Page 1

Operating instructions

Digital TransducerElectronics

AD104-R2,

AD104-R5

Page 2

Contents Page

Safety notes ..........................................................................................................................................2

1 Intended use................................................................................................................................3

2 Characteristic features ...............................................................................................................3

3 Mechanical construction ............................................................................................................4

4 Electrical construction ...............................................................................................................5

4.1 Function ...............................................................................................................................5

4.2 Signal processing ................................................................................................................6

Electrical connection ...........................................................................................................................8

5.1 Transducer Connection .....................................................................................................10

5.2 Serial Interface RS-232 (only AD104-R2).......................................................................... 10

5.3 Serial Interface RS485 (Bus mode with AD104-R5) .........................................................11

6 Command set ............................................................................................................................14

6.1 Command format ...............................................................................................................14

6.2 Answers to commands ......................................................................................................15

6.3 Output types for the measured values............................................................................... 15

6.4 Command overview ...........................................................................................................16

7 Individual descriptions of the commands .............................................................................. 17

7.1 Interface commands (asynchronous, serial)...................................................................... 17

7.2 Adjustment and scaling......................................................................................................27

7.3 Measuring ..........................................................................................................................35

7.4 Special functions................................................................................................................47

7.5 Error messages .................................................................................................................62

7.6 Bus termination for RS-485 version................................................................................... 63

7.7 Commands for Legal for trade Applications....................................................................... 64

7.8 Further commands.............................................................................................................67

7.9 Examples of communication.............................................................................................. 68

8 Technical data ...........................................................................................................................72

Page 3

2 / 75

Safety notes

• In the normal case the product causes no dangers, provided the notes and instructions for configuring,

installation, operation as intended and maintanance are complied with.

• The safety and accident prevention regulations applicable corresponding to the application must be

observed without fail.

• Installation and commissioning may be performed exclusively by qualified personell.

• Avoid the penetration of dirt and moisture into the interior of the unit when connecting the cables.

• When connecting the cables take measures against electrostatic discharges which can damage the

electronic unit.

• An extra low voltage with safe isolation from the mains is required for the power supply of the unit.

• When connecting additional devices, the safety regulations according to EN610101) must be complied with.

• Shielded cables are required for all connections. The shield must be connected flatly with ground at both

ends.

1) "Safety regulations for electrical measuring, control and laboratory equipment”

ba_aed104_8_e.doc

Page 4

AD104-R2, AD104-R5 3 / 75

1 Intended use

The digital sensor electronic units AD104 belong to the family of AED components which digitally condition and

network as bus-capable signals of mechanical measured value transducers. The objective of these components

is the digitization and conditioning of the measuring signals directly at the transducer. The AD104 and the

transducer (load cell) form a unit and cannot be replaced separately (transducer calibration of the measurement

chain with SZA/SFA is necessary).

As transducers, calibrated load cells or force transducers ( adjusted in TCZ,TCS, and zero point) can be used.

The measuring amplifier boards AD104 have different interface connections which are produced in the factory

by corresponding assembly:

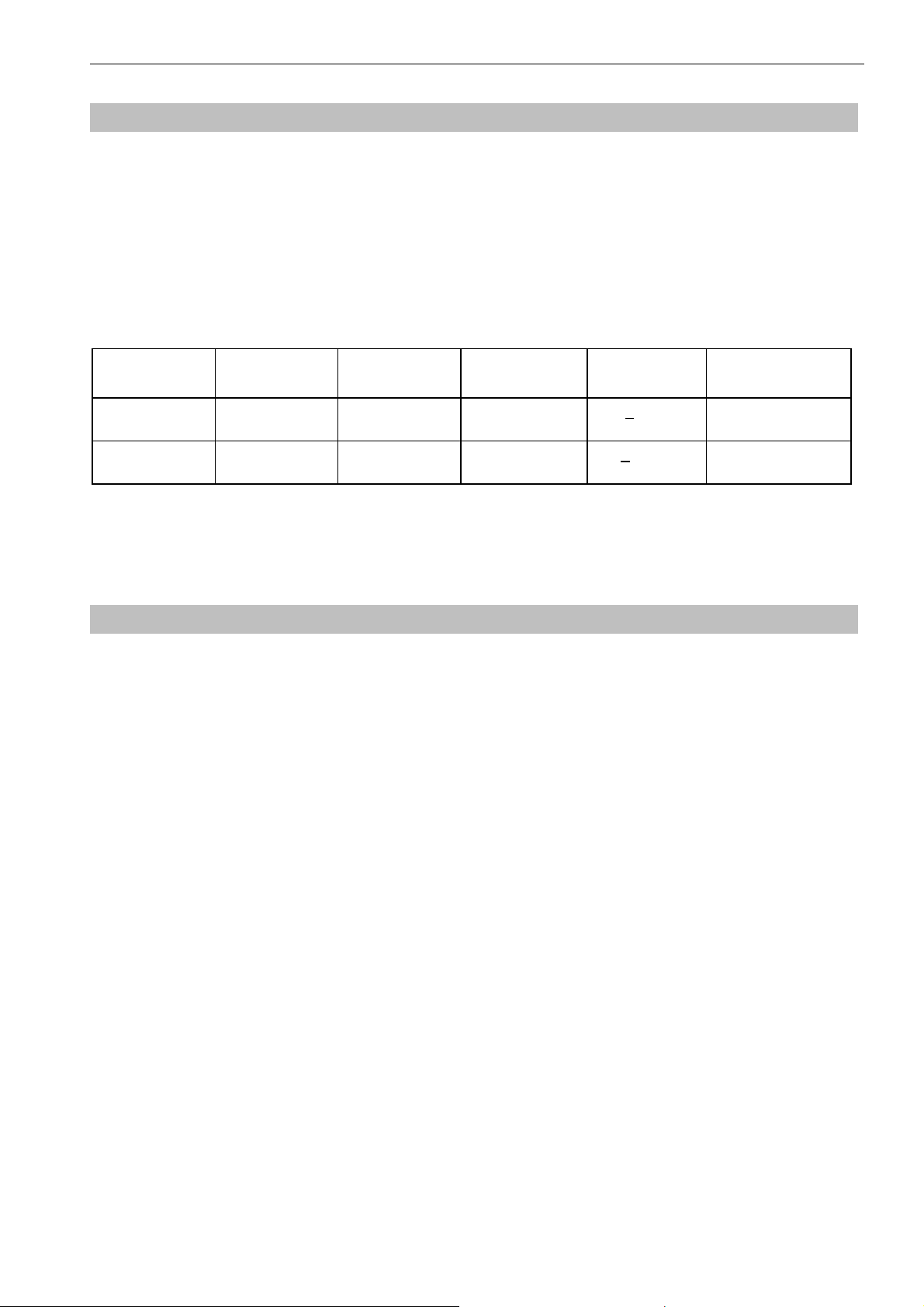

AD104-Type Interface Interface

Connect.

AD104-R2 Asynchronous,

serial

AD104-R5 Asynchronous,

serial

The transducer electronic units AD104 are also abbreviated with AED in the following text.

Old type: AD104-R4 Æ new type: is AD104-R5 with external trigger

New type: AD104-R2 with external trigger and RS232 interface.

RS-232 duplex no < 15m yes

RS-485 -4-wire,

full duplex

Bus mode Cable length external

Trigger

yes < 500m yes

2 Characteristic features

• Operating voltage 5.6V...15V DC

• 4 wire Interface for a full bridge sensor, nominal input range ±2 mV/V, maximal input range ±2.6 mV/V

• Serial interface RS-485 (bus mode) or through RS-232 interface (point - to - point mode)

• Digital filtering, choice of the output speed and scaling of the measured signal

• Separated calibration of transducer and application characteristic

• Storage of the parameters nonvolatile

• All settings are made through the serial interface

• Automatic zero tracking (1d/s, ±2%)

• Automatic intial zero setting (±2%...±20%)

• Trigger functions (level or external trigger)

ba_aed104_8_e.doc

Page 5

4 / 75

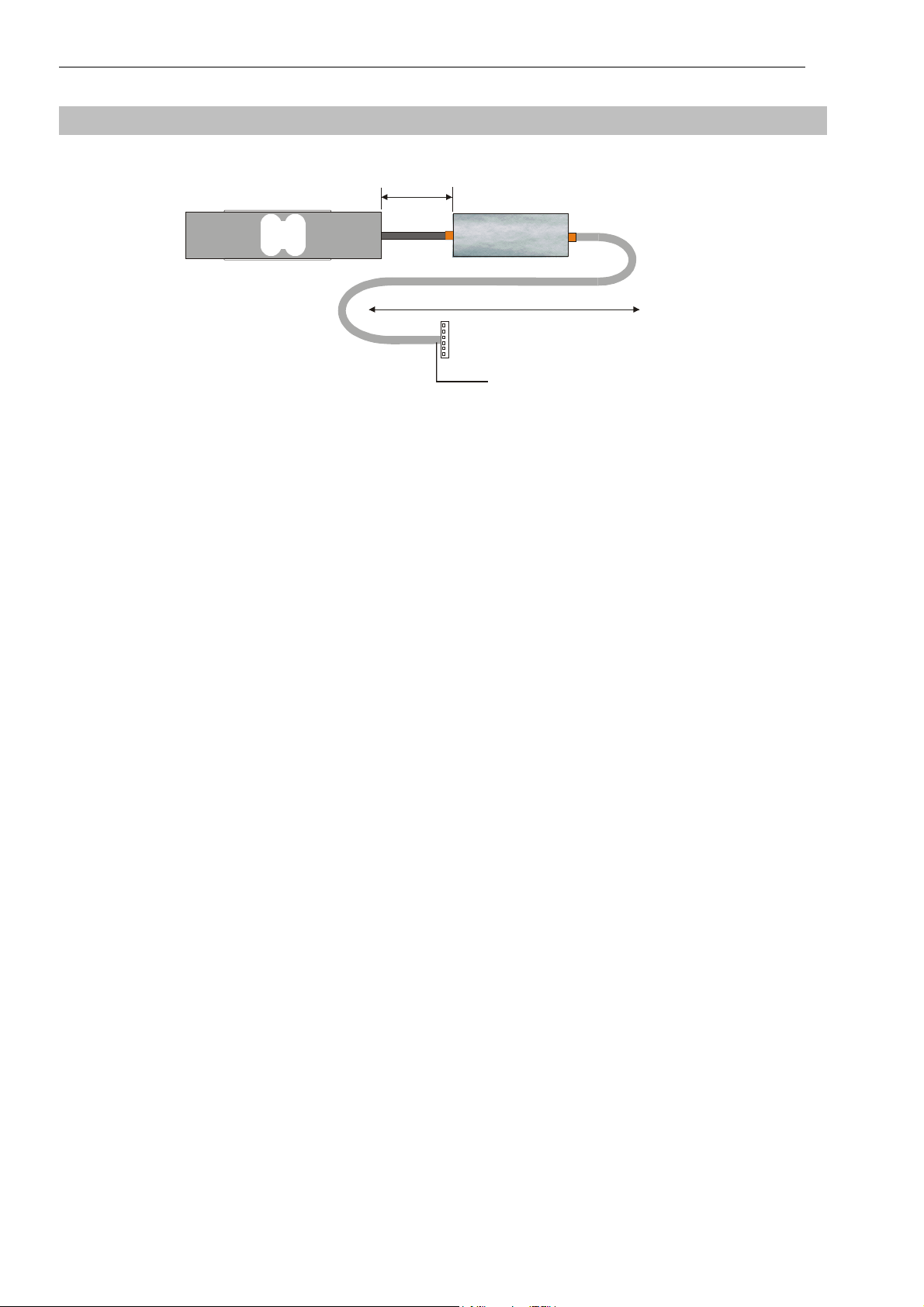

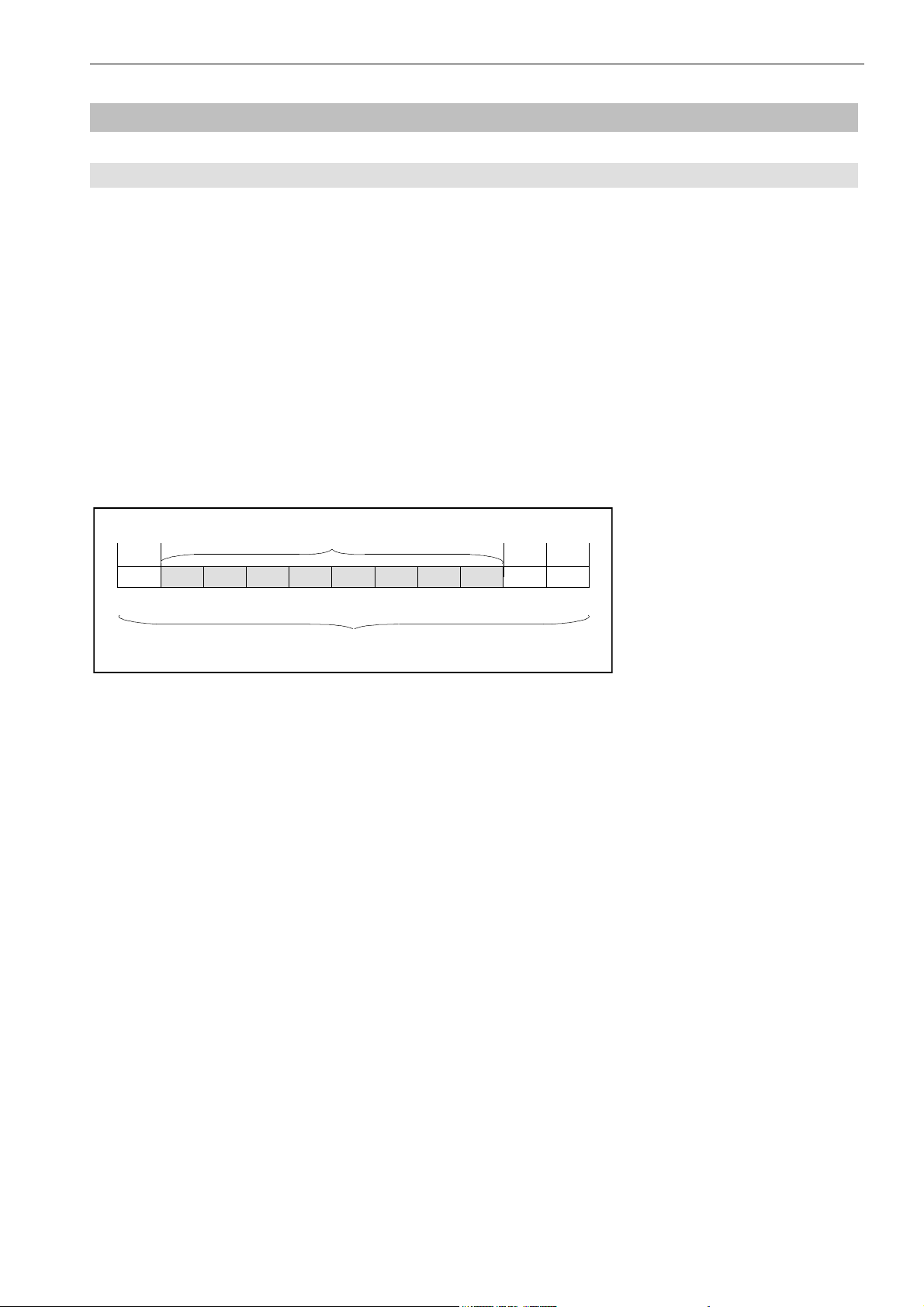

3 Mechanical construction

Load Cell

30 cm

AD104

1m...500m (depending on the type)

Pancon connector

female

Shield

Fig. 3.1: Example of a mechanical construction of a measuring chain (HBM)

The amplifier circuit board has to be placed in a shielded housing (EMC protection). The cable connections has

to be shielded leads.

