Hayward Pools H250IDL2, H400IDL2, H350IDL2 User Manual

®

HAYWARD

Installation, Operation & Service Procedures

Pool and Spa/Hot Tub Heaters

Models H250IDL2, H350IDL2 & H400IDL2

FOR YOUR SAFETY

WARNING: If the information in these

instructions is not followed exactly, a fire or

explosion may result causing property damage, personal injury, or death.

– Do not store or use gasoline or other flam

mable vapors or liquids in the vicinity of this

or any other appliance.

-

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance

• Do not touch any electrical switch; do not

use any phone in your building

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call

the fire department.

– Installation and service must be performed

by a qualified installer, service agency or the

gas supplier.

SAFETY

YOUR

FOR

This product must be installed and serviced by authorized personnel, qualified in

pool/spa heater installation. Improper installation and/or operation can create carbon

monoxide gas and flue gases that can cause serious injury

For indoor installations, as an additional measure of safety, Hayward strongly recommends installation of suitable Carbon Monoxide (CO) detectors in the vicinity of this appliance and in any adjacent occupied spaces. Improper installation and/or operation will

void the warranty

.

, property damage, or death.

PATENT NO. 6026804 1303026201 1105

Contents

Section I. General Information

ECTION I. GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

S

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Hayward heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

ECTION V. CONSUMER OPERATION & MAINTENANCE PROCEDURES . . . . .23

S

SECTION II. HEATER SIZING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Selecting the correct size heater . . . . . . . . . . . . . . . .4

For a swimming pool . . . . . . . . . . . . . . . . . . . . . . . . .4

For a spa or hot tub . . . . . . . . . . . . . . . . . . . . . . . . . .4

SECTION III. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Equipment inspection . . . . . . . . . . . . . . . . . . . . . . . . .5

Important notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Conformance with codes . . . . . . . . . . . . . . . . . . . . . .5

Sea Level/high altitude installation . . . . . . . . . . . . . . .5

Location of Heater . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Flooring

Reversible water connections . . . . . . . . . . . . . . . . . .5

Outdoor installation and venting . . . . . . . . . . . . . . . . .6

Indoor installation and venting . . . . . . . . . . . . . . . . . .7

Air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Equipment located in confined spaces . . . . . . . . . . .7

Vertical Venting—Negative Pressure . . . . . . . . . . . . .8

Indoor Adapter Kit Installation . . . . . . . . . . . . . . . . . .8

Vent Sizing Table . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Horizontal or Vertical Venting-Positive Pressure . . . . . .10

Special Gas Vent Adapter Kit Installation . . . . . . . . .10

Indoor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Connecting Special Gas Vent to the Heater . . . . . .11

Gas supply and piping . . . . . . . . . . . . . . . . . . . . . . .12

All gas installations . . . . . . . . . . . . . . . . . . . . . . . . . .13

Water piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Installation above pool/spa surface . . . . . . . . . . . . .16

Automatic chlorinators and chemical feeders . . . . .16

Pressure relief valve . . . . . . . . . . . . . . . . . . . . . . . . .16

Electrical connections . . . . . . . . . . . . . . . . . . . . . . . .17

Remote control connection . . . . . . . . . . . . . . . . . . .18

Remote thermostat connection

Connecting a remote . . . . . . . . . . . . . . . . . . . . . . . .18

2-Wire remote thermostat . . . . . . . . . . . . . . . . . . . .18

2-Wire Remote Switch . . . . . . . . . . . . . . . . . . . . . . .18

3-W

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

. . . . . . . . . . . . . . . .

ire Remote Switch

. . . . . . . . . . . . . . . . . . . . . . .

18

18

SECTION VI. QUALIFIED TECHNICIAN – MAINTENANCE/SERVICING . . . .28

SECTION VII. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . .36-39

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

SECTION IV

. INSTALLER CHECK-OUT AND START-UP . . . . . . . . . . . . . . .20

PARTS ILLLUSTRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Gas line testing

Gas pressure test procedure . . . . . . . . . . . . . . . . . .20

Installation below pool/spa surface . . . . . . . . . . . . .22

Two speed pump . . . . . . . . . . . . . . . . . . . . . . . . . . .22

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

20

W

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Pool/Spa water chemistry . . . . . . . . . . . . . . . . . . . .23

Using chlorinators and chemical feeders . . . . . . . . .23

Heater operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . .24

Temperature control operation . . . . . . . . . . . . . . . . .25

Set point adjustment . . . . . . . . . . . . . . . . . . . . . . . .25

Periodic inspection . . . . . . . . . . . . . . . . . . . . . . . . . .26

Winterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Opening drain valve . . . . . . . . . . . . . . . . . . . . . . . . .27

Spring start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Control

External heat exchanger inspection and cleaning . .28

Heat exchanger removal . . . . . . . . . . . . . . . . . . . . .29

Combustion chamber . . . . . . . . . . . . . . . . . . . . . . . .29

Burner inspection and cleaning . . . . . . . . . . . . . . . .30

Burner removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Burner Installation . . . . . . . . . . . . . . . . . . . . . . . . . .30

Gas valve replacement . . . . . . . . . . . . . . . . . . . . . .30

Ignitor removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Main burner orifices . . . . . . . . . . . . . . . . . . . . . . . . .31

Gas conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Control Locations . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Temperature controls . . . . . . . . . . . . . . . . . . . . . . . .31

Vent Pressure switch . . . . . . . . . . . . . . . . . . . . . . . .31

High limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Blower vacuum switch . . . . . . . . . . . . . . . . . . . . . . .32

Water pressure switch . . . . . . . . . . . . . . . . . . . . . . .33

Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

By-pass valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Thermal control valve . . . . . . . . . . . . . . . . . . . . . . . .34

ransformer

T

Combustion blower . . . . . . . . . . . . . . . . . . . . . . . . . .35

ARRANTY & WARRANTY CARD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35

42-43

Introduction:

his manual contains instructions for installation,

T

peration, maintenance, troubleshooting and parts

o

lists for the safe use of the Model H250IDL, H350IDL

and H400IDL Low NOxswimming pool/spa/hot tub

heaters.

