Page 1

Operating Manual | Bedienungsanleitung

English Deutsch

CX22B / CX22B-W

Data Recorder - Datenrekorder

Page 2

Hottinger Baldwin Messtechnik GmbH

Im Tiefen See 45

D-64239 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

info@hbm.com

www.hbm.com

Mat.: 7-2001.3169

DVS: A3169-8.0 HBM: public

08.2017

E Hottinger Baldwin Messtechnik GmbH.

Subject to modifications.

All product descriptions are for general information only.

They are not to be understood as a guarantee of quality or

durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allgemeiner

Form. Sie stellen keine Beschaffenheits- oder Haltbarkeits

garantie dar.

Page 3

Operating Manual | Bedienungsanleitung

English Deutsch

CX22B / CX22B-W

Data Recorder

Page 4

English

1 Safety instructions 4........................................

2 Markings used 10............................................

2.1 The markings used in this document 10..........................

2.2 Symbols on the module and their meaning 11....................

3 Introduction 13..............................................

4 Connections and displays 15.................................

4.1 Voltage supply 17.............................................

4.2 Ground connection and grounding 18............................

4.3 Connection of QuantumX modules 18...........................

4.4 Communication with the Data Recorder 19.......................

4.5 Connector strip for backplane integration 20......................

4.6 USB 2.0 and USB 3.0 interfaces 20.............................

4.7 RS232 interface 20...........................................

4.8 Digital inputs and outputs 21...................................

4.9 START/STOP button 21.......................................

4.10 LED displays 22..............................................

5 Connecting QuantumX modules 27...........................

6 Operating the Data Recorder 30..............................

6.1 Operation with monitor and keyboard/mouse 30...................

6.2 Operation via a PC 31.........................................

6.2.1 A direct Ethernet line between PC and Data Recorder 33..........

6.2.2 Connection via a network 39...................................

6.2.3 Connection via WLAN 40......................................

6.2.4 Connection via a tablet 42.....................................

6.3 Connection via remote desktop 43..............................

6.4 Detecting and resolving connection problems 48..................

6.5 Using Ethernet and WLAN in parallel 49.........................

2 A3169-8.0 HBM: public CX22B / CX22B-W

Page 5

7 The CX22B‒W Data Recorder start screen 51..................

8 The first DAQ job with catman[EASY 53......................

8.1 Creating a DAQ job 53........................................

8.2 Transferring data/files to the PC 58..............................

8.3 Data analysis 60..............................................

8.4 Monitoring functionality 61.....................................

9 Configuring the CX22B‒W for self-contained measurements 63.

10 Saving data on the Data Recorder 66..........................

10.1 Memory partitioning 66........................................

10.2 Removing and inserting the CFast memory card 68...............

10.3 Memory performance 69.......................................

10.4 EWF, safeguarding your settings against change 70...............

11 Operating the CX22B/CX22B-W as gateway 71.................

11.1 Description 71................................................

11.2 Activate/deactivate gateway mode 71...........................

11.3 Connect to a QuantumX module behind a CX22B-W 72............

11.4 Performances 74.............................................

12 System settings, update and recovery 75......................

12.1 Installing drivers 75...........................................

12.2 Changing system settings (Settings) 76..........................

12.3 Updating the software 77......................................

12.4 System restoration (Recovery) 78...............................

12.5 Potential sources of error and remedial action 78..................

13 FCC (USA) and CI (Canada) statement 80......................

14 Waste disposal and environmental protection 82..............

15 Index 83....................................................

CX22B / CX22B-W A3169-8.0 HBM: public 3

Page 6

Safety instructions

1 Safety instructions

Appropriate use

The QuantumX Data Recorder is to be used exclusively

for measurement tasks and directly related control tasks

within the application limits detailed in the specifications.

Use for any purpose other than the above is deemed to

be non-designated use.

In the interests of safety, the module should only be oper

ated as described in the Operating Manuals. It is also es

sential to comply with the legal and safety requirements for

the application concerned during use. The same applies to

the use of accessories.

Each time you start up the module, you must first run a

project planning and risk analysis that takes into account

all the safety aspects of automation technology. This par

ticularly concerns personal and machine protection.

Additional safety precautions must be taken in plants

where malfunctions could cause major damage, loss of

data or even personal injury. In the event of a fault, these

precautions establish safe operating conditions.

This can be done, forexample, by mechanical

interlocking, error signaling, etc.

4 A3169-8.0 HBM: public CX22B / CX22B-W

Page 7

Safety instructions

Notice

The module must not be connected directly to the power

supply system. Supply voltage DC 10 V … 30 V.

When modules are installed in a vehicle, we recommend

connection to a separate battery or integration of an unin

terruptible power supply (UPS), as battery voltage is par

ticularly likely to fall below 10 V when a combustion en

gine starts up, which would automatically cause the

modules to restart.

General dangers of failing to follow the safety

instructions

The QuantumX Data Recorder is state-of-the-art and fail

safe. The module may give rise to residual dangers if it is

inappropriately installed and operated by untrained

personnel.

Any person instructed to carry out installation, commis

sioning, maintenance or repair of the modules must have

read and understood the Operating Manuals and in par

ticular the technical safety instructions.

Conditions at the place of installation

S Protect the module from direct contact with water.

S Protect the module from dirt, moisture or weather con

ditions such as rain, snow, etc. The protection class

under the IP standard DIN EN60529 is IP20.

S Please observe the permissible maximum ambient

temperatures stated in the specifications.

S Make sure that the side ventilation openings are not

covered.

CX22B / CX22B-W A3169-8.0 HBM: public 5

Page 8

Safety instructions

S The permissible relative humidity at 31°C is 80% (non

condensing); linear reduction up to 50% at 40°C.

S Do not expose the device to direct sunlight.

S Install the device so that it can be disconnected from

the mains at any time without difficulty.

S It is safe to operate the module up to a height of

2000 m.

Maintenance and cleaning

The modules are maintenance-free.

S Before cleaning, disconnect all connections.

S Clean the housing with a soft, slightly damp (not wet!)

cloth. Never use solvent, as this could damage the

label or the housing.

S When cleaning, ensure that no liquid gets into the

module or connections.

Residual dangers

The scope of supply and performance of the QuantumX

system covers only a small area of measurement tech

nology. In addition, equipment planners, installers and

operators should plan, implement and respond to the

safety engineering considerations of measurement tech

nology in such a way as to minimize residual dangers.

On-site regulations must be complied with at all times.

Product liability

In the following cases, the protection provided for the de

vice may be adversely affected. Liability for device func

tionality then passes to the operator:

S The device is not used in accordance with the operat

ing manual.

6 A3169-8.0 HBM: public CX22B / CX22B-W

Page 9

Safety instructions

S The device is used outside the field of application

described in this chapter.

S The operator makes unauthorized changes to the de

vice.

Working safely

A device must not be directly connected to the power

supply system. Supply voltage DC 10 V … 30 V.

The supply connection and all other connections must be

installed in such a way that electromagnetic interference

does not adversely affect device functionality (HBM rec

ommendation: "Greenline shielding design", download

able from the Internet at http://www.hbm.com/greenline).

Automation equipment and modules must be designed in

such a way that adequate protection or locking against

unintentional actuation is provided (e.g. access checks,

password protection, etc.).

When the modules are working in a network, these net

works must be designed in such a way that malfunctions

in individual nodes can be detected and shut down.

Safety precautions must be taken both in terms of hard

ware and software, so that a line break or other interrup

tions to signal transmission, e.g. via the bus

interfaces, do not cause undefined states or loss of data

in the automation device.

Conversions and modifications

The module must not be modified from the design or

safety engineering point of view except with our express

agreement. Any modification shall exclude all liability on

our part for any resultant damage.

In particular, any repair or soldering work on

motherboards (exchanging components) is prohibited.

CX22B / CX22B-W A3169-8.0 HBM: public 7

Page 10

Safety instructions

When exchanging complete modules, use only original

parts from HBM.

The module is delivered from the factory with a fixed

hardware and software configuration. Changes can only

be made within the possibilities documented in the manu

als.

Qualified personnel

This device is only to be installed and used by quali

fied personnel strictly in accordance with the specifi

cations and with the safety rules and regulations

which follow.

Qualified personnel means persons entrusted with siting,

mounting, starting up and operating the product who

possess the appropriate qualifications for their function.

This includes people who meet at least one of the three

following requirements:

S Knowledge of the safety concepts of automation tech

nology is essential and as project personnel, they

must be familiar with these concepts.

S As automation plant operating personnel, they have

been instructed how to handle the machinery. They

are familiar with the operation of the modules and

technologies described in this documentation.

S As system startup engineers or service engineers,

they have successfully completed the training to qual

ify them to repair the automation systems. They are

also authorized to activate, ground and label

circuits and equipment in accordance with safety

engineering standards.

It is also essential to comply with the legal and safety

requirements for the application concerned during use.

The same also applies to the use of accessories.

8 A3169-8.0 HBM: public CX22B / CX22B-W

Page 11

Safety instructions

Maintenance and repair work on an open device with the

power on may only be carried out by trained personnel

who are aware of the dangers involved.

CX22B / CX22B-W A3169-8.0 HBM: public 9

Page 12

Markings used

2 Markings used

catman is a registered trademark of Hottinger Baldwin

Messtechnik GmbH.

All trademarks and brands used in this document are

trade names and/or trademarks belonging to the respec

tive product or the manufacturer/owner. Hottinger

Baldwin Messtechnik GmbH does not lay claim to any

other than their own trade names/trademarks.

