HAYWARD VR1000 service manual

PN: ISVR1000TECH Rev: J

_____________________________________________________________________________________________________________________________________

MODEL VR1000

SERVICE MANUAL

INSTALLATION & PARTS

WARNING – Improper installation, use, or maintenance of this Vacuum Release System or associated

equipment could cause serious or fatal injury. To reduce the risk of injury, read and follow all instructions in this

Manual and on the equipment. Make sure installation and any maintenance necessary are done by people who are

qualified and have the proper equipment to do the job right. All electrical wiring MUST be in conformance with

all applicable local codes, regulations, and the National Electrical Code (NEC).

Basic safety precautions should always be followed, including the following: Failure to follow instructions can cause severe

injury and/or death.

This is the safety-alert symbol. When you see this symbol on your equipment or in this manual, look for one of the

following signal words and be alert to the potential for personal injury.

WARNING warns about hazards that could cause serious personal injury, death or major property damage and if

ignored presents a potential hazard.

CAUTION warns about hazards that will or can cause minor or moderate personal injury and/or property damage

and if ignored presents a potential hazard. It can also make consumers aware of actions that are unpredictable and unsafe.

The NOTICE label indicates special instructions that are important but not related to hazards.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908.351.5400 www.haywardpool.com

Page 2 of 24 STRATUM™ Model VR1000 P/N: ISVR1000TECH Rev: J

READ AND FOLLOW ALL INSTRUCTIONS IN THIS SERVICE AND

INSTALLATION MANUAL AND ON EQUIPMENT.

IMPORTANT SAFETY INSTRUCTIONS

Before installing or servicing this electrical equipment, turn power supply OFF.

KEEP SAFETY LABELS IN GOOD CONDITION AND

WARNING – To reduce risk of injury, do not permit children to use or climb on the pumps and filters. Closely supervise children at all

times. Components such as the filtration system, pumps, and heaters must be positioned to prevent children from using them as a means of access to

the pool.

REPLACE IF MISSING OR DAMAGED.

CAUTION – This vacuum release system is intended for use on permanently installed swimming pools and may also be used with hot

tubs and spas. Do NOT use with storable pools. A permanently installed pool is constructed in or on the ground or in a building such that it cannot

be readily disassembled for storage. A storable pool is constructed so that it is capable of being readily disassembled for storage and reassembled to

its original integrity.

Though this product is designed for outdoor use, it is strongly recommended to protect the electrical components from the weather. Select a welldrained area, one that will not flood when it rains. It requires free circulation of air for cooling. Do not install in a damp or non-ventilated location. If

installed within an outer enclosure or beneath the skirt of a hot tub or spa, adequate ventilation and free circulation of air must be provided to prevent

overheating of the components

.

WARNING – All electrical wiring MUST be in conformance with all applicable local codes, regulations, and the National

Electrical Code (NEC). Risk of Electric Shock. Hazardous voltage can shock, burn, cause death or serious property damage. To

reduce the risk of electric shock, do NOT use an extension cord to connect unit to electric supply. Provide a properly located outlet.

All electrical wiring MUST be in conformance with applicable local and national codes and regulations. Before working on pump or

motor, turn off power supply to the pump.

WARNING – To reduce the risk of electric shock replace damaged wiring immediately. Locate conduit to prevent abuse from lawn

mowers, hedge trimmers and other equipment.

WARNING – All electrical wiring MUST be in conformance with all applicable local codes, regulations, and the National Electrical Code

(NEC) including a Ground Fault Circuit Interrupter (GFCI) in circuit. For size of GFCI required and test procedures for GFCI, see manufacturer’s

instructions. Pump MUST be permanently connected to GFCI.

WARNING – Failure to bond pump to pool structure will increase risk for electrocution and could result in injury or death. To reduce the

risk of electric shock, the electrician must comply with installation instructions and must bond the pump accordingly. In addition, the electrician

must also conform to local electrical codes for bonding requirements.

Notes to the electrician:

Use a solid copper conductor, size 8 or larger. Run a continuous wire from external bonding lug to reinforcing rod or mesh. Connect a No. 8 AWG

(8.4 mm

hot tub, and to all electrical equipment, metal piping (except gas piping), and conduit within 5 ft. (1.5 m) of inside walls of swimming pool, spa, or

hot tub. IMPORTANT - Reference NEC codes for all wiring standards including, but not limited to, grounding, bonding and other general wiring

procedures. NOTE - The National Electrical Code (NEC) permits use of a cord with a maximum 3 ft. (1 m) length. If your pump is equipped with a

cord complying with the NEC, the preceding four (4) hazards apply.

2

) solid copper bonding wire to the pressure wire connector provided on the motor housing and to all metal parts of swimming pool, spa, or

WARNING – Suction Entrapment Hazard.