Hayward strongly recommends that the manual be

read by the installer before installing the swimming

pool/spa/hot tub heater. If after reviewing the manual,

any questions still remain unanswered, contact the

factory or local representative. Following heater

installation, the installer should leave the manual with

the consumer for future reference.

Hayward heaters:

The H-Series gas-fired pool/spa heater is the

result of nearly 50 years in the engineering and production of the finest water heating equipment. The

direct fired finned-tube design of the pool/spa heaters

is the most advanced in the industry, offering highly

efficient, economical pool/spa heating and scale free

operation. No effort has been spared in making the

most rugged, highly dependable, easy-to-maintain

pool/spa heater available.

The H-Series heaters are suitable only for heating

of swimming pools, spas, or hot tubs. These heaters

should not be used as space heating boilers, general

purpose water heaters, or for heating salt water pools

and fish ponds. When installed and operated in accordance with the manual’s instructions, the H-Series

heater will provide many years of trouble free service

and increased pool/spa enjoyment.

Limited warranty summary:

e warrant the H-Series pool/spa heater to be

W

ree from defects in materials and workmanship, and

f

we will within one year from date of installation for all

users, for the original purchaser, repair or, at our

option, replace without charge any defective part.

We further warrant that if the heat exchanger or

exchanger headers (water-containing section) leak

within one year from date of such installation for all

users, due to defects in materials and workmanship,

we will provide a replacement part.

Under the terms of the special FireTile™ limited

warranty, we will replace any FireTile™ components

used in the combustion chamber of the pool/spa

heater which fail from defects in the workmanship and

materials under normal use and service in a single

family residential application for a period of (5) years.

Cost of freight, installation, fuel, and service labor

(after one year) is at user’s expense. For full details

of warranty agreement, see warranty certificate

included in this manual.

CAUTION: If the pool/spa heater is damaged or

destroyed by improper maintenance, excessive

water hardness, incorrect water chemistry, or

freezing it is not covered under the manufacturer’s warranty.

2

3

Section II. Heater Sizing

Temp. Rise F

Model

H250

25 3015 2010 35

2309

1540

1155

924 770 660

H400

3695 2463 1848 1478 1232 1056

H350

3233 2156 1617 1293 1078 924

Pool Surface Area In Square Feet

Figure 2 - Recommended Heater Model

Model

H400

Figure 3 - Recommended Heater Model

Spa/Hot Tub Size in Gallons

Time in Minutes to Raise Spa/Tub Temperature 30 F

200 300 400 500 600 700 800 900 1,000

9 14 19 23 28 33 37 42 47

H250

15 23 31 38 46 54 61 69 77

H350

11 16 21 27 32 37 43 48 54

1

5

7

12

10

4

2

6

8

11

9

3

Section III. Installation

Selecting the correct size heater:

ize, average wind velocity, ambient temperature, and

s

desired increase in temperature over ambient temperature, and desired increase in temperature over ambient. A pool/spa in a warm area with little or no wind

will not require as large a heater as one in a cool

windy location. Detailed sizing information is provided

below.

For a swimming pool:

1. Determine pool’s surface area in square feet.

2. Determine desired pool water temperature

3. Determine average air temperature of coldest

4. The temperature rise is difference between 2 & 3.

4

actors influencing heater sizing include pool/spa

F

For indoor pool installations divide the pool’s

surface area by 3.

Pool Surface

Figure 1

(usually 78 - 82º F).

month of use.

Area

5. Locate in Figure 2 the surface area equal to or just

greater than the pool’s surface area and the

temperature degree rise and select the appropriate

heater model.

Figure 2 is based on 3

elevation of up to 2,000 feet above sea level.

When not in use, keep pool covered to

reduce heat loss, chemical usage, and dirt load

on the filtering system.

For a spa or hot tub:

Determine spa capacity in gallons (surface area x

average depth x 71⁄2).

The reference table lists the time required in min-

utes to raise the temperature of the spa/hot by 30ºF,

read to the left and select the appropriate heater

model.

This guide can be adjusted for other temperature

rises. For example, if a 15ºF increase in temperature

is desired, simply divide the time for 30ºF rise by the

ratio of 30/15=2.

NOTE: Heat losses and /or heat absorbed by

spa walls (such as concrete) or other objects will

add to the heat-up time.

Spa sizing is based on an insulated and covered

spa. Always cover spa or hot tub when not in use to

minimize heat loss and evaporation.

1

⁄2 MPH wind velocity and

Equipment inspection:

n receipt of the heater equipment, inspect the

O

eater carton for damage. If any carton is damaged,

h

note it when signing for it. Remove the equipment

from the carton(s) and advise the carrier of any damages at once.

Important notice:

The instructions herein are intended for the use of

a qualified technician, specifically trained and experienced in the installation of this type of heating equipment. Some states or provinces require that installation be licensed. If this is the case in the state or

province where heater is located, the contractor must

be properly licensed.

WARNING: Failure to comply with the appliance and vent package installation instructions

and service instructions in this manual may result

in equipment damage, fire, asphyxiation, or carbon monoxide poisoning. Exposure to products

of incomplete combustion (carbon monoxide) can

cause cancer and birth defects or other reproductive harm.

Conformance with codes:

The heater shall be installed in accordance with all

local and state codes. The heater installation must

conform to the National Gas Code ANSI Z223.1 (latest edition) and with the requirements of the authority

having jurisdiction. Design Certification of the heater

is in compliance with ANSI Z21.56•CSA4.7.

For Canadian installations, the heater is to be

installed in accordance with the standards CAN/CGA

B149.1 and B149.2 – INSTALLATION CODES FOR

GAS BURNING APPLIANCES AND EQUIPMENT

and/or Local Codes, and if applicable, Standard CSA

C22.1 – CANADIAN ELECTRICAL CODE, Part 1.

Sea Level/high altitude installation:

The H-Series heaters may be installed up to 2,000

feet of elevation above sea level.

Location of heater:

Locate the pool/spa heater in an area where leak

age of heat exchanger or connections will not result

in damage to the area adjacent to the heater or to the

structure. When such locations cannot be avoided, it

recommended that a suitable drain pan, with drain

outlet, be installed under the heater. The pan must

not restrict air flow

This heater must be installed at least five feet from

the inside wall of a pool/spa unless separated from

the pool/spa by a solid barrier

installed also at least five feet from the wall of an

above-ground pool.

