Hayward TriStar VS 950 Omni, TriStar VS 900 Omni, Super Pump VS 700 Omni, MaxFlo VS 500 Omni Owner's Manual

VS Omni Pump

Owner’s Manual

Contents

Pump Warnings...............2

Overview.........................5

Installation......................7

Operation......................10

Troubleshooting............11

Maintenance.................12

Additional Information..13

Warranty........................13

Registration Card...........15

092708 RevA

TriStar VS 950 Omni

Tristar VS 900 Omni

Super Pump VS 700 Omni

MaxFlo VS 500 Omni

SAVE THIS INSTRUCTION MANUAL

Hayward Pool Products

620 Division Street, Elizabeth NJ 07207

Phone (908)-355-7995

www.hayward.com

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

IMPORTANT SAFETY INSTRUCTIONS

Basic safety precautions should always be followed, including the following: Failure to follow instructions can

cause severe injury and/or death.

This is the safety-alert symbol. When you see this symbol on your equipment or in this manual, look for

one of the following signal words and be alert to the potential for personal injury.

WARNING warns about hazards that could cause serious personal injury, death or major property damage and if ignored presents a potential hazard.

CAUTION warns about hazards that will or can cause minor or moderate personal injury and/or property damage and if ignored presents a potential hazard. It can also make consumers aware of actions that are

unpredictable and unsafe.

The NOTICE label indicates special instructions that are important but not related to hazards.

WARNING - Read and follow all instructions in this owner’s manual and on the equipment. Failure to follow

instructions can cause severe injury and/or death.

WARNING – This product should be installed and serviced only by a qualied professional.

CAUTION – All electrical wiring MUST be in conformance with all applicable local codes, regulations, and

the National Electric Code (NEC).

USE OF NON-HAYWARD REPLACEMENT PARTS VOIDS WARRANTY.

ATTENTION INSTALLER - THIS MANUAL CONTAINS IMPORTANT INFORMATION ABOUT THE INSTALLATION,

OPERATION, AND SAFE USE OF THIS VARIABLE SPEED PUMP THAT MUST BE FURNISHED TO THE END

USER OF THIS PRODUCT. FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS COULD RESULT IN SERI-

OUS INJURY.

WARNING – To reduce risk of injury, do not permit children to use or climb on this product. Closely

supervise children at all times. Components such as the ltration system, pumps, and heaters must be positioned to

prevent children from using them as a means of access to the pool.

CAUTION – This pump is intended for use on permanently installed swimming pools and may also be

used with hot tubs and spas if so marked. Do NOT use with storable pools. A permanently installed pool is constructed in or on the ground or in a building such that it cannot be readily disassembled for storage. A storable pool

is constructed so that it is capable of being readily disassembled for storage and reassembled to its original integrity.

Though this product is designed for outdoor use, it is strongly advised to protect the electrical components from the

weather. Select a well-drained area, one that will not ood when it rains. It requires free circulation of air for cooling.

Do not install in a damp or non-ventilated location. If installed within an outer enclosure or beneath the skirt of a hot

tub or spa, adequate ventilation and free circulation of air must be provided to prevent overheating of the motor.

SAVE THESE INSTRUCTIONS

2

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

WARNING – Pool and spa components (seals, gaskets, etc.) have a nite life. All components should be

inspected frequently and replaced at least every ten years, or if found to be damaged, broken, cracked, missing, or

not securely attached.

WARNING – Risk of Electric Shock. All electrical wiring MUST be in conformance with applicable local

codes, regulations, and the National Electric Code (NEC). Hazardous voltage can shock, burn, and cause death

or serious property damage. To reduce the risk of electric shock, do NOT use an extension cord to connect unit to

electric supply. Provide a properly located electrical receptacle. Before working on pump or motor, turn off power

supply to the pump.

WARNING – To reduce the risk of electric shock replace damaged wiring immediately. Locate conduit to

prevent abuse from lawn mowers, hedge trimmers and other equipment.

