Page 1

IS-1580-TL-98

HAYWARD HIGH-PERFORMANCE PUMPS

INSTALLATION AND OPERATING INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

When installing and using this electrical equipment, basic safety precautions should always be followed,

including the following: Failure to follow instructions may result in injury.

READ AND FOLLOW ALL INSTRUCTIONS

WARNING - To reduce risk of injury, do not permit children to use this product unless they are closely supervised at all times.

CAUTION - This pump is U.L. listed for permanently installed pools and may also be used with hot tubs and spas if so marked.

It is not U.L. listed for storable pools. A permanently installed pool is constructed in or on the ground and cannot be readily

disassembled for storage. Astorable pool is constructed so that it may be readily disassembled for storage and reassembled to

its original integrity.

If installed within an outer enclosure or beneath the skirt of a hot tub or spa, adequate ventilation and free circulation of air must

be provided to prevent overheating of the motor.

Use motor bonding lug to connect the motor with other bonding parts using a #8 AWG conductor as required by electrical codes.

NOTE: If your pump is equipped with a 3 ft. (1 m) cord and twist lock plug, items 5 through 8 apply.

WARNING - Risk of Electric Shock. Connect only to a grounding-type receptacle protected by a ground fault circuit interrupter

(GFCI). Contact a qualified electrician if you cannot verify that the receptacle is protected by a GFCI.

Do not bury cord. Locate cord to minimize abuse from lawn mowers, hedge trimmers, and other equipment.

WARNING - To reduce the risk of electric shock, replace damaged cord immediately.

WARNING - To reduce the risk of electric shock, do not use extension cord to connect unit to electric supply; provide a properly

located outlet.

1.

2.

3.

4.

5.

6.

7.

8.

SAVE THESE INSTRUCTIONS

GENERAL TIPS ON PUMP INSTALLATION

For best pump performance, locate the system below the

pool water line and as close to the pool as practical.

If

you own an above-ground pool, please see Note: NSPI-4

Article V , for safe and proper installation of the equipment

package.

Make sure suction joints are tight. Suction pipe

should be as large or larger than discharge pipe.

Damp, non-ventilated locations should be avoided.

Motors require free circulation of air to aid in cooling.

Insure that the electrical supply available agrees with the

motor’s voltage, phase and cycle, and that wire size is

adequate for the HP (KW) rating and distance from power

source. Motor must always be properly grounded. If cord

connected, use only a properly grounded outlet. Electrical

circuits must be protected by proper size ground fault

circuit interrupter (GFCI) as required by applicable

electrical codes. All electrical wiring must be performed

by qualified personnel, and must conform to local codes

and regulations.

STARTING AND PRIMING INSTRUCTIONS

Fill strainer housing with water to suction pipe level.

Never operate the pump without water. Water acts as a

coolant and lubricant for the mechanical shaft seal.

Open all suction and discharge lines and valves, as well

as air bleed (if available) on filter. (The air that is to be

displaced from the suction line must have some place to

go.)

CAUTION: All suction and discharge valves must be

open when starting the system. Failure to do so could

result in severe personal injury and/or property

damage.

Turn on power and allow a reasonable time for priming.

Priming time depends on suction lift and horizontal length

of suction piping. If the pump will not start, or will not

prime, see TROUBLE SHOOTING GUIDE on back page.

NOTE: NSPI-4 Article V, standard for above-ground and

on-ground pools, advises that components such as the

filtration system, pumps and heater be positioned so as to

prevent their being used as a means of access to the pool

by young children.