The heater must be installed such that the location

of the vent assembly outlet relative to adjacent public

.

This heater must be

.

-

walkways, adjacent buildings, openable windows, and

building openings complies with the National Fuel

Gas Code, ANSI Z223.1 and/or CAN/CGA B149

Installation Codes.

Flooring:

This heater can be installed on combustible flooring.

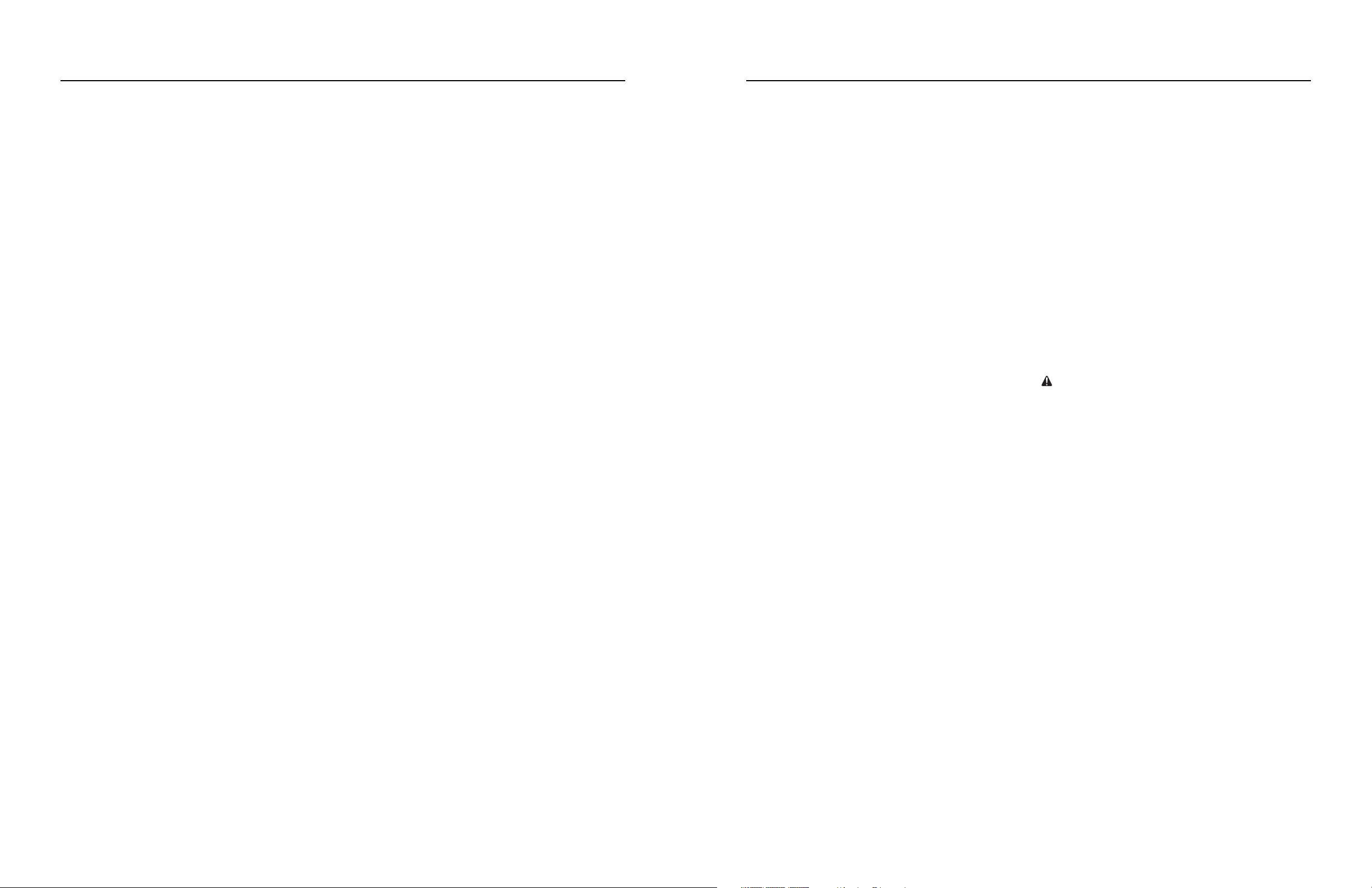

Reversible water connections:

This heater is designed so that it can be installed

with the water connections located on either the right

or left side. Heaters are shipped from the factory with

the water connections on the right side. To bring the

water connections to the left side, follow step-by-step

instructions below and refer to the illustration in

Figure 5. These procedures should be performed by

a trained service technician before the heater is

installed.

1. Remove four (hot) vent screws and remove

panel.

2. Remove heater top.

3. Remove screws from left and right side

access panels. Remove panels.

4. Remove the front panel.

5. Disconnect high limit wires and reroute them

to opposite side of heater. Disconnect the

thermistor leads from control panel and pull

through intermediate panel.

6. Remove pressure switch and tube.

7. Remove 12 nuts retaining front header and

carefully remove header.

CAUTION: By-pass and thermal governor may

become dislodged when removing front heater. They

must be reinstalled properly prior to reinstallation of

front header.

CAUTION: Header O-ring may be re-used if not

permanently deformed. if installing new O-rings,

Jack’s 327 Lube may be liberally applied to O-ring to

keep it in place during header installation.

8. Remove four screws retaining air deflector,

and remove air deflector.

9. Unplug wires and pressure tap tubes from

combustion blower

10. Remove screws retaining flue collector and

remove flue collector/combustion blower assembly.

1. Remove screws securing heat exchanger

1

from tube sheets on both front and rear of

heater.

.