WARNING – Risk of Electric Shock. In accordance with the National Electric Code (NEC), connect only

to a branch circuit protected by a ground-fault circuit-interrupter (GFCI). Contact a qualied electrician if you cannot

verify that the circuit is protected by a GFCI. The unit must be connected only to a supply circuit that is protected

by a ground-fault circuit-interrupter (GFCI). Such a GFCI should be provided by the installer and should be tested

on a routine basis. To test the GFCI, push the test circuit button. The GFCI should interrupt power. Push the reset

button. Power should be restored. If the GFCI fails to operate in this manner, the GFCI is defective. If the GFCI interrupts power to the pump without the test button being pushed, a ground current is owing, indicating the possibility of an electric shock. Do not use this pump. Disconnect the pump and have the problem corrected by a qualied

service representative before using.

WARNING – Failure to bond pump to pool structure will increase risk for electrocution and could result in

injury or death. To reduce the risk of electric shock, see installation instructions and consult a professional electrician on how to bond pump. Also, contact a licensed electrician for information on local electrical codes for bonding

requirements.

Notes to electrician: Use a solid copper conductor, size 8 or larger. Run a continuous wire from external bonding

lug to reinforcing rod or mesh. Connect a No. 8 AWG (8.4 mm2) [No. 6 AWG (13.3 mm2) for Canada] solid copper

bonding wire to the pressure wire connector provided on the pump housing and to all metal parts of swimming pool,

spa, or hot tub, and to all electrical equipment, metal piping (except gas piping), and conduit within 5 ft. (1.5 m) of

inside walls of swimming pool, spa, or hot tub. IMPORTANT - Reference NEC codes for all wiring standards including, but not limited to, grounding, bonding and other general wiring procedures.

WARNING – Suction Entrapment Hazard. Suction in suction outlets and/or suction outlet covers, which

are damaged, broken, cracked, missing, or unsecured cause severe injury and/or death due to the following entrapment hazards (symbols complements of APSP):

Hair Entrapment - Hair can become entangled in suction outlet cover.

Limb Entrapment - A limb inserted into an opening of a suction outlet sump or suction outlet cover that is damaged,

broken, cracked, missing, or not securely attached can result in a mechanical bind or swelling of the limb.

Body Suction Entrapment - A differential pressure applied to a large portion of the body or limbs can result in an

entrapment.

Evisceration/ Disembowelment - A negative pressure applied directly to the intestines through an unprotected

suction outlet sump or suction outlet cover which is damaged, broken, cracked, missing, or unsecured can result in

evisceration/disembowelment.

Mechanical Entrapment - There is potential for jewelry, swimsuits, hair decorations, ngers, toes, or knuckles to be

caught in an opening of a suction outlet cover resulting in mechanical entrapment.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

3

WARNING – To Reduce the risk of Entrapment Hazards:

• When outlets are small enough to be blocked by a person, a minimum of two functioning suction outlets per

pump must be installed. Suction outlets in the same plane (i.e. oor or wall), must be installed a minimum of

three feet (3’) [0.91 meter] apart, as measured from near point to near point.

• Dual suction ttings shall be placed in such locations and distances to avoid “dual blockage” by a user.

• Dual suction ttings shall not be located on seating areas or on the backrest for such seating areas.

• The maximum system ow rate shall not exceed the values shown in the “Pipe Sizing Chart” found in section 4.3

below.

• Never use pool or spa if any suction outlet component is damaged, broken, cracked, missing, or not securely

attached.

• Replace damaged, broken, cracked, missing, or not securely attached suction outlet components immediately.

• In addition to two or more suction outlets per pump installed in accordance with latest APSP standards and

CPSC guidelines, follow all national, state, and local codes applicable.

• Installation of a vacuum release or vent system, which relieves entrapping suction, is recommended.

WARNING – Hazardous Pressure. Pool and spa water circulation systems operate under hazardous

pressure during start-up, normal operation, and after pump shut-off. Stand clear of circulation system equipment

during pump start-up. Failure to follow safety and operation instructions could result in violent separation of the

pump housing and cover due to pressure in the system, which could cause property damage, severe personal injury,

or death. Before servicing pool and spa water circulation system, all system and pump controls must be in off position and lter manual air relief valve must be in open position. Before starting pump, all system valves must be set in

a position to allow system water to return back to the pool. Do not change lter control valve position while pump is

running. Before starting pump, fully open lter manual air relief valve. Do not close lter manual air relief valve until

a steady stream of water (not air or air and water mix) is discharged from the valve. All suction and discharge valves

MUST be OPEN when starting the circulation system. Failure to do so could result in severe personal injury and/or

property damage.

