Hayward SP1580, SP1540C, SP1580X15, SW1585X25, EP1550LX Owner's Manual

...

ISPFSERIES Rev G

PowerFlo LX

Pump Series

Owner’s Manual

™

/ PowerFlo II

Contents

Product Warnings……….………2

Installation……….……………..…4

Start-Up & Operation…….…….6

Shaft Seal Replacement……….7

Troubleshooting…………………..8

Replacement Parts………..….…10

Warranty …………………………..…11

Registration………………………….12

™

/ EP

INSTALLATION, OPERATION, & PARTS

IMPORTANT SAFETY INSTRUCTIONS

Basic safety precautions should always be followed, including the following: Failure to follow instructions can

cause severe injury and/or death.

This is the safety-alert symbol. When you see this symbol on your equipment or in this manual, look for

one of the following signal words and be alert to the potential for personal injury.

WARNING warns about hazards that could cause serious personal injury, death or major property

damage and if ignored presents a potential hazard.

CAUTION warns about hazards that will or can cause minor or moderate personal injury and/or property

damage and if ignored presents a potential hazard. It can also make consumers aware of actions that are

unpredictable and unsafe.

The NOTICE label indicates special instructions that are important but not related to hazards.

Hayward Pool Products

620 Division Street, Elizabeth, NJ 07207

Phone: (908) 355-7995

www.haywardnet.com

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS 1

R

R

s

p

a

i

o

u

e

a

R

Wbeap

h

e

ngu

n

R

s

R

r

R

y

a

h

R

R

R

C

s

R

o

p

e

g

a

c

h

n

n

v

e

e

e

c

r

i

i

y

o

e

o

w

v

l

e

n

c

e

m

s

v

v

e

u

h

z

n

o

e

a

c

e

E

o

e

m

n

n

a

e

g

a

n

s

p

c

c

e

v

t

s

c

v

c

s

r

j

t

s

m

t

Y

r

w

m

n

d

n

a

m

o

e

e

m

o

m

a

m

e

e

t

h

s

a

o

c

o

r

u

d

a

c

p

a

N

t

.

m

b

t

y

r

:

m

w

s

n

m

a

e

d

f

t

t

e

t

t

c

c

t

m

m

t

v

A

g

y

y

n

u

i

i

s

o

i

s

s

e

m

e

e

h

o

m

m

r

p

e

A

o

t

r

s

a

i

t

i

E

i

s

s

c

u

c

t

e

e

u

u

t

o

s

e

d

u

n

u

f

u

i

r

e

a

,

c

s

e

v

r

f

e

m

o

e

t

e

t

m

o

s

r

WA

NING

-

Re

to follow

Suction in

severe inju

Hair Entra

Limb Entr

cracked, m

Body Suct

Eviscerati

sump or s

disembow

Mechanic

opening of

WA

WA

o

o D

o D

o T

o N

o R

o I

o I

instructions

NING

– Su

uction outlets

ry and/or deat

ment- Hair ca

pment- A limb

issing, or not s

on Entrapme

n/ Disembow

ction outlet co

lment.

l Entrapment-

a suction outl

NING

- To R

hen outlets ar

installed. Su

art, as measu

ual suction fitt

ual suction fitt

e maximum s

ever use Pool

place damag

addition two

idelines, follo

stallation of a

d and foll

can cause s

tion Entrap

and/or suctio

due to the fol

become enta

inserted into

ecurely attach

t- A negative p

elment - A ne

er which is, d

There is poten

t cover resulti

duce the ri

small enough

tion outlets in

ed from near

ngs shall be pl

ngs shall not b

stem flow rate

r Spa if any su

d, broken, cra

r more suction

all National,

acuum releas

w all inst

vere injury a

ent Hazard.

outlet covers

lowing entrap

gled in suctio

n opening of a

d can result in

ressure applie

ative pressure

maged, broke

tial for jewelry,

g in mechanic

k of Entrap

to be blocked

the same plan

oint to near po

aced in such l

e located on s

shall not exce

tion outlet co

ked, missing,

outlets per pu

State, and Loc

or vent syste

uctions

in

nd/or death

hich are, da

ent hazards:

outlet cover.

suction outlet

a mechanical

to a large por

applied directl

, cracked, mis

swimsuit, hai

l entrapment.

ent Hazards

by a person, a

e (i.e. floor or

int.