With digital transducers (FIT, C16,...) the AD104 is build in the housing of the load cell. For digital measuring

chains the AD104 is included in a separate housing in the cable (degree of protection IP 40).

Warning: The AD104 board is not protected against electrostatic discharges. Appropriate safety

precautions must be taken for handling during assembly into the transducer.

ba_aed104_8_e.doc

Page 6

AD104-R2, AD104-R5 5 / 75

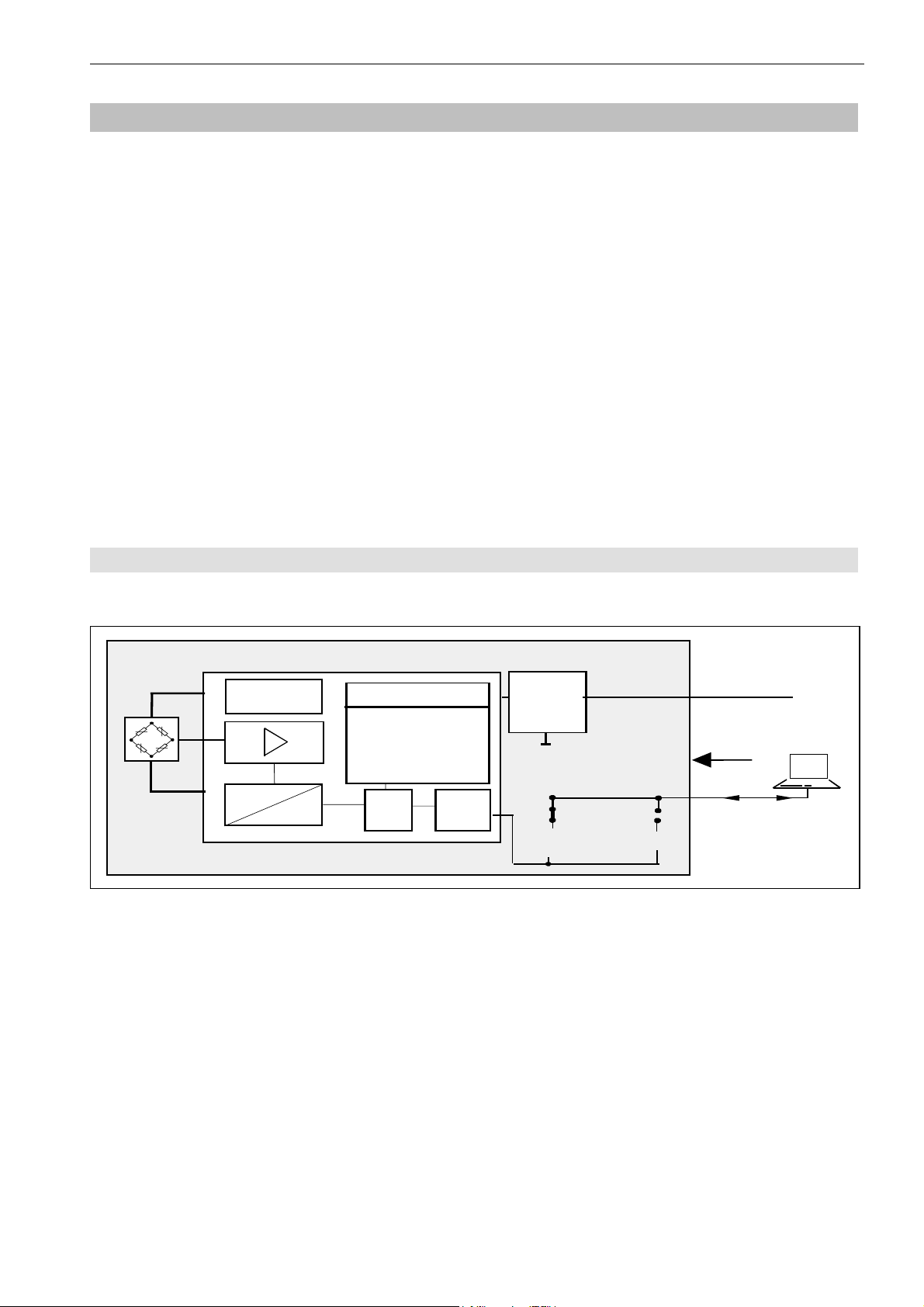

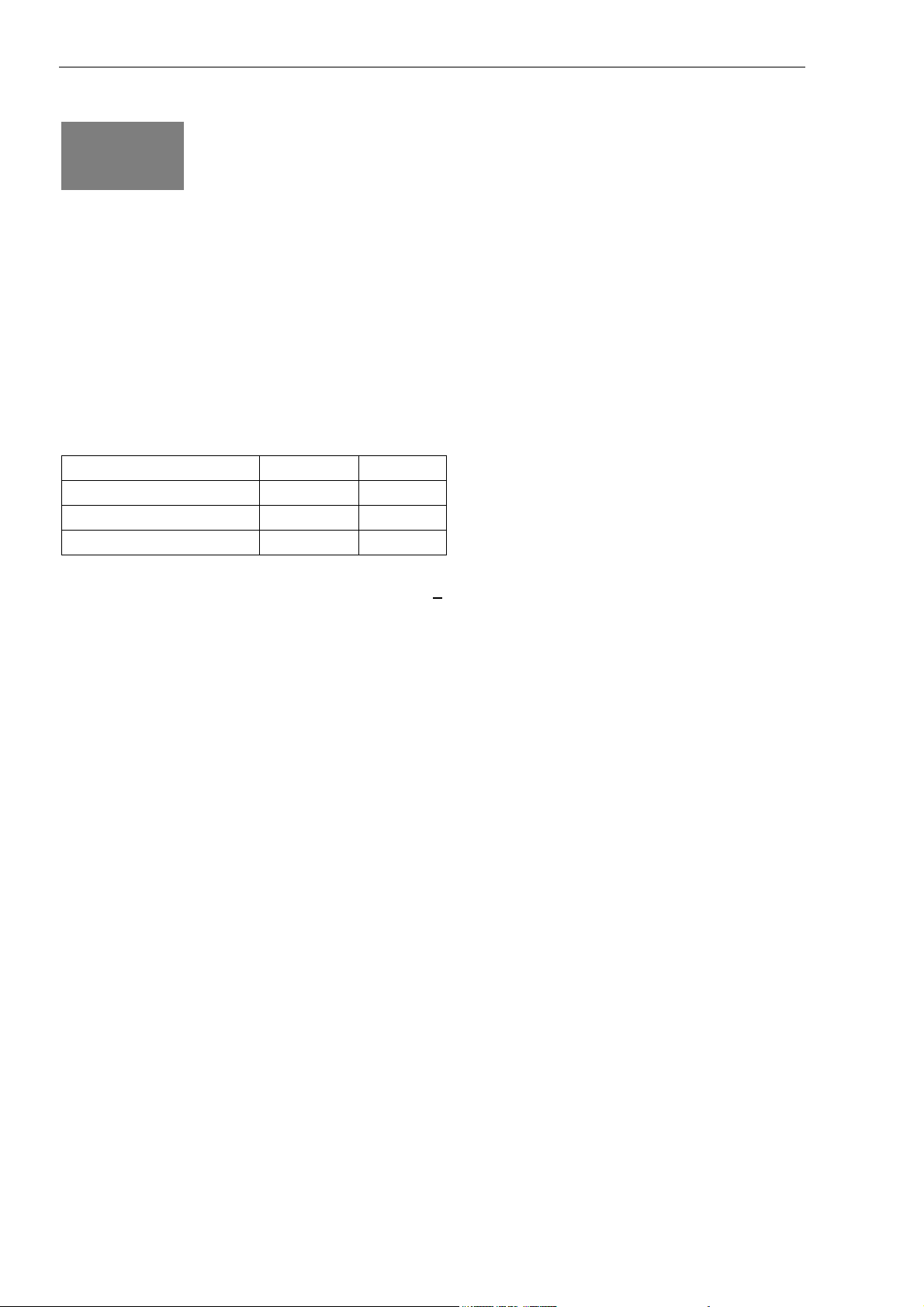

4 Electrical construction

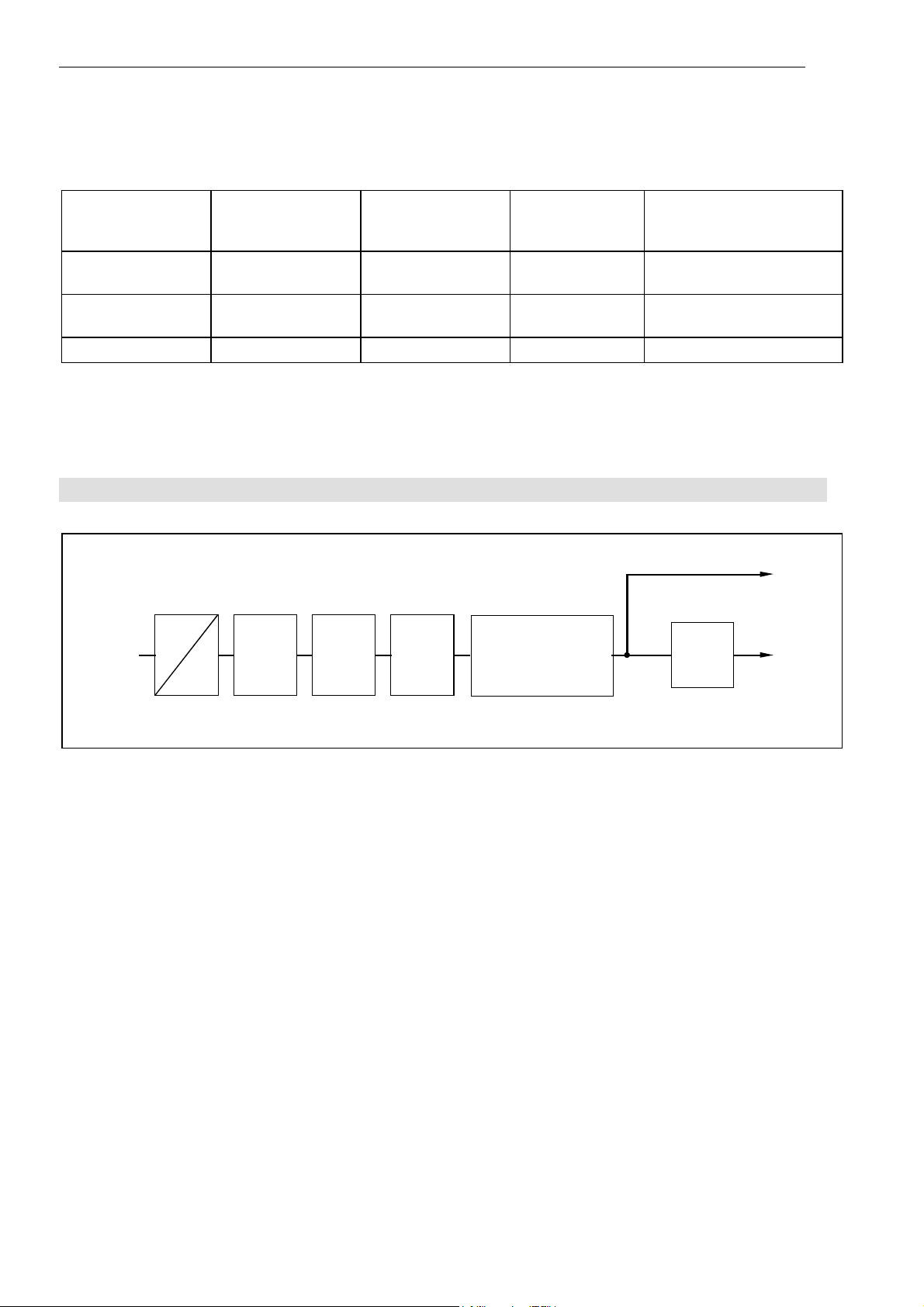

The circuit of the digital transducer electronic unit consists essentially of the following functional groups:

• Transducer supply

• Amplifier

• Analog-digital converter (A/D)

• Microprocessor unit (µP)

• Parameter memory (EEPROM) protected against power failure

• Serial interface (RS232- 2 wire or RS485)

• Power supply

• Trigger input

4.1 Function

Transducer

supply

A

D

Fig. 4.1: Measuring amplifier board AD104 block circuit diagram

EEPROM

Identifica tion.,

D igital filter, M e a s.

rate , S ca ling

Interface s etting

µP

Interfac e

Voltage

stabilize r

AD 104

RS-4854-wire

RS232

5.6 ...15V

< 60mA

Ext. Trigger

1200...38400 baud

The analog transducer signal is initially amplified, filtered and then converted into a digital value in the analogdigital converter. The digitized measuring signal is processed in the microprocessor. The conditioned signal is

then transmitted to a computer through the serial interface. All parameters can be stored in the EEPROM,

protected against power failures.

Power

unit

Com puter

ba_aed104_8_e.doc

Page 7

6 / 75

A

A

The transducer electronic unit is adjusted in the factory to the no-load and the nominal load of the transducer.

The electronic unit determines a factory characteristic through the commands SZA and SFA from these

measured values and images the measured values following later by means of this characteristic.

The following measured values are delivered according to output format (COF):

Output format Input signal Measured values

at

NOV = 0

Binary 2 characters

(Integer)

Binary 4 characters

(Long Integer)

ASCII 0...Nominal load 0 ... 1 000 000 Digit 0 ... NOV

You have the possibility of adapting the characteristic to your requirements (i.e. scale characteristic)

correspondingly with the parameter pair LDW and LWT and to standardize the measured values to the required

scaling value (e.g. 3000d) via the command NOV.

