Page 1

Operating Manual

Display and Control Unit

DT85

A1704-1.1 en

Page 2

Page 3

DT85

Contents Page

Safety information 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Scope of supply 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Application notes 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Connecting the DT85 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Establish the measurement chain 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Pin assignment 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Setup and operation 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Set the baud rate 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Startup 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Operating philosophy 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Communication with the PME Assistant 16 . . . . . . . . . . . . . . . . . . . . . .

3

4.5 ZOOM function 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Passcode query 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 Overview of display readings 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 DT85 menu navigation 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Typical measurement mode displays 27 . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Explanations for the fundamental display parameters 29 . . . . . . . . . . .

7 Explanation of the main setup parameters 31 . . . . . . . . . . . . . . . . . . . . .

8 Error messages 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Specifications (VDI/VDE2638) 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HBMA1704-1.1 en

Page 4

4

DT85

Safety information

Appropriate use

The DT85 with its connected amplifiers must only be used for measurement

tasks and directly associated control tasks. Use for any purpose other than

the above shall be deemed to be inappropriate.

In the interests of safety, the device should only be operated as described in

the Operating Manual. It is also essential to observe the appropriate legal and

safety regulations for the application concerned during use. The same applies

to the use of accessories.

General dangers of failing to follow the safety instructions

The DT85 is a state of the art unit and as such is fail-safe. The device may

give rise to further dangers if it is inappropriately installed and operated by

untrained personnel.

Any person instructed to carry out installation, commissioning, maintenance or

repair of the device must have read and understood the Operating Manual

and in particular the technical safety instructions.

Conditions on site

Protect the device from direct contact with water (IP52 at the front, IP20 at the

back).

Maintenance and cleaning

The DT85 is maintenance-free. Please note the following points when

cleaning the housing:

- Before cleaning, disconnect the device from the power supply.

- Clean the housing with a soft, slightly damp (not wet!) cloth. You should

never use solvent, since this could damage the labeling on the front panel

and the display itself.

- When cleaning, ensure that no liquid gets into the device or the

connections.

Remaining dangers

The scope of supply and performance of the DT85 covers only a small area of

measurement technology. In addition, equipment planners, installers and

operators should plan, implement and respond to the safety engineering

considerations of measurement technology in such a way as to minimize

remaining dangers. Prevailing regulations must be complied with at all times.

There must be reference to the remaining dangers connected with

measurement technology.

HBM A1704-1.1 en

Page 5

DT85

Any risk of remaining dangers when working with the DT85 is pointed out in

these instructions by means of the following symbols:

5

Symbol:

Meaning: Dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements can lead to death or serious physical injury.

Symbol:

Meaning: Potentially dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements could lead to damage to property and slight or moderate

physical injury.

Symbols for operating instructions and useful information:

Symbol:

WARNING

CAUTION

NOTE

Means that important information about the product or its handling is being

given.

Symbol:

Meaning: CE mark

The CE mark enables the manufacturer to guarantee that the product

complies with the requirements of the relevant EC directives (see Declaration

of Conformity at http://www.hbm.com/support/dokumentation).

Working safely

Error messages must only be acknowledged once the cause of the error has

been eliminated and the danger no longer exists.

The device complies with the safety requirements of DIN EN 61010 Part 1

(VDE 0411 Part 1); protection class I.

HBMA1704-1.1 en

Page 6

6

DT85

To ensure adequate immunity from interference, the bus lines must be

shielded cables.

The power supply connection cables only need to be shielded if the cables

are longer than 30 m or are routed outside closed buildings.

When connecting the cables (attaching and detaching terminals), action must

be taken to prevent electrostatic discharge which could damage the

electronics.

The DT85 must be operated on a safety extra-low voltage (supply voltage

18...30 V DC), which usually supplies power to one or more consumers within

a control cabinet.

1)

Should the device be operated on a dc voltage network

, additional

precautions must be taken to discharge excess voltages.

Conversions and modifications

The DT85 display must not be modified from the design or safety engineering

point of view except with our express agreement. Any modification shall

exclude all liability on our part for any damage resulting there from. In

particular, any repair or soldering work on motherboards is prohibited. When

exchanging complete modules, use only original parts from HBM.

Qualified personnel

This device is only to be installed and used by qualified personnel strictly in

accordance with the technical data and with the safety rules and regulations

which follow. It is also essential to observe the appropriate legal and safety

regulations for the application concerned during use. The same applies to the

use of accessories.

Qualified personnel means persons entrusted with the installation, assembly,

commissioning and operation of the product who possess the appropriate

qualifications for their function.

Maintenance and repair work on an open device with the power on must only

be carried out by trained personnel who are aware of the dangers involved.

1)

Distribution system for electrical energy with greater spatial expansion (e.g. over a number of control

cabinets) that may even supply consumers with large nominal currents.

