Page 1

Commercial Cleaner

Troubleshooting Guide

© 2012 Hayward Industries Inc.

Page 2

TABLE OF CONTENTS

Safety Precautions Page 1

Service Tools Page 2

Special Notes Pages 3-4

Removal of Hood Pages 5-6

Filter Removal Pages 7-8

Power Cord Removal Page 9

Swivel Removal Page 10

Accessing the Impeller Page 11

Drive Belt Removal Page 12

Intake Removal Page 13

Drive Wheel Pages 14-17

Motor Removal Page 18

Pump Housing / Gear Box Disassembly Page 19

Solenoid Disassembly Page 20

Bumper / Cable Assembly Removal Page 21

Cable Assembly Components Page 22

Control Panel Components Pages 23-25

Control Panel Troubleshooting Pages 26-28

Control Panel Timer / Relay PCB Testing Pages 29-31

Swivel Voltage Testing Page 32

Motor / Power Cord Voltage Testing Pages 33-35

KingShark 2 / KingShark 2 Plus Tips Page 36

Serial number locator Page 37-38

KingShark 2 and KingShark 2 Plus

Mako Shark 2 and KingShark Troubleshooting

begins on Page 39

Page 3

Disconnecting and removing the unit from the pool immediately after each use will

enhance the cleaner’s life. 150 minutes of operation in a 30’ x 60’ pool should be sufficient

with no more than a few twists in the cord which should be straightened out after each use.

Safety

Page 1

Page 4

Service Tools

Page 2

3/8“, 5/16“, 7/16“, 1/2"

Wrench

Snap Ring Pliers

Needle Nose Pliers

Flat Tip and Phillips

Screwdriver

Small Flat Tip

Screwdriver

3/8“ Ratchet

3/8“ Socket

Extension

1/4“ Socket

Driver

3/8“, 7/16“, 1/2“

Socket

5/32“, 1/4“ Allen Wrench

Page 5

Special Notes

When disassembling the KingShark 2 and the KingShark 2 Plus,

the ONLY DIFFERENCES between the two cleaners are as follows:

KingShark 2 KingShark 2 Plus

1. Standard 3 prong electrical cord

2. RCX400388 3/4 h.p. w/o swivel.

3. RCX4011 3/4 h.p. w/ swivel.

Page 3

The remote has a maximum communication line to the antenna of 150’.

1. Different pigtail connections.

2. KingShark 2 Plus has a remote.

3. KingShark 2 Plus has a cannon

plug for the control panel.

4. KingShark 2 Plus has solenoids

which control left and right

movement from the remote.

5. RCX4020 3/4 h.p.

Page 6

230 VAC Supply to Master Control Panel

ONLY move the E9 connection

E9

When supplying 230 VAC instead of 115 VAC to the Master control panel, the following

jumper cable switch must be moved.

1. Move the jumper wire connection E9 to E7 230 VAC connection on the RELAY

BOARD just above the transformer.

2. Hard wire the power cord to a dedicated 10-15 amp breaker. The master

control panel draws roughly 3 amps.

