Hayward Super Pump 700, Super Pump SP2670010X15, Super Pump SP2670007X10 Owner's Manual

Super Pump

Owner’s Manual

IS26700T Rev-A

®

700 Series

Contents

Product Specific Warnings………2

Introduction……….………………..…4

Installation……….……………..….….7

Shaft Seal Replacement..………..8

Replacement Parts………….……..10

Troubleshooting………….…..…….11

Warranty…………………………………13

Registration ……………………..……15

IMPORTANT SAFETY INSTRUCTIONS

Basic safety precautions should always be followed, including the following: Failure to follow instructions

can cause severe injury and/or death.

This is the safety-alert symbol. When you see this symbol on your equipment or in this manual, look for

one of the following signal words and be alert to the potential for personal injury.

WARNING warns about hazards that could cause serious personal injury, death or major property

damage and if ignored presents a potential hazard.

CAUTION warns about hazards that will or can cause minor or moderate personal injury and/or

property damage and if ignored presents a potential hazard. It can also make consumers aware of

actions that are unpredictable and unsafe.

The NOTICE label indicates special instructions that are important but not related to hazards.

Hayward Pool Products

620 Division Street, Elizabeth, NJ 07207

Phone: (908) 355-7995

www.hayward.com

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS 1

N

a

N

s

a

t

u

e

N

Wbe

p

h

e

ngu

n

N

u

N

a

N

a

T

d

N

o

p

e

g

N

n

n

m

d

w

h

a

b

e

w

v

e

e

c

r

i

i

y

o

e

o

w

v

i

s

a

n

o

e

a

c

e

a

o

s

Y

n

c

e

n

a

e

e

a

t

e

n

k

p

c

c

e

p

s

e

r

g

u

m

t

r

m

n

I

i

e

l

e

w

m

o

a

r

n

y

a

e

o

e

e

m

o

m

a

m

o

m

o

n

.

e

a

c

p

a

o

a

b

e

r

o

A

r

/

m

.

t

b

o

c

m

w

s

n

m

a

e

l

a

a

t

h

p

r

s

t

u

c

t

m

m

t

v

d

d

w

t

R

h

o

g

u

i

s

o

o

i

s

w

s

u

n

s

m

r

p

e

s

p

i

e

t

e

a

r

n

a

k

s

a

i

i

E

f

.

s

o

t

e

r

u

u

t

o

s

d

s

D

o

g

y

t

e

e

n

n

a

f

u

i

r

e

a

o

o

e

e

f

e

m

o

o

p

n

t

t

t

e

o

s

r

e

d

Suction in

severe inju

Hair Entra

Limb Entr

cracked, m

Body Suc

Eviscerati

sump or s

disembow

Mechanic

opening of

suction o

material c

replaced

being use

on this pro

positioned

WAR

WAR

WAR

o

o D

o D

o T

o N

o R

o I

o I

WAR

WAR

WAR

CAU

ING

–

Rea

F

ilure to follo

ING

– Suct

uction outlets

ry and/or deat

pment

- Hair c

pment

- A lim

issing, or not s

ion Entrapm

on/ Disembo

ction outlet co

lment.

l Entrapmen

a suction outl

ING

- To Re

hen outlets ar

installed. Su

a

art, as measu

ual suction fitt

ual suction fitt

e maximum s

ever use Pool

place damag

addition two

idelines, follo

stallation of a

ING

–

tlets can resu

ING

–

n result in an

ING

–

t least every s

ION

–

Comp

as means of

uct. Closely

to prevent chil

, understa

instructions

ion Entrapm

and/or suctio

due to the fol

n become ent

inserted into

ecurely attach

nt

elment

er which is, d

- There is pot

t cover resulti

duce the ris

small enough

tion outlets in

ed from near

ngs shall be pl

ngs shall not b

stem flow rate

r Spa if any su

d, broken, cra

r more suction

all National,

acuum releas

Failu

re to remove

lt in an increa

Failu

re to keep suc

increase pot

Suct

on outlet com

even years or

onents such a

access to the

upervise child

dren from usin

- A negative

- A n

d, and fol

an cause sev

nt Hazard.

