Hayward In Ground Pool, Spa Gas Heaters User Manual

51300004201B

IN GROUND POOL/SPA GAS HEATERS

INSTALLATION & OPERATIONS MANUAL

FOR YOUR SAFETY:

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, injury, or death.

• Do not store or use gasoline or other

flammable vapors or liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions. If you cannot reach your gas

supplier, call the fire department.

• Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

This product must be installed and serviced by

authorized personnel, qualified in pool/spa heater

installation. Improper installation and/or operation

can create carbon monoxide gas and flue gases

that can cause serious injury, property damage,

or death.

CONTENTS Pg

GETTING STARTED 2

INSTALLATION 10

LOCATING THE HEATER 11

ALTITUDE OF INSTALLATION 13

AIR SUPPLY 14

FLUE GAS VENTING 15

GAS SUPPLY 19

WATER PIPING 21

ELECTRICAL CONNECTIONS 24

CHECK-OUT & START-UP 25

CONTROL SETUP 26

GAS TESTING 28

WATER TESTING 31

MAINTENANCE & SERVICE 31

WATER CHEMISTRY 31

WINTERIZATION 32

COMPONENT SERVICE 32

TROUBLESHOOTING 39

PARTS 49

USE ONLY GENUINE REPLACEMENT PARTS 1

SAVE THESE

INSTRUCTIONS

51300004201B

INSTALLATION

Verify that product installation was performed

to local codes and according to this manual.

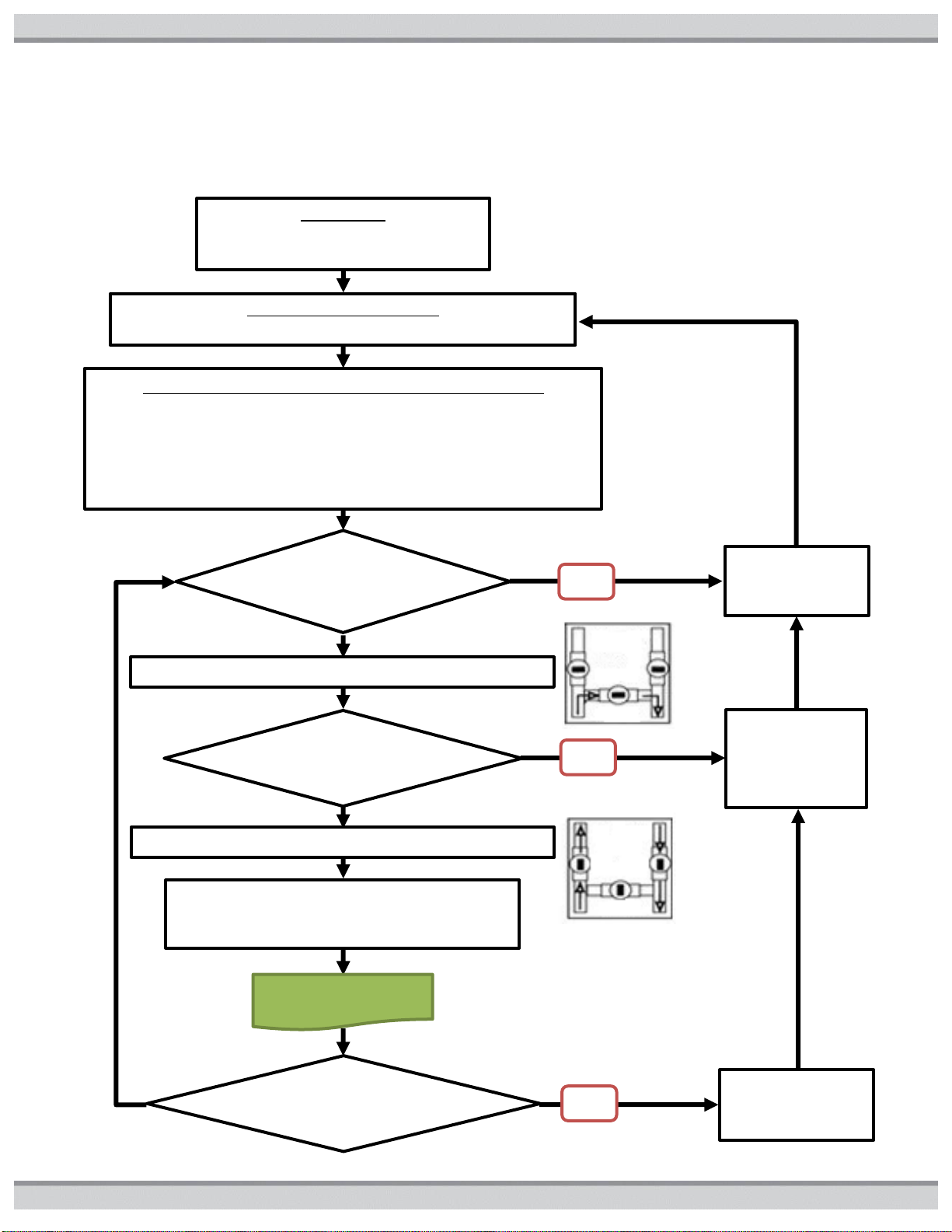

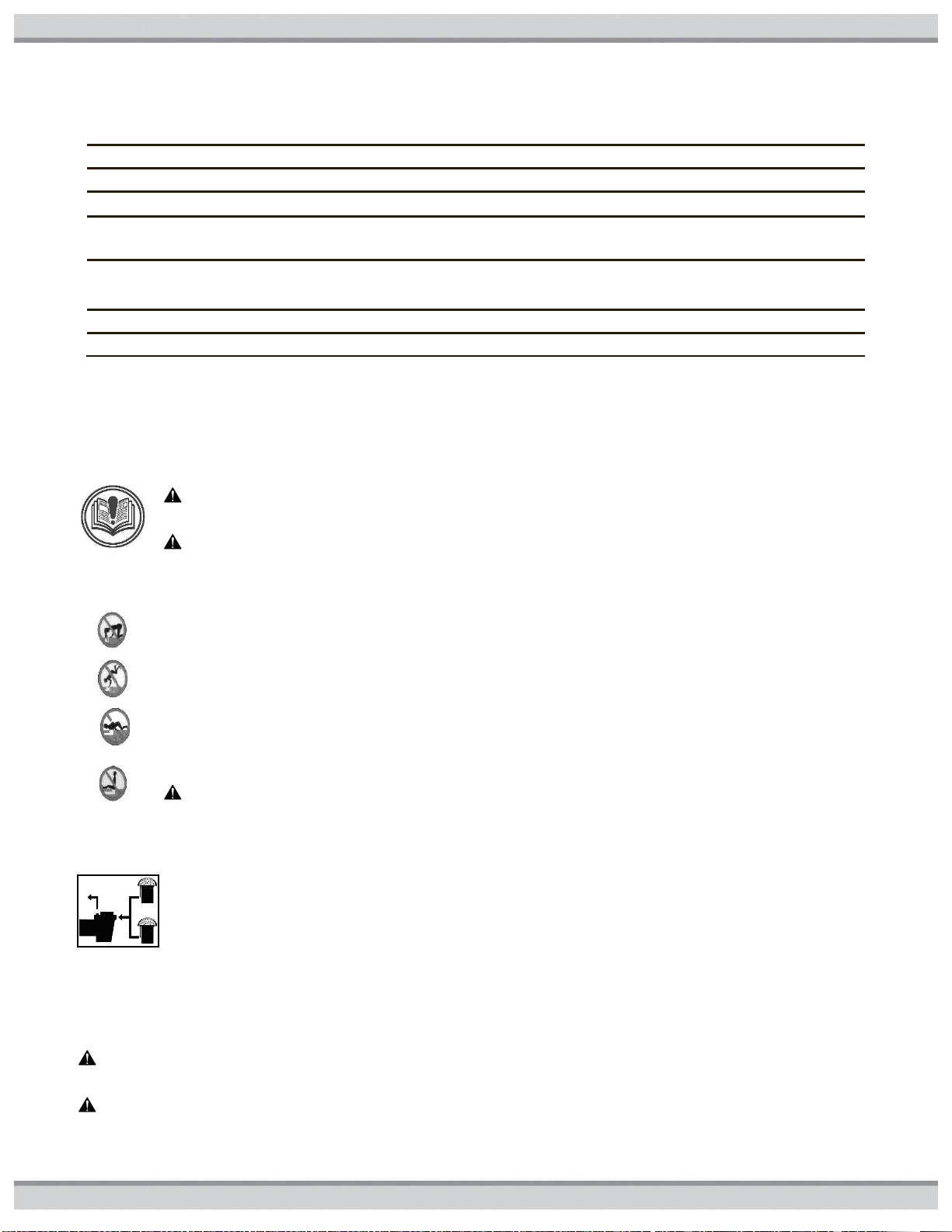

IS POOL/SPA IN

CHEMICAL BALANCE?

INITIAL USE OR SPRING STARTUP

Check all pool / spa water piping. Do not connect product to water piping.

BYPASS TO CLOSED POSITION, WATER DIRECTED TO PRODUCT

TURN ON ELECTRIC POWER AND GAS AS REQUIRED.

START PRODUCT. PROGRAM REQUIRED WATER

TEMPERATURE ON PRODUCT CONTROL PANEL.

IMPORTANT FOR POOL USER HEALTH AND PRODUCT PERFORMANCE

Verify Chlorine or Bromine level every 2-3 days

Verify PH level every week

Verify Alkalinity level every 3-4 weeks (2 weeks if using an Automatic

Chlorine or Bromine Feeder)

Verify Water Hardness and Total Dissolved Solids (TDS) every month (it is

recommended that a pool professional perform this testing)

IS HEATING/COOLING

NEEDED WITHIN 1 WEEK?

SET BYPASS TO

OPEN POSITION,

WATER DIVERTED

FROM PRODUCT

CONNECT WATER PIPING TO PRODUCT, BYPASS TO OPEN POSITION

IS HEATING/COOLING

NEEDED FOR REST OF YEAR?

DISCONNECT

WATER PIPING TO

PRODUCT

TURN OFF ELECTRIC

POWER AND GAS AS

REQUIRED

ENJOY YOUR POOL/SPA

NO

NO

NO

OPEN

PRODUCT

POOL/SPA

CLOSED

PRODUCT

POOL/SPA

GETTING STARTED

WHAT TO EXPECT WHEN OPERATING YOUR POOL HEATER

This flow chart provides guidance to protect pool users and product by maintaining good water quality.

2 USE ONLY GENUINE REPLACEMENT PARTS

51300004201B

Basic safety precautions should always be followed, including the following:

Failure to follow instructions can cause death and/or severe injury.

This is the safety-alert symbol. When you see this symbol on your equipment

or in this manual, look for one of the following signal words and be alert to the

potential for personal injury.

WARNING warns about hazards that could cause death and/or severe

injury or major property damage and if ignored presents a potential hazard.

CAUTION warns about hazards that could cause minor or moderate

personal injury and/or property damage and if ignored presents a potential

hazard. It can also make consumers aware of actions that are unpredictable

and unsafe.

NOTICE indicates special instructions that are important but not related to

hazards.

PLEASE READ BEFORE PROCEEDING

See product rating plate for manufactures information.