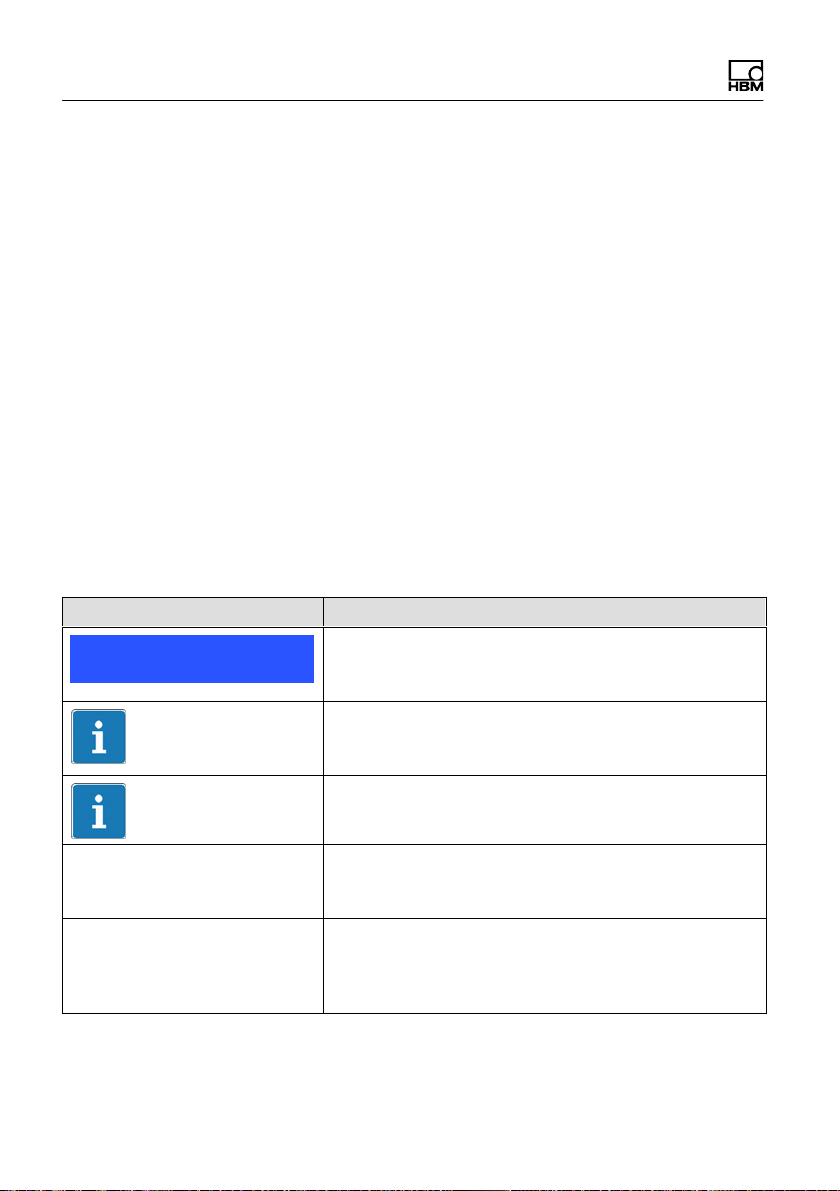

2.1 The markings used in this document

Important instructions for your safety are specifically

identified. It is essential to follow these instructions, in

order to prevent damage.

Symbol Significance

Notice

Important

Tip

Emphasize

See…

Device -> New Bold text indicates menu items, as well as dialog and

This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

This marking draws your attention to important infor

mation about the product or about handling the prod

uct.

This marking indicates application tips or other infor

mation that is useful to you.

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

window headings in the program environment.

Arrows between menu items indicate the sequence in

which the menus and sub-menus are called up

10 A3169-8.0 HBM: public CX22B / CX22B-W

Page 13

Markings used

SignificanceSymbol

Data rate Bold text in italics indicates inputs and input fields in

the user interfaces.

►

Instructions are marked by a small, right-pointing

triangle.

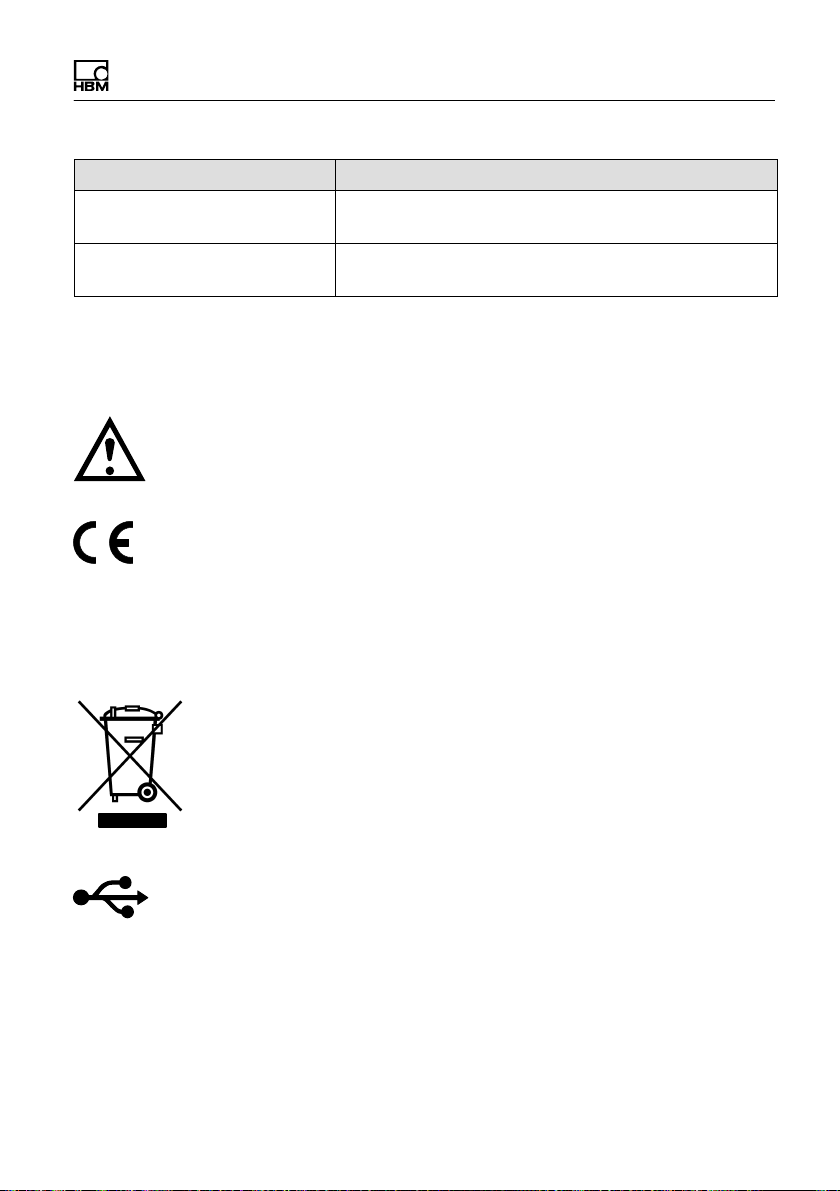

2.2 Symbols on the module and their meaning

Warning symbol on the module

Take the details in the operating manual into account.

CE mark

The CE mark enables the manufacturer to guarantee that

the product complies with the requirements of the rele

vant EC directives (the Declaration of Conformity can be

found on the HBM support website www.hbm.com/

support and HBMdoc).

Statutory waste disposal mark

The electrical and electronic devices that bear this sym

bol are subject to the European waste electrical and elec

tronic equipment directive 2002/96/EC. The symbol

indicates that the device must not be disposed of as

household garbage, see also Chapter, Page 82.

USB connections

For keyboard, mouse, external memory, for example

CX22B / CX22B-W A3169-8.0 HBM: public 11

Page 14

Markings used

Connection point for integration with a potential

equalization system

The connection should be applied to the protective con

ductor potential. If necessary, integrate the measurement

module into your functional grounding via this connection

so that interference currents can be discharged and inter

ference signal injection prevented.

12 A3169-8.0 HBM: public CX22B / CX22B-W

Page 15

3 Introduction

This manual is intended to support you in making the

basic settings of your QuantumX Data Recorder.

The CX22B‒W Data Recorder has an integrated WLAN

module. An antenna can be screwed on via the standard

ized SMA socket (RF coax type). A bendable antenna is

included with the product.

The CX22B Data Recorder does not have a WLAN con

nection, but this can be retrofitted by using an appropri

ate USB adapter.

All measurement technology settings are implemented

using the pre‐installed catmanEASY software, which

has an extensive online Help.

This manual shows you:

S How to start up the module.

S What can be connected and what to look out for.

Introduction

S How to start your first measurement and DAQ jobs

and how to get to the measurement data.

The following documentation is also available:

S General operating manual with the pin assignment of

the MX modules

S Data sheets

S Online Help in the catmanEASY and MX-Assistant

software

S Tips for use on topics such as Integration of GPS,

camera or how to connect wheel force transducers

like Kistler RoaDyn or KiRoad Performance.

CX22B / CX22B-W A3169-8.0 HBM: public 13

Page 16

Introduction

The data recorder’s functions can be extended with

packages such as:

- EasyRoadLoad: for road load data acquisition

(RLDA)

- EasyScript: for vehicle dynamics analysis (brake

tests, lane change...)

- EasyMonitoring: for infrastructure monitoring tasks

(connection to central data servers: Cloud)

The device is a QuantumX with the "Windows

Embedded‐8 StandardTM" operating system and

pre-installed catmanEasy software from HBM. Most of

the software functionality is described in the data sheet.

Interfaces on the back of the QuantumX Data Recorder:

S 2 x FireWire (ODU socket, 4-pin) for connecting

QuantumX modules such as MX840B, MX471B or

also SomatXR modules such as MX1615B-R.

S Connector strip for backplane integration. e.g.

BPX002

S Voltage supply (ODU socket, 4-pin)

S CFast slot (8 GB memory card is included in the

scope of supply)

The following interfaces and options can be found on the

front:

S 1 x RS232, e.g. for connecting position sensors (GPS,

GLONASS)