0...Nominal load 0 ... 20 000 Digit 0 ... NOV

0...Nominal load 0 ... 5 120 000 Digit 0 ... NOV

Measured

values at

NOV > 0

Delivery status

NOV=0

x

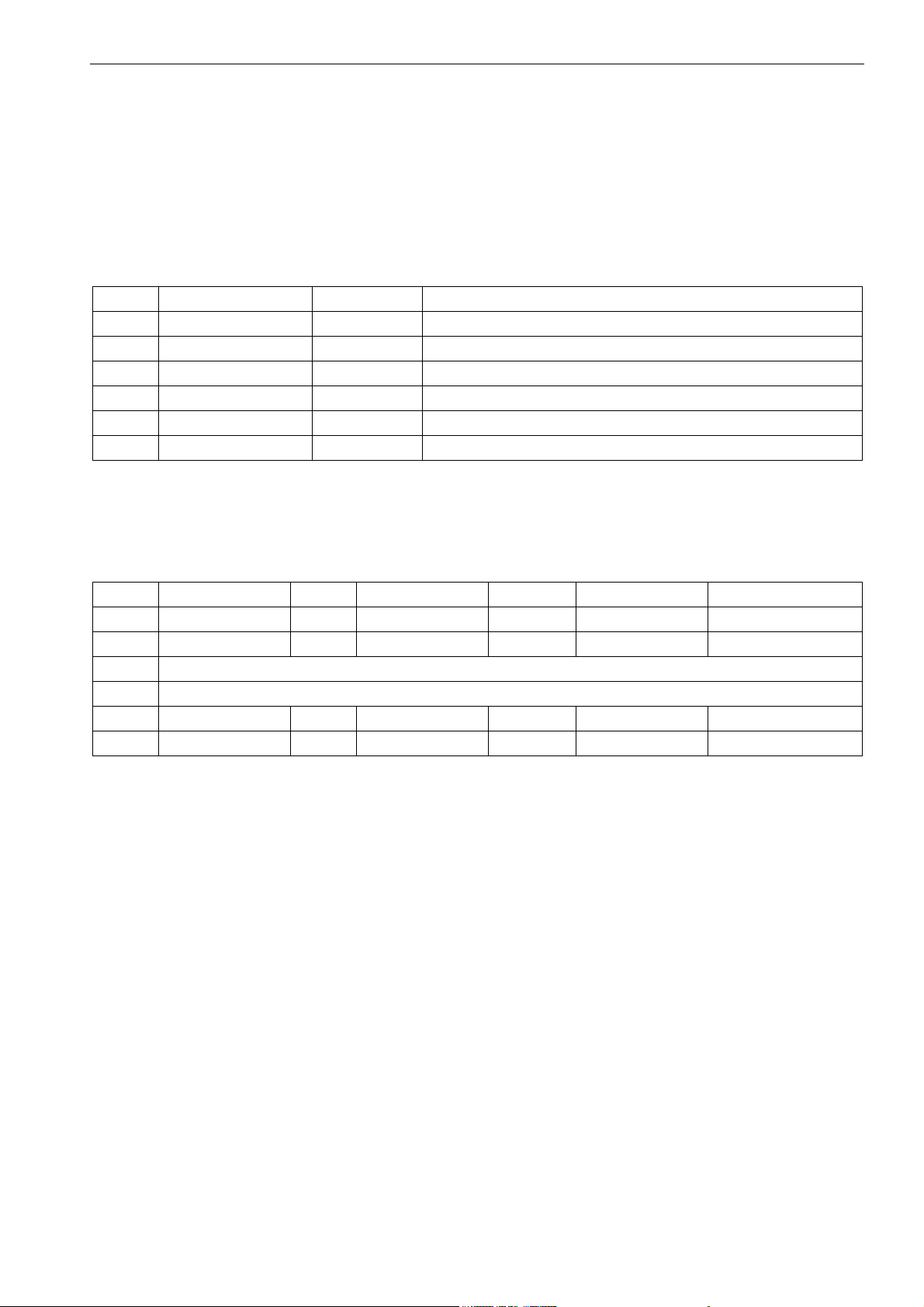

4.2 Signal processing

Gross

measured

value

Net

measured

value

Measuring

bridge

mpli-

fier

DC

FMD

ASF

Filter

ICR

Measur.

rate

SZA

SFA

Factory

scaling

LDW

NOV

LWT

User scaling,

Linearization

ZTR, ZSE

LIC

TAV, TAS

Net

TAR

Fig. 4.2.1: Signal flow diagram

After amplification and AD conversion, the signal is filtered by adjustable digital filters (command ASF). The

factory characteristic is determined with the aid of the commands SZA and SFA.

The measuring signal bandwidth (digital filter) is set with the command ASF. The measuring rate (number of

measurements per time unit) can be changed depending upon the filter bandwidth with the command ICR.

The user can set his own characteristic (commands LDW, LWT, NOV) without changing the factory calibration

(SZA/SFA). Furthermore, gross/net switch-over is available (command TAS). Using the command ZSE an

automatic switch-on zero setting can be activated. An automatic zero tracking function (ZTR) is also available.

For a linearization of the scale characteristic, the command (LIC) is available (with a polynomial of the 3rd

order). The polynomial parameters can be determined by means of a HBM PC program AED_LIC.

The current measured value is retrieved by the command MSV?. The format of the measured value (ASCII or

binary) is set by the command COF. An automatic measured value output can also be selected via the

command COF.

Two types of digital filters, which are switched over using the command FMD, are implemented in the AED. At

FMD0 filters lower than 1 Hz bandwidth are also available. In the filter mode FMD1, filters with fast transient

recovery are activated with high damping in the stop band. You will find detailed information in the chapter

‘Individual descriptions of the commands’.

ba_aed104_8_e.doc

Page 8

AD104-R2, AD104-R5 7 / 75

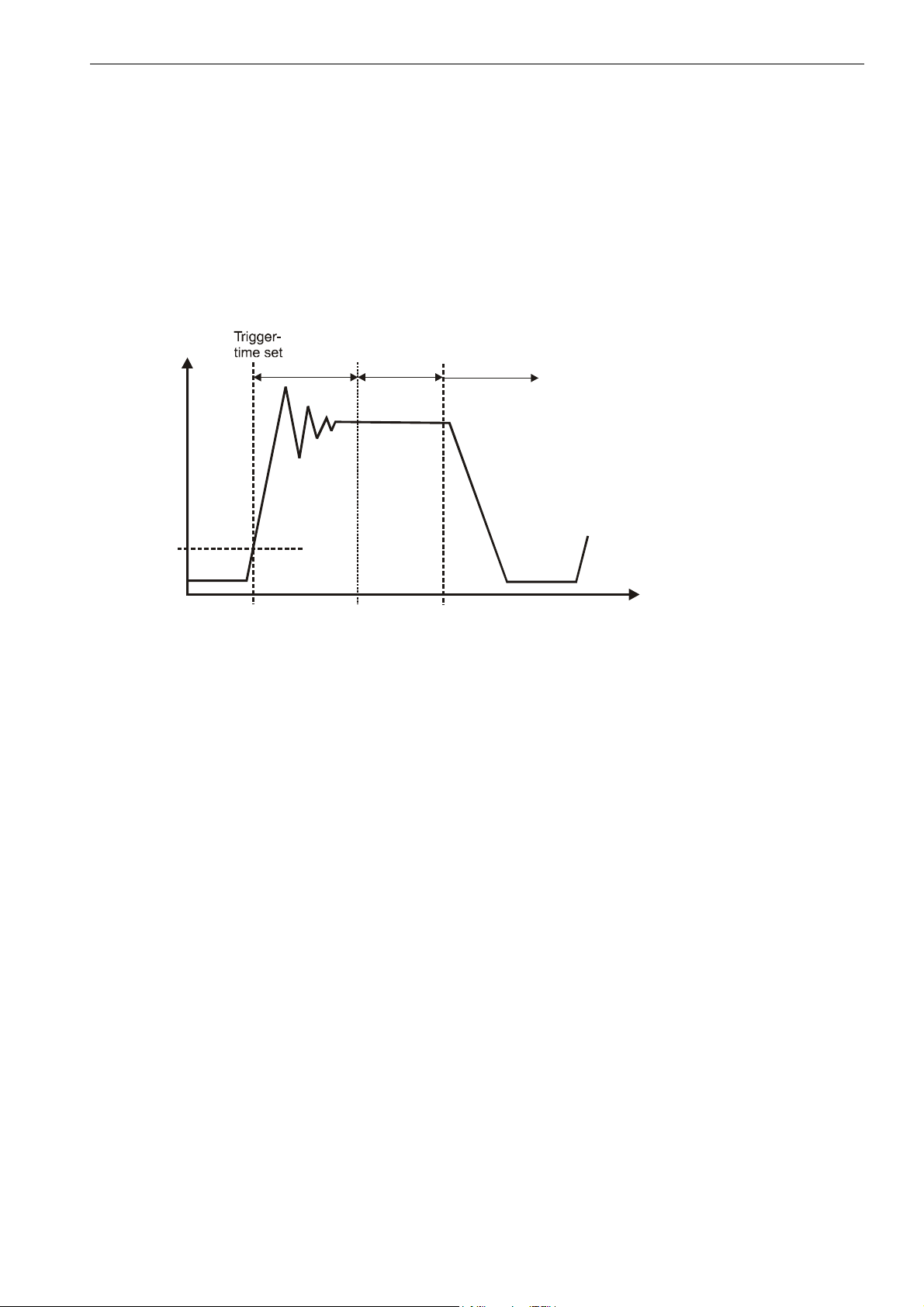

The AD104 comprises two trigger functions in order to support functions in packaging machines and

checkweigher:

• triggering by means of an adjustable level (gross and net measured value, for both types)

• external triggering by means of a trigger input

This special measuring mode is activated by means of the command TRC. The measured value determined is

output by means of the command MAV?. For this measuring mode, filter mode FMD1 should be set (fast

settling time).

The measuring speed depends on the preset stop time and the measuring period. The stop time should match

the fast transient recovery of the filter used (ASF).

Triggering

Weig ht

Trigger level

TRC- comm.

Parameter 3

if P2=0

(TRC-Command: Parameter 1=1)

Tr an s. Re cov.

time

TRC- command

Parameter 4

Measuring time

TRC- command

Parameter 5

Result in output memory

Time

Level triggering:

This measuring mode is suitable for weighing processes where the scale is relieved in between weighing

events.

The scale is in a no load condition. The material to be weighed will be placed on the scale, the trigger level is

exceeded, and stop time measurement starts. On expiry of this transient period, the actual weight will be

determined; and on expiry of this measuring period, the actual weight value will be stored in memory. The

weighing process can be restarted only once the weight value is again lower than the trigger level (place scale

in no load condition). In this measurement mode, weight determination does not need to be monitored by an

external computer at high speed. The output memory will contain an invalid value until a new measured value

has been created. After retrieving the contents of the measured value memory by means of the MAV?

command, this memory is reset to an invalid condition (invalid value < - 1600 000).

The periods (stop time and measurement period x 10ms at ICR0) and the trigger level can be freely set by

means of the command TRC. The trigger level will be on the user characteristic (NOV).

External trigger:

Both types support an external trigger instead of the limit value trigger. This trigger has a quiescent signal level

at 0V (=low) and uses the low/high edge to activate the measurement process.

The trigger flank starts the stop time measurement. On expiry of this transient period, the actual weight will be

determined over the measurement period, and the averaged actual weight value will be stored in memory. The

output memory will contain an invalid value until a new measured value has been created. After retrieving the

contents of the measured value memory by means of the MAV? command, this memory is reset to an invalid

condition. The periods (stop time and measurement period x 10ms at ICR0) and the trigger level can be freely

set by means of the command TRC. A renewed trigger flank will restart the measurement process. The scale

does not need to be placed into a no load condition.

During a measuring (waiting time + measuring time) a trigger signal is unvalid (no re-triggering). Within this

mode the parameter trigger level (P3) has no function.

