Hayward S-210T, S-220T, S-210TR, S-244T Quick Manual

®

Your Hayward Pro Series high rate sand lter is a high performance totally corrosion-proof lter that blends superior ow

characteristics and features with ease of operation. It represents the very latest in high rate sand lter technology. It is

virtually foolproof in design and operation and when

installed, operated and maintained according to instructions, your lter with produce clear, sparkling water with

only the least attention and care.

HOW IT WORKS

Your lter uses a special lter sand to remove dirt particles

from pool water. Filter sand is loaded into the lter tank and

functions as the permanent dirt removing media. The pool

water which contains suspended dirt particles is pumped

through your piping system and is automatically directed by

the patented lter control valve to the top of the lter tank.

As the pool water is pumped though the lter sand, dirt

particles are trapped by the sand bed, and ltered out. The

cleaned pool water is returned from the bottom of the lter

tank, through the control valve and back to the pool through

the piping system. This entire sequence is continuous and

automatic and provides for total recirculation of pool water

through your lter and piping system.

After a period of time the accumulated dirt in the lter

causes a resistance to ow, and the ow diminishes. This

means it is time to clean (backwash) your lter. With the

control valve in the Backwash position, the water ow is

automatically reversed though the lter so that it is directed

to the bottom of the tank, up through the sand, ushing the

previously trapped dirt and debris out of the waste line.

Once the lter is backwashed (cleaned) of dirt, the control

valve is manually re-sequenced to Rinse, and then Filter, to

resume normal ltering.

INSTALLATION

If you own an above ground pool please see note: NSP1-4

Article V, for safe proper installation of the equipment

package.

Only simple tools (screwdriver and wrenches), plus pipe

sealant for plastic adapters, are required to install and/or

service the lter.

The lter should be placed on a level concrete slab, very

rm ground, or equivalent, as recommended by your

pool dealer. Position the lter so that the piping connections, control valve and winter drain are convenient and

accessible for operation, servicing and winterizing.

Assemble pump and pump mounting base, (if supplied)

to the lter according to instructions packed with the

base.

1.

2.

STRAIGHT ADAPTER

RETURN TO POOL

FROM

POOL

PUMP

ELBOW ADAPTER

VARI-FLO

CONTROL VALVE

SIGHT GLASS

FILTER

CLAMP

PUMP

MOUNTING

SCREW/WASHER

TYPICAL INSTALLATION

24 - 1/2” (63 cm)

WASTE LINE

38” (96 cm) S-210T

38” (96 cm) S-210TR

41” (104 cm) S-220T

42” (106 cm) S-244T

IS 210T HC 13

www.haywardpool.ca

SPECIFICATIONS

MODEL NO.

a S-210T

b S-210TR

c S-220T

d S-244T

EFFECTIVE

FILTRATION AREA

FT2

2.20

2.20

2.64

3.14

M2

0.20

0.20

0.25

0.29

DESIGN FLOW RATE

GPM

44

44

53

63

MAXIMUM WORKING

LPM

166

166

200

238

PSI

50

50

50

50

Note: NSPI-4 Article V, standard for above ground

and on ground pools, advises that components

such as the ltration system, pumps and heater be

positioned so as to prevent their being used as a

means of access to the pool by young children.

