Page 1

User Manual

AED9101C

Digital Transducer Electronics

Basic Device for AD103C

with RS232, RS422, RS485

I1692-2.0 en

Page 2

Page 3

Content

Content

Typographical conventions................................................................................................3

Important information................................................................................................ ......... 4

Safety instructions.............................................................................................................. 5

1 Introduction and appropriate use......................................................................................6

2 Mechanical construction....................................................................................................7

3 Electrical connections........................................................................................................8

1

3.1 Transducer connection......................................................................................................................... 8

3.2 Connecting the supply voltage.............................................................................................................15

3.3 Connection to a computer ...................................................................................................................16

3.4 Multi-channel measurements (bus mode, RS485) ...............................................................................19

3.5 Connecting the diagnostic bus.............................................................................................................22

3.6 Trigger input........................................................................................................................................24

3.7 AED9101C cable connection via a PG gland.......................................................................................25

Index...................................................................................................................................26

AED9101C en HBM

Page 4

2

HBM AED9101C en

Page 5

Typographical conventions

Typographical conventions

For clear identification and improved legibility, the following conventions have been used in

this documentation:

Important paragraphs are marked with a symbol to draw attention to them.

CE Designation

Statutory marking requirements for waste disposal

3

Italics

“File Open“ All menus and menu commands appear in quotes, here the “File” menu and the “Open”

“Start”

MSV

Points out external documents and files

sub-menu.

Quotes and italics are used for buttons, input fields and user input.

All commands are set out in a bold font style or as a link to the command description.

AED9101C en HBM

Page 6

4

Important information

Neither the design of the device nor any technical safety aspects may be modified without

the express permission of Hottinger Baldwin Messtechnik GmbH. Any modification excludes Hottinger Baldwin Messtechnik GmbH from any and all liability for any damage resulting therefrom.

It is strictly forbidden to carry out any repairs and soldering work on the motherboards or to

replace any components. Repairs may only be carried out by persons authorized thereto

by Hottinger Baldwin Messtechnik GmbH.

All the factory defaults are stored safe from power failure at the factory, not in the measuring amplifier where they can be deleted or overwritten. They can be reset at any time by

using the command TDD0. For more information, see aed_help_e, AD103C; “Description

of the basic commands”.

The production number is set at the factory and cannot be changed.

The transducer connection must always be assigned.

It is essential for a transducer or a bridge model to be connected up for operation.

Important information

HBM AED9101C en

Page 7

Safety in

structions

Safety instructions

There are not normally any hazards associated with the product, provided the notes and

instructions for project planning, assembly, appropriate operation and maintenance are

observed.

Each time, before starting up the modules, you must first run a project planning and risk

analysis that takes into account all the safety aspects of automation technology. This

particularly concerns personal and machine protection.

It is essential to comply with the safety and accident prevention regulations applicable to

each individual case.

Installation and start-up must only be carried out by suitably qualified personnel.

Do not allow the equipment to become dirty or damp.

5

During installation and when connecting the cables, take action to prevent electrostatic

discharge as this may damage the electronics.

The required power supply is an extra-low voltage with safe disconnection from the

mains.

When connecting additional devices, comply with the local safety requirements.

All the interconnecting cables must be shielded cables. The screen must be connected

extensively to ground on both sides.

The power supply and digital I/O connection cables only need to be shielded if the cables are longer than 30 m (32.81 yd) or are routed outside closed buildings

(EN 61326-1).

The CE mark enables the manufacturer to guarantee that the product complies with the

requirements of the relevant EC directives (the declaration of conformity is available at

http://www.hbm.com/HBMdoc).

In accordance with national and local environmental protection and material recovery

and recycling regulations, old devices that can no longer be used must be disposed of

separately and not with normal household garbage.

If you need more information about waste disposal, please contact your local authorities

or the dealer from whom you purchased the product.

AED9101C en HBM

Page 8

6

1 Introduction and appropriate use

AED9101C digital transducer electronics are part of the AED component family that digitally

conditions signals from mechanical measurement sensors and networks them with bus capability. These include digital amplifier motherboards, basic devices with serial interfaces

and intelligent sensors with integrated signal processing. The purpose of these components

is to directly digitize and condition the measurement signals at the transducer location. Using

digital transducer electronics, you can connect SG1)transducers in a full-bridge circuit directly to a computer or a PC. This enables you to configure complete measurement chains

quickly and with little extra work.