Suction in suction outlets and/or suction outlet covers which are, damaged, broken, cracked, missing, or unsecured can cause severe injury

and/or death due to the following entrapment hazards:

Hair Entrapment- Hair can become entangled in suction outlets.

Limb Entrapment- A limb inserted into an opening of a suction outlet or suction outlet cover that is damaged, broken, cracked, missing,

or not securely attached can result in a mechanical bind or swelling of the limb.

Body Suction Entrapment- A differential pressure applied to a large portion of the body or limbs can result in an entrapment.

Evisceration/ Disembowelment - A negative pressure applied directly to the intestines through an unprotected suction outlet sump or

suction outlet cover which is damaged, broken, cracked, missing, or unsecured can result in evisceration (disembowelment).

Mechanical Entrapment- There is potential for jewelry, swimsuit, hair decorations, finger, toe or knuckle to be caught in an opening of a

suction outlet or suction outlet cover resulting in mechanical entrapment.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908.351.5400 www.haywardpool.com

Page 3 of 24 STRATUM™ Model VR1000 P/N: ISVR1000TECH Rev: J

WARNING - To reduce the risk of entrapment hazards:

o When suction outlets are less than a 18” x 23” equivalent, a minimum of two functioning ASME112.19.8 suction

outlets per pump must be installed. Suction outlets in the same plane (i.e. floor or wall), must be installed a

minimum of three feet (3’) [1 meter] apart, as measured from near point to near point .

o Dual suction outlets shall be placed in such locations and distances to avoid “dual blockage” by a user.

o Dual suction fittings shall not be located on seating areas or on the backrest for such seating areas.

o The maximum system flow rate shall not exceed the flow rating of any listed (per current revision of ASME/ANSI A112.19.8) suction

outlet cover installed.

o Never use the Pool or Spa if any suction outlet component is damaged, broken, cracked, missing, or not securely attached.

o Replace damaged, broken, cracked, missing, or not secure ly attached suction outlet components immediately.

o In addition two or more suction outlets per pump installed in accordance with latest APSP (formally NSPI) Standards and CPSC

guidelines, follow all National, State, and Local codes applicable.

This vacuum release system is designed to prevent body suction entrapment, but not evisceration.

WARNING – Failure to remove pressure test plugs and/or plugs used in winterization of the pool/spa from the suction outlets can

result in an increase potential for suction entrapment as described above.

WARNING – Failure to keep suction outlet components clear of debris, such as leaves, dirt, hair, paper and other material can

result in an increase potential for suction entrapment as described above.

WARNING – Suction outlet components have a finite life, the cover/grate should be inspected frequently and replaced at least

every ten years or if found to be damaged, broken, cracked, missing, or not securely attached.

WARNING – All suction and discharge valves MUST be OPEN when starting the circulation system. Failure to do so could result in

severe personal injury and/or property damage. All drains and suction outlets MUST have properly installed covers, securely attached using the

screws supplied with the covers. If screws are lost, order replacement parts from your supplier.