HBM A1704-1.1 en

Page 7

DT85

1 Scope of supply

• DT85 display and control unit

• DT85 operating manual

• 3-pin connector for the supply voltage

• Two 4-pin connectors for the CAN connection

Accessories (not included in scope of supply):

• Plug-in screw terminal, CAN and supply voltage for the MP85 and the

MP85DP

• 3-pin socket

Supplier : Phönix

Designation: MSTB 2.5/3 - ST5.08 Order no.: 1757022

7

• 4-pin socket

Supplier : Phönix

Designation: MSTB 2.5/4 - ST5.08 Order no.: 1757035

HBMA1704-1.1 en

Page 8

8

DT85

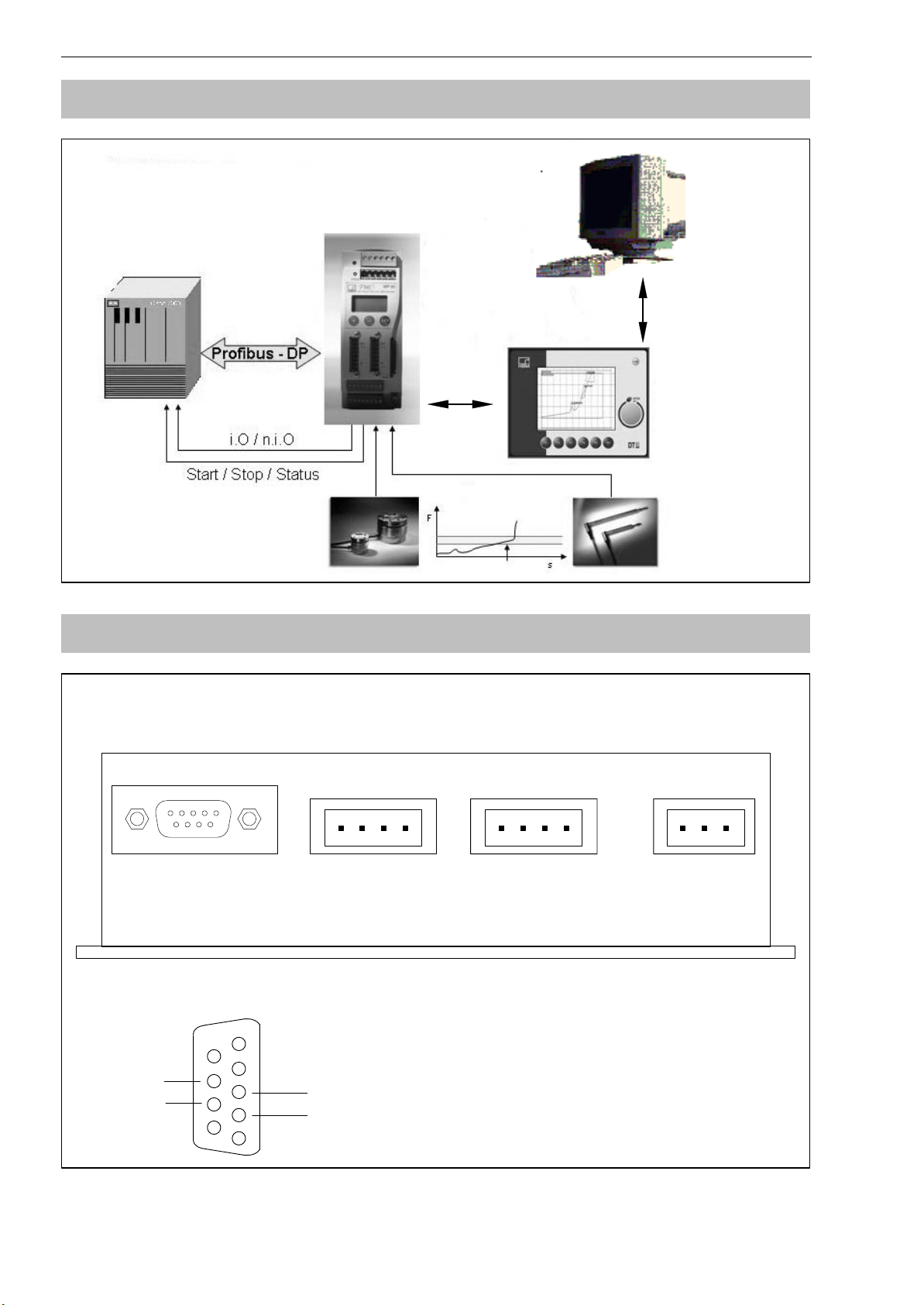

2 Application notes

The DT85 is an add-on for the twin-channel MP85 and MP85DP amplifiers of

the PME product family.

Most important applications of the DT85:

• Graphical representation of all measured values, evaluation windows and

press-fit curves with OK / NOK decision-making

• Displaying status information

• Viewing all the important MP85 settings

• Loading and storing parameter sets in/from flash or MMC memory

• Setting the most important parameters (e.g. tolerance windows) and

functions (sensor test)

• The DT85 is not suitable as a display for tolerance band mode, as an

evaluation criterion

NOTE

Measurement acquisition, analysis and curves/results storage

take place in the connected PME device. The DT85 serves as

a display and control unit.

