Page 1

Your Hayward S166T high-rate sand filter is a high

performance, totally corrosion-proof filter that blends

superior flow characteristics and features with ease of

operation. It represents the very latest in high-rate sand

filter technology. It is virtually foolproof in design and

operation and when installed, operated and maintained

according to instructions, your filter will produce clear,

sparkling water with only the least attention and care.

HOW IT WORKS

Your filter uses special filter sand to remove dirt particles

from pool water. The sand is loaded into the filter tank

and functions as the permanent dirt removing media.

The pool water, which contains suspended dirt particles,

is pumped through your piping system and is

automatically directed by the patented filter control

valve to the top of the filter tank. As the pool water is

pumped through the filter sand, dirt particles are

trapped by the sand bed, and filtered out. The cleaned

pool water is returned from the bottom of the filter tank,

through the control valve and back to the pool through

the piping system. This entire sequence is continuous

and automatic and provides for total recirculation of pool

water through your filter and piping system.

After a period of time, the accumulated dirt in the filter

causes a resistance to flow, and the flow diminishes. This

means it is time to clean (backwash) your filter. With the

control valve in the backwash position, the water flow is

automatically reversed through the filter so that it is

directed to the bottom of the tank, up through the sand,

flushing the previously trapped dirt and debris out the

waste line. Once the filter is backwashed (cleaned) of

dirt, the control valve is manually resequenced to Rinse,

and then Filter, to resume normal filtering.

