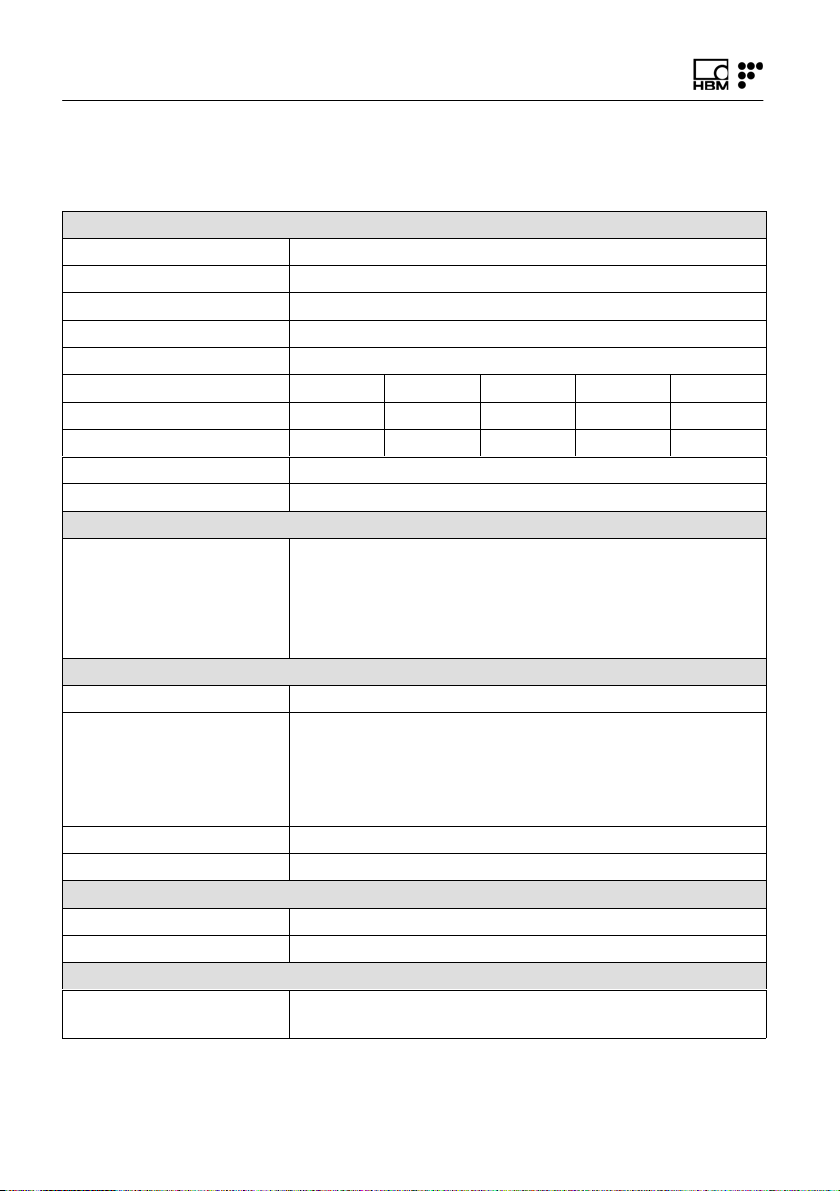

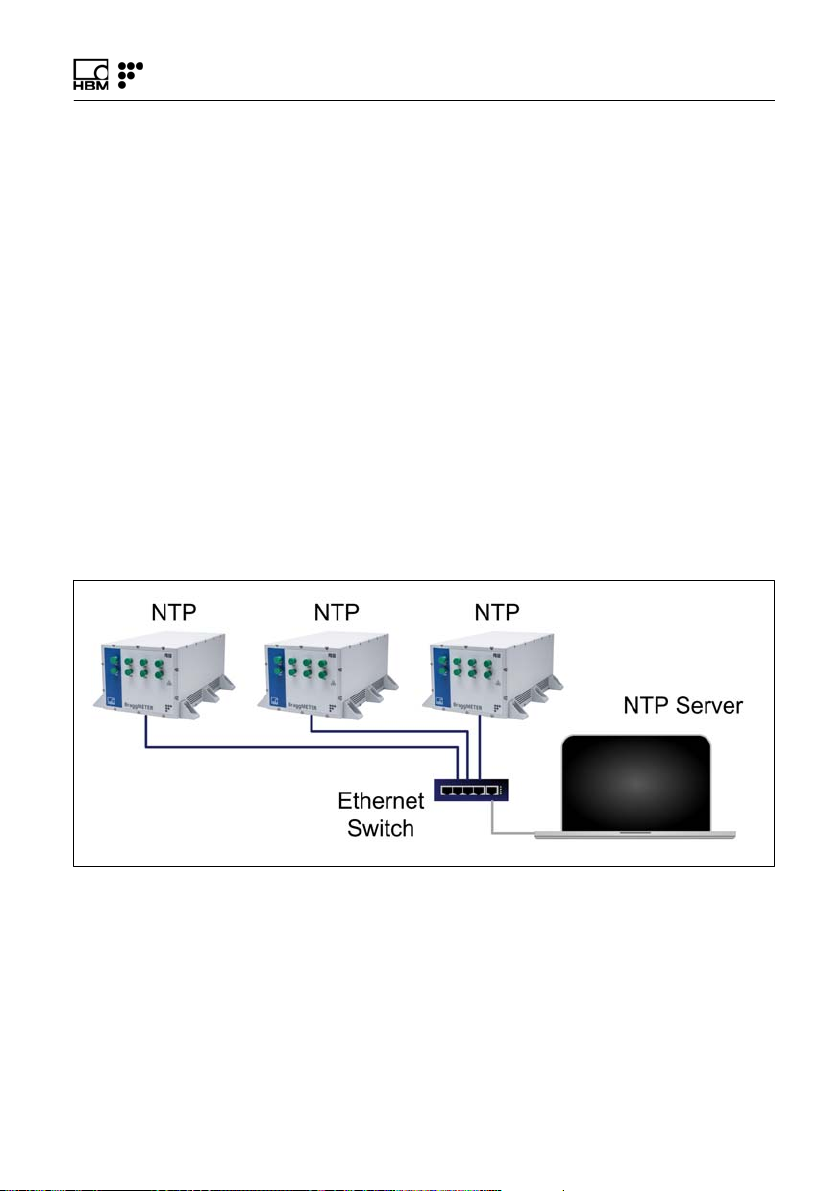

3.5.3 Synchronization

In order to achieve synchronous measurements between

different devices the NTP (Network Time Protocol) syn

chronization via Ethernet must be used.

Each optical Interrogator can synchronize its internal

clock with an NTP server. It is possible to achieve accu

racies of 1ms or higher, depending on whether or not a

dedicated NTP server is being used.

Further information about NTP can be found at

http://www.ntp.org

24 A4248-6.0 HBM: public FS22 DI

Page 25

Single interrogator

Multiple

interrogators

Operation

Measuring systems typology

A measurement system can be as simple as a single

interrogator or a bit more complex with combined inter

rogators with the same or different sampling rates, and

interrogators combined with other equipment.

For the usage of a single interrogator no special synchro

nization is needed.

BraggMONITOR DI software can only operate one inter

rogator at a time. If an NTP server is running on the

same PC as the BraggMONITOR DI, the interrogator

internal clock – hence BraggMONITOR DI – will sync.