HBM A1704-1.1 en

Page 9

DT85

9

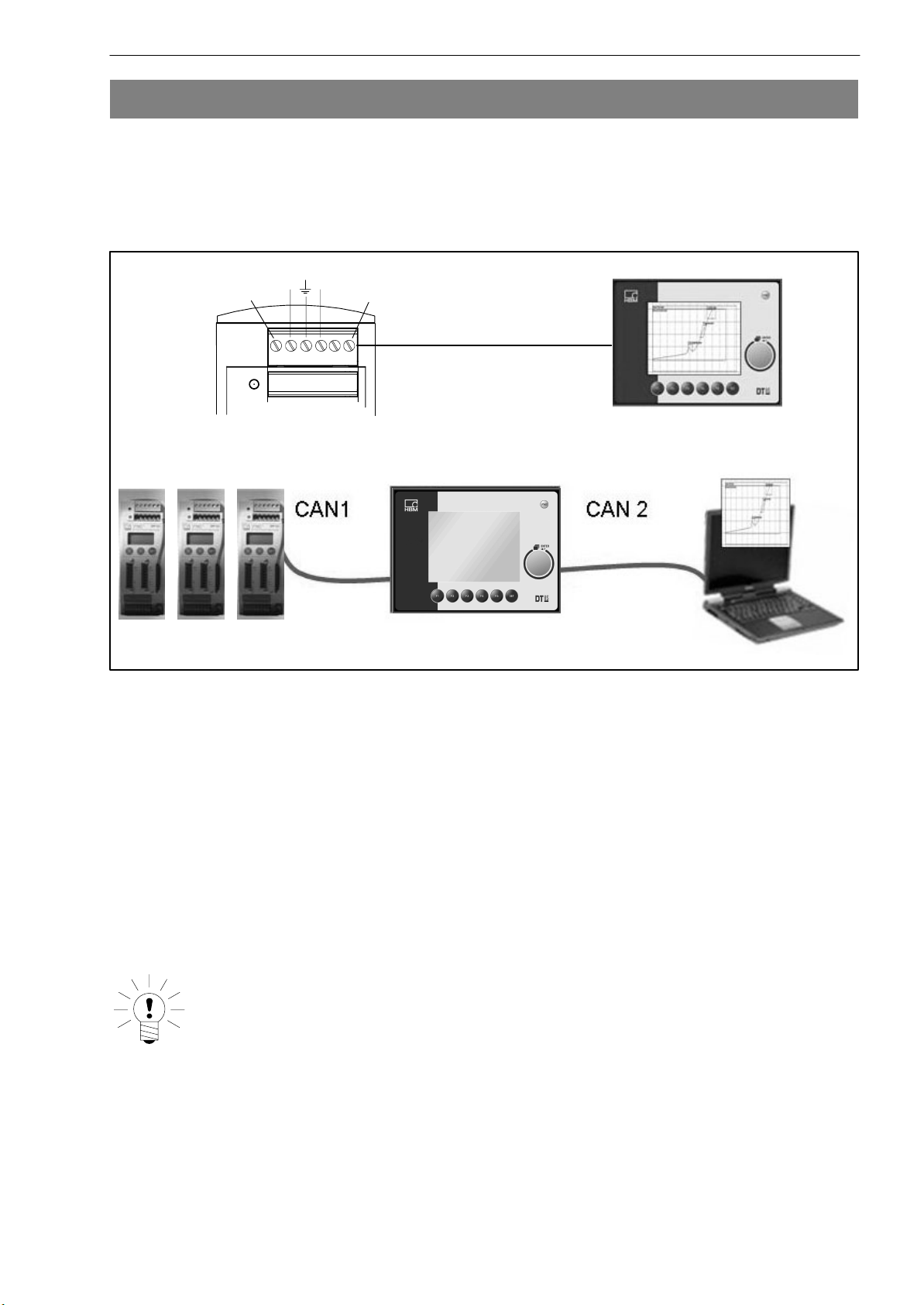

3 Connecting the DT85

Information is exchanged between the DT85 and the MP85(DP) modules via

the CAN bus.

Up to 10 MP85 modules can be connected and parameterized. The DT85 can

be supplied with voltage via the screw terminal of the MP85 module.

Low High

0V

+UB

X 2

Voltage supply and

CAN

CAN gateway

X 2

. . . . .max. 10

active

X 3

There are two possible applications:

• Connecting the DT85 display via the CAN bus on the MP85(DP) module

• Linking the PC with the DT85 via the second CAN interface (if necessary,

use a dongle at the PC, CAN-USB)

As soon as the PC is connected and the PME Assistant has been started up,

the display is muted and works as a gateway between the MP85 and the PC.

After closing the PME Assistant, the DT85 can be re-activated by the “DT85”

function.

NOTE

The DT85 can be both connected to the MP85(DP) module and

disconnected from the MP85(DP) module while measuring

mode is running, without detriment. This also applies to

connecting a PC to the PME Assistant.

HBMA1704-1.1 en

Page 10

10

3.1 Establish the measurement chain

PC with ”PME

Assistant” software

e.g. PLC

DT85

CAN

3.2 Pin assignment

Underneath the DT85 device

X4 X3 X2 X1

CAN

Sensors

CAN PC CAN MP85

External Display

DT85

RS232 programming

interface

1)

CAN

SCREEN

CAN GND

CAN L

CAN H

CAN

SCREE

N

CAN GND

CAN L

CAN H

+UB

GND

SCREEN

RS232 interface assignment 1):

GND

9

CTS

RTS

6

1)