Page 4

Jumper configured for 240 VAC

Page 7

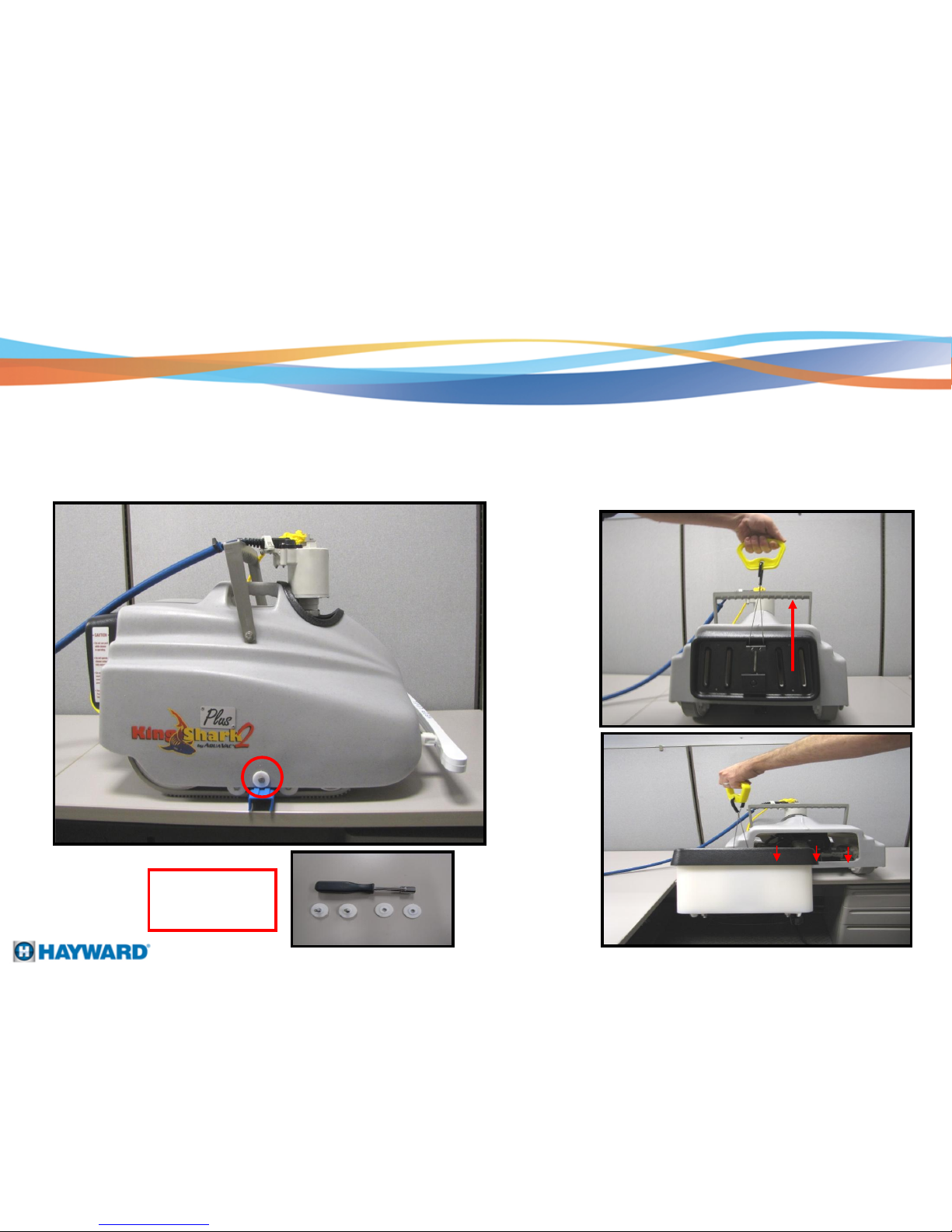

Removal of Hood

Step 1: Step 2:

Remove the two 1/4" – 20 X 3/4" SS bolts from both

sides of the cleaner using a 7/16” socket.

Pull the cartridge handle quick release

UP and then pull the cartridge assembly

back and away from the cleaner.

Note: 1 bolt and 2

plastic washers

per side

Page 5

Page 8

Step 3:

Unscrew the filter retainer knob using a

5/32” Allen Wrench.

Step 4:

Slide the hood cover over the swivel assembly.