cations and di

ating areas or

d the flow rati

ponent is da

r not securely

p installed in

l codes applic

, which reliev

his owner’s

aged, broken,

sump or suctio

ind or swellin

tion of the bod

to the intesti

sing, or unsec

decorations, f

:

minimum of tw

all), must be i

stances to avo

on the backre

g as listed on

aged, broken,

attached sucti

accordance w

able.

s entrapping

manual and

cracked, missi

n outlet cover

of the limb.

y or limbs can

es through an

red can result

nger, toe or kn

o functioning

nstalled a mini

d “dual block

t for such seat

the suction ou

cracked, miss

n outlet comp

th latest ASM

uction, is reco

n the equip

ng, or unsecur

hat is damage

esult in an ent

unprotected s

in evisceratio

uckle to be ca

uction outlets

mum of three

ge” by a user.

ng areas.

let cover.

ng, or not sec

onents immed

, APSP Standa

mmended.

ment. Failur

d can cause

, broken,

rapment.

ction outlet

/

ght in an

per pump mus

eet (3’) [1 met

rely attached.

ately.

ds and CPSC

r]

WA

NING

– Fai

from the

and othe

frequentl

securely

prevent t

all times.

as a mean

start up, n

follow safe

and clamp

pool and s

be in open

back to th

open filter

is dischar

WA

WA

CAU

WA

WA

WA

WA

uction outl

NING

– Fai

material ca

NING

– Su

and replac

ttached.

TION

– Co

eir being u

NING

NING

NING

of access to t

NING

ty and operati

due to pressur

position. Befo

pool. Do not

manual air reli

ed.

– Ne

– Ne

–

omponents s

To r

– Ha

rmal operatio

a water circul

ts can resul

lure to keep

result in an

tion outlet

d at least e

ponents su

ed as mean

er operate o

er change th

duce risk of in

ch as the filtra

e pool.

ardous Pres

, and after pu

n instructions

in the system

tion system, a

re starting sys

hange filter co

f valve. Do no

ure to remo

e pressure t

in an increa

uction outl

increase po

omponents

ery ten year

h as the filtr

of access t

test the cir

e filter contr

ury, do not pe

ion system, p

ure.

Pool an

p shut off. St

could result in

, which could

ll system and

em pump, all s

ntrol valve pos

t close filter m

st plugs an

se potential

t componen

ential for su

ave a finite

or if found

tion system

the pool by

ulation syst

l valve posi

mit children to

mps, and hea

spa water cir

nd clear of cir

violent separa

ause property

ump controls

ystem valves

ition while sys

nual air relief

/or plugs u

for suction e

s clear of d

ction entrap

life, the cov

o be damag

, pumps and

young childr

m at more t

tion while th

use or climb o

ers must be p

ulation syste

ulation syste

ion of the pum

damage, seve

ust be in off

ust be set in a

em pump is ru

alve until a st

ed in winter

ntrapment a

bris, such a

ment as des

r/grate sho

d, broken,

heater mus

en.

an 30 PSI.

e pump is ru

n this product.

sitioned to pr

s operate und

equipment d

p housing and

e personal inj

osition and fil

position to all

nning. Before

ady stream of

zation of th

described

leaves, dirt

ribed above

ld be inspe

racked, mis

be position

nning.

Closely super

vent children f

r hazardous p

ring pump sta

cover, and/or

ry, or death. B

er manual air r

w system wat

tarting syste

water (not air

pool/spa

bove.

hair, paper

.

ted

ing, or not

d so as to

ise children a

rom using the

essure during

rt up. Failure t

ilter housing

efore servicing

elief valve mu

r to return

pump, fully

r air and wate

t

)

US

ONLY HA

WARD GE

UINE REPL

CEMENT P

RTS

2

WARNING – Separation Hazard. Failure to follow safety and operation instructions could result in violent separation

of pump and/or filter components. Strainer cover must be properly secured to pump housing with strainer cover lock ring. Before

servicing pool and spa circulation system, filters manual air relief valve must be in open position. Do not operate pool and spa

circulation system if a system component is not assembled properly, damaged, or missing. Do not operate pool and spa

circulation system unless filter manual air relief valve body is in locked position in filter upper body.

WARNING – Risk of Electric Shock. All electrical wiring MUST be in conformance with applicable local codes,

regulations, and the National Electric Code (NEC). Hazardous voltage can shock, burn, and cause death or serious property

damage. To reduce the risk of electric shock, do NOT use an extension cord to connect unit to electric supply. Provide a properly

located electrical receptacle. Before working on any electrical equipment, turn off power supply to the equipment.

