Page 1

HAYWARD MICROPROCESSOR CONTROL/TIMER

OWNER’S MANUAL & INSTRUCTION SHEET

This high performance timer is adaptable to all 115 volt Flex-48 style aboveground pool pump motors.

Please follow all instructions closely.

(

m

WARNING: Electric Hazard. Failure to follow

instructions can result in serious injury or death.

Disconnect power supply before servicing.

All electrical connections must be performed by qualified

personnel in compliance with applicable electrical codes.

A ground fault circuit interrupter (GFCI) must be installed as

required by electrical codes.

Keep fingers and foreign objects away from openings and moving

parts.

Motor must be suitably grounded. Connect ground wire to green

Use motor bonding lug to connect the motor with other bonded

parts using a #8 AWG conductor (#6 AWG in CANADA) as required

by electrical codes.

Replace all covers before operation.

Power source must agree with nameplate.

•

•

•

•

•

•

•

•

WARNING—To reduce risk of injury, do not permit children to use this

product unless they are closely supervised at all times.

CAUTION—This pump is for use with permanently installed pools and

may also be used with hot tubs and spas if so marked. Do not use with

storable pools. A permanently installed pool is constructed in or on

the ground or in building such that it cannot be readily disassembled

for storage. A storable pool is constructed so that it is capable of

being readily disassembled for storage and reassembled to its original

integrity.

If installed within an outer enclosure or beneath the skirt of a hot tub

or spa, adequate ventilation and free circulation of air must be

provided to prevent overheating of the motor.

Use motor bonding lug to connect the motor with other bonding parts

using a #8 AWG conductor as required by electrical codes. NOTE:

The national Electrical Code (NEC) permits use of a cord with a

maximum 3 ft. (1m) length. If your pump is equipped with a cord

complying with the NEC, items 5 through 8 apply.

WARNING—To reduce risk of electric shock, replace damaged cord

immediately.

WARNING—To reduce risk of electric shock, do not use extension

cord to connect unit to electric supply; provide a properly located

outlet. Qualified personnel must do all electrical wiring. All electrical

wiring must be in conformance with applicable local codes and

regulations.

CAUTION—The NSPI–4 Standard (Above-Ground and On-Ground

Pools) advises that components such as the filtration system, pumps

and heater be positioned so as to prevent their beingused as a means

of access to the pool by young children.

CAUTION—All suction and discharge valves must be open when

starting the system. Failure to do so could result in severe personal

injury and/or property damage.

IMPORTANT SAFETY INSTRUCTIONS

When installing and using this electrical equipment, basic safety precautions should always be followed,

including the following: Failure to follow instructions may result in injury

READ AND FOLLOW ALL INSTRUCTIONS

CAUTION: We highly recommend having a qualified professional install the product. All suction and discharge valves must be

open when starting the system. Failure to do so could result in severe personal injury.

SAVE THESE INSTRUCTIONS

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

WARNING—Risk of Electric Shock. Connect

only to a grounding type receptacle protected

by a Ground Fault Circuit Interrupter (GFCI).

Contact a qualified electrician if you cannot

verify that the receptacle is protected by GFCI.

Do not bury cord. Locate cord to minimize

abuse from lawn mowers, hedge trimmers, and

other equipment.

DANGER—SUCTION ENTRAPMENT HAZARD.

Can cause serious injury or death. Do not use

this pump for pools or spas containing suction

drains unless pump is connected to at least two

(2) functioning suction outlets at least three (3)

feet apart. Installation of pump and suction

outlets must be in compliance with all

applicable local building codes.

grounding screw and for cord connected units use properly

grounded GFCI protected outlet.