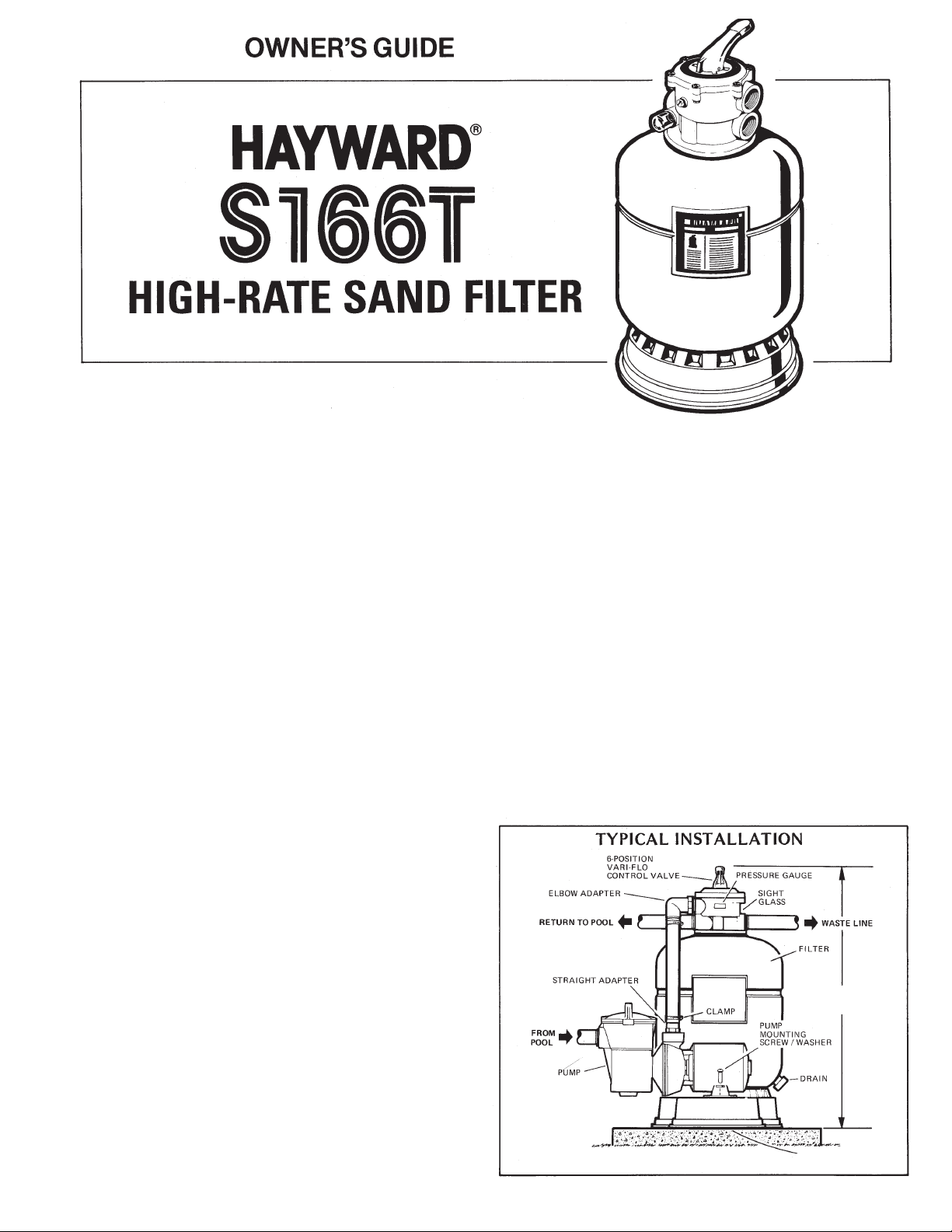

INSTALLATION

Only simple tools (screwdriver and wrenches), plus pipe

sealant for plastic adapters, are required to install and/or

service filter.

The filter should be placed on a level concrete slab,

very firm ground, or equivalent as recommended by

your pool dealer. Position the filter so that the piping

connections, control valve and winter drain are

convenient and accessible for operation, servicing

and winterizing.

Your filter is supplied complete with an optional

pump mounting base which is pre-drilled for use with

Hayward Power-Flo LX series pumps. The pump to

filter connecting hoses supplied will accommodate

Power-Flo LX pumps used with the mounting base,

and Max-Flo or Super Pump installed at surface

level. To connect pump to filter:

Screw straight adapter, using Teflon pipe sealant

tape or Permatex No. 2, securely into pump

discharge. (Do not overtighten.)

Screw elbow adapter, using Teflon pipe sealant

tape or Permatex No. 2, securely into opening in

control valve marked PUMP. (Do not overtighten.)

Elbow should point just over RETURN opening.

1.

2.

a.

b.

IS166TN2-00

PUMP MOUNTING

BASE (S164C)

33”

(84 cm)

Page 2

SPECIFICATIONS

MODEL

NUMBER

EFFECTIVE

FILTRATION AREA

DESIGN

FLOW RATE

MAXIMUM WORKING

PRESSURE

REQUIRED CLEARANCE MEDIA REQUIRED

FT

2

1.4

S166T

M

2

0.13

GPM

35

LPM

133

PSI

50

BAR

3.45

INCH

18

INCH

18

MM

457

MM

457

FILTER SAND*

0.45-0.55

LBS

100

KGS

45

ABOVE

SIDE TYPE AMOUNT

*Also known as No. 20 or No. 1/2 Silica Sand.

NOTE: ANSI/NSPI-4 Article V, standard for above-ground

and on-ground pools, advises that components such

as the filtration system, pumps and heater be

positioned so as to prevent their being used as a

means of access to the pool by young children.

