Page 1

Operating manual

Clip Electronic

Amplifier for installation

onto mounting rails

Clip IG

Industrial amplifier in

cast housing

A0114-6.3 en

Page 2

Clip

3

Contents Page

Safety instructions 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Application 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Mounting / Dismounting 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Connection 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

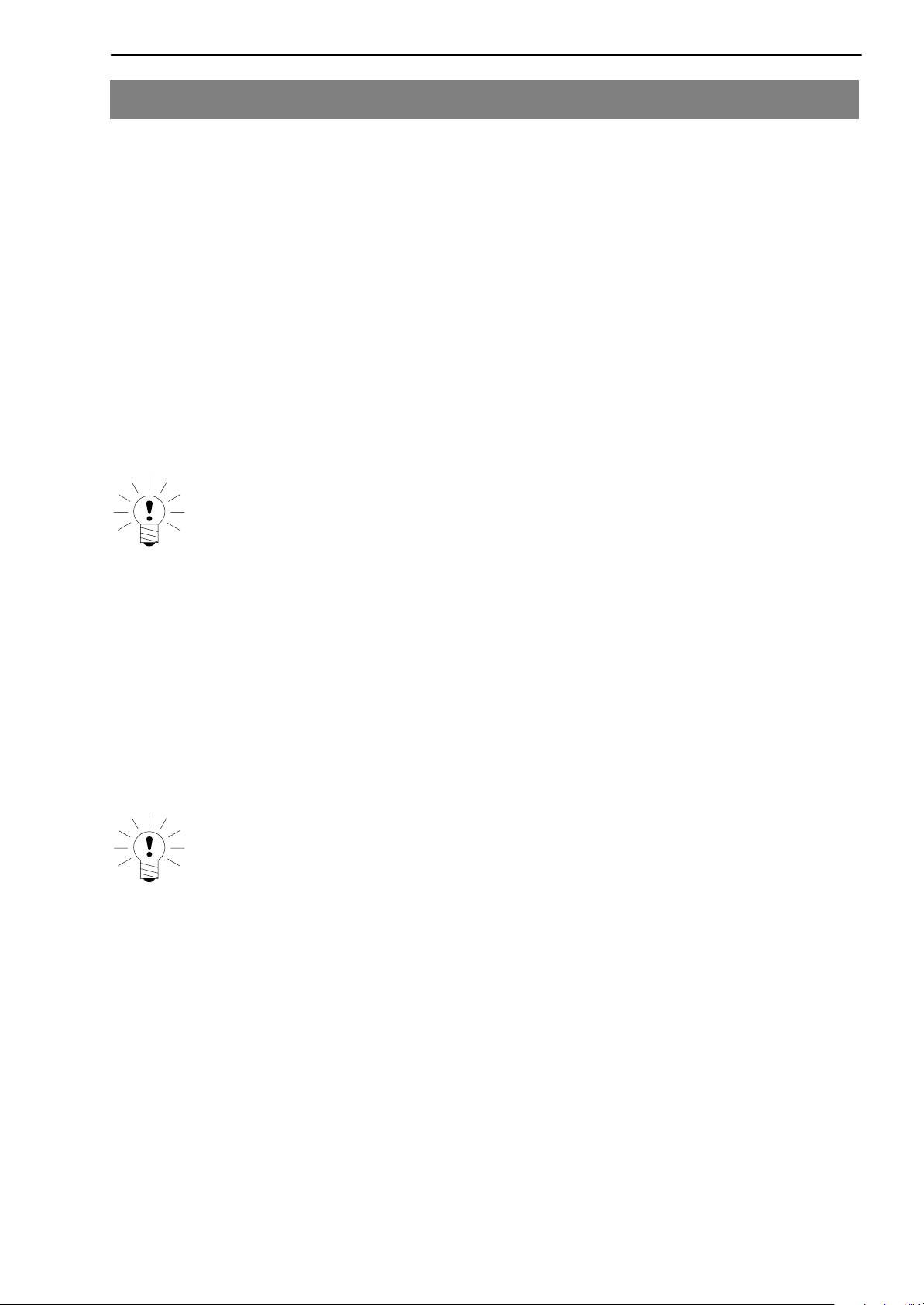

3.1 Measuring amplifiers AE101, AE301, AE501 10 . . . . . . . . . . . . . . .

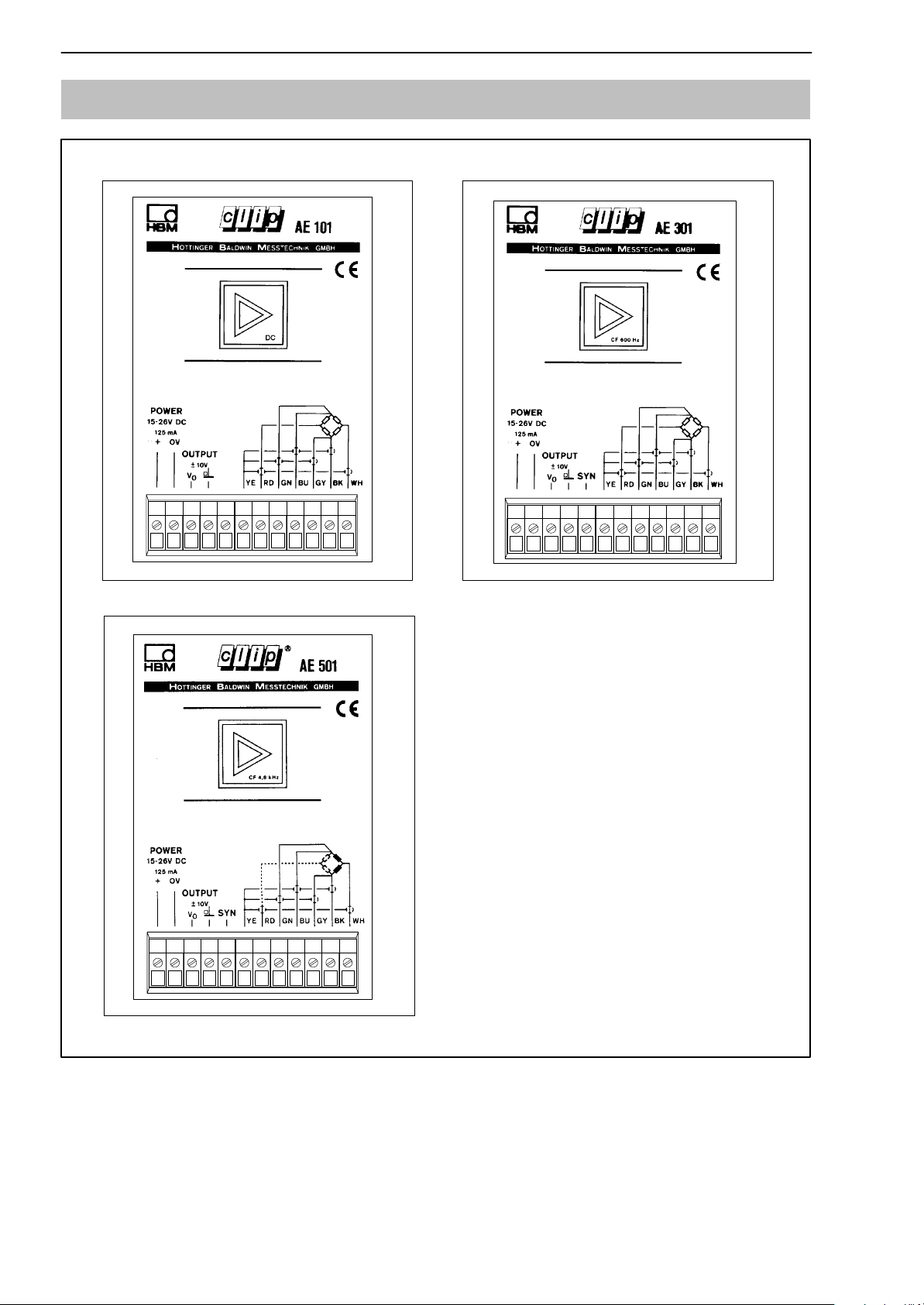

3.2 GR201, EM201, EM201K2, TS101additional units 12 . . . . . . . . . . . .

3.3 NT101A, NT102A Power supply 14 . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Setup 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 AE101 Measuring amplifiers 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 AE301 Measuring amplifier 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 AE501 Measuring amplifier 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 GR201 Double limit-value switch 25 . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 EM201 / EM201K2 Output stage 28 . . . . . . . . . . . . . . . . . . . . . . . . . .

5 TS101 Automatic tare and store unit 30 . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 General 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Function 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Taring 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Store unit 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Connection 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Voltage supply 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Inputs / Outputs 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Control inputs / Control output 34 . . . . . . . . . . . . . . . . . . . .

5.4 Adjustment 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 Factory setup 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Tare unit adjustment 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.3 Store unit adjustment 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Zero-point balance 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Component position diagram 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Safety barriers 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 CLIP IG 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Dimensions 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Specifications 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Accessories 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 Copy of Declaration of Conformity 52 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HBMA0114-6.3 en

Page 3

4

Clip

Safety instructions

The NT101A and NT102A Power Supplies Conform to Protection Class I. The

other Clip components correspond to Protection Class III (Symbol

III

)

when they are operated with safety extra-low voltage (SELV circuits).

In order to ensure sufficient immunity from disturbance only use Greenline

screening (see HBM‘s special publication ”Greenline” Screening Concept,

electromagnetic compatibility of measuring cable, G36.35.0)

Appropriate use

The Clip Electronic with the connected transducers may be used for measurement and directly related control and regulation tasks, only. Any other use is

not appropriate.

To ensure safe operation, the Clip Electronic may only be used according to

the specifications given in this manual. When using the transducer, the legal

and safety regulations for the respective application must also be observed.

The same applies if accessories are used.

General dangers in the case of non-observance of the safety

instructions

The Clip Electronic complies with the state of the art and is operationally reliable. If the device is used and operated inappropriately by untrained personnel, residual dangers might develop.

Any person charged with device installation, operation, maintenance or repair

must in any case have read and understood the operating manual and the

safety instructions, in particular.