Interface for service purposes: monitor, update, configuration

HBM A1704-1.1 en

5

TxD

RxD

1

Page 11

DT85

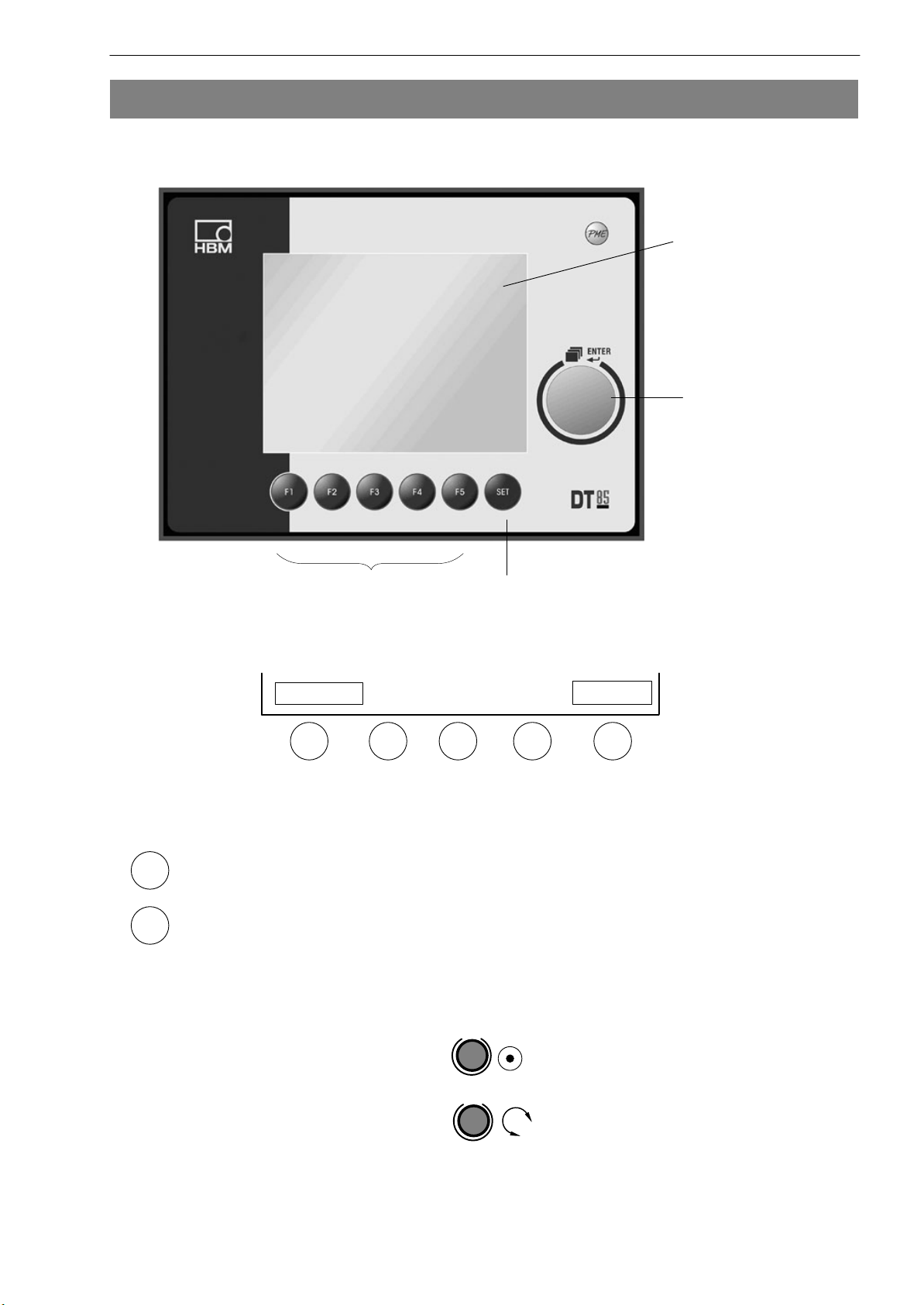

4 Setup and operation

Functions of the keys:

11

Display window

Rotary knob

with ENTER

key

F1 to F5 SET key

F1 to F5:

Example:

F1

- Key: Switching from setup level to display level

SET

- Key:

only assigned if shown in the display window

Measure

F1

In this example, keys F2 to F4 are not assigned.

Key F1 is assigned with MEASURE, key F5 with

PREVIOUS.

Switching from display level to setup level and navigating within setup

level

The following symbols are used below:

F2 F3 F4

Previous

F5

press:

rotate:

HBMA1704-1.1 en

Page 12

12

4.1 Set the baud rate

• Connect the DT85 to the MP85(DP) amplifier

• Switch on the devices

• Press keys F2 and F3 on the DT85 simultaneously

Display:

Main System

User Settings

CAN baud rate

Enter baud rate

Save and Exit

Exit

DT85

After exiting the system menu, the DT85 must be briefly disconnected from the

power supply (power-down-reset).

NOTE

The chosen baud rate must match the baud rate of the

connected PME device.

Factory setting 1 MBaud

HBM A1704-1.1 en

Page 13

DT85

4.2 Startup

Startup:

• Connect the DT85 to the MP85(DP) amplifier

• Switch on the devices

- DT85 performs a scan and displays all modules on the bus

Display (example):

NodeScan: 1 node found

113 MP85DP Ident. number of the detected device

.. (all the connected MP85(DP)s are shown)

13

• Rotate:

• Press ENTER:

Display:

- The DT85 is now in Display mode.

NOTE

Choose the required module

When several MP85(DP) modules are operated with one DT85, the SCAN

button can be used to display an overview of all devices on the bus and

switch the DT85 to another module.

HBMA1704-1.1 en

Page 14

14

4.3 Operating philosophy

Display level:

When it is switched on, the DT85 is in the display level.

Use to select the following display menus:

MEASURED VALUE DISPLAY – STATUS DISPLAY – GRAPHIC WINDOW LAST MEASUREMENT RESULT - STATISTICS

You cannot enter or set values at this level.

SET

Use to move to the main setup level menu from any window

Setup level:

Located under MAIN MENU. You can enter or set values here

(recognizable by text(figures) with a black background).

DT85

Example: MAINMEN

CHARACT. CURVE – ENTER CURVE – Zero pt.. electr. -0040.000

NOTE

Text marking at setup level:

Italics mean: read out only

non-italics: can be set with the ENTER key (see Page 21)

U - PREPARE MEASUREMENT - AMPLIFIER -

HBM A1704-1.1 en

Page 15

DT85

• Change setup values (black background):

Navigation with the ENTER key

15

- Select number

-

- Change last digit:

+0040.000

+0040.000

+0040.004

- Double-click

- Select previous digit:

- Double-click: Change digit

+0040.004

+0040.024

- Double-click: Change previous digit or use

- to exit change mode

Alternative way of changing setup values:

Navigation with keys F3 and F4

< - >

ƞ

Ɵ

(use F2 to change the sign)

- Select number

-F3

- Change digit:

+0040.000

(use F2 to change the sign)

+0040.004

- F3

- Select previous digit:

+0040.004

-F4

- Change digit

+0040.024

- F3 Select previous digit or use

- to exit change mode

Exit setup level:

Key F1 (MEASURE) will always take you to the last selected display mode.