S 2 x Gigabit Ethernet, 1 x WLAN (CX22B-W only), 1 x

USB 3.0 and 2 x USB 2.0, 1 x DVI‐D

S 3 x digital inputs and 3 x outputs and push button for

start/stop assignment

14 A3169-8.0 HBM: public CX22B / CX22B-W

Page 17

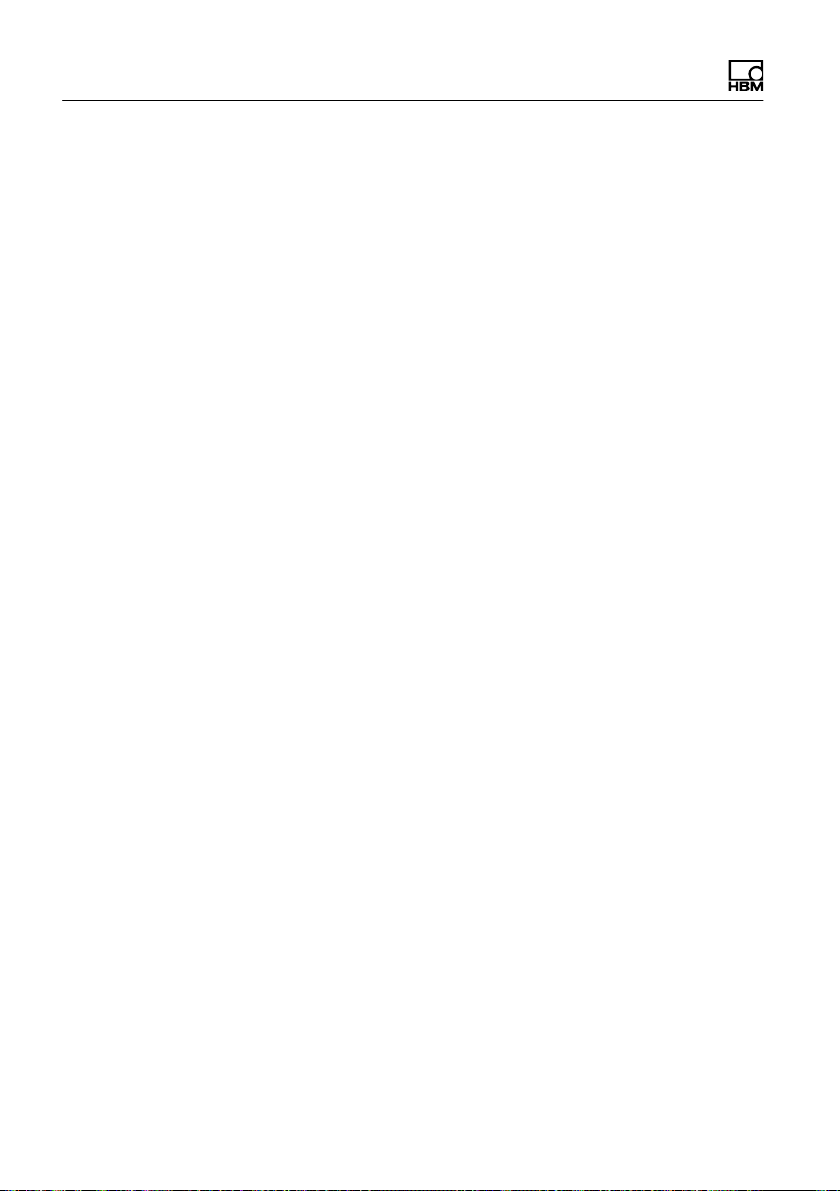

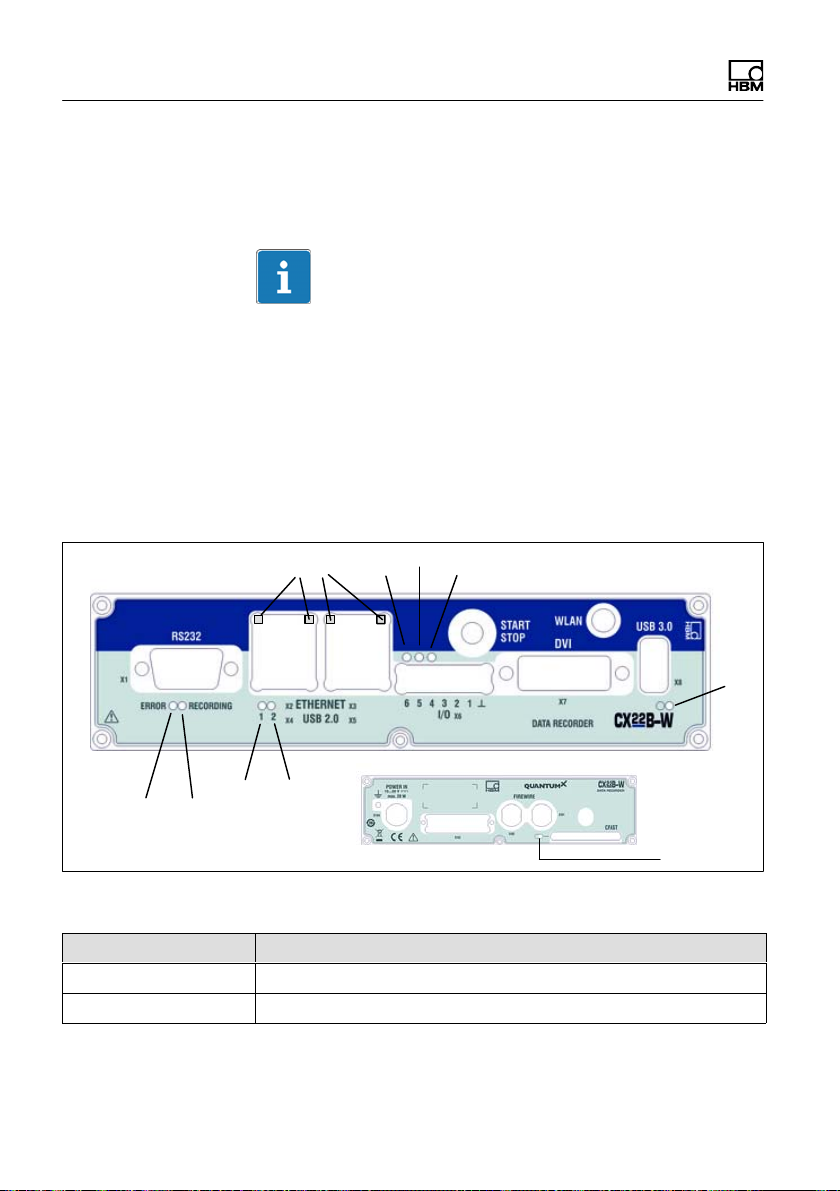

4 Connections and displays

Connections and displays

RS‐232‐C

Ethernet

Status LEDs

START/STOP

USB

Digital I/Os

WLAN antenna

button

USB 3.0

Monitor (DVI-D)

Fig. 4.1 CX22B‒W connections on the front

CX22B / CX22B-W A3169-8.0 HBM: public 15

Page 18

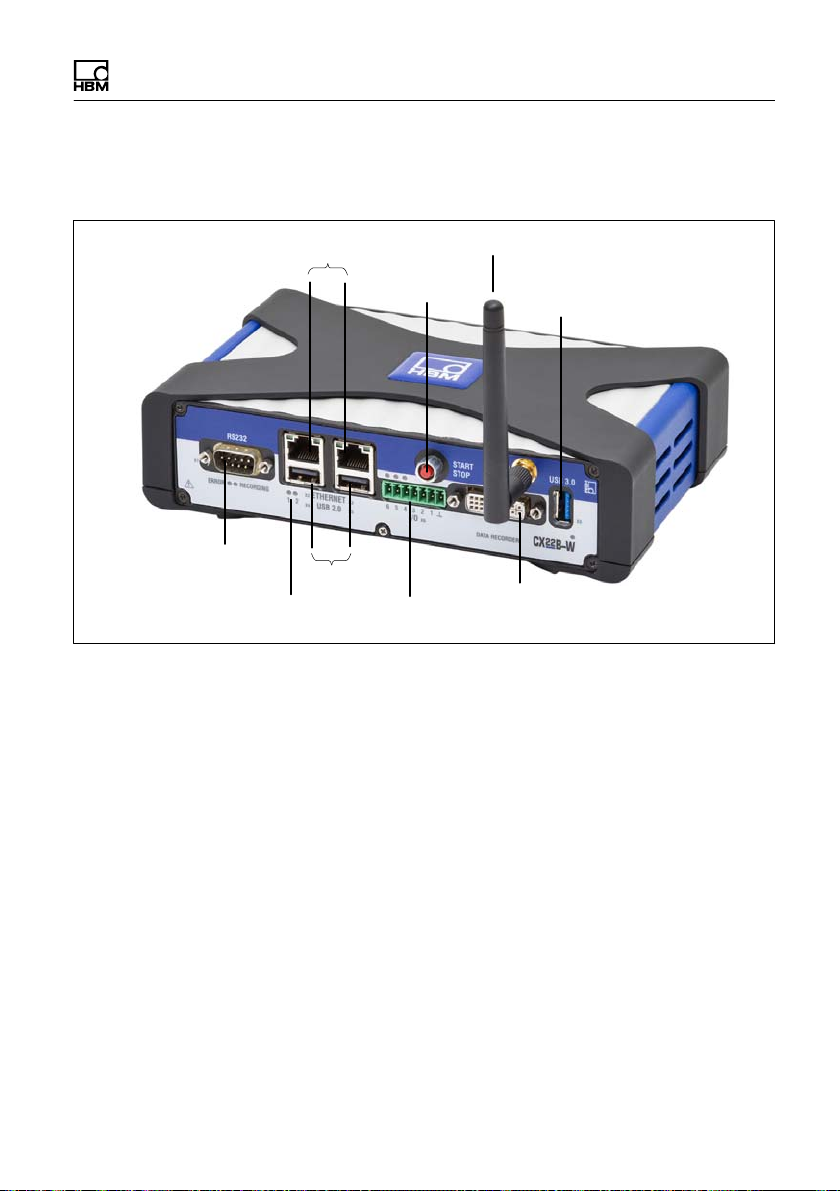

Connections and displays

Ethernet

RS‐232‐C

USB

Status LEDs

START/STOP button

Monitor (DVI-D)

Digital I/Os

USB 3.0

Fig. 4.2 CX22B connections on the front

Grounding

Supply voltage

DC 10 30V

Backplane con

nector strip

FireWire

CFast

Fig. 4.3 Connections on the back for CX22 and CX22B‒W

16 A3169-8.0 HBM: public CX22B / CX22B-W

Page 19

Connections and displays

4.1 Voltage supply

Apply a supply voltage of DC 10 - 30 V to connector

X104 (see Fig. 5.1). Use a voltage supply with sufficient

power, in case the QuantumX modules connected to the

CX22B‒W or devices such as GPS sensors, cameras or

data memory directly connected to the unit also need to

be supplied with power.

The DC voltage supply must be a SELV voltage supply,

meeting the requirements of IEC / EN / DIN EN 609501.

The supply voltage must be protected by an adequate

DC fuse (e.g. LITTELFUSE KLKD 6, LFPHV001) with a

maximum current of 5 A.

Notice

When modules are installed in a vehicle, we recommend

connection to a separate battery or integration of an unin

terruptible power supply (UPS), as battery voltage is par

ticularly likely to fall below 10 V when a combustion en

gine starts up, which would automatically cause the

modules to restart.

HBM offers the NTX001 power supply for laboratory or

general steady-state operation. On the primary side, this

provides a selection of international connector types and

24 V and 30 watts on the secondary side. A CX22B‒W

and one additional module can be supplied in this way.

See the respective module data sheets for precise details

of performance.

The Data Recorder can also be supplied with voltage by

a (FireWire) module group.

CX22B / CX22B-W A3169-8.0 HBM: public 17

Page 20

Connections and displays

The data recorder hosts a small buffer battery (type

CR2032, lithium). This battery keeps date and time

during power interruptions. The battery shall only be

replaced by HBM service.

4.2 Ground connection and grounding

Lay the signal and data leads separately from currentcarrying power lines. Cable ducts made of sheet metal

with an internal partition are ideal.

If there are differences in potential in or to the connected

measurement system, you must install a potential equal

ization line (recommended value: highly flexible stranded

wire, line cross-section 10mm2).

Important

4.3 Connection of QuantumX modules

The simplest way to connect measurement modules to

the CX22B‒W Data Recorder is via FireWire, or alterna

tively via Ethernet.

FireWire has the following advantages:

S Voltage supply, time synchronization, data communi

cation and real time in one cable and thus little effort

and low cost

S Every module has 2 FireWire connections, so flexible

topologies are possible: star, line or even hybrids with

an appropriate hub, also supplied with power via

FireWire.

Ethernet has the following advantages

18 A3169-8.0 HBM: public CX22B / CX22B-W

Page 21

Connections and displays

S The components used are readily available on the

market

S Up to 100 m line lengths to the module

S Synchronization via NTP or PTPv2 (IEEE1588:2008)

when using an appropriate switch

S Connection of modules via WLAN

4.4 Communication with the Data Recorder

You can work with the Data Recorder in the following

way:

S Directly connected peripherals

- Monitor or touchscreen (DVI, USB 3.0)

- Mouse and keyboard to USB

S Access via a PC or tablet by means of a "remote

desktop connection" (standard in Windows)

- Direct connection via an Ethernet patch cable

- Wireless connection (WLAN)

- In a network (LAN)

- Remote access via an Internet connection and a

mobile services provider using a mobile services

gateway

CX22B / CX22B-W A3169-8.0 HBM: public 19

Page 22

Connections and displays

4.5 Connector strip for backplane

The recorder can be integrated into the BPX001/002

backplane.

