Hayward SP0710XR50, SP0740DE, VariFlo Multiport, SP0715XR50 Owner's Manual

T

V

x

g

K

g

A

A

g

WARNING

Read

IS0710XR50 REV B

®

VariFlo

1 1/2” Filter Control Valve

Owner’s Manual

Model: SP0710XR50 (DE Filters)

Multiport

GENERAL

1. Proper fitting make-up is hand tight plus one to 1-

1/2 turns maximum. Always use Teflon pipe tape

or Permatex No.2 for connections to provide a

good, "living" seal.

IMPORTANT: Do not over tighten pipe fittings.

2. SERVICING VALVE: If it becomes necessary to

service or gain access to the key or valve seat

gasket:

a. Set handle in “Winterizing” position.

b. Remove cover screws.

c. Lift cover and key assembly out.

3. RE-ASSEMBLY VALVE:

a. Wipe debris from cover 0-ring.

b. Set handle in a “Winterizing” position. Align

flat edge on cover with body. Press down to

seat assembly.

c. Secure assembly to body with cover screws

and nuts. Tighten cover screws evenly and

alternately.

Do not over tighten.

TURN OFF PUMP BEFORE CHANGING VALVE POSITION

VALVE SETTING

FILTER

BACKWASH

RINSE

WASTE

CLOSED

RECIRCULATE

WINTERIZING:

CAUTION –Spring

Hazard – Release of

Valve spring

compression can

cause personal injury.

To avoid, only remove

handle pin if servicing

key O-ring. Remove

handle pin before

slowly removing Cover

screws in an alternate

pattern.

FUNCTIONS OF VALVE POSITIONS

FLOW DIRECTION THROUGH VALVE

PUMP - BOTTOM - THROUGH FILTER - TOP - RETURN

For normal filtration and vacuuming pool through

filter.

PUMP - TOP - THROUGH FILTER - BOTTOM - WASTE

For cleaning filter.

PUMP - BOTTOM - THROUGH VALVE - WASTE

For initial start-up and clearing valve of debris after

backwashing.

PUMP – THROUGH VALVE - WASTE

For vacuuming directly to waste, lowering pool level

and/or draining pool.

NO CIRCULATION PAST PUMP POR

For shutting off all flow to filter and pool.

PUMP – THROUGH

For bypassing filter, but circulating pool water.

Drain and winterize filter and pump per manufacturer's

instructions. To drain water from VariFlo® Multiport

valve—depress and rotate valve handle and place

handle pointer between any detente positions.