Conditions on site

Protect the device from moisture or atmospheric influences such as rain,

snow, etc.

Maintenance and cleaning

The Clip Electronic are maintenance-free. Please note the following points

when cleaning the housing:

• Remove the mains plug from the socket before cleaning.

• Clean the housing with a soft, slightly damp (not wet!) cloth. Never use sol-

vents, since they may damage the labelling on the front panel.

• When cleaning, please ensure that no liquid finds its way into the device or

onto the contacts.

HBM A0114-6.3 en

Page 4

Clip

Residual dangers

The Clip Electronic scope of performance and supply covers part of the measuring-technology, only. The plant designer/constructor/operator must in addition design, realize and take responsibility for the measuring-system’s safety

such that potential residual dangers are minimized. The respective regulations

must in any case be observed. Residual dangers regarding the measuring

system must be specified explicitly.

If there is any risk of remaining dangers when working with the, it is pointed

out in this introduction by means of the following symbols:

5

Symbol:

Meaning: Maximum danger level

Warns of an imminently dangerous situation in which failure to comply with

safety requirements will result in death or serious physical injury.

Symbol:

Meaning: Dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements can result in death or serious physical injury.

Symbol:

Meaning: Potentially dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements could result in damage to property or some form of

physical injury.

DANGER

WARNING

CAUTION

HBMA0114-6.3 en

Page 5

6

Symbols for using advices and helpful information:

Clip

Symbol:

Means that important information about the product or its handling is being

given.

Symbol:

Meaning: CE mark

The CE mark enables the manufacturer to guarantee that the product complies with the requirements of the relevant EC directives (see Declaration of

Conformity at the end of this document).

Safe operation

Do only quit error messages if the reason for the error has been eliminated

and there is no more danger.

Reconstruction and modifications

NOTE

HBM’s express consent is required for modifications regarding the Clip Electronic construction and safety. HBM does not take responsibility for damage

resulting from unauthorized modifications.

In particular, repair and soldering works on the boards are prohibited. If complete componentry is replaced use original HBM components, only.

Qualified personnel

The device may be used by qualified personnel, only; the technical data and

the special safety regulations must in any case be observed. When using the

device, the legal and safety regulations for the respective application must

also be observed. The same applies if accessories are used.

Qualified personnel means: personnel familiar with the installation, mounting,

start-up and operation of the product, and trained according to their job.

Maintenance and repair work on an open device with the power on should

only be undertaken by trained personnel who are aware of the above-mentioned dangers.

HBM A0114-6.3 en

Page 6

Clip

7

1 Application

The measuring amplifiers are suitable for the measurement of mechanical

quantities such as force, weight, torque, pressure, displacement, strain and

acceleration. Appropriate transducers complying with the international standards can be connected to the measuring amplifiers.

Transducers can be operated in potentially explosive areas, if safety barriers

are used.

The individual CLIP components can be arranged as desired and are wired by

terminals. Switches and potentiometers for adjustment have been provided on

the circuit boards. The accuracy class is 0.1.

The following units are available:

• AE101 (DC), AE301/301S6/301S7 (600 Hz CF), AE501 (4.8 kHz CF),

Measuring amplifier

• GR201 Double limit-value switch

• EM201, EM201K2 Output-stage modules with current output

• NT101A, NT102A Power supply units

• TS101 Automatic Tare and Store Unit

HBMA0114-6.3 en

Page 7

8

Clip

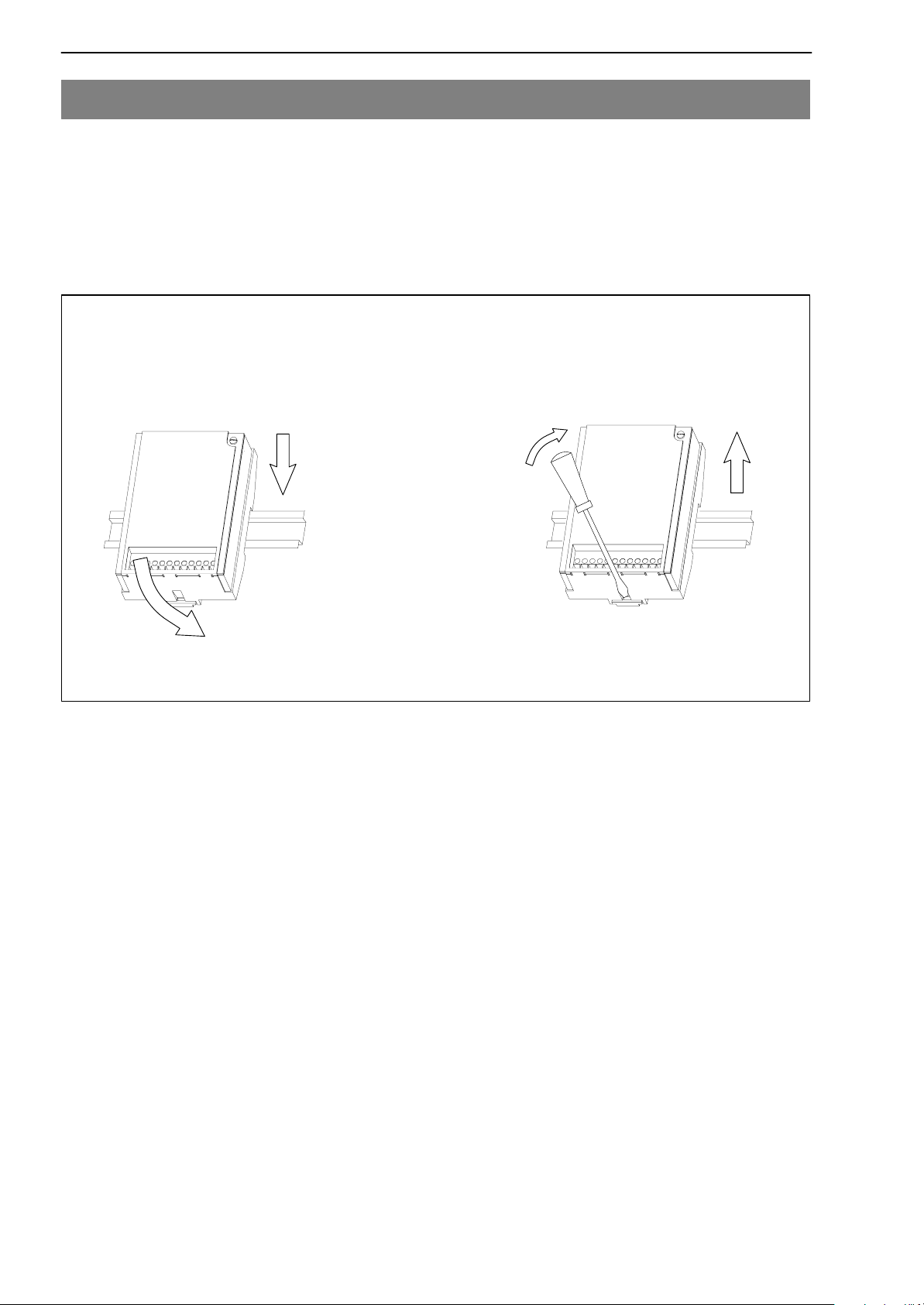

2 Mounting / Dismounting

The housings are installed onto mounting rails to DIN EN 50 022; they are

hooked onto the upper edge and snapped into the spring plate on the lower

edge.

For dismounting, use a screwdriver to push down the spring plate and unhook

the housing.

Mounting Dismounting

Hook in

Mounting rail

Lock

Fig. 2.1: Mounting / Dismounting

HBM A0114-6.3 en

Page 8

Clip

3 Connection

Use the 12-pin terminal strip to connect the transducers, to wire the modules

with each other and to connect the voltage supply. Individual wires can be

2

clamped in a range of 0.13 mm

connected to one terminal, e.g. with internal and external connections, the

conductor cross-sections must be matched accordingly. End sleeves (without

plastics hoop, length: 10 mm) should be used to connect the cores to the terminals. Cores with or without end sleeves must not be tin-plated. When connecting the lines, measures should be taken to prevent electrostatic discharge.

The subsequent figures give the respective connection diagrams that are

printed onto the housing cover.

... 1.5 mm2. If two conductor lines are to be

9

NOTE

The Clip modules have been designed for installation in closed metallic

housings (e. g. control cabinet); they can also be operated without any

additional housings.

The transducer connection lines and the analog signal lines (inputs and

outputs) have to be screened.

At the control cabinet, the screening must lie on a screen rail.

Supply lines and lines connected to the GR201 relay contacts must be

screened if the cable length exceeds 30 m or if the cables are routed outside closed buildings.

NOTE

Only after tightening the clamping screws (ensure good contact) will the

output signal be available on the terminals.

HBMA0114-6.3 en

Page 9

10

3.1 Measuring amplifiers AE101, AE301, AE501

Clip

11 11 11 11 11 11 11 11 11 11 11 11

122’33’4589101112

11 11 11 11 11 11 11 11 11 11 11 11

122’33’4589101112

122’33’4589101112

11 11 11 11 11 11 11 11 11 11 11 11

Fig. 3.1: Measuring-amplifier connections

HBM A0114-6.3 en

Page 10

Clip

Type AE101, AE301, AE501

Terminal Function Color ( HBM - cable)

1 Measuring signal WH (white)

2 Bridge excitation voltage BK (black)

2’ Sensor line GY (grey)

3 Bridge excitation voltage BU (blue)

3’ Sensor line GN (green)

4 Measuring signal RD (red)

5 Screen/Ground YE (yellow)

8 Synchronization (not with AE101)

9 Operating-voltage zero

10 Output voltage

11 Supply voltage zero

12 Supply voltage

Tab. 3.1: Amplifier connection

*)

*)

11

*)

Operating-voltage zero and supply-voltage are internally connected.

Terminal 5 of the Clip amplifier and the transducer’s screen connection should

be grounded (e. g. connected to the screen rail). If the transducers are

installed in a metallic housing with PG glands (e. g. control cabinet or ClipIG),

a large area of the transducer screen must be in contact with the PG gland.