WARNING – To reduce the risk of electric shock replace damaged wiring immediately. Locate conduit to prevent abuse

from lawn mowers, hedge trimmers and other equipment.

WARNING – Electrical ground all electrical equipment before connecting to electrical power supply. Failure to ground all

electrical equipment can cause serious or fatal electrical shock hazard.

WARNING – Do NOT ground to a gas supply line.

WARNING – To avoid dangerous or fatal electrical shock, TURN OFF POWER to all electrical equipment before working on

electrical connections.

WARNING – Failure to bond all electrical equipment to pool structure will increase risk for electrocution and could result

in injury or death. To reduce the risk of electric shock, see installation instructions and consult a professional electrician on how

to bond all electrical equipment. Also, contact a licensed electrician for information on local electrical codes for bonding

requirements.

Notes to electrician: Use a solid copper conductor, size 8 or larger. Run a continuous wire from external bonding lug to

reinforcing rod or mesh. Connect a No. 8 AWG (8.4 mm

pressure wire connector provided on the electrical equipment and to all metal parts of swimming pool, spa, or hot tub, and metal

piping (except gas piping), and conduit within 5 ft. (1.5 m) of inside walls of swimming pool, spa, or hot tub.

IMPORTANT - Reference NEC codes for all wiring standards including, but not limited to, grounding, bonding and other general

wiring procedures.

2

) [No. 6 AWG (13.3 mm2) for Canada] solid copper bonding wire to the

WARNING – Risk of Electric Shock. Connect only to a branch circuit protected by a ground-fault circuit-interrupter (GFCI).

Contact a qualified electrician if you cannot verify that the circuit is protected by a GFCI.

WARNING – Risk of Electric Shock . The electrical equipment must be connected only to a supply circuit that is protected

by a ground-fault circuit-interrupter (GFCI). Such a GFCI should be provided by the installer and should be tested on a routine

basis. To test the GFCI, push the test button. The GFCI should interrupt power. Push reset button. Power should be restored. If

the GFCI fails to operate in this manner, the GFCI is defective. If the GFCI interrupts power to the electrical equipment without the

test button being pushed, a ground current is flowing, indicating the possibility of an electrical shock. Do not use this electrical

equipment. Disconnect the electrical equipment and have the problem corrected by a qualified service representative before

using.

CAUTION – This pump is intended for use with permanently-installed pools and may be used with hot tubs and spas if so

marked. Do not use with storable pools. A permanently-installed pool is constructed in or on the ground or in a building such

that it cannot be readily disassembled for storage. A storable pool is constructed so that it is capable of being readily

disassembled for storage and reassembled to its original integrity.