USE ONLY GENUINE REPLACEMENT PARTS 3

51300004201B

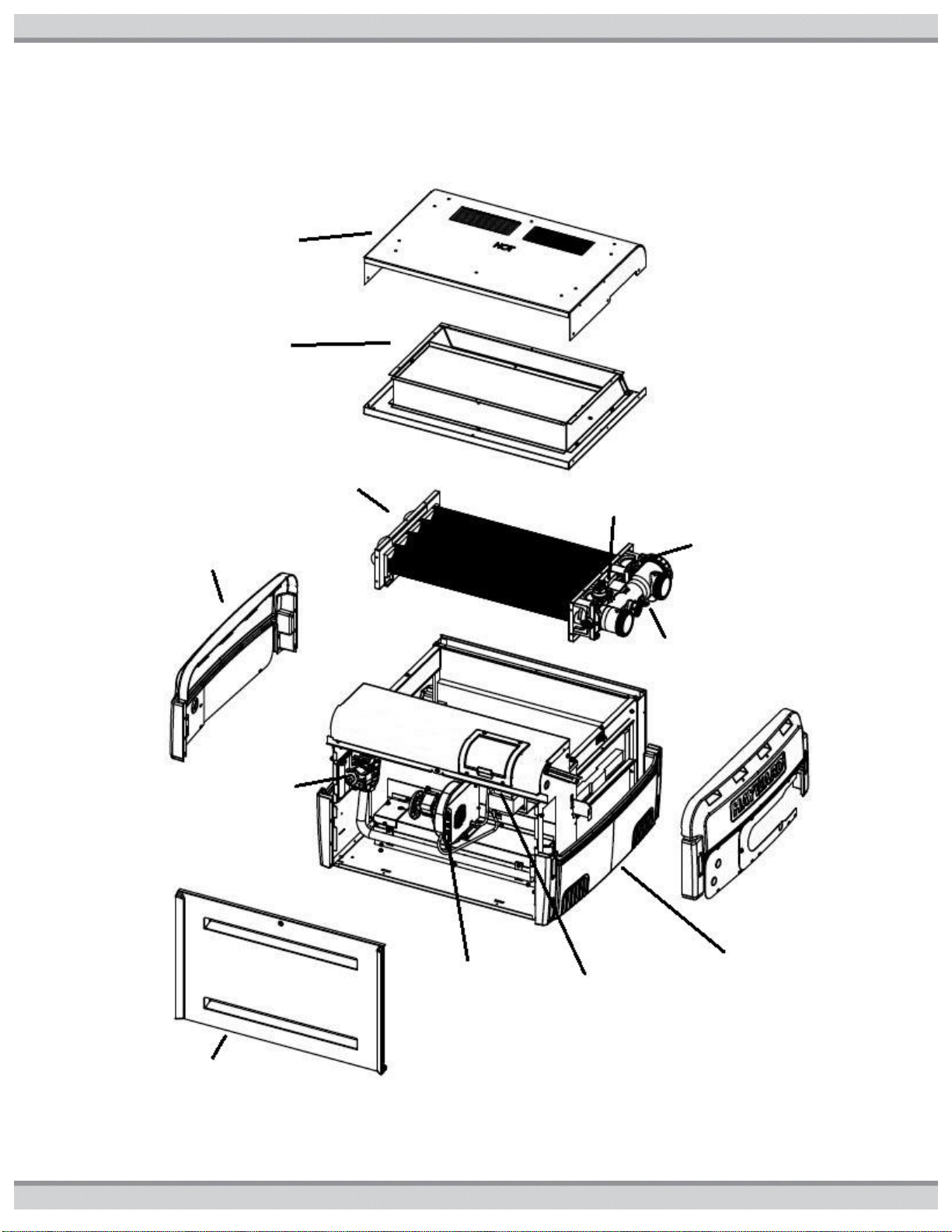

Top Flue Cover

Rain Shield

Assembly

Heat Exchanger

Assembly

Upper Side

Panels

Water Pressure

Switch

Water

Temperature

Switches

Drain Plug or

Relief Valve

Gas

Control

Combustion

Blower

Control Bezel

and Control

Lower Side

Panels

Front Access Panel

HEATER CONSTRUCTION

Figure1: Sub-Assemblies

4 USE ONLY GENUINE REPLACEMENT PARTS

51300004201B

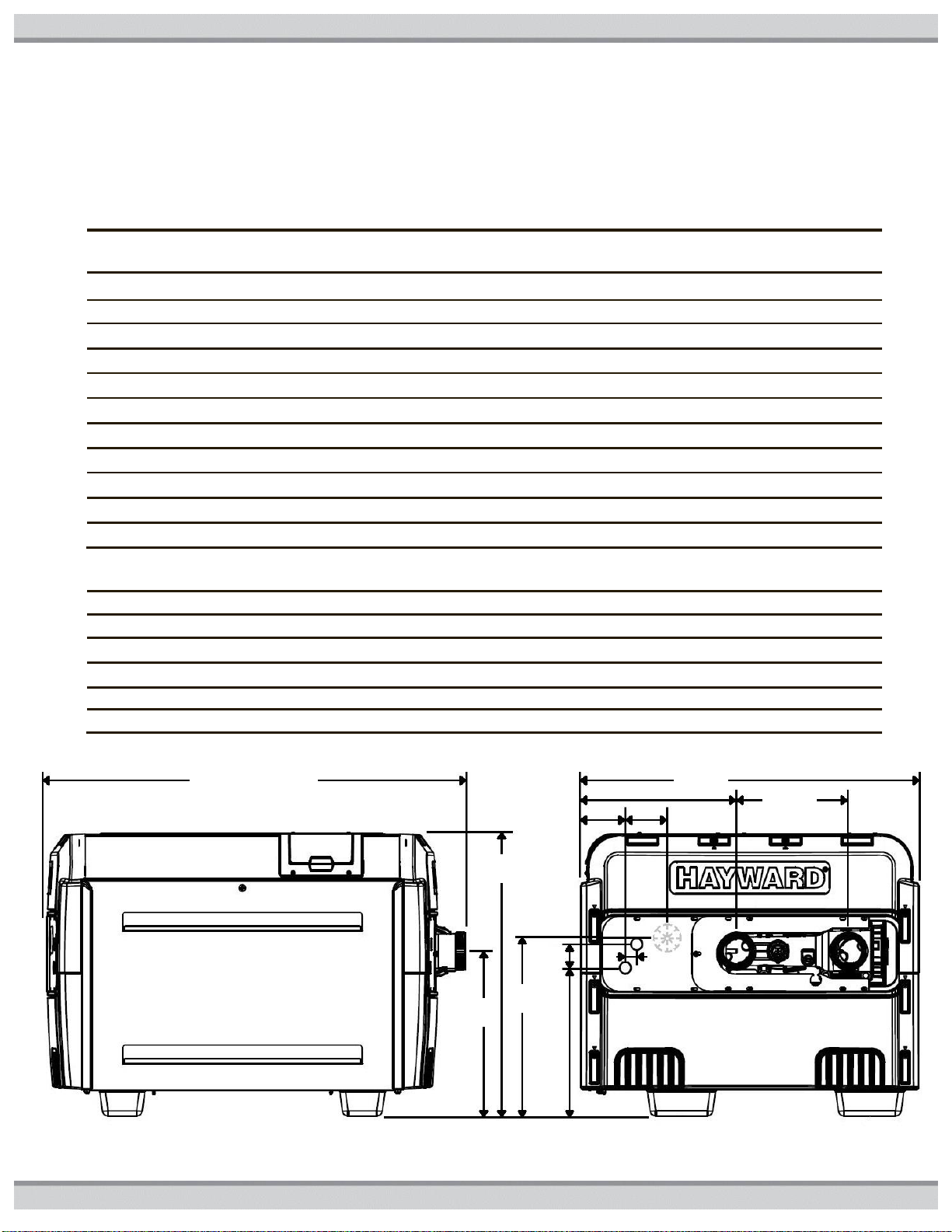

Model

Gas Input

Natural or Propane

Minimum

Water Flow

Thermal

Efficiency

Heater

Width

Heater

Weight

*xxx*

btu/hr

gpm

%

in.

lbs.

150

150,000

20

82.7

19

135

200

199,900

20

83

22

140

250

250,000

25

84

25

165

300

300,000

25

82.7

26

175

350

350,000

30

83

31

195

400

399,900

30

84

34

195

500

500,000

40

83

40

245

250ASME

250,000

25

84

28

195

400ASME

400,000

30

84

36.5

225

500ASME

500,000

40

83

40.5

260

OPERATING PRESSURES

Natural Gas (inwc)

Propane Gas (inwc)

Gas Manifold Pressure*

1.8 - 2.2

6.8 - 7.0

Gas Inlet Pressure, Minimum

4.5

10.0

Gas Inlet Pressure Maximum

10.5

13.0

GAS ORIFICE DRILL SIZES

#25

#43

GAS ORIFICE DRILL SIZES (500kbtu/hr)

#22

2.3mm

Heater Width

22.2

22.2

2.2

2.2

22.2

22.2

22.2

22.2

22.2

2.2

2.2

Table1: SPECIFICATIONS

Features:

120 or 240VAC, 60Hz, 1-phase, 5.5A maximum current

Forced draft combustion with silicon nitride hot surface ignition

Cupronickel water tubes standard

Integral low loss bypass, maximum water flow for all models is 125 GPM

GAS REQUIREMENTS

*Pressure range for allowable heating value variation.

USE ONLY GENUINE REPLACEMENT PARTS 5

51300004201B

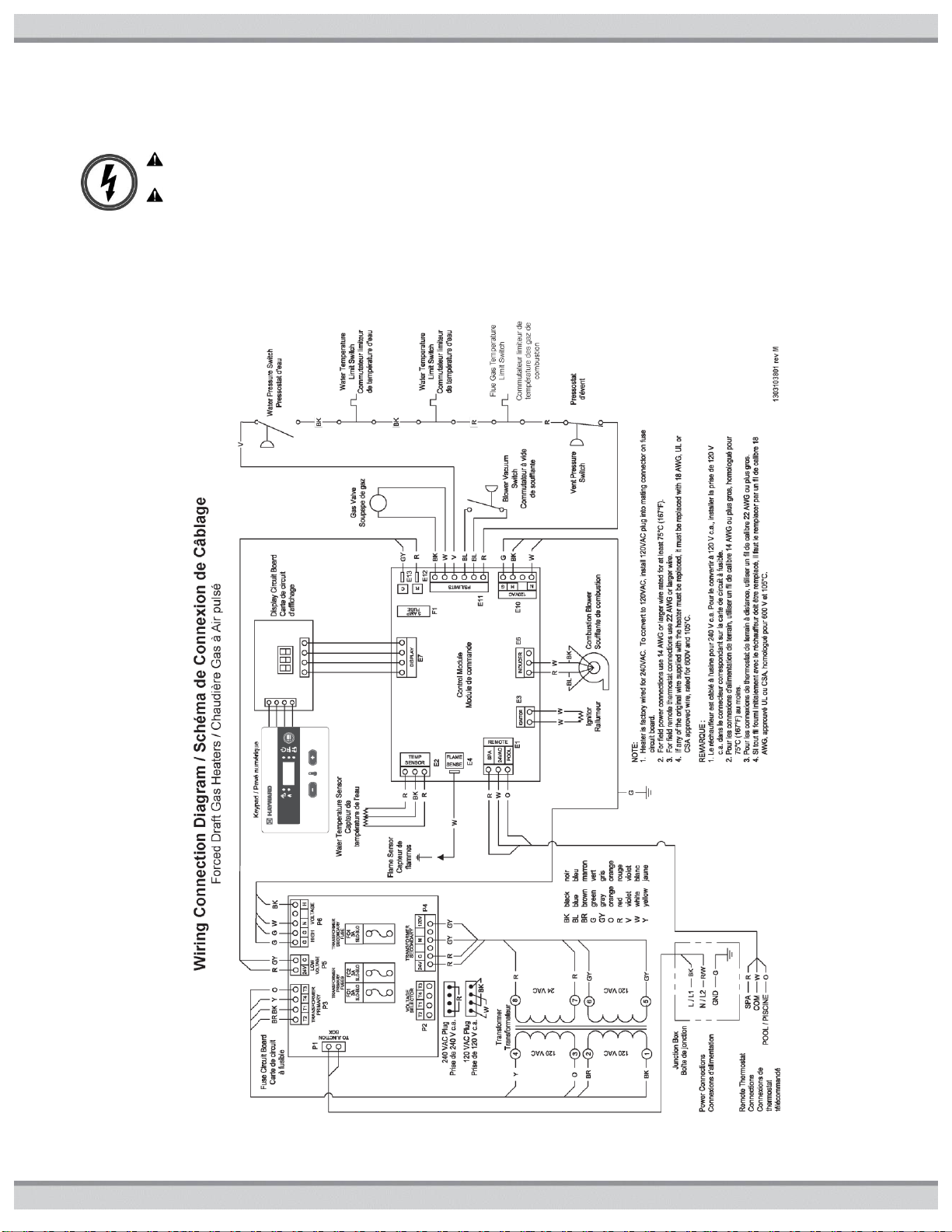

Wiring Connection Diagram

WARNING - Risk of Electric Shock Before working on any electrical equipment, turn off power supply to the

equipment.