Figure 4

5

R

OTATE

H

EAT EXCHANGER

180°

DO NOT FLIP

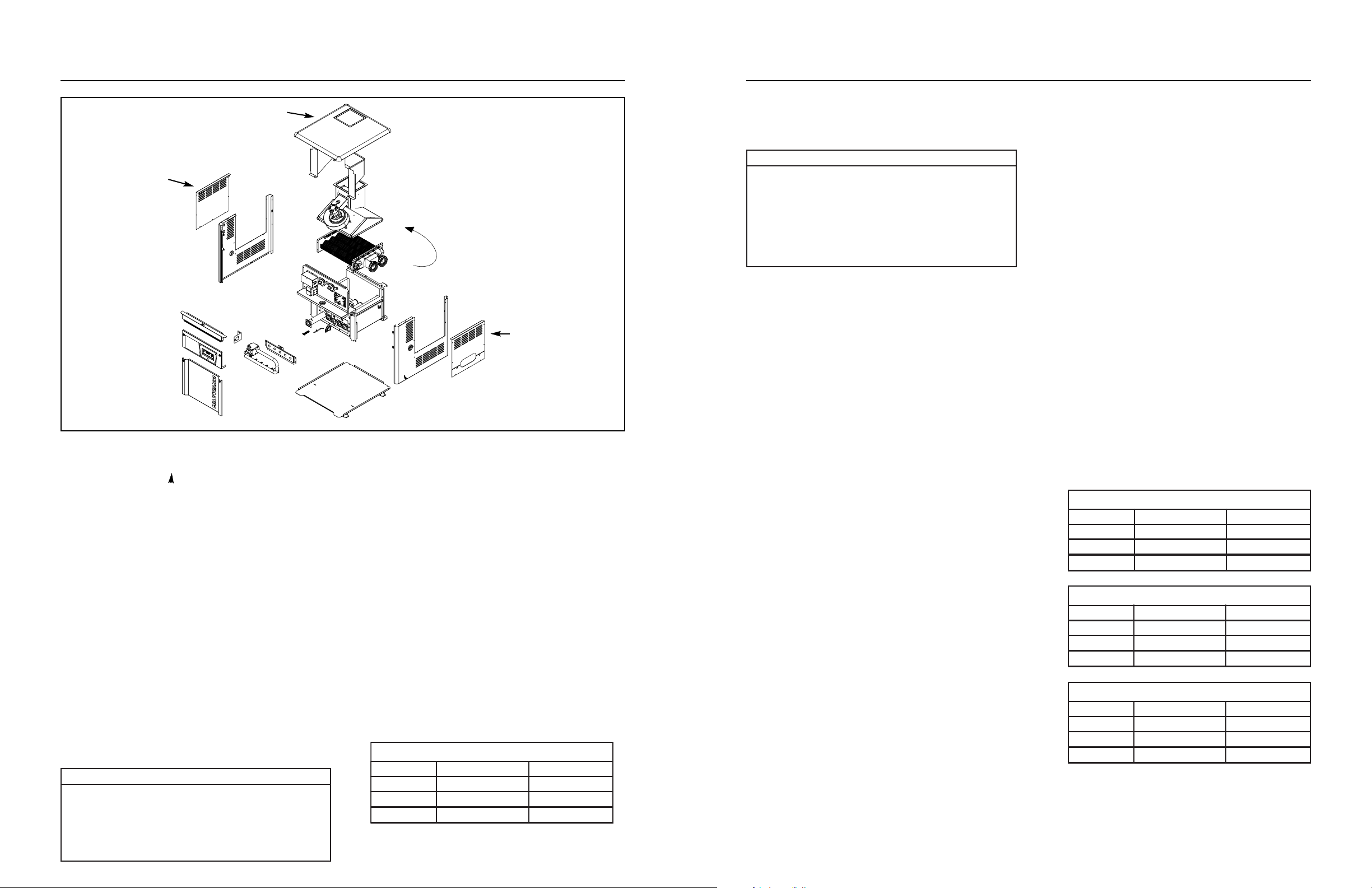

Outdoor Installations

Top - Open and unobstructed

Front - 24”

Back - 6”

Right side (Water side) - 12”

Left side - 6”

1 Square Inch Per 4000 BTU Per Hour

Input Combustion Air Ventilation Air

250,000

350,000

400,000

62.5 square in.

87.5 square in.

100 square in.

62.5 square in.

87.5 square in.

100 square in.

I

ndoor Installations

Top - 36”

Front - Unobstructed

Back - 6”

Right side (Water side) - 12”

L

eft side - 6”

For use on combustible floors.

Do not install in a closet.

1 Square Inch Per 4000 BTU Per Hour

Input Combustion Air Ventilation Air

250,000

350,000

400,000

62.5 square in.

87.5 square in.

100 square in.

62.5 square in.

87.5 square in.

100 square in.

Figure

10

1 Square Inch Per 2000 BTU Per Hour

Input Combustion Air Ventilation Air

250,000

350,000

400,000

125 square in.

175 square in.

200 square in.

125 square in.

175 square in.

200 square in.

Figure

11

1 Square Inch Per 1000 BTU Per Hour

Input Combustion Air Ventilation Air

250,000

350,000

400,000

250 square in.

350 square in.

400 square in.

250 square in.

350 square in.

400 square in.

Figure

9

eft Access

L

anels

P

12. Lift out heat exchanger and rotate it 180

degrees horizontally – DO NOT FLIP IT OVER.

(This End Up ) sticker should be pointing up.

13. Reinstall front header on heat exchanger

(“TOP” marking on header should now be on

the bottom).

14. Torque header nuts from 5 to 7 ft lbs. in the

sequence shown by Figure 4. Do not

overtighten.

15. Move the pressure switch tube over to the left

side of the heater and route through hole in

intermediate panel. Insert tube in header

fitting and tighten the ferrule down with the

nut.

16. Reattach the high limit wires to the switches.

Route thermistor leads through intermediate

panel, into control compartment, and plug into

control board.

17. Repeat steps 1-4 and 8-11 for reinstallaton.

Outdoor installation and venting:

The following installation and service clearances

must be maintained from surfaces to provide adequate air flow to the heater.

6

eater Top

H

Figure 6

Reversible Water Connections

Figure 5

Right Access

Panels

1. Outdoor models are self-venting and do not

require additional vent piping.

2. Do not install in a location where growing

shrubs may in time obstruct a heater’s

combustion air and venting areas.

3. Do not install this appliance under an overhang

less than 3 feet from the top of the appliance.

