Page 1

Operating Manual | Bedienungsanleitung

English Deutsch

ClipX

Page 2

Hottinger Baldwin Messtechnik GmbH

Im Tiefen See 45

64239 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

info@hbm.com

www.hbm.com

Mat.: 7-2001.4643

DVS: a4643-1.0 HBM: public

03.2018

© Hottinger Baldwin Messtechnik GmbH.

Subject to modifications.

All product descriptions are for general information only.

They are not to be understood as a guarantee of quality or

durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allgemeiner

Form. Sie stellen keine Beschaffenheits- oder Haltbarkeits-

garantie dar.

Page 3

Operating Manual | Bedienungsanleitung

English Deutsch

ClipX

Page 4

Contents Page

1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Symbols on the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 ClipX device types, scope of supply. . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Device types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Scope of supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Mounting on a support rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Dismounting from a support rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.3 Other mounting options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 Electrical connections, LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 Functionality (block diagram) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 Shielding and grounding design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3 Available connections and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4 Health monitoring, LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.5 Connecting the supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.6 Connecting transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.6.1 Strain gage full and half bridge, voltage-fed piezo-resistive sensors . 34

6.6.2 Strain gage full bridge for applications in areas with potentially

explosive atmospheres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.6.3 Potentiometric transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.6.4 Temperature measurement by Pt100 . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.6.5 Voltage source (±10V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.6.6 Current source (±20mA or 4 … 20mA). . . . . . . . . . . . . . . . . . . . . . . . 44

6.6.7 Current drain (4 … 20mA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.7 Connecting the digital inputs and outputs. . . . . . . . . . . . . . . . . . . . . . 46

6.8 Connecting the analog output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.9 Using multiple ClipX devices, ClipX bus . . . . . . . . . . . . . . . . . . . . . . . 49

6.10 Synchronizing multiple ClipX CF amplifiers . . . . . . . . . . . . . . . . . . . . 51

6.11 Signal propagation times within the ClipX and over the ClipX bus . . . 53

2 a4643-1.0 HBM: public ClipX

Page 5

7 Starting up the ClipX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.1 Power-up and operating behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.2 Connecting via Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.2.1 No device found? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7.2.2 Possible cases and their effects when connected via Ethernet . . . . . 62

7.2.3 Set Ethernet address of PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.2.4 Resetting Ethernet network settings . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.3 Setting the ClipX using a web browser . . . . . . . . . . . . . . . . . . . . . . . . 67

7.4 Ethernet API . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.5 Using parameter sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8 Operation via fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.1 Connecting the fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.2 Data types used by the ClipX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.3 Data transfer from the controller to the ClipX . . . . . . . . . . . . . . . . . . . 71

8.4 Data transfer from the ClipX to the controller . . . . . . . . . . . . . . . . . . . 76

8.5 Settings for the fieldbuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.5.1 Settings for PROFINET. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.5.2 Settings for EtherCAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.5.3 Settings for EtherNet/IP™. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.5.4 Settings for PROFIBUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.6 Flags and status bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8.6.1 Measured value status: List of status bits . . . . . . . . . . . . . . . . . . . . . . 97

8.6.2 System status: List of status bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

8.6.3 Flags: List of possible I/O flags (I/O status) . . . . . . . . . . . . . . . . . . . 101

8.6.4 The control word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

9 Calibration certificates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10 Diagnostics and error rectification, FAQs . . . . . . . . . . . . . . . . . . 105

10.1 Possible errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

10.2 FAQs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

11 Technical support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

12 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

13 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

14 Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

ClipX a4643-1.0 HBM: public 3

Page 6

4 a4643-1.0 HBM: public ClipX

Page 7

Safety instructions

1 Safety instructions

Read this operating manual before operating the device for the first time. Any

persons assigned to install, commission, operate or maintain the device must

have read at least the sections of the operating manual of relevance to them.

The operating manual forms part of the product. Keep it in a safe place so that it

is permanently accessible to all users. If you pass the device on to a third party,

always pass it on together with the relevant documents.

Intended use

The ClipX amplifier system is to be used exclusively for measurement tasks and

directly related control tasks (automation systems). Use for any purpose other

than the above is deemed to be non-designated use. In the interests of safety,

the device should only be operated as described in the operating manual.

The device may only be powered by a safety extra low voltage (DIN EN 61558

or VDE 0570, Safety of transformers, reactors, power supply units and combinations thereof). The supply voltage must be between 10V and 30V (DC).

Conditions at the place of installation

• Protect the device from direct contact with water.

• Protect the ClipX from moisture and dampness or weather such as rain,

snow, etc.

• Do not expose the device to direct sunlight.

• Please observe the permissible maximum ambient temperatures stated in

the specifications.

• The permissible relative humidity at 31°C is 95% (non condensing); linear

reduction up to 50% at 40°C.

• It is safe to operate the ClipX up to an altitude of 2000 meters.

Conversions and modifications

The device must not be modified from the design or safety engineering point of

view except with our express agreement. In particular, any repair or soldering

work on motherboards is prohibited. The device must not be opened. The

ClipX

a4643-1.0 HBM: public 5

Page 8

Safety instructions

product is delivered from the factory with a fixed hardware and software configuration. Changes can only be made within the possibilities documented in the

operating manual.

Qualified personnel

This device is only to be installed and used by qualified personnel (electricians

or persons trained in electrical engineering), strictly in accordance with the

safety regulations listed here. This includes personnel who meet at least one of

the three following requirements, depending on their assigned tasks:

• Knowledge of the safety concepts of measurement and automation technology is a requirement and as project personnel, they must be familiar with

these concepts.

• As measurement or automation system operating personnel, they have

been instructed how to use the equipment. They are familiar with the operation of the equipment and technologies described in this document.

• As commissioning engineers or service engineers, you have successfully

completed the training to repair the automation systems. You are also

authorized to operate, ground and label circuits and equipment in accordance with safety engineering standards.

Residual dangers

The ClipX system is a state-of-the art unit and as such is reliable. The scope of

supply and performance of the ClipX system covers only a small area of measurement technology however. In addition, equipment planners, installers and

operators should plan, implement and respond to the safety engineering considerations of measurement technology in such a way as to minimize residual dangers. For example, automation equipment and devices must be designed in

such a way that adequate protection or locking against unintentional actuation is

provided (e.g. access controls, password protection, etc.). When devices are

working in a network, these networks must be designed in such a way that malfunctions in individual nodes can be detected and shut down. Safety precautions must be taken both in terms of hardware and software, so that a line break

or other interruptions to signal transmission do not cause undefined states or

loss of data in the automation device.

6

a4643-1.0 HBM: public ClipX

Page 9

Safety instructions

Note

Safety notice used in this document

This symbol draws your attention to a situation in which failure to comply with

safety requirements may result in damage to property.

ClipX

a4643-1.0 HBM: public 7

Page 10

Safety instructions

8

a4643-1.0 HBM: public ClipX

Page 11

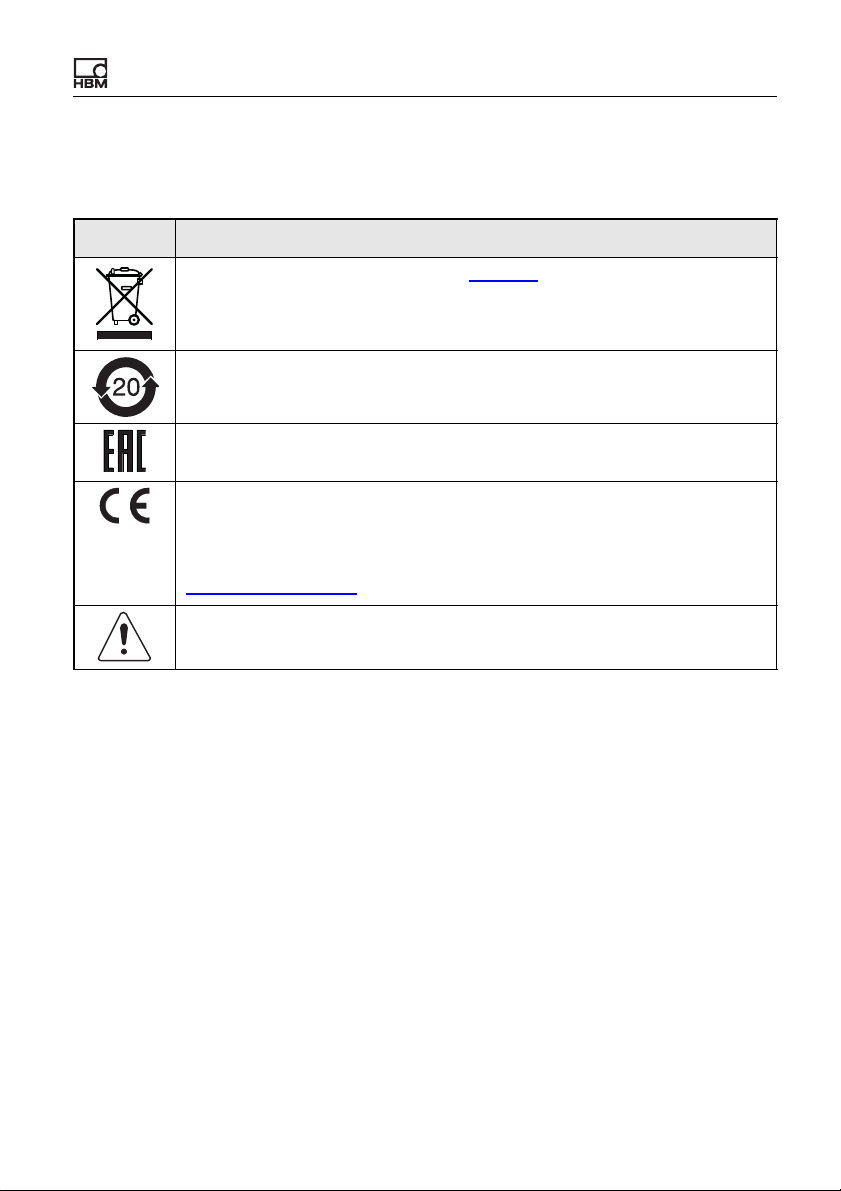

2 Symbols on the instrument

Symbol Meaning

Statutory waste disposal mark, see Disposal.

Statutory mark of compliance with emission limits in electronic equipment

supplied to China

Marking certifying approval for sale of the device in the Russian Federation.

CE mark

The CE mark enables the manufacturer to guarantee that the product

complies with the requirements of the relevant EC directives. The declaration of conformity can be found on the HBM website

https://www.hbm.com under HBMdoc.

Read and note the information given in this manual.

Symbols on the instrument

ClipX

a4643-1.0 HBM: public 9

Page 12

Symbols on the instrument

10

a4643-1.0 HBM: public ClipX

Page 13

Overview

3 Overview

Make sure you always have, and are using, the documentation version

matching your device. After a firmware update, for example, you can download

the current version of the full documentation from the HBM website:

https://www.hbm.com/ClipX

Acrobat Reader. You can download the Acrobat Reader free of charge from the

Adobe website.