Removal of Hood

Page 6

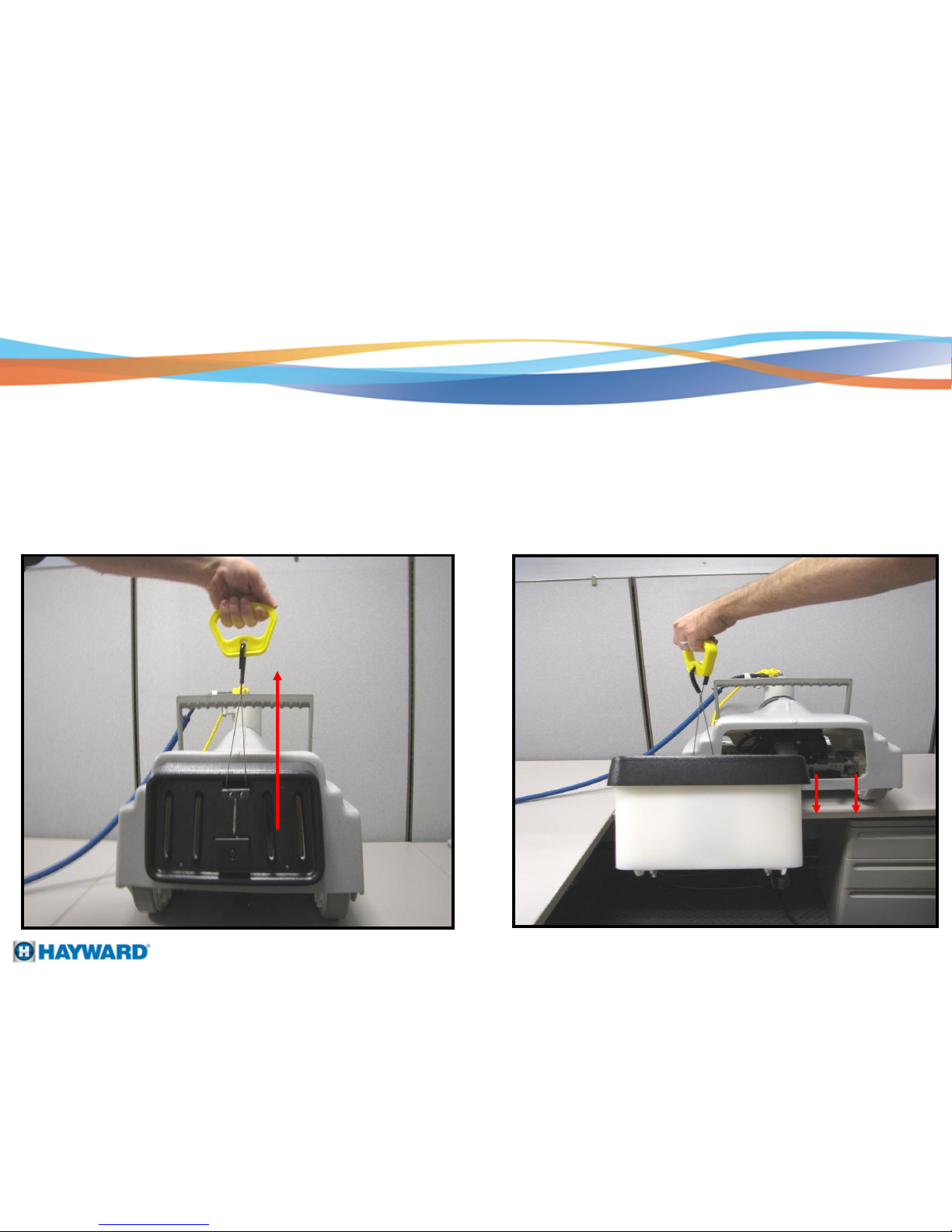

Page 9

Filter Removal

Step 5:

Pull up on the yellow quick release handle assembly.

Step 6:

Page 7

Pull and slide the filter assembly backwards and

away from the cleaner.

Page 10

Filter Removal

Step 7:

Remove the push style clips

Back Plate

Note : Never remove or adjust the 4 nuts

To clean the filters, spray with

clean water.

Page 8

Lift the housing assembly off the tie rods

/ back plate.

Lift the cartridges up and off the

back plate.

Page 11

Power Cord Removal

1. Using a flat tip screwdriver and 3/8” wrench, remove the swivel cord clamp.

2. Using a Phillips screwdriver, remove the four screws connecting the power end to the swivel.

3. When reconnecting the power end to the swivel or motor, make sure to use RTV # 162 silicone

rubber sealant and replace the o-ring.

Step 8:

1. 2. 3.

Page 9

o-ring

Page 12

Swivel Removal

Using a 7/16” socket, remove the two 1/4" –

20 X 1-1/4" hex head bolts from the swivel

mounting bracket.

Remove the four screws connecting the power

cord to the motor end.

Note: Make sure to use RTV # 162 Silicone Rubber

Sealant when reconnecting the power cord and replace

the o-ring.

Step 9:

Page 10

Page 13

Accessing the Impeller

1. Use a 7/16" socket to remove the two plastic bolts and impeller access plate from the pump housing.

Step 10:

1.

2. After removing the impeller access plate, this will allow you to inspect the impeller and check for

debris or damage inside the impeller area.

2.

Page 11

Page 14

Drive Belt Removal

1. Remove right side drive belt.

Note : When putting the drive belts back on, put the LEFT side on first, then the RIGHT side. This

will prevent possible torque damage where the gear box assembly meets the front housing bell,

since the larger support bracket is on the left side of the gearbox assembly.

2. Remove left side drive belt.

Step 11:

Page 12

Page 15

Intake Removal

Step 12:

1.

NOTE : When removing and reinstalling the Intake, be aware of the 2

plastic washers that seat between the Intake and the base plate.

2.