Page 2

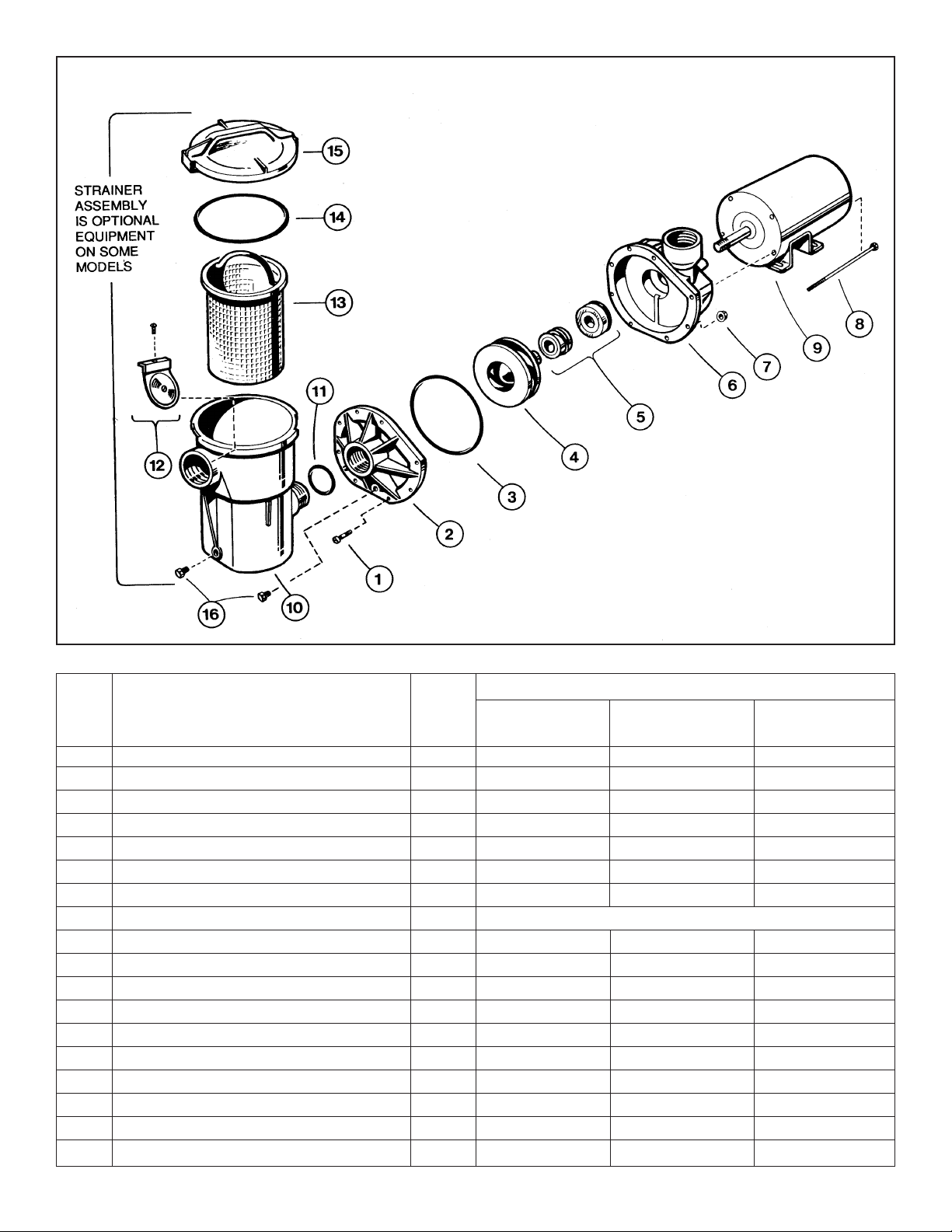

DWG.

NO.

NO.

REQ’D.DESCRIPTION

PART NUMBER

MODEL

SP-1575LXTL

MODEL

SP-1580TL

MODEL

SP-1580X15TL

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

---

---

8

1

1

1

1

1

8

4

1

1

1

1

1

1

1

2

1

1

Bolt, No. 10-24 Hex. Head

Housing Cover

Housing O-Ring

Impeller

Seal Assembly

Pump Housing

Nut, No. 10-24 Hex.