If more than one interrogator is used, synchronization

becomes important and if an NTP server is running the

equipment will start synching as soon as a first communi

cation from the server is received.

Fig. 3.10

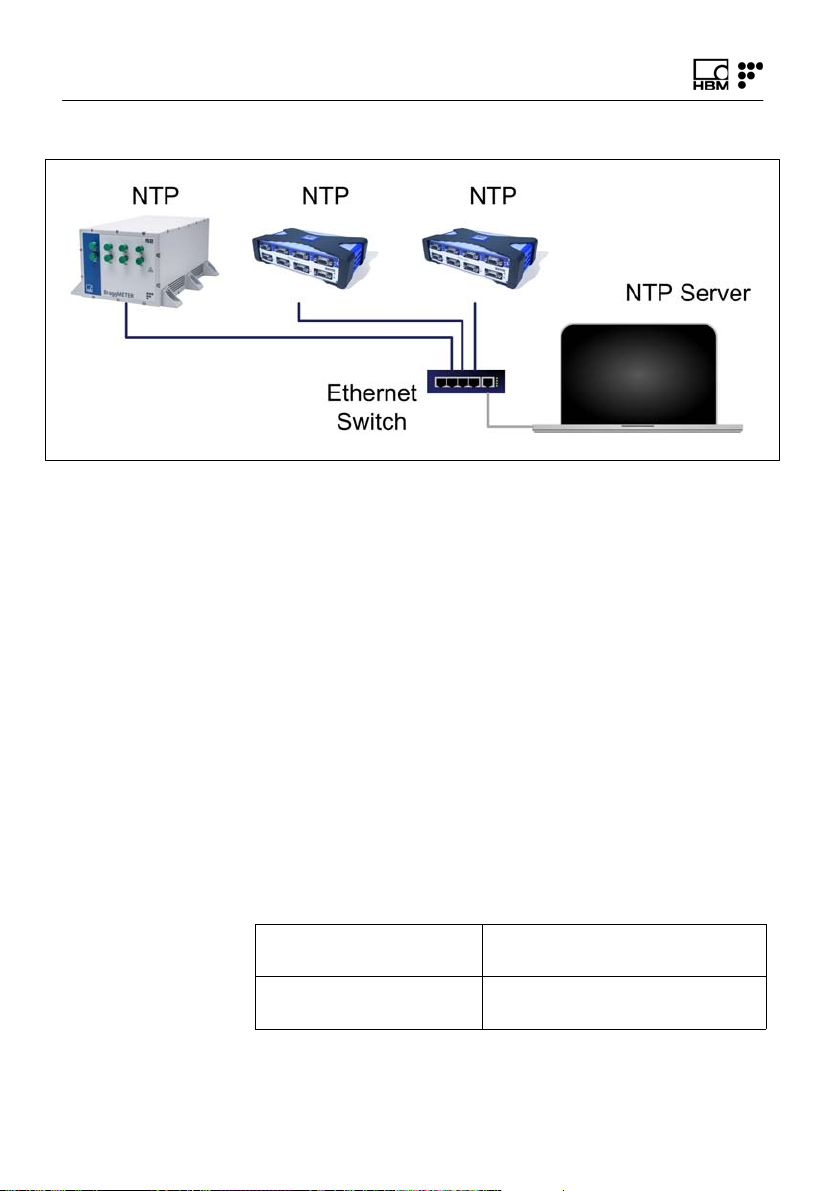

Hybrid

A hybrid measurement system is a system composed by

different equipment types and technologies that can be

operated with different sampling rates. Taking the exam

ple of HBM families a hybrid system could be a combina

tion of Interrogators with QuantumX.

FS22 DI A4248-6.0 HBM: public 25

Page 26

Operation

Fig. 3.11

Synchronization is again of extreme importance in such

systems. When an NTP server is running the Interrogator

will start synching as soon as a first communication from

the server is received.

For details on the other equipment please refer to their

respective user manuals.

Synchronization process

Each interrogator synchronizes its internal clock with the

NTP server. Upon starting, all devices and the NTP

server need some settling time to achieve the best syn

chronism possible.

The following features for NTP synchronization are avail

able:

Number of devices to

be synchronized

Synchronization

accuracy

Unlimited

100 μs to 10 ms

26 A4248-6.0 HBM: public FS22 DI

Page 27

Operation

Synchronization

settling time

Synchronization

master

Up to 30 min during first start,

up to 2 min during restart

External SyncMaster, e.g. PC

For a good synchronization, the dedicated NTP server

should run continuously. The accuracy is described by

the two values:

S Offset: average deviation from time server

S Jitter: typical variation range of the offset value

The clock synchronization is classified using the following

offset intervals:

S <500 μs: excellent

S <1 ms: very good

S <2 ms: good

S <5 ms: acceptable

S <10ms: poor

S >10ms: not acceptable

A successful NTP Sync is achieved if the offset between

the internal clock of the device and the NTP server is

below 5ms.

The quality of the NTP synchronization can be queried

using the SCPI commands (please refer to section “Syn

chronization” on page 53 for further details).

3.5.4 Operation

The FS22 - Industrial BraggMETER DI interrogator can

be fully controlled using standard SCPI syntax com

FS22 DI A4248-6.0 HBM: public 27

Page 28

Operation

mands (for a complete command list, please refer to sec

tion 5.1 “Communication Protocol Syntax” on page 40).

All valid answers to sent commands, start with :ACK.

Whenever there is a misspell or a wrong command sent,

an error message will be returned:

:NACK:INVALID COMMAND

That means that the command does not exist. Check if

the spelling is correct.

:NACK: COMMAND NOT ACCEPTED AT CURRENT

STATUS

It is not possible to execute the command sent at the cur

rent status.

Ask the current status of the interrogator (:STAT?) and

confirm with scheme from Fig. 3.12 to see how to change

it.

:NACK: '?' MUST BE THE LAST CHARACTER

The sent command should have a '?' at the end of the

command string.

Operational States

The FS22 - Industrial BraggMETER DI interrogator has

five operational states:

0 error

The error state corresponds to a malfunction of the opto

electronic module of the FS22 - Industrial BraggMETER

DI interrogator. The system can recover from this state

by resetting.

1 ready

In the ready state, the FS22 - Industrial BraggMETER DI

interrogator is ready to start acquisition.

28 A4248-6.0 HBM: public FS22 DI

Page 29

Operation

2 free acquisition

3 continuous

acquisition

5 warming-up

The free acquisition state enables the FS22 - Industrial

BraggMETER DI interrogator to perform single measure

ments on a specified optical channel. The FS22 - Indus

trial BraggMETER DI interrogator can be configured in

terms of gain, threshold and sampling rate. The corre

sponding configuration can be stored for future refer

ence.

The continuous acquisition state allows continuous wave

length acquisition over all optical channels at 50, 100,

200, 500 or 1000 S/s. The FS22 - Industrial BraggME

TER DI interrogator can also display continuous OSA

trace acquisition every second. For that the sampling rate

of the interrogator shall be set to 50 S/s.

The FS22 - Industrial BraggMETER DI interrogator starts

on the warming-up state that enables the settling of the

operation parameters and recall of the acquisition config

uration.

FS22 DI A4248-6.0 HBM: public 29

Page 30

Operation

Fig. 3.12

Commands for Different Operational States

0 error

In the error state, the FS22 - Industrial BraggMETER DI

interrogator only replies to the commands:

:IDENtification?