HBMA1704-1.1 en

Page 16

16

4.4 Communication with the PME Assistant

NOTE

Gateway communication is also possible while measuring

mode is running.

• Connect the PC to the DT85 (connector X3)

X 2

X 3

DT85

• Start the PME Assistant

Display:

- The DT85 is bypassed, the MP85(DP) communicates directly with the

PME Assistant program

1)

• Back to the DT85 display:

Close the PME Assistant.

- Press key F1 on the DT85

1)

PME Assistant functionality is described in detail in its online Help.

HBM A1704-1.1 en

Page 17

DT85

4.5 ZOOM function

17

Use the ZOOM function to scale the graphic window (magnifying glass

function). In the factory setting, the display detail corresponds to the set range

window. The ZOOM range can be moved to any of the four pages.

Use the PREVIOUS key to transfer the set ZOOM range to the graphic

window, which also sets it up for all further measurements. The ZOOM Off key

resets the screen detail back to the size of the range window.

To zoom the window, you must first use the keys to select the required page,

for example, X1. You can then use the ENTER key (rotary knob) to modify the

view. Should further changes be necessary, you can now select and modify

the next page.

4.6 Passcode query

Factory setting 0000

Activate passcode:

0: disabled

1: active, that is to say, the passcode will be queried

If the passcode has been forgotten:

Code 1703 will always take you to the setup level.

See Page 21 for further details.

HBMA1704-1.1 en

Page 18

18

4.7 Overview of display readings

MAIN MENU (Setup level)

SYSTEM

MP85 default settings View only

DT85 default settings View only

PREPARE

MEASUREMENT

Amplifier

Transducer Display only

Characteristic curve Enter zero point and sensitivity

Signal preparation Run a zero balance

DT85

Passcode input, language change-

over

Transducer test Run a transducer test

Evaluation criteria Enter the range window

Enter the tolerance window

Enter the control settings

Data storage Specify storage medium and stor-

age parameters

Additional functions

Limit values 1-4 Modifiable numerical values

Digital inputs/outputs View only

SAVE AND LOAD

PARAMETERS

MEASUREMENT AND VISUALIZATION (Display level)

MEASURED VALUE

DISPLAY

STATUS DISPLAY Process status, status of Digital I/Os, alert notices

x/y channel with limit values, measurement status,

Saving and loading flash and MMC

equipment scan

GRAPHIC DISPLAY Measurement curve, tolerance window, graphic output

with units and zoom function, measurement results, rea-

son for ending measurement

LAST MEASUREMENT

RESULT

STATISTICS Displaying OK and NOK results per tolerance window,

HBM A1704-1.1 en

Measurement result with tolerance window output in

table form and window results of the last measurement

and process number, display of the entry and exit condi-

tions, status and evaluation method of each tolerance

window

can be switched for each parameter set with process

counter

Page 19

4.8 DT85 menu navigation

Display level

SET

key

MAIN MENU

Passcode query

(see Page 17)

SYSTEM

PREPARE MEASUREMENT

SAVE / LOAD PARAMETERS

Main menu

(setup level)

ENTER key

Measured value display Status display Graphic display Last measurement result Statistics

x/y measured values x/y measured values Parameter set Measurement result: Process counter

x/y measurement channel

status

Limit values Process status

Digital I/O status Process counter Process counter

MEASURE

Number of measurement

points

Display level

Reason for ending Window results

Display level

MEASURE key (F1)

Setup level

(each menu of the

main menu)

Parameter set (next parameter set: F1;

previous parameter set: F2)

Equipment scan / Equipment

selection

Alarm cause

Readings in the display

use

A1704-1.1 de DT85

SET

to move to setup level (MAIN MENU)

Measurement curve and eval-

uation window

Result Window name / Result

Process status

Reason for ending

Reason for alarm

Zoom (key F5)

UnZoom

Window results Window name / number / OK / NOK

Window entry and exit

conditions

Window status and evaluation

method

19

Page 20

20

A

Display level:

SET

Main menu

Measured value display

Status display

Graphic display

Last measurement result

Statistics

SYSTEM PREPARE MEASUREMENT SAVE/LOAD PARAMETERS

MP85 (DP) default

settings

DT85 default

settings

Setup level

Amplifier

Evaluation criteria

Transducer

Characteristic curve

Signal preparation

Transducer test

Alarm range window

Tolerance window

Control settings

Chart mapping

SET

SET

Loading flash

Saving in flash

Loading from MMC

DT85

Load parameters

from flash

SET

Save parameters

in flash

SET

Load parameters

from MMC

SET

Data storage

Additional

functions

1704-1.1 en

Results

Curves

Statistical data

LV1 + 2

LV 3 + 4

Dig. outputs

Dig. inputs

SET

SET

Saving to MMC

Save parameters

to MMC

SET

Page 21

SET

Main menu

SYSTEM

Setup level: SYSTEM

DEFAULT SETTINGS MP85

CAN + ID :

Device name :

Amplifier type :

Program version :

Hardware version :

Serial number :

Date/Time :

DT85

Note

italic: read out only

non-italic: adjustable with

and

A1704-1.1 de

MP85 (DP) default

settings

DT85 default

settings

Hardware synchronization: Master

MEASURE PREVIOUS

DEFAULT SETTINGS DT85

CAN baud rate :