WARNING

IS1500ST-04

Rev . A

Page 2

TO SET TIMER:

1. Move switch from “OFF” to “PROGRAM” to “OFF” to achieve each setting.

1. Note: while switch is in “program position” a tone will be heard.

2. Move switch from “OFF” to “RUN”.

3. Repeat step 1 to achieve desired setting.

SINGLE SPEED MOTOR SETTINGS:

Setting 1—Pump runs 24 hours continuously–(tone heard once)

Setting 2—Pump runs 18 hours and is off for 6 hours–(tone heard twice)

Setting 3—Pump runs 12 hours and is off for 12 hours–(tone heard three times)

Setting 4—Pump runs 6 hours and is off for 18–(tone heard four times)

NOTE: When the timer is switched from “OFF” to “PROGRAM” an audible tone

sound is heard. This allows the pump to differentiate between settings.

DUAL SPEED MOTOR SETTINGS:

Setting 1—Pump runs 24 hours on Hi Speed–(tone heard once)

Setting 2—Pump runs 18 hours on Hi Speed and 6 hours on Low Speed–(tone heard twice)

Setting 3—Pump runs 12 hours on Hi Speed and 12 hours on Low Speed –(tone heard three times)

Setting 4—Pump runs 6 hours on Hi Speed and 18 hours on Low Speed–(tone heard four times)

TO OVERRIDE TIMER SETTING:

Move switch from “RUN” to “OFF” back to “RUN” within 3 seconds. The pump will run for 1 hour and then return

to the programmed mode you’ve selected.

If a power failure occurs: Once power is restored, the timer will automatically default to the

programmed mode, adding the length of time of the power failure.

FOR REPLACEMENT TIMER ORDER PART NUMBER—SP1500FT

INSTALLATION INSTRUCTIONS FOR EXISTING PUMPS:

HAYWARD MICROPROCESSOR CONTROL/TIMER

1. Only qualified personnel should field wire motor. All wiring must be done in accordance with applicable electrical codes.

Make certain that electrical power to pump has been disconnected before attempting to install pump timer SP1500FT.

2. Remove existing plastic motor canopy from motor by loosening canopy retaining screw in center of canopy. If motor is

equipped with a rocker or toggle switch remove the switch jumper wires from the motor terminal board. For single speed

motors: If one of the rocker or toggle switch jumper lead terminals is not accessible, disconnect the accessible terminal

and connect it to the motor terminal board position (5) formerly used by the other (discarded) jumper wire.