:STATus?

1 ready

In the ready state, the FS22- Industrial BraggMETER DI

interrogator replies to common commands:

:IDENtification?

:STATus?

:SYSTem:TIME?

:SYSTem:TIME:HH:MM:SS

30 A4248-6.0 HBM: public FS22 DI

Page 31

2 free acquisition

Operation

:SYSTem:DATE?

:SYSTem:DATE:YYYY:MM:DD

:SYSTem:NTPSync?

:SYST:IPAD:N.N.N.N:N.N.N.N:N.N.N.N

And is also responsive to start acquisition commands:

:ACQUisition:STAR

:ACQUisition:OSATrace:CONTinuous:STARt:X (com

mand is available at 50 S/s only)

:ACQUisition:WAVElength:CONTinuous:STARt

:ACQUisition:WAVElength:CONTinuous:NTP

Sync:STARt

The FS22 - Industrial BraggMETER DI interrogator runs

on the free acquisition state after receiving the :ACQUisi

tion:STARt command. In this state the, FS22 - Industrial

BraggMETER DI interrogator is responsive to all com

mands except:

:ACQUisition:WAVElength:CONTinuous:STARt

:ACQUisition:OSATrace:CONTinuous:STARt:X

:ACQUisition:WAVElength:CONTinuous:NTP

Sync:STARt

:SYSTem:TIME?

:SYSTem:TIME:HH:MM:SS

:SYSTem:DATE?

:SYSTem:DATE:YYYY:MM:DD

:SYST:IPAD:N.N.N.N:N.N.N.N:N.N.N.N

FS22 DI A4248-6.0 HBM: public 31

Page 32

Operation

3 continuous

acquisition

5 warm up

Important

The command :ACQUisition:OSATrace:CONTinu

ous:STARt:CHANnel:X is only available when the sam

pling rate is defined as 50 S/s.

The FS22 Industrial BraggMETER DI interrogator returns

to the ready state through the :ACQUisition:STOP com

mand.

The FS22 - Industrial BraggMETER DI interrogator runs

in the continuous acquisition state after receiving the

commands:

:ACQUisition:OSATrace:CONTinuous:STARt:CHANnel:X

(command is available at 50 S/s only)

:ACQUisition:WAVElength:CONTinuous:STARt

:ACQUisition:WAVElength:CONTinuous:NTP

Sync:STARt

The continuous acquisition commands can only be exe

cuted in the ready state.

In this operational state the FS22 - Industrial BraggME

TER DI interrogator only replies to the commands:

:ACQUisition:STOP

:IDENtification?

:STATus?

After receiving the :ACQUisition:STOP command, the

FS22 - Industrial BraggMETER DI interrogator returns to

the ready state.

In the warm up state, the FS22 - Industrial BraggMETER

DI interrogator only replies to the commands:

:IDENtification?

:STATus?

32 A4248-6.0 HBM: public FS22 DI

Page 33

Operation

Power Shortage

In case of power shortage when the FS22 - Industrial

BraggMETER DI interrogator is running in the ready, free

acquisition or continuous acquisition states, the opera

tional state will maintain the stored acquisition settings

once the power supply is reestablished.

FS22 DI A4248-6.0 HBM: public 33

Page 34

Measuring Examples

4 Measuring Examples

4.1 Typical Configuration

Typically, a fiber Bragg grating Sensing Network is

divided into branches of several sensors connected in

series. Fig. 4.1 shows a scheme of a possible fiber Bragg

grating sensing branch.

FS62 Strain

FS65 Acceleration Strain

Fig. 4.1

FS64 Tilt

A branch can accommodate sensors with wavelengths

corresponding to all standard HBM FS wavelengths. The

number of sensors in a channel can vary if there is previ

ous knowledge about the spectral range the sensors will

cover. The major concern is the overlap of adjacent sen

sors. The available optical channels have simultaneous

acquisition, meaning that the sensing network can have a

large number of fiber Bragg grating sensors interrogated

at the same time.

34 A4248-6.0 HBM: public FS22 DI

Page 35

Measuring Examples

The employed technology allows multi-functionality

meaning that on the same branch it is possible to mea

sure Strain, Temperature, Displacement, Pressure,

Acceleration, etc…

The sensing network can be placed up to 10 km from the

interrogator without significant losses on transmission

over the optical fiber, operating under EM/RF interfer

ences.

Each fiber Bragg grating sensor has a characteristic cen

tral wavelength (λ0) that depends only on the measurand.

This means that with this technology there is no need for

recalibrations every time the system is shut down. The

Industrial BraggMETER DI is a ruggedized interrogator

designed for 24/7 operation.

FS22 DI A4248-6.0 HBM: public 35

Page 36

Measuring Examples

4.1.1 HBM FS Wavelengths

The HBM FiberSensing standard wavelengths are:

FS Line OP Line

Central wavelength (nm)

N - 1503.3 1520

O - 1509.7 1525

K - 1516.1 1530

L - 1522.5 1535

A - 1528.9 1540

B - 1535.1 1545

C - 1541.5 1550

D - 1547.9 1555

E - 1554.3 1560

F - 1560.8 1565

G - 1567.2 1570

H - 1573.8 1575

I - 1580.2

J - 1586.6

36 A4248-6.0 HBM: public FS22 DI

Page 37

Measuring Examples

4.2 Definitions and Operation Methods

The following definitions are applicable to this equipment

only.

4.2.1 Wavelength

The Wavelength value corresponds to the wavelength at

the peak of the fiber Bragg grating reflection spectrum,

commonly referred as Bragg wavelength (Fig. 4.2).

FBG reflection spectrum

Wavelength

Power

Wavelength in nm

Fig. 4.2

FS22 DI A4248-6.0 HBM: public 37

Page 38

Measuring Examples

4.2.2 Power

The Power value corresponds to the optical power

reflected by the fiber Bragg grating at the peak wave

length (Fig. 4.3). It is a relative value from 0 to 4095.

FBG reflection spectrum

Power

Power

Wavelength in nm

Fig. 4.3

38 A4248-6.0 HBM: public FS22 DI

Page 39

Measuring Examples

4.2.3 Gain

The gain is an amplification value applied to the received

reflected signal in order to optimize the measured power.

It is a value from 0 to 255.

FBG reflection spectrum with Gain = 10

Power

FBG reflection spectrum

with Gain = 0

Wavelength in nm

Fig. 4.4

FS22 DI A4248-6.0 HBM: public 39

Page 40

Measuring Examples

Power

4.2.4 Threshold

The threshold value corresponds to the considered

power level for the FBG peak computation and can be

used to disregard side lobes and ground noise. It is a

value from 200 to 3200 definable for each optical channel

individually. It is measured bottom-up from the 0 (zero)

power value.

FBG reflection spectrum

Detected peaks

Disregarded peak

Threshold

Wavelength in nm

Fig. 4.5

40 A4248-6.0 HBM: public FS22 DI

Page 41

Measuring Examples

4.3 Common Measuring Difficulties

There may be the possibility of having measuring mal

functions due to problems in the sensing network or opti

cal connections. A list of some of the usual problems is

described below with the explanation for their occurrence

and correction.