Program version :

Specify passcode :

Activate passcode :

CHANGE OVER TO English language

Current language :

Program version :

MEASURE PREVIOUS

< - >

ƞ

Ɵ

NEXT

SYSTEM

SET

NEXT

SYSTEM

21

Page 22

Main menu

PREPARE MEASUREMENT

Setup level: PREPARE MEASUREMENT

22

DT85

Amplifier

Transducer

Characteristic

curve

Signal preparation

Transducer test

TRANSDUCER ID: 109

Channel x Channel y

Channel name Displacement Force

Transducer type Half bridge Full bridge

Measuring range

Decimal point

Unit

MEASURE

F5

Use to return to AMPLIFIER

PREVIOUS

NEXT

Transducer

Characteristic curve

Signal preparation

Transducer test

ENTER CURVE

ID 109

Zero pt. electr.

Zero pt. phys.

Sensitiv. electr.

Nom. val.. phys.

MEASURE

+ / -

Channel x Channel y

[mm ] [kN ]

< - >

ƞ

Ɵ

PREVIOUS

Transducer

Characteristic curve

Signal preparation

Transducer test

SIGNAL PREPARATION

ID 109

Channel x Channel y

[mm ] [kN ]

Zero balance START

Zero value

Zero reference

Low-pass filter.

NEXT NEXT

MEASURE PREVIOUS

START

TRANSDUCER TEST ID: 109

Channel x Channel y

[mm ] [kN ]

Setpoint

Deviation

Actual value=setpoint Yes

Yes

Transducer

Characteristic

curve

Signal preparation

Transducer test

A1704-1.1 en

Run test Start Start

Test ok?

MEASURE

PREVIOUS

NEXT

SET

TRANSDUCER

Page 23

Main menu

PREPARE MEASUREMENT

Setup level: PREPARE MEASUREMENT

DT85

Alarm and range windows

Evaluation criteria

Tolerance windows 1-3

Tolerance windows 4-6

Tolerance windows 7-9

Control setup

ENTER ALARM AND RANGE WINDOWS

ID: 109

Alarm window range window

Top right:

Channel X [mm] :

Channel Y [kN] :

Bottom left:

Channel X [mm] :

Channel Y [kN] :

MEASURE PREVIOUS

Use to return to

+ / -

F5

< - >

ƞ

Ɵ

EVALUATION CRITERIA

K

A1704-1.1 en

Alarm and range

windows

Tolerance windows 1-3

Tolerance windows 4-6

Tolerance windows 7-9

Control setup

NEXT

Alarm and range

windows

Tolerance windows 1-3

Tolerance windows 4-6

Tolerance windows 7-9

Control setup

TOLERANCE WINDOWS 1-3

Tol. wind: top/lft top/rt bot/lft bot/rt

#1 X[mm]:

#1 X[kN]:

#2X[mm]:

#2 X[kN]:

#3 X[mm]:

#3 X[kN]:

+ / -

PREVIOUS

CONTROL SETUP

ID: 109

Start condition: external

Start condition: external

Delta Channel X: mm

Delta Channel Y: kN

Max. meas. duration: s

MEASURE PREVIOUS

< - >

ƞ

Ɵ

NEXT

SET

Alarm and range

windows

Tolerance windows 1-3

Tolerance windows 4-6

Tolerance windows 7-9

Control setup

Alarm and range

windows

Tolerance windows 1-3

Tolerance windows 4-6

Tolerance windows 7-9

Control setup

TOLERANCE WINDOWS 4-6

Tol. wind: top/lft top/rt bot/lft bot/rt

#4 X[mm]:

#4 X[kN]:

#5X[mm]:

#5 X[kN]:

#6 X[mm]:

#6 X[kN]:

+ / -

PREVIOUS

TOLERANCE WINDOWS 7-9

Tol. wind: top/lft top/rt bot/lft bot/rt

#7 X[mm]:

#7 X[kN]:

#8X[mm]:

#8 X[kN]:

#9 X[mm]:

#9 X[kN]:

+ / -

ALARM AND RANGE WINDOWS

PREVIOUS

to K

23

Page 24

Main menu

PREPARE MEASUREMENT

Setup level: PREPARE MEASUREMENT

24

DT85

Data storage

F5

Use to return to

PREPARE MEASUREMENT

DATA STORAGE ID: 109

Target memory on MMC MMC:

on MMC via CAN

Storage method without loss of data

without loss of data Optimized to process

Save results: all

none all NOK only OK only

Save curves : all

none all NOK only OK only

Save statistical data: Save

MEASURE PREVIOUS

NEXT

SET

ADDITIONAL FUNCTIONS

A1704-1.1 en

Page 25

Main menu

PREPARE MEASUREMENT

Setup level: PREPARE MEASUREMENT

DT85

Additional

functions

Limit values 1+2

Limit values 3+4

Digital outputs

Digital inputs

LIMIT VALUE 1+2 ID: 109

Limit value 1: Channel x Channel y

Monitoring: On Off

Switching direction Overshoot Overshoot

Level:

Hysteresis:

Limit value 2: Channel x Channel y

Monitoring: Off Off

Switching direction Overshoot Overshoot

Level:

Hysteresis:

< - >

MEASURE PREVIOUS

Use to return to

+ / -

F5

ƞ

Ɵ

ADDITIONAL FUNCTIONS

A1704-1.1 en

Limit values 1+2

Limit values 3+4

Digital outputs

Digital inputs

LIMIT VALUE 3+4 ID: 109

Limit value 3: Channel x Channel y

Monitoring: Off Off

Switching direction Undershoot Undershoot

Level:

Hysteresis:

Limit value 4: Channel x Channel y

Monitoring: Off Off

Switching direction Undershoot Undershoot

Level:

Hysteresis:

< - >

NEXT NEXT

MEASURE PREVIOUS

+ / -

ƞ

Ɵ

DIGITAL INPUTS

Input Channel X Channel Y

Zero balance

Shunt calibr.