The area under the overhang must be open

on three sides.

4. Do not install heater where water spray from

ground sprinklers can contact heater.

Sprinkler water could cause operating problems.

5. Do not install under a deck.

6. Any enclosure around the heater must provide

a combustion air vent commencing within 12

inches of the bottom of the enclosure. The

vent opening shall have a minimum free area

of 1 square inch per 4,000 BTU per hour of

total input rating of all heaters in the

enclosure. See Figure 7.

Figure 7

Indoor installation and venting:

he following installation and service clearances

T

ust be maintained from combustible materials.

m

Figure 8

Air supply:

Indoor installations and outdoor shelters must be

provided with adequate combustion and ventilation air

NOTE: For more detailed methods of providing air for

combustion and ventilation, refer to latest edition of

the National Fuel Gas Code, ANSI Z223.1.

vents to assure proper heater operation. These vents

must be sized according to the requirements stated in

A and B below and must never be obstructed when

heater is in operation.

When air blowers are used in spa/hot tub installations, caution must be observed to insure sufficient

combustion air is available to the gas heater for proper combustion. A separate blower air duct is recommended.

Equipment located in confined spaces:

A. All Air Supply From Inside The Building: The

confined space shall be provided with two permanent openings communicating directly with an

additional room(s) of sufficient volume so that the

combined volume of all spaces meets the criteria

for an unconfined space (a space whose volume is

not less than 50 cubic feet per 1000 BTUH). The

total input of all gas utilization equipment installed

in the combined space shall be considered in

making the determination. Each opening shall have

a minimum free area of 1 square inch per 1,000

BTU per hour of the total input rating of all gas

utilization equipment in the confined space, but not

less than 100 square inches. See Figure 9. One

opening shall be within 12 inches of the top and

one within 12 inches of the bottom of the enclosure.

B. All

Air Supply From Outdoors:

The confined

space shall be provided with two permanent

openings, one commencing within 12 inches of

the bottom of the enclosure. The opening shall

communicate directly, or by ducts, with the

outdoors or spaces (crawl or attic) that freely

communicate with the outdoors.

When directly communicating with the

1.

outdoors, each opening shall have a

minimum free area of 1 square inch per 4,000

BTU per hour of total input rating of all

equipment in the enclosure. See Figure 10.

2. When communicating with the outdoors

through vertical ducts, each opening shall

have a minimum free area of 1 square inch

per 4,000 BTU per hour of total input rating of

all equipment in the enclosure. See Figure 10.

3. When communicating with the outdoors

through horizontal ducts, each opening shall

have a minimum free area of 1 square inch

per 2,000 BTU per hour of total input rating of

all equipment in the enclosure. See Figure 11.

4. When ducts are used, they shall be of the

same cross-sectional area as the free area of

the openings to which they connect. The

minimum dimension of rectangular air ducts

shall be not less than 3 inches.

7

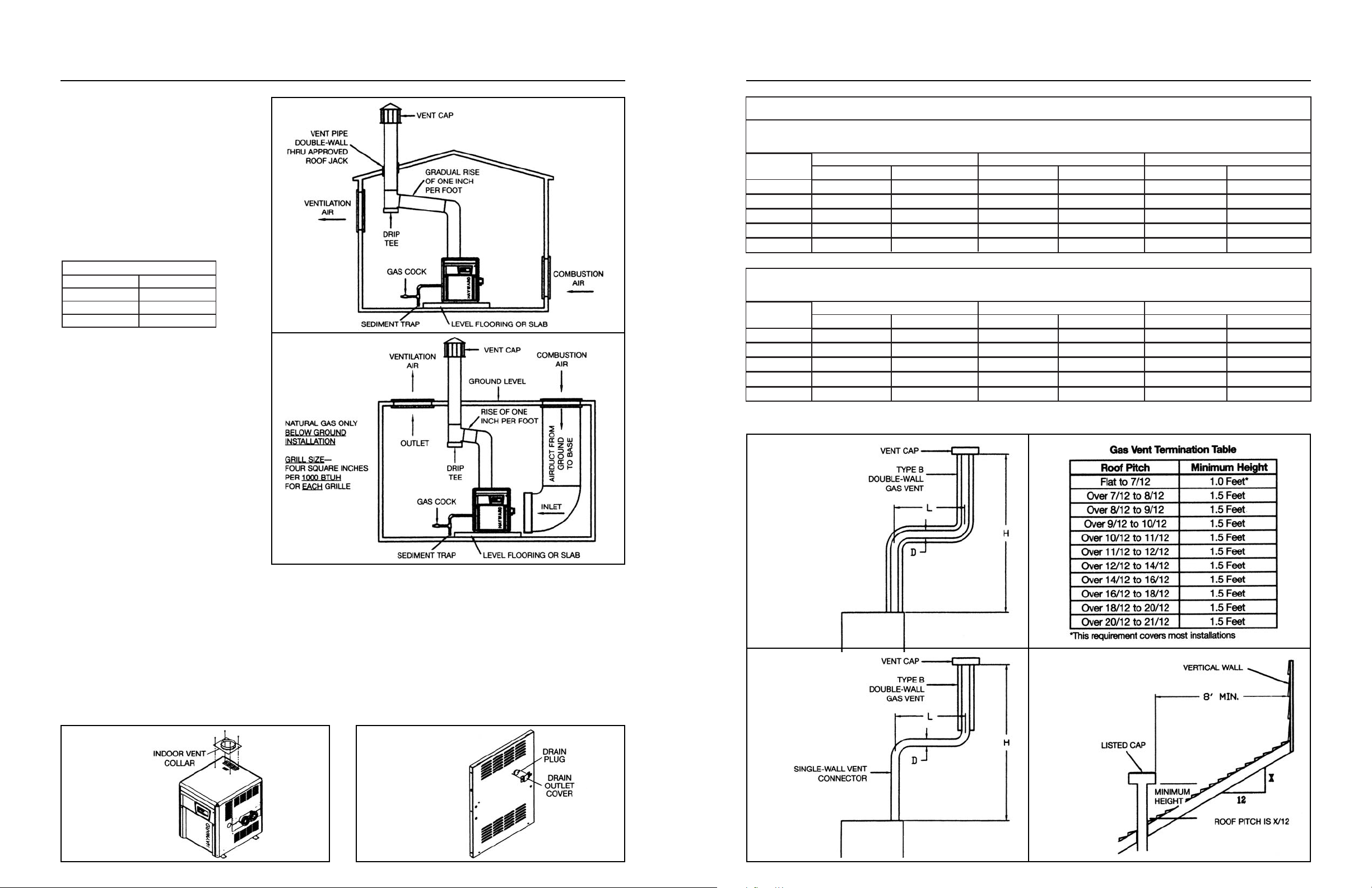

Vertical Venting—Negative

Vent Collar Diameters

Model Diameter

H250IDL

H350IDL

H400IDL

6 inches

8 inches

8 inches

Vent Diameter

6 in.