4.3.1 Dirty Connector

It is very important that the connectors are cleaned prior

to any connection. Otherwise, dust and moister can be

deposited in the interrogator's optical adaptors, which will

compromise measurements. In Fig. 4.6 a picture of a

magnified connector is presented. The dark gray circle

corresponds to the fiber cladding and the small light gray

circle is the core of the fiber. One picture of a clean con

nector and one picture of a dirty connector are pre

sented.

Clean connector

Fig. 4.6

Dirty connector

The most common effect of dirt on the connections is a

large amount of broad band light being reflected at the

connection, in both directions, meaning that the dynamic

range for measurements becomes smaller.

FS22 DI A4248-6.0 HBM: public 41

Page 42

Measuring Examples

Power

clean connector trace

dirty connector trace

dynamic range

reduction

Wavelength in nm

Fig. 4.7

To clean an optical interrogator adapter, use an appropri

ate cotton swab (there are several cleaning swabs in the

market frequently used for telecom fibers) embedded in

isopropyl alcohol. Insert it in the optical adapter as in

Fig. 4.8 and rotate the swab always in the same direc

tion.

Fig. 4.8

42 A4248-6.0 HBM: public FS22 DI

Page 43

Measuring Examples

4.3.2 Broken Connector

It may also occur that the interrogator adapter sleeve

breaks. In this case, when an optical connector is

inserted, it will not get proper alignment and measure

ments will be compromised. A broken sleeve will look as

shown in Fig. 4.9.

Fig. 4.9

To solve this problem you should contact HBM

FiberSensing.

4.3.3 Reflective Fiber Ending

Even when all connections have been performed cor

rectly, it may occur that the interrogator does not find any

sensor on an array. One of the reasons may be the

excess of reflected light saturating the detectors.

When a fiber is perfectly cut (Fig. 4.10 on the left), a

large amount of light is reflected right back to the fiber

core in the right direction, heading to the interrogator

detectors. When this occurs, an index matching gel or an

angled termination must be used. If these are unavail

able, the tip of the fiber can be smashed with a metallic

tool. This will destroy the perfect geometry (Fig. 4.10 on

the right) and the light that is reflected at the surface will

take random directions ending up outside the core.

FS22 DI A4248-6.0 HBM: public 43

Page 44

Measuring Examples

Reflective Fiber Ending

Fig. 4.10

4.3.4 Cut Fiber

When the fiber, for any reason, is broken between two

sensors in series, the sensors that are after the fault may

disappear from the optical spectrum and may not be

detected.

There may also be the case that the fiber is cut, but not

completely spread apart (e.g. the fiber is damaged in an

area covered with glue). This will cause a Fabry-Pérot

effect – the light will suffer multiple reflections inside the

cavity creating sinusoidal background reflection.

Fig. 4.11 shows a schematic representation of the

reflected spectrum for the three presented cases.

Refractive Fiber Ending

44 A4248-6.0 HBM: public FS22 DI

Page 45

Measuring Examples

Fig. 4.11

FS22 DI A4248-6.0 HBM: public 45

Page 46

Measuring Examples

4.3.5 Fuse Failure

Electrical shorts on the power supply may cause prob

lems to the interrogators. The Industrial BraggMETER DI

on its RackMountable format is directly connected to the

100240 V power line meaning that it has no external pro

tection. Replaceable fuses are available on the interroga

tor's backside next to the power connector (number 5 in

Fig. 3.2). To replace the fuses, release the top and bot

tom springs of the fuses’ support (Fig. 4.12) and then

remove the piece (Fig. 4.13).

Fuse characteristics:

S Rated voltage: 250 Volt AC

S Interrupting rate: 2 Ampere

S Number of fuses: 2

Fig. 4.12

46 A4248-6.0 HBM: public FS22 DI

Page 47

Measuring Examples

Fig. 4.13

The Standard format of the interrogator is powered at

1136 VDC, which means that the electrical protection

should be granted by the power source or the adapter. If,

by any chance, the power supply is overcome, the inter

rogator might be damaged and needs repair at HBM

FiberSensing.

FS22 DI A4248-6.0 HBM: public 47

Page 48

Remote Communications

5 Remote Communications

5.1 Communication Protocol Syntax

The interrogator is controlled using standard SCPI syntax

commands.

5.1.1 Command Syntax

Each command is an ASCII string with arguments sepa

rated by ":" followed by the carriage return "\r" and line

feed "\n".

Fig. 5.1

Communication on FS22 - Industrial BraggMETER DI is

made via port 3500. Continuous data streaming is

received via port 3365.

48 A4248-6.0 HBM: public FS22 DI

Page 49

Remote Communications

The commands for the FS22 - Industrial BraggMETER DI

have the following correspondence:

X Optical

Channel

S Sensor Integer.

T Threshold Integer. From 200 to 3200.

G Gain Integer. From 0 to 255.

R Sampling

Rate

N Number Integer.

HH:MM:SS Time Integer.

YYYY:MM:DD Date Integer.

Q NTP Quality Integer.

String.

Integer to:

FS22 Single Channel : 0.

FS22 Quad Cahnnel: 0 to 3.

FS22 Octo Channel: 0 to 7.

Character:

A.

Integer. Valid Sampling Rates: 1000, 500,

200, 100, 50 (S/s).

HH – hour

MM – minutes

SS – seconds

YYYY – year

MM – month

DD – day

0 for “Not acceptable”

1 for “Acceptable”.

FS22 DI A4248-6.0 HBM: public 49

Page 50

Remote Communications

5.1.2 Common Commands

Identification

Store configuration

Recall

:IDEN?

Queries the FS22 - Industrial BraggMETER DI interrogator

type and firmware revision. The return string is a list sepa

rated by ":" consisting of Manufacturer, Unit Name and Revi

sion, Number of Channels, Serial Number and Date.

Example:

Command :IDEN?

Answer :ACK:HBM FiberSensing:FS22DI

v2.0:08:046 840 200 188:20150202

Configuration

:STOR

Stores FS22 - Industrial BraggMETER DI interrogator acqui

sition settings to the internal configuration file. The gain and

threshold values of each channel are stored. This command

can only be executed in the free acquisition state (see sec

tion Operational States for state description).

Example:

Command :STOR

Answer :ACK

:RECA

Recalls previously saved FS22 - Industrial BraggMETER DI

interrogator settings from the internal configuration file. The

command restores the gain and threshold values of each

channel of the FS22 - Industrial BraggMETER DI interrogator

to the values previously stored in the configuration file.

Example:

Command :RECA

Answer :ACK

50 A4248-6.0 HBM: public FS22 DI

Page 51

Status

Remote Communications

Status query

Time query

:STAT?

Queries the operation condition status of the FS22 - Indus

trial BraggMETER DI interrogator. Returns the current status

of the instrument:

0 error;

1 ready;

2 free acquisition;

3 continuous acquisition;

5 warming up.

Example:

Command :STAT?

Answer :ACK:2

5.1.3 System Commands

Time

:SYST:TIME?

Queries the FS22 - Industrial BraggMETER DI interrogator

time.

The interrogator returns hours, minutes and seconds sepa

rated by ":".

Example:

Command :SYST:TIME?

Answer :ACK:15:33:56

FS22 DI A4248-6.0 HBM: public 51

Page 52

Remote Communications

Time setting

Date query

Date setting

:SYST:TIME:HH:MM:SS

Sets the FS22 - Industrial BraggMETER DI interrogator time.

Sent format must be hours, minutes and seconds separated

by ":".