outlet covers

lowing entrap

ngled in sucti

an opening of

d can result in

pressure appli

gative pressu

maged, broke

ntial for jewelr

g in mechanic

of Entrapm

to be blocked

the same plan

oint to near po

aced in such l

e located on s

shall not exce

tion outlet co

ked, missing,

outlets per pu

State, and Loc

or vent syste

ressure test p

e potential f

tion outlet co

ntial for sucti

ponents have

if found to be

s the filtratio

pool by young

en at all times

them as a m

ow all inst

re injury and

hich are, da

ent hazards:

n outlet cover

suction outle

a mechanical

d to a large p

e applied dire

, cracked, mis

, swimsuit, ha

l entrapment.

nt Hazards:

by a person, a

e (i.e. floor or

int.

cations and di

ating areas or

d the flow rati

ponent is da

r not securely

p installed in

l codes applic

, which reliev

lugs and/or p

r suction entr

ponents cle

n entrapmen

a finite life, t

damaged, bro

system, pum

children. To

Components

ans of access

uctions

or death.

aged, broken,

sump or sucti

ind or swellin

rtion of the bo

tly to the intes

sing, or unsec

ir decorations,

minimum of tw

all), must be i

stances to avo

on the backre

g of as listed

aged, broken,

attached sucti

accordance w

able.

s entrapping

lugs used in

pment as de

r of debris, s

as described

e cover/grate

ken, cracked,

ps and heater

educe risk of i

such as the filt

o the pool.

in t

his owner’s m

cracked, missi

on outlet cove

of the limb.

dy or limbs ca

tines through

red can result

finger, toe or

o functioning

nstalled a mini

d “dual block

t for such seat

n Table 1.

cracked, miss

n outlet comp

th latest ASM

uction, is reco

interization o

cribed above

ch as leaves,

above.

should be in

ration system,

missing, or n

must be posi

jury, do not p

nual and on

ng, or unsecur

that is damag

result in an e

n unprotected

in evisceratio

nuckle to be c

uction outlets

mum of three

ge” by a user.

ng areas.

ng, or not sec

onents immed

, APSP Standa

mmended.

the pool/spa

dirt, hair, pap

pected frequ

t securely att

ioned so as t

rmit children t

pumps, and h

he equipmen

d can cause

d, broken,

trapment.

suction outlet

/

ught in an

per pump mus

eet (3’) [1 met

rely attached.

ately.

ds and CPSC

from the

er and other

ntly and

ched.

prevent their

use or climb

aters must be

.

r]

WAR

start up, n

follow safe

and clamp

pool and s

be in open

back to th

open filter

is dischar

WAR

of pump a

servicing p

circulation

circulation

circulatio

air can cau

high volu

ING

– Haz

rmal operatio

ty and operati

due to pressur

a water circul

position. Befo

pool. Do not

manual air reli

ed.

ING

– Sep

d/or filter com

ool and spa cir

system if a sys

system unless

system at m

se component

e blower when

rdous Press

, and after pu

n instructions

in the system

tion system, a

re starting sys

hange filter co

f valve. Do no

ration Haza

ponents. Strai

culation syste

tem compone

filter manual a

re than 50 PS

to explode, w

air purging th

re.

Pool and

p shut off. St

could result in

, which could

ll system and

em pump, all s

ntrol valve pos

t close filter m

d.

Failure to f

ner cover must

, filters manu

t is not assem

ir relief valve b

. Do not purg

th risk of seve

pump, filter,

spa water circ

nd clear of cir

violent separa

ause property

ump controls

ystem valves

ition while sys

nual air relief

llow safety an

be properly se

l air relief valv

led properly,

ody is in locke

the system

e injury or dea

r piping.

lation system

ulation syste

ion of the pum

damage, seve

ust be in off

ust be set in a

em pump is ru

alve until a st

d operation in

cured to pump

e must be in o

amaged, or m

position in fil

ith compress

h to anyone n

operate unde

equipment d

p housing and

e personal inj

osition and fil

position to all

nning. Before

ady stream of

tructions coul

housing with

en position.

ssing. Do not

ter upper body

ed air. Purgin

arby. Use onl

hazardous pr

ring pump sta

cover, and/or

ry, or death. B

er manual air r

w system wat

tarting syste

water (not air

result in viole

trainer cover l

o not operate

perate pool a

. Never opera

the system wi

a low pressur

ssure during

rt up. Failure t

ilter housing

efore servicing

elief valve mu

r to return

pump, fully

r air and wate

nt separation

ck ring. Befor

ool and spa

d spa

e or test the

th compresse

e (below 5 PSI)

t

)