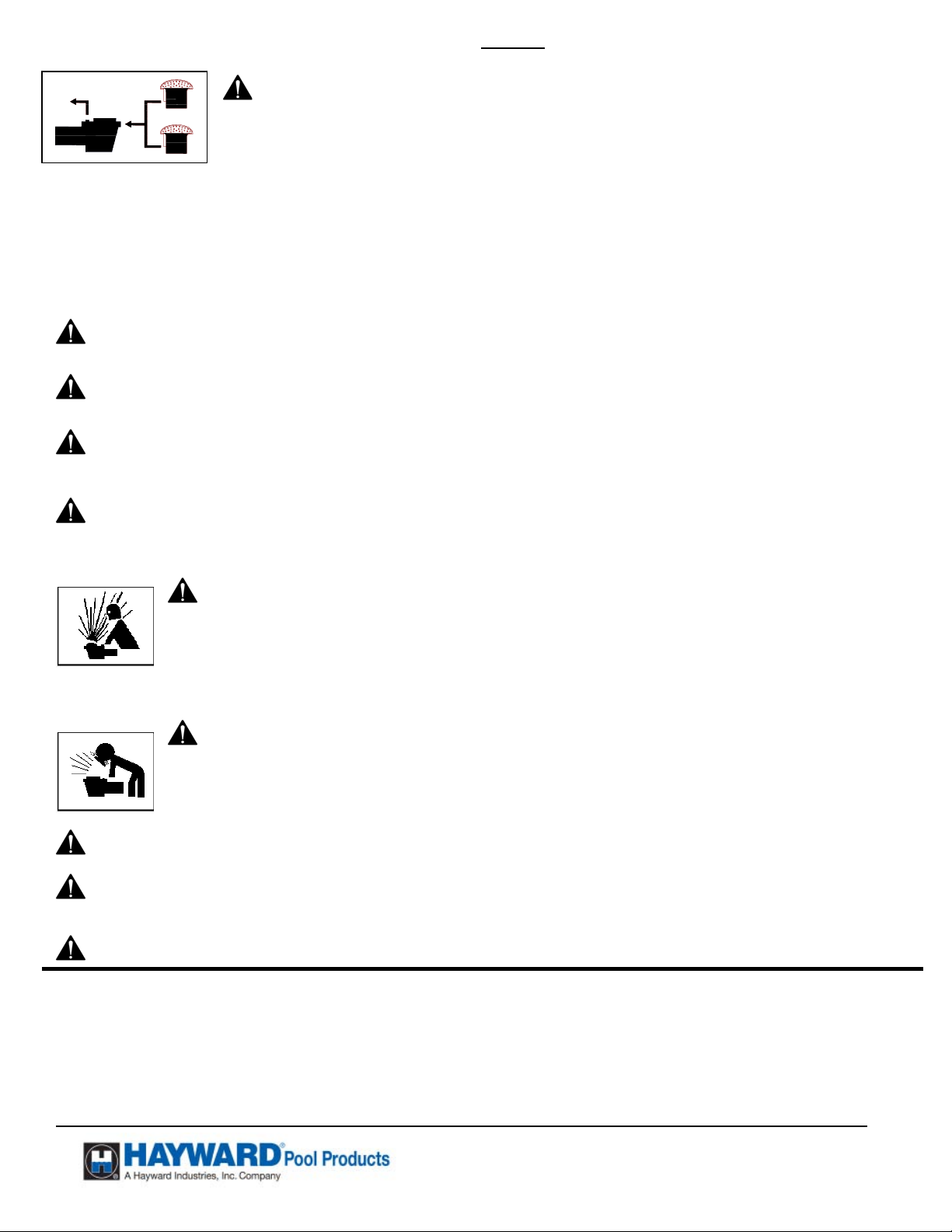

WARNING – Hazardous Pressure. Pool and spa water circulation systems operate under hazardous pressure during

start up, normal operation, and after pump shut off. Stand clear of circulation system equipment during pump start up. Failure to

follow safety and operation instructions could result in violent separation of the pump housing and cover due to pressure in the

system, which could cause property damage, severe personal injury, or death. Before servicing pool and spa water circulation

system, all system and pump controls must be in off position and filter manual air relief valve must be in open position. Before

starting system pump, all system valves must be set in a position to allow system water to return back to the pool. Do not change

filter control valve position while system pump is running. Before starting system pump, fully open filter manual air relief valve.

Do not close filter manual air relief valve until a steady stream of water (not air or air and water) is discharged.

WARNING – Separation Hazard. Failure to follow safety and operation instructions could result in violent

separation of pump components. Strainer cover must be properly secured to pump housing with strainer cover lock ring. Before

servicing pool and spa circulation system, manual air relief valve must be in open position. Do not operate pool and spa

circulation system if a system component is not assembled properly, damaged, or missing. Do not operate pool and spa

circulation system unless filter air relief valve body is in locked position in filter upper body.

WARNING – Never operate or test the circulation system at more than 40 PSI.

WARNING – Fire and burn hazard. Motors operate at high temperatures and if they are not properly isolated from any flammable

structures or foreign debris they can cause fires, which may cause severe personal injury or death. It is also necessary to allow the motor to cool for

at least 20 minutes prior to maintenance to minimize the risk of burns.

WARNING – Failure to install according to defined instructions may result in severe personal injury or death.

DEFINITIONS:

Suction Outlet – The term Suction Outlet is a fitting, fitting assembly, cover/grate and related components that provide a means for water to exit the

pool and into the pump circulating system.

Inches of Mercury (in Hg) - A unit for measuring pressure below atmospheric (“suction” or “vacuum”) (1.0 inch Hg = .491 PSI)

Main Drain – See Suction Outlet

PSI – An abbreviation for pounds per square inch.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908.351.5400 www.haywardpool.com