Example:

Command :SYST:TIME:14:26:10

Answer :ACK

Date

:SYST:DATE?

Queries the FS22 - Industrial BraggMETER DI interrogator

date.

The interrogator returns the year, month and day separated

by ":".

Example:

Command :SYST:DATE?

Answer :ACK:2011:09:23

:SYST:DATE:YYYY:MM:DD

Sets the FS22 - Industrial BraggMETER DI interrogator date.

Sent format must be year, month and day separated by ":".

Example:

Command :SYST:DATE:2011:09:23

Answer :ACK

52 A4248-6.0 HBM: public FS22 DI

Page 53

Synchronization

Remote Communications

NTP query

IP setting

:SYST:NTPS?

Queries for the NTP synchronization status. Retrieves infor

mation on three parameters separated by “:”

Q: NTP Quality:

0 = not acceptable if offset >= 10ms;

1 = acceptable if offset <10ms.

Offset: time difference in milliseconds between the server

clock and host clock.

Jitter: time difference in milliseconds between 2 samples.

Example:

Command :SYST:NTPS?

Answer :ACK:1:0.489:0.345

IP Address

:SYST:IPAD:N.N.N.N:N.N.N.N:N.N.N.N

Changes FS22 - Industrial BraggMETER DI interrogator IP

address, subnet mask and gateway. Address description

must have three characters to define each number. After this

command is successfully executed the FS22 will restart

automatically. The gateway content of this command (the

last set of N.N.N.N) is optional.

Example:

Command :SYST:IPAD:010.000.000.134:255.000.

000.000:000.000.000.000

Answer :ACK

FS22 DI A4248-6.0 HBM: public 53

Page 54

Remote Communications

5.1.4 Acquisition Commands

Aquisition start

Aquisition stop

Gain setting

:ACQU:STAR

Starts the acquisition of the fiber Bragg grating sensors in all

channels of the FS22 - Industrial BraggMETER DI. This

command can only be executed in the ready state (see sec

tion Operational States for state description).

Example:

Command :ACQU:STAR

Answer :ACK

:ACQU:STOP

Stops all types of acquisition of the fiber Bragg grating sen

sors in all channels of the FS22 - Industrial BraggMETER DI,

returning to the ready state.

Example:

Command :ACQU:STOP

Answer :ACK

Configuration

:ACQU:CONF:GAIN:CHAN:X:G

Sets the detection gain in the X channel of the FS22 - Indus

trial BraggMETER DI interrogator. The gain is a value from 0

to 255.

Example:

Command :ACQU:CONF:GAIN:CHAN:0:3

Answer :ACK

54 A4248-6.0 HBM: public FS22 DI

Page 55

Remote Communications

Gain query

Threshold setting

Threshold query

:ACQU:CONF:GAIN:CHAN:X?

Queries the detection gain in the X channel of the FS22 Industrial BraggMETER DI interrogator. The returned gain

value can range from 0 to 255.

Example:

Command :ACQU:CONF:GAIN:CHAN:0?

Answer :ACK:3

:ACQU:CONF:THRE:CHAN:X:T

Sets the threshold value for the peak detection algorithm in

the X channel of the FS22 - Industrial BraggMETER DI. The

threshold is a value from 200 to 3200.

Example:

Command :ACQU:CONF:THRE:CHAN:0:1000

Answer :ACK

:ACQU:CONF:THRE:CHAN:X?

Queries the threshold value for the peak detection algorithm

in the X channel of the FS22 - Industrial BraggMETER DI.

The threshold is a value from 200 to 3200.

Example:

Command :ACQU:CONF:THRE:CHAN:0?

Answer :ACK:1000

Rate setting

:ACQU:CONF:RATE:R

Sets the sampling rate value R of the FS22 - Industrial

BraggMETER DI for all channels. The sampling rate can

assume the following values: 1000, 500, 200, 100, 50 (S/s).

This parameter is automatically stored in the interrogator.

Example:

Command :ACQU:CONF:RATE:500

Answer :ACK

FS22 DI A4248-6.0 HBM: public 55

Page 56

Remote Communications

Rate query

Wavelength

acquisition

:ACQU:CONF:RATE:R?

Queries the sampling rate value of the FS22 - Industrial

BraggMETER DI. The sampling rate can assume the follow

ing values: 1000, 500, 200, 100, 50 (S/s).

Example:

Command :ACQU:CONF:RATE?

Answer :ACK:200

Free Acquisition

:ACQU:WAVE:CHAN:X?

Returns the peak wavelengths of the fiber Bragg grating

sensors in channel X of the FS22 - Industrial BraagMETER DI

interrogator according to the threshold settings. The central

wavelength values for different fiber Bragg sensors are separ

ated by a comma ",", the row of values ends with carriage

return "\r" and line feed "\n". The number of channels can be

"A" to retrieve the wavelength of all sensors in all channels

simultaneously. Wavelengths are presented in ascending

values.

Example:

Command

Answer

:ACQU:WAVE:CHAN:0?

:ACK:1560.0732,1554.9894,1547.8012,

1540.0954

56 A4248-6.0 HBM: public FS22 DI

Page 57

Remote Communications

Power aquisition

:ACQU:POWE:CHAN:X?

Queries the optical peak power of the fiber Bragg gratings in

channel X. Returns a value between 0 and 4095 for each

sensor on the channel. If the optical channel is saturated, a

value of 4095 will be returned. The peak power values for

different fiber Bragg sensors are separated by a comma ",",

the row of values ends with carriage return "\r" and line feed

"\n". The FS22 - Industrial BraggMETER DI does not reply, if

no sensor is detected. The number of channels can be "A" to

retrieve the power of all the sensors in all the channels

simultaneously.

Example:

Command :ACQU:POWE:CHAN:0?

:ACK:3875,3622,3161,3240

FS22 DI A4248-6.0 HBM: public 57

Page 58

Remote Communications

The following command is only available when the acqui

sition rate is set as 50 S/s.

Information

OSA acquisition

:ACQU:OSAT:CHAN:X?

Acquires the optical spectrum trace in the channel X of the

FS22 Interrogator. The acknowledged and data reply to this

command is sent through port 3500. The optical spectrum

trace reply is a list of power values and a list of wavelength

values separated by ":".There is a direct correspondence

between each power value and each wavelength value. The

wavelength data is sorted in descending order. Each power

value in arbitrary units is represented by a set of three hexa

decimal digits. For example, the value D13 represented with

hexadecimal digits corresponds to a power value of 3347 in

decimal notation. The wavelength values are separated by

"," and written in decimal notation (with 4 decimal digits and

"." for decimal separation). The reply string is terminated with

the carriage return "\r" and line feed "\n" characters. This

command can only be executed in the ready state with the

acquisition rate set to 50 S/s (see section 3.5.3 “Operation”,

subsection Operational States for state description).

Example:

Command :ACQU:OSAT:CHAN:1?

Answer Port 3500:

:ACK:...D13D03FA0B98...:...1563.1333,

1563.1194,1563.1054,1563.0915...\r\n

58 A4248-6.0 HBM: public FS22 DI

Page 59

Continuous Acquisition

Remote Communications

Continuous OSA

acquisition

:ACQU:OSAT:CONT:STAR:CHAN:X

Continuously acquires the optical spectrum trace in the

channel X of the FS22 interrogator. The acknowledged reply

to this command is sent through port 3500 while data is sent

through port 3365. The optical spectrum trace reply is a list

of power values and a list of wavelength values separated

by ":".There is a direct correspondence between each power

value and each wavelength value. The wavelength data is

sorted in ascending order. Each power value in arbitrary

units is represented by a set of three hexadecimal digits. For

example, the value D13 represented with hexadecimal digits

corresponds to a power value of 3347 in decimal notation.