Page 13

1. Unscrew the 4 screws holding the intake to the base plate, also remove the SS wire baffle.

2. Remove the intake stabilizer from the intake. The stabilizer prevents large debris from entering the cleaner.

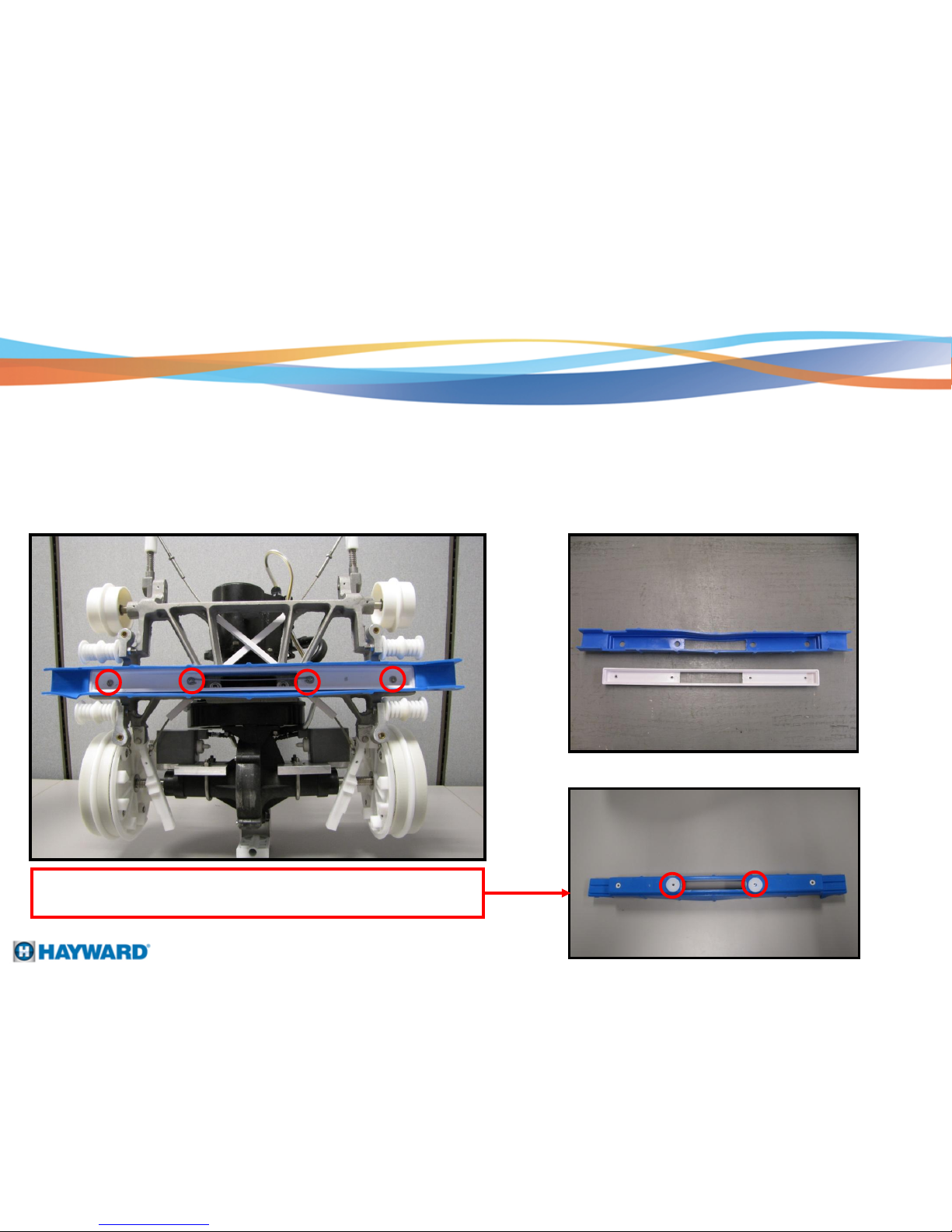

Page 16

Drive Wheel Disassembly

Step 13:

1. Using the snap ring pliers, remove the snap ring from the front wheels and the rear drive wheels.

2. After removing the snap rings from the wheels, pull the front wheels from the base plate and

remove the drive wheels from the gear box assembly.

Note : There is one SS washer on each

side of the gear arm.

1. Front Wheels 2. Drive Wheels

Page 14

Note: There is one 1/8" SS Key on each rear drive wheel It is

important the key is installed into the wheel prior to inserting the shaft.

Page 17

Drive Wheel Disassembly

1. Use the snap ring pliers to remove the 4 E-Clips from the L & R drive wheels. Remove the 4

plastic washers / spacers.

2. Remove the 2 indicator screws from the drive wheels – Each set of screws indicate LEFT

drive wheel specific or RIGHT drive wheel specific. Below the 2 indicator screws, the letter

L or R will be molded into the wheel.

1.

2.

Step 14:

Page 15

Page 18

Drive Wheel Disassembly

2. Remove the Gear Ring

3. Remove the Sun Gear

1. Remove the 4 Button Washers

Step 15:

4. Remove the 4 Planetary Gears 5. Remove the Wheel Lock

Page 16

Page 19

Drive Wheel Reassembly

1. When reinstalling the drive wheels, make sure the Wheel Locks are installed in the correct direction and

position. The photo’s below indicate the correct position and direction.

LEFT DRIVE WHEEL RIGHT DRIVE WHEEL

2. The outside wheel plate screws must match the L or R indicator markings on the outside wheel plates.

2.

L

Page 17

1.

R

Page 20

Motor Separation

Step 16:

1. Use a 1/4" allen wrench to remove the 2 bolts and washers. Once these are removed, lift the motor from

the base plate.

2. Use a 1/2" socket to remove the 5 bolts and washers that hold the motor to the pump housing.

1. 2.

3. Use a flat tip screw driver to remove the 4 impeller screws.

4. Unscrew the 2 screws and 1 - 7/16” bolt to separate the motor from the housing bell.

3.

Page 18

4.

Left View Right View

Page 21

Pump Housing / Gear Box Disassembly

Gear Box Assembly

Pump Housing

1. Use a 7/16" socket to remove the 3 bolts from the pump housing. Pull the pump housing from the

gear box assembly.