WARNING - Risk of Electric Shock. All electrical wiring MUST conform to applicable local codes, regulations,

and the National Electric Code (NEC). Hazardous voltage can cause death, shock, burn, and/or serious property

damage. To reduce the risk of electric shock, do NOT use an extension cord to connect unit to electric supply. Provide

a properly located electrical receptacle. To reduce the risk of electric shock replace damaged wiring immediately.

Locate conduit to prevent abuse from lawn mowers, hedge trimmers and other equipment. Do NOT ground to a gas

supply line.

Figure2: Wiring Diagram

6 USE ONLY GENUINE REPLACEMENT PARTS

51300004201B

CERTIFICATION CODES AND STANDARDS

USA

CANADA

DESIGN CERTIFIED

CSA

CSA

DESIGN COMPLIANT

ANSI Z21.56

CSA 4.7

INSTALLATION COMPLIANT GAS

NFPA 54/ANSI Z223.1

NFPA 58

CAN/CSA-B149.1-2

INSTALLATION COMPLIANT ELECTRIC

ANSI/NFPA 70

NEC

CSA C22.1 – Canadian

Electrical Code, Part I

EMISSIONS

SCAQMD 1146.2

SHIPPING COMPLIANT

ISTA 3B

ISTA 3B

Table2: CERTIFICATION AND COMPLIANCE

CONFORMANCE WITH CODES: The heater shall be installed in accordance with all local and state codes and with

the requirements of the authority having jurisdiction of the installing site. The heater installation must conform to the

latest edition of the above listed installation codes.

SAFETY INFORMATION

WARNING – Read, Understand, and Follow all instructions in this manual and on the equipment.

Failure to follow instructions can cause severe injury and/or death.

WARNING – Suction Entrapment Hazard.

Suction in suction outlets and/or suction outlet covers which are damaged, broken, cracked, missing, or unsecured

can cause severe injury or death due to the following entrapment hazards:

Hair Entrapment- Hair can become entangled in suction outlet cover.

Limb Entrapment- A limb inserted into an opening of a suction outlet sump or suction outlet cover that is damaged,

broken, cracked, missing, or not securely attached can result in a mechanical bind or swelling of the limb.

Body Suction Entrapment- A negative pressure applied to a large portion of the body or limbs can result in an

entrapment.

Evisceration/ Disembowelment - A negative pressure applied directly to the intestines through an unprotected

suction outlet sump or suction outlet cover which is damaged, broken, cracked, missing, or unsecured can result in

evisceration/disembowelment.

Mechanical Entrapment- There is potential for jewelry, swimsuit, hair decorations, finger, toe or knuckle to be caught

in an opening of a suction outlet cover resulting in mechanical entrapment.

WARNING - To Reduce the risk of Entrapment Hazards:

o When outlets are small enough to be blocked by a person, a minimum of two functioning suction outlets per pump

must be installed. Suction outlets in the same plane (i.e. floor or wall), must be installed a minimum of three feet (3’)

[1 meter] apart, as measured from near point to near point.

o Dual suction fittings shall be placed in such locations and distances to avoid “dual blockage” by a user.

o Dual suction fittings shall not be located on seating areas or on the backrest for such seating areas.

o The maximum system flow rate shall not exceed the flow rating as listed in TABLE1: SPECIFICATIONS.

o Never use Pool or Spa if any suction outlet component is damaged, broken, cracked, missing, or not securely

attached.

o Replace damaged, broken, cracked, missing, or not securely attached suction outlet components immediately.

o Install two or more suction outlets per pump in accordance with latest ASME, APSP Standards and CPSC

guidelines. Follow all applicable National, State, and Local codes.

o Installation of a vacuum release or vent system, which relieves entrapping suction, is recommended.

WARNING – Failure to remove pressure test plugs and/or plugs used in winterization of the pool/spa from the

suction outlets can result in an increase potential for suction entrapment as described above.

WARNING – Failure to keep suction outlet components clear of debris, such as leaves, dirt, hair, paper and other

material can result in an increase potential for suction entrapment as described above.

USE ONLY GENUINE REPLACEMENT PARTS 7

51300004201B

WARNING – Suction outlet components have a finite life, the cover/grate should be inspected frequently and

replaced at least every seven years or if found to be damaged, broken, cracked, missing, or not securely attached.

CAUTION – Components such as the filtration system, pumps and heater must be positioned so as to prevent their

being used as means of access to the pool by young children. To reduce risk of injury, do not permit children to use or

climb on this product. Closely supervise children at all times. Components such as the filtration system, pumps, and heaters

must be positioned to prevent children from using them as a means of access to the pool.

WARNING – Hazardous Pressure. Pool and spa water heating and circulation systems operate under

hazardous pressure during start up, normal operation, and after pump shut off. Stand clear of circulation system

equipment during pump start up. Failure to follow safety and operation instructions could result in violent

separation of the pump housing and cover, and/or filter housing and clamp due to pressure in the system, which

could cause death, severe personal injury and/or property damage. Before servicing pool and spa water circulation

system, all system and pump controls must be in off position and filter manual air relief valve must be in open

position. Before starting system pump, all system valves must be set in a position to allow system water to return

back to the pool. Do not change filter control valve position while system pump is running. Before starting system

pump, fully open filter manual air relief valve. Do not close filter manual air relief valve until a steady stream of

water (not air or air and water) is discharged.

WARNING – Separation Hazard. Failure to follow safety and operation instructions could result in violent

separation of pump and/or filter components. Strainer cover must be properly secured to pump housing with

strainer cover lock ring. Before servicing pool and spa circulation system, filters manual air relief valve must be in

open position. Do not operate pool and spa circulation system if a system component is not assembled properly,

damaged, or missing. Do not operate pool and spa circulation system unless filter manual air relief valve body is in

locked position in filter upper body. Never operate or test the circulation system at more than 50 PSI. Do not

purge the system with compressed air. Purging the system with compressed air can cause components to

explode, with risk of severe injury or death to anyone nearby. Use only a low pressure (below 5 PSI), high volume

blower when air purging the pump, filter, or piping.

WARNING – Risk of Electric Shock. All electrical wiring MUST be in conformance with applicable local

codes, regulations, and the National Electric Code (NEC). Hazardous voltage can shock, burn, and cause death or

serious property damage. To reduce the risk of electric shock, do NOT use an extension cord to connect unit to

electric supply. Provide a properly located electrical receptacle. Before working on any electrical equipment, turn

off power supply to the equipment. To reduce the risk of electric shock replace damaged wiring immediately.

Locate conduit to prevent abuse from lawn mowers, hedge trimmers and other equipment. Do NOT ground to a

gas supply line.

WARNING – Risk of Electric Shock. Failure to ground all electrical equipment can cause serious or fatal electrical shock

hazard. Electrically ground all electrical equipment before connecting to electrical power supply.

WARNING – Risk of Electric Shock. Failure to bond all electrical equipment to pool structure will increase risk for

electrocution and could result in injury or death. To reduce the risk of electric shock, see installation instructions and consult a

professional electrician on how to bond all electrical equipment. Also, contact a licensed electrician for information on local

electrical codes for bonding requirements.

Notes to electrician: Use a solid copper conductor, size 8 or larger. Run a continuous wire from external bonding lug to

reinforcing rod or mesh. Connect a No. 8 AWG (8.4 mm2) [No. 6 AWG (13.3 mm2) for Canada] solid copper bonding wire to the

pressure wire connector provided on the electrical equipment and to all metal parts of swimming pool, spa, or hot tub, and

metal piping (except gas piping), and conduit within 5 ft. (1.5 m) of inside walls of swimming pool, spa, or hot tub.

IMPORTANT - Reference NEC codes for all wiring standards including, but not limited to, grounding, bonding and other

general wiring procedures.

WARNING – Risk of Electric Shock. The electrical equipment must be connected only to a supply circuit that is protected

by a ground-fault circuit-interrupter (GFCI). Such a GFCI should be provided by the installer and should be tested on a routine

basis. To test the GFCI, push the test button. The GFCI should interrupt power. Push reset button. Power should be restored.

If the GFCI fails to operate in this manner, the GFCI is defective. If the GFCI interrupts power to the electrical equipment

without the test button being pushed, a ground current is flowing, indicating the possibility of an electrical shock. Do not use this

electrical equipment. Disconnect the electrical equipment and have the problem corrected by a qualified service representative

before using.

CAUTION – These heaters are intended for use with permanently-installed pools and may be used with hot tubs and spas

if so marked. Do not use with storable pools. A permanently-installed pool is constructed in or on the ground or in a building

such that it cannot be readily disassembled for storage. A storable pool is constructed so that it is capable of being readily

disassembled for storage and reassembled to its original integrity.

8 USE ONLY GENUINE REPLACEMENT PARTS

51300004201B

WARNING – Risk of Hyperthermia. To avoid hyperthermia the following “Safety Rules for Hot Tubs” are recommended by

the U.S. Consumer Product Safety Commission.

1. Spa or hot tub water temperatures should never exceed 104°F [40°C]. A temperature of 100°F [38°C] is considered

safe for a healthy adult. Special caution is suggested for young children. Prolonged immersion in hot water can

induce hyperthermia.

2. Drinking of alcoholic beverages before or during spa or hot tub use can cause drowsiness, which could lead to

unconsciousness and subsequently result in drowning.

3. Pregnant women beware! Soaking in water above 100°F [38°C] can cause fetal damage during the first three

months of pregnancy (resulting in the birth of a brain-damaged or deformed child). Pregnant women should adhere to

the 100°F [38°C] maximum rule.

4. Before entering the spa or hot tub, users should check the water temperature with an accurate thermometer; spa or

hot tub thermostats may err in regulating water temperatures by as much as 4°F (2.2°C).

5. Persons taking medications, which induce drowsiness, such as tranquilizers, antihistamines or anticoagulants, should

not use spas or hot tubs.

6. If the pool/spa is used for therapy, it should be done with the advice of a physician. Always stir pool/ spa water before

entering the pool/spa to mix in any hot surface layer of water that might exceed healthful temperature limits and cause

injury. Do not tamper with controls because scalding can result if safety controls are not in proper working order.

7. Persons with a medical history of heart disease, circulatory problems, diabetes or blood pressure problems should

obtain a physician’s advice before using spas or hot tubs.

8. Hyperthermia occurs when the internal temperature of the body reaches a level several degrees above normal body

temperature of 98.6°F [37°C]. The symptoms of Hyperthermia include: drowsiness, lethargy, dizziness, fainting,

and an increase in the internal temperature of the body.

The effects of Hyperthermia include:

Unawareness of impending danger.

Failure to perceive heat.

Failure to recognize the need to leave the spa.

Physical inability to exit the spa.

Fetal damage in pregnant women.

Unconsciousness resulting in danger of drowning.

DEFINITIONS:

Suction Outlet: The Suction Outlet is a fitting, fitting assembly, cover/grate and related components that provide a means for

water to exit the pool and return into the pump circulating system. This fitting may also be referred to as the “Main

Drain”

Bypass Valves: A valve or series of valves that direct the pool water to flow or not flow through the heater.

CSA: Canadian Standards Association

CGA: Canadian Gas Association

ANSI: American Nation Standards Institute

NFPA: National Fire Protection Association

NEC: National Electric Code

SCAQMD: South Coast Air Quality Management District

ISTA: International Safe Transit Association

Pressure measurement units:

Inches of Mercury (inHg) is typically used with atmospheric pressure measurements.

Pounds per square inch (PSI) is typically used with water “pressure”, “suction” or system measurements.