4.6 USB 2.0 and USB 3.0 interfaces

Devices such as a keyboard, mouse, monitor, printer, as

well as GPS sensors or data memory such as a USB

flash drive, can be connected.

Tips for use are available for the connection of GPS sen

sors via RS232 or USB.

Notice

If you have to install device drivers, please note Section

12.4.

integration

4.7 RS232 interface

An NMEA‐based GPS sensor can be connected via

RS232, for instance. The interface does not provide a

voltage supply. Other serial buses can be integrated to

the software on demand. A wide range of solutions is

already available.

20 A3169-8.0 HBM: public CX22B / CX22B-W

Page 23

Connections and displays

4.8 Digital inputs and outputs

Three inputs are available at terminals 1, 2 and 3 and

three outputs at terminals 4, 5 and 6. The status of the

outputs is indicated by LEDs, see Section 4.10.4.10.

Inputs

The level for the inputs is 5 volts in the open state

(HIGH), as it is pulled up to HIGH by a pull-up resistor

(active LOW). The maximum LOW level for the inputs is

0.7 volts.

Outputs

The level for the outputs is 5 volts (HIGH), when the cor

responding output is set, otherwise 0 volts (LOW). The

inputs and outputs are TTL-compatible, the line lengths

at the outputs must not exceed 3 m.

Tip

At the start of a DAQ job, outputs are reset to LOW if in

catman[EASY, in the options for the CX22B‒W (system

group), you activate the setting Reset all CX22B‒W

digital outputs at the start of a DAQ job.

4.9 START/STOP button

You can start and/or stop a DAQ job with the START/

STOP button. To do this, use a trigger for starting and/or

stopping the DAQ job and assign CX22B‒W digital in

put 3 - START/STOP button as the trigger channel.

CX22B / CX22B-W A3169-8.0 HBM: public 21

Page 24

Connections and displays

If you control the start and stop of the DAQ job via the

button, the DAQ job is started with the first press and

stopped with the next press of the button.

The START/STOP button is switched parallel to the input

on terminal 3. If you want to use the button, do not con

nect input 3. Otherwise the "Active" (LOW) state will be

triggered by pressing the button and by a LOW signal at

terminal 3.

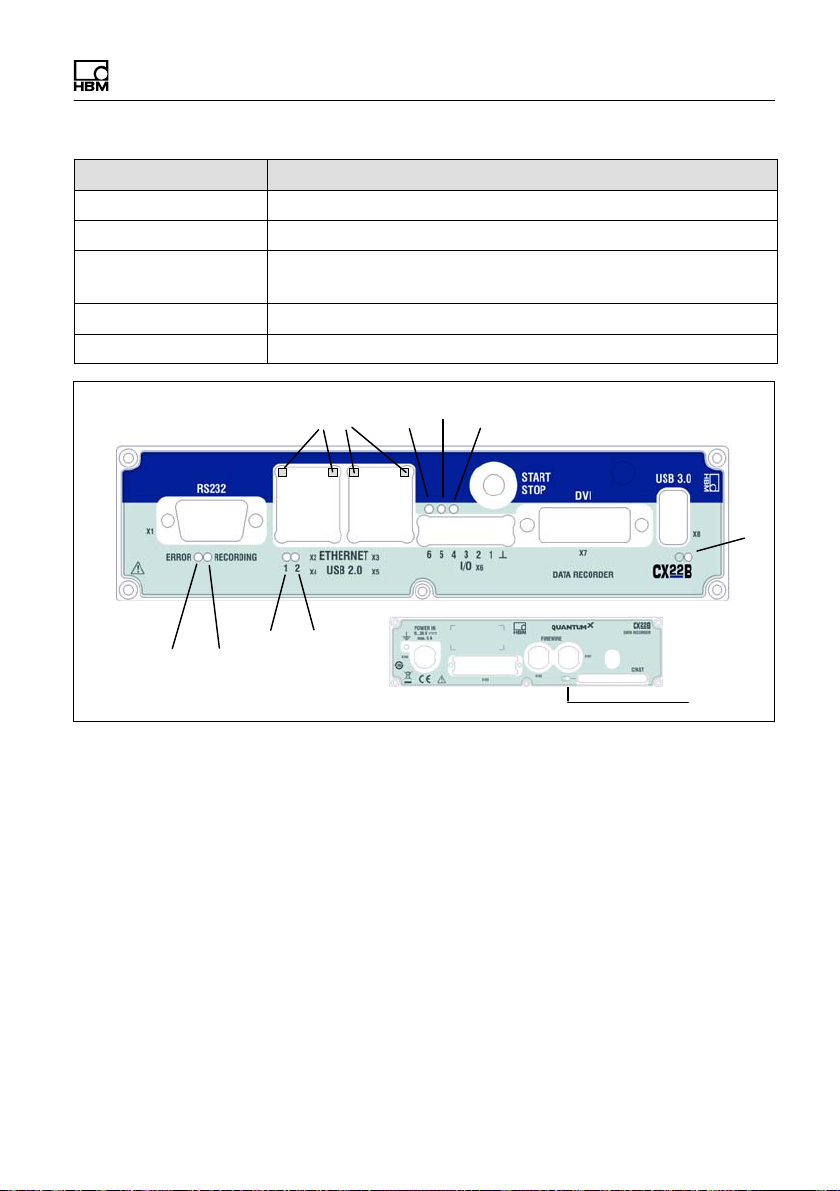

4.10 LED displays

Important

3

5

6

4

7

2

1

10

9

8

Fig. 4.4 Position of the LEDs

LED Function

1, 2 Operating condition status

3 Ethernet status

22 A3169-8.0 HBM: public CX22B / CX22B-W

Page 25

Connections and displays

FunctionLED

4, 5, 6 Status of digital outputs

7 Module LED

8 Operating condition of the CFast memory card

(rear of module)

9 ERROR

10 RECORDING

5

3

2

9

1

10

6

4

7

8

Fig. 4.5 Position of the LEDs without WLAN

CX22B / CX22B-W A3169-8.0 HBM: public 23

Page 26

Connections and displays

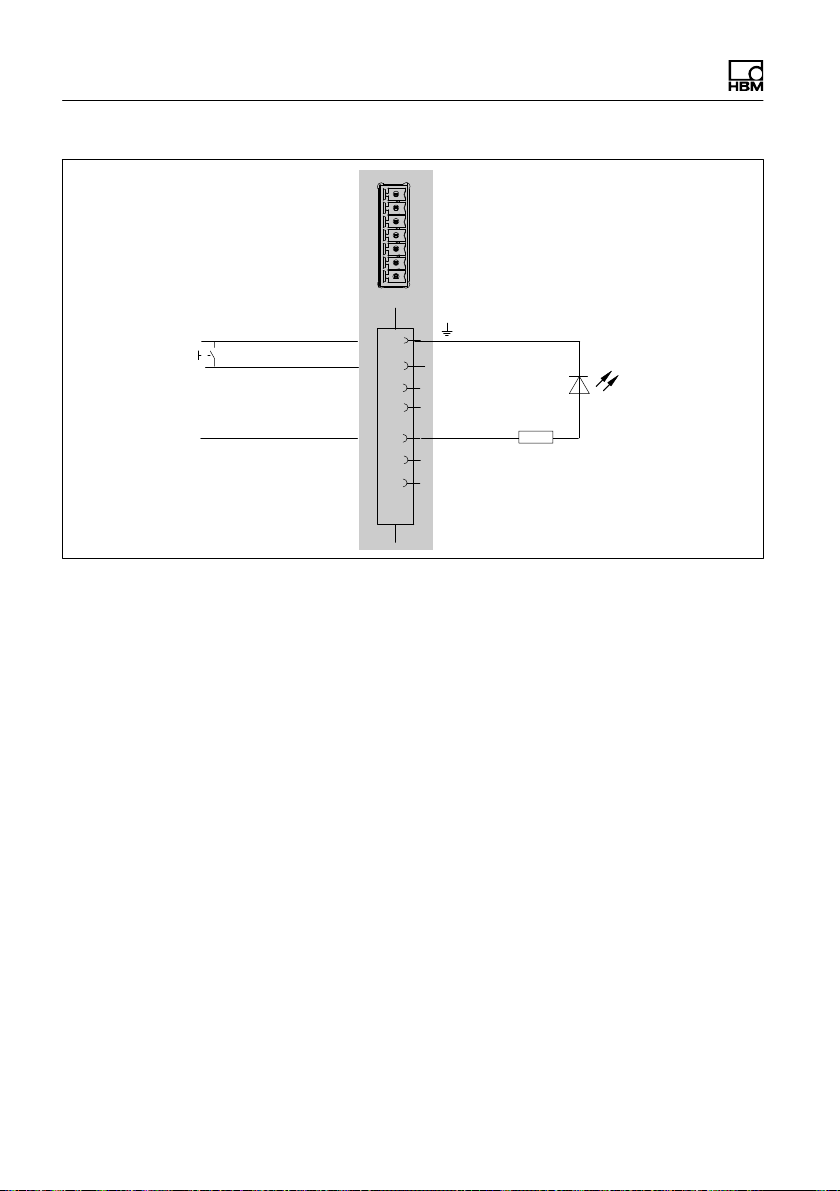

Digital In‐/Outputs

Dig In 2 (same for 1 and 3)

>

1 mA

Fig. 4.6 Pin assignment digital In ‐ and Output

Dig Out 4 (same for 5 and 6)

IN

1

2

IN

3

IN

OUT

4

5

OUT

6

OUT

R

24 A3169-8.0 HBM: public CX22B / CX22B-W

Page 27

Connections and displays

Module LED

The module LED (see Fig. 4.1 on Page 15) lights up

green when the CX22B‒W power supply is present. The

module requires approx. 1 minute after switch-on before

the boot process is complete.

LEDs on the Ethernet connection

The LEDs light up as follows (see number 3 in Fig. 4.1):

The left LED lights up when an Ethernet connection is

present and flashes for a 10/100MBit network con

nection.

The right LED lights up when the device is working at

1GBit.

Status LEDs for the operating status

The "RECORDING" LED

shows continuously yellow when measurement data

are being recorded. If a start trigger was set, the LED

flashes yellow while waiting for the trigger event.

The "ERROR" LED

lights up yellow if the software detects an error, e.g.

when no connection could be set up to the devices at

the start of the project. The LED flashes if the avail

able free memory drops below 1 GByte.

All Status LEDs can also be triggered via Limit values

and events in catman EASY. To do this select Set dig

ital output: CX22B digital output in the Configure

limit value and event monitoring dialog and enter the

required LED in Bit/Condition.