HBMA0114-6.3 en

Page 11

12

3.2 GR201, EM201, EM201K2, TS101 additional units

Clip

11 11 11 11 11 11 11 11 11 11 11 11

123456789101112

11 11 11 11 11 11 11 11 11 11 11 11

123456789101112

123456789101112

11 11 11 11 11 11 11 11 11 11 11 11

Fig. 3.2: Connection of the additional units

HBM A0114-6.3 en

Page 12

Clip

Type GR201 EM201, EM201K2 TS101

Terminal Function

1 Relay 1; Break contact Input 1; Ground*) Input; Ground

2 Relay 1; Make contact Input 1; "10 V Input ; "10 V

3 Relay 1; Center Output 1; Ground*) Output; Ground

13

4 Input 1; Ground Output 1;

"20 mA / 4 ... 20 mA

5 Input 1; "10 V Input 2; Ground*) (only with

EM201K2)

6 Relay 2; Break contact Input 2; "10 V

(only with EM201K2)

7 Relay 2; Make contact Output 2; Ground*) (only with

EM201K2)

8 Relay 2; Center Output 2;

"20 mA /

4 ... 20 mA

(only with EM201K2)

9 Input 2; Ground Ground

10 Input 2; "10 V Ground

11 Supply zero Supply zero

12 Supply voltage Supply voltage Supply voltage

Tab. 3.2: Connection of additional units

Output;

PVCS "10 V

Output;

TAR "10 V

Output;

TAR (24 V DC)

Control; Ground

Control;

Run/Hold

(24 V DC)

*)

Control;

Peak/Clear

(24 V DC)

*)

Control;

TAR (24 V DC)

*)

Supply zero

*)

Ground and supply zero are internally connected. GR201 has differential inputs.

HBMA0114-6.3 en

Page 13

14

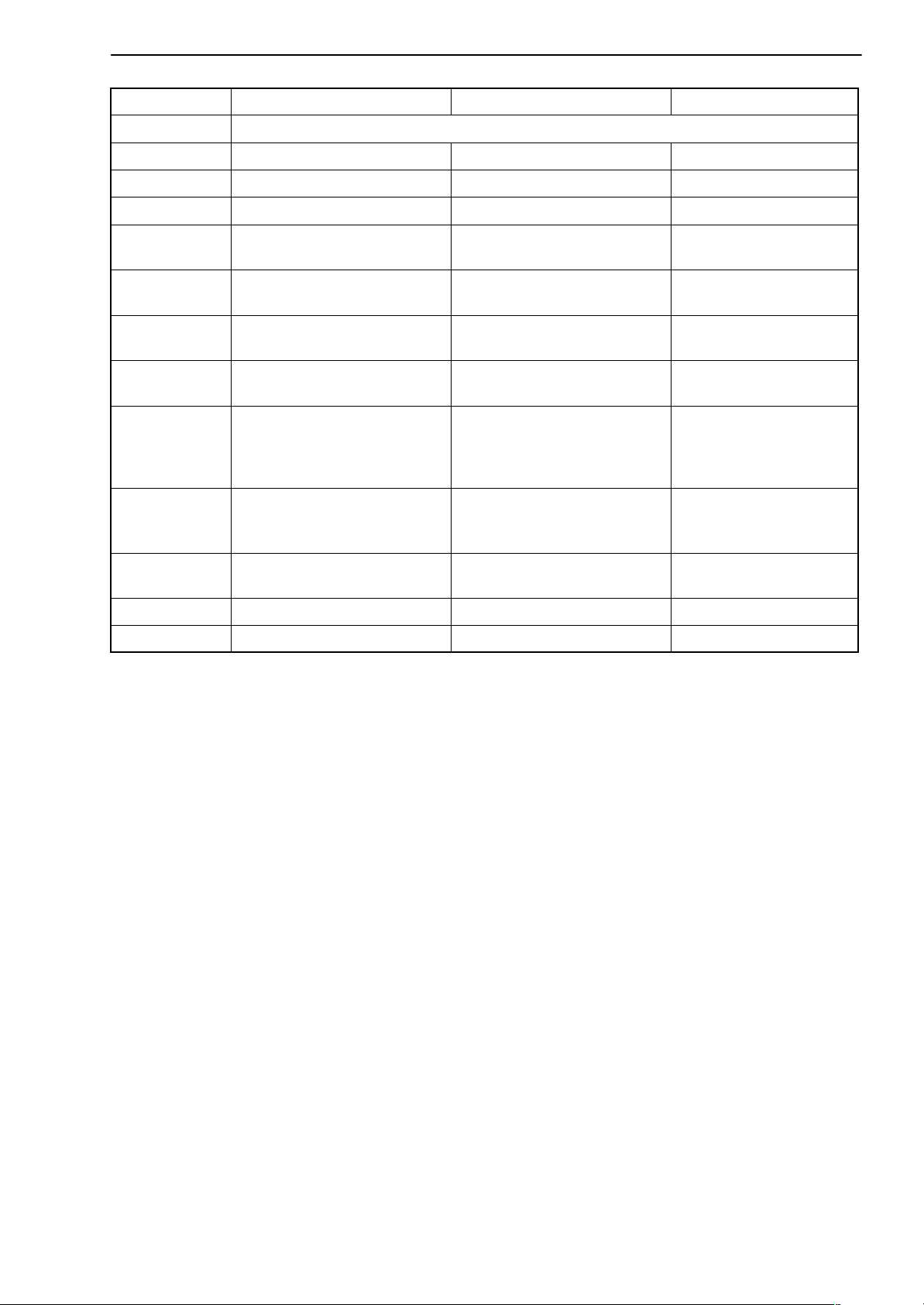

3.3 NT101A, NT102A Power supply

Clip

Fig. 3.3: Connection of the power supply

The mains voltage (230 V for NT101A, 115 V for NT102A) must be connected

to N and L (phase); the protective ground wire must be connected to .

The D.C..-voltage outputs are fed to pairs of internally connected terminals

(0 V and 15 V). The max. output current is 650 mA.

HBM A0114-6.3 en

Page 14

Clip

15

4 Setup

If all cables are connected, proceed as follows:

• Connect transducer cable

• Switch on supply voltage.

• Slacken screw on upper right housing edge and hinge down housing cover.

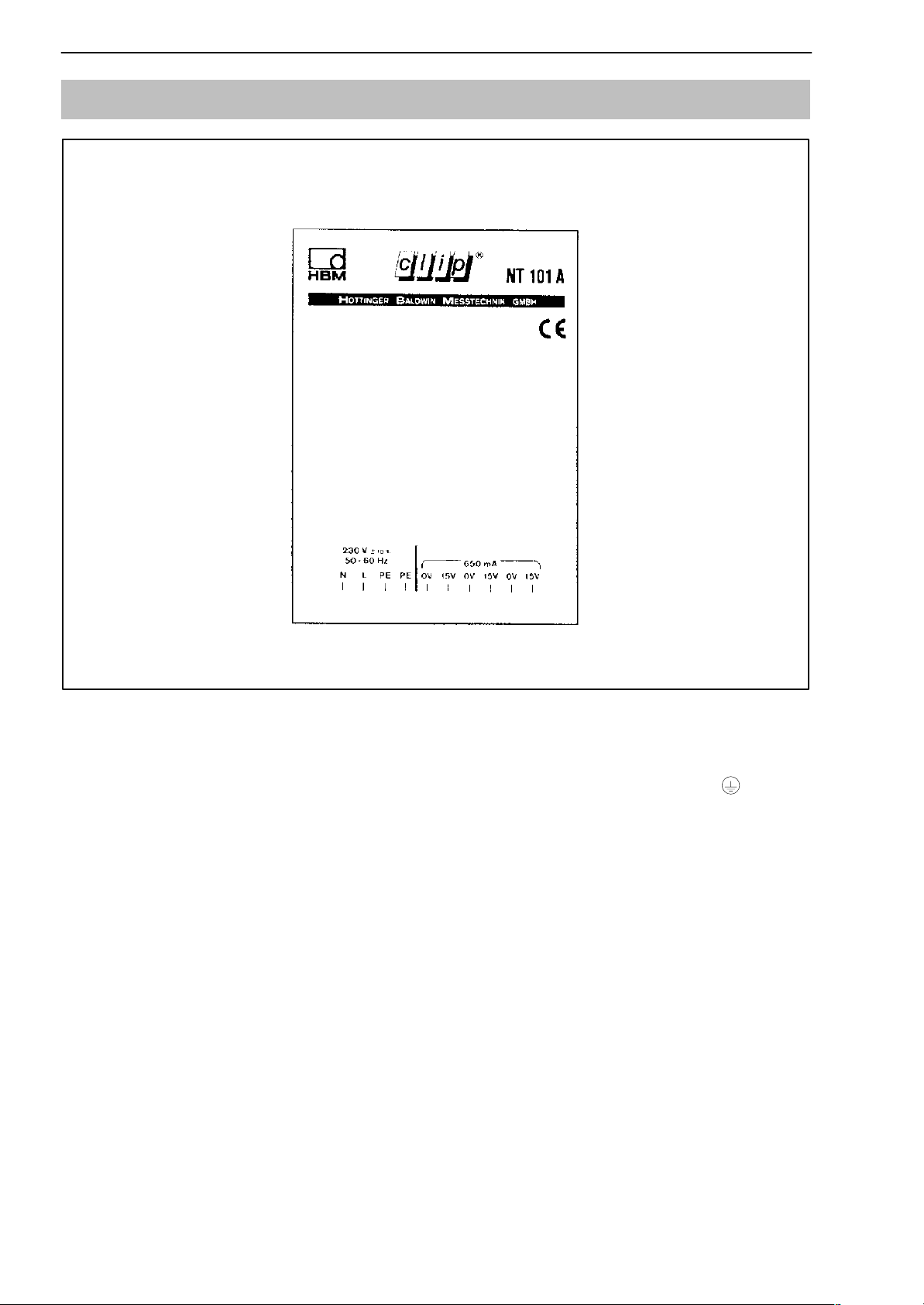

4.1 AE101 Measuring amplifiers

Fig. 4.1: Stick-on label in housing

• Connection method

The standard transducer connection-method is the 6-wire technique (with two

sensor lines). If the transducer is to be connected using a 4-wire circuit, the

terminals 2 and 2’ and 3 and 3’ must be provided with jumper wires.