ba_aed104_8_e.doc

Page 9

8 / 75

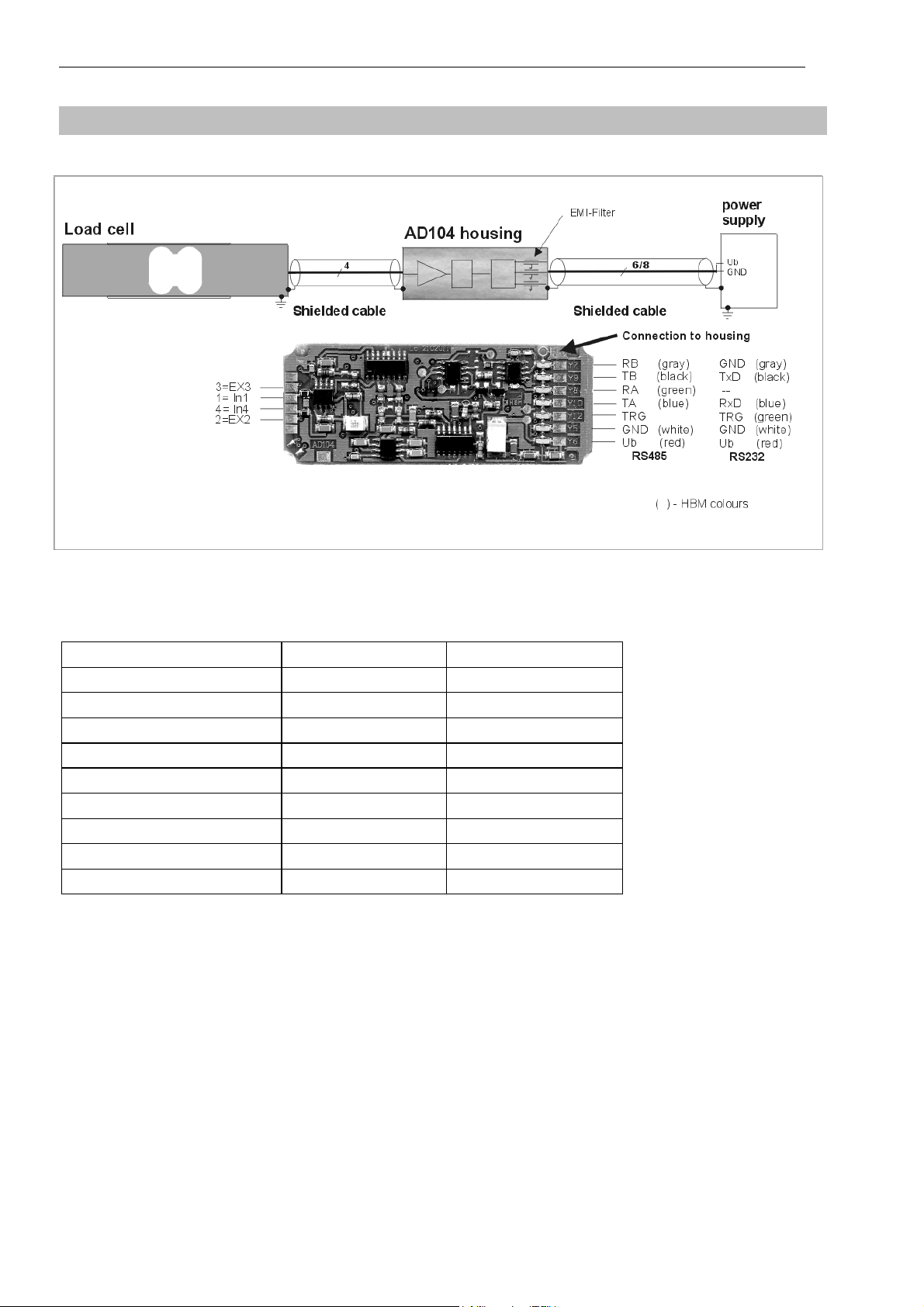

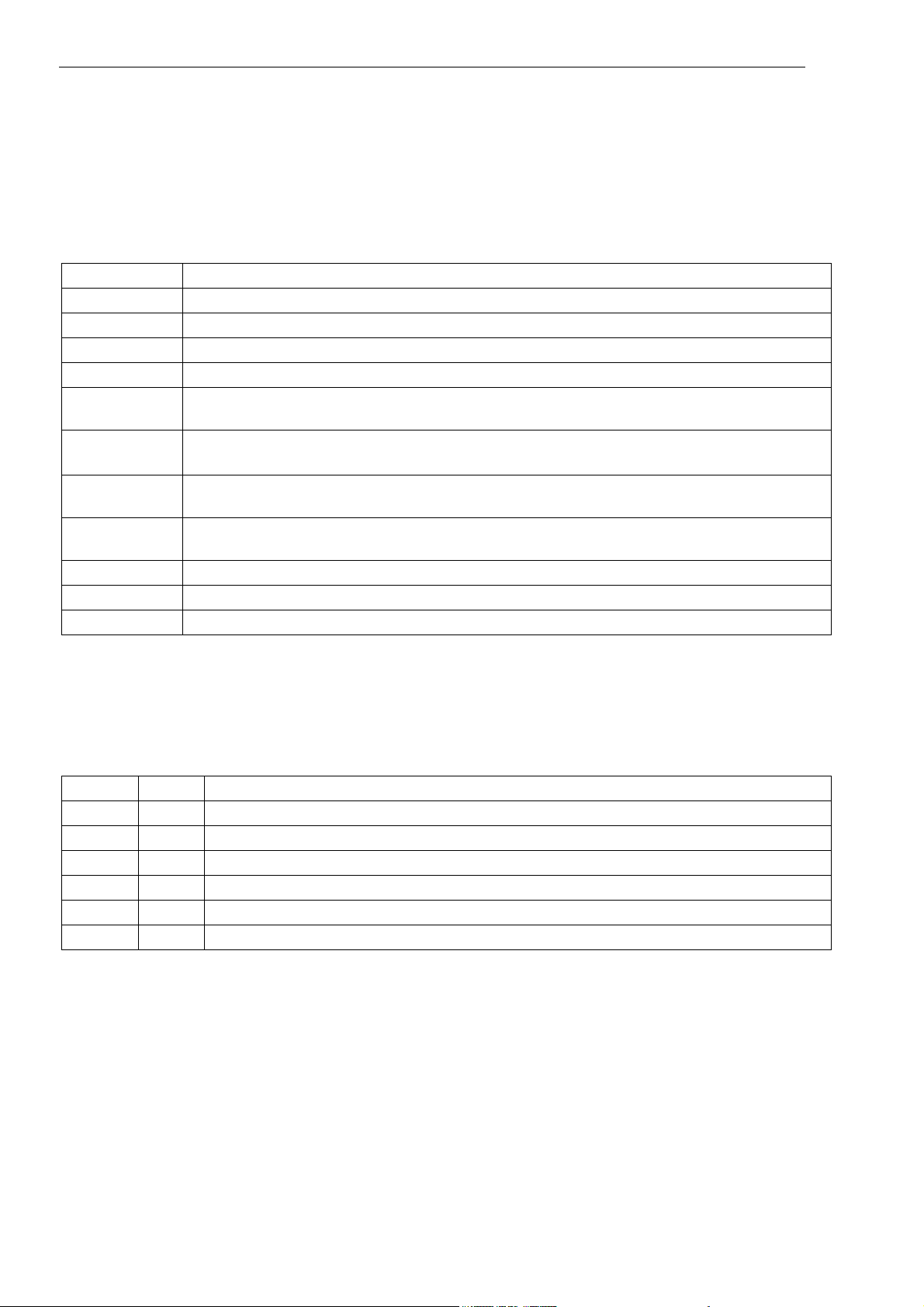

5 Electrical connection

(yellow)

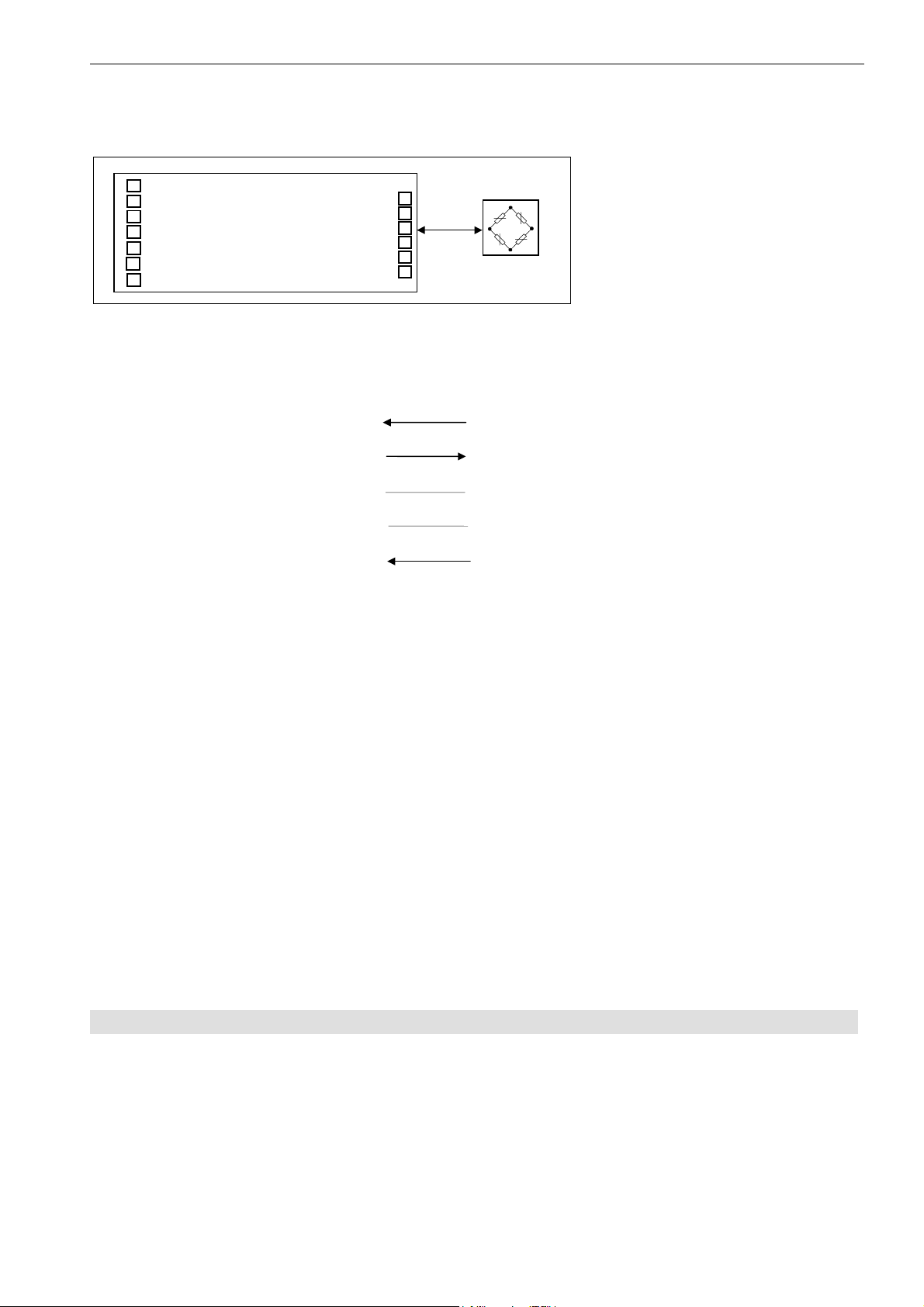

Fig. 5: Connection schema of the PCB and shielding concept of a measuring chain

The connection to the PC is effected by means of a 6 / 8 pin Pancon connector. The following pin wirings result

at the connector according to the set interface (i.e. measuring chains of HBM):

AD104 type AD104-R5 AD104-R2

Pancon Connector Signals RS-485 Signals RS-232

1. red UB UB

2. white GND GND

3. blue TA RxD

4. green RA TRG

5. black TB TXD

6. grey RB GND

7. yellow TRG -

8. - -

- do not connect!

The measuring chain of HBM with AD104-R5 has a 8 wire shielded cable.

The measuring chain of HBM with AD104-R2 has a 6 wire shield

Explanation: UB Supply voltage (+ 5.6V...15V)

GND Ground

RA 4-wire connection AED receiver, line A (=RX-)

RB 4-wire connection AED receiver, line B (=RX+)

TA 4-wire connection AED transmitter, line A (=TX-)

TB 4-wire connection AED transmitter, line B (=TX+)

RxD Receiver data (UART, RS-232)

TxD Transmit data (UART, RS-232)

TRG External trigger signal

ed cable.

ba_aed104_8_e.doc

Page 10

AD104-R2, AD104-R5 9 / 75

Trigger input (electrical data):

High: 3.2V ... 5V

Low: 0V ... 0.8V

Input current: <2.5 mA

Important notes on EMC protection:

The PCB AD104 alone has no EMC protection. The EMC protection can be achieved in addition with a shielded

housing for the electronic and the use of shielded cable.

Mount the load cell onto a metallic carrier which is connected to the ground connection of the device, or shield

AD104 with the load cell and load introduction parts as a complete unit. The cable shield needs to be connected

with the measuring body of the loadcell and the housing of the AED.

The housing of the AED or the load cell has to be connected via the solder pad to the PCB (see Fig. 5,

‘connection to housing’). The AED unit itself is provided with a protective filter for all interfaces and supply lines.

The connection between load cell and electronics should be as short as possible. Depending on the bridge

resistance of the transducer used, line length, and line cross-section of the transducer connection cable, voltage

drops arise that lead to a reduction in the bridge supply voltage. Additionally, the voltage drop on the connection

cable is also temperature-dependent ( copper resistance ). The transducer output signal also changes in

proportion to the bridge supply voltage.

With the 4-wire circuit used, there still result measurement errors in conditions with changing temperatures,

caused by the temperature-dependent cable resistance and possibly also by transitory resistances in the

connectors.

When setting up a measurement chain (electronics outside the transducer) it should also be noted that the

AD104 uses a rectangular carrier frequency for bridge supply. Therefore, the cable length between AD104 and

the transducer is limited to 100 cm max. For high precision applications(>= 3000d), the length should be

reduced to 30cm (shielded cable, shield connection on the measuring body and on the shielded housing for

AD104).

ba_aed104_8_e.doc

Page 11

10 / 75

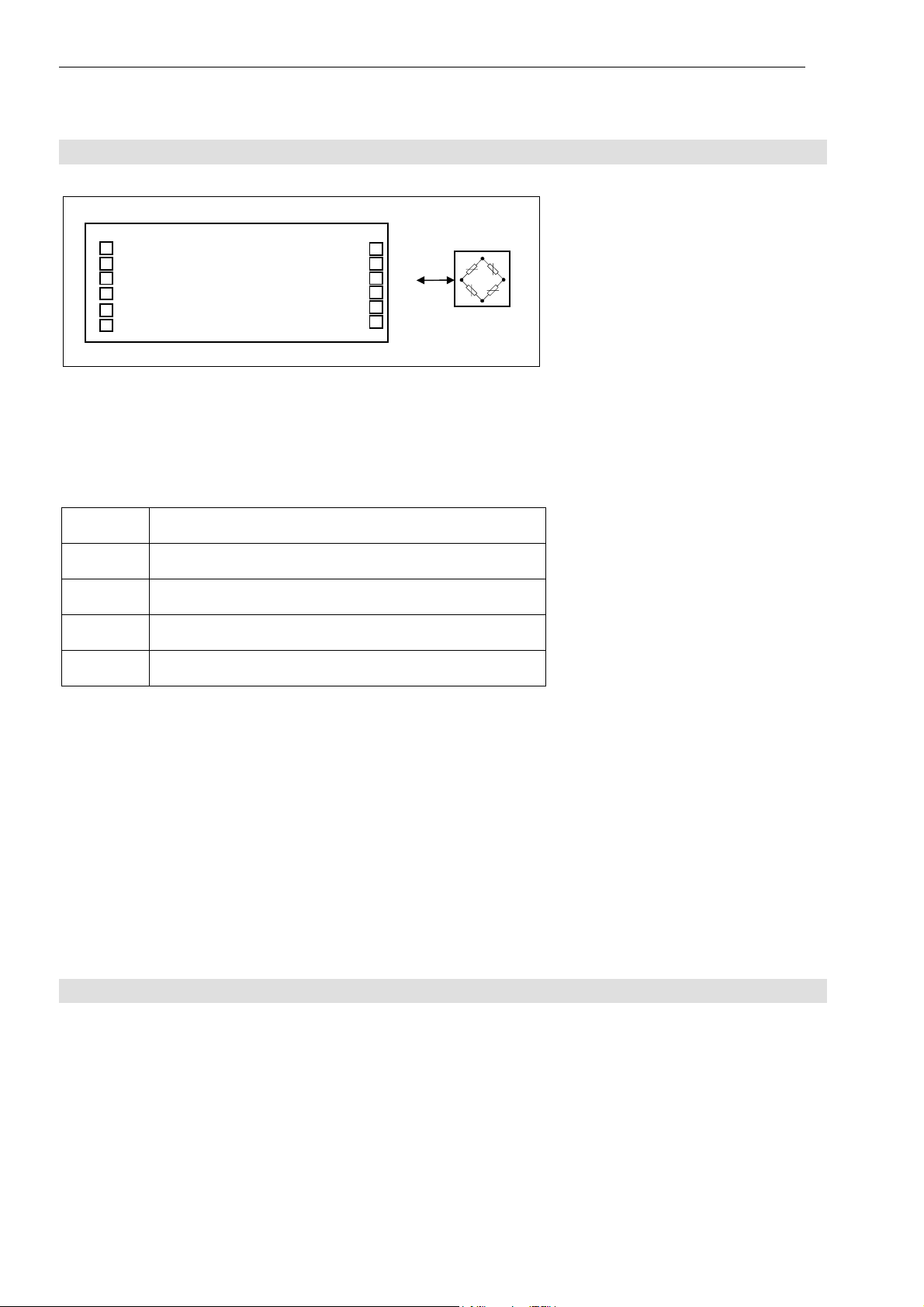

5.1 Transducer Connection

1-Ub

2-GND

3

4

5

6

Fig. 5.1: Transducer connection with the PCB (n.c. - not connected)

AD104

n.c.

U

IN4

IN1

U

n.c.

2

Br

4

3

Br

The AED amplifier is allready mounted with the transducer. A changing of the modules (AED or transducer) is

only allowed in HBM factory.

For the transducer connection a 4 core shielded cable has to be used.

Connection Pads for a full bridge:

Pad

Discription

UBr2 bridge excitation 2

IN4 amplifier input 4

IN1 amplifier input 1

UBr3 bridge excitation 3

Notes on cable length:

The connection between load cell and electronics should be as short as possible. Depending on the bridge

resistance of the transducer used, line length, and line cross-section of the transducer connection cable, voltage

drops arise that lead to a reduction in the bridge supply voltage. Additionally, the voltage drop on the connection

cable is also temperature-dependent ( copper resistance ). The transducer output signal also changes in

proportion to the bridge supply voltage.

With the 4-wire circuit used, there still result measurement errors in conditions with changing temperatures,

caused by the temperature-dependent cable resistance and possibly also by transitory resistances in the

connectors.