Load par. Bit 0

Load par. Bit 1

Load par. Bit 2

Load par. Bit 3

Load par. Bit 4

Start/Stop

Transducer test

Clear stats

Save stats

MEASURE PREVIOUS

NEXT

SET

Limit values 1+2

Limit values 3+4

Digital outputs

Digital inputs

Limit values 1+2

Limit values 3+4

Digital outputs

Digital inputs

DIGITAL OUTPUTS

Output Function Level

Output 1: LV 1x positive

Output 2:

Output 3:

Output 4:

Output 5:

Output 6:

Output 7:

Output 8:

MEASURE PREVIOUS

LIMIT VALUE 1+2

NEXT

25

Page 26

Main menu

SAVE/LOAD

PARAMETERS

Setup level: SAVE / LOAD PARAMETERS

26

DT85

SAVE AND

LOAD

PARAMETERS

Loading from flash

Saving in flash

Loading from MMC

Saving to MMC

LOAD PARAMETERS FROM FLASH

ID: 109

Load parameter set : 01

0 Factory setting

MEASURE PREVIOUSLOAD CANCEL

Loading from flash

Saving in flash

Loading from MMC

Saving to MMC

SAVE PARAMETERS IN FLASH

ID: 109

Save parameter set : 01

NEXT NEXT NEXT

MEASURE PREVIOUSSAVE CANCEL

Loading from flash

Saving in flash

Loading from MMC

Saving to MMC

Loading from flash

Saving in flash

Loading from MMC

Saving to MMC

LOAD PARAMETERS FROM MMC

ID: 109

Load parameter set : 01

MEASURE PREVIOUSLOAD CANCEL

SAVE PARAMETERS TO MMC

ID: 109

F5

Use to return to SAVE

AND LOAD PARAMETERS

A1704-1.1 en

Save parameter set : 01

MEASURE PREVIOUSSAVE CANCEL

NEXT

SET

LOAD PARAMETERS FROM FLASH

Page 27

DT85

5 Typical measurement mode displays

27

Device name of the selected PME

Device number of the selected PME

- Measurement channels displayed

as a numerical value with error

status. Error message output as

”plain text”.

- The other PME modules are

displayed and selected via the

Scan function.

- Status display of the digital

inputs/outputs (1=active / 0 =

inactive).

- Status display of the entire process

and of the possible alarm cause.

HBMA1704-1.1 en

Page 28

28

corresponds to the range window and can be modified with the ZOOM function

- Graphical representation of the

entire process with results display

and status messages.

- In a case of NOK, the screen is

switched to inverse, to make the

NOK processes easier to recognize.

- The upper X axis is used to display

the coordinates for relative

(dynamic) windows.

See Section 4.5 for a description of the

ZOOM function

DT85

- Detailed result display for each

tolerance window and of the overall

result.

This allows conclusions to be drawn

about the course and the status of

the production process.

- Exact statistics for each tolerance

window.

Statistics can be called up for each

parameter set (Use PS+ and PS- to

select the next or the previous

parameter set). PS = parameter set

HBM A1704-1.1 en

Page 29

DT85

6 Explanations for the fundamental display parameters

Display Parameters Meaning

29

MEASURED

VALUE DIS-

PLAY

Display Parameters Meaning

STATUS

DISPLAY

Display Parameters Meaning

GRAPHIC

DISPLAY

x/y measured

values

Limit values

SCAN Equipment scan looks for connected MP85 modules

Digital I/O status Switching status of the digital I/Os

Process status Status of the measurement process

Alarm cause Alarm window message

PS: Parameter

set

PN: Process

counter

MP: Number of

measurement

points

Measured value display for channels x and y with the

measurement status in plain text

Limit values 1-4; F = active, f = inactive

1: ON; 0: OFF

Active parameter set in the selected MP85 module

Current process number

Number of measurement curve measurement points

Measurement

curve and evalu-

ation window

Result Overall measurement result (OK / NOK)

Process status Status of the measurement process

End Reason for ending measurement

Alarm cause Alarm window message

Zoom Setting scaling for the x and y axes (detail function)

Course of the curve display with a set tolerance window

and an alarm and range window;

As a default, the display range is set to the size of the

range window; use the ZOOM function to modify the

display range.

HBMA1704-1.1 en

Page 30

30

Display Parameters Meaning

DT85

LAST MEASUREMENT

RESULT

Measurement

Overall measurement result (OK / NOK)

result:

Process number Current process number

Reason for end-

Reason for ending measurement

ing

Window 1... 9 Plain text display of the tolerance window with window

name and curve evaluation in this tolerance window

Display Parameters Meaning

STATISTICS Process number Current process number

Parameter set Selected parameter set for the statistics display; select

with ”PS+ and ”PS-”.

Number of pro-

cesses

Total number of processes on which the statistics dis-

play is based; since the last time the statistics were

cleared.

Windows 1...9 Plain text display of the tolerance window with the win-

dow name and the number of OK and NOK processes.