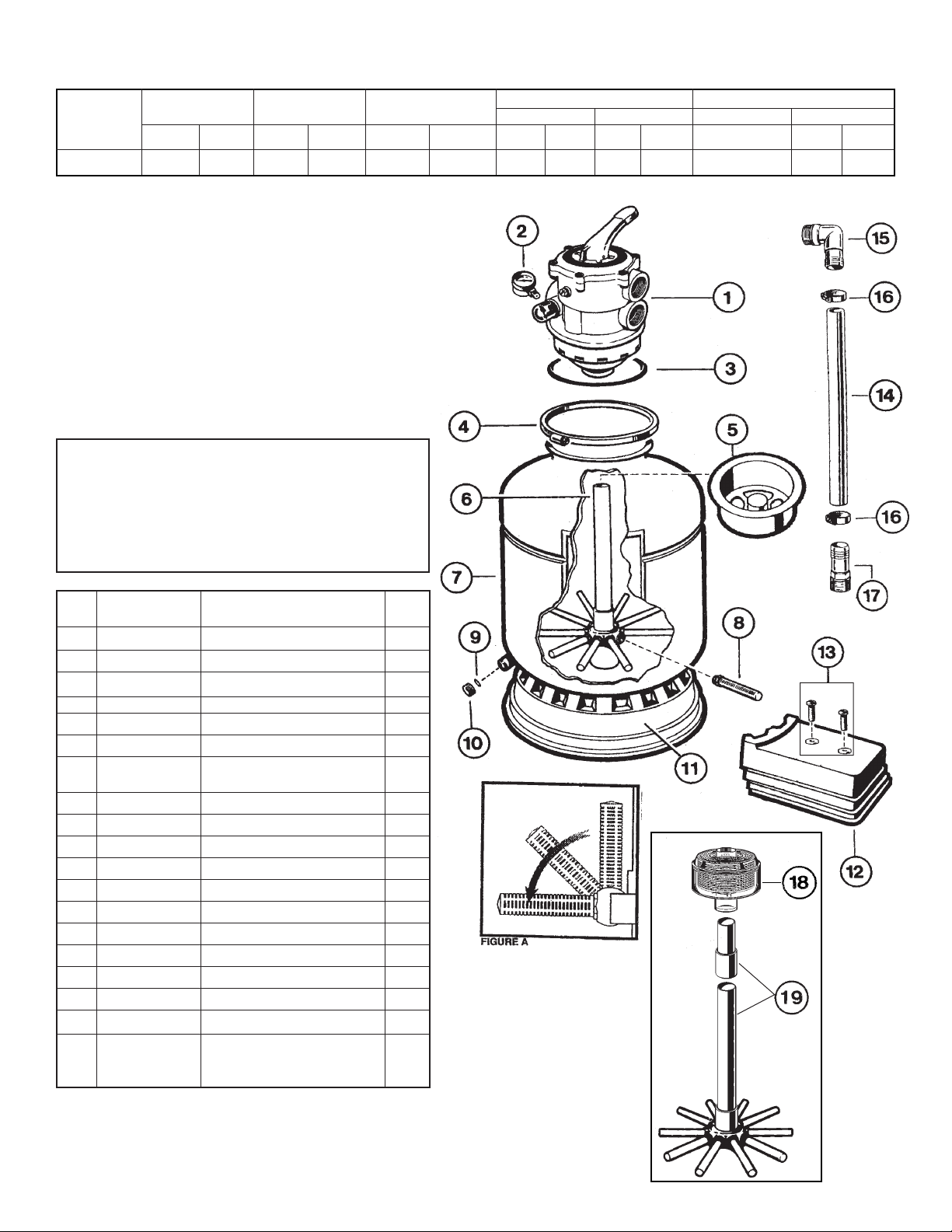

PARTS

Model S166T

S166T1575XS

S166T1575XSN2

REF.

NO.

1

2

3

4

5

6

8

9

10

11

12

13

14*

15*

16*

17*

18**

19**

NO.

REQ’D.

1

1

1

1

1

1

1

10

1

1

1

1

2

1

1

2

1

1

1

PART NO.

SP071113

ECX27081

GMX600F

GMX600NS

SX202S

SX164DA

SX200Q

SX180G

SX180H

SX164B

SX164C

ECX1108A

SX160Z5

SPX1105Z4

ECX18028

SPX1091Z2

N2SABG

SX164DAN2KIT

DESCRIPTION

Vari-Flo Control Valve Assembly

Pressure Gauge

Valve/Tank O-Ring

Flange Clamp (Valve-Tank)

Sand Shield

Lateral Assembly with Center Pipe

Filter Tank with Skirt,

Complete Lateral Assembly

Lateral

Gasket

Drain Cap

Filter Support Stand (Skirt)

Pump Base

5/16” x 3/4” Mounting Screw Kit

1-1/2” Hose

1-1/2” Elbow Adapter

Hose Clamp

1-1/2” Straight Hose Adapter

Nature2Canister

Folding Umbrella Lateral Assembly

w/Center Pipe for Nature

2

Canister

*Furnished with PAK or System only.

**Included only on filters supplied with SwimPure Canister

SX164AA17

SwimPure Option

Page 3

STOP here and load media per instructions (No. 3).

Place hose clamps on clear hose and fit hose over

straight and elbow adapters and secure with clamps. If

it is difficult to fit hose over the adapters, place hose in

hot water for several minutes.

NOTE: To prevent breakage and damage to pump and

control valve, use only pipe sealants specifically formulated

for plastics. Do not overtighten fittings or adapters.

Loading sand media. Filter sand media is loaded through

the top opening of the filter.

Loosen flange clamp and remove Filter Control Valve

(if previously installed).