USE ONL

HAYWARD G

ENUINE REPL

CEMENT PA

TS

2

WARNING – Risk of Electric Shock. All electrical wiring MUST be in conformance with applicable local codes,

regulations, and the National Electric Code (NEC). Hazardous voltage can shock, burn, and cause death or serious property

damage. To reduce the risk of electric shock, do NOT use an extension cord to connect unit to electric supply. Provide a properly

located electrical receptacle. Before working on any electrical equipment, turn off power supply to the equipment. To reduce

the risk of electric shock replace damaged wiring immediately. Locate conduit to prevent abuse from lawn mowers, hedge

trimmers and other equipment. Do NOT ground to a gas supply line.

WARNING – Risk of Electric Shock Failure to ground all electrical equipment can cause serious or fatal electrical shock

hazard. Electrical ground all electrical equipment before connecting to electrical power supply.

WARNING – Risk of Electric Shock Failure to bond all electrical equipment to pool structure will increase risk for

electrocution and could result in injury or death. To reduce the risk of electric shock, see installation instructions and consult a

professional electrician on how to bond all electrical equipment. Also, contact a licensed electrician for information on local

electrical codes for bonding requirements.

Notes to electrician: Use a solid copper conductor, size 8 or larger. Run a continuous wire from external bonding lug to

reinforcing rod or mesh. Connect a No. 8 AWG (8.4 mm

pressure wire connector provided on the electrical equipment and to all metal parts of swimming pool, spa, or hot tub, and metal

piping (except gas piping), and conduit within 5 ft. (1.5 m) of inside walls of swimming pool, spa, or hot tub.

IMPORTANT - Reference NEC codes for all wiring standards including, but not limited to, grounding, bonding and other general

wiring procedures.

2

) [No. 6 AWG (13.3 mm2) for Canada] solid copper bonding wire to the

WARNING – Risk of Electric Shock . The electrical equipment must be connected only to a supply circuit that is protected

by a ground-fault circuit-interrupter (GFCI). Such a GFCI should be provided by the installer and should be tested on a routine

basis. To test the GFCI, push the test button. The GFCI should interrupt power. Push reset button. Power should be restored. If

the GFCI fails to operate in this manner, the GFCI is defective. If the GFCI interrupts power to the electrical equipment without the

test button being pushed, a ground current is flowing, indicating the possibility of an electrical shock. Do not use this electrical

equipment. Disconnect the electrical equipment and have the problem corrected by a qualified service representative before

using.

CAUTION – HAYWARD

spas if so marked. Do not use with storable pools. A permanently-installed pool is constructed in or on the ground or in a

building such that it cannot be readily disassembled for storage. A storable pool is constructed so that it is capable of being

readily disassembled for storage and reassembled to its original integrity.

®

pumps are intended for use with permanently-installed pools and may be used with hot tubs and

WARNING – Risk of Hyperthermia. To avoid hyperthermia the following “Safety Rules for Hot Tubs” are recommended by

the U.S. Consumer Product Safety Commission.

1. Spa or hot tub water temperatures should never exceed 104°F [40°C]. A temperature of 100°F [38°C] is

considered safe for a healthy adult. Special caution is suggested for young children. Prolonged immersion

in hot water can induce hyperthermia.

2. Drinking of alcoholic beverages before or during spa or hot tub use can cause drowsiness, which could

lead to unconsciousness and subsequently result in drowning.

3. Pregnant women beware! Soaking in water above 100°F [38°C] can cause fetal damage during the first

three months of pregnancy (resulting in the birth of a brain-damaged or deformed child). Pregnant women

should adhere to the 100°F [38°C] maximum rule.

4. Before entering the spa or hot tub, users should check the water temperature with an accurate thermometer; spa or hot tub thermostats may err in regulating water temperatures by as much as 4°F

(2.2°C).

5. Persons taking medications, which induce drowsiness, such as tranquilizers, antihistamines or anticoagulants, should not use spas or hot tubs.

6. If the pool/spa is used for therapy, it should be done with the advice of a physician. Always stir pool/ spa water

before entering the pool/spa to mix in any hot surface layer of water that might exceed healthful temperature

limits and cause injury. Do not tamper with controls, because scalding can result if safety controls are not in

proper working order.

7. Persons with a medical history of heart disease, circulatory problems, diabetes or blood pressure

problems should obtain a physician’s advice before using spas or hot tubs.