HBMA0114-6.3 en

Page 15

16

• Bridge excitation voltage

Clip

Use switch S26 to select the bridge excitation voltage V

according to the

E

strain-gauge full-bridge’s resistance RB.

Bridge excitation voltage V

10 V 340 ... 5000 Ω

5 V 170 ... 5000 Ω

2.5 V 85 ... 5000 Ω

E

Transducer resistance R

B

• Measuring frequency range

Use S28 to adjust the measuring frequency range to 10 Hz or 6 kHz.

• Zero point

- Discharge the transducer or charge with preload.

- Use digital voltmeter to measure output voltage, and use rotary switch S23

to adjust minimum indication (if necessary, use S22 to switch polarity); fine

balancing with P21 to 0.000 V.

• Measuring range

To obtain the maximum measurement resolution, the max. amplifier outputvoltage ("10 V) should be used.

AE101

VE = 2.5 V VE = 5 V VE = 10 V switch position S21

mV/V mV/V mV/V 1 2 3 4 5 6 7 8

0.34-0.48 0.17-0.24 0.09-0.12 X X

0.44-0.64 0.22-0.32 0.11-0.16 X X

0.60-0.84 0.30-0.42 0.15-0.21 X X

0.78-1.1 0.39-0.55 0.20-0.28 X X

1.04-1.46 0.52-0.73 0.26-0.37 X X

1.36-1.94 0.68-0.97 0.34-0.49 X X

1.80-2.56 0.90-1.28 0.45-0.64 X X

2.36-3.38 1.18-1.69 0.59-0.85 X X

3.12-4.46 1.56-2.23 0.78-1.12 X X

4.14-5.88 2.07-2.94 1.04-1.47 X X

5.46-7.76 2.73-3.88 1.37-1.94 X X

7.22-10.26 3.61-5.13 1.81-2.57 X X

Tab. 4.1: Nominal measured value depending on the bridge excitation voltage V

HBM A0114-6.3 en

E.

Page 16

Clip

Formula:

17

Part load

Nominal load

•

Measuring range in V

10 V

• Sensitivity in mVńV +

Nominal measurement

value (Range) in

mVńV

Example 1

Force transducer 100 N ¢ 2 mV/V; measuring range wanted 60N ¢ 10 V

60 N

100 N

10 V

•

10 V

• 2mVńV + 1.2 mVńV

Load transducer with 60 N.

Use S21 to select appropriate interval as given in Tab. 4.1 (page 16) (switch

on 4 + 7), and use P22 to adjust the output voltage to 10 V exactly. The measuring range can also be adjusted with no transducer connected by means of

a calibration unit (e.g. K 3607) that simulates the transducer signal.

• Additive calibration signal

The measuring range can also be adjusted using the additive calibration signal (0.2 mV/V).

Example 2

Force transducer 100 N ¢ 2 mV/V; measuring range wanted: 60 N ¢ 10 V

60 N

100 N

10 V

•

10 V

• 2mVńV + 1.2 mVńV

Calculate nominal measurement value, execute zero balance (see above) and

use S21 to select the corresponding measuring-range interval. Connect additive calibration signal (set S25 to CAL) and use P22 to adjust with the transducer under no load. The amplifier has now been calibrated. Adjust S25 to

MEAS.

0.2 mVńV

1.2 mVńV

• 10 V + 1.667 V

HBMA0114-6.3 en

Page 17

18

4.2 AE301 Measuring amplifier

Clip

Fig. 4.2: Stick-on label in housing

• Connection method

The standard transducer connection-method is the 6-wire technique (with two

sensor lines). Cable lengths > 50 m require one resistor each with half the

bridge resistance value (R

/2) to be connected to the sensor line instead of

B

the feedback bridges. If the transducer is to be connected using a 4-wire circuit, the terminals 2 and 2’ and 3 and 3’ must be provided with jumper wires.

• Bridge excitation voltage

Use switch S26 to select the bridge excitation voltage V

according to the

E

strain-gauge full-bridge’s resistance RB.

Bridge excitation voltage V

5 V 170 ... 5000 Ω

2.5 V 85 ... 5000 Ω

E

Transducer resistance R

B

HBM A0114-6.3 en

Page 18

Clip

19

• Measuring frequency range

The measuring frequency range is 10 Hz.

• Zero point

- Discharge the transducer or charge with preload.

- Use digital voltmeter to measure output voltage, and use rotary switch S23

to adjust minimum indication (if necessary, use S22 to switch polarity); fine

balancing with P21 to 0.000 V.

• Measuring range

To obtain the maximum measurement resolution, the max. amplifier outputvoltage ("10 V) should be used.

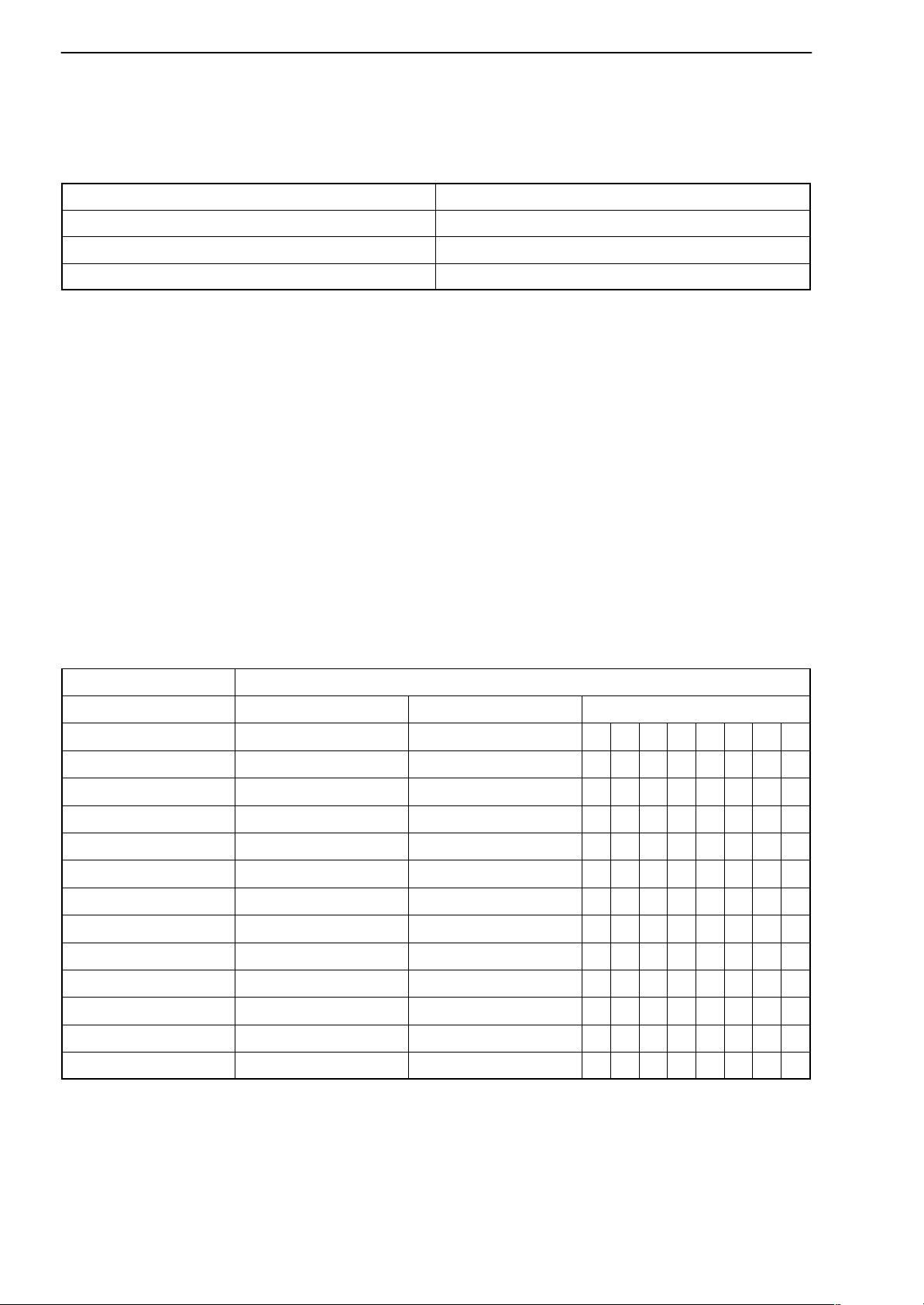

AE301

VE = 2.5 V VE = 5 V switch position S21

mV/V mV/V 1 2 3 4 5 6 7 8

0.34-0.48 0.17-0.24 X X

0.44-0.64 0.22-0.32 X X

0.60-0.84 0.30-0.42 X X

0.78-1.1 0.39-0.55 X X

1.04-1.46 0.52-0.73 X X

1.36-1.94 0.68-0.97 X X

1.80-2.56 0.90-1.28 X X

2.36-3.38 1.18-1.69 X X

3.12-4.46 1.56-2.23 X X

4.14-5.88 2.07-2.94 X X

5.46-7.76 2.73-3.88 X X

7.22-10.26 3.61-5.13 X X

Tab. 4.2: Nominal measured value depending on the bridge excitation voltage V

Factory setting: VE= 5 V; MR = 2 mV/V

E

HBMA0114-6.3 en

Page 19

20

AE301S6

Measuring frequency range: 2 Hz

Calibration signal: 0.1 mV/V

VE=5 V VE=2.5 V switch S21

mV/V mV/V 1 2 3 4 5 6 7 8

0.09-0.12 0.17-0.24 X X

0.11-0.16 0.22-0.32 X X

0.15-0.21 0.30-0.42 X X

0.20-0.28 0.39-0.55 X X

0.26-0.37 0.52-0.73 X X

0.34-0.49 0.68-0.97 X X

0.45-0.64 0.90-1.28 X X

0.59-0.85 1.18-1.69 X X

0.78-1.12 1.56-2.23 X X

1.04-1.47 2.07-2.94 X X

1.37-1.94 2.73-3.88 X X

1.81-2.57 3.61-5.13 X X

Clip

Factory setting: VE= 5 V; MR= 1 mV/V

AE301S7

Measuring frequency range: 60 Hz

Calibration signal: 1 mV/V

VE=5 V VE=2.5 V switch S21

mV/V mV/V 1 2 3 4 5 6 7 8

0.09-0.12 0.17-0.24 X X

0.11-0.16 0.22-0.32 X X

0.15-0.21 0.30-0.42 X X

0.20-0.28 0.39-0.55 X X

0.26-0.37 0.52-0.73 X X

0.34-0.49 0.68-0.97 X X

0.45-0.64 0.90-1.28 X X

0.59-0.85 1.18-1.69 X X

0.78-1.12 1.56-2.23 X X

1.04-1.47 2.07-2.94 X X

1.37-1.94 2.73-3.88 X X

1.81-2.57 3.61-5.13 X X

Factory setting: VE= 5 V; MR= 1 mV/V

Formula:

Part load

Nominal load

HBM A0114-6.3 en

•

Measuring range in V

10 V

• Sensitivity in mVńV +

Nominal measurement

value (Range) in

mVńV

Page 20

Clip

Example 3

Force transducer 100 N ¢ 2 m V/V; measuring range wanted: 60 N ¢ 10 V

21

60 N

100 N

10 V

•

10 V

• 2mVńV + 1.2 mVńV

Load transducer with 60 N.