When setting up a measurement chain (electronics outside the transducer) it should also be noted that the

AD104 uses a rectangular carrier frequency for bridge supply. Therefore, the cable length between AD104 and

the transducer is limited to 100 cm max. For high precision applications(>= 3000d), the length should be

reduced to 30cm (shielded cable, shield connection on the measuring body and on the shielded housing for

AD104).

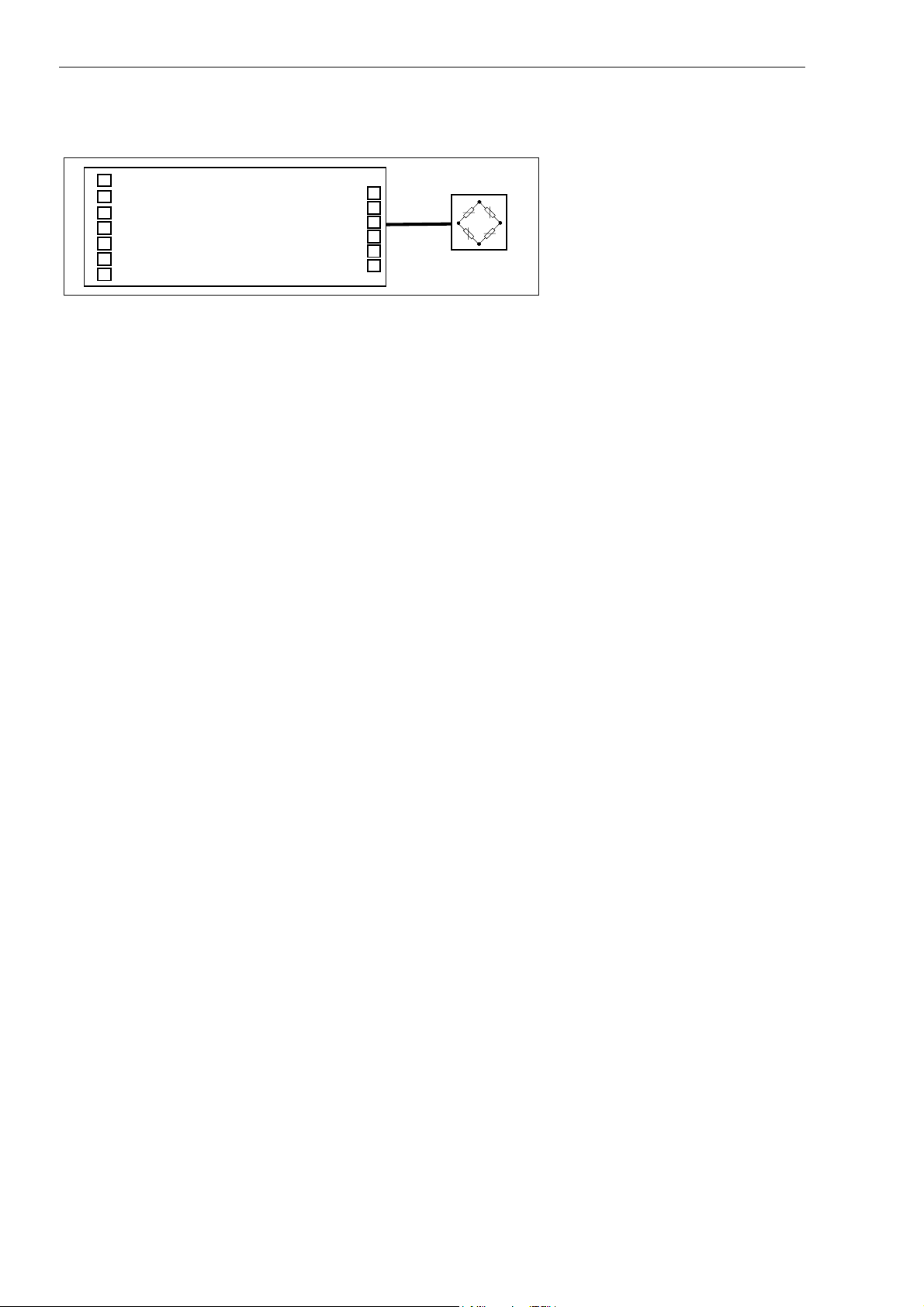

5.2 Serial Interface RS-232 (only AD104-R2)

The AD104-R2 is a version of the AD104 with an asynchronous, serial interface (UART interface with RS-232

line driver). This interface provide a point – to – point communication (no bus mode).

The baud rate of 1200...38400 baud can be selected for this interface. The following specifications result for the

transmission of one character:

Start bit: 1

Number of data bits: 8

Parity bit: none / even

Stop bit: 1

ba_aed104_8_e.doc

Page 12

AD104-R2, AD104-R5 11 / 75

Y

Y

Y

Y

Y

Y

Y

The connection is made through a six-core cable. The maximum cable length is 15 m. No bus mode is possible

in this type of communications (no bus driver).

6 -Ub

5 -GND

12-TRG

10-RxD

8 - n.c.

9 -TxD

7 - n.c.

Fig.5.2: Connections on the PCB (AD104-R2)

The connection scheme for the asynchronous interface results as follows:

AD104-R2 Master

Receiving line RxD TxD transmission line

Transmission line TxD RxD receiver line

AD104 – R2

Operating voltage U

B

supply voltage (5.6V..15VDC)

Ground GND GND Ground

Ext. trigger TRG external trigger signal

The levels on the RxD and TxD lines are RS-232 levels, whereby the quiescent-signal level is <-3V (Low).

External trigger signal:

Quiscent-signal level: TRG= 0V (Low)

Active measuring: TRG= Low-High edge (0V...5V)

If the external trigger is not used, the input remains open.

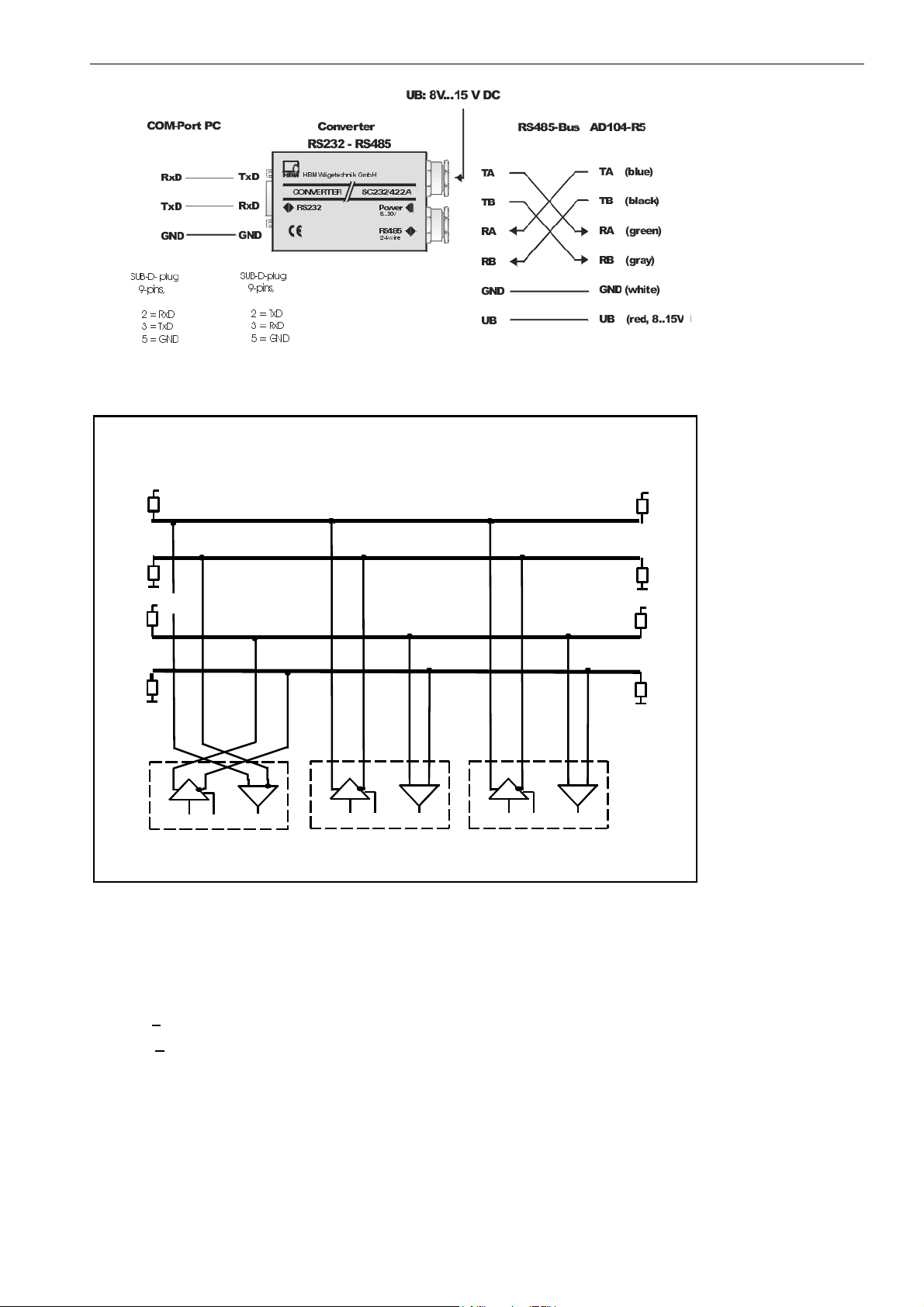

5.3 Serial Interface RS485 (Bus mode with AD104-R5)

Up to 32 AEDs can be connected to a common bus line through the RS-485 interface. The baud rate can be

selected between 1200 and 38400 baud in this version.

The following specification applies for the transmission of one character:

Start bit: 1

Number of data bits: 8

Parity bit: none / even

ba_aed104_8_e.doc

Page 13

12 / 75

Y

Y

Y

Y

Y

Y

Y

Stop bit:^ 1

6 -Ub

5 -GND

12-TRG

10-TA

8 -RA

9 -TB

7 -RB

Fig. 5.3.1: AD104-R5 for 4-wire bus mode (PCB connections)

1. Long lcable lengths (up to 500m) can be achieved with the aid of the RS485 bus drivers.

2. The bus mode of the AED is designed as master-slave configuration, whereby the AED implements a

slave. Thus all activities of the AED are initiated by the control computer. Each AED receives its own

communication address (00 ... 31) and can be activated through a select command Sii (ii= 00...31). A

broadcast command (S98) is implemented for certain cases of communication. This means that after such

a command, all AED execute the command of the master, but no AED answers. All commands of this

communication as well as corresponding examples are described in Chapter 7.

Figure 5.3.2 shows the connection of the bus to the RS232/RS485 Converter

(HBM Ordering-No. 1-SC232/422A).

AD104 – R5

Figure 5.3.3 shows the RS485 bus connection.

The terminating resistors of 500 ohms drawn in Figure 5.3.3 for the electrical function of the bus system are

important. These resistors protect the quiescent-signal levels for the receivers on the bus line. The master line

may be terminated with these resistors in this case only at the line ends. The master and the AED with the

address 31 should contain the terminating resistors for the local distribution of the bus connections shown in the

Figure. The AED contains these resistors already. These can be activated by the command STR1 (these

terminating resistors are switched off on factory delivery). These terminations may not be activated more than

twice in one bus.

The HBM interface converter also includes these terminators.

External trigger signal:

Quiscent-signal level: TRG= 0V (Low)

Active measuring: TRG= Low-High edge (0V...5V)

If the external trigger is not used, the input remains open.

ba_aed104_8_e.doc

Page 14

AD104-R2, AD104-R5 13 / 75

)

)

)

Fig: 5.3.2: Wiring of an AD104-R5 with an interface converter RS232/RS485

Line

Master line

4 - wire

termination

+5V

500

Ω

TB

TA

500

Ω

+5V

500

Ω

RB

RA

500

Ω

TB

TA RB RA

RT

RxDTxD on/off

TB TA RB RA

RT

TxD on/off

RxD

Computer=Master AED = Slave 00 Slave 31 . . .

TB TA RB RA

RT

TxD on/off

RxD

Line

termination

+5V

500

Ω

500

Ω

+5V

500

Ω

500

Ω

Fig: 5.3.3: Bus structure 4-wire bus (RS485)

The bus wiring is not to be allowed in star configuration. The leads of the slaves are not to be increased of 3m.

The best solution here: choin the main leads directly to the slaves.

The quiescent -signal level on the RS-485 master line results in the 4-wire mode at:

TB - TA > 0.35 V (quiescent -signal level due to the AED terminating resistors)

RB - RA > 0.35 V (quiescent -signal level due to the master terminating resistors)

Since the RS-485 is a differential bus interface, the quiescent-signal levels are also stated as a differential

voltage between the lines (and not related to ground). It must further be noted that this interface tolerates a

maximum common-mode range of +/-7V. If it is necessary, equipotential bonding should be established

between the bus subscribers through a separate line. The cable shield should not be used for this equipotential

bonding.

The shield of the master line is connected with the shield of the AED housing (not with the supply ground).

ba_aed104_8_e.doc

Page 15

14 / 75

6 Command set

The commands can be classified roughly into:

• Interface commands (ADR, BDR, Sxx, TEX, COF, CSM)

• Commands for adjusting and scaling (SZA, SFA, LDW, LWT, NOV, LIC)

• Commands for the measuring mode (MSV, ASF, ICR, TAR, TAS, TAV, FMD, STP)

• Special commands (ZSE, ZTR, TDD, RES, DPW, SPW, IDN, STR, TRC, MAV)

• Command for legal for trade applications (LFT, TCR, CRC)

6.1 Command format

General notes:

The commands can be input in uppercase or lowercase type.

Each command has to be terminated by a termination character. This can be optionally a line feed (LF) or a

semicolon (;). If only a termination character is sent to the AED, then the input buffer of the AED is cleared.

The statements made in round brackets () in the commands are urgently necessary and must be entered.

Parameters in pointed brackets <> are optional and can also be dispensed with. The brackets themselves are

not entered. Text must be included in “ “.

With numerical entries, leading zeros are suppressed. Numbers can be entered either directly or in exponent

format, e.g. +12000lf or +

exponent must not be more than 10 characters in length.

Answers consist of ASCII characters and are terminated with CRLF. The binary character output is an

exception (see command MSV).

Each command consists of the command initials, the parameter(s) and the termination character.

1,2e4lf. The exponent e can be one- or two-digit, but a number including sign and

Command initials Parameters End character

Input ABC X,Y LF or ;

Output ABC? X,Y LF or ;

Example: MSV?20

20 measured values are output after this command.

All ASCII characters <=- 20

except for 11

(ctrl q) and 13H (ctrl s).

H

(blank) may stand between command initials, parameters and end character,

H

H: Hexadecimal.

ba_aed104_8_e.doc

Page 16

AD104-R2, AD104-R5 15 / 75

6.2 Answers to commands

Answers to inputs (exception COF64...COF79):

Answer End character

Correct input 0 (zero) CRLF

Faulty input ? CRLF

Exceptions: The commands RES, STP, S00 ... S99 deliver no answer.

The command BDR delivers the answer in the new baud rate.

An error flag is received through the command ESR.