Basic device AED9101C can contain the AD103C amplifier board. It provides mechanical

protection, shields the amplifier board (EMC protection) and allows you to select the serial

interfaces RS422 (factory default), RS485 or RS232.

The AD103C amplifier mother board is not included in the scope of supply of the basic device and must be ordered separately.

Introduction and appropriate use

The AD101B amplifier is only required for replacement and will not be considered when new

AED basic devices are ordered.

The PC software AED PANEL 32 is available to facilitate parameter settings, to display dynamic measurement signals and for comprehensive analysis of the dynamic system.

The HBM display unit DWS2103 can be connected to all AED basic devices.

All basic devices of the AED family can be connected with the digital display unit DWS2103.

This unit supports all implemented functions of the AED.

All commands are described in the help file aed_help_e.

The abbreviation AED is also used for transducer electronics in the following text.

1)

Strain Gage

HBM AED9101C en

Page 9

Mechanical

construction

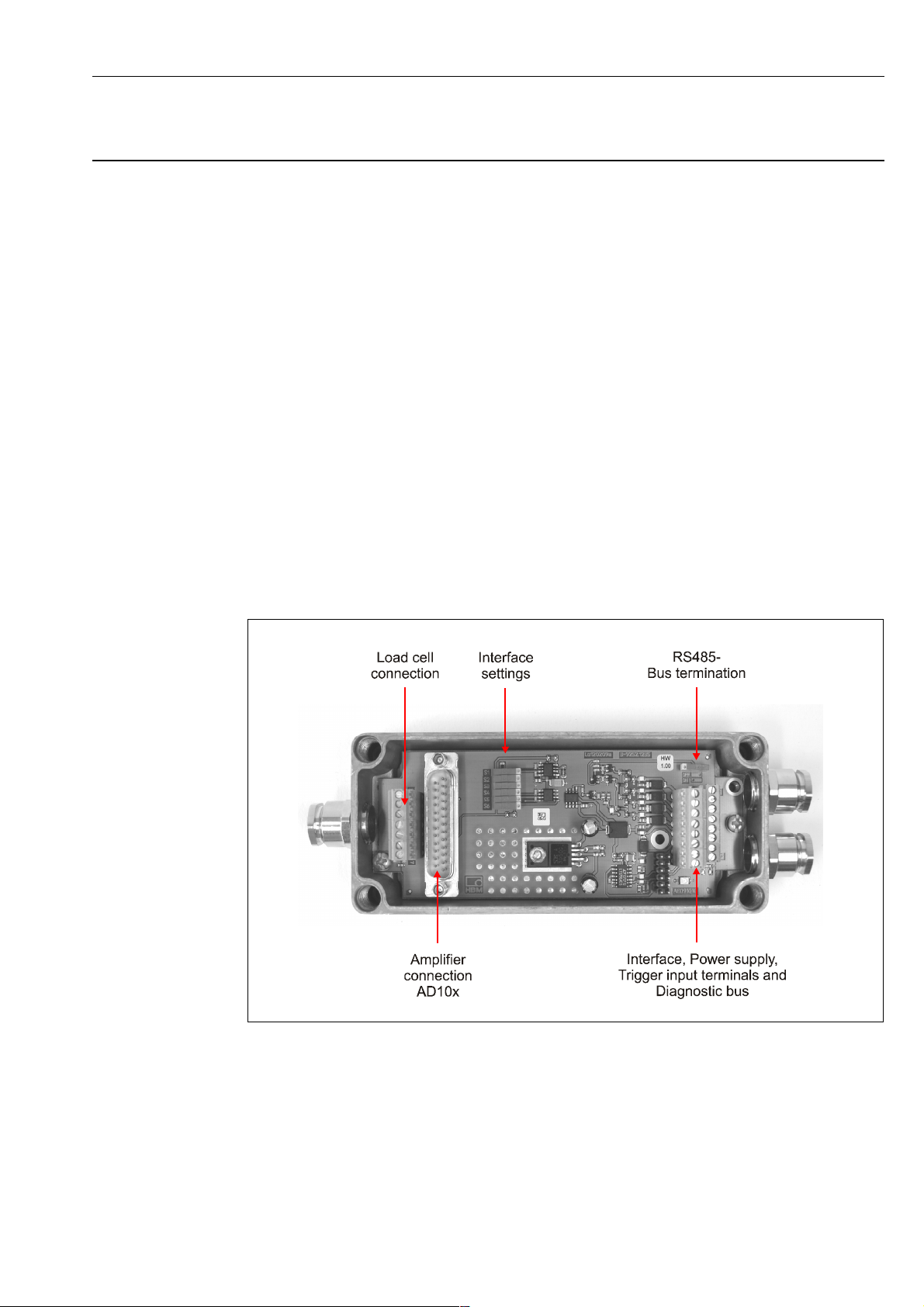

2 Mechanical construction

The basic device extends the functionality of the AD amplifier boards and provides:

mechanical protection (IP65)

the power supply for the amplifier motherboard and transducer excitation

total transducer bridge resistance 40…4000

a choice of serial interfaces RS422, RS485, RS232

EMC-tested

Diagnostic bus

(The AED9101A basic device can be replaced by the AED9101C basic device)

7

The amplifier motherboard is designed as a plug-in board that can be plugged into the carrier

board of the basic device via a 25-pin D-connector. The basic device contains terminals for

the transducer, power pack and interface connections, slide switches for interface selection

and the voltage stabilizer. The connection cables exit the casing via PG glands on the side.

Fig. 2-1: Mechanical construction

AED9101C en HBM

Page 10

8

3 Electrical connections

A connection diagram is attached inside the lid of the AED9101C basic device.

When making the connections, please ensure that the wires of the cable do not protrude

beyond the connection terminals (risk that loops may form). Please make sure that the

cable shielding is properly connected to the PG gland.

If it should be necessary, a separate cable can be used to establish potential equalization

between the transducer and the AED and between the AED and the Master control unit

(grounding concept). The cable shielding must not be used for this potential equalization.

Electrical connections

3.1 Transducer connection

The transducer connection must always be assigned (connect the transducer).