Use S21 to select appropriate interval as given in Tab. 4.2 (page 19) (switch

on 4 + 7), and use P22 to adjust the output voltage to 10 V exactly. The measuring range can also be adjusted with no transducer connected by means of

a calibration unit (e.g. K 3607) that simulates the transducer signal.

• Additive calibration signal

The measuring range can also be adjusted using the additive calibration signal (0.2 mV/V).

Example 4

Force transducer 100 N ¢ 2mV/V; measuring range wanted: 60 N ¢ 10 V

60 N

100 N

10 V

•

10 V

• 2mVńV + 1.2 mVńV

Calculate nominal measurement value, execute zero balance (see above) and

use S21 to select the corresponding measuring-range interval. Connect additive calibration signal (set S25 to CAL) and use P22 to adjust with the transducer under no load. The amplifier has now been calibrated. Adjust S25 to

MEAS.

0.2 mVńV

1.2 mVńV

• 10 V + 1.667 V

• Synchronization

For synchronization of several CF amplifiers, one master device must be defined by adjusting S24 to MASTER. The other devices must be set to SLAVE

using S24. Then, interconnect terminals 8. Synchronization is also possible

with AE501 measuring amplifiers.

HBMA0114-6.3 en

Page 21

22

4.3 AE501 Measuring amplifier

Clip

Fig. 4.3: Stick-on label in housing

• Connection method

The standard transducer connection-method for inductive halfbridges is the

5-wire technique for inductive fullbridges the 6-wire technique. If the transducer is to be connected using a 3-wire circuit (inductive half bridge) or a

4-wire circuit (inductive full bridge), the terminals 2 and 2’ and 3 and 3’ must

be provided with jumper wires.

• Bridge type

Use switch S27 to select the bridge type (inductive half bridge, inductive full

bridge).

• Bridge excitation voltage

Use switch S26 to select the bridge excitation voltage V

ductance L

of the half-bridge or full-bridge transducer. When using SI01

B

according to the in-

E

safety barriers, the bridge excitation voltage must in any case be adjusted

to 1 V.

HBM A0114-6.3 en

Page 22

Clip

23

Bridge excitation voltage V

2.5 V 2.5 ... 20 mH

1 V 6 ... 19 mH

E

Transducer inductance L

B

• Measuring frequency range

The measuring frequency range is 10 Hz.

• Zero point

- Bring transducer into initial position (e.g. mechanical center position).

- Use digital voltmeter to measure output voltage, and use rotary switch S23

to adjust minimum indication (if necessary, use S22 to switch polarity); fine

balancing with P21 to 0.000 V.

• Measuring range

To obtain the maximum measurement resolution, the max. amplifier outputvoltage ("10 V) should be used.

AE501

VE = 1 V VE = 2.5 V switch position S21

mV/V mV/V 1 2 3 4 5 6 7 8

17.0-24.0 6.8-9.6 X X

22.0-32.0 8.8-12.8 X X

30.0-42.0 12.0-16.8 X X

39.0-55.0 15.6-22.0 X X

52.0-73.0 20.8-29.2 X X

68.0-97.0 27.2-38.8 X X

90.0-128.0 36.0-51.2 X X

118.0-169.0 47.2-67.6 X X

156.0-223.0 62.4-89.2 X X

207.0-292.5 82.8-117.0 X X

272.0-387.5 109.0-155.0 X X

360.0-512.5 144.0-205.0 X X

Tab. 4.3: Nominal displacement depending on the bridge excitation voltage V

E

Formula:

Part load

Nominal load

•

Measuring range in V

10 V

• Sensitivity in mVńV +

Nominal measurement

value (Range) in mVńV

HBMA0114-6.3 en

Page 23

24

Example 5

Displacement transducer, nominal displacement " 20 mm ¢ " 80 mV/V

Measuring range wanted: 16 mm ¢ 10 V

Clip

16 mm

20 mm

•

10 V

10 V

• 80 mVńV + 64 mVńV

Position transducer to 16mm displacement, e.g. using gauge blocks. Use S21

to select the appropriate interval as given in Tab. 4.3 (page 23) (switch on

4 + 8), and use P22 to adjust the output voltage to 10V exactly. The measuring range can also be adjusted with no transducer connected by means of a

calibration unit (e.g. BN 4800) that simulates the transducer signal.

• Additive calibration signal

The measuring range can also be adjusted using the additive calibration signal (8mV/V).

Example 6

Displacement transducer, nominal displacement " 20mm ¢ " 80mV/V;

Measuring range wanted: 16mm ¢ 10V.

16 mm

20 mm

•

10 V

10 V

• 80 mVńV + 64 mVńV

Calculate nominal measurement, execute zero balance (see above) and use

S21 to select the corresponding measuring-range interval. Activate additive

calibration signal (set S25 to CAL) and use P22 to adjust with the transducer

in displaced position. The amplifier has now been calibrated. Adjust S25 to

MEAS.

8mVńV

64 mVńV

• 10 V + 1.250 V

• Synchronization

The maximum number of modules that can be synchronized is 16.

For synchronization of several CF amplifiers, one master device must be de-

fined by adjusting S24 to MASTER; the other devices must be set to SLAVE

using S24. Then, interconnect terminals 8. Synchronization is also possible

with AE301 measuring amplifiers.

HBM A0114-6.3 en

Page 24

Clip

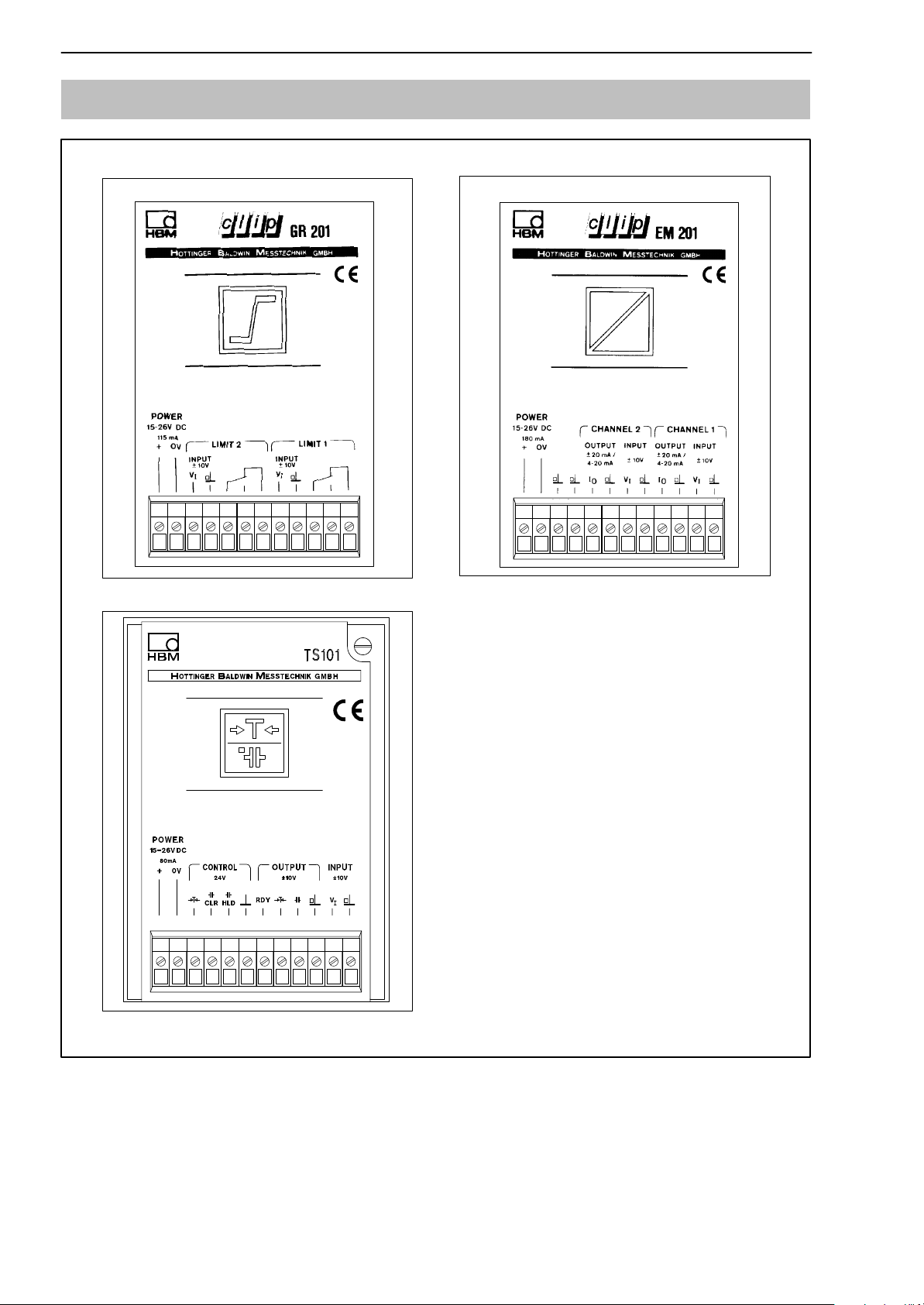

4.4 GR201 Double limit-value switch

M 4

M 3

25

Fig. 4.4: Stick-on label in housing

• Reference voltage

Use the potentiometers P21 (coarse) and P22 (fine) for limit 1 or P23 (coarse)

and P24 (fine) for limit 2 to adjust the relay response point (reference voltages

V

Ref1

and V

). The reference voltages V

Ref2

Ref1

and V

are available at the

Ref2

measuring points M4 (for limit1) and M5 (for limit 2). Connect a digital voltmeter to adjust the reference voltages as follows:

Limit 1 to measuring point M4 and terminal 4

Limit 2 to measuring point M3 and terminal 9

CAUTION

When the amplifier and limit value switch are supplied from several

power supply units their ground connections have to be interconnected.