2. After removing the 3 - 7/16" bolts, note the length and location of each bolt for reinstallation.

1. 2.

Step 17:

Page 19

Page 22

Solenoid Disassembly

1. Use a 7/16" wrench to remove the 4 retention nuts from the U bolts.

2. Once the 4 retention nuts are removed, the solenoids can be set aside. To separate the solenoids

from the motor, pull and separate at the quick connection at the solenoid.

Note: Solenoids are marked left (L) and right (R) . The power cord that has the black lines

indicates the right solenoid connection. (see insert picture, photo #2)

Step 18:

Page 20

1. 2.

Page 23

Bumper / Cable Assembly Removal

1. Remove the two 3/8” nuts (top), four flathead screws (center), and two pins (bottom).

2. Slide the bumper from the arm sensor bar.

1.

Step 19:

Page 21

Note: Both the reversing arms and cable assembly can be

turned over and be reused

2.

Page 24

Note the proper location of the washers

and spacer when reinstalling the L & R

reversing arms.

L side top view R side top view

underneath view

Back to front view - TOP

(TOP)

(BOTTOM)

2 plastic spacers

1 plastic spacer

Cable Assembly

1. Tension cables / cable assembly are adjustable.

Once the cable assembly is reinstalled, push in

should touch the inside of the drive wheels.

Cable assembly’s do not come pre-tensioned from the manufacturer

Instructions for Reinstalling the Cable Assembly

Page 22

Release the sensor bar, it should “spring“ back to it’s

on the sensor bar. The L & R reversing arms

normal position, if it doesn’t, tighten or loosen accordingly

(blue).

3.

2.

Page 25

Master Control Panel

Relay Board

Transformer

Receiver Board

24 VDC relays

24 VDC relays

Power out to cleaner

Relay Board / Receiver Board

Antenna

Page 23

Incoming power supply

AC to DC rectifier

Page 26

Master Control Panel

Fuse

Power Indicator Light Auto Turn On / Off

Switch

Power On / Off

Switch

Note: Ribbon cable

disconnects at the Timer

Board

Timer Board

Page 24

(Back Side of Front Panel)

Display ribbon cable

Page 27

Master Control Panel

Power cord MUST be plugged

outlet equipped with a

( GFCI )

1.

1.

into a grounded electrical

Ground Fault Circuit Interrupter

If you supply power to the master control panel and you

have no display, this is NORMAL.

Unless you have the Cannon Plug power cord from the

swivel connected to the 2 center ports, the display will be

blank. This will prevent any shocking hazards that may

occur with the power connection at the master control panel.

Step 20:

Page 25

Page 28

Master Control Panel

Step 21:

Page 26

Correct power to Master Control Panel but NO display

1. 2.

Put meter lead on the on/off switch and one lead to ground, 115 VAC should be present.

1.

2.

NOTE: Check voltage on LEFT

connection of switch

Make sure power is ON. Put one meter lead on L1 connection and one lead on L2, 115 VAC should

be present.