7 in.

8 in.

9

in.

1

0 in.

H

250IDL

H

350IDL

H

400IDL

Vent Sizing Table for Vertical Negative Pressure Vending

Minimum Height (H) Maximum Hieight (H) Minimum Height (H) Maximum Hieight (H) Minimum Height (H) Maximum Hieight (H)

T

able 1: Type B Vertical Vent with Type B Vent Connector

L

ateral Length (L) must be less than Ω of the Vertical Vent Height (H)

V

ent System can have up to three 90 degree elbows.

F

8

'

6'

6'

6' 6'

6'

6'

6'

6'

6'

6'

6'50'50'

5

0'

50'

50'

50'

50'

50'50'

50'

Not RecommendedNot Recommended

N

ot Recommended Not Recommended

Not Recommended

N

ot Recommended

Not Recommended

50'

Vent Diameter

6 in.

7 in.

8 in.

9 in.

10 in.

H250IDL

H350IDL

H400IDL

Minimum Height (H) Maximum Hieight (H) Minimum Height (H) Maximum Hieight (H) Minimum Height (H) Maximum Hieight (H)

Table 2: Type B Vertical Vent with Single Wall Vent Connector

Lateral Length (L) must be less than Ω of the Vertical Vent Height (H)

Vent System can have up to three 90 degree elbows.

8'

6'

6'

6'6'

6'

50'

20'

50'

30'30'

N

ot RecommendedNot Recommended

Not Recommended Not Recommended

N

ot Recommended

Not Recommended

N

ot Recommended

50'

Not Recommended Not Recommended Not RecommendedNot RecommendedNot RecommendedNot Recommended

Not Recommended

Not RecommendedNot Recommended

Not RecommendedNot Recommended

Pressure:

ocate the pool/spa heater as close

L

s practical to a chimney and gas sup-

a

ply according to the Figures 12 and 13.

Size vent according to the venting

tables. The maximum vent height

should not exceed 50’. The total vent

length should not exceed one half of

the total vertical vent height. The vent

system can have up to three 90 degree

Below Ground Installation

elbows. See Figure 16 on page 9.

The cap opening of the vent must

terminate in accordance with Figure

16. The vent cap location shall have a

minimum clearance of 4 feet horizontally from electric meters, gas meters

regulators and relief openings.

The weight of the vent or chimney

must not rest on the heater. Support

must be provided in accordance with

applicable codes. The vent pipe must

be supported to maintain proper clearances from combustibles.

Venting extending above the roof by

more than five feet should be guided or

braced above or below the roof to protect

the vent from wind and/or snow damage.

Indoor Adapter Kit Installation:

Before connecting vent to heater

must be installed to the heater exhaust outlet, and a

drain plug and outlet cover must be installed. These

components are contained in the indoor

The installation of the kit is done as follows:

1. Remove the 4 screws that fasten the vent cover

Indoor Vent Collar

Installation

Figure 14

8

to the internal vent assembly. Discard the vent

, a vent collar

Figure 13

Adapter Kit.

cover. Install the vent collar and gasket over

exhaust using 4 screws previously removed.

See Figure 14.

2. Install plug into drain at rear of heater. Install

drain outlet cover over the drain outlet using 2

screws. See Figure 15.

3. Install vent pipe on the indoor vent collar. The

collar will accept 6” or 8” vent diameter, depending

upon the model of heater

“Indoor Installation and Venting” for indoor

installation and venting guidelines.

Drain Outlet Cover

Installation

Figure 15

Indoor Installation

Figure 12

. See section titled

Table 1 is used

when sizing

Type B

double-wall

gas vent

connected

directly to the

appliance.

Table 2 is used

when sizing a

single-wall metal

vent connector

attached to a

Type B doublewall gas vent.

Figure 16

The vent

termination

should not

be less

than 8 FT.

from a

vertical

wall.