AED9101C with AD103C

You can connect SG transducers in a full-bridge circuit with a total bridge resistance of

RB= 40...4000 . With a transducer resistance of > 1000 , increased noise (measurement

ripple) must be taken into account. The bridges are supplied with power in the AED9101C

basic device (5 VDC).

HBM AED9101C en

Page 11

Transducer

connection

9

Fig. 3.1-1: Transducer connection in 6-wire circuitry (HBM color-coding)

The 6-wire connection avoids the effect of a long cable on the measured value. When several transducers and a junction box are used, the 6-wire circuitry is routed to the junction

box.

Fig. 3.1-2: Transducer connection in the AED9101C basic device for a 6-wire connection

AED9101C en HBM

Page 12

10

transducer electronics

Cable shield

Transducer connection

There are two methods of connection for transducers implemented in four-wire circuitry:

Connection via a 6-core extension cable; bridged sensor circuit in the transducer con-

nector.

Plug-in connection

Transducer

Fig. 3.1-3: Transducer connection in 6-wire circuitry via a 6-core cable extension

bu

rd

wh

bk

bu

gn

wh

gy

bk

Cable to

HBM AED9101C en

Page 13

Transducer

connection

11

Connection without an extension cable; sensor circuit bridged at the transducer electron-

ics.

Fig. 3.1-4: Transducer connection in 4-wire circuitry without a cable extension (jumpers 2 – 2‘

and 3 – 3‘)

Connection without an extension cable; sensor circuit at transducer electronics. When connecting several transducers, it is advisable to use an HBM junction box VKKx. In general, the

feed lines running to the AED should be shielded cables.

When connecting several transducers to the AED, the number of load cells that can be connected (and the resultant bridge resistance) must be taken into consideration with regard to

the external supply voltage, so that the maximum power loss in the basic device is not exceeded.

AED9101C en HBM

Page 14

12

U in (V)

30

24

21

16

13

Transducer connection

O O

23 C [73.4 F]

O O

70 C [158 F]

Impedance ( )

350 175 87 58

1 2 3 4 5 6 7 8

Fig. 3.1-5: Maximum operating voltage for the AED9101C basic device, with regard to the number of

transducers and the ambient temperature

43

Number of transducers

Notes on type of connection, length and cross-section of cables:

Depending on the bridge resistance of the load cell being used and the length and crosssection of the load cell connection cable, there may be voltage drops that can reduce the

bridge excitation voltage. The voltage drop at the connection cable is also dependent on

temperature (copper resistance). Likewise, the output signal of the load cell changes in proportion to the bridge excitation voltage.