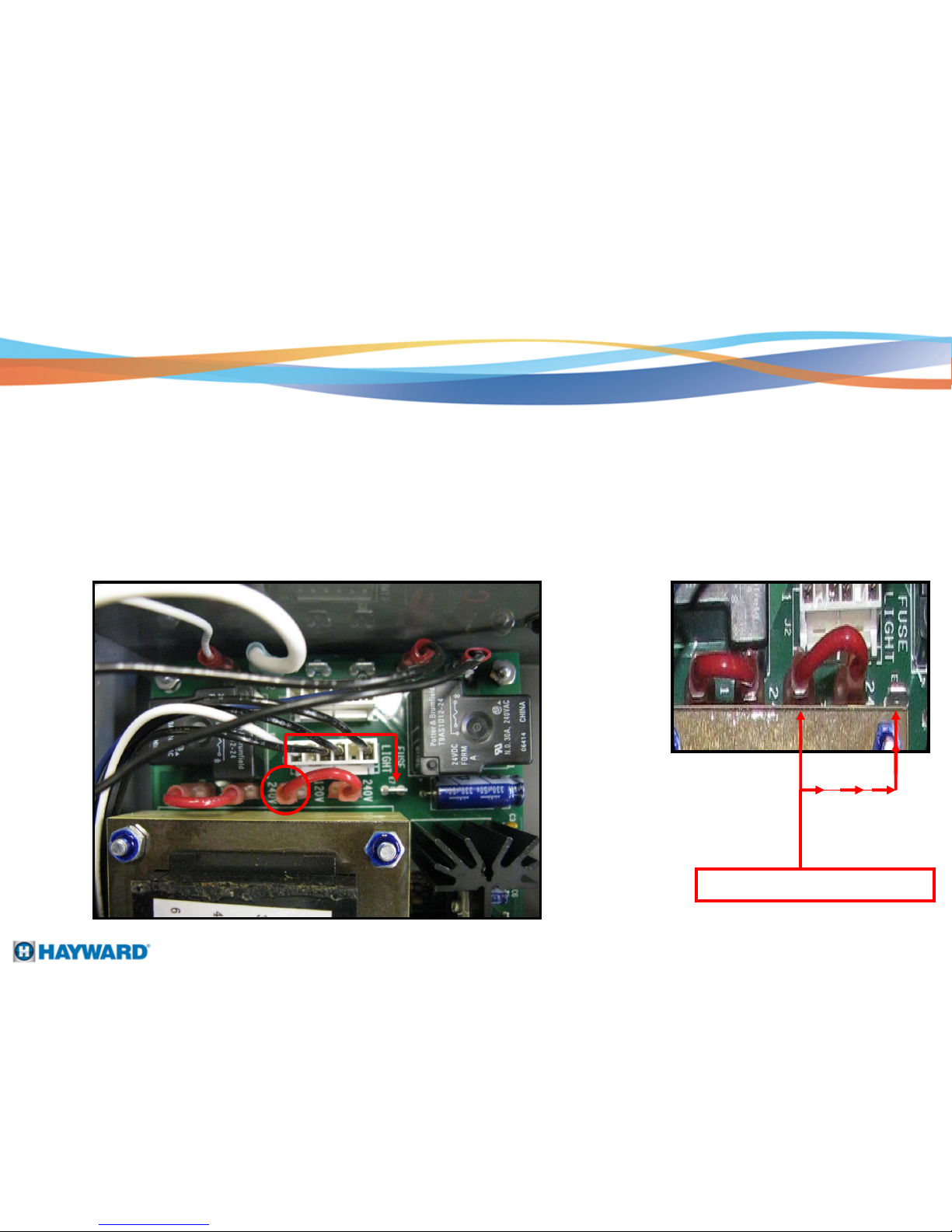

Page 29

Master Control Panel

Correct power to Master Control Panel and NO display

Check for a blown fuse. Twist the fuse left and pull out for access.

Page 27

Slo-Blo 1 amp / 250VP

Do a continuity check on the fuse to verify if fuse is good or bad

Page 30

BRN YEL BL

R R

BLACK

GR

WH

24 VDC

115 VAC

Master Control Panel Cannon Plug

Step 22:

Page 28

To verify 115 VAC is being supplied through the female cannon plug receiver, install

a jumper wire into the 2 center ports. Power the unit on and press the“Start“ button

until “RUN“ is on the display. Then, stick one meter lead into the black port and the

other lead into the white or green port. 115 VAC + or - should be present.

Page 31

Master Control Panel

Timer PCB Testing

On RELAY PCB at REMOTE J4

Step 23:

If the unit still does not run, proceed to Step 25 on Page 32.

Page 29

- Using RED lead of DC voltmeter at green wire on J4 and BLACK lead of DC voltmeter at

COM (E12). Voltmeter should read 24 VDC. Now, push RIGHT TURN button on the remote,

voltmeter should read 0 VDC

- Do the same test procedure on the RED wire – push LEFT TURN button on the remote,

voltmeter should read 0 VDC

Page 32

Master Control Panel

RELAY PCB Testing

On RELAY PCB at J3 (B A G H F)

Yellow wire is the common wire to both solenoids

Blue wire is the LEFT Turn solenoid

Brown wire is the RIGHT Turn solenoid

- Using DC Voltmeter, check voltage between the yellow wire and the blue wire. 24 VDC should be

present while pushing the LEFT TURN button on the remote

- Using DC Voltmeter, check voltage between the yellow wire and the brown wire. 24 VDC should be present

while pushing the RIGHT TURN button on the remote.

- Using DC Voltmeter, check voltage between either the brown or blue wire to yellow. 24 VDC should be

present while pushing the REVERSE TURN button on the remote.

or

Step 24:

Page 30

Note: Voltage can vary

between 22-28 VDC

Page 33

Master Control Panel

1.

2.

Step 25:

Page 31

1. After testing the RELAY PCB Board (Step 24), if the tests do not match the correct voltages, then

the RELAY PCB Board will need to be replaced.

2. If the problem still exists after replacing the RELAY PCB Board, remove the cannon plug from the

master control panel. Insert the jumper wire into the 2 center ports of the connector plug at the

master control panel. Repeat steps 24 & 25. If steps 24 & 25 pass the testing, the motor and cord

need to be test separately to determine which one needs to be replaced.

Page 34

Voltage Check to Swivel

To verify voltage is passing through the power supply cord to the swivel :

1. Power the system off

2. Disconnect the power end connection at the swivel

3.Power the system ON and make sure the RUN light is illuminated.

4. Put meter leads on the black and white ports. 115 VAC should be present. If not, verify

breaker is good, ON switch is ON, and all power is correct.