Inches of Water (inwc) is typically used with gas or air pressure measurements

(1.0 inHg = .49 PSI = 13.5inwc)

USE ONLY GENUINE REPLACEMENT PARTS 9

51300004201B

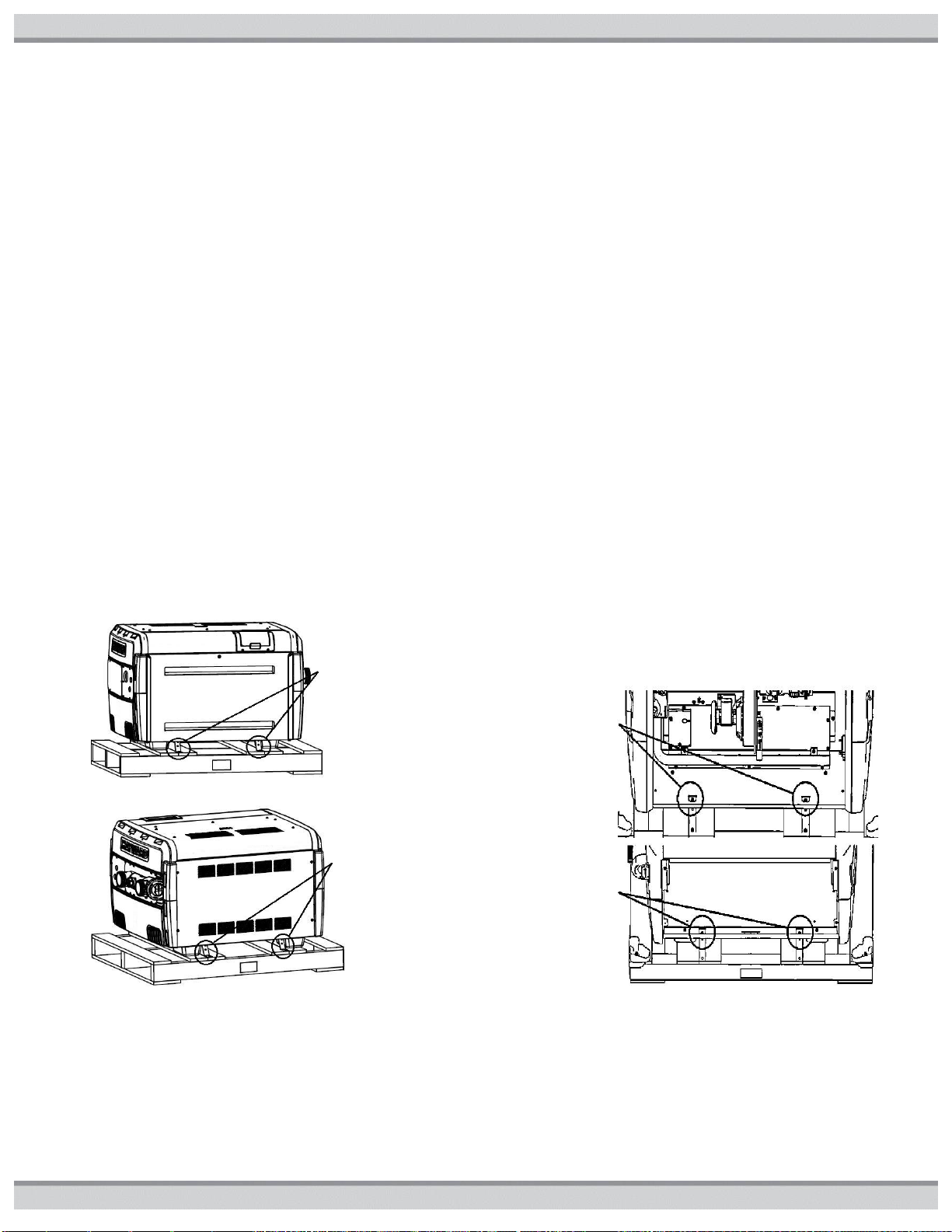

Front shipping

screws and

brackets

Rear shipping

screws and

Front

shipping

screws

Rear

shipping

screws

INSTALLATION:

This manual contains instructions for installation, operation, maintenance, troubleshooting, and parts lists for the proper operation of

the swimming pool/spa/hot tub heaters. It is strongly recommended that the installer read the manual before installing the

swimming pool/spa/hot tub heater. If after reviewing the manual any questions remain unanswered, contact tech services or local

representative. Following heater installation, the installer should leave all manuals with the consumer for future reference.

NOTICE: The installation instructions are intended for the use of a qualified technician, specifically trained and experienced

in the installation of this type of heating equipment. Some states or provinces require that installer be licensed. If this is the

case in the state or province where heater is located, the contractor must be properly certified.

THE USE OF A POOL COVER IS RECOMMENDED. A pool cover reduces heat loss, conserves chemicals, lowers the

load on filter systems and may provide a valuable safety feature

EQUIPMENT INSPECTION: On receipt of the heater, inspect the heater carton(s) for damage. If any carton(s) is damaged,

note it when signing for it. Remove the heater from the carton(s) inspect it and advise the carrier of any damages at once.

NOTICE: Do not drop the heater from a pickup truck tailgate to the ground. This may damage the heater.

UNCRATING THE HEATER: Follow these steps to

remove the shipping carton from the heater:

1. Remove the corrugated carton from the heater. The

carton, top pad, bottom pad, and the four corner posts can

be recycled.

2. There are four (4) external screws (see figure3) used to

secure the heater to the wood pallet. All four must be

removed to separate the heater from the pallet.

Figure3: External Shipping Screw Locations

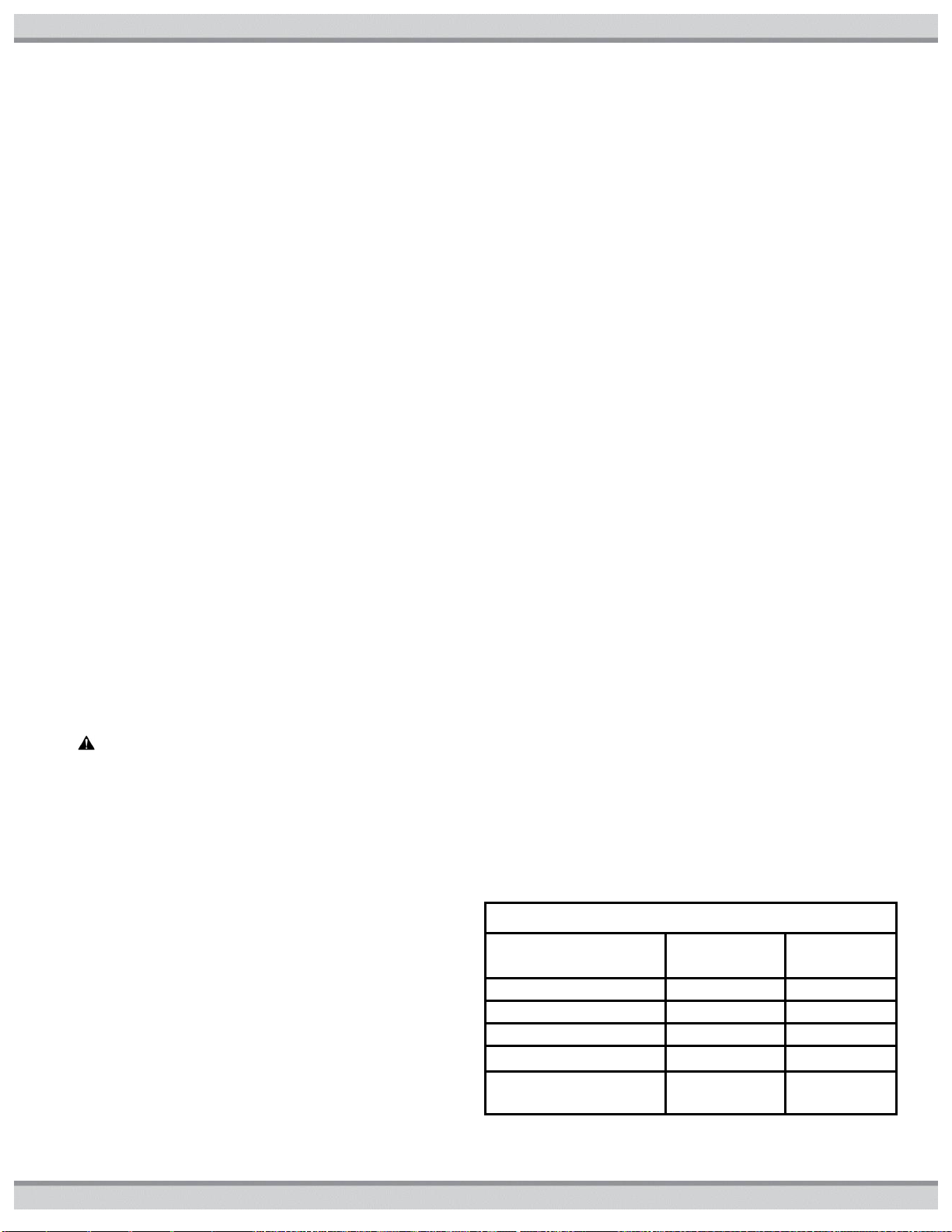

3. To access the four (4) internal screws (see figure4), open

the front access panel by removing the single top screw.

Then remove the two (2) screws and brackets which hold

the heater base pan to the pallet shown in Figure3. Next

open the rear access panel by removing the four (4)

screws holding this panel. Then remove the two (2)

screws and brackets which hold the heater base pan to

the pallet as shown in Figure3.

4. Lift the heater clear of the corrugated bottom pad and off

of the pallet. Discard bottom corrugated tray and pallet

appropriately.

Figure4: Internal Shipping Screw Locations

10 USE ONLY GENUINE REPLACEMENT PARTS

51300004201B

Table3: Installation Required Clearances (in.)

Heater Panel

Outdoor

Clearance

Indoor

Clearance

Top

Unobstructed

36

Front

18

18

Back*

6

6

Water Side Connection

12

12

Opposite Water Side

Connection

6

6

SPRINKLER HEADS: The heater is designed to handle the wettest weather conditions that are typical of rain and high

humidity. Sprinkler heads force high-pressure water into the unit from the side at an odd angle. Make sure there are no sprinkler

heads near the heater that will spray on or into the unit. Many sprinkler systems are connected to a well system, whose water is

high in minerals, Sulphur, salt and other aggressive contaminates, that will leave a buildup on the unit and electronics causing

corrosion and shortens life.

NOTICE: Damage from sprinkler interaction is not covered under the warranty agreement. Make sure that sprinklers are

placed at a sufficient distance away so that normal wind will not carry the mist to the Heater.

NOTICE: If located in an oceanfront area, the Heater should be placed out of direct spray of sand and salt. This will clog,

damage, and corrode the unit. You may also consider protecting the unit by creating a physical barrier outside of the minimum

clearances between the unit and the prevailing beachfront wind. Damage caused by sand or salt spray is not covered by the

warranty.

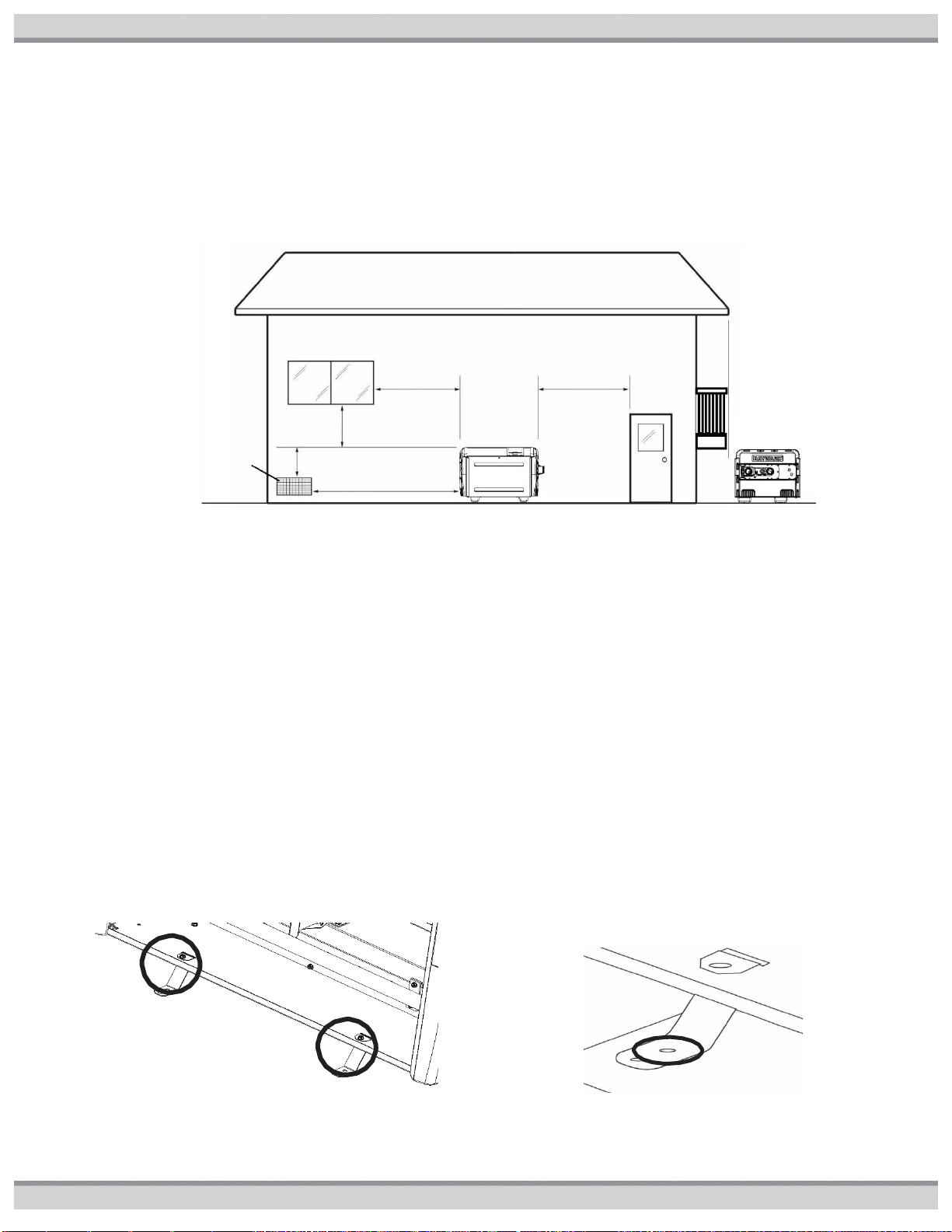

LOCATING THE HEATER:

Locate the pool/spa heater in an area where leakage of the heat exchanger or connections will not result in damage to the area

adjacent to the heater or to the structure. When such locations cannot be avoided, it is recommended that a suitable drain pan, with

drain outlet, be installed under the heater. The pan must not restrict airflow. This heater must be installed at least (5) feet from the

inside wall of a pool (in-ground or above-ground)/spa/hot tub unless separated from the pool/spa/hot tub by a solid barrier. The

heater must be installed such that the location of the exhaust gas vent assembly outlet relative to adjacent public walkways,

adjacent buildings, openable windows, and building openings complies with the National Fuel Gas Code (ANSI Z223.1/NFPA 54)

and/or CAN/CGA B149 installation codes.

1. Level surface for proper rain water draining and removal.

2. Suitable electrical supply line. See rating plate on the heater for electrical specifications. A junction box is not needed at the

heater; connections are made inside the unit electrical compartment. Minimum wire size to be selected per NEC.

3. Electric disconnect switch that will interrupt all power to the unit. This switch MUST be within line of sight of the heater.

4. The heater does not require additional vent piping when installed outdoors.

5. Do not install in a location where growing shrubs may in time obstruct a heater’s combustion air and venting areas.

6. Do not install this appliance under an overhang less than 72in from the top of the appliance. The area under the overhang must

be open on (3) sides.

7. Do not install the heater where water spray from ground level can contact the heater. The water could reach the controls

causing electrical damage.

8. Do not install under a deck.

9. Do not install within 24in of any outdoor HVAC equipment.

10. Do not install where water may run-off a roof into the heater. A gutter may be needed to protect the heater.

CAUTION: Make sure the heater is not located where large amounts of water may run-off from the roof into the unit. Sharp

sloping roofs without gutters will allow massive amounts of rainwater, mixed with debris from the roof to be forced through the

unit. Failure to follow the instructions may result in property damage and void warranty.

11. Any enclosure around the heater must provide a combustion air vent large enough to accommodate input ratings of all gas

appliances in the enclosure. See AIR SUPPLY section for more detail

12. For minimum exhaust vent clearances for all building openings, including but not limited to vented eaves, doors, windows, or

gravity inlets, see Figure5. In Canada, the heater must be installed with the top of the vent at least 10 feet (3m) below, or

to either side of, any opening into a building.

OUTDOOR AND INDOOR INSTALLATION AND SERVICE

CLEARANCES: For both outdoors and indoors installations,

the installation clearances from combustible materials and

service clearances shown in Table3 and Figure5 must be

maintained. Do not install heater in a closet or enclosed space

(consult NFGC)

*If the heater is to be installed with vinyl siding at back,

increase the clearance in Table3 to 12 inches to avoid potential

discoloration of siding

USE ONLY GENUINE REPLACEMENT PARTS 11

51300004201B

4 ft.

minimum

4 ft.

minimum

4 ft.

minimum

3 ft.

minimum

10 ft. minimum

Force Air

Inlet

Free

from rain

run off or

blockage

from

above

EQUIPMENT PAD: Place the heater on a level surface such as concrete or a fabricated slab (pad). This allows proper

drainage of condensation and rainwater from the base of the unit. If possible, the pad should be placed at the same level or slightly

higher than the filter system equipment pad.

FLOORING: This heater may be installed on either non-combustible flooring or combustible flooring that does not reduce the

bottom clearance of the heater. Ultralite™ or equivalent concrete-over-foam HVAC pads are acceptable.

Figure5: Outdoor Minimum Clearances

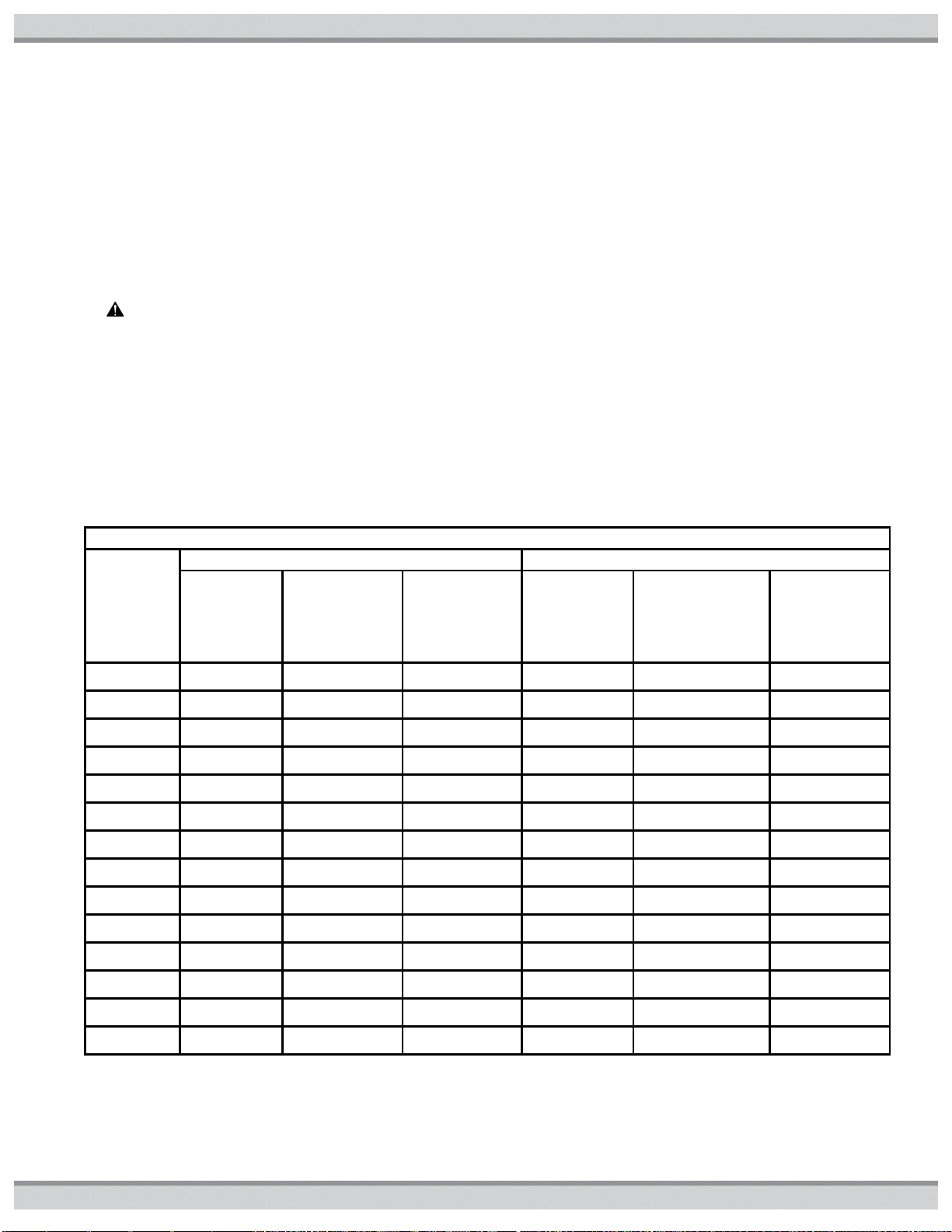

ANCHORING: The heater is equipped for installation of factory supplied tie-down brackets when required by local codes.

Follow all relevant Local, State and National requirements regarding wind load anchoring. The brackets are shipped in the

consumer kit. You will need the following to complete the installation:

Tie-down brackets (FACTORY-SUPPLIED, qty = 4)

Sheet metal screws (FACTORY-SUPPLIED, qty = 4)

Concrete tapping screws (FIELD-SUPPLIED, Tapcons®, qty = 4, stainless steel, size to be ¼”diameter with a minimum

length of 1-1/2”)

Fender washers (FIELD SUPPLIED, stainless steel, qty = 4, size to be at least 1-1/2”)

INSTALLING TIE-DOWN BRACKETS:

1. Locate the tie-down brackets and the sheet metal screws.

2. Obtain the Tapcons®. Be sure the overall length of the concrete tapping screw is at least1-1/2”.

3. Remove the front (1 screw) and rear access panel (4 screws).

4. Position the heater on the pad so that all Tapcons® can “bite” into the pad. Observe local codes regarding pad construction,

some jurisdictions specify a minimum thickness for concrete pads.

5. Position the tie-down brackets into the slots in the front of the heater base pan so they are positioned as shown in Figure6. Install

the sheet metal screws through the holes in the bracket to secure the bracket to the heater base pan.

6. Install the Tapcons® through the inner set of holes in the tie-down brackets into the pad (see figure7).

7. Repeat Steps 6 & 7 at the rear of the heater.

8. Tie down is completed when (4) brackets are secured to the heater and the pad. Re-install the access panels in locations (front

and rear), front shown

Figure6: Tie-Down Installation Locations

Figure7: Use 2nd Hole for Ground Mount of

Tie-Down Brackets with 2 Holes

12 USE ONLY GENUINE REPLACEMENT PARTS

Install supplied screws at these locations.

51300004201B

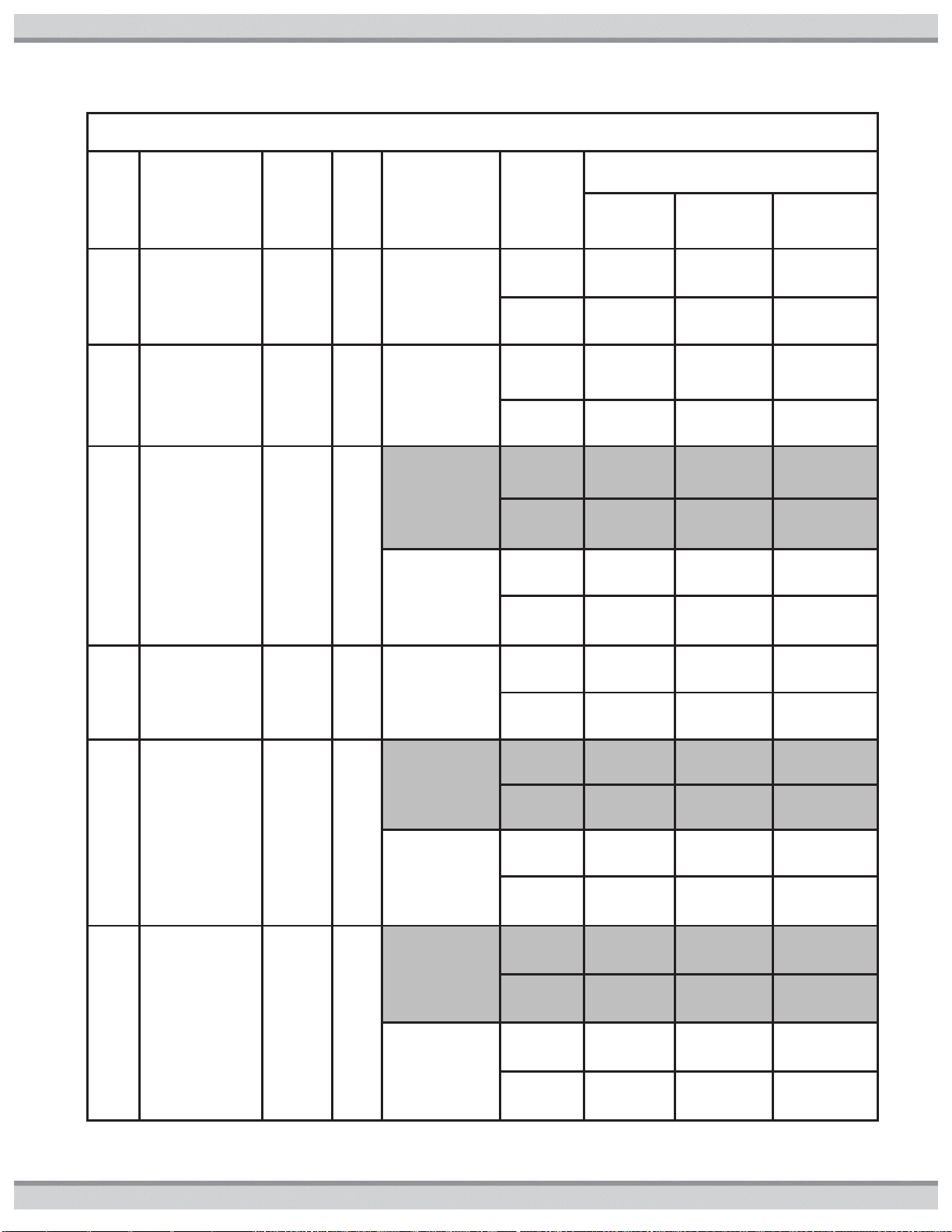

Table4 High Altitude Conversions in (ft.)