Page 4 of 24 STRATUM™ Model VR1000 P/N: ISVR1000TECH Rev: J

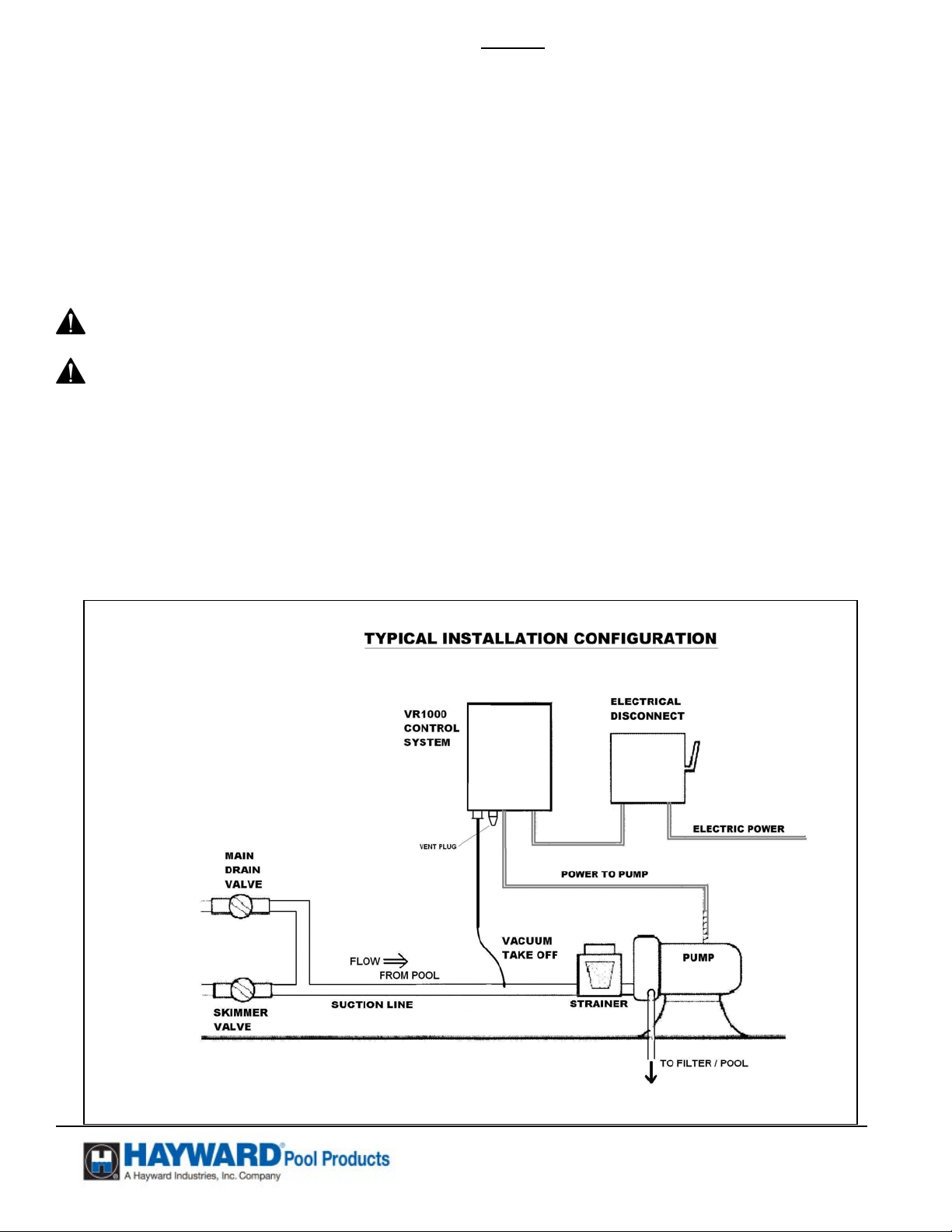

General Information:

The VR1000 Vacuum Release System is designed as a pump controller. The system will protect pool and spa equipment from certain

known mechanical failures, such as clogged drains and pipe breakage; which can cause premature pump motor failure. The system

monitors and recognizes a change in pressure and electrical power. When a change occurs, it will shut down the pump, and vent the

suction line. Automatic soft start should provide notice to swimmers or bathers on pump startup. The VR1000 meets the

requirements of ASTM Specification F2387-04. Meets ASME Standard 112.19.17. Meets UL standard 1563 as well as certified to

Can/CSA Std. C27.2 No. 218.1.

The VR1000 system will automatically restart in most instances. Should a manual restart be required, pressing the “OK” button will

restart the system

30 minutes, providing NO protection for sw immers or bathers. DO NOT ALLOW SWIMMERS OR BATHERS IN THE PO OL OR

SPA WHEN THE SYSTEM IS IN “UNPROTECTED” MODE.

For proper installation and to avoid unnecessary service calls, read this manual carefully and completely.

. “Unprotected” Mode can be entered, after restart, by holding “NO” & “OK” buttons. “Unprotected” mode lasts

WARNING – This product should be installed and serviced only by a qualified professional. Failure to install and/or

operate according to defined instructions and/or use of non-Hayward replacement parts will void the warranty.

CAUTION – All electrical wiring MUST be in conformance with all applicable local codes, regulations, and the National

Electrical Code (NEC).

Introduction:

This manual contains information for the proper installation and operation of the Hayward VR1000 Vacuum Release System.

The instructions in this manual MUST be followed precisely.

NOTICE – ALL PRESSURE TESTING OF THE SYSTEM MUST BE COMPLETED BEFORE

NOTICE – The filter must be cleaned or cartridge replaced before installing the STRATUM™.