About ClipX

By buying a ClipX measuring amplifier, you have chosen a high-quality HBM

measurement system that is compact, powerful and variable. You can connect

the ClipX via the standard Ethernet port to a PC, and parameterize and control

the device via its internal web server. You can connect to an automation system

via the digital and analog inputs/outputs and/or via one of the fieldbus interfaces

PROFIBUS

®

, PROFINET®, EtherNet/IP™1) or EtherCAT2) (depending on

device type). One input per device is provided for different sensors (strain gage,

voltage, current, potentiometer or Pt100), and you can connect sensors with

zero-wire TEDS or 1-wire TEDS. The device additionally features a peak value

memory, instantaneous value memory, limit value switches, and six calculated

channels, as well as offering the facility to display one signal from each of up to

five additional devices and forward the signals to the interfaces. The ClipX is

normally mounted on a support rail; the mounting materials are supplied.

. To read this documentation you need the Adobe

The ClipX documentation

• Quick Start Guide (supplied)

• This manual in PDF format

• Data sheet listing the technical data

• Online help on the device's internal web server

1)

EtherNet/IP™ is a trademark of ODVA Inc. For more information regarding ODVA, visit

www.odva.org.

2)

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff

Automation GmbH, Germany.

ClipX

a4643-1.0 HBM: public 11

Page 14

Overview

Contents of this manual

This manual has a table of contents at the beginning. The index

at the end of the

manual enables you to search for specific terms. The most frequently asked

questions are summarized in the

FAQs section.

All the marks mentioned in this manual are the property of their respective

owners.

Symbols used in this manual

See also

Safety instructions.

Important: This symbol indicates an important detail or a special feature.

Paragraphs with this symbol provide a tip or explain an interesting feature.

Paragraphs marked by this symbol contain additional information.

12

a4643-1.0 HBM: public ClipX

Page 15

ClipX device types, scope of supply

4 ClipX device types, scope of supply

The ClipX is mounted directly on a support rail, though other mounting methods

are also possible. The ClipX is supplied as standard with easy-fit push-in type

plug terminals. You can also use screw-type plug terminals from Phoenix Contact – see Electrical connections, LEDs

You can connect strain gage full or half bridges, voltage-fed piezo-resistive sensors, current or voltage sensors and currents or voltages, potentiometer transducers or Pt100s to the transducer connector. Two freely configurable digital

input/outputs and an analog output for current or voltage are additionally available.

Important: All basic settings are made via the web server integrated

into the ClipX and your web browser. The web server includes its own

help, which explains all the ClipX settings. Depending on the design,

you can also connect the ClipX to various fieldbuses.

4.1 Device types

.

The ClipX comes in three different design versions. All the design versions feature the same sensor inputs, two freely configurable digital input/outputs, and an

analog output switchable for current (4 … 20mA) or voltage (±10V):

1. BM40

This version does not include a fieldbus.

2. BM40PB

This version includes a PROFIBUS

®

interface.

3. BM40IE

You can operate this version with a PROFINET

2)

EtherCAT

1)

EtherNet/IP™ is a trademark of ODVA Inc. For more information regarding ODVA, visit

www.odva.org.

2)

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff

Automation GmbH, Germany.

ClipX

®

interface. The interfaces can be switched using the software.

a4643-1.0 HBM: public 13

®

, EtherNet/IP™1) or

Page 16

ClipX device types, scope of supply

Fig. 1: The ClipX device types from left to right: BM40, BM40PB and BM40IE

To aid the design process, pre-compiled ePLAN macros (licensefree) and 3D-STEP files are available free of charge at

https://www.hbm.com/ClipX.

14

a4643-1.0 HBM: public ClipX

Page 17

ClipX device types, scope of supply

4.2 Scope of supply

• ClipX with mounted support rail holder.

• Bag containing three plug terminals, ordering number 1-CON-S1019 for

sensor connection (13-pin), supply, digital I/O and ClipX bus (12-pin) as well

as the analog output (3-pin). You can also order this plug terminal set separately.

• A Quick Start Guide with safety instructions (a4838).

You can download a full operating manual as well as additional information resources from the HBM website:

https://www.hbm.com/ClipX. Pre-compiled ePLAN macros (license-

free) and 3D-STEP files to aid the design process are also available

to download. To read this documentation you need the Adobe Acrobat Reader. You can download the Acrobat Reader free of charge

from the

Adobe website.

ClipX

a4643-1.0 HBM: public 15

Page 18

ClipX device types, scope of supply

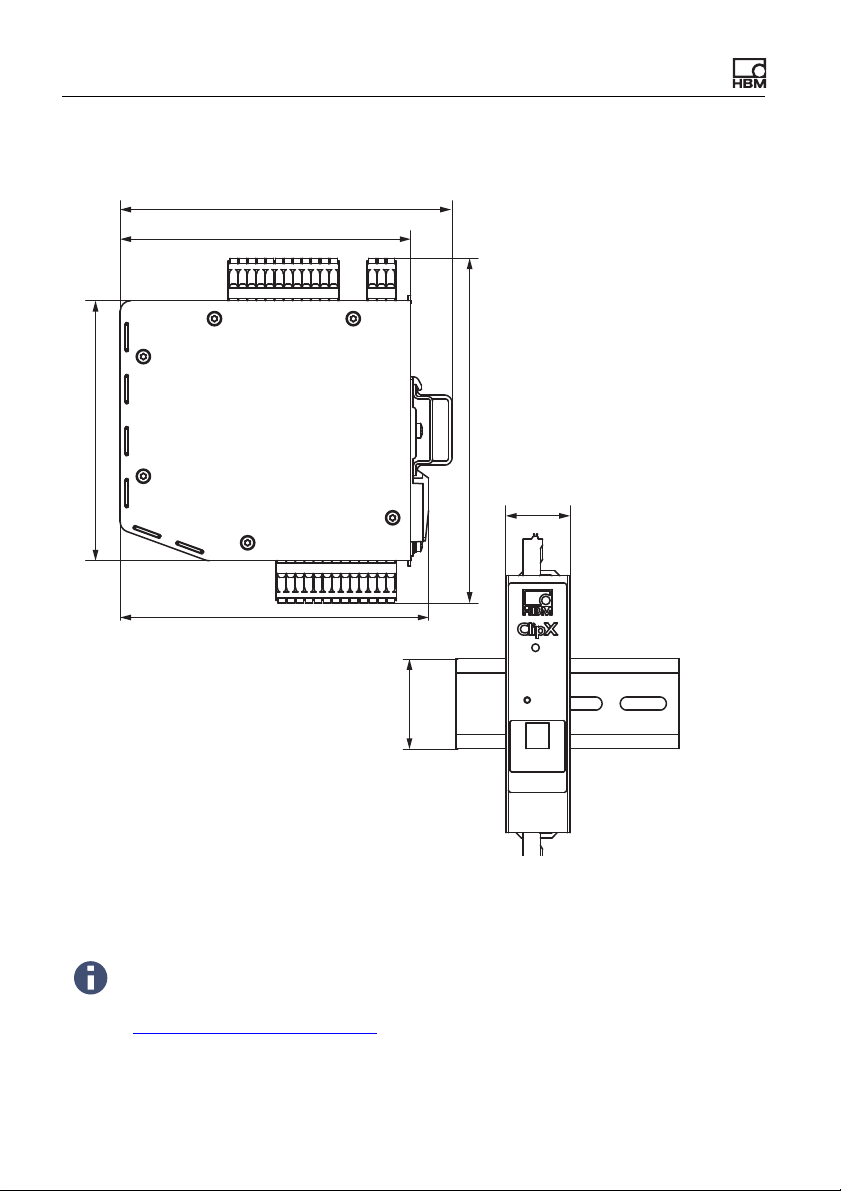

25

35

132.6

111. 7

127.7

118.6

100

4.3 Dimensions

Fig. 2: ClipX dimensions when mounted on support rail (DIN rail 35mm to DIN

EN 60715) with 16mm depth, all measures in mm

To aid the design process, pre-compiled ePLAN macros (licensefree) and 3D-STEP files are available free of charge at

https://www.hbm.com/ClipX.

16

a4643-1.0 HBM: public ClipX

Page 19

Mounting

5 Mounting

The ClipX is designed for mounting on a support rail (35mm DIN rail to DIN

EN 60715). You can choose different mounting methods if you want though. The

support rail on which you mount the ClipX may be 8.5 or 16mm deep.

Important: You must ground the support rail.

5.1 Mounting on a support rail

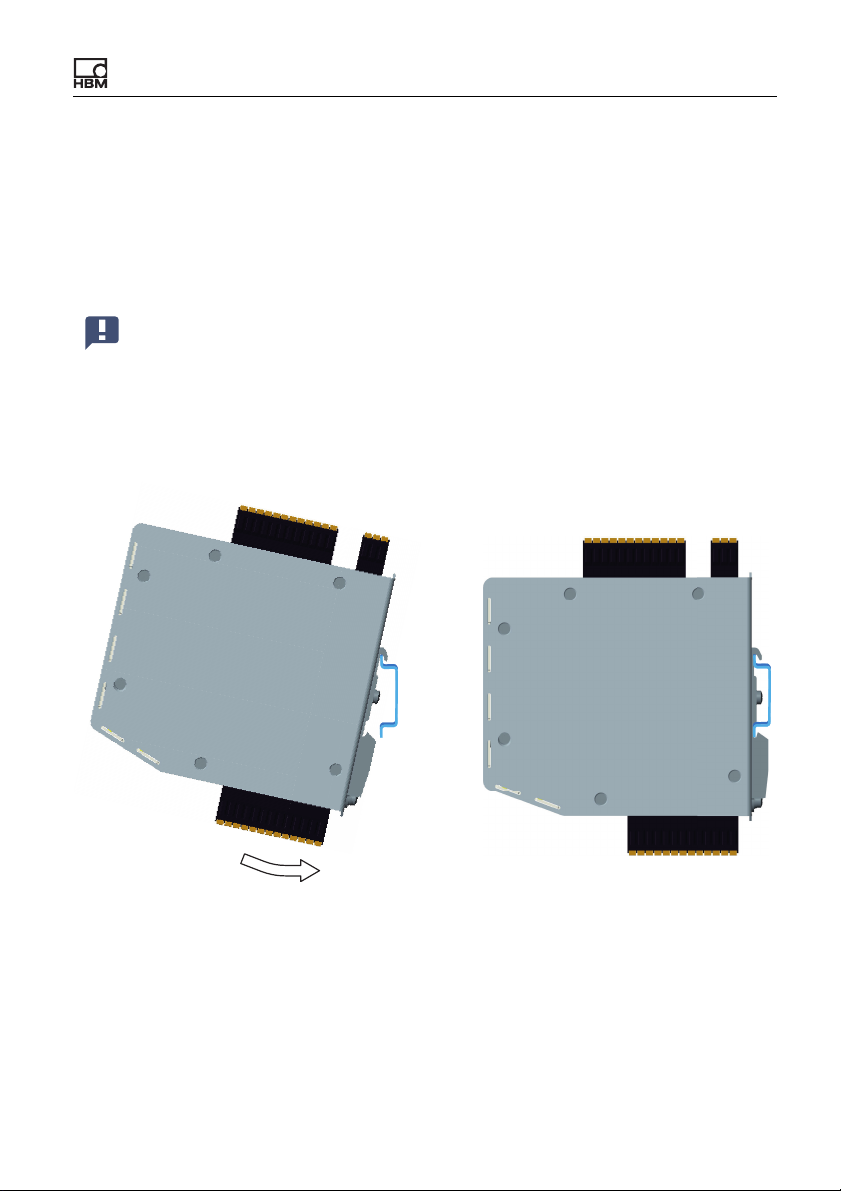

Fig. 3: Mounting on a support rail

1. Hang the ClipX from the top edge of the support rail.

2. Push the ClipX onto the support rail in the direction of the arrow as shown in

the picture.