CX22B / CX22B-W A3169-8.0 HBM: public 25

Page 28

Connections and displays

Status LEDs for digital outputs

The LEDs show the status of digital outputs 4 to 6. The

outputs are addressed via LEDs 4 to 6 in catmanEASY.

Set the outputs via limit value and event monitoring: En

ter 0 HIGH (LED 4) for Bit/Condition if output 4 is to be

active when the event occurs (LED 4 lights up green).

Outputs 5 and 6 are activated via bit 1 (LED 5) and bit 2

(LED 6).

The corresponding digital output is simultaneously

triggered in LEDs 4 to 6. The LEDs light up when the rel

evant output is set to HIGH.

LED for the operating condition of the CF card

The LED on the rear of the module flashes yellow when

data are written to or read from the CF card.

26 A3169-8.0 HBM: public CX22B / CX22B-W

Page 29

Connecting QuantumX modules

5 Connecting QuantumX modules

The simplest way to connect QuantumX modules to the

Data Recorder is via FireWire. Connect cable

1-KAB272-x to any of the Data Recorder's connections

and the other end to connection X102 of the nearest

measurement module.

Then keep threading: connection X102 to X101 of the

second measurement module, etc. Remember the maxi

mum current of 1.5 A. As a rule, you must introduce a

voltage supply again after 3 modules. You can also con

nect measurement modules at the other connection.

Alternatively, you can connect all the QuantumX modules

to the CX22B‒W via Ethernet. If you have more than two

modules, you will also require an Ethernet switch.

In the configuration shown below, the module supply volt

age is looped through via FireWire (max. 1.5 A via

FireWire). The power consumption of a module is ex

plained in the data sheet.

You can connect up to 12 modules to the CX22B‒W

Data Recorder via FireWire, with a supply feed required

for at least every 4th module, with approximately the

same voltage value. The general QuantumX operating

manual contains more detailed data on this.

CX22B / CX22B-W A3169-8.0 HBM: public 27

Page 30

Connecting QuantumX modules

Important

If you are already using QuantumX modules and want to

connect them to a CX22B‒W Data Recorder, please up

date the device firmware. CatmanEASY checks the

firmware automatically and if necessary, prompts you to

update the firmware. The relevant firmware package is

supplied with the Data Recorder and is located in the

sub-directory C:\Program Files

(x86)\HBM\catmanEasy_EN\Firmware\QuantumX-B\

X102

DC 10V ... 30V

X101

MX

FireWire connection

1-Kab272-x: connection cables of various lengths (x m)

Fig. 5.1 Connecting QuantumX modules to the Data

Recorder via FireWire

MX CX

28 A3169-8.0 HBM: public CX22B / CX22B-W

Page 31

X102

X101

Ethernet

Connecting QuantumX modules

DC 10V ... 30V

MX

DC 10V ... 30V

WLAN

Fig. 5.2 Connecting QuantumX modules to the Data

Recorder via Ethernet

MX

CX

CX22B / CX22B-W A3169-8.0 HBM: public 29

Page 32

Operating the Data Recorder

6 Operating the Data Recorder

6.1 Operation with monitor and keyboard/mouse

This type of operation is the simplest. It does not require

any configuration, but you will need a monitor with digital

input (DVI) and a mouse and keyboard with USB connec

tion.

Connect the mouse and keyboard to the USB sockets of

the CX22B‒W. The monitor is connected to the DVI

socket with a commercially available DVI monitor cable

(see Fig. 4.1 on Page 15 for all connections). Connection

via VGA is not possible, not even with a DVI/VGA

adapter plug, as the leads required for VGA are not as

signed.

Switch on the power supply and wait until the boot

process is complete and the module is ready.

Important

The CX22B‒W factory setting for input language (key

board layout) is EN (English). If you connect a keyboard

with a different layout, you should select Exit to Win

dows in the start screen and then press Shift and Alt, or

change the input language via the language bar in the

task bar.

If necessary, use the Windows control panel ("Regional

and Language Options") to set the Location) to your

country. The setting influences the digit settings and the

time, for example.

Make other settings via the Data Recorder start screen.

30 A3169-8.0 HBM: public CX22B / CX22B-W

Page 33

Operating the Data Recorder

Initial start-up

The pre-installed catmanEasy software can be updated

free of charge for 12 months from the date of delivery. To

run an update, you must first register with HBM, in order

to benefit from software maintenance. To do this, simply

send us the registration file created during initial start-up.

This contains the software license number and the

device serial number.

You can do this later at any time via the catman soft

ware.

6.2 Operation via a PC

In this case, the CX22B‒W Data Recorder is connected

to the PC via Ethernet. There are different variants, de

pending on your PC/network configuration, and the

procedure used to set up the connection depends on the

variant:

CX22B / CX22B-W A3169-8.0 HBM: public 31

Page 34

Operating the Data Recorder

S The CX22B‒W and PC are connected directly via an

Ethernet cable.

S The CX22B‒W Data Recorder is connected to an Eth

ernet network (the network configuration is usually

assigned automatically via DHCP, Dynamic Host Con

figuration Protocol).

For a detailed description, see Section 6.2.2, Page .

S The CX22B‒W Data Recorder is connected via

WLAN (ad‐hoc to a PC or hotspot integration into lo

cal area network-LAN).

Wait approx. 1 minute after switching on the CX22B‒W

before setting up a connection so that the boot process is

complete and the module is ready. Otherwise you may

receive an error message that the device could not be

found.

Important

To make it easier to set up a connection when the

CX22B‒W settings are unknown, use the HBM program

HBM Device Scan, which is part of the system software

and included in the package as a DVD. It is also available

to download from (www.hbm.com -> Support -> Down

loads).

You can also set up a direct remote desktop connection

(standard program of the Windows operating system).

You need to know the IP address of the device to do this.

The device is delivered with factory settings and DHCP.

So you must use the "HBM Device Scan" software for

the initial start-up at least, or work with the direct periph

erals.

32 A3169-8.0 HBM: public CX22B / CX22B-W

Page 35

Operating the Data Recorder

In Windows 7, for example, the remote desktop connec

tion program is found under:

All programs −> Accessories.

6.2.1 A direct Ethernet line between PC and Data Recorder

► Connect your PC and CX22B‒W via an Ethernet ca

ble, category CAT5e or higher.

► Install the HBM Device Manager program, which can

be found on the HBM support sites or in the software

package QuantumX / SomatXR system software.

► Launch the HBM Device Manager program on the PC:

Windows Start menu−> All programs−> HBM −>

HBM Device Manager.

► Click on Find devices.

► Select the Data Recorder from the list, the current

address(es) of the interface (WLAN only with

CX22B‒W) are also displayed. The module in Fig. 6.1

has the IP address 172.19.204.252.

CX22B / CX22B-W A3169-8.0 HBM: public 33

Page 36

Operating the Data Recorder

Fig. 6.1 Display of the found modules and whether

connection is possible

► The IP addresses and subnet masks of the interfaces

of your PC and the found modules are displayed In

the Settings section. Depending on the configuration

of your PC, you can configure the CX22B‒W end.

The simplest setting is DHCP/APIPA. Suitable IP ad

dresses are automatically organized between the two

devices and you can start work immediately.

► Alternatively, you can use permanent addresses for

both devices. In this case, you can change the

CX22B‒W address, for example. The latter is de

scribed below.

► Select the CX22B‒W from the list.

► In the TCP/IP settings for CX22B‒W field, click on

LAN and enter the required IP address and subnet

34 A3169-8.0 HBM: public CX22B / CX22B-W

Page 37

Operating the Data Recorder

mask. An address and subnet mask that lie within the

address range of your PC are automatically proposed,

you can however change this proposal. Enter an IP

address in which the first three digit groups match the

digit groups of the PC and only the last digit group

contains a different number between number from 1

to 254. The last digit group must not match the digit

group in the PC!

Example for IP address and subnet mask

IP address of the PC: 192.168.0.1/ subnet mask

255.255.255.0.

Possible combination:

IP address of the CX22B-W: 192.168.0.2 / sub

net mask 255.255.255.0

► Click on Apply and wait until the new address is

shown at the top. The symbol indicates that a con

nection is possible.

► Select the CX22B‒W once again in the list at the top

and then click on Remote connect.

► If Windows asks whether the connection should be

set up to this remote computer, set up the connection

(Fig. 6.2).We recommend activating the option Don't

ask me again for connections to this computer.

CX22B / CX22B-W A3169-8.0 HBM: public 35

Page 38

Operating the Data Recorder

Fig. 6.2 Windows-dialog: setting up the connection

► Depending on the configuration of your Windows

operating system, another query as to whether the

connection should be set up may be displayed (iden

tity of the remote computer, Fig. 6.3). If necessary,

activate the option to prevent the query.

36 A3169-8.0 HBM: public CX22B / CX22B-W

Page 39

Operating the Data Recorder

Fig. 6.3 Identity of the remote computer display

The connection to the CX22B‒W Data Recorder will now

be implemented and you must register with the device

(Windows login dialog).

CX22B / CX22B-W A3169-8.0 HBM: public 37

Page 40

Operating the Data Recorder

Fig. 6.4 Identity of the remote computer display

The following applies in the factory settings:

User name: HBMCX22

Password: hbm

Important

If you change the IP address and subnet mask, this is

not yet permanently saved. So in the start screen, click

on Commit changes and reboot or Save and restart, if

you have yet to change the language in the settings. This

will permanently save the new settings. The recorder will

then restart. You will have to set up the connection again

after the restart.

38 A3169-8.0 HBM: public CX22B / CX22B-W

Page 41

Operating the Data Recorder

6.2.2 Connection via a network

The settings for the CX22B‒W Data Recorder again de

pend on your network configuration. Please contact your

network administrator to obtain the correct settings.

► Install the "HBM Device Manager" program from the

system CD.

► Launch the program on your desktop or via the Win

dows Start menu −> All programs −> HBM −> HBM

Device Manager

► Click on Find modules.

► All the QuantumX and Somat modules, including the

Data Recorder, will appear in the list.

► The IP addresses and subnet masks of the PC inter

faces are displayed in the Settings of my computer

section on the left.

► In the TCP/IP settings for CX22B‒W section, click

on LAN and select DHCP off - normal in networks.

Please note the specifications of your network admin

istrator.

► Click on Apply and wait until the new setting is shown

at the top. The symbol should change to the

symbol and thereby indicate that a connection is

possible.

► Select the CX22B‒W once again in the list at the top

and then click on Remote connect.

For the next steps, please proceed as in the previous

Section.

CX22B / CX22B-W A3169-8.0 HBM: public 39

Page 42

Operating the Data Recorder

6.2.3 Connection via WLAN

The connection via WLAN can be implemented in two

different ways:

► You can set up a direct connection to the CX22B‒W

wirelessly from your PC or tablet. This type of connec

tion is known as an Adhoc network .

► You can integrate the CX22B‒W into an existing wire

less network. This requires a configured Access Point

and information regarding the network name, login

and password.