NOTICE –The STRATUM™ is rated for 115 VAC 50/60Hz for up to a 1 horsepower pump motor or 208/230

INSTALLING THE STRATUM™.

VAC 50/60Hz for up to a 3 horsepower pump motor.

FIG 1

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908.351.5400 www.haywardpool.com

Page 5 of 24 STRATUM™ Model VR1000 P/N: ISVR1000TECH Rev: J

Installation Instructions

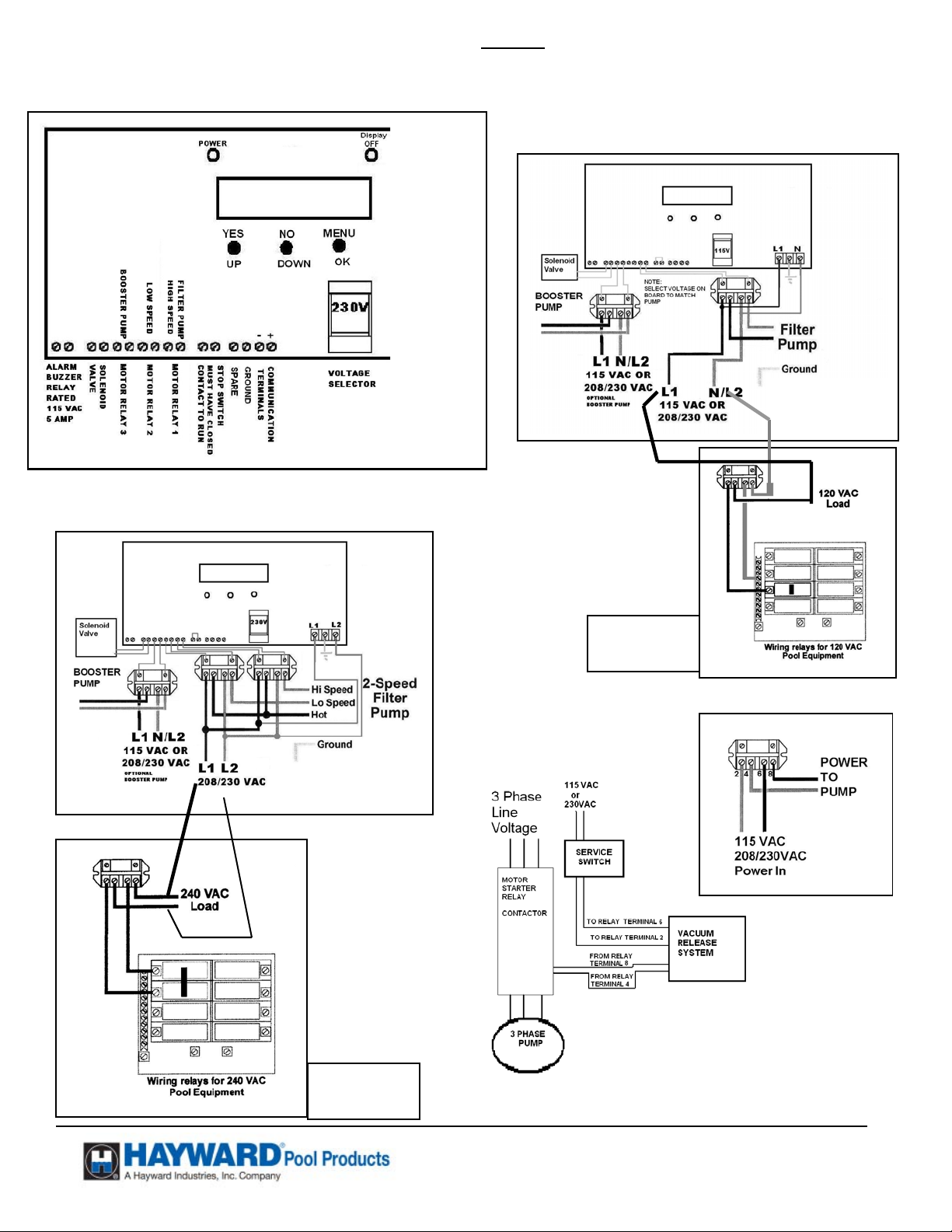

DIP Switches Battery BR2032

FIG 2.

LIST OF NEEDED ITEMS FOR INSTALLATION

1. VR1000 system

2. Location on vertical surface to install the VR1000 within ten feet of the pump and above the pump.

3. 25’ length of tubing (Supplied in package.)

4. For Pipe installation,

a. 3/8” electric drill

b. 3/8” drill bit

c. Saddle Gasket CL220C (Supplied in package.)

d. Saddle Fitting CL220G (Supplied in package.)

e. Saddle Clamp CL220K (Supplied in package.)

f. Ferrule Nut and Ferrule (Supplied in package.)