SAVE THESE INSTRUCTIONS

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS 3

Installation Instructions

Pump Location

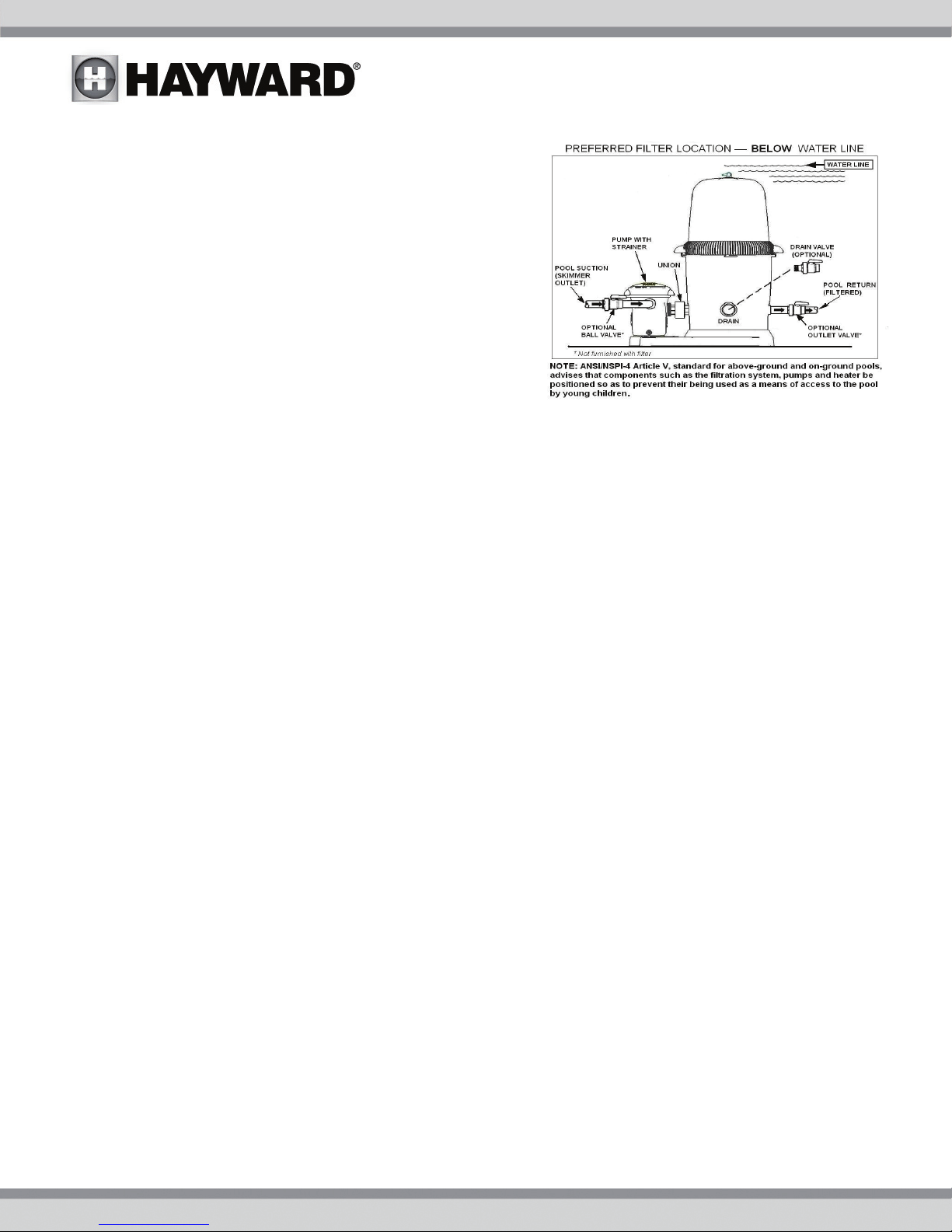

The PowerFlo LX™ and EP series pumps MUST be installed

below the pool water line (see Figure to right).

Self-priming PowerFlo II™ pumps may be installed up to four

(4) feet above the pool water line.

Install pump on a firm, level base or pad to meet all local and

national codes. The field supplied base or pad must be level

and vibration-free.

Pump motors require free circulation of air for cooling.

Do NOT install pump in a damp or non-ventilated location.

Though the pump is designed for outdoor use, it is strongly

advised to protect the electrical components from the

weather. Select a well-drained area, one that will not flood

when it rains.

Pump Mounting

Fasten pump to base or pad with screws or bolts to further reduce vibration and stress on pipe or hose joints. The

base MUST be solid - level - rigid - vibration free.

Pump mount must:

Allow pump inlet height to be as close to water level as possible.

Allow use of short, direct suction pipe (to reduce friction losses).

Allow for ball valves in suction and outlet piping.

Be protected from excess moisture and flooding.

Allow adequate access for servicing pump and piping.

Plumbing

Use TFE tape to seal threaded connections on molded plastic components. All plastic fittings must be new or

thoroughly cleaned before use. NOTE: Do NOT use Plumber’s Pipe Dope as it may cause cracking of the plastic

components.

When applying TFE tape to plastic threads, wrap the entire threaded portion of the male fitting with one to two layers

of tape. Wind the tape clockwise as you face the open end of the fitting, beginning at the end of the fitting.

The pump suction and outlet ports have molded-in thread stops. Do NOT attempt to force hose connector fitting

past this stop. It is only necessary to tighten fittings enough to prevent leakage. Tighten fitting by hand and then

use a tool to engage fitting an additional 1 ½ turns. Use care when using TFE tape as friction is reduced

considerably; do NOT over-tighten fitting or you may cause damage. If leaks occur, remove connector, clean off old

Teflon tape, re-wrap with one to two additional layers of TFE tape, and re-install connector.

Piping - Flexible Hose, PVC, or Reinforced Hose are all acceptable piping methods

For pump outlet use 1-1/2" PVC pipe or reinforced hose. For pump suction on ALL models, use 1-1/2" reinforced

hose. Increase size if a long run is needed. For pipe larger than port, use reducing fitting in strainer port.

To avoid pump strain, support suction and outlet independently. Place supports near pump. To avoid strain left by a

gap at last connection, start all piping at pump and run pipe AWAY from pump.

NEVER use suction pipe SMALLER than pump suction connections. Suction pipe inlet must be lower than pump

inlet port.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS 4

Loading...

Loading...