Model

Outdoor Installation

Indoor Installation *

No

Modifications

to Heater

Included

Conversion

Plate Installed

Kit

FDXLHAK1930

Installed

No

Modifications

to Heater

Included

Conversion Plate

Installed

Kit

FDXLHAK1930

Installed

150FDN

7,700

N/A

10,100

10,100

N/A

N/A

150FDP

7,700

N/A

10,100

2,000

10,100

N/A

200FDN

10,100

N/A

N/A

10,100

N/A

N/A

200FDP

5,400

10,100

N/A

2,000

10,100

N/A

250FDN

5,400

10,100

N/A

2,000

10,100

N/A

250FDP

2,000

7,700

10,100

2,000

7,700

10,100

300FDN

10,1001

N/A

N/A

10,100

N/A

N/A

300FDP

2,000

10,100

N/A

2,000

10,100

N/A

350FDN

2,000

10,100

N/A

2,000

10,100

N/A

350FDP

2,000

7,700

10,100

2,000

7,700

10,100

400FDN

10,100

N/A

N/A

10,100

N/A

N/A

400FDP

2,000

7,700

10,100

2,000

7,700

10,100

500FDN

10,100

N/A

N/A

10,100

N/A

N/A

500FDP

5,400

7,700

10,100

5,400

7,700

10,100

GAS CONVERSION:

Where permitted by local codes, the factory-installed gas train may be changed from natural gas to propane or from propane to

natural gas, using the appropriate conversion kits. Gas conversions are to be performed only by a qualified service agency. Detailed

instructions are included with each kit.

ALTITUDE OF INSTALLATION:

Heaters may be installed at any altitude up to 10,100 ft. above sea level, provided the appropriate modification(s) are performed.

The altitudes which require modification vary depending on the model. Parts necessary to convert the heater for outdoor installation

at altitudes up to 7,700 ft. (minimum) are included with the heater.

WARNING: Failure to comply with the appliance and vent package installation instructions and service instructions in

this manual may result in equipment damage, fire, asphyxiation, or carbon monoxide poisoning. Exposure to products of

incomplete combustion (carbon monoxide) can cause cancer and birth defects or other reproductive harm.

Conversion is accomplished by replacement of the blower air inlet plate, and for indoor applications, installation of the appropriate

vent pressure switch. The blower air inlet plates are clearly marked with the compatible heater model(s), vent configuration(s), and

altitude range(s). Care should be taken to verify the correct plate and vent pressure switch is being used to ensure proper heater

performance. The vent pressure switch will be provided with the indoor adapter kit, or if you have an older indoor adapter kit, order

p/n FDXLVPS1931 for the high-altitude indoor vent pressure switch. Table4 lists the maximum altitudes for which each model is

designed with: a) no modifications, b) the included conversion plate installed, and c) the accessory conversion kit FDXLHAK1930

installed (sold separately).

* All indoor installations at altitudes above 2,000 require a vent pressure switch to be installed in addition to the blower inlet plate.

The vent pressure switch is included with the appropriate indoor vent kit (UHXNEGVT1xxx or UHXPOSHZ1xxxx), or the highaltitude vent pressure switch kit FDXLVPS1931.

USE ONLY GENUINE REPLACEMENT PARTS 13

51300004201B

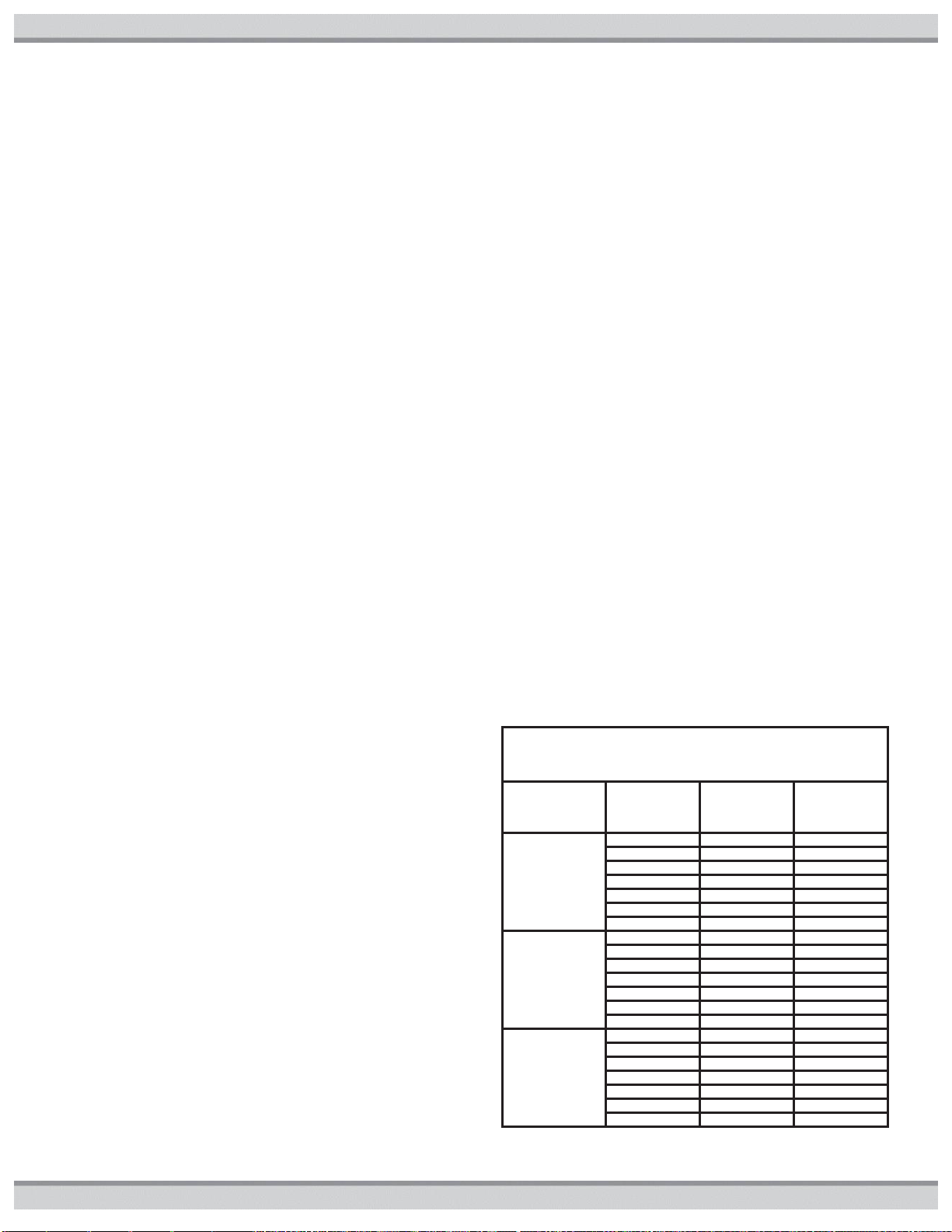

Table5 Combustion and Ventilation Air

Requirements (sq. in.)*

Free Area per

Total Btu

Requirement

Total

Input

(Btu/hr)

Combustion

Air Free Area

Required

Ventilation

Air Free Area

Required

1

sq. in. per

1,000 Btu/hr

(Indoor Air)

150,000

150

150

200,000

200

200

250,000

250

250

300,000

300

300

350,000

350

350

400,000

400

400

500,000

500

500

1

sq. in. per

2,000 Btu/hr

(Outdoor Air thru

Horz duct)

150,000

75

75

200,000

100

100

250,000

125

125

300,000

150

150

350,000

175

175

400,000

200

200

500,000

250

250

1 sq. in. per

4,000 Btu/hr

(Outdoor Air

direct or thru Vert

duct )

150,000

37.5

37.5

200,000

50

50

250,000

62.5

62.5

300,000

75

75

350,000

87.5

87.5

400,000

100

100

500,000

125

125

High-Altitude Conversion Procedure:

1. Identify the altitude of the installation site. This may be done using a GPS device, or by looking up the altitude for the geographic

location. Altitudes for all locations in the United States and Canada may be found using the zip/postal code database at

www.zip-codes.com. If the altitude for the installation site is greater than 10,100 ft., the heater may not be installed. Note that if

installing outdoors, some heaters may be compatible with your altitude without modification. Table4 lists the altitude ranges for

heaters without modification. All indoor heaters installed above 2,000 ft. require the appropriate vent pressure switch, see indoor

installation kit instructions.

2. Select the appropriate blower air inlet plate to use based on the heater model, vent configuration (outdoor or indoor), and altitude

needed. Extra plate(s) are included with the heater, packaged in the plastic bag with this manual. Each plate has a label which

identifies which model(s), vent configuration(s), and altitude range(s) for which it is designed. Table4 lists the maximum

installation altitudes using the included conversion plate(s). If installing above 7,700 ft., the high-altitude kit FDXLHAK1930 (sold

separately) may be necessary.

3. If installing indoors, select the appropriate high-altitude indoor vent pressure switch from the indoor adapter kit or from the

FDXLVPS1931 kit. Each switch has a label which identifies which model(s) and altitude range(s) for which it is designed.

4. If connected, turn pump, main gas valve, and heater power off, remove heater front access door.

5. Remove the 4 #10 hex head screws that fasten the blower air inlet plate to the blower, and remove the blower air plate and

discard. Save the 4 screws as they will be needed to install the new plate. See Figure29: Blower

6. Install the appropriate blower plate from the kit using the 4 screws. It may be helpful to drive the screws in and out of the plate

outside of the heater first to “thread” the holes before installing it in the heater.

7. If the installation is configured for indoor venting, a special high-altitude vent pressure switch must be installed. Follow the

instructions provided in listed vent kits (see Tables 6 and 9), and use the appropriate blower air inlet plate and vent pressure

switch for your altitude.

8. Re-install heater front door, if connected, turn pump, main gas valve, and heater power back on.

9. Activate heater and check for proper operation.

AIR SUPPLY:

Indoor installations and outdoor shelters (confined spaces) must be provided with adequate combustion and ventilation air openings

to assure proper heater operation. These openings must be sized according to the requirements stated in paragraphs below (ALL

AIR SUPPLY FROM INSIDE THE BUILDING or ALL AIR SUPPLY FROM OUTDOORS whichever applies to the installation). These

air openings must never be obstructed when heater is in operation. These confined spaces shall be provided with 2 permanent

openings, one commencing within 12 inches of the bottom and one commencing within 12 inches of the top of the enclosure. The

openings shall communicate directly or by ducts, with the outdoors or spaces (crawl or attic) that freely communicate with the

outdoors. Ducts shall be of the same cross-sectional area as the free area of the openings to which they connect. The minimum

dimension of rectangular air ducts shall not be less than 3 inches. When air blowers are used in spa/hot tub installations and are

located in proximity to the heater, caution must be observed to ensure sufficient combustion air is available to the heater for proper

combustion. A separate blower air duct is recommended. Table 3 indoor clearances apply.