5. Adjustable wrench

6. #2 Phillips screw driver

7. Small bladed screw driver

8. Large bladed screw driver

Mounting hardware for VR1000 Electrical box (Not Supplied)

MECHANICAL MOUNTING INSTRUCTIONS FOR INGROUND POOLS WITHOUT FLOODED SUCTION.

Note: If the installation is for an above ground pool or for flooded suction, the VRX100F assembly is suggested.

The VR1000 is designed to be used on a single pump or a combination of a single pump with a booster pump, on a

common suction line.

1. TURN OFF THE ELECTRICAL POWER AT THE CIRCUIT BREAKER.

2. Remove all check valves from the suction lines of the Pool/Spa system.

WARNING- Check Valves must be removed from the circulation systems. The presence of a check valve used to

carry the water flow within the circulation system has been shown to prolong the high vacuum present at the

drain, even though the drain is protected by a SVRS. For this reason, check valves which carry the water flow

within the circulation system must be removed.

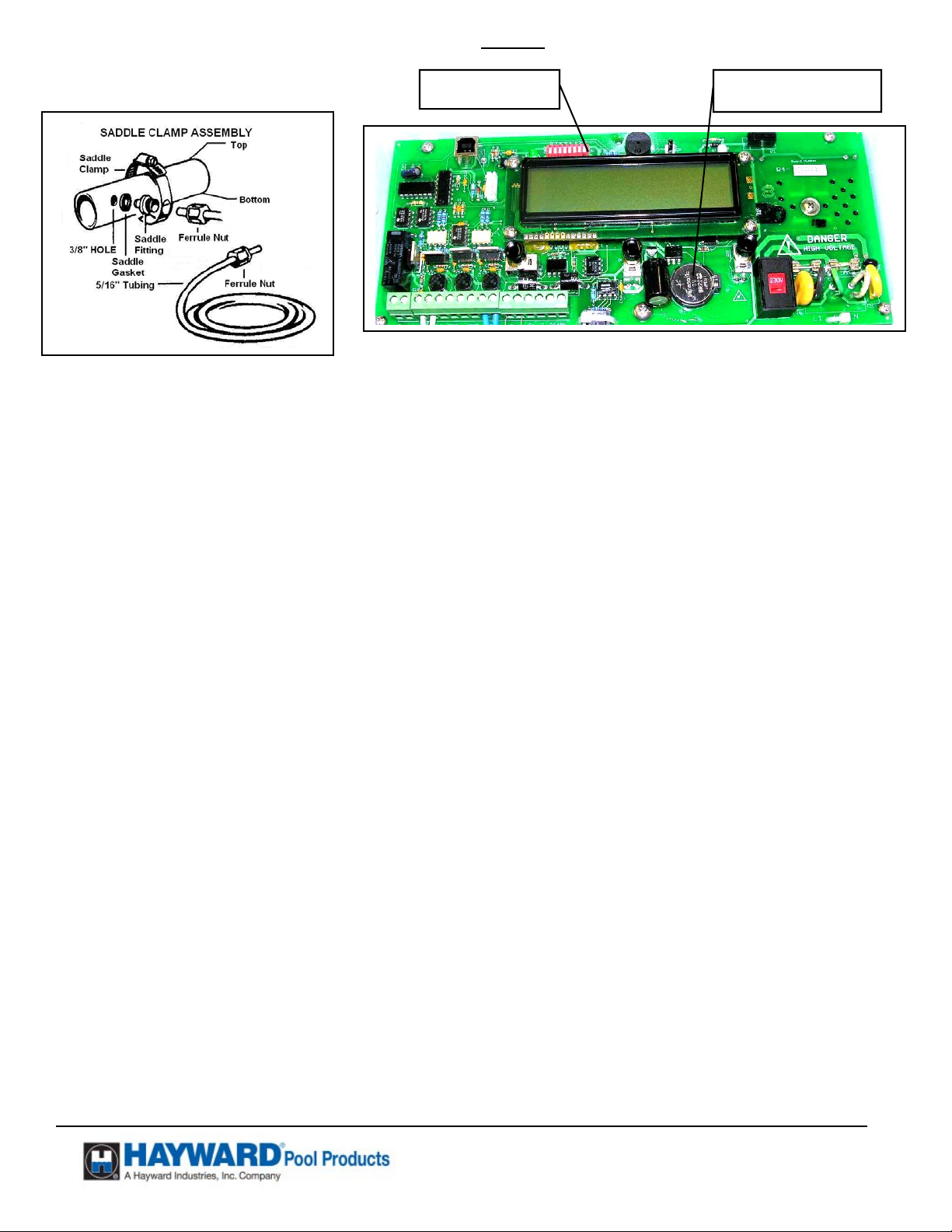

3. For installation of the vacuum sensing tube into the suction line of the pump: (See Page 17 for additional pictures)

a. Locate a straight section of pipe approximately one foot long, as close to the inlet of the pump as practical.

b. On this straight pipe about in the middle, go 45º from the top. (This will minimize the air entrapment in the system

and help keep the system stable.) Drill a 3/8” hole. (See FIG 2)

c. Install the Saddle Gasket on the end of the Saddle fitting. Place the assembly in the drilled hole. Place the saddle

clamp over the saddle fitting. Tighten the Saddle clamp to assure a leak free joint. DO NOT OVERTIGHTEN.