The clip at the bottom secures the ClipX by a spring.

ClipX

a4643-1.0 HBM: public 17

Page 20

Mounting

1

2

3

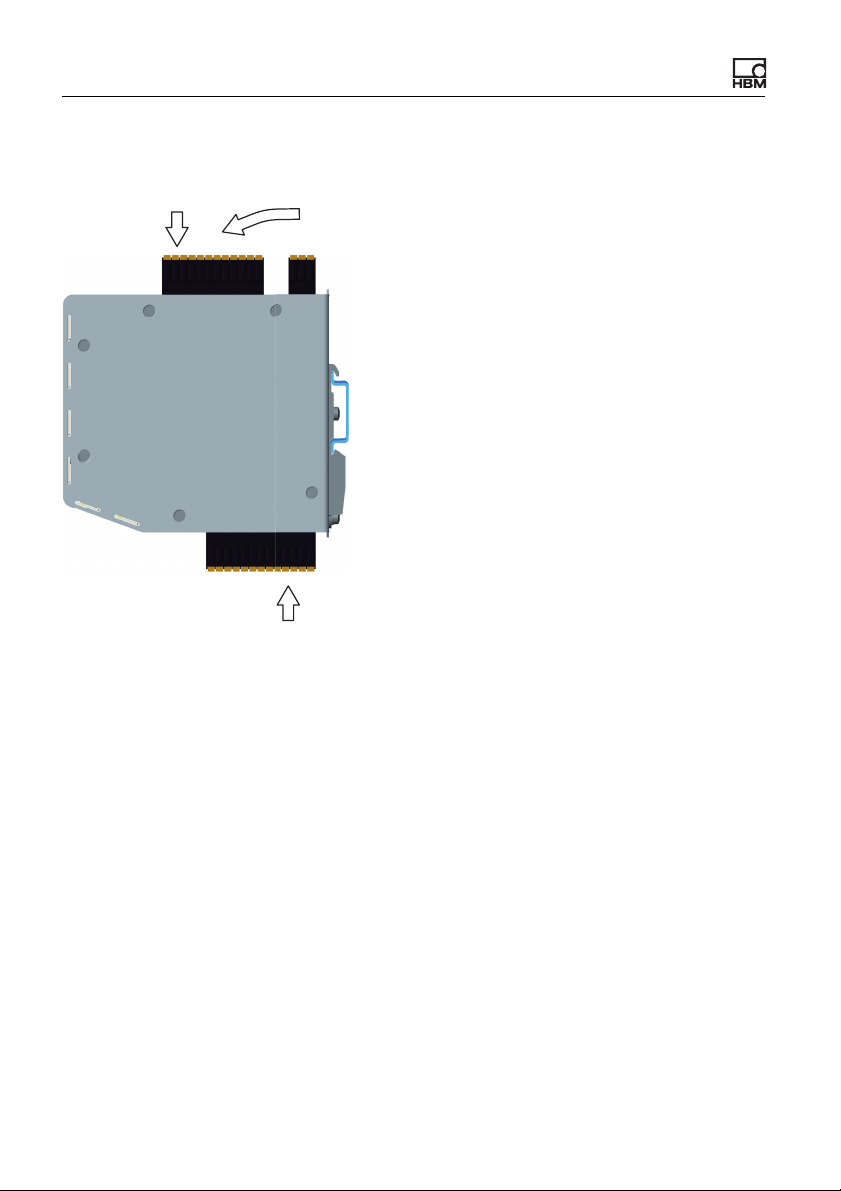

5.2 Dismounting from a support rail

Fig. 4: Dismounting from a support rail

1. Push the ClipX up.

The spring mechanism allows you to release it from the top locator on the

support rail.

2. Tilt the ClipX forward, rotating it as you do so.

3. Detach the ClipX downwards.

18

a4643-1.0 HBM: public ClipX

Page 21

Mounting

5.3 Other mounting options

Instead of using a support rail, you can mount the ClipX on a wall, for example,

using an appropriate bracket. To do so, make a mounting bracket to fit on the

back of the ClipX.

Important: The vents on the back must not be covered over. The minimum clearance between the back of the device and a wall in the area

of the vents is 8mm.

Fig. 5: Screws to remove the support rail mount

ClipX

a4643-1.0 HBM: public 19

Page 22

Mounting

Procedure

1. Use a size T10 Torx screwdriver to remove the screws indicated in the picture.

2. Keep the screws, because you should reuse them.

3. Make your mounting bracket.

The material should be about 1 to 2mm thick, to enable you to reuse the

original (M3) screws. The space between the two screws is 43.7 mm.

4. Fix your mount either using the original screws or using M3 screws penetrating a maximum of 5mm into the housing. Fasten the screws only handtight.

Important: You must ground the ClipX housing, such as by way of the

mount.

20

a4643-1.0 HBM: public ClipX

Page 23

Electrical connections, LEDs

6 Electrical connections, LEDs

The ClipX features IP20 protection in accordance with EN 60529 (protection

against touch by fingers; protection against foreign bodies of Ø > 12mm).

The ClipX is supplied as standard with easy-fit push-in terminals. But you can

also obtain screw-type terminals from Phoenix Contact

(https://www.phoenixcontact.com

– MC 1.5/3-ST-3.5 BK for the analog output,

– MC 1.5/12-ST-3.5 BK for the power supply, digital I/O, ClipX bus and syn-

chronization of the TF amplifiers,

– MC 1.5/13-ST-3.5 BK for connection of sensors.

Other variants, such as with locking clips, are also available from Phoenix Con-

tact, e.g. MCVW 1.5/…, MCVR 1.5/…, FK-MCP 1.5/…

The clamping range of the plug terminals is 0.2mm

(AWG16). If you need to connect multiple wires to one terminal, adapt the wire

cross-sections accordingly. Use 10mm wire end ferrules (without plastic collars)

to connect the wires to the terminals wherever possible.

The plug terminals can be protected against interchanging by the supplied

coding pins. To do so, plug a coding pin into one of the slots in the device

sockets and remove the lug of the corresponding connection on the plug terminal.

) (BK = black variant), e.g.:

2

(AWG24) to 1.5mm2

To aid the design process, pre-compiled ePLAN macros (licensefree) and 3D-STEP files are available free of charge at

https://www.hbm.com/ClipX.

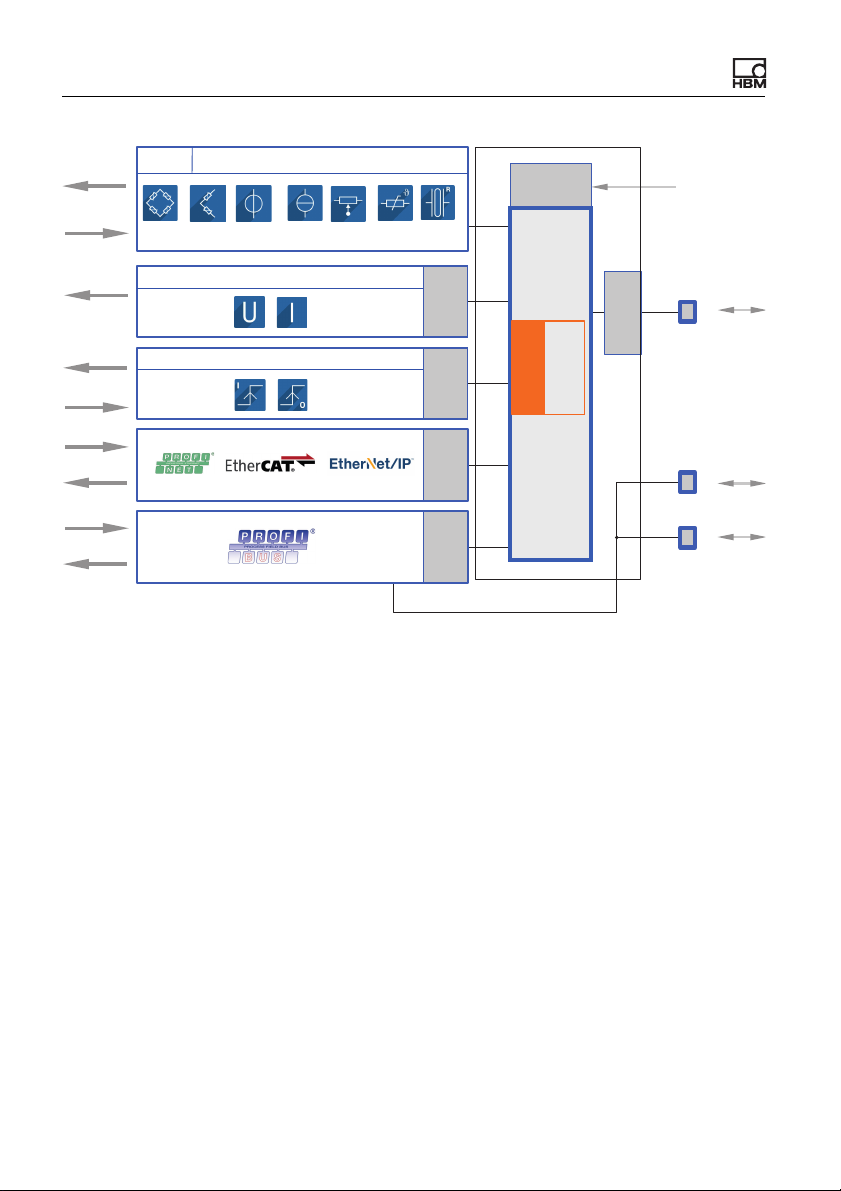

6.1 Functionality (block diagram)

The following diagram presents the functionality and interaction of the various

inputs and outputs of the ClipX. The electrical isolation of the various function

blocks is also shown: there is electrical isolation between the power supply and

all signal inputs and outputs.

ClipX

a4643-1.0 HBM: public 21

Page 24

Electrical connections, LEDs

Galvanic

isolation

TEDS

Transducer

DC / CF

Signal

Signal

Signal

DO 1/2

DO GND

DI 1/2

DI GND

Signal

Bridge

excitation

Galvanic

isolation

Galvanic

isolation

Galvanic

isolation

Analog output

Digital I/Os

FPU

Floating point

unit

Galvanic

isolation

Galvanic

isolation

Ethernet

ClipX SYNC

24 V

0 V

ClipX bus

CPU

Fig. 6: Function blocks and electrical isolation of the ClipX

Electrical isolation of the GND connections

The following connections are electrically isolated from each other:

• DI, GND (Ground) Digital-In: Reference potential for DI1 and DI2.