Answers to output commands:

Correct command Parameter1, ... Parameter n, or measured values CRLF

Faulty command ? CRLF (error flag via command ESR )

6.3 Output types for the measured values

You can select two types of output and a data delimiter (command TEX).

Output type 1:

The measured values are output arranged beneath one another.

Measured value1 CRLF

Measured value2 CRLF

. . . . . . . .

Measured value n CRLF

Output type 2:

The measured values are output arranged next to one another.

Measured value1 (data delimiter) Measured value2 (data delimiter) ... Measured value n CRLF

The measured value query works with fixed output lengths

(see command COF):

Format command AED answer Number of bytes

COF0; msv?; yyyy CR LF (y- binary) 6

COF2; msv?; yy CR LF (y- binary) 4

COF3; msv?; xxxxxxxx CR LF (x- ASCII) 10

COF9; msv?; xxxxxxxx,xx,xxx CR LF (x- ASCII) 17

There is always a CRLF or the data delimiter defined by the command TEX as end identification of the

measured value output. However these characters must not be filtered out as end identification in the binary

output, since these characters can also be contained in the binary code of the measured value. Therefore only

counting the bytes helps in the binary output. The corresponding places after CR or LF or the data delimiter can

then be enquired for subsequent syntax testing.

Password protection:

The password protection of the AED comprises important settings for the characteristic of the scale

and its identification. Commands with password protection are activated only after the password is

entered. These commands are answered with “?“ without entry of the password through the command

SPW.

ba_aed104_8_e.doc

Page 17

16 / 75

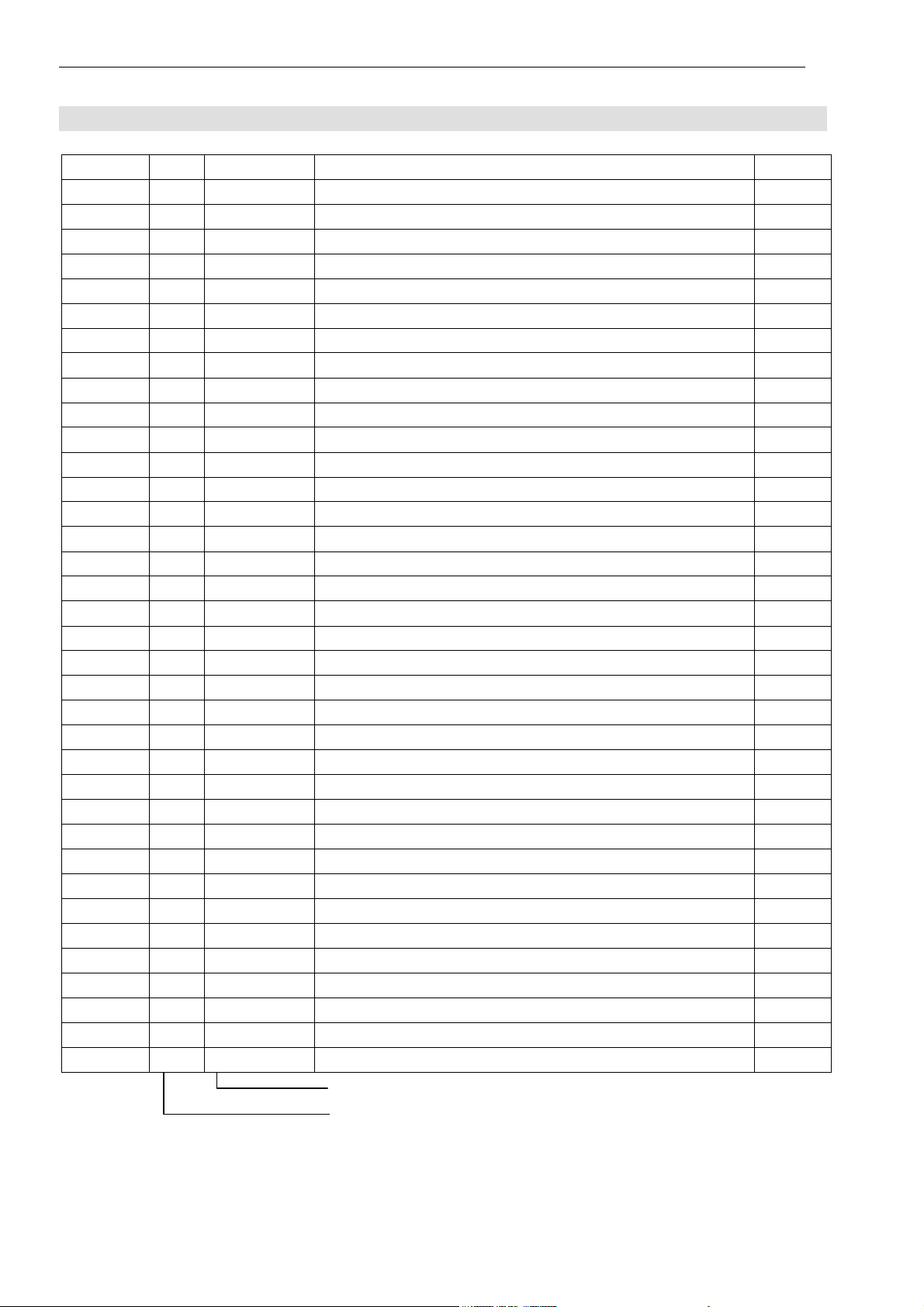

6.4 Command overview

Command PW TDD 1 Function Page

ADR

ASF

BDR

COF

CRC

CSM

DPW

ENU

ESR

FMD

ICR

IDN

LDW

LFT

LIC

LWT

MAV

MSV

NOV

RES

S...

SFA

SPW

STP

STR

SZA

TAR

TAS

TAV

TDD1/2

TDD0

TEX

TCR

TRC

ZSE

ZTR

x Zero point, user characteristic 32

x Linearization 57

x Nominal value, user characteristic 33

x x Nominal value scaling 34

x Internal nominal value, factory characteristic 30

x Stop measured value output 29

x Factory setting 52

xAdress18

x Digital filter 40

x Baud rate 19

x Output format in MSV? 20

external checksum for legal for trade applic. 66

x checksum in MSV status 24

Define password 47

Dimensional unit 50

Status 62

x Filter mode 42

x Measuring rate 43

Identification of transducer type and serial number 51

x Legal for trade applications 64

Measured value, trigger function 58

Measured value output 36

Reset 49

Select of AED in bus operation 26

Password entry 48

Messwertausgabe stoppen 39

x Switch bus termination resistors on/off 63

Tare mode 44

x Gross/net switch-over 46

x Tare value 45

Store setting in EEPROM, read EEPROM 52

x Data delimiter for measured value output 25

Trade counter 65

x Trigger setting 59

x Initial zero setting 55

x Automatic zero tracking 56

TDD1 – stored with TDD1 command

PW – protected by password with commands DPW/SPW

The following commands result in no change to the AED setting:

ACL, ASS, CAL, COR, GRU (compatibility with other AED versions).

ba_aed104_8_e.doc

Page 18

AD104-R2, AD104-R5 17 / 75

7 Individual descriptions of the commands

7.1 Interface commands (asynchronous, serial)

Characteristic data of the interfaces

Start bit: 1

Word length: 8 bits

Parity: none / even

Stop bit: 1

Software handshake (XON / XOFF) is possible

Baud rate: 1200; 2400; 4800; 9600;19200; 38400 baud

The asynchronous interface of the AED is a serial interface, i.e. the data are transmitted bit for bit after one

another and asynchronously. Asynchronous means that the transmission works without a clock signal.

A start bit is set before each data byte. The bits of the word, a parity bit for the transmission protocol (optional)

and a stop bit then follow.

1 Bit Word length = 8 data bits 1 Bit 1 Bit

Start Parity Stop

1 character

Fig. 7.1.1: Composition of a character

Since the data are transmitted after one another, the transmission speed must agree with the reception speed.

The number of bits per second is called baud rate.

The exact baud rate of the receiver is synchronized with the start bit for each transmitted character. The data

bits which all have the same length then follow. After the stop bit is reached, the receiver goes into a ‘waiting

position’ until it is reactivated by the next start bit.

The number of characters per measured value depends upon the selected output format (COF command) and

can be 2 to 17 characters (see also COF command).

The interface must be configured to build up the communication between AED and computer. The following

commands are provided in the AED for this : ADR; BDR; COF; TEX; S..;

ba_aed104_8_e.doc

Page 19

18 / 75

Address

ADR

Range: 0...31

Factory setting: 31

Response time: <15ms

Parameters: 2

Password protection: none

Parameter protect.: with command TDD1

Input: ADR(new address),<"Serial No.">;

The serial number can also be stated optionally as 2nd parameter. The new address is then entered only for the

AED with the stated serial number. This makes it possible to change device addresses in the case of several

AEDs with the same address (initialization of the bus mode).

The serial number must be stated in “ “ as in the command IDN.

(device address)

Entry of the device address as decimal number 0...31.

Example: ADR25,"007" CRLF

Query: ADR?; 25CRLF (Example)

Effect: Output of the device address as decimal number 0...31

ba_aed104_8_e.doc

Page 20

AD104-R2, AD104-R5 19 / 75

Baud Rate

BDR

Baud rates: 1200, 2400, 4800, 9600, 19200, 38400 Baud

Factory setting: 9600 Baud and even parity

Response time: <15ms

Parameters: 1

Password protection: none

Parameter protect.: with command TDD1

Input: BDR <Baudrate>,<Parity>

Entry of the required baud rate as decimal number.

Possible baud rates are:

1200, 2400, 4800, 9600, 19200, 38400 Baud

Input or the requested parity:

0= without parity bit

1= with even parity bit

(Baud rate)

Important Note

The answer is given in the new setting (baud rate, parity). Communication is no longer possible initially after a

changed baud rate. The computer must also be changed over to the newly selected baud rate setting.So that

the baud rate remains changed permanently, it must be stored in the EEPROM with the command TDD1. This

procedure serves also as safeguard that no baud rates can be set in the AED which the remote station does not

support. If the newly entered baud rate is not stored, the AED reports after a reset or power On again in the

previously valid baud rate.

Query: BDR?;

Effect: Output of the set baud rate, Identification for parity bit

Example: BDR?; 9600,1 CRLF corresponds to 9600 baud, even parity

ba_aed104_8_e.doc

Page 21

20 / 75

Configurate Output Format

COF

Range: 0...255

Factory setting: 9

Response time: <15ms

Parameters: 1

Password protection: none

Parameter protect.: with command TDD1

Input: COF(0...255);

Input of the output format for measured value command MSV

The possible formats and the decimal number to be entered for them are listed in the following Table. The

measured value output refers here to the set nominal value of the AED (see command NOV).

Output at max. capacity NOV> 0 NOV= 0

2 Byte binary NOV value 20000

4 Byte binary NOV value 5120000

ASCII NOV value 1000000

(Ausgabeformat für die Messwertausgabe)

For the 2-bytes binary output, the NOV value must be < 30000, otherwise the measured value is output with

overflow or underflow (7fff H or 8000H). With NOV30000, the overload range is only still approx. 2700 digits.

Query: COF?;

Effect: Output of the selected output format as three-digit decimal number from 0...255

ba_aed104_8_e.doc

Page 22

AD104-R2, AD104-R5 21 / 75

COF formats:

The following combinations result on entry of COF0 to COF12:

• MSB = most significant byte

• LSB = least significant byte

In binary output, the sequence of the bytes MSB Æ LSB or LSB Æ MSB can be selected. In ASCII output, the

device address and/or measured value status information can be output in addition to the measured value.

Binary format:

Parameter Length Sequence of the measured value output

COF0

COF2

COF4

COF6

COF8

COF12

Measured value 4 Byte MSB before LSB LSB=0 (no Status)

Measured value 2 Byte MSB/LSB

Measured value 4 Byte LSB before MSB LSB=0 (no Status)

Measured value 2 Byte LSB/MSB

Measured value 4 Byte MSB before LSB LSB=Status/CRC

Measured value 4 Byte LSB before MSB LSB=Status/CRC

ASCII format:

In ASCII output, a freely selectable data delimiter is set between the parameters (see command TEX). crlf or the

selected data delimiter follows after the last parameter.

T = Data delimiter () = Number of characters

1st Parameter T 2nd Parameter T 3rd Parameter End character

COF1

COF3

COF5

COF7

COF9

COF11

Important Note

In bus mode, the output format must not be set to COF9.

Meas. value (8) T(1) Adress (2) — CRLF or T

Meas. value (8) — — CRLF or T

identical with COF1

identical with COF3

Meas. value (8) T(1) Adress (2) T(1) Status(3) CRLF or T

Meas. value (8) T(1) — — Status(3) CRLF or T

ba_aed104_8_e.doc

Page 23

22 / 75

Bus mode: COF16 to COF 28

If the decimal number 16 is added to the above stated output formats COF0...COF12, then the AED is switched

into the bus output mode. A measured value is output. The AED switches over to the partially active mode (each

new measured value is stored in the output buffer but not output). The measured value is output on the bus with

the select command S..;.

Example: 2 AED’s in bus operation

Command Effect

S98;

COF18;

ICR0;

MSV?0;

S01;

S02;

All AED are partially active (listening but not transmission)

Output in 2 byte binary output

Maximum measuring rate

Continuous measurement in AED

Read measured value from 1st AED, immediate output of current measured value, without

measuring time

Read measured value from 2nd AED, when response from first AED has been received

completely. Immediate output of current measured value, without measuring time

S01;

S02;

... ...

STP;

S01;

Binary measured value output without CRLF: COF32 to COF44

If the decimal number 32 is added to the above stated binary output formats COF0...COF12, the AED is

switched into the following output mode for the measured values.

In the binary measured value output, the end character CR LF is left out, so that only 2 or 4 characters per

measured value are output. This measure increases the output speed of the measured values.

Format Length Sequence of the measured value output

COF32

COF34

COF36

COF38

COF40

COF44

Read measured value from 1st AED, when response from second AED has been received

completely

Read measured value from 1st AED, when response from second AED has been received

completely

Stop measured value output

Poss. new setting for 1st AED

4 Byte MSB before LSB LSB=0 (no status)

2 Byte MSB before LSB

4 Byte LSB before MSB LSB=0 (no status)

2 Byte LSB before MSB

4 Byte MSB before LSB LSB=status/CRC

4 Byte LSB before MSB LSB=status/CRC

2-wire bus mode: COF64 ... COF76 (do not use for variants AD104-R2 and AD104-R5)

If the decimal number 64 is added to the above stated output formats COF0...COF12, then the AED is switched

into the 2-wire bus mode. This means that the AED answers no longer with “0“ or “?“ on command inputs. The

answer with the parameter or in the case of MSV? with the measured value occurs only for command enquiries

(e.g. ASF?). The command MSV?0; (continuous measured value transmission) may no longer be used in this

case since otherwise it is no longer possible to stop this output (apart from supply voltage off).

ba_aed104_8_e.doc

Page 24

AD104-R2, AD104-R5 23 / 75

Continuous output after power On: COF128 to COF 140

If the decimal number 128 is added to the above stated output formats COF0...COF12, then the AED is

switched into the continuous output mode. After the power On or RES command, the AED outputs the

measured values without MSV? request. The continuous output can be switched off with the command STP.