4. Find a location for the VR1000 on a wall, or post, out of the direct sunlight, which will not be flooded, and above the pump.

If the box is mounted below the water level, the vent should be extended to above the water level.

5. Place the Ferrule Nut over the tubing. (See FIG 2) Make sure the tubing bottoms out in the saddle fitting. Holding the

tubing in place, tighten the Ferrule Nut firmly by hand. DO NOT OVERTIGHTEN. Run the 5/16” vacuum tube from the

fitting on the suction line to the fitting on the VR1000 unit. Make sure the vacuum tubing has no kinks and is strain free.

The fitting on the STRATUM™ does not require tooling to install the tubing. Just insert the end of the tubing firmly into the

fitting, a slight pull should not dislodge the tubing.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908.351.5400 www.haywardpool.com

Page 6 of 24 STRATUM™ Model VR1000 P/N: ISVR1000TECH Rev: J

INITIAL REQUIRED SETTINGS:

1. The VR1000 unit is factory set for 230VAC input. Leave the switch in this “FACTORY SET” position unless a low voltage

error occurs, in which case turn the power off, and move the switch to 115VAC.

2. NOTICE: THE CIRCUIT BOARD AND COMPONENTS MAY BE DAMAGED IF 208/230 VAC IS APPLIED TO

THE BOARD WHEN THE “SWITCH” IS IN THE 115VAC POSITION.

3. The VR1000 is factory set to English, the following three language settings are available by adjusting the dip switches 1, 2 at

the top of the board: A “ON” setting is down and toward the board. Please use a pen or pencil to gently move the switch as

required. See Fig 3

Language 1 2 3 4 5 6 7 8

English OFF OFF 2-Speed Pump Timers Manufacturing Test Booster Pump Specials Pinch Test

Spanish ON OFF

French OFF ON

4. To activate the component test, set Dip Switch 5 to ON. (This should NEVER be done unless directed to do so by Hayward

Technical Service.)

5. For 2 Speed pumps, set Dip Switch 3 to ON. Special wiring required. (See FIG 6)

6. To activate the timer cycle, set Dip Switch 4 to ON.

7. To activate the Booster Pump Timer, Set Dip Switch 6 to ON.

8. Dip Switch 7 is for Welded Contactor settings and High lift situations. (See Page 19) Must be set for flooded suction.

9. Dip Switch 8 performs special functions related to the detection of a pinched vacuum tube. After the pinched tube settings

have been made this switch should be turned to the OFF position to disable the screens (but not the function).

ELECTRICAL CONNECTION INSTRUCTIONS:

1. ASSURE POWER IS DISCONNECTED FROM SOURCE.

2. To install optional contactors the factory-installed wires attached must be connected to the proper terminals on the circuit

board. For a booster pump always use motor relay 3 on the board as shown in FIG. 4.

3. Connect pump to contactor terminals 4 & 8 (See FIG 7). If a booster pump is used, with a pool cleaner, connect this pump to

4 & 8 on a second contactor (Optional Contactor VRX100KIT). The contactor control (2 wires supplied) MUST be

connected onto the board next to the solenoid valve terminals, that is, in motor relay position 3. One reason to connect the

booster pump through this system is to protect the booster pump motor from burn out if the VR1000 were to stop the primary

filter pump. Additionally the timers can then be used to control the timing of the Booster pump.

4. If a two-speed pump is used connect the “Low Speed” to terminals 4 & 8 on a contactor (Optional Contactor VRX100KIT).

The contactor control (2 wires supplied) MUST be connected onto the board in motor relay position 2. NOTE: If the pump

horsepower is greater than 3 HP, the contactors can be used in series with the motor starters. (See Illustration below

FIG 8)

5. Connect a ground wire from the primary electrical panel to the VR1000 and connect the system to the pool bonding system

by an 8AWG (6AWG for Canada) wire. A lug for bonding is provided on the outside/bottom of the enclosure.

6. Connect incoming power to 2&6 on the power relay(s) (See FIG 7). Assure that the earth ground wire connector between the

conductors is secured.