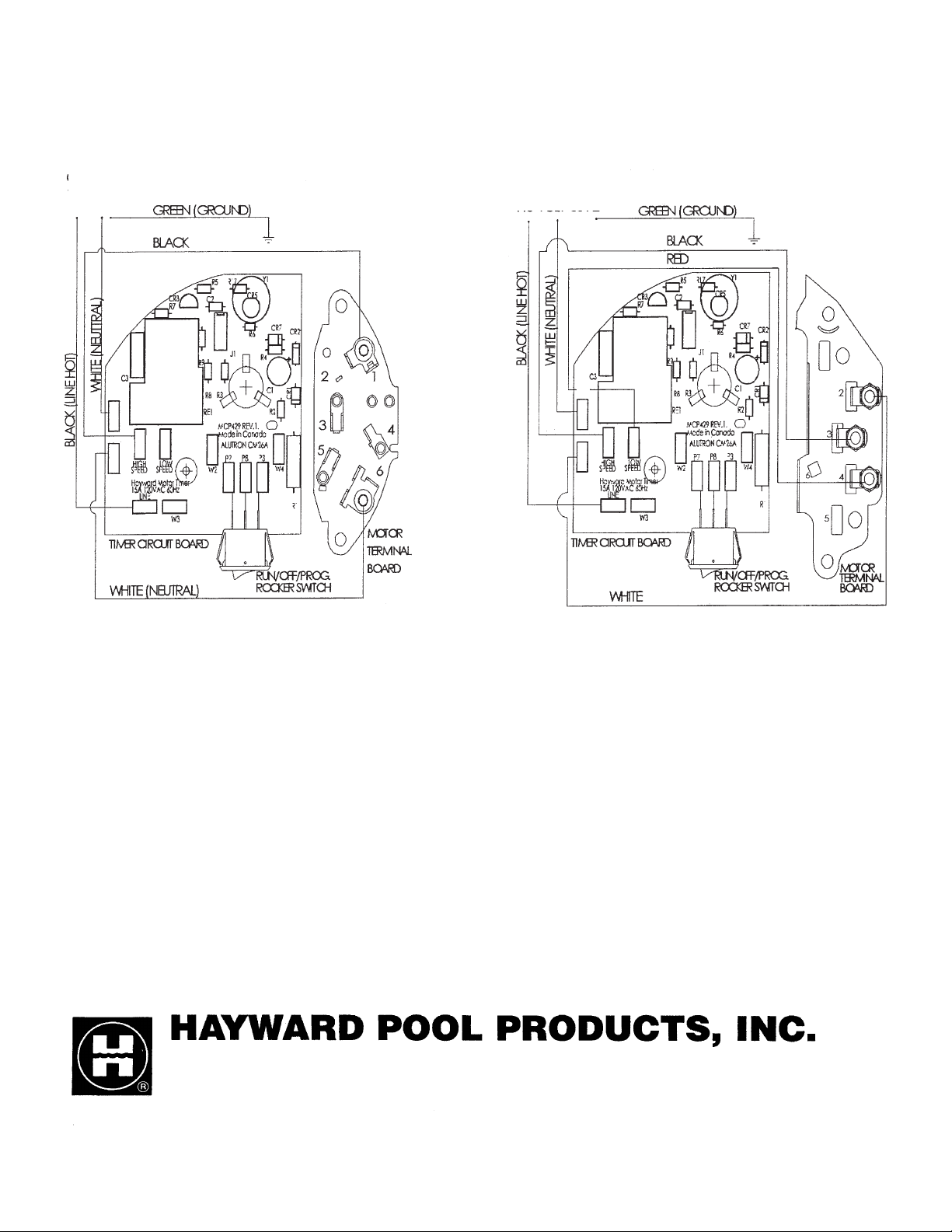

3. Use the red, (not provided with all SP1500FT units) black and white jumper wires provided to make the required

connections between the timer printed circuit board located in the new motor canopy and the motor terminal board. If your

pump is a single speed model you will not need the red jumper wire. The connection points for the jumper wires are

shown on the schematic wiring diagrams below. Make certain you refer to the correct diagram for your pump as both the

single speed and two speed diagrams are shown.

4. The black and white supply voltage wires (either cordset or conduit) must be connected to printed circuit board

terminals (P1) and (P2) respectively. In order to accomplish these field connections the black and white supply voltage

leads must have .250 inch push-on electrical terminals.

5. Make certain that the field supply green grounding lead is secured to the green #10 grounding screw positioned in the

motor end frame. Install the new timer canopy by locating and tightening the canopy retaining screw. Exercise care not to

pinch the jumper or cordset leads while installing the timer canopy onto the motor.

6. Reconnect electrical power to pump and follow operating instructions to program timer.

OPERATIONAL INSTRUCTIONS:

Your integrated timer module has been designed with four (4) possible timer settings plus a manual override

control.

***Run duration is set at the time of programming.

Page 3

SINGLE-SPEED MOTOR TWO-SPEED MOTOR

Visit our website at www.haywardnet.com

CORDSET OR CONDUIT

115 VOLT 60HZ

CORDSET OR CONDUIT

115 VOLT 60HZ

Hayward Pool Products Europe

Parc Industriel de la Plaine de L’Ain

Allee Des Chenes

01150 Saint Vulbas

France

Hayward Pool Products, Inc.

620 Division Street

Elizabeth, NJ 07207

Hayward Pool Products, Inc.

2875 Pomona Boulevard

Pomona, CA. 91768

Hayward Pool Products Canada

2880 Plymouth Drive

Oakville, Ontario L6H 5R4

© 2004 Hayward Printed in U.S.A.

P2

P6

P4

P5

P1

P1

P2

P4

P5

P6

Loading...

Loading...