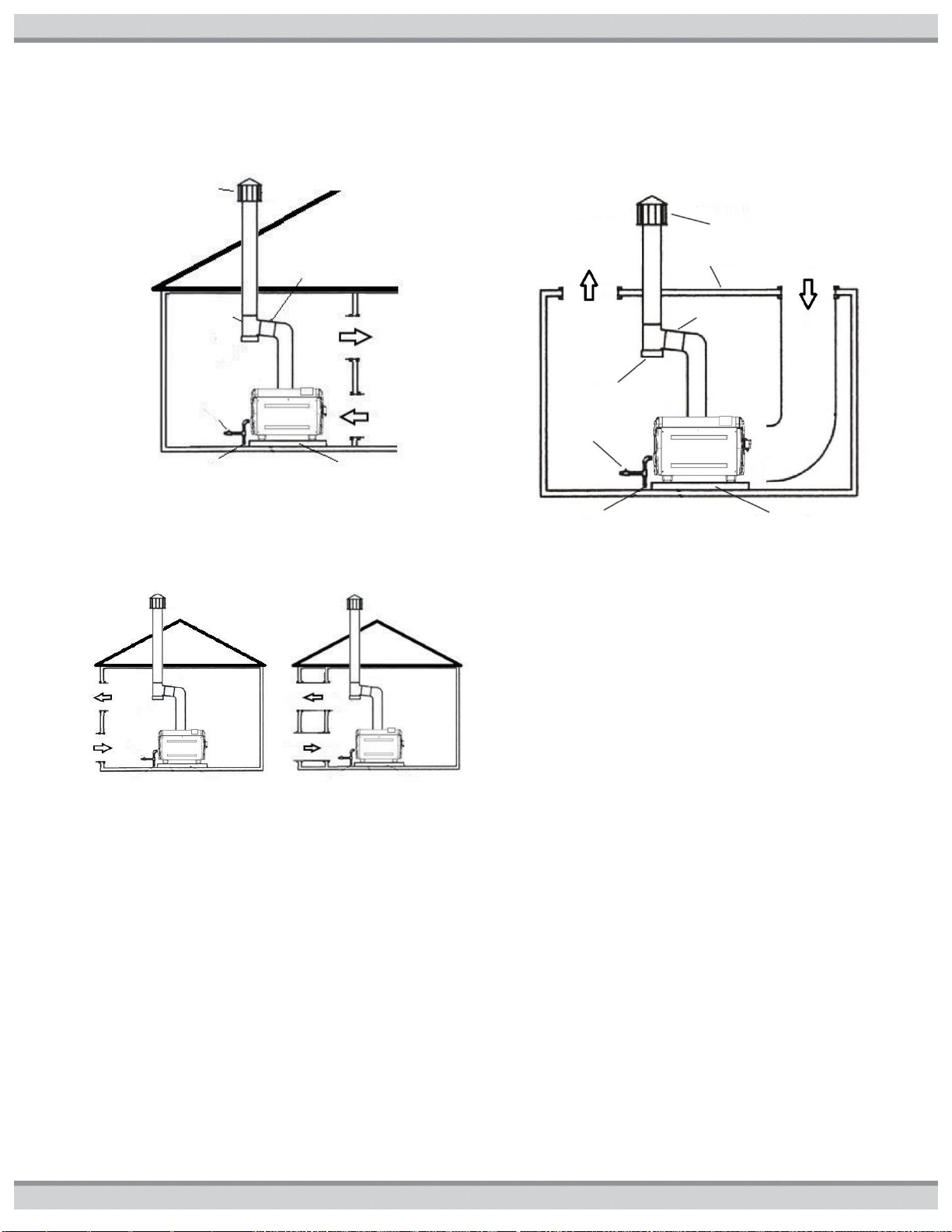

ALL AIR SUPPLY FROM INSIDE THE BUILDING: The

confined space shall be provided with 2 permanent openings

communicating directly with an additional room(s) of sufficient

volume so that the combined volume of all spaces meets the

criteria for an unconfined space (a space whose volume is not

less than 50 cubic feet per 1,000 btu/hr of total input all gas

utilization equipment installed in the combined space shall).

Each opening shall have a minimum free area of 1 square inch

per 1,000 btu/hr of the total input, but not less than 100 square

inches. See Table5 and Figure8.

ALL AIR SUPPLY FROM OUTDOORS: When communicating

with the outdoors through horizontal ducts, each opening shall

have a minimum free area of 1 square inch per 2,000 btu/hr of

total input See Table5 and Figure9B. When communicating

with the outdoors (either directly or through vertical ducts),

each opening shall have a minimum free area of 1 square inch

per 4,000 btu/hr of total input rating of all equipment in the

enclosure. See Table5 and Figure9A. When installing a heater

below ground (in a pit, for use with Natural Gas only),

combustion and ventilation air openings must be provided as

shown in Figure10.

14 USE ONLY GENUINE REPLACEMENT PARTS

*For detailed methods of providing combustion and ventilation air, see

latest edition of the National Fuel Gas Code (ANSI Z223.1/NFPA 54).

51300004201B

Ventilation

Air

Combustion

Air

Ventilation

Air

Combustion

Air

Drip

Tee

Vent Cap

Ground

Rise 1in/ft.

Gas Shut Off

Sediment Trap

Level Floor/Slab

Rise 1in/ft.

Drip

Tee

Vent Cap

Gas Shut

Off

Sediment Trap

Level Floor/Slab

Figure8: Air from Inside Building Installation

1 square inch per 1,000 btu/hr of the total input

Table3 Indoor Clearance Apply

Figure9: Air from Outside Building Installation

A)1 square inch per B)1 square inch per

4,000 btu/hr of 2,000 btu/hr of

total input total input

Figure10: Air Below-Ground

(Pit for Natural Gas only Installations)

1 square inch per 4,000 btu/hr of total input

Table3 Indoor Clearance Apply

FLUE GAS VENTING:

For installation outdoors, no additional venting is required for operation. Ensure top of unit remains unobstructed.

INDOOR INSTALLATION WITH NEGATIVE (CATI) OR POSITIVE (CATIII) PRESSURE VENTING SYSTEMS: The heater is

designed such that it may be vented using either a negative-pressure or a positive-pressure venting system. The appropriate

system of venting for a particular site will depend on many factors such as vent termination needs (horizontal/vertical), clearance of

vent termination, length of vent and the cost of venting system. Table6 (CATI) and Table9 (CATIII) list the required indoor venting

kits available for each system. Multiple forced- or induced-draft units should never be vented using common venting or vent

terminations. Never common vent this heater with other gas-burning appliances.

NEGATIVE PRESSURE (VERTICAL ONLY, CATI) VENTING:

NEGATIVE PRESSURE CATI VENT SIZING: Size the vent pipe according to the venting Tables in the National Fuel Gas Code

(ANSI Z223.1/NFPA 54) for a Category I gas appliance using single-wall or double-wall (Type B) gas vent. Vent pipe diameter

should not be less than the size of the vent pipe adapter on the heater with the appropriate vent kit adapter installed (see Table6).

Single-wall vent may be used in conditioned spaces only. Clearance to combustible materials for single-wall vent is 9 inches.

Double-wall (Type B) vent may be used in conditioned spaces, but must be used in non-conditioned spaces. Clearance to

combustible materials for double-wall vent is 6 inches. Smaller clearances may be available; consult the National Fuel Gas Code.

USE ONLY GENUINE REPLACEMENT PARTS 15

51300004201B

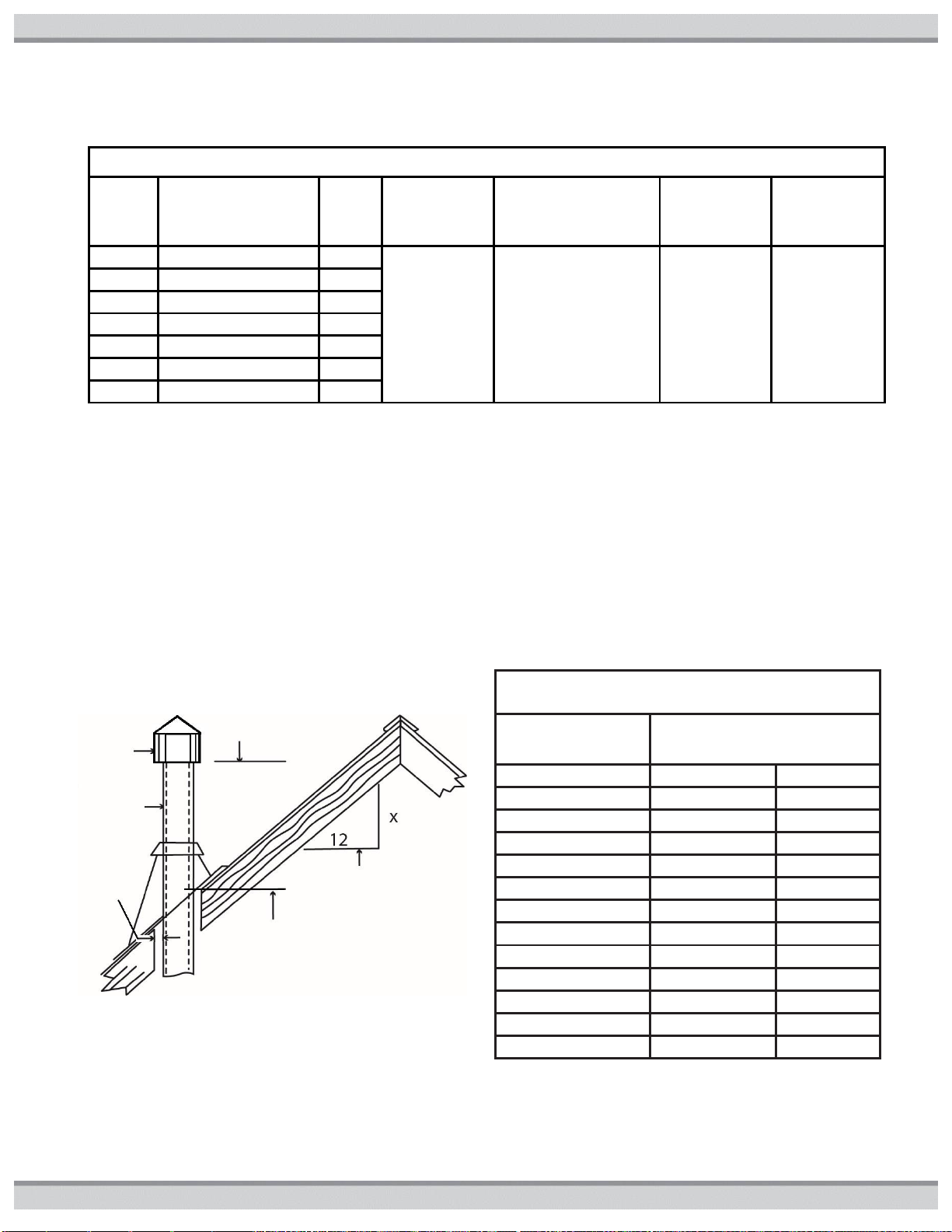

Table6 Negative-Pressure (CATI) Indoor Vent Kits with Vent Pipe & Terminal Specifications

Models

Indoor Vent Kit

Part Number

Vent

Dia(in)

Description

Vent Pipe

Application

Vent Pipe

Material

Vent

Termination

Requirement

150

UHXNEGVT11506

6

Indoor Vent

Adapter Kit,

Negative

Pressure

CATI, Vertical

Venting

Applications

Vent pipe to be

installed according to

the venting Tables in

the National Fuel

Gas Code (ANSI

Z223.1/NFPA 54) for

a Category I gas

Single or

Double Wall,

Galvanized,

Non-Sealed

Vent Pipe

Vertical

Only

200

UHXNEGVT12006

6

250

UHXNEGVT12506

6

300

UHXNEGVT13008

8

350

UHXNEGVT13508

8

400

UHXNEGVT14008

8

500

UHXNEGVT15008

8

Table7 Height Requirements for Negative

Pressure (CATI) Vent Caps (see Figure11)

Roof

Slope

Min. Height

H

from Roof to

Lowest Discharge Opening

(ft.) (m)

Flat to 6/12

1.0 0.30

Over 6/12 to

7/12

1.25 0.38

Over 7/12 to

8/12

1.5 0.46

Over 8/12 to

9/12

2.0 0.61

Over 9/12 to

10/12

2.5 0.76

Over 10/12 to

11/12

3.25 0.99

Over 11/12 to

12/12

4.0 1.22

Over 12/12 to

14/12

5.0 1.52

Over 14/12 to

16/12

6.0 1.83

Over 16/12 to

18/12

7.0 2.13

Over 18/12 to

20/12

7.5 2.27

Over 20/12 to

21/12

8.0 2.44

Listed

Cap

Lowest Discharge

Min. Height (H) from Roof to

Lowest Discharge Opening

Roof Slope at X/12

CATI MECHANICAL DRAFT SYSTEMS: Vent systems requiring power venting must use mechanical draft systems listed in

accordance with UL378 Draft Equipment. Selection of power venter and required clearances from combustible materials must

follow draft equipment manufacture’s instructions, National Fuel Gas Code, local codes and the information in this manual.