• X, GND ClipX bus: Reference potential for ClipX bus (CxA, CxB) and Sync;

on the BM40PB PROFIBUS-GND is also connected by this.

• AI, GND Analog-In: Reference potential for U-In and I-In; the adjacent measurement inputs for voltage and current.

• S GND for the inner shield on double-shielded cable; with 1-wire TEDS,

TEDS (–) is also connected here.

• AO, GND Analog-Out: Reference potential for the analog output.

22

a4643-1.0 HBM: public ClipX

Page 25

Electrical connections, LEDs

S

S

S

6.2 Shielding and grounding design

The supply voltage connection, as well as the signal and sense leads, must be

installed in such a way that electromagnetic interference does not adversely

affect module functionality (HBM recommendation: “Greenline shielding design”

– see http://www.hbm.com/Greenline

shortest possible length to the plug terminals and, as far as possible, lay the

shield flat at the control cabinet inlet with shield connection terminal blocks, e.g.

type SKS 8-SNS35 – 3062786 from Phoenix Contact – see illustration.

Fig. 7: Shield connection terminal block for flat contacting of cable shields (ex-

ample)

Double-shielded connecting cables, e.g. for sensors

We recommend using HBM cable Kab 7.5/00-2/2/2 wherever possible. The

cable is double-shielded and low in capacitance. When using double-shielded

cables, connect the outer shield only to the connection for the housing (ground

). Always connect the cable shield by the

symbol , labeled “Outer cable shield” in the connection diagrams), not to one

of the GND connections ( ). In the case of control cabinets, also lay this shield

contacting on the cabinet – see illustration of shield clamp. Connect the inner

shields of the sensor cables to the connection labeled “Inner cable shield” ( ).

Use the shortest lines possible for the connections.

Applications in areas with potentially explosive atmospheres are exceptions.

There connect all cable shields to the potential equalization connection.

Single-shielded cables

Connect the shields of single-shielded cables to the connection for the housing

(ground symbol , labeled “Outer cable shield” or “Cable shield” in the connection diagrams), not to one of the GND connections ( ). In the case of control

cabinets, also lay this shield contacting on the cabinet – see illustration of shield

clamp.

ClipX

a4643-1.0 HBM: public 23

Page 26

Electrical connections, LEDs

Grounding

Important: You must ground the support rail on which you mount the

ClipX. If you want to mount the ClipX in a different way, such as on a

wall, you must ground the housing by way of the mount.

6.3 Available connections and LEDs

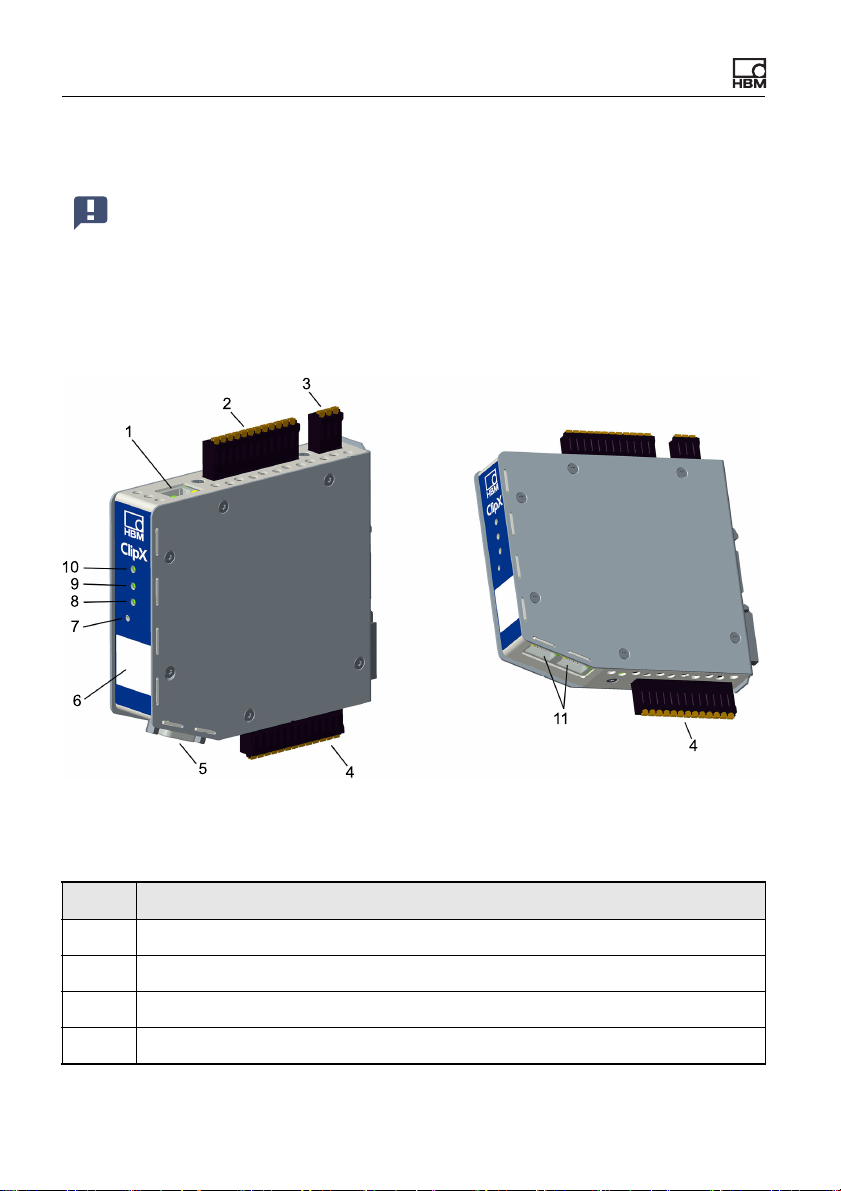

Fig. 8: Locations of the connections and LEDs; the connector designations X1

to X7 are imprinted on the housing; for meanings see table.

No. Description

1 X1: Ethernet port

2 X2: Power supply, Digital I/O, ClipX bus

3 X3: Analog output

4 X4: Transducer connection, TEDS

24

a4643-1.0 HBM: public ClipX

Page 27

Electrical connections, LEDs

No. Description

5 X5: Fieldbus, here PROFIBUS (only BM40PB)

6 HBM calibration label and free labeling space

7 Reset button

Fieldbus LED 1, only BM40IE; EtherCAT: ERR, PROFINET: BF, Ether-

8

Net/IP™: NS

Fieldbus LED 2, only BM40IE and BM40PB; EtherCAT: RUN, PROFINET:

9

SF, EtherNet/IP™: MS; PROFIBUS: BUS

10 System LED

X6, X7: 2 x RJ45; P1/IN (X7) and P2/OUT (X6) for EtherNet/IP™ or PROF-

11

INET or EtherCAT (only BM40IE)

See also Electrical connections, LEDs for plug terminals with screw connections.

Electrical isolation of the GND connections

The following connections are electrically isolated from each other:

• DI, GND (Ground) Digital-In: Reference potential for DI1 and DI2.

• X, GND ClipX bus: Reference potential for ClipX bus (CxA, CxB) and Sync;

on the BM40PB PROFIBUS-GND is also connected by this.

• AI, GND Analog-In: Reference potential for U-In and I-In; the adjacent measurement inputs for voltage and current.

• S GND for the inner shield on double-shielded cable; with 1-wire TEDS,

TEDS (–) is also connected here.

• AO, GND Analog-Out: Reference potential for the analog output.

ClipX

a4643-1.0 HBM: public 25

Page 28

Electrical connections, LEDs

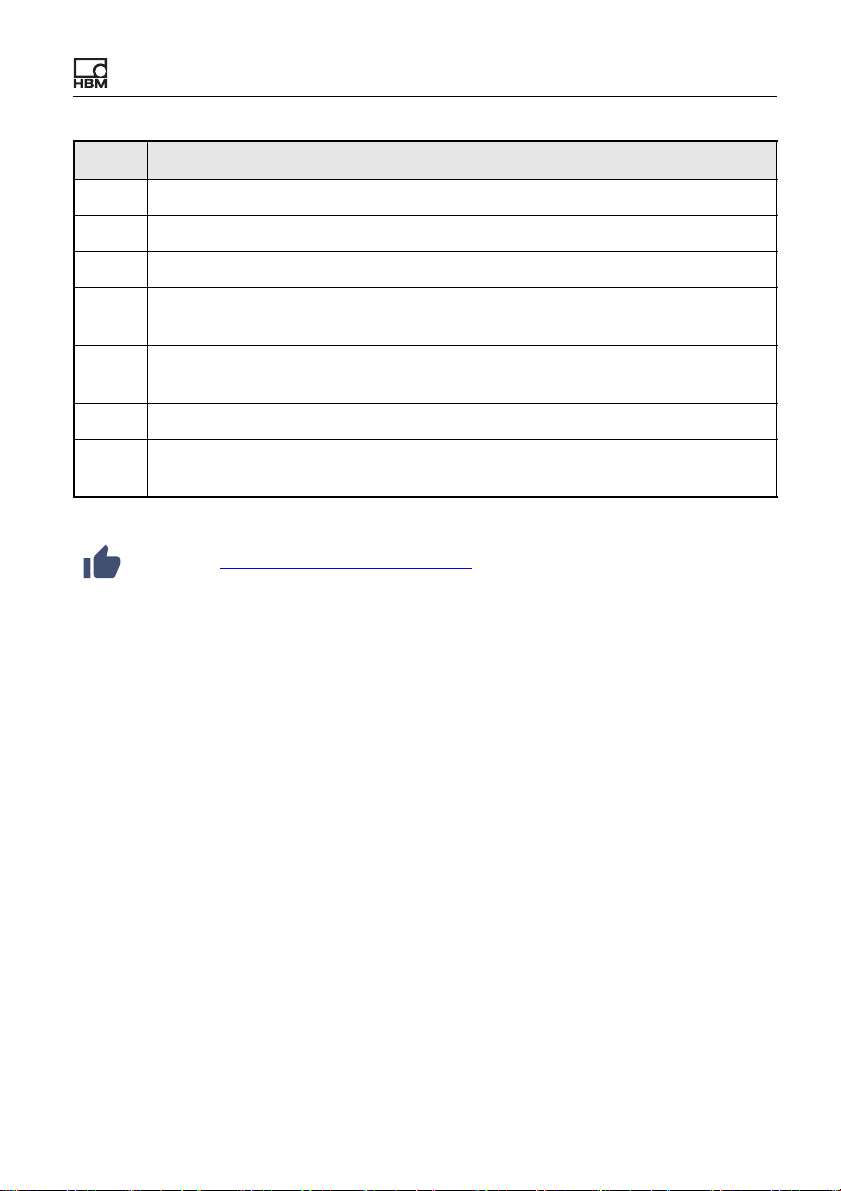

6.4 Health monitoring, LEDs

There are 1 to 3 LEDs on the front, depending on the device type. On the

BM40IE the LEDs have different meanings, indicated by differing labels,

depending on the fieldbus.