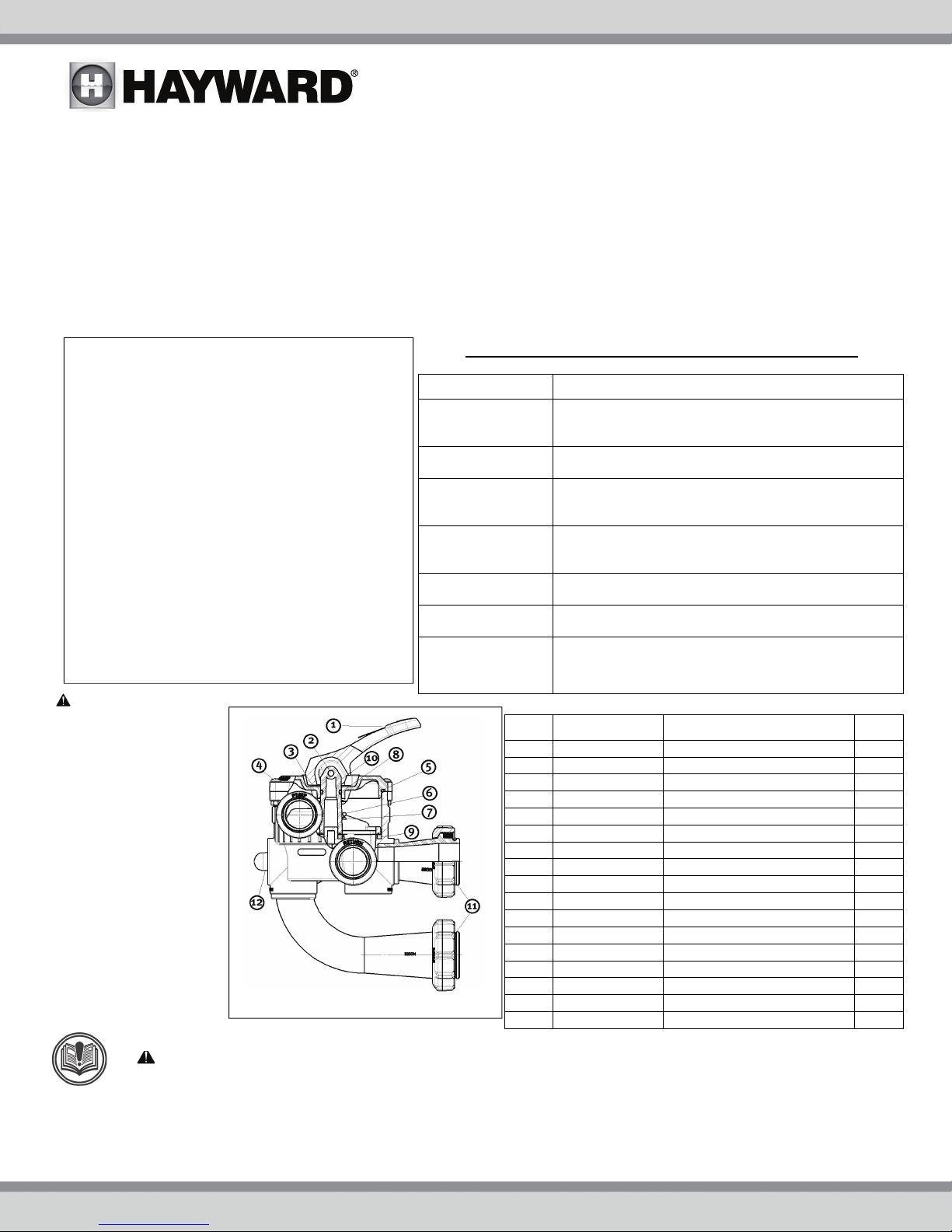

REF

NO.

10 SPX0710xC Key 1

11 SX200Z4PAK2 Valve O-ring (Set of 2) 1

12 SPX0710M

PART NUMBER DESCRIPTION

1SPX0710XFHandle, Standard 1

2 SPX0710XZ7 Pin, for Handle 1

3 SPX0710Z16 Non-Metallic Bearing(Pack of 5) 1

SPX0710G Valve Position Label 1

4SPX0710Z1ACover screw set with nuts (Set of 6) 1

5SPX0710

6SPX0603SSprin

7 SPX0710Z62 Spring Washer Set (Set of 2) 1

8SPX0735GAO-ring & TFE Shaft seal set 1

9 SPX0710XD Valve Seat Gasket 1

SPX0710BA17 Key, Cover and Handle Assy 1

SPX0710XR50A

Z5 Cover O-ring 1

SPX0710

SX200Z9 Gasket for Sight Glass 1

ALVE - RETURN

1

¼” Plastic Pipe Plu

Sight Glass with Gasket 1

Valve body with gasket and pipin

NO.

REQ’D

1

-

and follow all instructions in this owner’s manual and on the equipment.

Failure to follow instructions can cause severe injury and/or death.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS 1

Hayward Pool Products

620 Division Street, Elizabeth, NJ 07207

Phone: (908) 355-7995

WWW.HAYWARD.COM

e

N

s

a

t

u

e

N

o

o

u

u

a

u

e

t

a

a

N

o

N

m

N

c

T

o

r

N

u

e

h

.

m

o

n

d

m

e

t

m

g

r

r

e

w

G

p

c

l

o

h

a

b

e

w

v

a

e

n

a

a

f

t

c

m

e

i

e

t

a

r

t

f

t

t

a

c

b

N

h

e

m

l

s

o

t

t

d

s

O

n

a

e

e

a

e

n

k

o

a

d

s

p

s

p

c

r

o

e

u

s

p

e

t

m

a

a

e

t

u

i

o

i

r

r

e

f

n

a

t

d

w

r

A

w

m

o

a

r

n

y

a

e

n

a

d

s

s

r

m

n

o

a

m

f

c

o

e

f

s

f

m

h

w

c

O

r

e

o

u

t

a

a

N

m

.