HBMA0114-6.3 en

Page 25

26

Clip

• Switching direction

There are two possible switching directions.

1. S23/24 and S27/28 in upper position

The make contact (terminal 2 or 7) closes upon exceeding of reference voltage V

teresis voltage V

V

V

Ref

V

Hys

and opens upon falling below reference voltage V

Ref

.

Hys

I

minus the hys-

Ref

Contact

open

Contact

closed

Contact

open

Fig. 4.5: GR201 Switching behavior, S23/24 and S27/28 in upper position

2. S23/24 or S27/28 in lower position

The make contact (terminal 2 or 7) closes upon falling below reference voltage V

teresis voltage V

V

V

Ref

V

Hys

and opens upon exceeding of reference voltage V

Ref

.

Hys

I

plus the hys-

Ref

t

Contact

open

Contact

closed

Contact

open

t

Fig. 4.6: GR201 Switching behavior, S23/24 and S27/28 in lower position

HBM A0114-6.3 en

Page 26

Clip

NOTE

Under normal operating conditions, the relays switch as described at

V

or V

Ref

- V

Hys

or V

before V

switching states are always unambiguous.

• Changing the hysteresis voltage

The hysteresis voltage is 220 mV. It can be varied by changing R43 resp.

R48. The following applies:

respectively. With signal levels in the hysteresis range (V

Hys

Ref

Hys

or V

- V

), EMC influences may cause the relays to switch

Ref

has been reached. Outside the hysteresis range the

Hys

27

Ref

R43 (R48) +

670 mV

[mV]

V

Hys

kΩ

• Changing the response and releasing times

, t

The response/releasing time (t

rise

) is less than 5ms. It can be varied by

fall

changing C31a/C34a and C27/C28 (max. 6.8µF). The capacitor’s dielectric

strength must be ≥35 V. The following applies:

• C31a (C34a)

) 3ms

µF

• C31a (C34a)

) 3ms

µF

t

t

fall

rise

18 ms

+

710 ms

+

w Changing the releasing time only

Change C27 (C28) to vary the relay releasing times (max. 47µF). The follow-

ing applies:

• C27 (C28)

) 3ms

µF

HBMA0114-6.3 en

t

fall

6ms

+

Page 27

28

4.5 EM201 / EM201K2 Output stage

Clip

Fig. 4.7: Stick-on label in housing

The EM201 Output stage has been equipped with one EM002 module, the

EM201K2 Output stage has been equipped with two EM002 modules. The

EM002 module converts the amplifier output-voltage into a proportional current signal. For both versions the same housing has been used. Depending

on the switch positions, the following current outputs are available:

• "20 mA current output

S21/22 (S25/26) in upper position

S23 (S27) in lower position

S24 (S28) in OFF position

• 4 ... 20 mA current output

S21/22 (S25/26) in upper position

S23 (S27) in upper position

S24 (S28) in ON/OFF position

HBM A0114-6.3 en

Page 28

Clip

29

With S24 (S28) ON, the minimum output current is 3 mA. Even with negative

input voltages, this value will not be fallen below. Consequently, a following

device that monitors an interruption of cable, for example, will not respond erroneously, or an externally supplied following device will be supplied continuously.

• Gain

Use P22 (P23) to adjust the gain for both output stages in the range

of 0.9 ... 1.1 Instead of the EM002 module, the EM001 module can also be

used. It makes available an additional "10 V/20 mA voltage output. A separate zero balance is also possible.

• Zero balance

Since a zero balance is not provided in the EM002 module, the zero point has

to be adjust on the amplifier.

HBMA0114-6.3 en

Page 29

30

Clip

5 TS101 Automatic tare and store unit

5.1 General

The TS101 automatic tare and store unit is an additional Clip electronics module for further signal processing. The TS101 enables signals supplied by an

amplifier connected in series to be tared and stored.

5.2 Function

The TS101 enables the below functions to be activated at the same time:

D tare and save a current value or a peak value (Minimum value or maximum

value or peak-to-peak-value or envelope curve)

or

D save minimum value and maximum value (no taring)

5.2.1 Taring

Use the ”Tare” control input (terminal 10) to start taring. To ensure correct acquisition of the tare value even in the case of unstable input signals, an adjustable low-pass can be used to filter the tare unit’s input signal. In addition,

the net signal can be amplified.

Input

"10 V

Supply

15 ... 30 V DC

Output ("10 V)

Tare

or peak value

(max.)

Output ("10 V)

Peak value

(min, max,

peak-to-peak,

envelope curve)

RDY

Valid tare

0V

24 VDC (15...30 V)

Clear/Peak TareRun/Hold

Control inputs

Fig. 5.1: Block diagram

HBM A0114-6.3 en

Page 30

Clip

31

5.2.2 Store unit

Upon storage, you can select as input signal for the store unit either the amplifier signal (gross signal) or the tare unit’s output signal (net signal, not amplified). The selected input signal as well can be filtered and amplified. Use terminals 8 and 9 to control the store unit’s operating mode (current value/peak

value) and the Run/Hold function. With the ”High” level the control output

(RDY) signals a valid tare value.

• Current value operating-mode

When the store unit is used to acquire current values, the store contents is

permanently kept up to date (”Run” function). Use the ”Hold” control contact to

hold the store contents; then, the value is present at the output as an analog

signal.

NOTE

With the ”Run” function, the TS101 output signal does correspond to the

amplifier’s output signal up to a frequency of 15 Hz.

Meas. signal

o

TS101 output

Run Run

t

Hold

Current value

Function

Operating mode

V

, V

i

Fig. 5.2: Current value operating-mode (Clear)

HBMA0114-6.3 en

Page 31

32

Peak value operating-mode

The peak value operating-mode enables the below values to be acquired:

• minimum value or

• maximum value or

• peak-to-peak values

Use the ”Hold” control contact to hold the store contents.

Store contents

TS101 output

Vi, V

o

Clip

t

Function

Operating

mode

Peak value

HoldRun Run

Hold

Current value

Fig. 5.3: Peak values operating-mode (PEAK)

Upon acquisition of peak values, enabling and adjusting the discharge rate

enables an envelope-curve function to be prepared (Fig. 5.4 and Fig. 5.5). By

adjusting the discharge rate you determine the speed of linear discharging of

the peak-value store to the current value.

Discharge rate: too highDischarge rate: too lowDischarge rate: correct

Fig. 5.4: Envelope-curve function

HBM A0114-6.3 en

Page 32

Clip

V

, V

i

o

Discharge rate=0 V/s

Discharge rate=1 V/s

t

Fig. 5.5: Adjusting the discharge rate

5.3 Connection

Before starting up the device, read the safety instructions on page 4.

33

12 series terminals for wire diameters from 0.13 ... 1.5 mm (10 mm end

sleeves for strands) are used to connect the TS101.

1

11121111111011911811711611511411311211

Voltage

supply

inputs

Fig. 5.6: TS101 connection terminals

InputOutputsControl

HBMA0114-6.3 en

Page 33

34

Clip

Terminal

1 Operating-voltage zero

2 Input voltage "10 V

3 Operating-voltage zero

4 Peak-value store output-voltage "10 V

5 Tare unit output-voltage "10 V

6 Control output: valid tare (24 V DC)

7 Ground (external for control inputs)

8 Run/Hold peak-value store (24 V DC) control input

9 Peak/Clear peak-value store (24 V DC control input)

10 Tare (24 V DC control input)

11 Supply voltage 0 V

12 Supply voltage 15 ... 30 V DC (unregulated)

Function

Tab. 5.1: Terminal assignment

5.3.1 Voltage supply

The automatic tare and store unit must be supplied with an external supply

voltage of 15 V to 30 V. Terminals 11 and 12 are used for connection.

5.3.2 Inputs / Outputs

Inputs

Connect to terminals 1 and 2 the output signal supplied by the amplifier connected in series.

Outputs

The TS101 output signals can be picked up at terminal 4 (peak value) and terminal 5 (net value). They can be used as the input signal for an indicator (load

resistance >5 kΩ) as shown in Fig. 5.7.

NOTE

Screened cable should be used for the analog input and output signals

to ensure proper functioning even if the components are exposed to

high EMC-levels.

5.3.3 Control inputs / Control output

The control inputs (terminals 7 ... 1 0) are electrically isolated from the processor. They must be connected to an external ground (e.g. PLC) and 24 V (as

control signal).

HBM A0114-6.3 en

Page 34

Clip

35

Open control contacts correspond to the ”Low” state (”Peak values” operating

mode; ”Run” function).

The RDY control output (terminal 6) signals a valid tare value. The signal level

corresponds to the level of the supplied voltage (15 ... 26 V).

Fig. 5.7 shows the connections required for TS101 operation. For the terminal

assignment refer to table Tab. 5.1.

1234567891011122’3’ 124589101112 3

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

Output

"10 V/5 kΩ

Fig. 5.7: TS101 connection (example)

HBMA0114-6.3 en

Page 35

36

S100/6

5.4 Adjustment

5.4.1 Factory setup

See below for the automatic tare and store unit’s factory setup:

Tare unit: Tare value will not be stored upon power failure

Low-pass filter active (0.4 Hz ... 12.5 Hz)

Amplification v=1

Store unit: Peak-value store (maximum value) on

Low-pass filter off

Amplification v=1

Envelope curve off

Clip

5.4.2 Tare unit adjustment

Taring is started when the voltage level on terminal 10 changes over from 0 V

to 24 V (positive edge). The tare value is held during voltage supply, even if

the voltage level goes down to 0 V again (also refer to next chapter).