9

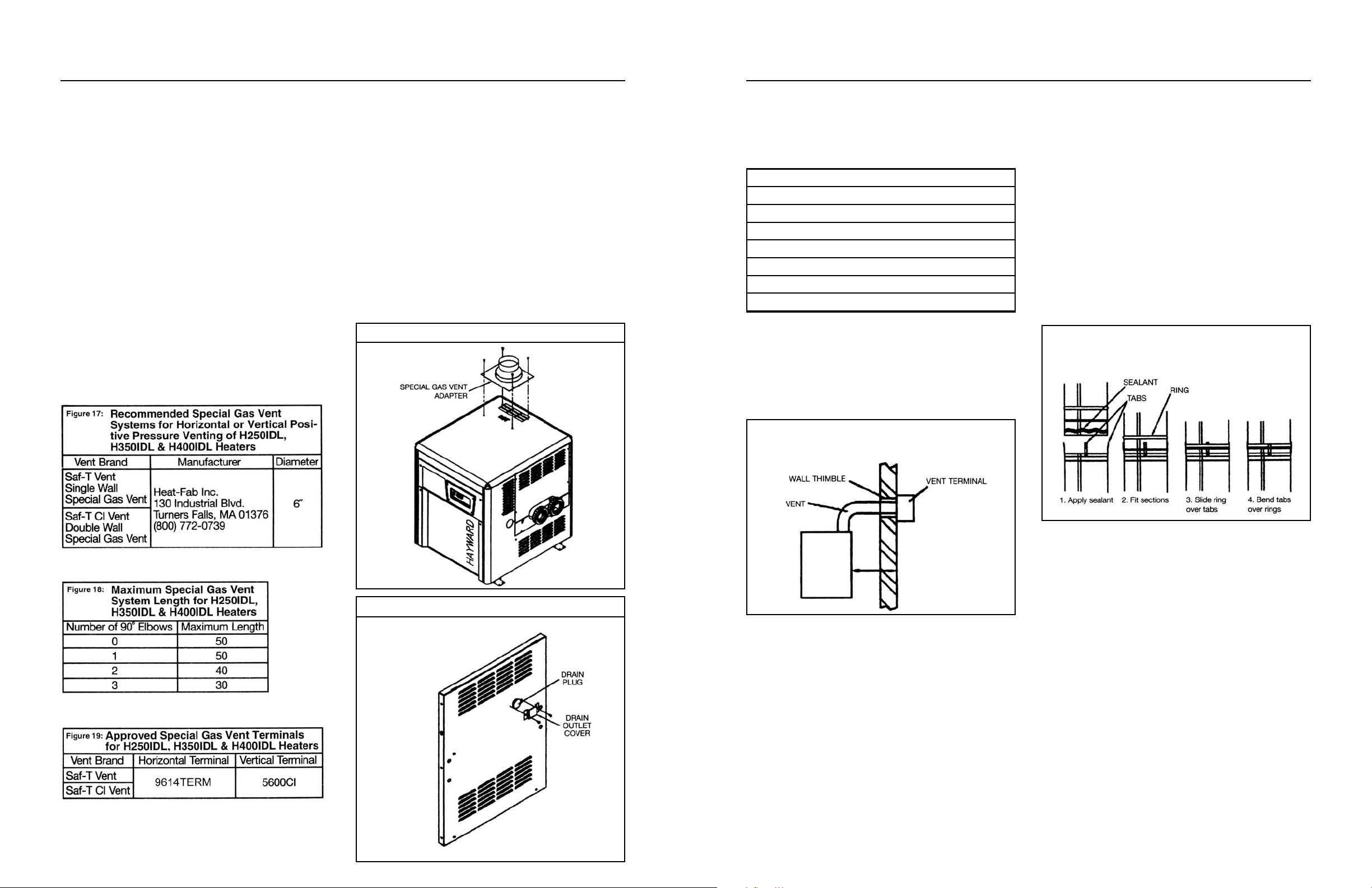

Horizontal or Vertical Venting—Positive

Pressure:

he heater can be vented either horizontally or

T

vertically with positive pressure vent system if one of

the Special Gas Vent Systems listed in Figure 17 is

used. Do not use a draft hood with this heater. The

vent system must be installed in accordance with the

National Gas Code ANSI Z223.1 or the CAN/CGA

B149 Installation Codes, Local Codes and the Vent

Manufacturer’s Instructions.

See Figure 17 for permissible vent diameters for

these heaters.

See Figure 18 for maximum permissible vent

lengths.

The Vent System must terminate with a Vent

Terminal approved for this Pool Heater. See figure 19

for a list of approved vent terminals.

A Special Gas Vent Adapter Kit must be installed

on heater before connecting the Special Gas Vent to

the Heater.

Special Gas Vent Adapter Kit

Installation:

A Special Gas Vent Adapter collar must be installed

to the heater exhaust outlet, and a drain plug and outlet cover must be installed. These components are

contained in the Special Gas Vent Adapter Kit.

The installation of the kit is done as follows:

1. Remove the 4 screws that fasten the vent

cover to the internal vent assembly. Discard

the vent cover. Install the vent adapter and

gasket over exhaust using 4 screws

previously removed. See Figure 20.

2. Install plug into drain outlet at rear of heater.

Install drain outlet cover over the drain outlet

using 2 screws. See Figure 21.

Special Gas Vent Adapter Installation Figure 20

Indoor Installation:

he following installation and service clearances

T

ust be maintained from the heater to combustible

m

materials. See Figure 22.

Indoor Installation Figure 22

Top - 36”

Front - Unobstructed

Back - 6”

Right side (Water side) - 12”

Left side - 6”

For use on combustible floors.

Do not install in a closet.

*For installations in which the vent terminates

in a wall directly behind the heater, allow 23”

between the rear of the heater and the outside of

the wall. See Figure 23.

Clearance for Vent Termination in Wall

Directly Behind Heater

Figure 23

Connecting Special Gas Vent to the

Heater:

ttach the Special Gas Vent to the Vent Adapter

A

using the adhesive specified by the vent manufacturer. Do not drill holes or use screws to connect Vent to

Vent Adapter.

1. Apply a bead of adhesive, about 1⁄8” in diameter,

completely around the male end of the vent section,

between

2. Fully insert the male section into the female fitting

of the Vent Adapter.

3. Secure vent section Vent Adapter by sliding the

ring of the vent section over the tabs of the Vent

Adapter and bending the tabs over the ring. See

Figure 24.

Attaching Vent to Vent Adapter

Figure 24

1

⁄4” to 3⁄8” from the end of the section.