The wavelength values are separated by "," and written in

decimal notation (with 4 decimal digits and "." for decimal

separation). The power and wavelength values are updated

every second. The consecutive data reply strings are termi

nated with the carriage return "\r" and line feed "\n" charac

ters. This command can only be executed in the ready state

with the acquisition rate set to 50 S/s (see section 3.5.3

“Operation”, subsection Operational States for state descrip

tion).

Example:

Command :ACQU:OSAT:CONT:STAR:CHAN:1

Answer Port 3500:

:ACK

Port 3365:

:...D13D03FA0B98...:...1563.1333,1563

.1194,1563.1054,1563.0915...\r\n

FS22 DI A4248-6.0 HBM: public 59

Page 60

Remote Communications

Continuous wave

length acquisition

:ACQU:WAVE:CONT:STAR

Continuous acquisition of the peak wavelengths of the fiber

Bragg grating sensors in all channels of the FS22 - Industrial

BraggMETER DI interrogator. Wavelength data is is sent

continuously with updated time data at every second.

On each second one data packet with time stamp informa

tion is sent, followed by the n data packets corresponding to

each sample within that second.

Each time stamp data packet starts with ":" followed by the

date and time with the format «YYYY.MM.DD:HH.MM.SS».

Sample data packets also start with ":" and the central wave

length values for different fiber Bragg sensors are separated

by a comma ",", being the information corresponding to dif

ferent channels separated by ":". The row of values is termi

nated by carriage return "\r" and line feed "\n". This com

mand can only be executed in the ready state (see sec

tion 3.5.4 “Operation”, subsection Operational States for

state description).

Example:

Command :ACQU:WAVE:CONT:STAR

Answer Port 3500:

:ACK

Port 3365:

:1554.9891,1560.0732:1547.8027:::

:TS:2017:02.20:11.13.25

:1554.9897,1560.0741:1547.8030:::

:1554.9894,1560.0727:1547.8029:::

:1554.9893,1560.0732:1547.8027:::

60 A4248-6.0 HBM: public FS22 DI

Page 61

Remote Communications

Continuous Wave

length Acquisition

with Binary Data

:ACQU:WAVE:CONT:NTP:STAR

Continuous acquisition of wavelengths of all the channels of

the interrogator. This command is sent via port 3500 and

corresponding data is received through port 3365. The

received data is in binary format and contains information on

Timestamp, Wavelength values of all sensors from all optical

channels with the following structure:

1) Fixed Header (30 bytes) [always sent independently of

the payload content (even without sensors)]:

a) 2 bytes (sync “#0”)

b) 4 bytes (remaining header length 24 bytes + payload

length)

c) 8 bytes (timestamp):

- LWORD1: seconds since 1.1.1970

- LWORD2: fraction of current second mapped to an

integer range of 32 bit (i.e. 0.5 s would correspond

to ½*2^32)

d) 2 bytes #sensors CH0 + 2 bytes #sensors CH1 + 2

bytes #sensors CH2 + 2 bytes #sensors CH3 + 2 bytes

#sensors CH4 + 2 bytes #sensors CH5 + 2 bytes

#sensors CH6 + 2 bytes #sensors CH7

2) Payload:

a) Payload on interrogator with 1 optical channel:

4 bytes CH0/wvl0 + 4 bytes CH0/wvl1 + (…)

b) Payload on interrogator with 4 optical channels:

4 bytes CH0/wvl0 + 4 bytes CH0/wvl1 + (…) +

CH3/wvl0 + CH3/wvl1 + (…)

c) Payload on interrogator with 8 optical channels:

4 bytes CH0/wvl0 + 4 bytes CH0/wvl1 + (…) +

CH7/wvl0 + CH7/wvl1 + (…)

with wavelengths in ascending order [wvl0 < wvl1 < (…) ].

FS22 DI A4248-6.0 HBM: public 61

Page 62

Remote Communications

Example:

Command :ACQU:WAVE:CONT:NTPS:STAR

Answer Port 3500 » :ACK

Port 3365 »

62 A4248-6.0 HBM: public FS22 DI

Page 63

BraggMONITOR DI Software Details

6 BraggMONITOR DI Software Details

6.1 Software Version

This document refers to BraggMONITOR DI Software

version v1.7.

6.2 Install and Uninstall Software

6.2.1 System Requirements

To operate the current version of BraggMONITOR, your

PC must have the following requirements:

S Intel Pentium or equivalent processor upwards from

1 GHz

S Windows® XP (32 Bit and 64 Bit versions), Windows

Vista® (32 and 64 Bit versions), Windows® 7 (32 Bit

and 64 Bit versions, Home, Professional or Ultimate

editions) or Windows® 8/8.1 (32 Bit and 64 Bit ver

sions) or Windows° 10 (32 Bit and 64 Bit versions)

S Main memory (RAM):

- at least 512 Mbyte for Windows® XP

- at least 1,024 Mbyte for Windows Vista®

- at least 2,048 Mbyte for Windows®7 or higher

S Graphics card (and screen) with a resolution of

1,024 x 768 pixel or higher

S Approx. 1 GByte of free storage capacity for the pro

gram installation; at least a further 1 GByte is needed

FS22 DI A4248-6.0 HBM: public 63

Page 64

BraggMONITOR DI Software Details

for the temporary storage of data; however you can

also use a different drive for this.

S Ethernet interface (100/1000 MBit)

The above requirements are sufficient if you use low

sample rates and some sensors. You must use a more

powerful PC if you wish to use a large number of sensors

with high sample rates.

Information

Using windows display settings with the size of text not

set to 100% might compromise the correct visualization

of BraggMONITOR DI software.

6.2.2 Software Installation

To install HBM FiberSensing BraggMONITOR DI Soft

ware on a PC, please follow the described steps:

► Insert the provided disk with software in the PC;

► Run Setup.exe;

Information

When the operating system is Windows Vista or higher,

open setup.exe as an Administrator with a right-click

(see Fig. 6.1).

64 A4248-6.0 HBM: public FS22 DI

Page 65

BraggMONITOR DI Software Details

Fig. 6.1

► Follow the described steps and press finish.

The installation is now completed. You will need to

restart the computer before using the application.

6.2.3 Software Uninstall

To uninstall the application use the Add and Remove pro

grams tool in Windows

► Go to the Control Panel

► Select Programs and Features

► Select BraggMONITOR DI Software

► Click Uninstall/Change Option and follow the steps.

6.3 Running the Software

6.3.1 Network Properties

To operate the interrogator, the PC network properties

should be set so that both elements are configured in the

same subnet.

FS22 DI A4248-6.0 HBM: public 65

Page 66

BraggMONITOR DI Software Details

To configure your personal computer so that it is on the

same subnet as the default for the interrogator, proceed

as described on section 3.5.1 “Network Properties" on

page 19.

6.3.2 Run as Administrator

The BraggMONITOR DI Software should run with full

administrator privileges. To have these privileges when

the operating system is Windows Vista or higher, rightclick the BraggMONITOR DI Software icon and then

select the "Run as administrator" option (see Fig. 6.2).