t

b

o

c

t

v

e

n

c

w

g

l

a

h

r

p

a

u

o

v

u

r

r

n

r

v

o

w

u

T

t

n

e

o

o

o

r

o

o

t

o

g

u

s

a

i

i

p

E

w

s

u

d

k

h

s

y

t

e

u

u

o

D

m

c

e

m

o

e

e

e

r

u

e

R

r

n

a

k

e

,

e

t

s

f

b

o

s

n

t

o

o

r

e

e

m

s

l

w

n

n

c

a

l

u

e

o

e

a

a

o

s

e

e

n

n

a

o

e

e

t

o

m

e

p

o

e

s

e

e

v

n

n

o

r

t

r

t

o

l

Bas

ic safety prec

sev

re injury and

The NOTICE

This is th

the follo

WARNIN

ignored

CAUTION

damage

unpredi

autions shou

/or death.

safety-alert

ing signal w

warns abou

resents a po

warns about

and if ignore

table and un

abel indicate

d always be

ymbol. Whe

rds and be

hazards tha

ential hazar

hazards that

presents a p

afe.

s special inst

ollowed, incl

you see this

lert to the po

could cause

.

ill or can c

otential haza

uctions that

ding the foll

symbol on y

ential for pe

serious pers

use minor or

rd. It can als

re importan

wing: Failur

ur equipmen

sonal injury.

nal injury, d

moderate pe

make cons

but not relat

to follow ins

t or in this m

ath or major

sonal injury

mers aware

d to hazard

tructions can

nual, look fo

property dam

nd/or prope

f actions tha

.

cause

r one of

age and if

ty

are

WAR

Suction in

severe inju

Hair Entra

Limb Entr

cracked, m

Body Suc

Eviscerati

sump or s

disembow

Mechanic

opening of

WAR

o When

outlets

near p

o Dual s

o Dual s

o The m

o Never

o Replac

o In addi

Nation

o Install

WAR

sucti

WAR

WAR

repla

CAU

being

climb

heate

WAR

start

Failur

filter

death

filter

positi

runni

a stea

WAR

of pu

Befor

pool a

pool a

opera

syste

only a

WAR

regula

dama

prope

To red

mowe

ING

– Sucti

uction outlets

ry and/or deat

pment

- Hair c

pment

- A lim

issing, or not s

ion Entrapm

on/ Disembo

ction outlet co

lment.

l Entrapmen

a suction outl

ING

- To Re

utlets are small

in the same pla

int.

ction fittings sh

ction fittings sh

ximum system fl

se Pool or Spa i

damaged, brok

ion two or more

l, State, and Lo

tion of a vacuu

ING

–

Failu

n outlets can

ING

–

–

–

Comp

– Haz

– Sep

– Risk

Failu

Suct

aterial can r

ING

ed at least ev

ION

used as mean

n this produc

s must be posi

ING

p, normal ope

to follow safe

ousing and cla

Before servici

anual air relie

n to allow sys

g. Before star

y stream of w

NING

p and/or filter

servicing pool

nd spa circulat

nd spa circulat

e or test the

with compres

low pressure (

NING

tions, and the

e. To reduce t

ly located elec

uce the risk of

s, hedge trim

n Entrapmen

and/or suctio

due to the fol

n become ent

inserted into

ecurely attach

nt

- A negative

elment

er which is, d

- There is pot

t cover resulti

duce the ris

nough to be bl

e (i.e. floor or w

ll be placed in s

ll not be locate

w rate shall not

any suction outl

en, cracked, mis

suction outlets

al codes applica

release or vent

re to remove

result in an in

re to keep suc

sult in an inc

on outlet com

ry ten years

onents such a

s of access to

. Closely supe

tioned to prev

rdous Press

ation, and afte

y and operatio

mp due to pre

ng pool and s

valve must b

em water to re

ing system pu

ter (not air or

aration Haz

components.

and spa circul

ion system if a

ion system unl

irculation sys

sed air can ca

elow 5 PSI), h

of Electric Sh

ational Electr

e risk of elect

trical receptacl

lectric shock

ers and other

- A n

USE

t Hazard.

outlet covers

lowing entrap

ngled in sucti

an opening of

d can result in

pressure appli

gative pressu

maged, broke

ntial for jewelr

g in mechanic

of Entrapm

cked by a perso

ll), must be inst

ch locations an

on seating area

exceed the 6 ft/

et component is

ing, or not secu

er pump installe

ble.

ystem, which re

ressure test p

rease potenti

tion outlet co

ease potentia

ponents have

r if found to b

s the filtratio

the pool by y

rvise children

nt children fro

re.