8. Hyperthermia occurs when the internal temperature of the body reaches a level several degrees above normal

body temperature of 98.6°F [37°C]. The symptoms of Hyperthermia include: drowsiness, lethargy,

dizziness, fainting, and an increase in the internal temperature of the body.

The effects of Hyperthermia include:

1. Unawareness of impending danger.

2. Failure to perceive heat.

3. Failure to recognize the need to leave the spa.

4. Physical inability to exit the spa.

5. Fetal damage in pregnant women.

6. Unconsciousness resulting in danger of drowning.

SAVE THESE INSTRUCTIONS

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS 3

General Information

Introduction

This manual contains information for the proper installation and operation of the Hayward Super Pump® 700 Series.

The instructions in this manual MUST be followed precisely. Failure to install according to defined instructions

will void warranty.

Product Benefits

Super-sized 110 cubic-inch basket has extra leaf-holding capacity and extends time between cleanings. Rigid

construction with load extender ribbing assures free flowing operation even with heavy debris loads.

Exclusive swing-aside hand knobs make strainer cover removal simple and easy.

See-thru strainer cover lets you see when the basket needs cleaning.

All components molded of corrosion-proof reinforced thermoplastic for extra durability and long life.

Uni-bracket mounting base provides stable, stress-free support, plus versatility for any installation requirement.

Adapts to 48 and 56 frame motors.

Heat resistant, industrial size ceramic seal.

Rugged, one-piece housing, with full-flow ports, assures rapid priming and continuous operation.

Service-ease design gives simple access to all internal parts. By disengaging just four (4) bolts, motor and

entire drive group assembly can be removed, without disturbing pipe or mounting connections.