To configure the application to always open with Adminis

trator privileges, right-click on the software icon and

select "Properties > Compatibility". Check the box "Run

this program as administrator" (see Fig. 6.2).

66 A4248-6.0 HBM: public FS22 DI

Page 67

BraggMONITOR DI Software Details

Fig. 6.2

FS22 DI A4248-6.0 HBM: public 67

Page 68

BraggMONITOR DI User Interface

7 BraggMONITOR DI User Interface

The BraggMONITOR DI Software graphical interface is

divided in two different areas (Fig. 7.1):

1 General Bar

2 Graphical Area

Fig. 7.1

68 A4248-6.0 HBM: public FS22 DI

Page 69

BraggMONITOR DI User Interface

7.1 General Bar

The General Bar, which is always active, is where the

main acquisition actions can be performed.

The current date and time are shown on the left (num

ber 1 in Fig. 7.2).

Before starting acquisition, it is necessary to establish

connection between the interrogator and the software.

For that, press the “connect” button (number 2 in

Fig. 7.2). If the software finds the device, the “connect”

button changes to “disconnect", as shown in Fig. 7.3, and

the “start” button (number 3 in Fig. 7.2) becomes active.

Fig. 7.2

Fig. 7.3

If a interrogator is not found in the previously used IP

Address, a window will pop up (Fig. 7.4) and a new IP

Address has to be defined (number 1 in Fig. 7.4), tested

(number 2 in Fig. 7.4) and confirmed (number 3 in

Fig. 7.4) by the user.

FS22 DI A4248-6.0 HBM: public 69

Page 70

BraggMONITOR DI User Interface

Fig. 7.4

Information

The FS22 – Industrial BraggMETER DI interrogators

default IP is 10.0.0.150 which is the IP Address used in

the first connection with the BraggMONITOR DI Soft

ware.

7.1.1 Acquisition

Start Acquisition

Press the “start” button (number 3 in Fig. 7.2) to start

acquisition. This will start the acquisition and representa

tion of the measured values for all optical channels. The

button will change from start to stop status (Fig. 7.5).

Fig. 7.5

70 A4248-6.0 HBM: public FS22 DI

Page 71

BraggMONITOR DI User Interface

Information

Before starting acquisition make sure that the network

configuration on «Configuration» tab is up to date. For

more details refer to section 7.2.5, page 81.

Save Data

To start saving data, select the file path to define the

folder where data is to be stored (see section 7.2.3,

page 78).

The naming of the file is automatic and corresponds to

the timestamp of the last measurement recorded (ex.

BraggMONITOR DI Data [2015.07.16.14.48.40;

2015.07.16.14.49.06].txt).

Saved data file collects the data between the instant the

save button is pressed and the instant it is pressed back.

Data files are divided in accordance to a predefined max

imum size. To define the maximum size of the data files,

see section 7.2.5, page 81.

The first row of data files indicates the acquisition rate

and the second row indicates the columns meaning. The

data file is organized in columns as follows, see Fig. 7.6.

1 1st column – UTC Date: «DD-MM-YYYY»

nd

2 2

column – UTC Time: «HH:MM:SS.SSS»

rd

3 3

column – Sample: Sample number

4 Following columns – Sensor Name (Formula): mea

sured values (formula computed) ordered by optical

channel, then by wavelength.

FS22 DI A4248-6.0 HBM: public 71

Page 72

BraggMONITOR DI User Interface

Fig. 7.6

Open Data in Microsoft Excel

To import the data file to a Microsoft Office Excel Work

book proceed as follows:

Once Microsoft Excel is opened, press button “From

Text" from menu Data>Get External Data (see Fig. 7.7)

and select the file data file.

Fig. 7.7

Then it is necessary to complete text import wizard. All

options must be set as shown in Fig. 7.8, Fig. 7.9,

Fig. 7.10, Fig. 7.11 and Fig. 7.12.

72 A4248-6.0 HBM: public FS22 DI

Page 73

Fig. 7.8

BraggMONITOR DI User Interface

Fig. 7.9

FS22 DI A4248-6.0 HBM: public 73

Page 74

BraggMONITOR DI User Interface

Fig. 7.10

Fig. 7.11

74 A4248-6.0 HBM: public FS22 DI

Page 75

BraggMONITOR DI User Interface

Fig. 7.12

Stop Acquisition

To stop acquisition, press the “stop” button (number 3 in

Fig. 7.2).

7.1.2 Software and Interrogator Information

General information about the software and the inter

rogator can be displayed by pressing the “info" button

(number 5 in Fig. 7.2).

7.1.3 Exit Application

To exit BraggMONITOR DI Software application, press

the “exit” button (number 6 in Fig. 7.2).

7.2 Graphical Area

The graphical area is divided into six tabs:

S Graphical View

S Numerical View

S Spectral View

S FFT View

FS22 DI A4248-6.0 HBM: public 75

Page 76

BraggMONITOR DI User Interface

S Configuration

S SCPI Interface

7.2.1 Graphical View

On the Graphical View, graphical representation of 1000

measured values can be found every second (number 1

in Fig. 7.13).

Fig. 7.13

Select the sensors to be displayed using the drop-down

arrow next to the legend (number 2 in Fig. 7.13). Tick the

channel box to enable or disable their representation.

76 A4248-6.0 HBM: public FS22 DI

Page 77

BraggMONITOR DI User Interface

Zoom In and Zoom Fit

To adjust the graphical representation, use the zoom in

and zoom fit functions. Zoom in by selecting an area on

the displayed graph and zoom fit by pressing number 3 in

Fig. 7.13. Alternatively, scale numbers can be edited.

Clear Graph

All displayed data can be deleted from the graph by

pressing the “clear” button (number 4 in Fig. 7.13).

7.2.2 Numerical View

The Numeric View shows the acquired values (in accor

dance to the configuration formula - see table Tab. 7.1 on

page 85) for each optical channel, organized in columns

as in Fig. 7.14.

Fig. 7.14

FS22 DI A4248-6.0 HBM: public 77

Page 78

BraggMONITOR DI User Interface

7.2.3 Spectral View

The Spectral View tab is only accessible when data

acquisition is stopped.

This tab represents the spectral response of the sensors

connected to the interrogator. The full spectrum contains

approx. 7020 data points corresponding to the reflected

optical power in dBm from 1500 nm to 1600 nm with an

approx. 15 pm sampling resolution (number 1 in

Fig. 7.15). For each detected FBG peak the pair of wave

length and power values are represented in a table for

mat (number 10 in Fig. 7.15)

Fig. 7.15

The Spectral View can only represent one channel at a

time. Channel selection can be performed on number 9 in

Fig. 7.15.

78 A4248-6.0 HBM: public FS22 DI

Page 79

Gain

Threshold

BraggMONITOR DI User Interface

The number of FBGs identified in the selected channel is

represented in number 11 in Fig. 7.15.

Information

The number of detected peaks per channel is limited in

accordance to the sampling rate. In case there are more

peaks than the limit, the lower wavelengths will be elimi

nated from the list.

Measurement Configuration

Measurement settings can influence sensor readings.

Gain and Threshold values should be defined according

to the FBG sensing network status, so that peak ampli

tude is around 3000 and no FBG side lobes are detected

as peaks. These settings can be configured indepen

dently for each optical channel.