Cap internal pipe with sand shield to prevent sand

from entering it. Be sure pipe is securely in place in

bottom underdrain hub.

We recommend filling tank approximately 1/2 way with

water to provide a cushioning effect when the filter

sand is poured in. This helps protect the underdrain

laterals from excessive shock. (Be sure the winter

drain cap is securely in place on drain pipe.) Note:

Check to confirm all laterals are in the down

position before loading with sand. (See Figure Aon

Page 2.)

Carefully pour in correct amount and grade of filter

sand, as specified. (Be sure center pipe remains

centered in opening). Sand surface should be leveled

and should come to about the middle of the filter tank.

Remove sand shield from center pipe.

NOTE: If your sand filter is equipped with the SwimPure

system or you are installing the SwimPure Retrofit Kit, then

please follow the steps in the Instruction Sheet included in

the SwimPure carton.

Assemble Filter Control Valve to filter tank.

Wipe filter flange clean.

To install clamp, loosely preassemble both halves of the

clamp with one screw and one nut, turning the nut two

or three times. Place clamp assembly on the filter neck.

Insert filter control valve (with valve/flange O-ring in

place) into the tank neck, taking care that the center

pipe slips into the hole in the bottom of the valve.

Install clamp around tank and valve flange and

assemble second screw and nut. Tighten both sides of

clamp alternately and evenly. Make sure you tighten

just enough so that the valve may be rotated on the

tank for final positioning.

Carefully screw the pressure gauge, with pipe tape,

into 1/4” tapped hole in valve body. Do not overtighten.

Connect pump to control valve opening marked

“PUMP” according to the instructions.

Tighten both sides of clamp alternately and evenly. Use

a correctly sized large screw driver and tighten firmly

to obtain a good seal.

Please be sure to place vinyl protector caps over ends of

screws.

Make return to pool pipe connection to control valve

opening marked RETURN and complete other necessary

plumbing connections, suction lines to pump, waste, etc.

Make electrical connections to pump per pump

instructions. Be sure all circuits are protected by a

properly-sized ground fault circuit interrupter (GFCI).

To prevent water leakage, be sure winter drain cap is

securely in place and all pipe connections are tight.

NOTE: If you have installed a SwimPure system, then

please refer to Step 2 in the SwimPure Instruction Sheet

(“Balance the Pool Water”).

INITIAL START-UP OF FILTER

Be sure correct amount of filter sand media is in tank and

that all connections have been made and are secure.

Depress Vari-Flo control valve handle and rotate to

BACKWASH position. (To prevent damage to control

valve seal, always depress handle before turning.)

Prime and start pump according to pump instructions

allowing the filter tank to fill with water. CAUTION: All

suction and discharge valves must be open when

starting the pump. Failure to do so could cause

severe personal injury and/or property damage.

Once water flow is steady out the waste line, run the

pump for at least 1 minute. The initial backwashing of

the filter is recommended to remove any impurities or fine

sand particles in the sand media.

Turn pump off, set valve to RINSE position. Start pump

and operate until water in sight glass is clear—about 1/2

to 1 minute. Turn pump off, set valve to FILTER position

and restart pump. Your filter is now operating in the

normal filter mode, filtering particles from the pool water.

Adjust pool suction and return valves to achieve desired

flow. Check system and filter for water leaks and tighten

connections, bolts, nuts, as required.

Note the initial pressure gauge reading when the filter is

clean. (It will vary from pool to pool depending upon the

pump and general piping system). As the filter removes

dirt and impurities from the pool water, the accumulation

in the filter will cause the pressure to rise and flow to

diminish. When the pressure gauge reading is 6-8 lbs.

(2.7-3.6 kgs.) higher than the initial “clean” pressure you

noted, it is time to backwash (clean) the filter (see

BACKWASH under Filter Control Valve Functions).

NOTE: During initial clean-up of the pool water, it

may be necessary to backwash frequently due to the

unusually heavy initial dirt load in the water.

CAUTION: To prevent unnecessary strain on piping

system and valving, always shut off pump before

switching Filter Control Valve positions.

To prevent damage to the pump and filter and for proper

operation of the system, clean pump strainer and skimmer

baskets regularly.

FILTER CONTROL VALVE FUNCTIONS

FILTER–Set valve to FILTER for normal filtering. Also use

for regular vacuuming.