WARNING – Separation Hazard. Failure to follow safety and operation instructions could result in violent

separation of pump components. Strainer cover must be properly secured to pump housing with strainer cover lock

ring. Before servicing pool and spa circulation system, all system and pump controls must be in off position and

lter manual air relief valve must be in open position. Do not operate pool and spa circulation system if a system

component is not assembled properly, damaged, or missing. Do not operate pool and spa circulation system unless

lter manual air relief valve body is in locked position in lter upper body. All suction and discharge valves MUST be

OPEN when starting the circulation system. Failure to do so could result in severe personal injury and/or property

damage.

WARNING – Never operate the circulation system at more than 50 PSI maximum.

WARNING – Fire and burn hazard. Motors operate at high temperatures and if they are not properly iso-

lated from any ammable structures or foreign debris they can cause res, which may cause severe personal injury

or death. It is also necessary to allow the motor to cool for at least 20 minutes prior to maintenance to minimize the

risk for burns.

WARNING – Failure to install according to dened instructions may result in severe personal injury or

death.

SAVE THESE INSTRUCTIONS

4

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Overview

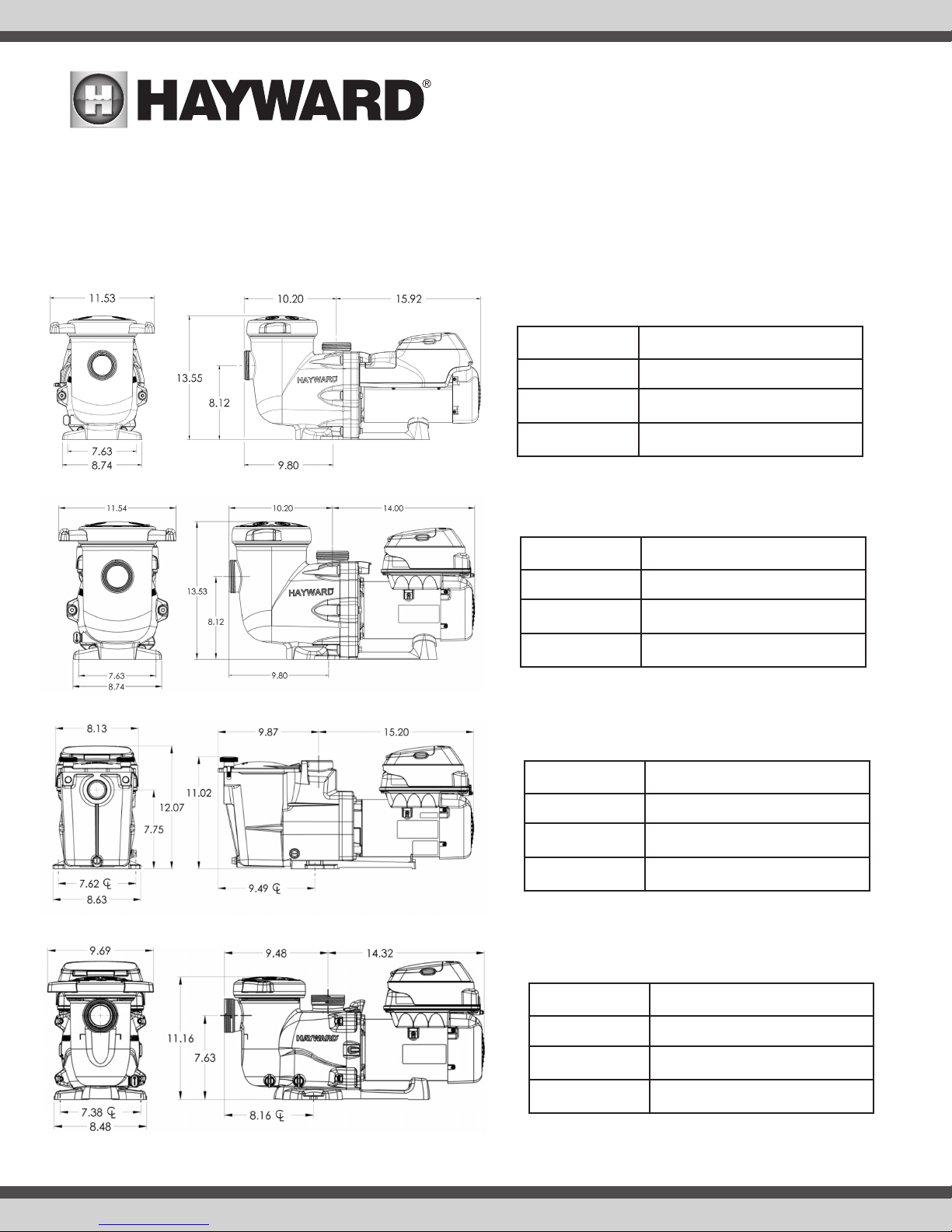

The new family of VS Omni variable speed pumps offer incredible energy savings via their advanced hydraulic design combined with a totally enclosed

permanent magnet motor. The four different VS Omni pump models are shown below with their dimensions and specs. Although very similar in design, this

manual will point out any differences with installation, wiring and operation. Refer to the label on your pump to determine which model you have and follow

any specific instructions related to your pump throughout this manual.

TriStar VS 950 Omni

Voltage: 230 VAC, 60Hz, Single Phase

Amps: 10.9 amps

Speed Range: 600 - 3450 RPM

Horsepower: 2.7 hp

TriStar VS 900 Omni

Voltage: 230 VAC, 60Hz, Single Phase

Amps: 0.4 - 11.0 amps

Speed Range: 600 - 3450 RPM

Horsepower: 1.85 hp

Super Pump VS 700 Omni

Voltage: 230 VAC, 60Hz, Single Phase

Amps: 0.4 - 10.0 amps

Speed Range: 600 - 3450 RPM

Horsepower: 1.65 hp

MaxFlo VS 500 Omni

Voltage: 230 VAC, 60Hz, Single Phase

Amps: 0.4 - 10.0 amps

Speed Range: 600 - 3450 RPM

Horsepower: 1.65 hp

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

5

Energy Efficiency Overview and Power consumption

uclights

vsp

heater cleaner

POOL

features

schedule

The energy consumed by a pool pump is measured in terms of Watts (W) or Kilowatts (kW). Because the VS Omni displays power consumption in watts, you