Window parame-

ters

En

Ex

St

Ev

En = entry ( from the left, from the right)

Ex = exit ( from below, from above)

St = window status (A = activ / I = inactiv)

Ev = evaluation method (A = absolute, R = relative,

AV = mean value, Rt = real-time window)

HBM A1704-1.1 en

Page 31

DT85

7 Explanation of the main setup parameters

SYSTEM Parameters Meaning

31

MP85 (DP)

default set-

tings

DT85 default

settings

PREPARE

MEA-

SUREMENT

Device ID

Device name

Hardware and

firmware ver-

sions

Serial number

Program

version

Passcode speci-

fication

Language

changeover

Parameters Meaning

Specifying and activating the 4-digit passcode (1=ac-

When the passcode is active, the setup level pages are

disabled; should the passcode have been forgotten,

use the master passcode 1703 to enable them.

Changing the language used by the DT85 and the

MP85(DP) settings

Display ONLY

DT85 program version display

tive / 0=inactive);

MP85(DP)

Amplifier Transducer Display of selected transducers for both measurement

channels

Characteristic

curve

Signal

preparation

Transducer test Running a transducer test for both measurement

Evaluation

criteria

Data storage Target memory Choice of storage medium; display of available

Alarm range

window

Tolerance

window

Control settings Display of the start and stop conditions for

Adjustment of the transducer characteristic for both

measurement channels

Running a zero balance for both measurement

channels

Display of zero value and the set low-pass filter

channels

Display of the range and alarm window coordinates;

the range window can be modified

Display and adaptation of the coordinates of tolerance

windows 1 to 9

measurement;

Displaying and setting the increment for the measure-

ment points of the curve and the max. sampling time

memory when MMC card inserted

Results curves Choice of results and curves that are to be stored

HBMA1704-1.1 en

Page 32

32

DT85

Statistical data Save statistical data in the MP85(DP)

Additional

functions

SAVE/LOAD

PARAME-

TERS

LV1 + 2

LV3 +4

Digital outputs Display of the set digital output functions of the

Digital inputs Display of the set digital input functions of the

Parameters Meaning

Loading flash Loading a parameter set (full device setup) of the

MP85(DP) from flash memory in the RAM of the

The process only starts once the ”Load” key is

Saving flash Saving a parameter set (full device setup) of the

MP85(DP) from the RAM to the flash memory of the

The process only starts once the ”Save” key is

Display of limit value settings,

level and hysteresis can be adjusted

MP85(DP)

MP85(DP)

MP85(DP);

(00 = factory setting).

pressed.

MP85(DP);

pressed.

Loading MMC Loading a parameter set (full device setup) of the

MP85(DP) from the MMC card in the RAM of the

MP85(DP).

The process only starts once the ”Load” key is

pressed.

Saving to MMC Saving a parameter set (full device setup) of the

MP85(DP) from the RAM to the MMC card.

The process only starts once the ”Save” key is

pressed.

HBM A1704-1.1 en

Page 33

DT85

33

8 Error messages

The messages displayed as status messages on the DT85 result from the

MP85. Therefore, MP85 settings have to be changed accordingly or the errors

must be corrected.

Error message Cause Remedy

TransdErr. Input signal overflow

Transducer not connected

Transducer wrongly connected

Amplifier not adapted to transducer

type

No sensor circuits connected

ADC ovfl. Input signal of the A/D converter too

high

Grs ovfl. Gross value overflow Reduce display by one decimal

Scal.Err Input characteristic too steep Modify input characteristic

Connect transducer

See pin assignment

Connect sensor circuits

Adjust hardware measuring

range

place

Flash error An error occurred when reading out

the Flash EOROM.

This can be a one-off read error,

please repeat the operation. If

the error occurs again, please

contact HBM Service.

For more details, please refer to the MP85 online help and operating manual.

If CAN bus communication between DT85 and MP85 does not work

properly, the below message is displayed:

The MP85 still remains operative and will not be affected.

If the interruption has been only temporary, press the ENTER key

or F1

for acknowledgement. Otherwise, the wiring has to be checked or the devices

must be restarted.

HBMA1704-1.1 en

Page 34

34

DT85

9 Specifications (VDI/VDE2638)

DT85

Display Backlit LCD-Display, monochrome background

illumination with auto contrast function

Resolution Pixels 320 x 240 (1/4 VGA)

Active display area mm 120 x 90

Faceplate Plexiglas

Operation 6 function keys with tactile touch

Password Certain levels can be assigned password protection

Dialog Can be changed to German or English

Supply voltage V

Power consumption W 5

Electrical connections 2 x CAN bus (elec. isolated), COMBICON connector,

Nominal (rated) temperature

range

Storage (rated) temperature

range

Relative humidity % 20 ... 80 (non-condensing)

Shock (11 ms), max. G 5

Vibration (5-65 Hz), max. G 0,5

Dimensions mm 216 x 158 x 45 (W x H x D)

Mounting 6 x M3 fastening bolts

Cutout in panel frame mm 185 x 130 (W x H)

Degree of protection IP52 at the front

Weight g 800

C

C

DC

1 x power supply / COMBICON connector, 3-pin

1 x RS232 for service

o

o

18 ... 30

4-pin

0 ... +50

-20 ... +70

HBM A1704-1.1 en

Page 35

DT85

35

HBMA1704-1.1 en

Page 36

pp

A1704-1.1 en

Modifications reserved.

All details describe our products in general form only. They are

not to be understood as express warranty and do not constitute

any liability whatsoever. and constitute no form of liability.

Hottinger Baldwin Messtechnik GmbH

Postfach 10 01 51, D-64201 Darmstadt, Germany

Im Tiefen See 45, D-64293 Darmstadt, Germany

Tel.: 061 51/ 8 03-0; Fax: 061 51/ 8039100

E-mail: su

ort@hbm.com www.hbm.com

Loading...

Loading...