The setting is made with the following entries (COF≥128):

1. ... make necessary settings

2. ICRi; set measuring rate of the AED

3. COFx+128; the AED transmits measured values continuously,

time interval corresponding to ICR, x=0...12

4. STP; stop continuous transmission

5. TDD1; store protected against power failure

6. COFx+128; the AED transmits measured values continuously,

time interval corresponding to ICR.

The AED starts with the measured value output without separate request also after switching on the voltage.

These output formats have another special feature (depending on how triggering is set, command TRC):

Trigger deactivated: continuous automatic measured value output

Trigger activated: automatic measured value output only if a new measured value has been

created after triggering (MAV? output value).

Output speed of measured values:

The AD104 can output a maximum of 100 measured values per second. This data rate also depends upon the

baud rate (BDR), the data format of the measured value output and the set averaging (ICR).

Table 1 shows this relationship in the continuous measured value output (MSV?0):

Measured values/s 100 50 25 12 6 3 2 1

(ICR)

Time in ms 10 20 40 80 160 330 500 1000

Output format (COF) necessary baud rates for MSV0; (BDR)

Binary format

2 characters at COF2/COF6

Binary format

4 characters at COF0/COF4

ASCII format

Meas. value 10 characters at COF3

ASCII format

Meas. value + Adress

13 characters at COF1

ASCII format

Meas. value + Adress + status

17 characters at COF9

2400 1200 1200 1200 1200 1200 1200 1200

4800 2400 1200 1200 1200 1200 1200 1200

19200 9600 4800 2400 1200 1200 1200 1200

19200 9600 4800 2400 1200 1200 1200 1200

38400 19200 9600 4800 2400 1200 1200 1200

Note for the evaluation of the binary measured values:

The binary codes for CR and LF can occur inside the bytes representing the measured value in the measured

value output in binary format. Therefore the contents of the measured value output must not be tested for the

characters CR/LF in order possibly to check the end of the measured value transmission. Rather the number of

characters which are received should be registered for the binary output. The control characters CR/LF are also

appended to the measured value in the binary output (sole exception: MSV?0;).

ba_aed104_8_e.doc

Page 25

24 / 75

Checksum

CSM

Range: 0/1

Factory setting: 0

Response time: <15ms

Parameters: 1

Password protection: none

Parameter protect.: with command TDD1

Input: CSM(0/1);

Query: CSM?;

Effect: The adjusted fuction is given out as: (0/1).

The command checksum can be used to find out transmitting errors within 4 Byte binary output.

If CSM=0 the normal status will be transmitted (see MSV).

If CSM=1 in stead of the status a checksum will be transmitted in the binary output format COF8 and COF12

(+i∗16, i=0,1...7). The checksum is a EXOR over the 3 bytes of the measured value.

(Cheksum only in MSV binary status)

ba_aed104_8_e.doc

Page 26

AD104-R2, AD104-R5 25 / 75

Terminator Execution

TEX

Range: 0...255

Factory setting: 172

Response time: <15ms

Parameters: 1

Password protection: none

Parameter protect.: with command TDD1

Input: TEX(0...255);

The wanted data delimiter is input in decimal form as ASCII character (e.g. comma = 2C

TEX44; H: Hexadecimal, D: Decimal). Any ASCII character from 0...127

delimiter. The data delimiter is set between the parameters in the measured value output (see also commands

MSV and COF).

Example: TEX44;

Measuring value output: -0123456, 12, 000, -0123457, 12, 000, etc. (at COF9)

If the selected ASCII character is entered with an offset of 128

(above example: comma = 44

then the parameters of a measured value are separated by comma as before, but crlf is output at the end of the

measured value.

(Data delimiter between measured values)

(0...7FH) can be taken as data

D

+ 128 D = 172 D Æ entry TEX172;),

D

= 44 D Æ input

H

Example: TEX172;

This results in: -123456,12,000

-123457,12,000 etc.

Query: TEX?;

Effect: The set data delimiter is output as 3-digit decimal number (0...255).

ba_aed104_8_e.doc

Page 27

26 / 75

Select

S...

Range: 0...31, 98

Factory setting: —

Response time: <15ms

Parameters: 1

Password protection: none

Parameter protect.: no data to be protected

Input: S(00...31, 98); (only with semicolon, not with CRLF!)

The select command generates no answer. Several AEDs connected together to form a BUS can be addressed

individually or jointly with it. An AED is always active after reset or power On (except for COF>127) and must

therefore be addressed through the select command. A maximum of 32 addresses (00...31) can be allocated

through the command ADR.

Important Note

(Selection of AEDs in bus mode)

The command S.. alone generates no answer. The selected AED answers only together with a further

command. Except in the bus mode: COF16...COF28 (after MSV?0;).

Example: S00;

Command 1

Command 2...n

S01;

Command 1 etc.

The command S98; is provided for special functions (broadcast). In this case all AEDs connected to the bus are

addressed. All AEDs execute the following commands. No AED answers. This occurs as long as only one AED

is addressed through S00 ... S31 again.

A measured value query in the bus can be performed as follows:

1. All AED selected via command S98;.

2. Measured value query MSV?;, all AED form the measured value and places value after the integration

time (ICR) in the output buffer, but no AED transmits

3. Select AED with address 1 with command S01;. The AED with adress 01 outputs the measured value

4. Select AED with address 1 with command S02;. The AED with adress 02 outputs the measured value

etc.

ba_aed104_8_e.doc

Page 28

AD104-R2, AD104-R5 27 / 75

7.2 Adjustment and scaling

The commands described below serve for setting the factory characteristic as well as the user characteristic:

• Commands for adjusting the transducer characteristic: SZA, SFA

• Commands for adjusting the user characteristic: LDW, LWT

• Scaling of the measured values: NOV

Setting the characteristic

As delivered, the AED works initially with a factory characteristic SZA / SFA (range 0...2 mV/V). This

characteristic can be used for calibrating the the transducer characteristic. This characteristic should not be

changed. It has to be print ore stored to keep the data.

The user can adapt the AED characteristic to his requirements with the command pair LDW, LWT

(application or scale characteristic).

In the following, the balance of a measuring chain will be described with the balancing of a scale. This example

can also be used for other kinds of transducers.

Important Note

The characteristic commands LDW, LWT must be entered or executed in the sequence LDW , then LWT... The

input data are not computed until both parameters have been entered or measured in pairs The scaling must be

switched off when determining the characteristic (NOV0).

After the values for zeropoint and nominal value of the user characteristic have been measured or entered, the

range LDW Æ LWT (at NOV=0) is mapped to the following numerical ranges:

Output at nom. load (COF) NOV=0 NOV>0

2 Byte binary 20000 NOV value

4 Byte binary 5120000 NOV value

ASCII 1000000 NOV value

For the 2-bytes binary output, the NOV value must be < 30000, otherwise the measured value is output with

overflow or underflow (7fff H or 8000H ; H: Hexadecimal). With NOV30000, the overload range is only approx.

2700 digits.

ba_aed104_8_e.doc

Page 29

28 / 75

A

A

A

Set user characteristic with LDW, LWT

ction

Enter password

Load = 0, scale

Load = Nominal value, scale

Digit

1.000.000

COF3

700.000

100.000

1.000.000

COF3

I

0,2 2

pplication measuring range

Digit

Command string

SPW"AED";

LDW;

LWT;

II

1,4

Factory characteristic

Load

in mV

User characteristic

II

I

0,2

pplication measuring range

1,4

Fig. 7.7-1: Setting the user characteristic

Load

in mV

ba_aed104_8_e.doc

Page 30

AD104-R2, AD104-R5 29 / 75

Sensor Zero Adjust

SZA

Range: 0...1,599999e6

Factory setting: adjusted on unloaded transducer

Response time: <15ms...4.2s

Parameters: 1

Password protection: yes

Parameter protect.: after input of SFA

Input: SZA; (Response time: <4.2s)

Effect: Using this command, the transducer electronic system measures an input signal

Input: SZA<zero value>; (Response time: <15ms)

(Factory characteristic – zero point)

between ±2.5mV/V, stores the measured value as the zero point of the factory

characteristic, but only starts the calculation of the new characteristic after

entering the parameter for SFA.

Effect: Instead of causing the AED to measure the applied signal, the value is entered

here. The entered value is stored, but accounted for only after entry of the

parameter for SFA as the zero point of the factory characteristic.

Query: SZA?; (Response time <15ms)

Effect: The value used in the AED for calculating the factory characteristic for the zero

point is output in ±7 digits (e.g. -0000345crlf).

Important Note

Entry the command SZA and SFA ore execute. The data will be calculated if both parameters were given in

pairs ore been measured.

ba_aed104_8_e.doc

Page 31

30 / 75

Sensor Fullscale Adjust

SFA

Range: 0...1,599999e6

Factory setting: adjusted to nominal load of transducer

Response time: <15ms...4.2s

Parameters: 1 (0)

Password protection: yes

Data protect.: with input

Input: SFA; (Response time: <4,2s)

(Factory characteristic – fullscale value)

Effect: Using this command, the transducer electronic system measures an input signal

Input: SFA <fullscale value>; (Response time: <15ms)

Effect: Instead of causing the AED to measure the applied signal, here the value is

Query: SFA?; (Response time <15ms)

Effect: The value used in the AED for calculating the factory characteristic for the zero

Important Note

Entry the command SZA and SFA ore execute. The data will be calculated if both parameters were given in

pairs ore been measured.

Procedure for entering the factory characteristic:

1. Enter password by means of command SPW

between ±2.5mV/V, stores the measured value as the fullscale value of the

factory characteristic and calculates the new characteristic together with the

previously entered value for SZA.

entered directly as the fullscale value of the factory characteristic, stored and

used together with the previously entered value for SZA.

point is output in ±7 digits (e.g. -0915345CRLF).

2. Switch off the scaling withNOV 0; output (scaling off)

3. Deactivate user characteristic by means of LDW0; and LWT1000000;

4. Adjust the ASF filter such that a maximally quiescent display is effected

5. Transducer (not scale) without load, wait until standstill

6.

Determine measured value with MSV?; , note value1 for SZA

7. Load transducer (not scale) with nominal load, wait until standstill

8. Determine measured value with MSV?; , note value2 for SFA

9. Enter new characteristic with : SZA value1; subsequently SFA value2

10. Redetermine the user characteristic LDW/LWT

The points 3...8 are not applicable if the factory characteristic is entered anew using already known parameters.

ba_aed104_8_e.doc

Page 32

AD104-R2, AD104-R5 31 / 75

User settings:

The commands LDW and LWT work like the commands SZA and SFA . It is possible with these commands to

make a system-specific calibration (e.g. of a scale), without changing the transducer settings performed with

SZA and SFA.

The user-specific settings LDW/LWT result as an ASCII output within the range 0... 1000000. This characteristic

is converted into the NOV by means of the parameters

Example: NOV 0; User setting 0...1000000 (ASCII signal

with 0 = unloaded scale, 1000000 at nominal load

NOV 4000; User setting 0...4000

With output 0 at load =0 or 4000 at nominal load

Attention:

In an adjustment with SZA and SFA, the parameters for LDW and LWT are reset (default: LDW=0 and

LWT=1000000) .There is the option to determine the characteristic with SZA and SFA at any time by entering

LDW0 and LWT1000000. Before setting your new characteristic, enter LDW0,LWT1e6, and NOV0.

ba_aed104_8_e.doc

Page 33

32 / 75

Load Cell Dead Weight

LDW

Range: 0...1.599999e6

Factory setting: 0

Response time: <15ms...4.2s

Parameters: 1

Password protection: yes

Parameter protect.: after input of LWT

Take the zero point of user characteristic with LDW

Input: LDW; (Response time: <4.2s)

1. The scale is unloaded.

Take the zero point with LDW; command.

Using this command, the transducer electronic system measures an input signal between ±2.5mV/V ( i.e.

=measured value for scale in no load condition), stores the measured value, but only starts the calculation

of the new user characteristic after entering the parameter for LWT.

(Zero point of the user characteristic)

Individual input of the zero point of the user characteristic via LDW

Input: LDW<Zero point> (Response time: <15ms)

1. Insert the value for the zero point of the scale via LDW<Zero point> command. The entered value is

stored, but accounted for only after entry of the parameter for LWT.

Query: LDW?; (Response time<15ms)

Effect: Output in ±7 digits (e.g. -0915345crlf) of the zero point value. The value is not converted via

NOV.

ba_aed104_8_e.doc

Page 34

AD104-R2, AD104-R5 33 / 75

Load Cell Weight

LWT

Range: 0...1,599999e6

Factory setting: 1000000

Response time: <15ms...4.2s

Parameters: 1 (0)

Password protection: yes

Parameter protect.: with input

Take the full scale value of user characteristic with LWT command

Input: LWT; (Response time <4,2s):

Individual input of the full scale value of the user characteristic via LWT:

Input: LWT<Nominal value>; (Reaktionszeit<1,5s):

(nominal value of the user characteristic)

Using this command, the transducer electronic system measures an input signal

between ±2.5mV/V ( i.e.= measured value at scale nominal load), stores this

measured value as the nominal value and calculates the new user characteristic

together with the previously entered value for LDW. The values for SZA and

SFA are not changed.

Instead of causing the AED to measure the applied signal, the value for the end value of the

user characteristic is entered here directly and, in combination with the previously entered

value for LWT, used in calculating the user characteristic.

Query: LWT?; (Response time <15ms)

Effect: Output the the value for the user characteristic in ±7 digits (e.g. -0000345CRLF) of the

nominal value or the loaded transducer (nominal load). The value is not converted via NOV.

Important Note

An input or measurement of the factory characteristic with SZA/SFA resets the user characteristic to the default

values LDW=0, LWT=1000000.

Procedure for entering the user characteristic:

1.

Enter password by means of command SPW.

2. NOV 0; output (scaling off).

3. Adjust the ASF filter such that a maximally quiescent display is effected

4. Scale at no load , wait for standstill

ba_aed104_8_e.doc

Page 35

34 / 75

5.

Nominal Value

NOV

Range: 0...1,599999e6

Factory setting: 0 (=deactivated)

Response time: <15ms

Parameters: 1

Password protection: yes

Parameter protect.: with command TDD1

Input: NOV<Wert>;

Query: NOV?; (Response time <15ms)

Effect: The value stored in the AED is output with 7 digits complete with sign ( e.g.

(Resolution of the user characteristic)

0001000CRLF 0000345crlf ).

The NOV value is used for scaling the measured value. At NOV=0 this output scaling is deactivated. The ASCII

measured value output is scaled to 1000000 at the factory. If a measured value output of 2000 digit at nominal

load is required, then use this command to set the nominal value NOV2000. The input parameters or tara

values are not changed by this scaling.

Measured value output format at nominal

load

2 Byte binary 20000 NOV value

4 Byte binary 5120000 NOV value

ASCII 1000000 NOV value

With the 2 byte binary type of output, the NOV value must be < 30000. Otherwise the measured value will be

output complete with overflow or underflow ( 7fffH or 8000H ; H: Hexadecimal). With NOV30000, the overload

range is only approx. 2700 digits.