Motor-to-Housing Bolt

Motor

Strainer Housing

O-Ring

Check Valve Assembly (Optional)

Basket

Strainer Cover O-Ring

Strainer Cover, Clear Lexan

©

Drain Plug (Optional - special models)

Strainer Shim Ring (Horizontal Outlet Pumps Only)

Twist Lock Cord Set

SPX1500-N2

SPX1580-BP

SPX1580-Z-1

SPX1500-F

SPX1250-XZ-2

SPX1580-AAP

SPX1500-Y-2

SPX1500-N2

SPX1580-BP

SPX1580-Z-1

SPX1500-L

SPX1250-XZ-2

SPX1580-AAP

SPX1500-Y-2

SPX1500-N2

SPX1580-BP

SPX1580-Z-1

SPX1500-L

SPX1250-XZ-2

SPX1580-AAP

SPX1500-Y-2

SPX1510-Z-1E

SP-1500-CP

SPX1500-W

SPX1500-RA

SPX1500-LX

SPX1500-P

SPX1500-D-2

SPX1700-FG

SPX1500-X1

SPX1550-WA-1

SPX1510-Z-1XE

SP-1500-CP

SPX1500-W

SPX1500-RA

SPX1500-LX

SPX1500-P

SPX1500-D-2

SPX1700-FG

SPX1500-X1

SPX1550-WA-1

SPX1515-Z-1E

SP-1500-CP

SPX1500-W

SPX1500-RA

SPX1500-LX

SPX1500-P

SPX1500-D-2

SPX1700-FG

SPX1500-X1

SPX1550-WA-1

To order, specify motor manufacturer, HP and pump model no.

Page 3

SEAL CHANGE INSTRUCTIONS

Power Flo™ LX Series with Twist Lock Cord

GENERAL

Exercise extreme care in handling and installing the new seal and ceramic seat assembly.

The lapped and polished surfaces may easily be damaged by dirt or scratching.

For safety, all service must be performed with all power shut off.

Remove pump and motor assembly from piping

system.

Remove pump housing cover (with strainer

attached) by removing the eight (8) housing bolts

and nuts which fasten housing cover to pump

housing. The impeller is now exposed.

To remove impeller, insert screwdriver in slot at

end of motor.* Hold screwdriver so as to keep

shaft from turning, and rotate the impeller in a

counterclockwise direction. The spring portion of

the seal assembly is now exposed.

Note carefully the position of the spring seal and

pull it off the impeller.

To remove the stationary (ceramic seat) part of

the seal assembly:

a. Loosen the four (4) motor securing bolts and

disengage the motor from the pump housing.

b. With motor removed, press the clear plastic

and ceramic seat assembly out of the pump

housing recess. If tight, tap lightly from the

“motor” side.

Clean and lubricate the impeller hub shaft and

pump housing seal recess with a dilute solution

of non-granulated liquid-type soap. The use of

petroleum or silicone lubricants can contribute to

seal leakage.

Press the new spring portion of the assembly

onto the impeller, black polished surface facing

away from the impeller.

Carefully press ceramic seat, with O-ring, into

clear plastic seat retainer—polished surface

facing out. Be sure O-ring is in place on cut ridge

of clear plastic retainer. Press plastic retainer,

with ceramic seat inside, into recess of pump

housing—O-ring end first. Replace the assembly

firmly and evenly.

Carefully insert the motor shaft through the seat

assembly, and secure motor to pump housing

with four (4) motor securing bolts. (Be sure motor

base is positioned properly.)

Screw the impeller, with spring seal, onto the

motor shaft, hand tight, by turning clockwise.

Clean fiber gasket (replace if necessary) and

fasten housing cover to pump housing with

eight (8) bolts and nuts. Tighten bolts and nuts

alternately and evenly.

Reconnect pump to piping system. Be sure to fill

strainer with water before restarting.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

* For A.O. Smith Canopy Style Motors: Remove motor end cover and

carefully

apply wrench to flat on motor shaft to hold shaft from turning.