10

Drain Outlet Cover Installation Figure 21

11

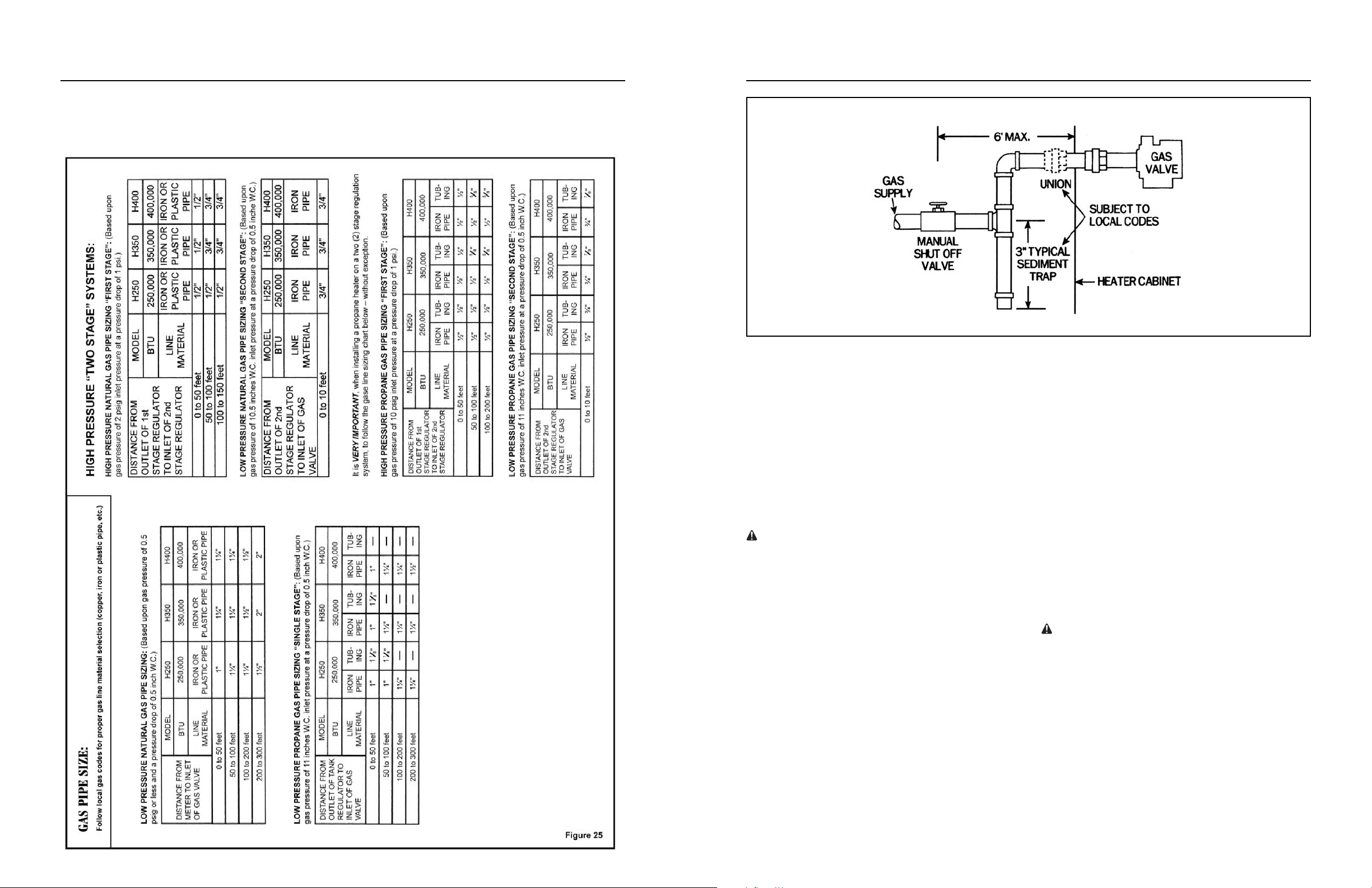

Gas supply and piping:

efer to the charts on Figure 25 for gas pipe sizing for low pressure natural gas, low pressure single state

R

ropane gas, and high pressure two stage propane gas systems

p

.

ediment Trap

S

Figure 26

All gas installations:

The H-series heater is to be installed with a gas

connection located on the left side. Insert the pipe to

the gas valve through the grommet in the cabinet

side. It is recommended that a ground-joint union be

installed inside (or outside if space does not allow)

the heater cabinet to facilitate servicing the burner

assembly tray. See Figure 26.

A C.S. A. Certified main gas valve shutoff must be

installed outside of cabinet and within 6 feet of the

heater. Gas shutoff valve must have and I.D. large

enough to supply the proper amount of gas volume to

the heater.

NOTE: Apply joint compounds (pipe dope) sparingly and only to the male threads of pipe joints. Do

not apply joint compound to the first two threads. Use

joint compounds resistant to the action of liquefied

petroleum gas. Do not overtighten the gas inlet pipe

or damage may result. See Figure 26.

o prevent dirt and moisture from entering gas

T

valve, a sediment trap should be installed in the gas

line close to the valve. See Figure 26.

Do not use flexible appliance connectors on

any gas connections unless the connector is

C.S.A. approved for outdoor installation, is

marked with BTUH capacity (which must be equal

to or greater than the heater rated input), and the

type of gas (Natural or LP) to be used.

Reduction of gas supply pipe or tubing to the inlet

of the heater gas valve must be made at the valve

only and must match the valve inlet size (3⁄4”).

If more than one appliance is installed on the gas line,

consult the local gas company for the proper gas line size.

Any questions concerning the installation of the

proper gas line size can be directed to Hayward

echnical Service.

T

NATURAL GAS

The gas meter must have the capacity to supply

enough gas to the pool heater and any other gas

appliances if they are on the same pipeline (Example:

225 meter = 225,000 BTUH). If doubt exists as to the

meter size, consult local gas utility for assistance.

Hayward will not be responsible for heaters that soot

up due to improper meter and gas line sizing resulting

in improper gas volume.

PROPANE GAS

All Propane gas tanks must be located outdoors

and away from pool/spa structure and in accordance

with the standard for storage and handling of propane

gas, ANSI/NFPA 58 (latest edition) and applicable

local codes. If propane gas tank is installed underground, the discharge of the regulator vent must be

above the highest probable water level.

Propane tanks must have sufficient capacity to

provide adequate vaporization for the full capacity of

the equipment at the lowest expected temperatures.

Consult a propane company expert for correct sizing.

NOTE: Whenever a high-pressure double regulation system is utilized for propane gas, consult a

propane professional for accurate pipe and pressure

sizing. Make sure that 1

large enough to handle the BTUH input listed for the

heater(s) being used.

Hayward will not be responsible for heaters that

soot up due to improper gas line or propane tank siz

ing resulting in improper gas volume.

st

and 2ndstage regulators are

Water piping:

The H-Series heater is designed for use with pool

and spa/hot tub water only, as furnished by municipal

water distribution systems. The warranty does not

cover heater use with mineral water

other non-potable waters.

Do not install any restriction in the water pipe

between heater outlet and pool/spa with the

, sea, salt, or

-

12

13

Loading...

Loading...