POWER END CONNECTION

WH

BLACK

power cord

Step 26:

Page 32

.

Page 35

Voltage Check to Motor

Step 27:

Old motor New motor

Power end connection

WH

BLACK

To verify voltage is getting through the swivel to the MOTOR :

1. Power the system off

2. Disconnect the power end connection at the motor

3. Power the system on and make sure the RUN light is on the display

4. Put meter leads on the white and black ports, you should get 115 VAC

Page 33

cord

Page 36

Ohm Check at Motor

Step 28:

Ohm meter

-0.9 ohms-1.3 ohms

for 115 VAC

-4.3 ohms-6.3 ohms

for 240 VAC

Page 34

Page 37

Cord Inspection

SWIVEL CONNECTOR END

cord

direction

WH BR BLACK

BLUE

GR

YELLOW

Step 29:

Page 35

1. Make sure the cannon plug is connected. Power the unit on. Press the start button

until Run is displayed.

1.

2. Put one meter lead into the white port, and one meter lead into the black port at the swivel

connector end where it connects to the swivel. 115 VAC should be present.

2.

Undo the power connection at the swivel. Remember to replace the o-ring and to use RTV #162

silicone rubber sealant when reconnecting the swivel connector end.

Page 38

Page 36

Sensor Bar adjustments and other minor repairs (Make all adjustments in ¼" increments)

A. Raise Sensor Bar if machine:

1. Fails to climb out of deep end.

2. Turns or hesitates on pool drain.

3. Turns away from curved wall too soon.

B. Lower Sensor Bar if:

1. Tips over before tripping or sensing wall.

2. Turns or hesitates on pool drain.

C. Sensor Bar adjustments required if machine turns in circles or twists cord:

1. Sensor bar not level or too high, possibly hitting the hood.

2. Thread on reversing arm is worn or stripped, not allowing reversing mechanism to disengage.

3. Sensor Bar Cable screws are loose.

4. Sensor Bar Cable is broken.

5. Drive Wheel is broken.

Check Sensor Bar regularly and keep the sensor bar level at all times !

Loss of vacuuming action

1. Filter may be clogged, slowing the flow of water through the unit. Clean the filters.

2. Suction area may be obstructed by large debris. Unplug power cord and remove obstruction.

No apparent power

1. Electrical outlet may be dead. Check electrical GFCI outlet. Check Fuses and breakers. Verify power switch is on.

2. Object lodged in the impeller.

3. Unit runs for a short distance and stops. Check for over load of the electrical circuit or faulty motor. DO NOT USE EXTENSION CORDS

4. Motor runs but machine becomes or is motionless. Gear box could be worn or drive pin could be sheared.

Machine tips over

1. Filters are dirty.

2. Sensor Bar set too high.

3. Tipping in certain situation can be prevented by purchasing a float and installing per instructions.

Disconnecting and removing the unit from the pool immediately after each use will enhance the life of the cleaner. 4 hours operation in a

50’ x 100’ pool should be sufficient with not more than a few twists in the cord which should be straightened out after each use.

KingShark 2 / KingShark 2 Plus Tips

Page 39

Serial Number Locations – March 2010 & prior

Page 37

(bottom side of Gear Box Assembly)

Serial numbers for the Commercial Units can be found in the three locations indicated below

First two numbers of a serial number:

10 = MAKOSHARK

30 = MAKOSHARK2

50 = KINGSHARK

70 = KINGSHARK2

90 = KINGSHARK2 PLUS

LETTER:

A=January

B=February

C=March

D=April

E=May

F=June

G=July

H=August

J=September

K=October

L=November

M=December

* Fourth Position indicates year of manufacture

For example, 9 = 2009

Page 40

Currently we are using the 17 digit serial number sequence

used on Hayward products. This will be located on the

gear box assembly and on the motor.

Example:

Model # Serial #

RC9860DCC 21121102005246000

2112 - location made

11 - year made

02 - month made

Page 38

Serial Number Locations after March 2010

Page 41

Mako 2 & King Shark Troubleshooting

TABLE OF CONTENTS

Filter Removal Page 40

Handle Removal Page 41

Filter Housing Removal Page 42

Hood Removal Page 43

Cord Assembly Removal Page 44

Drive Belt Removal Page 45

Gearbox Assembly Removal Page 46

Impeller and Motor Removal Pages 47-48

Pump Housing and Base Disassembly Pages 49-52

Troubleshooting Pages 53-54

Page 39

Page 42

Filter Removal

Remove both clips from the rear

of the unit.

.

Note: Elements can be cleaned by gently spraying

with a garden hose. Be careful not to use high

pressure as this may cause damage to the elements.

Step 3: Remove filter elements.

Step 1: Step 2: Remove the back cover from the

filter housing.

Page 40

Page 43

Handle Removal

Step 1: Use a flat head screwdriver on both ends of the handle pin to unscrew and remove.