BACKWASH–For cleaning filter. When filter pressure

gauge rises 6-8 lbs. (2.7-3.6 kgs.) above start-up (clean

pressure):

Stop the pump, set valve to BACKWASH. Start pump and

backwash, approximately 2 minutes or less, depending on

dirt accumulation, until water in sight glass is clear . Proceed

to RINSE.

3.

a.

b.

c.

d.

4.

a.

b.

c.

d.

e.

f.

g.

h.

5.

6.

1.

7.

2.

3.

c.

4.

5.

6.

Page 4

RINSE—After backwashing, with pump off, set valve to

RINSE. Start pump and operate for about 1/2 to 1 minute. This

ensures that all dirty water from backwashing is rinsed out of

the filter to waste, preventing possible return to the pool. Stop

pump, set valve to FILTER and start pump for normal filtering.

WATER—To bypass filter for draining or lowering water level

and for vacuuming heavy debris directly to waste.

RECIRCULATE—Water is recirculated through the pool

system, bypassing the filter.

CLOSED—Shuts off flow from pump to filter.

VACUUMING—Vacuuming can be performed directly into the

filter. When vacuuming heavy debris loads, set valve to WASTE

position to bypass the filter and vacuum directly out to waste.

WINTERIZING

Completely drain tank by unscrewing drain cap at base of

filter tank. Leave cap off during winter.

Depress Vari-Flo control valve handle and rotate so as to set

pointer on valve top between any two positions. This will

allow water to drain from the valve. Leave valve in this

“inactive” position.

Drain and winterize pump according to pump instructions.

SERVICE & REPAIRS

Consult your local authorized Hayward dealer or service center.

No returns may be made directly to the factory without the

expressed written authorization of Hayward Pool Products, Inc.

PROBLEM SOLVING LIST

LOW WATER FLOW SHORT FILTER CYCLES POOL WATER WON’T CLEAR UP

Check skimmer and pump

strainer baskets for debris.

Check for restrictions in

intake and discharge lines.

Check for air leak in intake

line (indicated by bubbles

returning to pool).

Backwash filter.

Check for algae in pool and

superchlorinate as required.

Be sure chlorine and pH

levels are in proper range

(adjust as required).

Check surface of filter sand

for crusting or caking

(remove 1” of sand if

necessary).

Check chlorine, pH and total

alkalinity levels and adjust

as required.

Be sure flow rate through

filter is sufficient.

Operate filter for longer periods.

Be sure Vari-Flo valve is set

on “Filter” position.

1.

2.

3.

4.

1.

2.

3.

1.

2.

3.

4.

REMEDY

POOL CHEMISTRY GUIDELINES

ACTION REQUIRED TO CORRECT POOL CHEMISTRY

TO RAISE TO LOWER

SUGGESTED POOL CHEMISTRY LEVELS

pH

TOTAL ALKALINITY

CHLORINE (UNSTABILIZED)

CHLORINE (STABILIZED)

CHLORINE STABILIZER

(Cyanuric Acid)

7.2 to 7.6

100 to 130 ppm

0.3 to 1.0 ppm

1.0 to 3.0 ppm

40 to 70 ppm

Add Soda Ash

Add Sodium Bicarbonate

Add Chlorine Chemical

Add Chlorine Chemical

Add Stabilizer

Add Muriatic Acid or Sodium Bisulphate

Add Muriatic Acid

No action - chlorine will naturally dissipate

No action - chlorine will naturally dissipate

Dilution - partially drain & refill pool with water

that has not been treated with Cyanuric Acid.

© 2000 Hayward Printed in U.S.A.

Rev. 11/00

PLEASE REALIZE . . .

Pure, clear swimming pool water is a combination of two

factors–adequate filtration and proper water chemistry balance.

One without the other will not give the clean water you desire.

Your filter system is designed for continuous operation.

However, this is not necessary for most swimming pools. You

can determine your filter operation schedule based on your pool

size and usage. Be sure to operate your filtration system long

enough each day to obtain at least one complete turnover of your

pool water.

To properly sanitize your pool, maintain a free chlorine level of

1 to 3 ppm and a pH range of 7.2 to 7.6. Insufficient chlorine or

an out of balance pH level will permit algae and bacteria to grow

in your pool and make it difficult for your filter to properly clean

the pool water.

1.

2.

3.

Loading...

Loading...