NOTE

Taring with input voltages greater than "10.5 V is not possible due to

amplifier overflow. A valid tare value (<10.5 V) is signalled by an LED on

the board and the ”High” voltage level on terminal 6.

• Save tare value and protect it from power failure

The tare value can be stored for reuse after a power failure or after power-off.

For this, set switch S100/6 to ”ON” position before taring.

Switch Switch position Effect

OFF Tare value will be lost upon power-off

ON Tare value will be permanently stored in EEPROM

*)

Factory setup

HBM A0114-6.3 en

*)

Page 36

Clip

37

• Signal amplification

The net signal can be amplified to obtain a sufficiently high resolution even

with measurement tasks with great initial load. Use switch S101 to adjust the

amplification in four steps:

S101/2 S101/3 S101/4 S101/5 Amplification

ON OFF OFF OFF v=1

OFF ON OFF OFF v=2

OFF OFF ON OFF v=5

OFF OFF OFF ON v=10

Example

A load cell with 10 kg nominal load is used with an initial load of 4 kg. The

mass to be weighed is 1 kg.

To avoid amplifier overload the amplifier’s measuring range must be adjusted

to maximum signal (here 5 kg=10 V output voltage). The automatic tare unit

connected in series is used to tare the initial load (4 kg=8 V). The remaining

residual signal of 1 kg corresponds to an output voltage of 2 V. Subsequent

amplification by factor 5 enables the residual signal to be raised to 10 V.

• Low-pass filter adjustment

Use switch S100/5 to activate the filter for the automatic tare unit, only, or also

for the peak-value store. Upon taring, the low-pass filter influences the input

signal. However, it has no effect on the tare output’s bandwidth.

S100/5 Position P1 (cutoff frequency) Influences

OFF

ON

Tab. 5.2: Low-pass filter

5 Hz

12.5 Hz

0.4 Hz

1.7 Hz

3.1 Hz

0.1 Hz

tare unit

tare and

store unit

HBMA0114-6.3 en

Page 37

38

8

9

Clip

Procedure

− Set switch S100/7 to ”OFF” position

− To activate the filter for the peak value as well, set switch S100/5 to

”ON”position

− Push and hold switch S6 and turn potentiometer P1. Refer to Tab. 5.2 for

the cutoff frequency and the appropriate potentiometer position.

NOTE

The filter frequencies for taring and peak value always bear a constant

relationship and cannot be adjusted independently of each other.

5.4.3 Store unit adjustment

• Adjust operating mode

Use the signal levels on terminals 8 and 9 to select the operating mode (current value/peak value) and the Run/Hold function.

Terminal Level Function Effect

High Run Store contents is permanently kept up to date

Low Hold Store contents is held

High Peak Peak value operating-mode

Low Reset Current value operating-mode

High=24 V; Low=0 V

NOTE

The peak-value store is cleared by switching from the peak value operating-mode to current value.

HBM A0114-6.3 en

Page 38

Clip

• Select peak value and amplification

Use the switches S100/1... 4 and S101/1 to define the type of peak value to

be stored (min/max, peak-peak) and the amplification.

S101/1 S100/1 S100/2 S100/3 S100/4 Function

ON OFF OFF OFF OFF Peak value minimum

ON ON OFF OFF OFF Peak value maximum

ON OFF ON OFF OFF Peak-to-peak

ON ON ON OFF OFF (Peak-to-peak) x 0.5

ON OFF OFF ON OFF Tared minimum value (v=1)

ON ON OFF ON OFF Tared maximum value (v=1)

ON OFF ON ON OFF Tared minimum value (v=2)

ON ON ON ON OFF Tared maximum value (v=2)

ON OFF OFF OFF ON Tared minimum value (v=5)

ON ON OFF OFF ON Tared maximum value (v=5)

ON OFF ON OFF ON Tared minimum value (v=10)

ON ON ON OFF ON Tared maximum value (v=10)

OFF OFF OFF ON ON Minimum value (peak-value output)

and maximum value (tare output)

*)

39

Tab. 5.3: Adjust peak value and amplification

*)

Factory setup

NOTE

With the minimum and maximum value setup selected, no taring is possible due to the fact that the tare output is used for output of the maximum value. Please make sure that for the maximum value (tare output)

amplification v=1 has been adjusted (switches S101/2...5, see page 37).

• Adjust envelope curve

Use switch S100/7 and potentiometer P1 to adjust the envelope curve operating-mode.

Procedure:

− First make sure that the ”Peak value” operating mode has been adjusted

(see page 38).

− Make sure that the type of peak value to be stored has been adjusted (see

Tab. 5.3).

− Set switch S100/7 to ”ON” position.

− Push and hold switch S6 and turn potentiometer P1.

HBMA0114-6.3 en

Page 39

40

Clip

Refer to Tab. 5.4 for the discharge rate and the appropriate potentiometer

position. For more precise acquisition of the change in discharge rate use an

oscilloscope.

Switch S100/7 P1 Envelope-curve function

ON At right-hand stop Off

Discharge rate 0.005...1 V/s

ON

OFF No effect Off

Turn anticlockwise

from right-hand stop

0.5 V/s

1 V/s

0.005 V/s

0 V/s

Tab. 5.4: Envelope-curve adjustment

• Low-pass filter

It is possible to filter the peak-value store’s input signal. Refer to Tab. 5.2,

page 37 for the required setups. Please remember that the filter frequencies

cannot be adjusted independently of each other because they bear a constant

relationship.

5.5 Zero-point balance

A zero-point balance has been made at the factory. Should the output signals

for tare unit and store unit vary from zero, it is possible to correct them. Use

switches S100/1... 4 and S101/1 to define the output to be corrected.

S101/1 S100/1 S100/2 S100/3 S100/4 Function

ON ON OFF ON ON Tare output (terminal 5)

ON OFF ON ON ON Peak-value output (terminal 4)

Procedure

− Push and hold key S6.

− Use potentiometer Pl to adjust the zero point.

Should the balancing range available not be sufficient:

− Release key S6.

− Turn potentiometer to initial position.

− Restart the balancing procedure.

HBM A0114-6.3 en

Page 40

Clip

5.6 Component position diagram

S6

LED

41

S10

0

P1

11121111111011911811711611511411311211

Fig. 5.8: TS101 tare and store unit

S10

1

1

HBMA0114-6.3 en

Page 41

42

Clip

6 Safety barriers

Connect HBM safety barriers to obtain intrinsically safe measuring circuits

[EEx ia] IIC. A test certificate is required for transducers used in such applications.

Measuring amplifier Safety barrier

AE101 SD01A

AE301 SD01A

Due to the safety barriers’ high internal resistance, the bridge excitation voltage V

transducer inductance LB respectively. Refer to the below table to obtain the

minimum permissible transducer resistance.

must be reduced according to the transducer resistance RB or the

E

Measuring amplifier V

AE101 10 V not permissible

AE301 5 V 320 Ω

*)

With longer cables the supply-line resistance must be added.

E

5 V 320 Ω

2.5 V 130 Ω

2.5 V 130 Ω

R

(minimum)

B

*)

, L

B

7 CLIP IG

For use in industrial environments, the CLIP modules can be installed in an

aluminium-die-cast wall housing. The degree of protection is IP65. The housing enables max. 4 modules incl. power supply unit to be inserted; it is also

possible to insert two measuring amplifiers with safety barriers.

The wall-housing version is particularly suitable for rough environments. It is

protected from electromagnetic interference in the surroundings.

The CLIP IG devices are mounted at the factory and wired internally.

All combinations are available on request.

Attached to CLIP IG devices accessory bags 2-9278.0339 are delivered including a standard set of earthing bushes, end sleeves for strands (0.5 mm

2

,

10mm long) and non-buckling bushes that fit HBM cables of type

2

KAB8/00-2/2/2 (6 x 0.14 mm

Order No. 4-3301.0082, blue (6 x 0.14 mm

4-3301.0071, gray (6 x 0.14 mm

HBM A0114-6.3 en

) or

2

) or

2

)

Page 42

Clip

8 Dimensions

AE101

AE301

AE501

EM201

EM201K2

GR201

TS101

77

111.3

112.9

35

43

42

15

110.1

NT101A

NT102A

113.5

102

69

53

56

10.5

10

37

HBMA0114-6.3 en

Page 43

44

Clip

100

hole pattern for screw / 6

Clip IG

HBM A0114-6.3 en

Weight of housing: 3.2kg

Page 44

Clip

9 Specifications

Clip IG

Type of protection IP65

Wight approx. kg 4.3

Wight (empty) kg 3.2

Ambient temperature °C -20 ... +50

Operating voltage

with Power supply unit 101A (Type WG 010)

with Power supply unit NT 102A (Type WG 011)

without Power supply unit (Type WG 012)

Mechanical strain

(examination similar DIN IEC 68)

Oscillate (30 min each direction)

Impact

(3 times each direction, impact duration 6ms)

V

V

V DC

m/s

m/s

2

2

230 "10 %

115 "10 %

15 ... 30

50 (5 ... 65 Hz)

350

45

HBMA0114-6.3 en

Page 45

46

AE101, AE 301, AE501 Measuring amplifiers

Type AE101 AE301 AE501

Accuracy class 0.1 0.1 0.1

Transducers that may be connected

strain gauge full bridge

V

E

V

E

V

E

=10 V

= 5 V

=2.5 V

Ω

Ω

Ω

Inductive half/full bridge

=5 V

V

E

=2.5 V

V

E

V

=1 V

E

Bridge excitation voltage VE (symmetrical)

mH

mH

mH

V

V

V

Permissible cable length

between transducer and amplifier

m 500

Carrier frequency Hz DC 600 4800

Bridge zero balance

coarse approx.

fine approx.

mV/V

mV/V

Measuring ranges

V

E

V

E

V

E

V

E

=10 V

= 5 V

= 2.5 V

= 1 V

mV/V

mV/V

mV/V

mV/V

Calibration signal, in addition to the

meas. signal

mV/V + 0.2 " 1 % + 0.2 " 1 % + 8 " 1 %

Input impedance MΩ >10 / 2 nF > 1 / 3 nF > 1 / 1.5 nF

Common mode voltage. max. perm. Vpp " 10 V " 5V

Common mode rejection

0... 300 Hz

> 300 Hz

dB

dB

Linearity deviation % full

scale

Output voltage

Slew rate. max.