NOV=0 NOV>0

ba_aed104_8_e.doc

Page 36

AD104-R2, AD104-R5 35 / 75

7.3 Measuring

All commands acting directly on a measured value belong to measuring, these are:

• MSV Measured value output

• STP Stop measured value output

• ASF Filter setting

• FMD Filter mode

• ICR Measuring rate

• TAR Tare mode

• TAV Set tare memory

• TAS Gross/net switch-over

ba_aed104_8_e.doc

Page 37

36 / 75

Measured Signal Value

MSV

Range: Integer ±32767

Factory setting: ASCII

Response time: < 2

Parameters: 1

Password protection: none

Parameter protect.: Output measured values

(Output measured values)

Long Integer ±8388607

ASCII ±1000000

ICR

∗ 10ms + 5ms

with ICR = Measuring rate

Query: MSV?(0); (not to be used in 2-wire connection)

Effect: Outputs measured values constantly until the output is stopped with the

command STP

Query: MSV?(1...65535);

Effect: Outputs the stated number of measured values.

(The measured values are output without the control character CR/LF, CR/LF is appended only to the last

output measured value).

The measured value is output in ASCII or binary format (see command COF).

ba_aed104_8_e.doc

Page 38

AD104-R2, AD104-R5 37 / 75

The output format for the measured value must be set previously via the command COF.

The measured value is output related to the relevant measuring range. The measured value can be a gross or

net measured value (command TAS). This COF command generates answers of constant length.

The output length for the command MSV?; depends in this case upon the output format (see COF command):

Output format AED answer No. of characters

Binary 4 Byte yyyy CRLF (y – binär) 6

Binary 2 Byte yy CRLF (y – binär) 4

ASCII (COF3;) xxxxxxxx CRLF (x - ASCII) 10

ASCII (COF9;) xxxxxxxx,xx,xxx CR LF (x - ASCII) 17

CR: Carriage Return, LF: Line Feed

Delimiter can be set (command TEX)

Selected delimiter

-1001500,25,000,

Meas. value status optional

2 Byte adress (00...31) optional

8 Byte measuring value (pos. sign = Blank)

Example: Definition of a measuring value in ASCII format (COF9)

ba_aed104_8_e.doc

Page 39

38 / 75

The output scaling depends upon the parameter of the command NOV.

Output format of the measuring value at

nominal load

2 Byte binary 20000 NOV value

4 Byte binary 5120000 NOV value

ASCII 1000000 NOV value

With the 2-byte binary output, the NOV value must be < 30000, otherwise the measured value is output with

overflow or underflow ( 7fffH or 8000H ; H: Hexadecimal). With NOV30000, the overdriving reserve is only still

approx. 2700 digits.

The response time for the measured value query is determined by the integration time (command ICR):

Filter settings with FMD0 (Querry: MSV?;)

ICR Output rate Mv/s Response time [ms], approx. with MSV?;

0 100 10

150 20

225 40

312 80

4 6 165

5 3 333

6 2 500

7 1 1000

NOV=0 NOV>0

A predefined number P1 of measured values can be output via a command MSV?P1;. The reaction time lies

between the output of two measured values. The end identification (CR LF) is output only for the last measured

value. The total time for the acquisition of P1 measured values is calculated as:

Measuring time [ms] = P1

with ICR = Measuring rate

There is a continuous output of measured values with MSV?0;. This output can be stopped only through the

commands STP, RES or voltage switch-off. No other parameters can be changed during the continuous output.

In the 4-byte binary output or in the ASCII output, the measured value status can be transmitted with the

measured value (see commands COF).

Error messages in the measured value status

Contents of the status byte in

the measured value output

Bit 0 = 1, Nett-Overflow

Bit 1 = 1, Gross-Overflow

Bit 2 = 1, ADU-Overflow

Bit 3 1= Standstill Measuring values are in the range of still standing (±1d/s).

Bit 7, 6 = Measured values not coherent

ICR

∗

2

∗ 10ms + 5ms,

Possible cause

Tare value too large

Scaling too sensitive

ADU

overdrives (input >± 2.5mV/V)

Do not fit together. Measured values cannot be output

justified in the selected configuration

ba_aed104_8_e.doc

Page 40

AD104-R2, AD104-R5 39 / 75

Stop

STP

The measured value output is ended with this command. STP acts only on the command MSV.

A started measured value is output completely.

(Stop of the measured value output)

ba_aed104_8_e.doc

Page 41

40 / 75

Amplifier Signal Filter

ASF

Range: 0...8

Factory setting: 5

Response time: <15ms

Parameters: 1

Password protection: none

Parameter protect.: with command TDD1

Input: ASF(0...8);

Query: ASF?;

Effect: Entry of the filter stage as decimal number from (0...8)

(Digital filter setting)

The AED has a multi-stage filter chain:

• An analog 3rd order filter (cut-off frequency approx. 50 Hz)

• Averaging over 2 measured values (at 200 Hz scan rate, fixed setting)

• Standard filter (FMD0) or a FIR filter (FMD=1); cut-off frequency selectable through ASF, fixed scan rate =

100 Hz

• Averaging for output rate reduction (selectable through ICR, scan rate <=100 Hz)

Thus the wanted filter effect and output rate can be set through the two commands (ASF, ICR). Further new

efficient digital filters have been implemented apart from the standard filter properties. The command FMD is

used for switching over between the two filter modes:

FMD 0; Standard filter

FMD 1; FIR filter (with fast settling time)

Filter characteristics of standard filters (FMD0):

ASF Settling time

in ms to 0.1%

1 130 8 -20

2 320 3,5 -34

3 700 1,5 -48

4 1400 0,7 -60

5 2900 0,3 -72

6 5800 0,2 -82

7 11800 0,1 -90

8 23800 0,05 -96

Cut-off frequency [Hz]

at –3dB

max. attenuation [dB]

at 300Hz

The filter is switched off at ASF0. The cut-off frequency of the filter determines the settling time. The higher the

filter index, the better is the filter effect but the longer is the settling time on changing the weight. The filter

setting should be chosen as small as possible, whereby the measured value quiescence (standstill) must be

guaranteed at unchanging weight.

ba_aed104_8_e.doc

Page 42

AD104-R2, AD104-R5 41 / 75

The FIR-Filter (FMD1) can be described with the following Table:

ASF Filter

length

(Tabs)

1 12 7.6 17 23 50...100 >25

2 14 6.6 15 19 50...80 >20

3 16 6.2 14 17 50...90 >19

4 16 5.5 12.5 16 50...80 >17.5

5 18 4.7 11 14 45...80 >15

6 20 4 9.5 12 45...85 >12.5

7 22 3.5 8 10 40...85 >10

8 22 3 7 8 40...80 >8

The filter is switched off with ASF0.

The filters ASF6...ASF8 are limited additionally in bandwidth by averaging (ICR>4).

The transient recovery time of the filters is calculated from filter length (12...24) multiplied by the filter scan rate

of 10ms.

Settling time filter : 120ms ... 240ms

Mean value formation (ICR) does affect the total settling time of the measuring chain. The total settling time

depends additionally upon the mechanical construction of the transducer, the dead load of the scale and the

weight to be weighed.

Cut-off

frequency [Hz]

at -3dB

20dB

attenuation at

frequency in

Hz

40dB

attenuation at

frequency in

Hz

Attenuation in

the Stop band

[dB]

Stop band

[Hz]

ba_aed104_8_e.doc

Page 43

42 / 75

Filter Mode

FMD

Range: 0/1

Factory setting: 0

Response time: <15ms

Parameters: 1

Password protection: none

Parameter protect.: with command TDD1

Input: FMD(0/1);

Query: FMD?;

Effect: Output of the set filter stage (0 or 1)

(Filter selection for the command ASF)

Entry of the filter stage as decimal number of 0 or 1:

The description of the filter selection can be found in the ASF command description.

ba_aed104_8_e.doc

Page 44

AD104-R2, AD104-R5 43 / 75

Internal Conversion Rate

ICR

Range: 0...7

Factory setting: 0

Response time: <10ms

Parameters: 1

Password protection: none

Parameter protect.: with command TDD1

Input: ICR(0...7);

The integration time determines the output data rate of the measured values and thus also the response time to

the measured value query with the command MSV?;.

ICRx = Averaging over 2

The following setting possibilities result from this:

(Output rate of measured values)

Entry of the measuring rate as decimal number from 0...7

x

measuring values , with x= 0...7

ICR Output rate Mv/s

0 100

150

225

312

46

53

62

71

Observe the baud rate setting when setting the measured value rate. A high baud rate must be set at high

measured value rates to avoid measured data losses (see command COF).

Query: ICR?;

Effect: Output of the set measuring rate (0...7)

Important Note

At ICR1 there is an especially good suppression of a 50 Hz mains frequency which may possibly cause

interference.

ba_aed104_8_e.doc

Page 45

44 / 75

Tare

TAR

Range: —

Factory setting: —

Response time: < 2

Parameters: 0

Password protection: none

Parameter protect.: no data to be protected

The current measured value is tared with the command TAR. After taring, the system switches over to "Net

measured value" (TAS0). The current value is filed in the tare memory (see also command TAV) and subtracted

from the measured value and all following measured values.

(Tare modus)

ICR

∗ 10ms + 5 ms

ba_aed104_8_e.doc

Page 46

AD104-R2, AD104-R5 45 / 75

Tare Value

TAV

Range: 0...±8388607

Factory setting: 0

Response time: <20ms

Parameters: 1

Password protection: none

Parameter protect.: with command TDD1

Input: TAV(±Tare value);

(Set / read tare memory)

Enter tare value 7digit with sign (max. ±8 388 607).

This value is set off with the LDW/LWT characteristic

scaled with the parameter NOV (0...NOV). The tare

memory is cleared (contents = 0) after characteristic

entries with the commands SZA, SFA or LDW, LWT.

Query: TAV?;

Effect: The contents of the tare memory are output.

The tare value is converted to the NOV value.

Output format

measured value

at nominal load

2 Byte binary ±NOV value ±150% NOV value ±1000000 ±8 388 607

4 Byte binary ±NOV value ±150% NOV value ±1000000 ±8 388 607

ASCII ±NOV value ±150% NOV value ±1000000 ±1 599 999

Example:

NOV3000; (Scaling the scale)

TAS1; (Gross output switched on)

MSV?; 1500CRLF (Measured value lies at 50% = nominal load of the scale)

TAR; (Taring and switching over to net output)

TAV?; 1500CRLF (Enquire tare value)

MSV?; 0CRLF (Net measured valuet)

TAS?; 0CRLF (Net is switched on)

TAS1; 0CRLF (Switching over to gross)

MSV?; 3000CRLF (Measured value is at 100% = nominal load of the scale)

TAV?; 1500CRLF (Enquire tare value, unchanged)

Nominal

taring range at

NOV>0

Maximum

taring range at

NOV>0

Nominal

taring range at

NOV=0

Maximum

taring range at

NOV=0

ba_aed104_8_e.doc

Page 47

46 / 75

Tare Set

TAS

Range: 0...1

Factory setting: 1 (Gross)

Response time: <10ms

Parameters: 1

Password protection: none

Parameter protect.: with command TDD1

Input: TAS(0...1);

TAS0: Net measured value

The value in the tare memory is subtracted from the current measured value.

TAS1: Gross measured value

The value in the tare memory is not offset.

(Gross/net switch-over)

Query: TAS?;

Effect: Current setting is output.

ba_aed104_8_e.doc

Page 48

AD104-R2, AD104-R5 47 / 75

7.4 Special functions

Define Password

DPW

Range: 1...7 Letters or numbers (ASCII-characteristics

Factory setting: AED

Response time: <80ms

Parameters: 1

Password protection: none

Parameter protect.: with input

Input: DPW("Password");

(Defining a password)

The user can enter an arbitrary max. 7digit password

with this command. All ASCII characters are

permissible. The entry must be in inverted commas (“...“).

ba_aed104_8_e.doc

Page 49

48 / 75

Set Password

SPW

Range: The password defined with DPW

Factory setting: AED

Response time: <15ms

Parameters: 1

Password protection: none

Parameter protect.: no data to be protected

Input: SPW("Passwd");

Use of the protected commands is also disabled after RES or power On.

The following commands are protected by a password:

LDW, LWT, NOV, TDD0, SFA, SZA, LIC

(Write enable for all password-protected parameters)

The command SPW with the correctly entered

password authorizes data entry with all commands. The

command SPW with a wrong password disables the

data entry for protected commands. No password is

required for outputs. A distinction is made between

uppercase and lowercase letters in the password entry.

ba_aed104_8_e.doc

Page 50

AD104-R2, AD104-R5 49 / 75

Restart

RES

Range: —

Factory setting: —

Response time: <3s

Parameters: —

Password protection: none

Parameter protect.: no data to be stored

The command RES produces a warm start. This command generates no answer. All parameters are set as they

were stored with the last TDD command, i.e. EEPROM values are taken over into the RAM.

(Device start)

ba_aed104_8_e.doc

Page 51

50 / 75

Engineering Unit

ENU

Range: 4 letters or numbers (ASCII characters)

Factory setting: none

Response time: Output: <15ms

Parameters: 1

Password protection: none

Parameter protect.: with input

Input: ENU("abcd");

Query: ENU?;

Effect: Output of the unit with 4 characters.

(User engineering unit)

Input: <40ms

Entry of a unit. An arbitrary unit with max. 4 characters can be entered. If less

than 4 characters are input, the entry is supplemented with blanks. The entered

unit is not appended to the measured value. The characters

must be entered in quotation marks (“...“).

ba_aed104_8_e.doc

Page 52

AD104-R2, AD104-R5 51 / 75

Identification

IDN

(Identification of transducer type and serial number)

Range: Transducer type: 15 ASCII characters

Factory setting: depending on transducer

Response time: Output: <15ms

Parameters: 1

Password protection: none

Parameter protect.: with input

Input: IDN<"Transducertype">,<"Serial number">;

The serial number is entered by the factory and may have maximum 7 characters, it is entered like the type

designation. The serial number must not be changed. If less than the maximum allowed number of characters is

entered for the type designation or serial number, the entry is automatically filled up with blanks up to the

maximum allowed number. The manufacturer and the software version cannot be entered.

Query: IDN?;

Serial number: 7 ASCII characters

Input: <180ms

Entry of the transducer type and of the serial number.

The type and serial number of the transducer are filed in

the EEPROM of the transducer electronic unit. The type

designation may have maximum 15 characters and it

must be entered as string in quotation marks ("..."). If

only the serial number has to be changed, a comma is

entered for the transducer type parameter, e.g. IDN,“0815“;

Effect: An identification string is output (33 characters).

Sequence: Manufacturer, transducer type, serial number, software version, e.g.

HBM, "AED104","1234", P20crlf

The number of the output characters is fixed. The transducer type is always

output with 15 characters, the serial number always with 7 characters.

ba_aed104_8_e.doc

Page 53

52 / 75

Transmit Device Data

TDD

Range: 0...2

Factory setting: —

Response time: TDD0:<2.2s

Parameters: 1

Password protection: TDD0:yes

Parameter protect.: no data to be protected

Input: TDD(0);

(Protect device parameters)

TDD1:<0.1s

TDD2:<1.3s

TDD1: none

TDD2: none

Cold start, the parameters are reset to the factory settings (see table

next page)