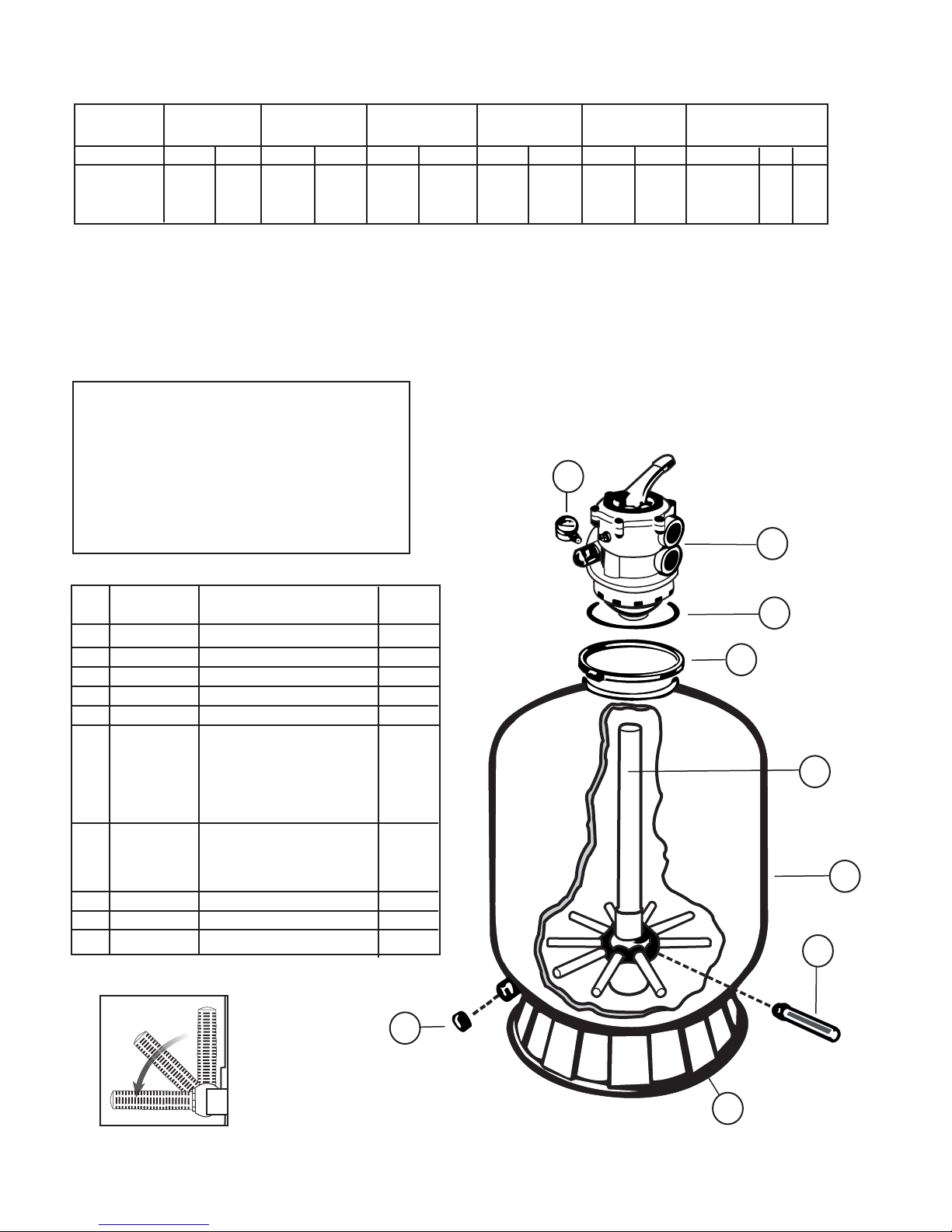

PARTS

Model S-210T, S-210TR, S-220T, S-244T

PRESSURE

BAR

3.45

3.45

3.45

3.45

SIDE CLEARANCE

INCH

18

18

18

18

CM

45

45

45

45

ABOVE CLEARANCE

INCH

18

18

18

18

2

CM

45

45

45

45

MEDIA REQUIRED

TYPE

.45 mm - .55 mm

No 20 or No 1/2

Silica Filter Sand

LBS

225

225

250

300

1

KG

100

100

114

136

REF.

NO.

1

1

2

3

4

5a

5b

5c

5d

5e

6a

6b

6c

6d

7

8

9

PART NO.

SP-0714-TC

SP071620T

EC-2708-61

GM-600-F

GM-600-NM

S-210-DA

S-210-DA

S-220-DA

S-244-DA

S-270-DA2X

S-210-AA-1

S-210-AAB

S-220-AA-1

S-244-AA-1

S-240-D

S-180-LM

S-200-J

DESCRIPTION

1½” Vari-o Control Valve Ass’y

2” Vari-Flo Control Valve

Pressure Gauge

Valve / Tank O-Ring

Flange Clamp (Valve Tank)

Lateral Assembly with Center

Pipe - 1½”

}

Lateral Assembly with Center

Pipe - 2”

Filter Tank with Skirt,

Complete Lateral Assembly

Lateral

Drain Cap & Gasket

Filter Support Stand (Skirt)

NO.

REQ’D.

1

opt.

1

1

1

1

1

10

1

1

8

3

4

a

b

5

c

d

e

a

b

6

c

d

7

Figure A

9

www.haywardpool.ca

Loading...

Loading...