Fig. 9: Assignment of the LEDs to the interfaces on the BM40IE and BM40PB.

The BM40 only has the system LED.

The following tables list the states indicated by the LEDs. The LEDs flash about

once a second in flash mode, and about five times a second in rapid-flash

mode.

26

a4643-1.0 HBM: public ClipX

Page 29

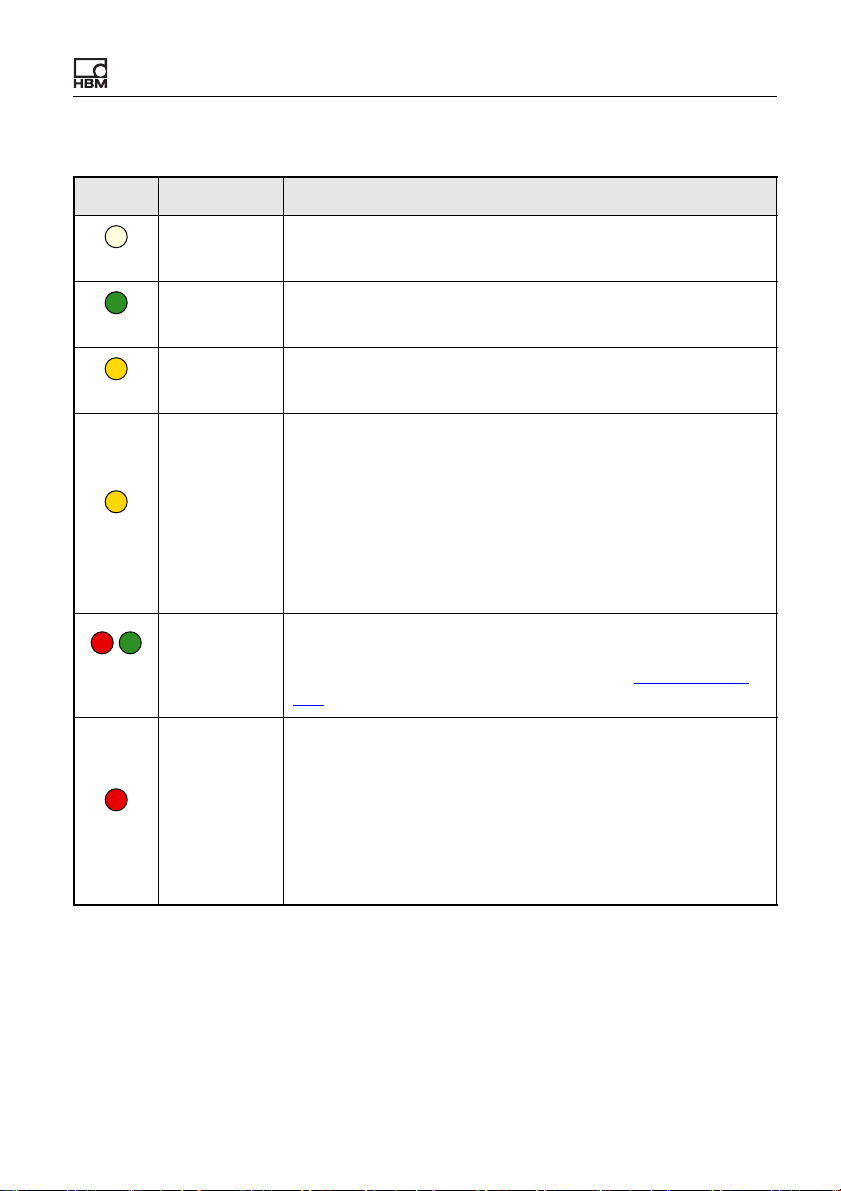

System LED (SYS)

LED Status Meaning

Off No supply voltage, or ClipX defective.

Off

On The ClipX has fully booted up, and is ready.

Green

Flashing Manual device detection (via the browser) has been started.

Yell ow

Error on ClipX bus:

– One or more of the expected devices is not transmitting,

– Errors in data transfer

If an invalid external measurement value is correctly trans-

mitted, it does NOT result in a yellow or red system LED. It

causes an invalid status of the external measurement value

in question (one bit per value).

Yell ow

On

Electrical connections, LEDs

or not responding

Red/

green

Red

ClipX

/

Flashing

Flashing rap-

idly

The ClipX is not ready.

None of the meanings listed above applies. If this state lasts

longer than a few seconds, please contact Technical sup-

port at HBM.

The self-test has failed. This may be due to the following

causes:

– Error in the internal file system

– Error in the A/D converter

– IRQ or DMA error

– Error in the D/A converter

– TEDS error: No communication possible

a4643-1.0 HBM: public 27

Page 30

Electrical connections, LEDs

LED Status Meaning

The ClipX is booting up (initializing everything)

or

The parameter set is being changed

or

One or more of the following measured values is invalid:

– Raw value of A/D converter

– Filtered value of A/D converter

– Fieldbus value

– Process value, gross

– Process value, net

– Analog output (e.g. overflow)

Red

On

28

a4643-1.0 HBM: public ClipX

Page 31

EtherCAT LEDs (RUN, ERR, only BM40IE)

Electrical connections, LEDs

RUN

LED

Off

Green

ERR

LED

Off

Red

Status Meaning

Off The ClipX is in the INIT state.

Flashing at

2.5Hz

Single flash The ClipX is in the SAFE-OPERATIONAL state.

On The ClipX is in the OPERATIONAL state.

The ClipX is in the PRE-OPERATIONAL state.

Status Meaning

Off No error.

The EtherCAT communication is running and error-free.

Flashing

(2.5Hz)

Single flash Local error: The ClipX has autonomously changed the

Invalid configuration.

Possible cause: A change specified by the master is not

possible.

EtherCAT status.

Possible causes:

– A host watchdog timeout has occurred,

– synchronization error. In this case the device switches

automatically to the SAFE-OPERATIONAL state.

ClipX

Double flash A process data watchdog timeout has occurred.

Possible cause: A synchronization timeout (Sync Manager

watchdog).

a4643-1.0 HBM: public 29

Page 32

Electrical connections, LEDs

PROFINET LEDs (SF, BF, only BM40IE)

SF

LED

Off

Red

BF

LED

Off

Red

Status Meaning (system error LED)

Off No error.

Flashing

(1Hz, 3 sec-

onds)

On Watchdog timeout.

A DCP signal service is triggered over the bus.

There is a system error, or a channel, generic or extended

diagnosis.

Status Meaning (bus error LED)

Off No error.

Flashing

(2Hz)

On Error: No configuration, slow physical connection or no con-

No data exchange.

nection.

30

a4643-1.0 HBM: public ClipX

Page 33

EtherNet/IP™ LEDs (MS, NS, only BM40IE)

Electrical connections, LEDs

MS

LED

Off

Green

/

Red/

green

Red

NS

LED

Off

Status Meaning

Off The ClipX is not on.

Flashing

(1Hz)

On The ClipX is running and error-free.

Flashing

(1Hz)

Flashing

(1Hz)

On Serious error: There is an irreparable error. Please contact

Standby: The ClipX has not been configured.

The ClipX is running a self-test.

Simple error: The ClipX has detected a reparable error, e.g.

an incorrect configuration.

Technical support at HBM.

Status Meaning

Off The ClipX is not on, or has no IP address.

Green

Red/

green

ClipX

Flashing

(1Hz)

On The ClipX is connected to a network device, e.g. a switch.

/

Flashing

(1Hz)

No network connection. But the ClipX has been assigned

an IP address.

The ClipX is running a self-test.

a4643-1.0 HBM: public 31

Page 34

Electrical connections, LEDs

NS

LED

Red

Status Meaning

Flashing

(1Hz)

On Duplicate IP address.

Connection timeout.

One or more connections to this ClipX are in timeout. This

status will only be terminated when all connections have

been restored or you reset the ClipX.

The ClipX has detected that the IP address assigned to it

(and set) is already being used in the network.

PROFIBUS LED (BUS, only BM40PB)

LED

BUS

Off

Green

Status Meaning

Off The ClipX is not on, or the network has no power.

Flashing

cyclically

(2Hz)

On The ClipX is in the RUN state; cyclic communication is run-

The master is in the CLEAR state.

ning.

32

Red

Flashing

briefly (1Hz)

Flashing

cyclically

(2Hz)

On Incorrect PROFIBUS-DP configuration.

The ClipX is not configured.

The ClipX is in the STOP state.

No communication; a connection error has possibly

occurred.

a4643-1.0 HBM: public ClipX

Page 35

Electrical connections, LEDs

Note

Plug terminal X2, supply, DIO, Sync, ClipX bus

X

Housing

ClipX bus

ClipX bus GND

ClipX bus

Synchronization

Sync

Digital In GND

Digital In 2

DI2

DI1

DI

DO2

DO1

Digital In 1

Digital Out 2

Digital Out 1

Supply 0 V

0V

24V

Supply 10 … 30 V

CxA

CxB

6.5 Connecting the supply voltage

Connect the supply voltage from 10 to 30VDC to terminal X2 (top).

See also Available connections and LEDs

.

Voltages above 30V

can destroy the ClipX.

DC

Make sure that the supply voltage is between 10 and 30V

Fig. 10: Supply voltage at plug terminal X2

DC

.

For each ClipX you must provide a power output of 5W plus the power required

for analog and digital outputs. Use an appropriately dimensioned cable for the

supply voltage, so as to avoid an excessive voltage drop when operating multiple devices. We recommend using wire end ferrules and a cable cross-section

of 1.5mm

ClipX

2

(AWG16).

a4643-1.0 HBM: public 33

Page 36

Electrical connections, LEDs

6.6 Connecting transducers

Important: Refer to the information on the connection clamps (Avail-

able connections and LEDs) and cable shielding (Shielding and

grounding design).

The signals of the connected sensor or signal are digitized by the ClipX at

19.2kHz. You can view various signal processing data values in your browser:

• the field value, i.e. the input signal,

• the ADC value, i.e. the signal of the A/D converter in digits,

• the filtered ADC value, i.e. the signal of the A/D converter based on your

selected filter, also in digits,

• the gross signal, i.e. the signal after zero balancing and scaling,

• the net signal, i.e. the signal after taring.

The taring level is located in the signal path after the gross signal. Normally the

taring function is only required for weighing applications, such as to record the

content and total weight of a container.

6.6.1 Strain gage full and half bridge, voltage-fed piezo-resistive sensors

The use of TEDS is not yet supported by the current firmware version.

It will be in one of the future versions however.

When connecting transducers in a 6-wire configuration, you can also use zerowire TEDS instead of the 1-wire TEDS connection. In this case the TEDS

module is looped into the sense lines.

See also Available connections and LEDs

34

a4643-1.0 HBM: public ClipX

, Shielding and grounding design.