ELECTRICAL GUIDE — 60 CYCLE MOTORS — SINGLE PHASE

VOLTS

MOTOR CIRCUIT BREAKER

RATINGS - AMPS

BRANCH FUSETRON

RATINGS - AMPS

RECOMMENDED

WIRE SIZE

0-50’

KW

HP

#14

#12

#12

15

20

20

15

20

20

115

115

115

3/4

1

1-1/2

.55

.75

1.1

A separate electrical circuit, utilizing a rating as above, is recommended.

Page 4

TROUBLE SHOOTING GUIDE

MOTOR WON’T START

Check for improper or loose connections, open switches

or relays, blown circuit breakers or fuses.

Manually check rotation of motor shaft for free

movement and lack of obstruction.

MOTOR CUTS OUT — Check for:

Wiring, loose connections, etc.

Low voltage at motor (frequently caused by

undersized wiring).

Binding and overload. (Amperage reading)

NOTE: Your Hayward pump motor is equipped with

Automatic Thermal Overload Protection. The

motor will automatically shut off, under normal

conditions, before heat damage build-up, due to

an improper operating condition, can occur. The

motor will auto-restart when safer heat level is

reached.

MOTOR HUMS, BUT DOES NOT START—Check for:

Centrifugal switch stuck in open position.

Binding of motor shaft.

PUMP WON’T PRIME

Make sure pump/strainer housing is filled with water and

that cover O-ring is clean and properly seated. Make

sure strainer cover is locked firmly in position.

Make sure all suction and discharge valves are open

and unobstructed, and that pool water level is above all

suction openings.

Block off suction as close to pump as possible and

determine if pump will develop a vacuum.

A.

1.

2.

B.

1.

2.

3.

C.

1.

2.

D.

1.

2.

3.

If pump develops a vacuum, check for blocked suction

line or strainer, or air leak in suction piping.

If pump does not develop a vacuum and pump has

sufficient “priming water”:

Tighten all bolts and fittings.

Check voltage to make sure pump is up

to speed.

Open pump and check for clogging or

obstruction.

Remove and replace shaft seal.

LOW FLOW — Generally, check for:

Clogged or restricted strainer or suction line;

undersized pool piping.

Plugged or restricted discharge line of filter

(high discharge gauge reading).

Air leak in suction (bubbles issuing from return fittings).

Pump operating underspeed (low voltage).

Plugged or restricted impeller.

NOISY PUMP — Check for:

Air leak in suction causing rumbling in pump.

Cavitation due to restricted or undersized suction line

and unrestricted discharge lines. Correct suction

condition or throttle discharge lines, if practical.

Vibration due to improper mounting, etc.

Foreign matter in pump housing.

Motor bearings made unserviceable by wear, rust, or

continual overheating.

a.

b.

1.

2.

3.

4.

E.

1.

2.

3.

4.

5.

F.

1.

2.

3.

4.

5.

MAINTENANCE

Clean strainer basket regularly. Do not strike basket

to clean. Inspect strainer cover gasket regularly and

replace as necessary.

Hayward pumps have self-lubricating motor bearings

and shaft seals. No lubrication is necessary.

Keep motor clean. Insure air vents are free from

obstruction.

Occasionally, shaft seals must be replaced, due to

wear or damage. See instructions.

STORAGE/WINTERIZING

Pump and motor must be protected from freezing. Shut off

all electric power. Disconnect cord/electrical connections

and plumbing connections. Drain thoroughly and clean out

any debris. Store pump and motor in a dry, well-ventilated

room.

1.

2.

3.

4.

SERVICE & REPAIRS

Consult your local authorized Hayward dealer or service center. No pumps or motors may be returned directly to the factory

without the expressed written authorization of Hayward Pool Products, Inc.

© 1998 Hayward Printed in U.S.A.

Rev: 8/98

Loading...

Loading...