V

V/µs

Load resistance kΩ ≥ 4

Internal resistance Ω < 2

1)

AE301S6 and AE301S7: 0.1...2

2)

AE301S6 and AE301S7: 0.2...4

3)

AE301S6 and AE301S7: 0.2...4

340 ... 5000

170 ... 5000

85 ... 5000

-

-

-

10

5

2.5

" 2

" 0.08

0.1 ... 2

0.2 ... 4

0.4 ... 8

-

> 100

>85

typ 0.03

" 10

0.4

170 ... 5000

< 0.05

-

85 ... 5000

-

-

-

5

2.5

-

" 1

" 0.05

-

0.2 ... 4

0.4 ... 8

1)

2)

-

-

-

-

5 ... 20

2.5 ... 20

1 ... 20

2.5

1

-

" 80

" 3.2

-

-

8 ... 160

20 ... 400

> 100

< 0.1

typ 0.05

" 10

-

Clip

HBM A0114-6.3 en

Page 46

Clip

Technical data continued

Type AE101 AE301 AE501

Measuring frequency range

3rd-order changeover low-pass filter. Bessel (-1 dB)

3rd-orderlow-pass filter Bessel(-1 dB)

Hz

kHz

Hz

Phase velocity

with 0...10 Hz filter

with 0...6 kHz filter

ms

µs

Rise time with 0...10 Hz filter ms 25

Overshoot in the case of voltage surge

with 0 ... 10 Hz filter

with 0 ... 6 kHz filter

%

%

Noise voltage

measuring range 0.2 mV/V (10 Hz)

measuring range 2 mV/V (10 Hz)

measuring range 1 mV/V (10 Hz)

measuring range 10 mV/V (10 Hz)

measuring range 8 mV/V (10 Hz)

measuring range 80 mV/V (10 Hz)

measuring range 0.2 mV/V (6 kHz)

measuring range 2 mV/V (6 kHz)

mV

mV

mV

mV

mV

mV

mV

mV

rms

rms

rms

rms

rms

rms

rms

rms

Long term drift over 48 hours (after 1 h

warm-up time)

µV/V

Effect of a 10 K-change in ambient temperature

on sensitivity

% full

scale

on zero point

measuring range 0.2 mV/V

measuring range 2 mV/V

meas. range 8 mV/V (1 mV/V)

meas. range 80 mV/V(10 mV/V)

mV

mV

mV

mV

Effect of a +15 ... 30 V change in operating voltage

on sensitivity

zero point (350 Ω bridge resistance)

mV

mV

5V-synchronization (square wave) kHz - 76.8

Residual carrier voltage mV - < 5

Operating voltage (DC) V +15 ... 30

Power consumption mA ≤ 125 ≤ 100

Nominal temperature range °C -20 ... +60

Service temperature range °C -20 ... +60

Storage temperature range °C -25 ... +70

Degree of protection IP20

Weight g 200

3)

AE301S6: 0...2 (-1dB)

AE301S7: 0...60 (-1dB)

4)

AE301S6: <80 (filter frequency 2 Hz)

AE301S7: <2,8 (filter frequency 60 Hz)

5)

Rise time with AE301S7 6 ms

Rise time with AE301S6 200 ms

0 ... 10

0 ... 6

-

< 18

< 20

0

<10

< 4

< 4

-

-

-

-

< 30

< 6

< 0.2

< 0.1

typ 0.05

< 60

< 10

-

-

-

-

0 ... 10

4)

< 16

-

5)

< 4

< 4

-

-

-

-

-

-

< 0.1

< 0.1

typ 0.05

< 10

< 4

-

-

< 1

< 1

-

-

3)

0 ... 10

< 17

-

<2

-

-

-

-

< 4

< 4

-

-

< 0.8

< 0.1

typ 0.05

-

-

<10

< 4

47

HBMA0114-6.3 en

Page 47

48

GR201 Limit value switch

Accuracy class 0.1

Differential input

Voltage

Impedance

Reference voltage

coarse approx.

fine approx.

V

kΩ

V

V

" 10

> 50

" 10

" 0.5

Clip

Switching hysteresis

Factory setting: R43, R48

to be changed by R43 and R48

Influence of a 10K-change in ambient temperature on the switching point

Switching-point error % < 0.05 full scale

Relay capacity

max. voltage

max. current

max. power

Switching times (Factory setting)

Response time

Releasing time

Use C31a. C34a to change the response or

releasing time

Response time

Releasing time

Use C27. C28 to change the releasing time

only

Releasing time

mV

kΩ

kΩ

% < 0.05 full scale

V

A

W

ms

ms

ms

ms

ms

45 (Protective low voltage)

18 . C31a (C34a) +3

710

220

3.01

670 mV

V

Hyst.

1

30 (25 VA)

< 5

< 5

µF

.

C31a (34a) +3

µF

.

C27 (C28) +3

6

µF

Operating voltage V DC +15 ... 30

Power consumption mA < 100 (20 mA no relay closed)

Nominal temperature range °C - 20 ... + 60

Service temperature range °C - 20 ... + 60

Storage temperature range °C - 25 ... + 70

Degree of protection IP20

Weight g 200

HBM A0114-6.3 en

Page 48

Clip

EM201 Output stage module (with one module EM002)

EM201K2 Output stage module (with two modules EM002)

Accuracy class 0.1

Input

Voltage

Impedance

V

kΩ

Operating voltage V DC +15 ... 30

Power consumption

(fully assembled with 2 x EM002)

mA < 180

" 10 (0 ... + 10 V)

> 11.5

49

Nominal temperature range

Service temperature range

C - 20 ... + 60

°

C - 20 ... + 60

°

Storage temperature range °C - 25 ... + 75

Weight g 200

EM002

Output signal. selectable mA " 20 4 ... 20

Output current

with V

with V

=10 V

E

= 0 V

E

mA

mA

20 " 0.02

< " 0.04

20 " 0.5

4 " 0.2

Output current limit - - > 3 (switchable)

Permissible load resistance Ω < 500

Linearity deviation % full scale < 0.05

Internal resistance kΩ > 100

Measuring frequency range kHz 3 (-1 dB)

Degree of protection IP20

NT 101A, NT 102A*) power supply

Type NT101A NT102A

Input voltage V 230 "10 % 115 " 10 %

Permissible frequency range Hz 47 ... 63

Output voltage V

Output current at >25° ... +60° A

DC

DC

15.3" 2 %

0.4

Output power W 6.75

Efficiency approx. % 60

Current limiter (protected against sustained

1.2 x

(permanently adjusted)

I

n

short circuit) at

Residual ripple mV

Maximum permissible cable length between

m 3

pp

< 10

NT101A or NT102A and Clip module

Ambient temperature

Excess-temperature protection

Test voltage kV

°

C - 20 ... + 60

C typ.105 (trafo temperature)

°

eff

3.75 (prim/sec and prim/housing)

Degree of protection IP20

Weight g 420

*)

Version to DIN -VDE0551, EN60742 Protection class 1.

The maximum permissible continuous current is 450 mA.

HBMA0114-6.3 en

Page 49

50

TS101 tare and store unit

Accuracy class 0.1

Input voltage V "10

Input impedance kΩ 100

Output voltage V " 10

Permissible load resistance kΩ ≥5

Linearity deviation % < 0.04 of full scale

Effect of a 10 K-change of the ambient

temperature

Effect of a 15 ... 26 V-change of the operating voltage

Long-term drift over 48 h (after 1 hour

warm-up time)

Noise voltage of the output mV

Control inputs (floating)

High signal level

Low signal level

Control output

High signal level

Low signal level

Output current mA <500

% < 0.1 of full scale

% < 0.01 of full scale

% < 0.02 of full scale

pp

V

V

V

V

11...30 (24 V nominal)

< 20

0 ... 5

Vb-2

<1

Clip

Tare unit

Output ms Net value (alternatively pos. peak val.)

Net-value amplification 1, 2, 5, 10-fold, selectable in steps, for tar-

ing of major initial loads

Tare error (with v=1) mV <4

transient time for the output voltage

after taring

Low-pass filter (before taring) Hz 0.1 ... 12.5; adjustable

Transmission bandwidth kHz >10

Storage time for tare value Unlimited as long as V

Control input Taring with rising edge

Delay time for taring ms <1

Control output Valid taring

ms 40 (to 99.9 %)

is present (alterna-

tively, storage in EEPROM)

b

HBM A0114-6.3 en

Page 50

Clip

Technical data continued

Peak-value store unit

Output Peak value (alternatively, pos./neg. peak,

peak/peak 0.5 x peak/peak or current

value or envelope-curve value, tared and

amplified (1, 2, 5, 10-fold))

Peak-value store update-rate ms <1.3

51

Accuracy %

%

Transmission bandwidth Hz 15 (-1 dB)

Transient time for the output voltage ms 40 (to 99.9 %)

Discharge rate for envelope curve mV/s 5 ... 1000, adjustable

Control inputs Run/Hold;

Delay time for the control signals ms <8

Connection 12 series terminals for

wire ∅ 0.13 ... 1.5 mm2; 10 mm end

Operating voltage V

Power consumption mA <90

Nominal temperature range °C -20 to +60

Service temperature range °C -20 to + 60

Storage temperature range °C - 25 to +70

Weight g ca. 200

Protection to EN60529 IP20

Mounting On mounting rails to EN 50022

b

V DC 15...30, unstabilized

0.25 (in 6 ms)

0.05 (in 20 ms)

(clear/peak)

sleeves for strands

10 Accessories

To be ordered separately:

• Brackets 3-6450.0001

HBMA0114-6.3 en

Loading...

Loading...