Page 37

Electrical connections, LEDs

3

2

14

rd

wh

gy

bk

gn

bu

Pt100

TEDS

Pt100

Cable wire colors (HBM transducer):

Plug terminal X4, transducer connection

bu = blue; gn = green; gr = gray;

rd = red; bk = black; wh = white;

1

2'

3

3'

2

I

U

AI

S

4

Measurement signal +

Sense lead -

Bridge excitation voltage +

Sense lead +

Bridge excitation voltage -

Outer cable shield

Inner cable shield

Measurement signal -

1-Wire-TEDS

1

2

Strain gage full bridge, voltage-fed piezo-resistive sensors in 6-wire configuration (1-wire TEDS)

Fig. 11: Plug terminal X4, 6-wire pin assignment, TEDS optional

ClipX

a4643-1.0 HBM: public 35

Page 38

Electrical connections, LEDs

Pt100

TEDS

Pt100

Cable wire colors (HBM transducer):

Plug terminal X4, transducer connection

bu = blue; gn = green; gr = gray;

rd = red; bk = black; wh = white;

1

2'

3

3'

2

I

U

AI

S

4

Measurement signal +

Sense lead -

Bridge excitation voltage +

Sense lead +

Bridge excitation voltage -

Outer cable shield

Inner cable shield

Measurement signal -

Zero-Wire-TEDS

3

2

14

rd

wh

gy

bk

gn

bu

TEDS

Strain gage full bridge, voltage-fed piezo-resistive sensors in 6-wire configuration (zero-wire TEDS)

Fig. 12: Plug terminal X4, 6-wire pin assignment, TEDS optional

36

a4643-1.0 HBM: public ClipX

Page 39

Electrical connections, LEDs

3

2

1

wh

gy

bk

gn

bu

Pt100

TEDS

Pt100

1

2'

3

3'

2

Measurement signal +

Sense lead -

Bridge excitation voltage +

Sense lead +

Bridge excitation voltage -

I

U

AI

S

Outer cable shield

Cable wire colors (HBM transducer):

bu = blue; gn = green; gr = gray;

rd = red; bk = black; wh = white;

Plug terminal X4, transducer connection

Inner cable shield

4 Measurement signal -

1-Wire-TEDS

1

2

Strain gage half bridge in 6-wire configuration (1-wire TEDS)

Fig. 13: Plug terminal X4, 6-wire pin assignment, TEDS optional

ClipX

a4643-1.0 HBM: public 37

Page 40

Electrical connections, LEDs

Pt100

TEDS

Pt100

1

2'

3

3'

2

Measurement signal +

Sense lead -

Bridge excitation voltage +

Fühlerleitung +

Bridge excitation voltage -

I

U

AI

S

Outer cable shield

Cable wire colors (HBM transducer):

bu = blue; gn = green; gr = gray;

bk = black; wh = white;

Plug terminal X4, transducer connection

Inner cable shield

4 Measurement signal -

Zero-Wire-TEDS

3

2

1

wh

gy

bk

gn

bu

TEDS

Strain gage half bridge in 6-wire configuration (zero-wire TEDS)

Fig. 14: Plug terminal X4, 6-wire pin assignment, TEDS optional

38

a4643-1.0 HBM: public ClipX

Page 41

Electrical connections, LEDs

3

2

14

rd

wh

bk

bu

Pt100

TEDS

Cable wire colors (HBM transducer):

bu = blue; gn = green; gr = gray;

rd = red; bk = black; wh = white;

Plug terminal X4, transducer connection

Feedback bridges for 4-wire circuitry

1

2'

3

3'

2

I

U

AI

S

4

Measurement signal +

Sense lead -

Bridge excitation voltage +

Sense lead +

Bridge excitation voltage -

Cable shield

Measurement signal -

1-Wire-TEDS

1

2

Strain gage full or half bridge in 4-wire configuration

When connecting in a 4-wire configuration, you can only use 1-wire TEDS (as

shown in the diagram).

Important: When connecting in a 4-wire configuration, you must connect the inputs of the sense lines via jumpers to the supply voltage

outputs, otherwise the measurement value will always be invalid.

Fig. 15: Plug terminal X4, 4-wire pin assignment; pin 4 is not used for half bridge

circuits, TEDS optional

ClipX

a4643-1.0 HBM: public 39

Page 42

Electrical connections, LEDs

Pt100

TEDS

Pt100

Plug terminal X4, transducer connection

HBM cable KAB7.5/00-2/2/2

Cable wire colors:

bu = blue; gn = green; gr = gray;

rd = red; bk = black; wh = white;

1

2'

3

3'

2

I

U

AI

4

Measurement signal +

Sense lead -

Bridge excitation voltage +

Sense lead +

Bridge excitation voltage -

Cable shields

Measurement signal -

Potential equalization

Explosion hazard

area

Safe

area

3

2

14

rd

wh

gy

bk

gn

bu

S

851

4

Z961H

851

4

Z961

851

4

Z961H

6.6.2 Strain gage full bridge for applications in areas with potentially

explosive atmospheres

It is not possible to use transducers with TEDS when using Zener barriers.

Use cable KAB 7.5/00-2/2/2 and safety barriers 1-SD01A from HBM to connect

transducers in areas with potentially explosive atmospheres to the ClipX. The

connection resistance of the sensor (or of multiple parallel configured sensors)

must be between 80 and 350Ohms.

See also Available connections and LEDs

.

Strain gage full bridge in 6-wire configuration

Fig. 16: Plug terminal X4, 6-wire pin assignment

40

Important: Observe the permissible cable lengths depending on the

excitation voltage and transducer resistance, the safety instructions

for the Zener barrier SD01A, and the rules for operating plant in areas

with potentially explosive atmospheres.

a4643-1.0 HBM: public ClipX

Page 43

6.6.3 Potentiometric transducer

3

2

1wh

gy

bk

gn

bu

Pt100

TEDS

Pt100

Plug terminal X4, transducer connection

1

2'

3

3'

2

I

U

AI

S

4

Measurement signal +

Sense lead -

Bridge excitation voltage +

Sense lead +

Bridge excitation voltage -

Outer cable shield

Inner cable shield

Measurement signal -

1-Wire-TEDS

1

2

The use of TEDS is not yet supported by the current firmware version.

It will be in one of the future versions however.

Electrical connections, LEDs

See also Available connections and LEDs

Fig. 17: Plug terminal X4, pin assignment for potentiometric transducer

Important: Connect the sense leads to the corresponding excitation

voltage leads by wire bridges (2 at 2' and 3 at 3') if you are not using

a 6-wire configuration (with 5 wires assigned). Otherwise a sensor error will be signaled, and you will not be able to measure (invalid mea-

, Shielding and grounding design.

sured value).

ClipX

a4643-1.0 HBM: public 41

Page 44

Electrical connections, LEDs

1 4, 3'

ϑ

1-Wire-TEDS

Pt100

TEDS

Pt100

1

2

Plug terminal X4, transducer connection

1

2'

3

3'

2

I

U

AI

S

4

Measurement signal +

Sense lead -

Bridge excitation voltage +

Sense lead +

Bridge excitation voltage -

Cable shield

GND

Measurement signal -

6.6.4 Temperature measurement by Pt100

The use of TEDS is not yet supported by the current firmware version.

It will be in one of the future versions however.

With the ClipX, temperatures can be measured in degrees Celsius, Kelvin or

Fahrenheit using a Pt100 resistor. The cable resistance is adjusted by way of

the sense line.

See also Available connections and LEDs

.

Fig. 18: Plug terminal X4, pin assignment for Pt100

42

a4643-1.0 HBM: public ClipX

Page 45

6.6.5 Voltage source (±10V)

U

1-Wire-TEDS

Pt100

TEDS

Pt100

1

2

Plug terminal X4, transducer connection

1

2'

3

3'

2

I

U

AI

S

4

Measurement signal +

Sense lead -

Bridge excitation voltage +

Sense lead +

Bridge excitation voltage -

Cable shield

Analog GND

Voltage input

Current input

Measurement signal -

GND

The use of TEDS is not yet supported by the current firmware version.

It will be in one of the future versions however.

Electrical connections, LEDs

See also Available connections and LEDs

Fig. 19: Plug terminal X4, pin assignment for electrical voltage source

.

ClipX

a4643-1.0 HBM: public 43

Page 46

Electrical connections, LEDs

I

Plug terminal X4, transducer connection

1-Wire-TEDS

TEDS

Pt100

1

2

1

2'

3

3'

2

I

U

AI

S

4

Measurement signal +

Sense lead -

Bridge excitation voltage +

Sense lead +

Bridge excitation voltage -

Cable shield

Analog GND

Voltage input

Current input

Measurement signal -

GND

6.6.6 Current source (±20mA or 4 … 20mA)

The use of TEDS is not yet supported by the current firmware version.

It will be in one of the future versions however.

See also Available connections and LEDs

Fig. 20: Plug terminal X4, pin assignment for current source

.

44

a4643-1.0 HBM: public ClipX

Page 47

6.6.7 Current drain (4 … 20mA)

Digital In 2

DI2

DI1

DO2

DO1

Digital In 1

Digital Out 2

Digital Out 1

Supply 0 V

0V

24V

Supply 10 … 30 V

AI

Plug terminal X4, transducer connection

Plug terminal X2

1-Wire-TEDS

TEDS

Pt100

1

2

1

2'

3

3'

2

S

4

Measurement signal +

Sense lead -

Bridge excitation voltage +

Sense lead +

Bridge excitation voltage -

Cable shield

Measurement signal -

I

U

Analog GND

Current input

Voltage input

GND

Sensor

The use of TEDS is not yet supported by the current firmware version.

It will be in one of the future versions however.

Electrical connections, LEDs

See also Available connections and LEDs

Fig. 21: Plug terminals X2 and X4, pin assignment for current drain

.

ClipX

a4643-1.0 HBM: public 45

Page 48

Electrical connections, LEDs

DI2

DI1

DI

DO2

DO1

0V

24V

X

Plug terminal X2, supply, DIO, Sync, ClipX bus

Housing, cable shield optional

ClipX bus

ClipX bus GND

ClipX bus

Sync Synchronization

Digital In GND

Digital In 2

Digital In 1

Digital Out 2

Digital Out 1

Supply 0 V and Digital Out GND

Supply 10 … 30 V

CxA

CxB

LOW: 0 V … 5 V

HIGH: 10 V … 30 V

6.7 Connecting the digital inputs and outputs

The digital inputs and the flags or bits for the outputs are analyzed after 1ms at

the latest in the event of a change.

See also Available connections and LEDs

Digital inputs

.

Fig. 22: Plug terminal X2, pin assignment of digital inputs

The digital inputs must be switched against a positive voltage (≥10V). An open

input will be detected as LOW.

46

a4643-1.0 HBM: public ClipX

Page 49

Digital outputs

DI2

DI1

DO2

DO1

0V

24V

X

DI

Plug terminal X2, supply, DIO, Sync, ClipX bus

Housing, cable shield optional

ClipX bus

ClipX bus GND

ClipX bus

Synchronization

Digital In GND

Digital In 2

Digital In 1

Digital Out 2

Digital Out 1

Supply 0 V and Digital Out GND

Supply 10 … 30 V

CxA

Sync

CxB

Electrical connections, LEDs

Fig. 23: Plug terminal X2, pin assignment of digital outputs

Start-up behavior of the digital outputs

On starting up the ClipX (power on), each output initially has a high output resistance. After initializing, the status of the settings is determined in the Start

parameter set. When an output is active, the supply voltage (10 … 30V) is

switched through to it.