This is balanced out when connecting in 6-wire circuitry.

6-wire circuit (standard mode of operation):

This will correct all the effects of the load cell cabling up to the feedback points. Even changing the length of a cable after calibration will not make any difference to the measurement

results.

For load cells with a 6-wire connection, feedback lines 2´ and 3´ are bridged in the load cell

with excitation 2 and 3 (Fig. 3.1-2). For load cells with a 4-wire connection, the feedback

bridges must be implemented directly at the load cell connection (Fig 3.1-3 or 3.1-4).

HBM AED9101C en

Page 15

Transducer

connection

13

4-wire circuit:

As correction through AUTOCAL can only ever take place up to feedback points 2´, 3´, all

the changes of cable resistances affect the measurement result. This means that even if no

further changes are made to the 4-wire cable used for calibration, there will still be measurement errors when there are temperature changes, because the cable resistance and possibly the contact resistances at the connectors are temperature-dependent. With the 4-wire

circuit, feedback lines 2´ and 3´ are directly connected at connection terminals 2 and 3 in the

AED (see Fig. 3.1-4).

Equivalent circuit of the bridge with bridge resistance RBand supply lines with

line resistances R

and RL2:

L1

R = R = (4 p / ) (I [m] / A [mm ])

R

L1

R

B

R

U

L2

BR

L1 L2 CU

p = 0,0178 [ mm /m] for copper

CU

= 3,14 I = Length of cable, A = Cross-section of cable

R = R = 1,6 at I = 10 m and A = 0,14 mm

Fig. 3.1-6: Bridge equivalent circuit diagram

L1 L2

2

2

2

AED9101C en HBM

Page 16

14

Transducer connection

The voltage drop over the bridge feeder cables can be determined from bridge resistance

RB, cable length l, cable cross-section A and the bridge excitation voltage:

UB+ U

RL1

+ U

RL2

= U

BR

For

RB= 80 , R

= RL2= 1,6 (l = 10 m) and UBR= 5 V

L1

there is an excitation current of

IBR= UBR/(RL1+ RL2+ RB) = 60 mA

and thus a voltage drop over the two line resistances totaling approx. 0.2V (U

Bridge

= 4.8 V).

For

RB= 80 , R

= RL2= 16 (l = 100 m) and UBR= 5 V

L1

there is an excitation current of

IBR= UBR/(R

+ RL2+ RB) = 45 mA

L1

and thus a voltage drop over the two line resistances totaling approx. 1.4 V

(U

= 3.6 V = 80 0.045).

Bridge

This is irrelevant for the 6-wire circuit, as the voltage drop over the sensor lines is taken into

account in the measurement signal.

But with a 4-wire circuit, the dependency of the copper resistance of the cables on temperature goes directly into the measurement result, as the bridge excitation voltage U

Bridge

changes:

RL(t) = RL20 (1 + (t –20 °C)),

where R

is the line resistance at 20 °C and is the temperature coefficient of the cop-

L20

per.

R

– for calculation, see page 23, CU: = 0.00392 [1/K]

L20

With a cable length of l = 100m and a temperature differential of 10 °C, there is a line resistance of

RL1(t) = RL2(t) = 16 (1 + 0.00392 10) = 16.6

This changes the bridge excitation voltage of

U

= 3.6 V (at 20 °C) to U

Bridge

Bridge

= 3.53 V.

This change in bridge excitation voltage directly at the transducer changes the measurement

signal of the bridge by 1.9 % (= 100 % (1 – 3.53 V / 3.6 V)).

This typical calculation shows that if long cables are involved, only 6-wire circuitry should be

used.

HBM AED9101C en

Page 17

Connecting

the supply voltage

3.2 Connecting the supply voltage

The power supply must meet the following requirements:

15

AED9101C with AD103C

Calculation the total current consumption:

DC voltage +6...+30 V

current consumption

250 mA (for a 40 bridge)

Fig. 3.2-1: Power supply connection

The voltage feed must be shielded. It can be applied within the interface cable or be implemented as a separate cable.