Page 41

Page 44

Slide Ring Adapter off the housing and remove the two screws to remove the ring

adapter from cord.

Lift the filter housing from the cleaner.

Filter Housing Removal

Step 1:

Step 2:

Page 42

Page 45

Hood Removal

Remove the bolt from the handle

riser using 7/16” socket.

Remove the handle riser.

Remove the hat riser. Lift the body off.

Step 1: Step 2:

Step 3: Step 4:

Page 43

Page 46

Cord Assembly Removal

Remove the bolt from the pump

housing using a 7/16" socket.

Remove the 4 screws

from the motor.

Pull the plug away from the motor.

Note: When replacing the cord assembly

clean surface thoroughly and use

new o-ring and RTV #162 White

Silicone for a water tight seal.

Step 1:

Step 2:

Step 3:

Page 44

Page 47

Drive Belt Removal

Looking at the cleaner from the rear, remove the RIGHT drive belt from

the rear wheel, and then the front wheel.

Step 2: Remove the LEFT belt.

Note: Look at the

cleaner from the rear

and note that the gear

box has a Support on

the left side of the unit.

Left Right

Note: When installing the drive

belts install the left belt first and

then the right belt. This will remove

stress from the right side of

the gearbox which does not have

the additional support.

Step 1:

Page 45

1. 2.

3.

4.

Page 48

Step 1: Remove the five bolts from the rear of the gear box assembly using a 7/16" socket.

Gear Box Assembly Removal

1

2

3

4

5

Step 2: Pull the gear box away from the pump housing.

Gear Box

Page 46

Page 49

Impeller and Motor Removal

Pull the impeller from the

impeller drive collar.

Pull the impeller drive collar

from the motor shaft.

Step 1:

Step 2:

Page 47

Page 50

Impeller and Motor Removal

Step 3: Remove the 3 motor screws.

Step 4: Slide the motor away from the pump housing.

1. 2. 3.

Page 48

Page 51

Pump Housing and Base Disassembly

Step 1: Remove the 2 blue intake blades by pulling them from the slide.

Step 2: Remove the two bolts from the bottom of the unit using a 1/2" socket.

Step 3: Remove the pump housing from the base.

Page 49

Page 52

Pump Housing and Base Disassembly

Step 4: Remove the snap ring from the front wheel.

Step 5: Slide the wheel off of the axle.

Step 6: Repeat the 2 previous steps on the opposite side of the base.

Note: Sensor Bar and Reversing Arms are both reversible. As they become worn, they can

be turned over to use the other side. This will extend the life of the part.

Page 50

Page 53

Pump Housing and Base Disassembly

Remove the 2 flat head screws from the sensor bar. This will allow removal of

the sensor bar from the base.

Pull the 2 cotter pins at the opposite end of the cables.

Step 7:

Step 8:

Page 51

Page 54

Step 9: Remove the two bolts from the reversing arms using a 5/16” socket.

Note: There are washers

located on either side of the

reversing arm to allow

smooth movement.

Pump Housing and Base Disassembly

Washer locations

Page 52

Note: The steps to disassemble & reassemble the drive wheels are identical to those of

the KingShark II and KingShark II Plus. Detailed steps can be found on pages 14 – 17.

Page 55

Troubleshooting

Sensor Bar adjustments and other minor repairs (make all adjustments in ¼” increments).

A. Raise Sensor Bar if machine:

1. Fails to climb out of the deep end.

2. Turns or hesitates on pool drain.

3. Turns away from curved wall too soon.

B. Lower Sensor Bar if:

1. Tips over before tripping or sensing wall.

2. Turns or hesitates on pool drain.

C. Sensor Bar adjustments required if machine turns in circles or twists cord.

1. Sensor Bar not level or too high possible hitting hood.

OR

2. Thread on reversing arm #RC1703 is worn or stripped not allowing

reversing mechanism to disengage.

3. Sensor Bar cable screws are loose.

4. Sensor Bar cable is broken.

5. Drive wheel is broken.

D. Remember this basic rule:

Check Sensor Bar regularly and keep the Sensor Bar level at ALL times.

Page 53

Page 56

Troubleshooting

Loss of vacuuming action:

A. Filter may be clogged, slowing the flow of water through the unit. Clean the filters.

B. Suction area may be obstructed by large object.

No apparent power:

A. If the machine does not move:

1. Verify power at the electrical outlet.

2. Object lodged in impeller.

3. A short in the motor, check the ground fault interrupter.

4. Unit runs for a short distance and stops. Check for overload of the

electrical circuit or faulty motor. (DO NOT use extension cords.)

5. Motor runs but machine becomes or is motionless. Gear box could be

worn or drive pin could be sheared.

Machine tips over:

A. Filter loaded with sand or debris.

B. Sensor Bar is set too high.

Page 54

Loading...

Loading...