The factory default setting is: Output deactivated.

ClipX

a4643-1.0 HBM: public 47

Page 50

Electrical connections, LEDs

AO

AO

analog output

Analog-Out ‒

Cable shield

Analog-Out +

6.8 Connecting the analog output

You can output voltage (±10V) or current (4 … 20mA). The analog output is

short-circuit-proof, the bandwidth is 3.8kHz, the update rate is 19.2kHz.

See also Available connections and LEDs

Fig. 24: Plug terminal X2, pin assignment for analog output

Start-up behavior

On starting up the ClipX (power on), the analog output initially has a high output

resistance. After initializing, the status of the settings is determined by the Boot

parameter set.

The factory default setting is: Output deactivated, gross signal as input (source),

zero value 0V, scaling 0/0 and 5/5, value in case of “invalid” signal 0 V and test

signal 0V (both inactive).

.

Value in case of error

Which value is outputted depends on whether you activate the value in case of

an “invalid” signal or not. Make the setting via the ClipX web server in your

browser.

1. Value in case of “invalid” signal active (switch in browser on the right and

red)

If the input signal becomes invalid, or the output signal would be outside the

range of ±11V or less than 3mA or greater than 21mA, the specified value is

outputted.

2. Value in case of “invalid” signal not active (switch in browser on the left and

gray)

The highest or lowest possible value is outputted depending on the signal

(±11V, or 3mA or 21mA).

48

a4643-1.0 HBM: public ClipX

Page 51

Electrical connections, LEDs

SYS

SF MS

BF NS

RUN

ERR

BM40IE

OUT

IN

P2

P1

max. 30 cm

PROFIBUS

SYS

40

PB

BUS

BM

SYS

40

BM

SYS

40

BM

6.9 Using multiple ClipX devices, ClipX bus

You can transfer one measured value with status from each of up to six other

ClipX devices over the ClipX bus to a ClipX and then capture them simultaneously with the values of that device. The connections use line topology. The

maximum cable length between two devices is 30cm.

Interconnect the CxA terminals and CxB terminals respectively of up to six

devices. Lay the lines from the first device to the second, from the second to the

third device, etc. (line topology). The ClipX bus GND connection is additionally

required. The CxA and CxB lines must be twisted and shielded.

See also Available connections and LEDs

amplifiers.

, Synchronizing multiple ClipX CF

Fig. 25: Transferring a measured value from multiple ClipX devices

The ClipX bus synchronizes automatically. All you have to do is enter the

highest address (Highest Address) (number of devices) and the Own Address

a4643-1.0 HBM: public 49

ClipX

Page 52

Electrical connections, LEDs

Housing, cable shields

ClipX bus

ClipX bus GND

ClipX bus

Synchronization

Sync

Sync

Digital In GND

Digital In 2

DI2

DI1

DI

DO2

DO1

Digital In 1

Digital Out 2

Digital Out 1

Supply 0 V

0V

24V

Supply 10 … 30 V

CxA

CxB

CxA

CxB

X

X

DI2

DI1

DI

DO2

DO1

0V

24V

Plug terminal X2, supply, DIO, Sync, ClipX bus

(location where the own device is to appear) in your browser (ClipX Bus menu).

Address 1 serves as the bus master; all the other addresses are slaves. Specify

which signal to transmit for each device. The status (valid/invalid) is transmitted

along with the measurement signal. 1000 values per second are transmitted per

device (including CRC check).

If you set Own Address for a device to 0, the ClipX bus will be deactivated for that device, meaning no other devices are visible, and no

own signal can be transmitted.

Fig. 26: Plug terminal X2, pin assignment for ClipX bus

50

Important: Termination resistors are not necessary, and must not be

used. The maximum line length between two devices is 30cm.

a4643-1.0 HBM: public ClipX

Page 53

Electrical connections, LEDs

SYS

SF MS

BF NS

RUN

ERR

BM40IE

OUT

IN

P2

P1

max. 30 cm

PROFIBUS

SYS

40

PB

BUS

BM

SYS

40

BM

SYS

40

BM

6.10 Synchronizing multiple ClipX CF amplifiers

You should synchronize multiple ClipX devices that supply sensors with carrier

frequency (CF) so that the carrier frequency measuring amplifiers do not interfere with each other. This will prevent crosstalk between adjacent sensor

cables, resulting in disturbance to measurements. If you are using only sensors

with direct voltage (DC) amplifiers, no synchronization is necessary.

To synchronize, interconnect the Sync terminals of the devices and the ClipX

bus GND terminals, unless you have already connected the latter to transmit

measured values. Lay the lines from the first device to the second, from the

second to the third device, etc. (line topology). The cable must have twisted-pair

wires, and be shielded. The ClipX bus GND and Sync lines must be twisted and

shielded.

See also Available connections and LEDs

bus.

, Using multiple ClipX devices, ClipX

Fig. 27: Synchronizing multiple ClipX devices

a4643-1.0 HBM: public 51

ClipX

Page 54

Electrical connections, LEDs

Housing, cable shields

ClipX bus

ClipX bus GND

ClipX bus

Synchronization

Sync

Sync

Digital In GND

Digital In 2

DI2

DI1

DI

DO2

DO1

Digital In 1

Digital Out 2

Digital Out 1

Supply 0 V

0V

24V

Sipply 10 … 30 V

CxA

CxB

CxA

CxB

X

X

DI2

DI1

DI

DO2

DO1

0V

24V

Plug terminal X2, supply, DIO, Sync, ClipX bus

Important: On the first device you must enable Sync Mode Master

[Master sync mode]. All the others operate as slaves, so the switch

must not be active. Make the setting in your browser using the Am-

plifier and Sensor Type menu items. Synchronization is only possible for sensor types with carrier frequency (CF), not for DC. No

synchronization of the time base or the A/D converters takes place.

Fig. 28: Plug terminal X2, pin assignment for Sync signal

a4643-1.0 HBM: public ClipX

Important: Termination resistors are not necessary, and must not be

used. The maximum line length between two devices is 30cm.

52

Page 55

Electrical connections, LEDs

A/D converter

(ADC)

Filter

1)

ADC unfiltered

ADC filtered

Field value (el. value)

Gross value

Net value

Minimum

2)

Maximum

2)

Peak-to-peak

2)

Limit value switch

2)

Analog output

3)

min. 52 μs

1)

Filter off: 0 s; Bessel filter: 0.43/fg; Butterworth filter: 0.66/fg; The result is time in seconds for an

output signal of 50% of the full scale value with a jump at the input.

2)

These signals can also use other sources. The phase delays of the source signals must then be

added.

3)

If the analog output is to output a value from this group, you must add on 52 μs. If you are using

a source from a different group, you must add the phase delay of the source signal to the 52 μs.

260 μs

6.11 Signal propagation times within the ClipX and over the ClipX bus

The various modules in the ClipX are combined into a number of groups, each

with fixed cycle times. This makes it easier to calculate the total propagation

time of a signal. The following diagrams indicate the propagation times of the

various groups as well as any potential additions you might need to allow for the

hardware of inputs/outputs. To calculate the maximum propagation time of signals running through more than one group, such as min/max values obtained

from calculated channels, simply add together the propagation times of the

respective groups.

Pay attention to the sequencing of the analysis within a group. If source signals

are formed only later in the group, this will double the propagation time until the

result is available.

Group 1: Measured values

Fig. 29: Minimum propagation time for group 1: 52µs plus A/D converter conver-

sion time

ClipX

a4643-1.0 HBM: public 53

Page 56

Electrical connections, LEDs

1 ms

Flags and

values from

fieldbus

Digitale

inputs

Computed

channels

Digital flags

(I/O flags)

1)

Digital

outputs

2)

ClipX bus:

Start

transfer

3)

1)

Changes in digital flags are analyzed in the following order: Zeroing, taring, clear zero value,

clear tare value, reset limit value switch, reset peak values, hold held values, clear hold values.

3)

Asynchronous transfer of the values on the ClipX bus is complete after max. 1 ms, i.e on the next

cycle.

2)

The digital outputs have an additional response time of max. 0.25 ms.

Some signals might also have sources from other groups. For example, the

analog output might deliver a signal from the ClipX bus. In these cases,you

must add the propagation time of the source signal's group in order to get the

total propagation time.

Example 1

Propagation time from input, e.g. 10V, 20mA or DC full/half bridge, to analog

output (10V) with a Bessel filter at 1kHz:

• A/D converter (ADC): 260µs

• Filter: 0.43/1000 = 430µs

• Analog output: 52µs

Added to this is a jitter of up to 52µs, as the A/D converter only starts a new con-

version every 52µs. So the total propagation time is 742 … 797µs.

Group 2: Flags, Digital I/Os, calculated values, ClipX bus

Fig. 30: Maximum propagation time for group 2: 1ms

Example 2

Propagation time from input (see group 1) to a digital output with a Bessel filter

at 1kHz, limit value switch at half the step height.

• A/D converter (ADC): 260µs

• Filter: 0.43/1000 = 430µs

•Group 2: 1ms

• Digital output: max. 250µs response time

54

a4643-1.0 HBM: public ClipX

Page 57

Electrical connections, LEDs

Polling rate

EtherCAT/

PROFINET

ca. 250 μs250 μs

1)

1 ms

1)

At 4 kHz frame rate.

ClipX

fieldbus

controller

Period duration

of frame rate

of fieldbus

Polling rate

EtherNet/IP /

PROFIBUS

0.25 … 1 ms

Added to this is a jitter of up to 52µs, as the A/D converter is not synchronized

with group 1. In the best case, a value is available at the start of the analysis in

group 2 and can be outputted directly at the digital output for example. So the

total propagation time is 940 … 1992µs.

Example 3

Propagation time of a value from the ClipX bus via a limit value switch to a digital output.

• ClipX bus: 1ms

• Limit value switch: 52µs

• Digital output: 1ms plus max. 250µs response time

This result in a total propagation time of 2.3ms. However, you must add the

propagation time in the device that places the value on the ClipX bus in order to

get the time from the sensor until a response occurs.

Group 3: Data from fieldbus master to ClipX

Fig. 31: Propagation time for group 3

ClipX

a4643-1.0 HBM: public 55

Page 58

Electrical connections, LEDs

Update rate

EtherCAT/

PROFINET

250 μs

1)

1 ms

1)

At 4 kHz frame rate.

Update rate

EtherNet/IP/

PROFIBUS

approx. 250 μs 0.25 … 1 ms

ClipX

fieldbus

controller

Period duration

of frame rate

of fieldbus

Group 4: Data from ClipX to fieldbus master

Fig. 32: Propagation time for group 4

56

a4643-1.0 HBM: public ClipX

Page 59

Starting up the ClipX

7 Starting up the ClipX

The first section of this chapter explains the general power-up and operating

behavior of the ClipX following a successful installation. Then the steps required

to put the ClipX into operation are explained. For initial start-up, you should connect the ClipX via Ethernet to a PC. The description of operation via one of the

fieldbuses can be found in chapter Operation via fieldbus

If you want to operate multiple ClipX devices, you should first connect

each ClipX device individually to a PC and perform a basic configuration (e.g. IP address and Name).