Setting up the CX22B‒W for Adhoc operation

► Make the following setting: Activate WLAN Adhoc

connection on startup

► Save the changes permanently (the Data Recorder is

rebooted after this action. The WLAN connection that

was previously set-up is lost).

► You can then remove the network cable and use your

PC to find the CX22B‒W wireless network and con

nect to it.

40 A3169-8.0 HBM: public CX22B / CX22B-W

Page 43

Operating the Data Recorder

► Now use the HBM Device Manager tool to set up an

Adhoc connection to the CX22B‒W.

Configuring the CX22B‒W for an Access Point

► To set up the wireless connection, you must first cre

ate access to the CX22B‒W. This is done convention

ally with a monitor and keyboard or remotely via the

LAN cable.

► Exit to Windows and click on the small pictogram at

the bottom right.

► Connect to the network and if necessary, enter the

network key. We recommend that you always work

with encryption (WPA2) and never use unsecured

networks.

► Save the changes permanently (the Data Recorder is

rebooted after this action. The WLAN connection that

was previously set-up is lost).

CX22B / CX22B-W A3169-8.0 HBM: public 41

Page 44

Operating the Data Recorder

If setting up the connection in the Adhoc network takes

too long, you can also assign permanent IP addresses

for the CX22B‒W and PC. The connection will then be

set up faster.

6.2.4 Connection via a tablet

Apple computers, smartphones or tablet PCs can also

set up a connection to the CX22B‒W. This is on condi

tion that a suitable program is installed on the particular

device. The screen resolution should be 1000 x 750

pixels, as otherwise only parts of the CX22B‒W Data

Recorder screen will be visible and you will have to keep

moving the pane.

For Intel‐based Macs, use the Microsoft

"Remote Desktop Connection Client" program (available

as a free download from the Microsoft website).

Tip

For other operating systems, there are numerous pro

grams for setting up a remote desktop connection to a

Windows PC, such as the Remote Desktop for Mobiles

RDM+ program for BlackBerry, Android or iPad.

42 A3169-8.0 HBM: public CX22B / CX22B-W

Page 45

Enter the IP address of

the CX22B‒W here

Operating the Data Recorder

6.3 Connection via remote desktop

If you do not want to use HBM's HBM Device Manager

program or are working with a permanent IP address at

the recorder end, you can also set up the connection di

rectly via the "remote desktop" program (the program is a

component of the Windows operating system). In Win

dows 7, the program can be found under

All programs −> Accessories.

Fig. 6.5 Enter the IP address of the QuantumX Data

Recorder

Procedure

► Enter the IP address of the CX22B‒W.

► Click on Connect.

Configuration of remote desktop

The HBM Device Manager program uses a minimal re

mote desktop configuration, that allows only the

CX22B‒W screen to be displayed on your PC. You can

fully configure a remote desktop connection, so that you

can also directly use your PC drives on the CX22B‒W,

CX22B / CX22B-W A3169-8.0 HBM: public 43

Page 46

Operating the Data Recorder

for example, or can use Ctrl-C (Copy) and Ctrl-V (Paste)

to exchange data between the PC and the CX22B‒W.

You can:

S Create your own definition for the remote desktop

connection. Launch the remote desktop connection

program. Enter the IP address of the CX22B‒W and

click on Options.

S Change the definition used by the HBM Device Man

ager program. To do this, open the CX22B.rdp file in

the installation directory of the HBM Device Manager

software.

The group policy of the network administrator can limit or

totally prevent changes being made to the settings for the

remote desktop connection. Contact your network

administrator if one of the settings mentioned below is

not available to you.

Important

Further procedure

► Go to the Local resources tab and activate Clip

board , for example, and/or Printers (Fig. 6.6).

This allows you to use the clipboard of your PC to copy

and paste data, as well to use your PC's printer from the

CX22B‒W.

44 A3169-8.0 HBM: public CX22B / CX22B-W

Page 47

Activate data exchange

via the clipboard

Operating the Data Recorder

Fig. 6.6 Remote desktop connection local resources tab

► Click on Next in the Local resources tab.

► Enable the required drives of your PC for use in the

CX22B‒W (Fig. 6.7).

CX22B / CX22B-W A3169-8.0 HBM: public 45

Page 48

Operating the Data Recorder

Enable drives for

use in the CX22B‒W

Fig. 6.7 Dialog for enabling additional resources

► Close the dialog.

► Save the configuration via the General tab either

under a new name (Save as) or as a default setting

for the connection via HBM Device Manager (Save),

see Fig. 6.8.

46 A3169-8.0 HBM: public CX22B / CX22B-W

Page 49

Domain and user

name (optional data)

Allow user name and

password to be

saved

Save settings

Operating the Data Recorder

Fig. 6.8 Saving the remote desktop configuration

If you double-click this configuration file (or a link to it), a

connection to the CX22B‒W is immediately set up, and

you only have to enter the password. If you authorize

Save credentials (see Fig. 6.8), this is done automati

cally.

CX22B / CX22B-W A3169-8.0 HBM: public 47

Page 50

Operating the Data Recorder

6.4 Detecting and resolving connection

If the CX22B‒W does not appear in the HBM Device

Manager list, or the setup of the remote desktop connec

tion is canceled, there are several possible causes.

Check the following points and then repeat the search:

S Has the CX22B‒W been switched on for at least 1

minute and is the module LED green.

S Is the Ethernet switch working properly?

If you cannot check functionality because you are not

operating any other devices on the switch, try to set

up a direct connection between the PC and the

CX22B‒W.

S Have you waited long enough for the PC to specify its

address?

If the PC cannot find a server in the network, the

search for the server looks in the "DHCP" settings

(Obtain an IP address automatically) and the "Alterna

tive configuration" (user-defined address) first of all

(the symbol for the interface in the Windows tray indi

cates the search, but the symbol may only appear if

the display is configured). It then takes about 20 to 30

seconds to set an automatic address (in DHCP) or the

stated alternative address. During this time, a scan

has not found a CX22B‒W either.

problems

S Could your firewall be responsible for blocking the

UDP scan?

Try deactivating your firewall or enable the following

TCP ports: 31416 & 31417

S Could your antivirus program be responsible for block

ing the UDP scan?

48 A3169-8.0 HBM: public CX22B / CX22B-W

Page 51

Operating the Data Recorder

Try deactivating your antivirus protection to locate the

cause. If the CX22B‒W can then be found, read your

antivirus program documentation to discover how to

enable individual programs to access the network

(local subnet). You must enable the same ports as

those described under the firewall.

S If a WLAN is also active in your PC, you must test

whether the module can be found when you

temporarily switch off the WLAN (just for the search

period). With some WLAN configurations, problems

can occur across all interfaces during a scan.

S If your PC has several Ethernet interfaces, try

deactivating all the other Ethernet interfaces.

S If the HBM Device Manager cannot find the

CX22B‒W, try setting up a "standard" remote desktop

connection.

S If you are using the CX22B‒W in a larger network,

contact your network administrator. There are a series

of options in managed networks to limit or completely

prevent data transmission between the individual

nodes. Administrative enabling may also be

necessary here.

6.5 Using Ethernet and WLAN in parallel

With the CX22B‒W Data Recorder, you can connect

modules via Ethernet and also connect your PC to the

CX22B‒W via Ethernet. But you can also connect the

modules via Ethernet and your PC to the CX22B‒W via

WLAN. The following combinations are possible, in addi

tion to connecting the modules via FireWire:

S Connect PC to CX22B‒W via Ethernet, connect

modules via the WLAN hub.

CX22B / CX22B-W A3169-8.0 HBM: public 49

Page 52

Operating the Data Recorder

S Connect PC to CX22B‒W via Ethernet, also connect

modules via Ethernet (switch or hub required).

S Connect PC to CX22B‒W via WLAN (Adhoc also pos

sible), connect modules via Ethernet (switch or hub

required).

S Integrate the CX22B‒W in the WLAN network, con

nect PC (and modules) via the (Ethernet) network.

50 A3169-8.0 HBM: public CX22B / CX22B-W

Page 53

The CX22B‒W Data Recorder start screen

7 The CX22B‒W Data Recorder start screen

Fig. 7.1 Start screen of the CX22B‒W Data Recorder

In the CX22B‒W start screen (CX22Shell), you can:

S Launch the catman EASY program.

S Change important CX22B‒W settings: Settings.

You can use this to change the device name (CX se

rial number) and the password, for example, as well

as the language of catman EASY. The Info tab con

tains information about the CX22B‒W hardware (ID),

the device serial number and the firmware version.

Also see Section12.2.

S Permanently store configuration changes: Commit

changes and reboot..

You must always click on this button if you have im

plemented any changes via the Settings button or in

CX22B / CX22B-W A3169-8.0 HBM: public 51

Page 54

The CX22B‒W Data Recorder start screen

the (Windows) system. This permanently stores the

changes that have been made.

S Terminate the remote desktop connection: Close re

mote connection.

You can also terminate the connection by closing the

remote desktop window.

S Switch to the system level (Windows): Exit to Win

dows.

This is necessary, for example, when you want to ac

tivate the CX22B‒W WLAN.

S Shut down the CX22B‒W Data Recorder: Shut

down.

This switches off the CX22B‒W. Interrupt the power

supply for approx. 5 seconds, to switch it back on

again.

S Call up the directory with the QuantumX system docu

mentation: Help.

S Call up the default directory with the measurement

data: Data.

This opens the directory specified in Settings on the

General tab.

Recalling the start screen

If you have used Exit to Windows to exit the start

screen, you can recall it via CX22Shell (on the Windows

desktop).

The link brings the start screen to the top.

52 A3169-8.0 HBM: public CX22B / CX22B-W

Page 55

The first DAQ job with catmanEASY

8 The first DAQ job with catmanEASY

Launch catmanEASY in the start screen.

► Run a device scan

► Select the required devices.

8.1 Creating a DAQ job

A DAQ project contains all the settings for the devices,

transducers (sensors) and calculations used, how the

measurement is to be carried out, and which data should

be visualized online and saved.

Setting up DAQ channels

If you are not using transducers with TEDS (Transducer

Electronic Data Sheet) assign the connected sensors

(transducers) to the channels: find your sensors in the

sensor list (Sensor database component window), then

drag&drop each sensor to the channel to which it is con

nected. Set up your sensors in the sensor database, as

required.

Assign unique channel names

You can generate channel names with sequential

numbering or accept the sensor designation via the Re

name context menu. In catmanEASY, each channel is

identified by its name, so you must use meaningful

names where possible.

► Mark the channels to be set to zero and run a zero

balance (zero balance, group zero balance).

CX22B / CX22B-W A3169-8.0 HBM: public 53

Page 56

The first DAQ job with catmanEASY

► Deactivate any unused channels

(group General, Active Deactivate channels without

sensors).

► Define calculations − if required − : Generate in the

group Calculation channels.

► Activate Live‐Display (DAQ channels , tab General

group), to display continuous measured values and

check that all channels are working correctly.

Set up the DAQ job

► Select your measurement conditions: data rate(s),

measurement start and stop.