7. (Optional) If a remote stop button is used, remove jumper from terminal pair marked “STOP Switch”. The switch must be a

“locking type “STOP” switch with a normally closed set of contacts in the “UP” position. Install the “STOP” switch across

the terminals where jumper was located. A Steward 28A0640-0A0-1/2 turn ferrite core or equal must be added to the stop

switch cable within 2” of the outside of the STRATUM™ box. (Stop switch can be Square D # KR9RH6 or equivalent

mounted in a rain tight box.)

8. (Optional) If a remote alarm is to be installed, the terminals “Buzzer” are connected to an alarm relay which will supply a

closed contact rated at 115 VAC, 5 amp, when the system alarm trips. External power must be supplied for the alarm to

sound. Can be used with Audible Alarms from Federal Signal Model 350-120-30 or equivalent available from Grainger.

9. The terminal marked “SPARE” when connected to the terminal marked “GROUND” will turn the pump on to “High Speed”

and maintain the “High Speed” mode until these two terminals are disconnected. Thus if a “Manual” override is desired a

maintained contact switch can be used to between these terminals.

10. For Flooded Suction and Pumps located more than 3’ above the pool turn on Dip Switch 7.(See Page 19)

11. Replace the inner barrier and secure with two screws included.

12. Power should be applied to the system while watching the display. Follow the directions on the display. This

operation will confirm the available voltage is suitable for proper operation of the VR system.

NOTICE: THE CIRCUIT BOARD AND COMPONENTS MAY BE DAMAGED IF 208/230VAC IS APPLIED TO THE

BOARD WHEN THE “SWITCH” IS IN THE 115VAC POSITION.

13. Close the electrical enclosure.

14. Apply power to system.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908.351.5400 www.haywardpool.com

Page 7 of 24 STRATUM™ Model VR1000 P/N: ISVR1000TECH Rev: J

FIG 5

Internal Control

FIG 4

FIG 6

Internal

Aqua Logic

Aqua Logic

FIG 7

FIG 8

THREE PHASE PUMP MOTOR

SUGGESTED CONNECTION

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908.351.5400 www.haywardpool.com

Page 8 of 24 STRATUM™ Model VR1000 P/N: ISVR1000TECH Rev: J

N

Note: For Flooded Suction and Pumps installed more than 3’ above the surface of the pool Turn on Dip

Switch 7 before Appling power to the STRATUM™ (See Page 19)

VR1000 VER X.X

Initial Start OK

Initial Set-up

Complete? Y/N

INITIAL SCREENS: These will disappear after the Initial Set up is complete.

The start delay allows the installer to be ready for the system to start.

During initial start-up and set-up the start delay should not be disabled.

A press of the “OK” button will start the system.

Answering “YES” will allow the system to restart during normal operation.

Answering “No” will cause the system to come up to the “VR1000 VER XX Initial Start OK” screen

above and stop, when there is a loss of power.

SCREENS ON VR1000

For the set-up of the VR1000 we recommend that the system be placed in the “Unprotected mode”, which does not protected

swimmers or bathers from entrapment. It does allow the system to read the vacuum in various plumbing configurations.

HAYWARD POOL

PRODUCTS

Unprotected

Mode Entry Y/N

Press “NO” and “Menu” simultaneously and hold in until the screen changes to place system in

“Unprotected mode”.

Answer “Yes”.

Suction in suction outlets can cause severe injury and/or death due to a differential pressure applied to a large portion

of the body or limbs. STRATUM™ “Unprotected” Mode: Is when the pump is operating and the STRATUM™ is

NOT

and spa when the STRATUM™ is in “Unprotected” mode. The STRATUM™ only provides a layer of protection

against Body Suction Entrapment in monitoring mode.

o Swimmers Allow

In pool/Spa

Is Anyone in

Pool or Spa? Y/N

Unprotected Mode

Press OK to End

Unprotected Pool

Vacuum = X.X

Exiting

Unprotected Mode

WARNING - Body Suction Entrapment Hazard

providing any protection against Body Suction Entrapment. Do Not allow Swimmers and Bathers in the pool

NOTICE: The STRATUM™ will beep to indicate the unit is in unprotected mode.

Various configurations of the plumbing system for the Pool and Spa should be should be set-up with

the resulting vacuum level recorded. (See “Run and Record” Work Sheet page 17.)

Set up the Pool or Spa in the plumbing configuration that showed the lowest vacuum level for

column (B). This configuration should be used for the initiation of the VR1000.

Pressing “YES” will not allow activation mode and return you to the TECH Mode Screen

Pressing “No” will allow the system to go into “Unprotected” Mode for 30 minutes.

To stop “Unprotected” mode before the 30 minute period has expired press “OK”.

These two screens alternate and are for information purposes only.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Pomona, CA Clemmons, NC Nashville, TN

Tel: 908.351.5400 www.haywardpool.com

Loading...

Loading...