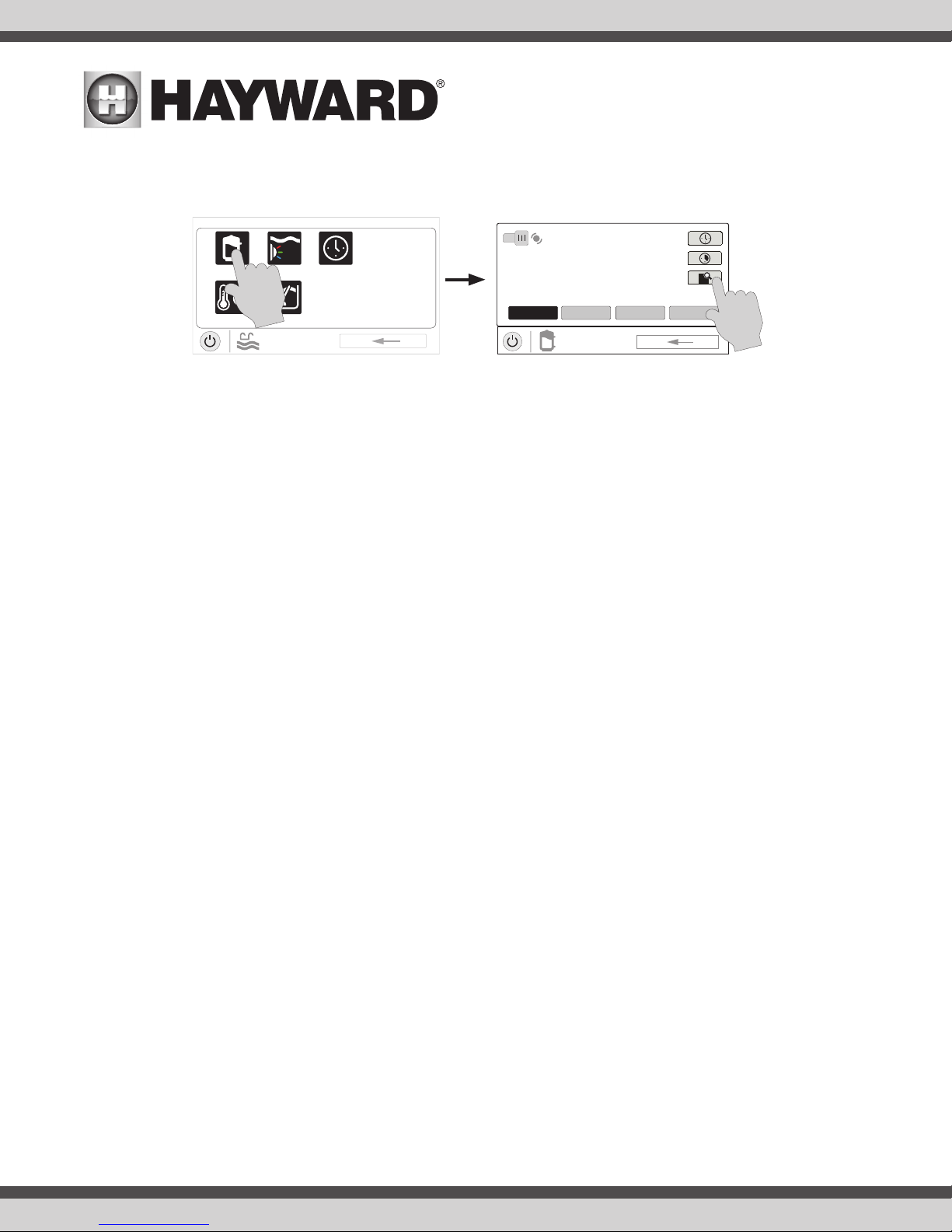

can easily determine the cost of operating the pump at the given speed. After installation, to display power consumption at any time, follow the screens below:

ON

ON

MED HIGH CUSTOMLOW

POOL

vsp pump

Pool Features Screen Pump Control Screen

The power consumption will be displayed in watts. To calculate power costs, refer to the example below:

VS Omni Variable Speed Pump operating at 300 W. Cost of electricity = *$0.10 per kWh

Convert Watts to Kilowatts: 300 W = 0.3 kW

0.3 kW X $0.10/kWh = $0.03 per hour

*National Average (use your actual cost of electricity for more accurate results)

Note the power consumption is greatly affected by the speed of the pump. Lowering the speed of the pump can drastically reduce the power that is consumed.

Below are some of the major benefits of running the pump at lower speeds.

• Save electricity and money

• Improved filtration – the filter can often remove smaller particles when the water moves slower

• Quiet operation

• Reduced Total Dynamic Head – less stress on equipment (e.g. filter) which can lengthen equipment life

When determining the speed(s) to operate your pump, you must also take into account the minimum requirements for proper sanitation and equipment/water

feature functionality.

It is recommended you filter (“turnover”) all the water in the pool at least once every 24 hours. Check with local requirements for the minimum turnover rate.

Running the pump at a lower speed may require running the pump for a longer period of time in order to meet the turnover requirements for proper sanitation.

Equipment such as heaters, skimmers, and chlorinators require minimum flows to operate correctly. Refer to individual equipment manuals for specific flow

requirements.

After setting the pump speed(s), it is recommended you check that all other equipment/water features are functioning as intended. For example, when running

at a low speed for daily filtration, verify water is adequately flowing over the skimmer weirs. Operate the pump at higher speeds for the shorter periods of time

needed to operate a heater, water feature, etc.

6

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Loading...

Loading...