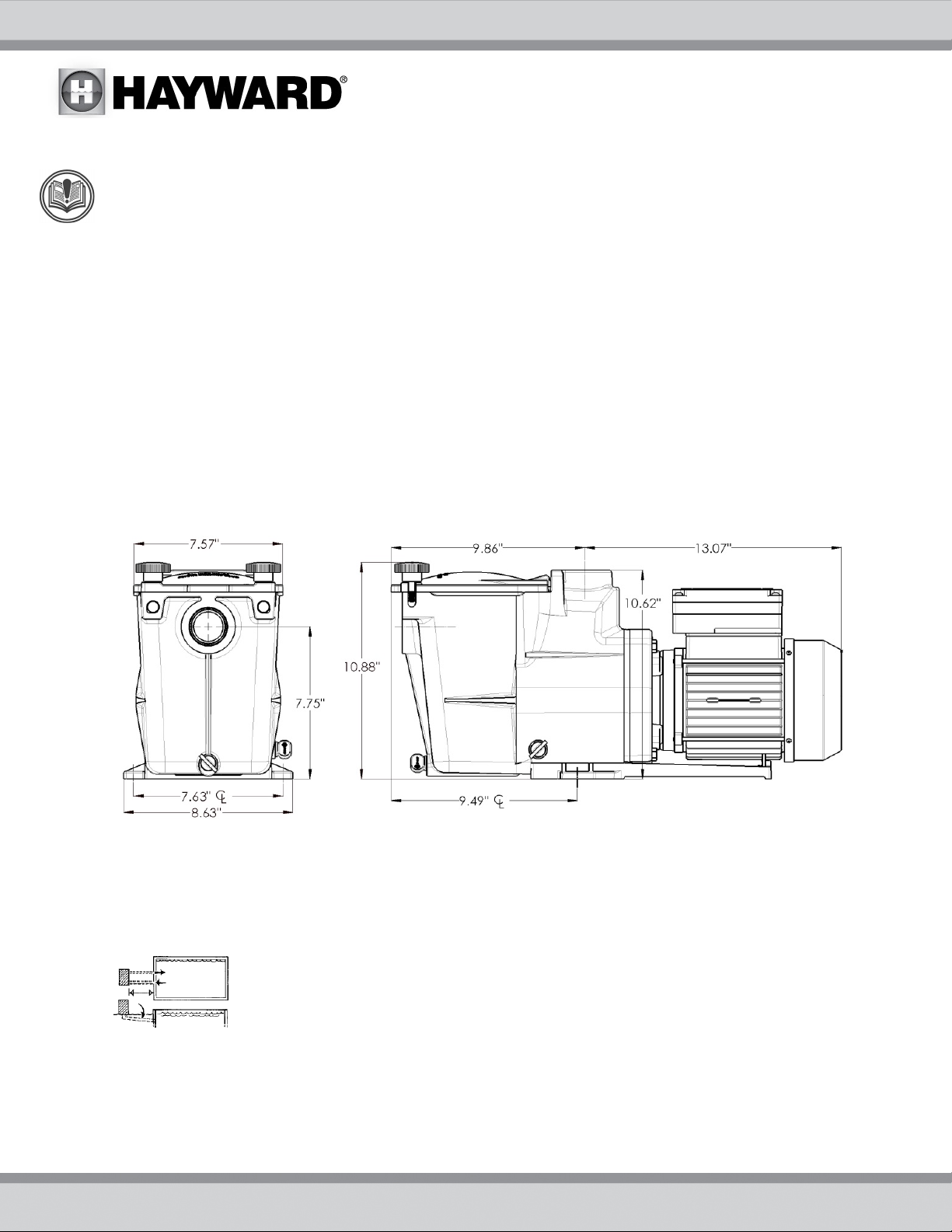

Product Specifications

Installation Instructions

NOTICE

Pump Location

Though the pump is designed for outdoor use, it is strongly advised to protect the electrical components from the

weather. Select a well-drained area, one that will not flood when it rains. Do NOT install pump in a damp or nonventilated location. Keep motor clean. Pump motors require free circulation of air for cooling.

– This product should be installed and serviced only by a qualified professional.

Locate pump as close to pool as practical and run suction lines as direct as possible to reduce

friction loss. Suction lines should have continuous slope upward from lowest point in line.

Joints must be tight (but not over-tightened). Suction line diameter must equal or be larger than

the discharge line diameter.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS 4

Pump Mounting

Install pump on a firm, level base or pad to meet all local and national codes. Fasten pump to base or pad with

screws or bolts to reduce vibration and stress on pipe or hose joints. The base MUST be solid, level, rigid, and

vibration free.

Pump mount must:

Allow pump inlet height to be as close to water level as possible.

Allow use of short, direct suction pipe (to reduce friction losses).

Allow for ball valves in suction and discharge piping.

Be protected from excess moisture and flooding.

Allow adequate access for servicing pump and piping.

Incorporate a straight portion of pipe prior to pump inlet no less than (5) pipe diameters in length.