Then read the section headed

plifiers so as to avoid interference between the devices.

Synchronizing multiple ClipX CF am-

7.1 Power-up and operating behavior

When the ClipX is powered up, all the inputs and output remain at 0 or 0.0V as

appropriate. The start parameter set is loaded and activated first (= initialization). As soon as the ClipX has initialized, the outputs are set to the preset or

calculated values (factory setting for the digital outputs: 0, not inverted). If the

analog output is inactive, the output has a high internal resistance. If the source

signal for the analog output is invalid, the specified value in case of an invalid

signal is outputted (factory setting 11V but disabled).

The digital inputs and outputs and the calculations are updated at the sampling

rate (1000Hz). The signal at the analog output is updated at 19.2kHz. If the

source signal has a smaller rate of change, the value is outputted multiple times.

Values are transferred from synchronized ClipX devices at a maximum of 1000

values per second, so with six connected device you get 6000 values per

second. The maximum time delay between the ClipX values transmitted over

the ClipX bus is 1ms.

.

ClipX

Up to three clients (PCs) can connect to a ClipX; any further connection is then rejected.

a4643-1.0 HBM: public 57

Page 60

Starting up the ClipX

Important: Some browsers make more than one connection. In this

case, the number of possible additional connections is reduced.

See also Using parameter sets.

7.2 Connecting via Ethernet

Connecting

You have two options for connecting to the ClipX:

1. Make a direct 1:1 connection.

Connect your PC and the ClipX by an Ethernet cable. In rare cases, you will

need an Ethernet cross cable for this. Normally the PC will adapt automatically to the cable.

2. Connect over a network.

Connect your PC to the network or switch, and connect the ClipX in turn to

the network or switch – in each case using an Ethernet cable.

Important: The transfer of commands and data is not encrypted or secure (no https). So you should only operate the ClipX in an internal

network with no connection to the Internet or – if an Internet connection is essential – connect via a VPN tunnel.

In both cases, your PC should use the DHCP setting (Obtain an IP address

automatically) to connect. With fixed IP addresses this is only possible if the

PC and ClipX are using addresses from the same network segment (ClipX factory default setting: DHCP). The connections use IPv4; IPv6 is not supported.

Use the first variant if you want to use multiple ClipX devices. First connect to each individual ClipX, and assign each one a unique device

name through your web browser. This will enable you to identify the individual ClipX devices later, otherwise (depending on the connection

method you use) it will not always be possible to distinguish between

them.

58

a4643-1.0 HBM: public ClipX

Page 61

Starting up the ClipX

Connecting

1. Launch your web browser.

The latest versions of Firefox, Chrome and Microsoft Internet Explorer (version 11 or higher) are supported and have been tested by HBM.

2. Enter ClipX/ or http://ClipX/ or http://ClipX.local in the address bar.

The Home page is displayed.

Important: Do not use https; only http.

If you have already changed the device name, you must enter the new name in

place of ClipX. If you have forgotten the name, try one of the alternative options.

Click on in the header and the SYS LED on the ClipX you are using

will flash red/green.

Alternative options

If the method described above does not work, in Windows 7 or higher you can

try the following (detect via UPnP):

1. Open Windows Explorer.

2. Click on Network.

3. In the Other devices section you should see the ClipX device (with the

device name, factory default ClipX).

4. Double-click on the icon.

If you know the device's IP address, you can also type it in your browser's

address bar, e.g. http://192.168.169.130.

Install one of the following apps from the Google Play Store if you want to connect the ClipX using Android:

ClipX

a4643-1.0 HBM: public 59

Page 62

Starting up the ClipX

https://play.google.com/store/apps/details?id=com.hbm.devices.scan.ui.android

https://play.google.com/store/apps/details?id=com.tjjang.upnptool

https://play.google.com/store/apps/details?id=com.melloware.zeroconf

The apps use different connection methods – see also No device found?

Under Linux you can also type one of the following lines to call up a list of ClipX

devices and their IP addresses or MAC addresses respectively and enter them

in your browser:

$ nmblookup clipx

$ avahi-browse --all

Which line works is dependent on which method (NetBIOS or Bonjour) you are

able to use, i.e. what software is installed on your PC.

7.2.1 No device found?

If no connection is made, there may be a number of reasons.

General reasons

• Is the device actually on (connected to the power supply)?

• Is the system LED on the ClipX lit? See also Health monitoring, LEDs.

• Is the interface cable connected?

• Have you enabled the correct interface or correct interface adapter on the

PC?

Problems with the interface

• Are you using the correct Ethernet cable?

Use an Ethernet switch with a standard cable or a direct connection by a

cross cable.

• Is your Ethernet switch operating correctly?

If you are not operating any other devices on the switch with which you can

check the function, try to set up a direct connection between the PC and the

measuring device.

60

a4643-1.0 HBM: public ClipX

Page 63

Starting up the ClipX

• Have you waited long enough for the PC to specify its address?

If the PC cannot find a server in the network, the search for the server looks

in the DHCP setting (Obtain an IP address automatically) first of all. (The

icon for the interface in the Windows 7 tray indicates the search, but the icon

might only appear if it is configured to do so. In Windows 8 and higher it is

no longer displayed.) It then takes about 30 seconds before an automatic

address or the specified alternative address (if any) is set. No device is

found during this time.

• Is it possible that your firewall is blocking the connection?

Try deactivating your firewall or open the following ports:

• For communication with the device via a browser, TCP ports 80 and

8081 are required.

• Different ports are required to locate the ClipX depending on the variant.

For UPnP TCP 80 and UDP-Multicast at IP address 239.255.255.250

(sending and receiving) with port 1900, for NetBIOS UDP 137, for Avahi

or Zeroconf (similar to Bonjour) UDP-Multicast is required at IP address

224.0.0.251 (sending and receiving) with port 5353.

• If a WLAN is also active with your PC, test whether the device is found when

you temporarily switch off the WLAN (only for the time of the scan). With

some WLAN configurations, problems can occur if multiple Ethernet ports

are enabled.

• If your PC has several Ethernet interfaces, try deactivating all other Ethernet

interfaces.

• If you are using the device in a large network, contact your network adminis-

trator. There are a series of options in managed networks to limit or completely prevent data transmission between the individual nodes. Administrative access control settings may therefore by needed here.

Notes

• In Windows XP only the name resolution under NetBIOS is available.

• For name resolutions via NetBIOS, you should only ever connect one ClipX

as long as you have not changed the device names.

ClipX

a4643-1.0 HBM: public 61

Page 64

Starting up the ClipX

• UPnP is only available as from Windows 7.

• Avahi or Zeroconf (similar to Bonjour) is only available if a corresponding

service, such as Bonjour print services, is installed.

See also Possible cases and their effects when connected via Ethernet,

Set Ethernet address of PC.

7.2.2 Possible cases and their effects when connected via Ethernet

When connecting between the PC and ClipX the following cases may arise:

1. No server in the network, the PC has no address (DHCP is used), and the

ClipX is likewise set to DHCP (factory default setting).

When using Windows XP or higher, temporary addresses are automatically

assigned by the PC (APIPA), the ClipX connection can be made.

2. No server in network, PC has no setting or is using DHCP, the ClipX has a

fixed address

No connection can be established with this combination.

3. No server in the network, PC and ClipX have a fixed address

A connection can normally be made only if the addresses of the PC and

ClipX are in the same network segment and both are using the same subnet

mask.

4. DHCP server in network, PC has a fixed address or uses DHCP, the ClipX

has a fixed address.

A connection can normally be made only if the addresses of the PC and

ClipX are in the same network segment.

5. DHCP server in network, PC and ClipX are using DHCP

The connection can be established.

62

a4643-1.0 HBM: public ClipX

Page 65

Starting up the ClipX

7.2.3 Set Ethernet address of PC

Procedure for Windows 10

1. Use the icon in the notification area of the task bar to open the Network

and Internet Settings (right mouse button).

2. In the Change network settings section click on Change adapter options.

3. Right click on the relevant adapter (port), select Properties and specify an

Administrator account or confirm the security prompt.

4. Select Internet protocol version 4 (TCP/IPv4) and click on Properties.

5. Activate Use the following IP address and enter an address with which the

first three groups of numbers match the groups of numbers of the HBM

device and only the last group of numbers contains a different number

between 1 and 254. The last group of numbers must not match the one on

the HBM device.

6. For Subnet mask enter the same groups of numbers as are present on the

HBM device.

7. Then click OK or Close to close all open dialogs.

See also Example

.

Procedure for Windows 8/8.1

1. From the Charms menu on the Windows desktop (not in tile view) open

Settings -> Control Panel -> Network and Sharing Center (View by:

Small icons) or Show network status and tasks (View by: Categories).

2. Click in the Show active networks area on the connection you want (usu-

ally LAN connection).

3. Click on Properties and specify an administrator account or confirm the

confirmation prompt.

4. Select Internet protocol version 4 (TCP/IPv4) and click on Properties.

5. Activate Use the following IP address and enter an address with which the

first three groups of numbers match the groups of numbers of the HBM

device and only the last group of numbers contains a different number

between 1 and 254. The last group of numbers must not match the one on

the HBM device.

ClipX

a4643-1.0 HBM: public 63

Page 66

Starting up the ClipX

6. For Subnet mask enter the same groups of numbers as are present on the

HBM device.

7. Then click OK or Close to close all open dialogs.

See also Example

.

Procedure for Windows 7

1. Use the Windows Start menu to open the Control Panel -> Network and

Sharing Center (View by: Small icons) or Show network status and

tasks (View by: Categories).

2. Click in the Show active networks area on the connection you want (usually LAN connection).

3. Click on Properties and specify an administrator account or confirm the

confirmation prompt.

4. Select Internet protocol version 4 (TCP/IPv4) and click on Properties.

5. Activate Use the following IP address and enter an address with which the

first three groups of numbers match the groups of numbers of the HBM

device and only the last group of numbers contains a different number

between 1 and 254. The last group of numbers must not match the one on

the HBM device.

6. For subnet mask enter the same digit groups as those available on the

HBM device.

7. Then click OK or Close to close all open dialogs.

See also

Example.

Procedure for Windows XP

1. Use the Windows Start menu to open Settings -> Network connections.

From the context menu (right-click), choose the Properties of the relevant

LAN connection.

2. Select Internet protocol (TCP/IP) and click on Properties.

3. Activate Use the following IP address and enter an address with which the

first three groups of numbers match the groups of numbers of the HBM

device and only the last group of numbers contains a different number

64

a4643-1.0 HBM: public ClipX

Page 67

Starting up the ClipX

between 1 and 254. The last group of numbers must not match the one on

the HBM device.

4. For subnet mask enter the same digit groups as those available on the

HBM device.

5. Then click OK to close all open dialogs. You may have to restart the PC to

activate the setting.

Example

The IP address of the ClipX is 192.168.169.80, the subnet mask is

255.255.255.0.