► Select Measurement start via Trigger and Digital

input for Trigger mode, so that you can use the digi

tal inputs or the START/STOP button of the

CX22B‒W

Start Stop

Pre-Trigger Post-Trigger

Fig. 8.1 Starting and stopping measurement with a trigger.

All the measured values between start and stop, as

well as those in the pre-trigger and post-trigger

periods are recorded

► Click on Data storage (Settings group) and specify

the settings for saving the data after or during mea

surement. We recommend using the Automatically

at end of job setting for data storage. Otherwise a

monitor must be connected during measurement in

order to save the data.

► Generate visualization − if a monitor is connected.

54 A3169-8.0 HBM: public CX22B / CX22B-W

Page 57

The first DAQ job with catmanEASY

► Save your DAQ project: File menu −> Save −>

Project.

► Start your DAQ project via Start in the Measurement

group.

If you have not generated a visualization you will be

asked if one of the default settings for visualization

should be used.

► Click on Measure without display, if a monitor is not

connected during measurement.

CX22B‒W measurement mode is activated. If you have

defined a start trigger, e.g. The START/STOP button,

this will be waited for, if not, measurement will start. The

"RECORDING" LED flashes while waiting for the start

trigger and glows continuously as soon as measurement

starts.

Important

The "ERROR" LED lights up yellow if there is an error in

catmanEASY, e.g. if the connection to the devices at

project start cannot be set up or if the DAQ job cannot be

started. The "ERROR" LED flashes if the available free

memory drops below 1 GByte.

Tip

More information about catman[EASY can be found in

the catman[EASY online Help.

CX22B / CX22B-W A3169-8.0 HBM: public 55

Page 58

The first DAQ job with catmanEASY

General default settings, data storage and

directories

You should also consider whether additional directories

should be specified as default settings, and how to pro

ceed with the sensor database.

Procedure for directories

► In the catmanEASY start window, click on Addi

tional options.

► Use System −> Folders to specify the default

directories for your data and images. Set up additional

folders, e.g. "E:\Projects".

The settings are only used the first time the data or

images are saved, after this, catmanEASY always

retains the last folder used.

► If you want to carry out a great many calculations with

vast data sets, and a sizable CFast card has been

installed, also create the catman working directory on

drive E:, e. g. "E:\HBM\catWorkingDir".

Sensor database

The sensor database is an easy way to adjust the mea

suring chain to the sensor being used. You only need to

enter the characteristic values of a sensor once, after

which you can click to assign the sensor to the channel

to which it is connected. The device is then set to the

characteristic values of this transducer.

In the default setting (condition at the time of delivery) an

English sensor database is used once catman is

launched. But you can switch this to a German or French

language database. To do this, you first have to change

the language in the settings and then launch catman.

56 A3169-8.0 HBM: public CX22B / CX22B-W

Page 59

The first DAQ job with catmanEASY

The data are identical, it is just the sensor group names

that are in the respective languages.

Procedure for modifying the sensor database

► In catmanEASY, use the Sensor database context

tab and the File menu to load the relevant sensor

database from the installation directory "C:\Program

Files (x86)\HBM\catmanEasy_DE\" or "C:\Program

Files (x86)\HBM\catmanEasy_FR\".

► Save this sensor database under a different name to

drive D or E, and open it again. catman EASY will

automatically save the new path and file name and

use it the next time the program is launched.

If you want to keep the English version, merely save it

under a different name to drive D or E.

Use a different name if possible, as a sensor database

called HBM_SensorDatabase.sdb could be overwritten

when the system is updated (although you will be asked

whether this should happen). Import a new sensor

database to your sensor database to incorporate new

CX22B / CX22B-W A3169-8.0 HBM: public 57

Page 60

The first DAQ job with catmanEASY

sensors, as required. A description of this can be found

in the catmanEASY online help for the sensor data

base.

8.2 Transferring data/files to the PC

There are several ways for you to transfer the measure

ment data acquired by the CX22B‒W Data Recorder to

your PC:

1. Directly from CFast:

a.) CX22B switched off

Switch off the module, remove the CFast and plug the

card into your PC. Then copy the data from the card.

b.) CX22B during operation

Go to the Data Recorders start screen, push “Eject

memory card” and pull out the CFast card.

2. Via a USB flash drive, e.g. a USB memory stick:

Plug the USB flash drive into one of the CX22B‒W's

USB interfaces and connect the keyboard and moni

tor. In the start screen, click on Exit to Windows and

use the operating system (Windows Explorer) to copy

the files.

3. Data exchange via the clipboard:

Configure your remote desktop connection so that you

can exchange data via the clipboard, see Section on

Page.

4. Data exchange via a PC drive integrated into the

CX22B‒W as an external drive:

Configure your remote desktop connection so that

one or more of your PC's drives are integrated as

additional CX22B‒W drives, see Section 6.3.

58 A3169-8.0 HBM: public CX22B / CX22B-W

Page 61

The first DAQ job with catmanEASY

5. Via Windows Explorer:

Enter the IP address of the CX22B‒W in Windows

Explorer (Fig. 8.2, enter \\ in front of the address).

IP address entry

Fig. 8.2 Entering the IP address of the CX22B‒W in

Windows Explorer

In the logon dialog, enter the name of the CX22B‒W,

the user name and the password. In the factory set

tings, the device name is "CX serial number" and the

user name is HBMCX22. In this case, enter

HBMCX22 and the password hbm (Fig. 8.3).

CX22B / CX22B-W A3169-8.0 HBM: public 59

Page 62

The first DAQ job with catmanEASY

User name entry

Password entry

Fig. 8.3 Entering the device name, user name and password

The enabled CX22B‒W drives and directories are dis

played. In the factory settings, this is partition E:

enabled (enable name "E").

8.3 Data analysis

There are basically two ways to evaluate the measured

data:

S On the CX22B‒W (via remote desktop):

To do this, start an evaluation project in

catmanEASY or switch from measurement mode to

evaluation mode.

S On your PC:

To do this, you can use catmanEASY/AP, catman

Post Process or GlyphWorks from HBM, for example.

The recorded file formats can basically be converted

into any other format, such as MAT, ASCII and many

60 A3169-8.0 HBM: public CX22B / CX22B-W

Page 63

The first DAQ job with catmanEASY

others. If binary files (BIN) have been recorded, there

are also import filters for programs such as Glyph

Works, FAMOS and others.

8.4 Monitoring functionality

Since catman 5.0 a new module for monitoring applica

tions is introduced, which might be helpful as well for

other applications. The key features of this module are

explained below.

Important

All these functions are not included in catman Easy,

which comes with the CX22B. They need an additional

EasyMonitoring license or a catman®AP license.

- Parallel data recorders

A data recorder is similar to a DAQ job in that is has its

own start/stop conditions, storage file and other settings.

But while ordinary DAQ jobs can not run in parallel,

recorders can do this! A good example for the use of

recorders is the monitoring of a railway bridge, where

each of two tracks should be monitored separately.

A data recorder always belongs to a normal DAQ job.

This DAQ job is the "parent" or "base" job for the

recorders. Each base job can have a subset of up to 15

data recorders where each recorder runs a separate and

independent data storage process based upon individual

start/stop trigger conditions. It has its own set of

channels to be recorded and individual sample rates

including downsampling. Recordings can be repeated,

i.e. after one recording the recorder again starts waiting

CX22B / CX22B-W A3169-8.0 HBM: public 61

Page 64

The first DAQ job with catmanEASY

for a trigger. Each recorder generates its own data file

and also supports FTP upload.

If a base job containing recorders is launched (i.e. when

you click the green arrow symbol) the recorder objects

are created and put into "Waiting for start trigger" state.

To view the recorder statuses a separate window, called

the "Recorder console" will be shown.

- (S)FTP upload

Data files generated after a DAQ job can be automati

cally uploaded to an FTP server. SFTP with authentifica

tion and data encryption is supported. The FTP upload

runs asynchronously in the background so it does not

block further DAQ jobs. If a DAQ job contains video cap

ture the video files can also be uploaded. FTP configura

tion is part of the DAQ job settings, register tab "Remote

data storage".

- Push‐Notifications

Push notifications are short messages which can be

send via the HBM Push Server (a service offered by

HBM in the Internet) to any mobile smart device (e.g.

iPhone, Android based devices) worldwide. On the

mobile device you only need to install the HBM Push App

("HBM Push") which you can download from the App

Store (e.g. Google Play Store for android based devices

or Apple App Store for iPhone or iPad). Push notifica

tions are especially useful in unattended monitoring appli

cations, e.g. to observe signals crossing a certain level.

catman can send push notifications either event driven

(see Event monitoring) or via EasyScript. The message

may contain placeholders (e.g. a measurement value or

the name of the channel triggering the event). For more

information about this module, please see the knowledge

base of catman.

62 A3169-8.0 HBM: public CX22B / CX22B-W

Page 65

Configuring the CX22B‒W for self-contained measurements

9 Configuring the CX22B‒W for self-contained

measurements

Catman can be launched via the start screen (Settings

button).

Fig. 9.1 CX22 catman start‐up settings

CX22B / CX22B-W A3169-8.0 HBM: public 63

Page 66

Configuring the CX22B‒W for self-contained measurements

Settings must be made in two areas to configure the

CX22B‒W for self-contained measurement:

S You must make the applicable settings in DAQ jobs

and options in catmanEASY so that catmanEASY

loads a DAQ project and launches the DAQ job after

startup.

S You must ensure that catmanEASY starts when the

CX22B‒W is switched on.

As usual, measurement can be started and stopped

immediately, or via a trigger. But you can also use the

START/STOP button of the CX22B‒W, see Section 4.9

on Page 21.

Procedure

► Configure your DAQ project as described in Section

8.1. Set up the DAQ jobs so that the data are saved

with the Automatically on DAQ termination setting

(Data saving in the Settings group, Data storage

parameter).

► Save the DAQ project.

► Call up the catmanEASY options (file menu) and go

to Program start (System group).

► For Start mode, select an Existing DAQ project and

choose the project created above in the DAQ project

line.

► Activate the option Execute first DAQ job automati

cally.

► Go to DAQ channels in the Channels and sensors

group.

► Activate the option Automatically deactivate faulty

channels and continue measurement (behavior if

channel initialization fails).

64 A3169-8.0 HBM: public CX22B / CX22B-W

Page 67

Configuring the CX22B‒W for self-contained measurements

► Exit the dialog by clicking on OK.

► Exit catmanEASY.

► In the start screen, click on Settings.

► On the General tab, activate the option Launch DAQ

software (catmanEASY) at CX22B‒W startup and

click on OK.

► Click on Commit changes and reboot to perma

nently save the new settings.

This project will then start automatically the next time the

CX22B‒W is switched on. If the power supply is inter

rupted during measurement, the project will be reloaded

and measurement continued when the power supply is

restored. The module restart, up to the continuation of

measurement, will require approx. 3 minutes, depending

on the number of connected devices and channels.

Important

The data already present in the catman[EASY tempo

rary measurement data memory are not lost if the power

supply is interrupted. Any additional files will be assigned

a counter at the end of the file name.