NEGATIVE PRESSURE CATI VENT TERMINATION: Any vent extending through a roof or wall must be listed double-wall (Type B)

vent, and pass through an approved roof jack, or roof thimble. A listed vent cap must be used. Terminations for Gas vents with

listed 12in or less diameter size and located not less than 8ft from a vertical wall or similar building feature shall terminate per

Figure11 and Table7 using the roof pitch to find the minimum termination height value of H. Terminations for Gas vents with listed

12in or less diameter size located less than 8ft from a vertical wall or similar building feature shall terminate not less than 2ft above

the highest point where they pass through the roof and not less than 2ft above any portion of a building within 10ft horizontally

Figure11: Minimum Height from Roof

for Vent Cap

16 USE ONLY GENUINE REPLACEMENT PARTS

51300004201B

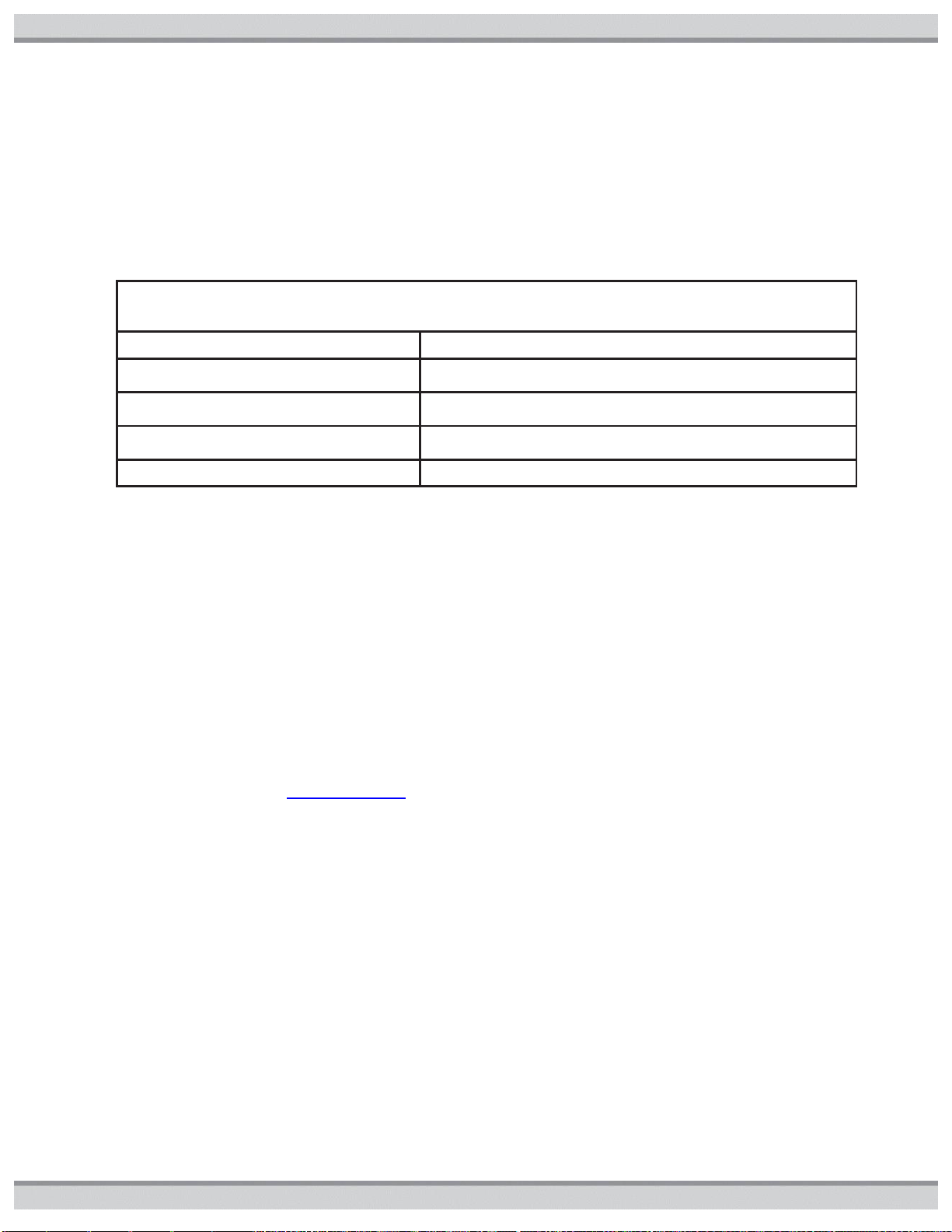

Table8 Positive-Pressure (CATIII) Indoor Vent Maximum Vent Lengths

Using Specified Positive Pressure Indoor Vent Kits

Number of 90- degree Elbows

Maximum Vent Pipe Length horizontal & vertical (ft.)

0

50 1 50 2 40

3

30

M&G DuraVent Inc.

Selkirk Corporation

6 Jupiter Ln.

Heatfab Division

Colonie, NY 12205

OR

130 Industrial Blvd

(800) 835-4429

Turners Falls, MA 01376

www.duravent.com

(800) 772-0739

DuraVent FasNSeal (W2)

www.heatfab.com

Heatfab Saf-T Vent EZ

Seal (CI Plus)

POSITIVE PRESSURE (HORIZONTAL OR VERTICAL, CATIII) VENTING:

When installed according to the following instructions, heaters meet the criteria for category III venting.

VENT SIZING: Vent pipe diameter must match the vent pipe diameter on the heater (see Table9). The vent pipe must be single or

double-wall stainless steel sealed vent as listed in Table9. Double-wall vent must be used in non- conditioned spaces. The

maximum total length of vent pipe, and number of 90-degree elbows cannot exceed the limits specified in Table8.The venting

system must be installed in accordance with the vent manufacturer’s installation instructions and guidelines. The installer is urged to

visit the vent system manufacturer’s website (see below) and review the installation information found there.

VENT TERMINATION: The vent system must terminate with a vent terminal approved for this pool heater. Termination may be

either horizontal or vertical. See Table9a for approved vent terminals and 9b for termination locations.

OBTAINING VENT PIPE AND TERMINATIONS: A variety of vent components, including terminals, elbows, and straight lengths,

are available for use with this appliance. Approved parts are listed in Table9 and in the service parts section in the back of this

manual. If you need more specialized fittings, you may order them directly from the manufacturer, or one of their authorized

dealers. To locate an authorized dealer for venting parts, contact the appropriate manufacturer at:

Notes for Table9 Positive-Pressure (CATIII) Indoor Vent Kits with Vent Pipe & Terminal Specifications

* For Heatfab single-wall vent pipe section length, “x” to be: 1, 2, 4, 5, or 7, where 1=6 inches, 2=12 inches, 4=18 inches, 5=24 inches, and

7=36 inches.

** For Heatfab double-wall vent pipe section length, “x” to be: 06, 09, 12, 18, 24, or 36, indicating the length of the vent pipe section in

inches.

† For DuraVent vent pipe section length, “x” to be: 6, 12, 18, 24, or 36, indicating the length of the vent pipe section in inches.

‡ For these horizontal terminals, the wall penetration is included from the vent manufacturer. On all others, it must be ordered separately.

USE ONLY GENUINE REPLACEMENT PARTS 17

51300004201B

Table9 Positive-Pressure (CATIII) Indoor Vent Kits with Vent Pipe & Terminal Specifications

Heater

Model

Indoor Vent Kit

Part Number

Maximum

Installation

Altitude (ft.)

Vent

Pipe

Dia.

(in)

Appliance

Adapter

Vent Pipe

Type

Heatfab Saf-T Vent EZ Seal (CI Plus) or

DuraVent FasNSeal (W2)

Vent Pipe

Part

Number

Horizontal

Vent Terminal

Part Number

Vertical Vent

Terminal

Part Number

150

200

UHXPOSHZ11506

UHXPOSHZ12006

10,100

6

Heatfab adapter

included in kit

Single-Wall

HeatfabP/N

960x *

HeatfabP/N

9614TERM

HeatfabP/N

5600CI

Double-Wall

HeatfabP/N

CCA06Lx **

HeatfabP/N

9614TERM

HeatfabP/N

CCA06RC

250

UHXPOSHZ12506

10,100

6

Heatfab adapter

included in kit

Single-Wall

HeatfabP/N

960x *

HeatfabP/N

5690CI ‡

HeatfabP/N

5600CI

Double-Wall

HeatfabP/N

CCA06Lx **

HeatfabP/N

CCE06WP ‡

HeatfabP/N

CCA06RC

250FDN

(NAT

ONLY)

UHXPOSHZ12504

2,000

4

UHXDVA004

(4” Duravent

adapter)

Single-Wall

DuraVentP/N

FSVLx04 †

DuraVentP/N

FSTT4

DuraVentP/N

FSRC4

Double-Wall

DuraVentP/N

W2-x04 †

DuraVentP/N

FSTT4

DuraVentP/N

W2-RC4

UHXHFA004

(4” Heatfab

adapter)

Single-Wall

HeatfabP/N

940x *

HeatfabP/N

9414TERM

HeatfabP/N

5400CI

Double-Wall

HeatfabP/N

CCA04Lx **

HeatfabP/N

9414TERM

HeatfabP/N

CCA04RC

300

350

400

UHXPOSHZ13008

UHXPOSHZ13508

UHXPOSHZ14008

10,100

8

Heatfab adapter

included in kit

Single-Wall

HeatfabP/N

980x *

HeatfabP/N

5890CI ‡

HeatfabP/N

5800CI

Double-Wall

HeatfabP/N

CCA08Lx **

HeatfabP/N

CCE08WP ‡

HeatfabP/N

CCA08RC

400

UHXPOSHZ14006

2,000

6

UHXDVA006

(6” Duravent

adapter)

Single-Wall

DuraVentP/N

FSVLx06 †

DuraVentP/N

FSTT6

DuraVentP/N

FSRC6

Double-Wall

DuraVentP/N

W2-x06 †

DuraVentP/N

FSTT6

DuraVentP/N

W2-RC6

UHXHFA006

(6” Heatfab

adapter)

Single-Wall

HeatfabP/N

960x *

HeatfabP/N

9614TERM

HeatfabP/N

5600CI

Double-Wall

HeatfabP/N

CCA06Lx **

HeatfabP/N

9614TERM

HeatfabP/N

CCA06RC

500

UHXPOSHZ15006

10,100

6

UHXDVA006

(6” Duravent

adapter)

Single-Wall

DuraVentP/N

FSVLx06 †

DuraVentP/N

FSTT6

DuraVentP/N

FSRC6

Double-Wall

DuraVentP/N

W2-x06 †

DuraVentP/N

FSTT6

DuraVentP/N

W2-RC6

UHXHFA006

(6” Heatfab

adapter)

Single-Wall

HeatfabP/N

960x *

HeatfabP/N

9614TERM

HeatfabP/N

5600CI

Double-Wall

HeatfabP/N

CCA06Lx **

HeatfabP/N

9614TERM

HeatfabP/N

CCA06RC

18 USE ONLY GENUINE REPLACEMENT PARTS

Loading...

Loading...