Pool and

r pump shut of

n instructions

sure in the sys

a water circula

in open positi

urn back to th

p, fully open

ir and water) i

rd.

Failure to

Strainer cover

ation system, f

system compo

ss filter manu

em at more t

se component

gh volume blo

ck. All electri

c Code (NEC).

ic shock, do N

e. Before wo

eplace damag

quipment. D

NLY HAYW

hich are, da

ent hazards:

n outlet cover

suction outle

a mechanical

d to a large p

e applied dire

, cracked, mis

, swimsuit, ha

l entrapment.

nt Hazards:

, a minimum of

lled a minimum

distances to a

or on the backr

ec in outlet pipi

damaged, broke

ely attached su

d in accordance

lieves entrappin

lugs and/or p

al for suction

ponents cle

l for suction e

a finite life, t

e damaged, b

system, pum

ung children.

t all times. Co

using them

spa water circ

. Stand clear

ould result in

tem, which co

tion system, al

n. Before sta

pool. Do not

ilter manual ai

discharged.

ollow safety a

ust be prope

ilters manual a

nent is not ass

al air relief val

an 50 PSI. D

to explode,

er when air p

al wiring MUS

Hazardous vol

T use an exte

king on any el

d wiring imme

NOT ground t

RD GENUI

aged, broken,

sump or sucti

ind or swellin

rtion of the bo

tly to the intes

sing, or unsec

ir decorations,

wo functioning

of three feet (3’)

oid “dual block

st for such seat

ng.

n, cracked, miss

tion outlet com

ith latest ASM

suction, is reco

lugs used in

entrapment a

r of debris, s

ntrapment as

e cover/grate

roken, cracke

ps and heater

To reduce ris

mponents suc

s a means of a

lation system

f circulation s

iolent separa

ld cause prop

l system and p

ting system p

change filter c

r relief valve.

d operation in

ly secured to p

ir relief valve

embled proper

e body is in lo

not purge th

ith risk of seve

rging the pum

be in confor

age can shock

sion cord to c

ctrical equipm

diately. Locat

a gas supply

E REPLAC

cracked, missi

on outlet cove

of the limb.

dy or limbs ca

tines through

red can result

finger, toe or

uction outlets p

[1 meter] apart

ge” by a user.

ng areas.

ng, or not secur

onents immedia

, APSP Standard

mmended.

interization o

described a

ch as leaves,

described ab

should be in

, missing, or

must be posi

of injury, do n

as the filtrati

ccess to the p

operate unde

stem equipm

ion of the pum

rty damage, s

ump controls

mp, all system

ntrol valve po

o not close filt

structions cou

ump housing

ust be in ope

ly, damaged, o

ked position i

system with

re injury or de

p, filter, or pipi

ance with app

, burn, and ca

nnect unit to

ent, turn off p

conduit to pr

line.

EMENT PA

ng, or unsecur

that is damag

result in an e

n unprotected

in evisceratio

nuckle to be c

r pump must be

as measured fr

ly attached.

ely.

s and CPSC guid

the pool/spa

ove.

dirt, hair, pap

ve.

pected frequ

not securely a

ioned so as t

ot permit child

n system, pu

ol.

hazardous pr

nt during pum

p housing and

vere personal

ust be in off p

valves must b

ition while sy

er manual air r

d result in viol

ith strainer co

position. Do

r missing. Do

filter upper b

ompressed a

th to anyone n

ng.

licable local co

se death or se

lectric supply.

wer supply to

vent abuse fro

TS

d can cause

d, broken,

trapment.

suction outlet

/

ught in an

installed. Sucti

m near point to

lines, follow all

from the

er and other

ntly and

tached.

prevent their

ren to use or

ps, and

ssure during

start up.

cover, and/or

injury, or

sition and

set in a

tem pump is

lief valve unti

nt separation

er lock ring.

ot operate

ot operate

dy. Never

ir. Purging the

earby. Use

des,

ious property

Provide a

he equipment.

m lawn

2

n

Loading...

Loading...