Gain is directly related to the optical power used on the

measurement of the optical channel. The gain value

should be raised to overcome losses on the network.

Gain is an integer value between 0 and 255. The current

gain value can be found using the get gain button (num

ber 3 in Fig. 7.15). The gain value is updated every time

the Spectral View tab is selected or a new channel is

defined. To define a new gain value, write it on the gain

box (number 4 in Fig. 7.15) and press “set gain” button

(number 5 in Fig. 7.15).

Threshold defines the line between usable signals and

noise. It is an integer value between 200 and 3200.

Operations for getting and defining threshold values can

be performed on a similar way to the gain, but using the

threshold buttons (number 6, 7 and 8 in Fig. 7.15). The

threshold value is updated every time the Spectral View

tab or a new channel are selected. This value is also rep

FS22 DI A4248-6.0 HBM: public 79

Page 80

BraggMONITOR DI User Interface

resented graphically as a horizontal line on the power bar

graph.

7.2.4 FFT View

FFT View tab shows the Fast Fourier Transform (FFT)

graph of the acquired measurements. This computation

is based on a predefined FFT function, considering the

measured values exponential weighted (with no averag

ing), being the latest signals more significant for the cal

culations.

Once the “start” button is pressed, all previous measure

ments are erased from the FFT temporary memory. FFT

is shown for the active sensors on the sensors list (num

ber 4 in Fig. 7.16) as defined on the Graphical View tab.

This list of sensors cannot be edited on the FFT View

tab. To enable/disable any sensor, tick the sensor tick

box.

Information

To choose sensors that are not present in the sensors

list, edit the list on the Graphical View tab.

80 A4248-6.0 HBM: public FS22 DI

Page 81

Fig. 7.16

BraggMONITOR DI User Interface

7.2.5 Configuration

Acquisition configuration allows sensors' configuration for

the acquisition of engineering values to be performed. To

accomplish this step correctly, the sensors' calibration

sheets might be needed.

The BraggMONITOR DI allows editing, saving and open

ing sensor configurations. The configuration corresponds

to the identification and the definition of the calibration

formula that converts measured wavelengths into engi

neering values of the sensors.

The easiest way to start measuring and creating a config

uration is to perform an auto-scan (refer to section

«AutoScan» on page 82).

FS22 DI A4248-6.0 HBM: public 81

Page 82

BraggMONITOR DI User Interface

Fig. 7.17

Clear Configuration

If an old configuration is set, it is possible to clear it and

start a new configuration by pressing the “new” button

(number 8 in Fig. 7.17). Be aware this operation will dis

card all previous unsaved configurations of all channels.

AutoScan

When autoscan (number 2 in Fig. 7.17) is performed for

the first time, the interrogator executes a measuring

sweep and the BraggMONITOR DI defines a new config

uration with all the found sensors. This configuration sets

the current measured wavelength as central wave

length (λ0) with a default range of 2.5 nm.

82 A4248-6.0 HBM: public FS22 DI

Page 83

BraggMONITOR DI User Interface

Important

Confirm that gain and threshold values are correctly

defined so that no sensor is left out and that no noise is

configured as a sensor (see section «Measurement Con

figuration»).

Sensor Names are set by default as CHxSzzz, where x is

the optical channel and zzz is the number of the sensor

on that optical channel ordered by wavelength.

Example: CH0S001 corresponds to the 1st sensor of opti

cal channel 0.

Add and Edit Configuration

In order to add new sensors to an existing configuration,

repeat the autoscan and tick the checkbox “Update only

the new or deleted sensors on the network" as shown in

Fig. 7.18. If this option is not selected, all sensors config

urations (including formulas) will be lost and new

autoscan configurations will be created.

Fig. 7.18

FS22 DI A4248-6.0 HBM: public 83

Page 84

BraggMONITOR DI User Interface

To configure a sensor individually, select its cell and click

on the “edit” button (number 11 in Fig. 7.17). A dialog box

will pop up (Fig. 7.19). Additional info about this dialogue

box might be found at Tab. 7.1.

Fig. 7.19

Sensor Name

Central Wave

length (CWL)

Range Safety bands defined to avoid crosstalk between sensors.

Sensor's identification field. It is not possible to have two

sensors with the same name.

Reference wavelength from which wavelength shift (Δλ=x) is

calculated.

Each sensor has its own operation range. For instance, if we

have a central wavelength of 1522.659 nm and a range

spanning 3 nm, only wavelength values between 1525.659

and 1519.659 are accepted. Wavelength values out of the

defined bands are returned as -998.

84 A4248-6.0 HBM: public FS22 DI

Page 85

BraggMONITOR DI User Interface

Formula Function defining the correlation between the wavelength

shift (Δλ=x) and the engineering values.

x corresponds to the difference between the measured

wavelength (λ) at each instant and the defined central wave

length (λ

Here it is possible to set a formula manually, although it is

also possible to copy and paste from other locations. If the

desired output is wavelength shift, insert x on formula

textbox.

Do Do Not

-11.3*x -11.3x

-11.3*x^2+105.4*x+30 =-11.3*x^2+105.4*x+30

Note: For decimal separation, use comma or dot according to

the regional settings of the computer.

Tab. 7.1

).

0

Test Configuration

Test configuration (number 3 on Fig. 7.17) allows the

user to check the current values from each sensor

according to their configuration.

Information

Error code will be displayed as -998 when no sensor is

found within the defined range.

Save and Load configuration

Acquisition configuration can be saved in .txt extension

file by pressing the “save” button (number 10 in Fig. 7.17)

and choosing a save path as shown in Fig. 7.20.

FS22 DI A4248-6.0 HBM: public 85

Page 86

BraggMONITOR DI User Interface

Fig. 7.20

In the configuration file the information is divided by opti

cal channel identified between brackets (number 1 in

Fig. 7.21). For each sensor there are four columns,

namely: Sensor's Name, Central wavelength (nm),

Range (nm) and Formula separated by semicolons (as in

numbers 2, 3, 4 and 5 in Fig. 7.21).

86 A4248-6.0 HBM: public FS22 DI

Page 87

Fig. 7.21

BraggMONITOR DI User Interface

This file might be edited in Notepad or Excel (see «Open

ing Data in Microsoft Excel» section on page 72) and

saved as .txt extension file after editing.

Configuration file can always be loaded by pressing the

“load” button (number 9 in Fig. 7.17) and picking the con

figuration file (see Fig. 7.22).

FS22 DI A4248-6.0 HBM: public 87

Page 88

BraggMONITOR DI User Interface

Fig. 7.22

File Options

Data Path

Saved data files are named automatically (refer to sec

tion "Save Data" in section 7.1.1). Measured data is

recorded in the directory defined on the Data Folder box

(number 7 in Fig. 7.17). To choose this directory, write on

the box or press the folder button next to the box, drive to

the right directory and then press the “current folder" but

ton.

File Length

Each saved file has a limited length defined by time. The

maximum time interval for each data file can be defined

on number 5 in Fig. 7.17. When this interval is over, the

data file is created and named with the timestamp of the

last recorded measurement.

Sampling Rate

The sampling rate can be defined in samples/second on

number 6 in Fig. 7.17.

88 A4248-6.0 HBM: public FS22 DI

Page 89

BraggMONITOR DI User Interface

7.2.6 SCPI Interface

This tab allows the user to send Standard Commands for

Programmable Instruments (SCPI) to the equipment.