When supplying several AEDs via one cable, the voltage drop over the cable must be taken

into consideration. The voltage drop depends on the supply current required and on the line

resistance.

AED9101C en HBM

Page 18

16

3.3 Connection to a computer

The basic device can be set up for several interface variants:

Connection to a computer

Fig. 3.3-1: Pin assignment and settings for the interfaces

HBM AED9101C en

Page 19

Connection

to a computer

17

No bus mode

The RS232 interface allows the AED to be connected directly to a PC. The cable length is

limited to 15 m and bus mode is not possible.

Fig. 3.3-2: Connecting an AED to a computer via the RS232 interface

For the RS232 interface setting, the “bus termination switch must be set to OFF”.

The RS422 interface is a 4-wire interface also with a maximum cable length of 1000 m. To

connect the AED to the COM port of a PC (RS232), you need an interface converter. This interface is not designed for bus mode, as the transmitter is always active.

AED9101C en HBM

Page 20

18

RS 485-Bus AED 9101C

Connection to a computer

Bus mode

The RS485 interface with a 4-wire connection allows the full range of AED functions with a

maximum cable length of 1000 m. To connect the AED to the COM port of a PC (RS232),

you need an interface converter.The RS485 interface with a 2-wire connection also allows

cable lengths of 1000 m. To connect the AED to the COM port of a PC (RS232), you need

an interface converter

(1-SC232/422B from HBM, with 2-wire mode selected). However, the AED must be operated

in half-duplex mode (command COFxxx must be set). The command MSV?0; must not be

used, as it is not possible to interrupt data output with the STP; command.

Basically, shielded cables should be used for the interface wiring, with the cable shielding

being connected to the AED housing via the PG (see AED9101C cable connection via the

PG gland). The power supply can also be connected via this cable, with a 6-core, shielded

cable being necessary.

If it should be necessary, a separate cable can be used to establish potential equalization

between the bus nodes. The cable shielding must not be used for this potential equalization.

For reasons of electromagnetic compatibility, it is advisable to use a double-shielded cable

(from the HBM program, for example: 3 2 0.14 m², 4-3301.0071).

The shielding of the physical circuit is connected to the AED line (not to the power supply

ground).

U : 8 V...30 V

B DC

Interface converter

PC COM port

RxD

TxD

GND

SUB-D connector

9-pin (PC)

PIN

2 = RxD

3 = TxD

5 = GND

TxD

RxD

GND

RS232 - RS485

HBM Wägetechnik GmbH

CONVERTER

RS232

SUB-D female connector

9-pin (converter)

PIN

2 = TxD

3 = RxD

5 = GND

SC232/422A

8...30V

RS485

2/4-wire

TA

TB

RA

RB

GND

U

B

Equivalent

Interface marking:

TA = T- TB = T+

RA = R- RB = R+

TA

TB

RA

RB

GND

U

B

(blue)

(black)

(green)

(grey)

(white)

(red, 8...30 V )

DC

HBM AED9101C en

Fig. 3.3-3: Connecting an AED (RS422 or RS485 4-wire) to a computer via the interface converter

Page 21

Mult

i-channel measurements (bus mode, RS485)

3.4 Multi-channel measurements (bus mode, RS485)

With the RS485 interface, several AEDs can be connected to a common bus line. The bus

cabling for 4-wire mode is shown in Fig. 3.4-1.

With the RS485 interface, up to 32 AEDs can be connected to a common bus line. With the

aid of the RS485 bus driver, it is possible to implement long cables (up to 1000 m

(1,093.61 yd) in length).

AED bus mode is set out as a Master-Slave configuration, with the AED implementing a

slave.

This means that all the AED activities are initiated from the control computer. Each AED is

given a separate communication address (00...89) and can then be activated by an

Sii (ii = 00...89) Select command.

A broadcast command (S98) is implemented for specific communication situations. This

means that after a command of this type, all the AEDs execute the command of the Master,

but none of the AEDs respond. All these communication commands are described with relevant examples in file aed_help_e, AD103C; “Description of the basic commands”.

19

Fig. 3.4-1: Bus structure 4-wire bus (general)

AED9101C en HBM

Page 22

20

Multi-channel measurements (bus mode, RS485)

The termination resistances of 500 marked in the above diagram are important for the

electrical function of the bus system. These resistances safeguard the quiescent level for the

receiver on the bus line. The physical circuit must only be connected with these resistances

at the line ends.