CX22B / CX22B-W A3169-8.0 HBM: public 65

Page 68

Saving data on the Data Recorder

10 Saving data on the Data Recorder

10.1 Memory partitioning

The available memory in the CX22B‒W Data Recorder

allocated as follows:

S 16 GByte are used for the operating system and are

specifically protected against (unintentional) change

(partition C, EWF filter).

S 48 GByte are readily available for the application and,

optionally, for measured data (partition D).

C:\ Windows 8

Embedded

including

catmanEASY

16 GB

Internal SSD Internal SSD

D:\ Application and

measurered data

48 GB

Fig. 10.1 Partitioning of the available memory

E:\ Measurement

Removable CFast card (in

scope of supply 8 Gbyte)

data

Important

All changes made in partition C: are only temporary, as

this partition is protected against change (EWF,

see Section 10.4). In the start screen, click on Commit

changes and reboot, to permanently save the new set

tings or the newly installed software. The CX22B‒W is

then rebooted, so you must set up the connection again

after the restart.

66 A3169-8.0 HBM: public CX22B / CX22B-W

Page 69

Saving data on the Data Recorder

Important

Only ever save the measurement data to the internal

SSD (partition D), the removable CFast card or to mem

ory connected via USB. Data storage to the removable

CFast card and checking the quality of the storage

medium at regular intervals is recommended.

Important

CFast cards only have a limited number of write cycles,

i.e., they age (typically 1,000,000 write

cycles). You should therefore check the CF card regu

larly for errors in Windows and replace with a new card

where necessary. The life of a CF card depends on the

demands made on it, and the manufacturer.

Make sure that you use an up-to-date, high-quality

CFast, in order to achieve a high data transfer rate.

The scope of supply for the CX22B‒W Data Recorder

includes an 8GByte CF card, although cards with a

higher memory capacity can also be used (for example

64, 128, 256 or 512 GB).

CX22B / CX22B-W A3169-8.0 HBM: public 67

Page 70

Saving data on the Data Recorder

10.2 Removing and inserting the CFast

memory card

Notice

Do not replace the CFast when data are being written to

it. If this is combined with a sudden loss of power, the

memory card or the device could be damaged, or − if

measurement data are being recorded − all the data of

the test could be lost. When operation is ongoing, the

memory card can be disabled under Windows. It is best

to switch off the CX22B‒W before replacing the CFast.

► Undo the retaining screw for the CFast. The screw

must not be removed, it should just be loosened.

► Swivel the cover plate upwards to expose the slot for

the CFast.

► Press on the memory card with your finger to remove

it.

► Hold the CFast with the top facing upwards and slide

it into the slot until the memory card engages. The

CFast must disappear completely inside the slot.

► Swivel the cover plate downwards and secure the

card.

► Tighten the retaining screw by hand.

68 A3169-8.0 HBM: public CX22B / CX22B-W

Page 71

Saving data on the Data Recorder

Important

In the factory settings, the measurement data on the

removable CFast medium is written to Drive\Data and

enabled in the network as "External CFast data". Some

catman

[

EASY default directories are also set to this

directory.

So also create the directory on the new CFast. Enabling

is not necessary for working with catman[EASY .

10.3 Memory performance

Maximum cumulative recording rate

(data storage)

Internal memory SSD

With (temporary) dynamic measurement

data memory (BIN)

1)

With (temporary) static measurement data

memory (BIN)

In FastStream mode2

2)

2)

For the installed CFast

With (temporary) dynamic measurement

data memory (BIN)

1)

With (temporary) static measurement data

memory (BIN)

In FastStream mode

1)

Test conditions: 14 modules (FireWire), 56 DAQ channels, 8 bytes per measured value, 2 data

rate groups, no visualization objects

2)

Test conditions: 14 modules (FireWire), 56 DAQ channels, 8 bytes per measured value, 1data

rate group, no visualization objects

2)

2)

MS/s

MS/s

MS/s

MS/s

MS/s

MS/s

4

> 5

> 5

3

> 5

> 5

CX22B / CX22B-W A3169-8.0 HBM: public 69

Page 72

Saving data on the Data Recorder

As a rough guideline, data throughput should be calcu

lated in MByte/s. A signal (sample) can be calculated

with 8 bytes. The opportunity is also available to experi

mentally check whether the chosen configuration works.

Diagnostic options are available via the lower status bar

in catman, to gain an overview of processor and memory

utilization at the start of acquisition.

10.4 EWF, safeguarding your settings

against change

The program called EWF (Enhanced Write Filter) pre

vents the files on partition C: being (unintentionally)

changed or overwritten. This could happen, for example,

if the voltage supply fails and Windows is not properly

shut down. In this situation, the program always restores

the "previous" state when the CX22B‒W is next switched

on.

All the data or programs saved on C: are therefore only

stored temporarily, and are deleted again once the sys

tem is switched back on.

If you want to permanently save settings or programs on

C:, you must use Commit changes and reboot in the

start screen ("CX22Shell"). Changes will then be perma

nently applied and will also be available the next time you

restart the CX22B‒W.

70 A3169-8.0 HBM: public CX22B / CX22B-W

Page 73

Operating the CX22B/CX22B-W as gateway

11 Operating the CX22B/CX22B-W as gateway

11.1 Description

The gateway mode allows to route QuantumX modules

that are connected via firewire to other network adapters

of the CX22B-W (e.g. ethernet or WLAN). In this mode,

the data recorder acts like any other gateway module

such as the CX27B, however, with higher data through

put.

Important

When the CX22B-W is in gateway mode, it cannot be

used as a recorder. This means that catman shall not run

on the recorder while the CX22B-W is configured in gate

way mode.

11.2 Activate/deactivate gateway mode

To activate/deactivate the gateway mode, go in the Shell

settings of the CX22B-W into the "General" tab. Check

the option "Activate gateway functionality" to activate the

option and uncheck it to deactivate it.

CX22B / CX22B-W A3169-8.0 HBM: public 71

Page 74

Operating the CX22B/CX22B-W as gateway

Notice

The CX22B-W will have to reboot to activate/deactivate

the gateway mode.

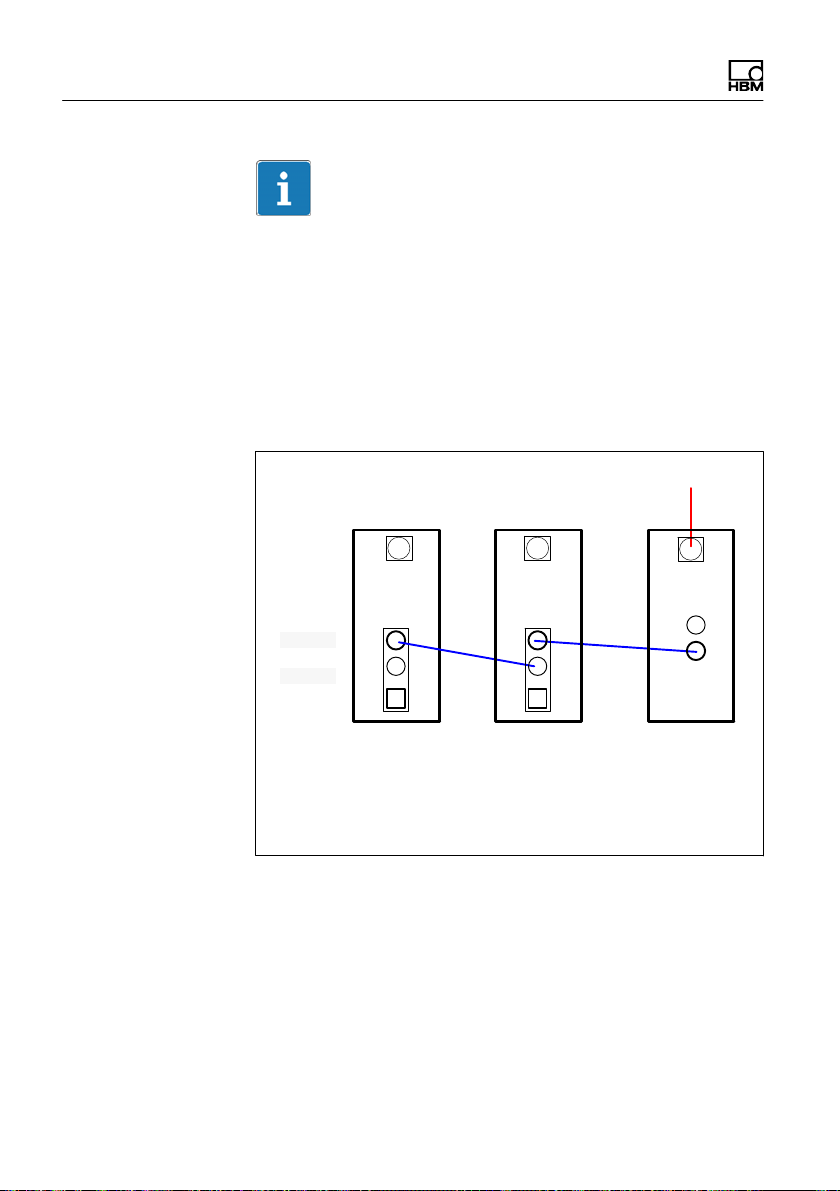

11.3 Connect to a QuantumX module

behind a CX22B-W

To connect to a QuantumX module being routed by a

CX22B-W, start catman on your PC and search for mod

ules in the device manager..The modules routed by the

CX22B-W are displayed as child elements of the

CX22B-W. Unlike the CX27B Ethernet / EtherCAT gate

way, you can select QuantumX modules individually.

72 A3169-8.0 HBM: public CX22B / CX22B-W

Page 75

Operating the CX22B/CX22B-W as gateway

Important note: You can connect only time simultane

ously to a QuantumX module being routed by the

CX22B-W.

CX22B / CX22B-W A3169-8.0 HBM: public 73

Page 76

Operating the CX22B/CX22B-W as gateway

11.4 Performances

The CX22B-W can route up to 3MS/s.

The following table shows the different tests we made to

benchmark the performances of the gateway mode in the

CX22B-W:

Maximum cumulative data througput (gateway mode)

LAN (Gigabit)

WLAN interface (adhoc)

1)

Test conditions: 12 modules (FireWire), 48 DAQ channels

2)

Test conditions: 14 modules (FireWire), 108 DAQ channels

1)

2)

MS/s

MS/s

> 3

> 0.2

74 A3169-8.0 HBM: public CX22B / CX22B-W

Page 77

System settings, update and recovery

12 System settings, update and recovery

12.1 Installing drivers

Drivers, for USB peripherals, for example, can be

installed at any time. Although the installation of other

software packages is also possible in principle, we do not

recommend this on a large scale, in order not to endan

ger the stability of the CX22B‒W Data Recorder. If addi

tional software is installed, the functionality of the

CX22B‒W Data Recorder can no longer be guaranteed

and HBM can no longer provide support for any faults

arising in this connection.

In practice, drivers have already been successfully

installed and operated for the following terminal equip