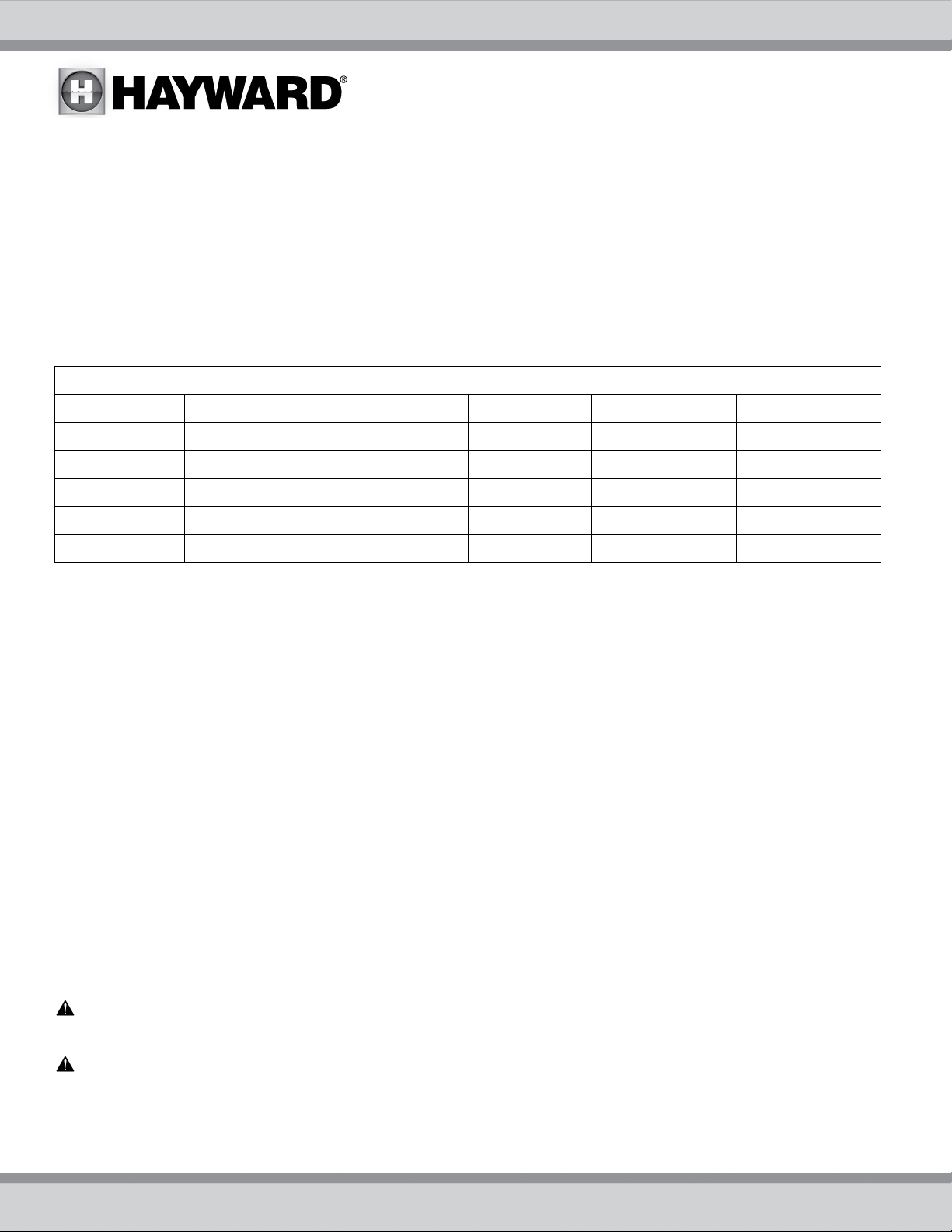

Pipe Sizing Chart

MAXIMUM RECOMMENDED SYSTEM FLOW RATE BY PIPE SIZE

Pipe Size Flow rate Water Velocity Pipe Size Flow rate Water Velocity

inches [mm] GPM [Liter/Min] ft/sec [meters/sec] inches [mm] GPM [Liter/Min] ft/sec [meters/sec]

1 ½” 50.76 8 2 ½” 119 8

[50] [192] [2.44] [75] [452] [2.44]

2” 84 8 3” 184 8

[63] [317] [2.44] [90] [698] [2.44]

NOTE – System design should allow a maximum of 8-ft/sec [2.44 meters/sec] water velocity in residential pool or spa

piping. It is recommended that a minimum length of piping, equivalent to 10 pipe diameters, be used between the

pump suction inlet and any plumbing fittings.

Plumbing

Use PTFE tape to seal threaded connections on molded plastic components. All plastic fittings must be new or

thoroughly cleaned before use. NOTE - Do NOT use Plumber’s Pipe Dope as it may cause cracking of the plastic

components.

When applying PTFE tape to plastic threads, wrap the entire threaded portion of the male fitting with one to two

layers of tape. Wind the tape clockwise as you face the open end of the fitting, beginning at the end of the fitting.

The pump suction and outlet ports have molded-in thread stops. Do NOT attempt to force hose connector fitting

past this stop. It is only necessary to tighten fittings enough to prevent leakage. Tighten fitting by hand and then

use a tool to engage fitting an additional 1 ½ turns. Use care when using PTFE tape as friction is reduced

considerably; do NOT over-tighten fitting or you may cause damage. If leaks occur, remove connector, clean off

old PTFE tape, re-wrap with one to two additional layers of PTFE tape, and re-install connector.

Fittings

Fittings restrict flow. For better efficiency, use the fewest possible fittings. Avoid fittings that could cause an air

trap. Use two or more suction outlets per pump installed in accordance with latest ASME, APSP Standards and CPSC

guidelines, follow all National, State, and Local codes applicable.

Electrical

NOTICE – All wiring must be done by a licensed electrician and must conform to all local and national codes

and regulations.

WARNING – Risk of Electric Shock. Before working on any electrical equipment, turn off power supply to the

equipment.

WARNING – Fire Hazard. Match supply voltage to motor nameplate voltage.

Insure that the electrical supply available agrees with the motor’s voltage, phase, and cycle, and that the wire size is

adequate for the HP (kW) rating and distance from the power source. NOTE - All electrical wiring MUST be

performed by a licensed electrician, and MUST conform to local codes and NEC regulations

.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS 5

Loading...

Loading...