For the local bus termination distribution shown in the diagram, the Master and the AED with

address 89 should include the termination resistances. Which is why in this AED, the bus

termination is activated using the “bus termination ON” switch. This bus termination in the

AD103C must also be activated using the commands STR1; and TDD1 (see file aed_help_e,

AD103C; “Description of the basic commands”). If the “bus termination switch is set to OFF”,

the command STR will have no effect, which means that bus termination is deactivated.

The HBM interface converter also includes these bus termination resistances (do not deactivate them).

These terminations must not be activated more than twice in one bus.

The ground of the interface driver is related to the GND terminal. The interface driver of

the master should be also connected to this GND.

The quiescent level on the RS485 physical circuit is produced in 4-wire mode at:

TB - TA > 0.35 V

RB - RA > 0.35 V

(quiescent level though AED termination resistances)

(quiescent level though Master termination resistances)

As the RS485 is a differential bus interface, the quiescent level is also specified as a differential voltage between the lines (and not ground-related). Furthermore, please note that this

interface tolerates a maximum common-mode range of ±7 V. If it should be necessary, a

separate cable can be used to establish potential equalization between the bus nodes. The

cable shielding must not be used for this potential equalization.

HBM AED9101C en

Page 23

Mult

i-channel measurements (bus mode, RS485)

RS485 2-wire mode

21

Fig. 3.4-2: Bus structure RS485 2-wire bus (general, TB/RB = T/R+, TA/RA = T/R-)

Termination resistances are also necessary for the electrical function of this bus system.

These resistances safeguard the quiescent level for the receiver on the bus line. These termination resistances are already included in the AED and should be set with the “bus termi-

nation switch” (see 4-wire circuit). The quiescent level on the RS485 physical circuit is produced in 2-wire mode at:

TB/RB - TA/RA 0.35 V

For the local bus termination distribution shown in the diagram, the Master and the AED with

address 89 should include the termination resistances. Which is why in this AED, the bus

termination is activated using the “bus termination ON” switch. This bus termination in the

AD103C must also be activated using the commands STR1; and TDD1 (see file aed_help_e,

AD103C; “Description of the basic commands”). If the “bus termination switch is set to OFF”,

the command STR will have no effect, which means that bus termination is deactivated.

AED9101C en HBM

Page 24

22

3.5 Connecting the diagnostic bus

The diagnostic bus is used to analyze dynamic processes. The bus is set out as an RS485

2-wire bus (lines: TB/RB and TA/RA, GND).

Connecting the diagnostic bus

Fig. 3.5-1: Connecting the diagnostic bus via terminal KL4

The interfaces setting of the bus is defined and cannot be changed (38400 bit/s, 8E1).

External bus termination resistances are not necessary for this bus.

The HBM interface converter (1-SC232/485B) can be used to connect the RS485 bus to an

(RS232) COM port of the PC.

HBM AED9101C en

Page 25

Connecting

the diagnostic bus

23

Fig. 3.5-2: Diagnostic RS485 bus

The ground of the interface driver is related to the GNDext terminal. The interface driver of

the master should be also connected to this GNDext.

Only a connecting cable with a screen grounded on two sides should be used as the interconnecting cable between the AED 9101C and the bus and the master (see also:

AED9101C cable connection via a PG gland)

The functions and commands of the diagnostic channel are described in the help file

aed_help_e Diagnosis. The address corresponds to the address of the AD103C amplifier,

command ADR (00...89, factory setting: 31), see aed_help_e, Basic Commands). This address is independently from the CANOpen address.

The following functions can also be executed via this bus:

Parameters

Read only (changes are not possible)

Measured values Reading individual measured values MSV?; (MSV?i not possible)

Results

Trigger results and dosing results can be read

The diagnostic functions can be executed using the HBM AED_Panel32 program (as from

Version V3.0.0).

The HBM display unit DWS2103 can be connected with this interface. Than all implemented

functions and parameters are accessible. This is independent from the main communication

channel.

AED9101C en HBM

Page 26

24

3.6 Trigger input

An external sensor (light barrier, contact, etc.), can be connected to the trigger input of the

AD103C, to drive the trigger measurement function (see file aed_help_e, AD103C; “Description of the signal processing”).

The input is activated as an external trigger by the TRC command.

Trigger input

Fig. 3.6-1: Trigger input

The trigger input has the following properties:

Quiescent level: Low

Active edge: High – Low

High level: 2...30 V

Low level: 0...1 V

Input current:

If the input is not required, the input remains unassigned. The GND of the trigger input is

connected to the GND of the supply voltage.

3 mA (for 30 V), 10 k input resistance

HBM AED9101C en

Page 27

AED9101C

cable connection via a PG gland

Slidecablescrew

connectionwithsealing

ringandclampingring

s

overtheendofthecable.

3.7 AED9101C cable connection via a PG gland

Only a connecting cable with a screen grounded on both sides (and metal connectors)

should be used as the connecting cable between the AED9101C and its partner device.

Bring the screen extensively into contact on both sides at the PG gland (and at the metal

shell of the connector). If the partner device does not have a metal connector, connect the

cable shielding extensively to ground. If there are vast differences between the ground potential of the AED9101C and its partner device, a potential equalization line must be provided in addition.

Remove outer sheathofcable

to expose required length

wire L.

25

Fig. 3.7-1: Connecting the transducer, supply voltage and computer to the PG gland

AED9101C en HBM

Page 28

26

Index

Index

4

4-wire circuitry.................................................................................................................................................10, 11

6

6-wire connection..............................................................................................................................................9, 12

B

basic box ............................................................................................................................................................... 7

bridge excitation voltage .................................................................................................................................12, 14

bridge resistance ...................................................................................................................................... 12, 13, 14

bus

bus line ............................................................................................................................................................ 19

bus structure ...............................................................................................................................................19, 21

bus mode........................................................................................................................................................16, 19

RS232.............................................................................................................................................................. 17

RS485.......................................................................................................................................16, 18, 19, 20, 21

bus termination...............................................................................................................................................20, 21

bus termination RS485..................................................................................................................................... 19

C

cable connection.................................................................................................................................................. 17

cable connection - serial interface..................................................................................................................... 16

cable connection supply voltage

cable connection AED9101C.......................................................................................................................15, 25

cable length....................................................................................................................................................12, 14

computer connection............................................................................................................................................ 16

connection to a computer, AED9101C.............................................................................................................. 16

connecting the diagnostic bus.............................................................................................................................. 22

D

diagnostic bus...................................................................................................................................................... 22

E

electrical connections............................................................................................................................................. 8

I

interface............................................................................................................................................................... 16

interface converter..........................................................................................................................................16, 18

HBM AED9101C en

Page 29

Index

27

L

load cell connection ............................................................................................................................................. 12

M

manufacturer’s notes ............................................................................................................................................. 6

mechanical construction......................................................................................................................................... 7

multi-channel measurements............................................................................................................................... 19

P

PG gland ....................................................................................................................................................8, 16, 25

potential equalization........................................................................................................................................... 16

Q

quiescent level

RS485.............................................................................................................................................................. 19

R

RS232 ..........................................................................................................................................................6, 7, 16

RS232 serial interface.......................................................................................................................................... 16

RS422 ..........................................................................................................................................................6, 7, 16

RS485 with 2-wire................................ ................................................................................................................ 16

RS485 with 4-wire................................ ................................................................................................................ 16

S

serial interface................................................................................................................................................... 6, 7

RS232............................................................................................................................................................ 6, 7

RS422.......................................................................................................................................................6, 7, 16

RS485.............................................................................................................................................................. 16

supply voltage...................................................................................................................................................... 15

supply voltage AED9101C................................................................................................................................ 25

T

trigger input.......................................................................................................................................................... 24

U

use........................................................................................................................................................................ 6

AED9101C en HBM

Page 30

HBM AED9101C en

Page 31

AED9101C en HBM

Page 32

Modifications reserved.

All details describe our products in general form only.

They are not to be understood as express warranty

and do not constitute any liability whatsoever.

I1692-2.0 en

Hottinger Baldwin Messtechnik GmbH

Postfach 100151 D-64201 Darmstadt

Im Tiefen See 45 D-64293 Darmstadt

Tel.: +49/6151/803-0 Fax: +49/6151/8039100

E-mail: support@hbm.com · www.hbm.com

Loading...

Loading...