Hayward hydrorite uvo3 Owner's Manual

HydroRite UVO3

2” Residential UV/Ozone Sanitizing System

Owner’s Manual

092596 RevA

Contents

Safety Instructions..........1

Before you Begin.............2

Installation.....................3

Operation.......................7

Maintenance...................7

FAQs.............................10

Troubleshooting............11

Replacement Parts.........12

Warranty.......................14

Model: HYD-UVO

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Hayward Pool Products

620 Division Street, Elizabeth NJ 07207

Phone (908)-355-7995

www.hayward.com

IMPORTANT SAFETY INSTRUCTIONS

When installing and using this electrical equipment, basic safety precautions should

always be followed, including the following:

READ AND FOLLOW ALL INSTRUCTIONS

This product should be installed by a professional service technician or similar person who is qualied in electrical

equipment installation. Improper installation and/or operation could cause serious personal injury, property damage or

death. Improper installation and/or operation will void the warranty.

• The device must be connected only to a supply circuit that is protected by a Ground Fault Circuit Interrupter

(GFCI). FAILURE TO CONNECT THIS DEVICE TO A GFCI SUPPLY CIRCUIT COULD RESULT IN ELECTRICAL

SHOCK CAUSING SERIOUS BODILY INJURY, INCLUDING DEATH.

• WARNING - Disconnect all AC power during installation.

• CAUTION - To prevent possible re or electrical shock, use only replacement lamp specied by the manufacturer.

• A bonding lug is provided on the external surface. To reduce the risk of electric shock, connect the local common

bonding grid in the area of the swimming pool, spa, or hot tub to these terminals with an insulated or bare copper

conductor not smaller than 8 AWG US / 6 AWG Canada.

• Replace damaged cords immediately.

• Lamps and quartz sleeves are made of glass and are extremely delicate. Care should be taken when handling or

replacing these components. Wear cotton gloves when handling lamps or sleeves. Hold bulbs by the ends only.

Never touch the glass with bare hands. Wipe any ngerprints from lamps and sleeves with alcohol.

• CAUTION - this device is for swimming pool use only. Do not use this device for potable (drinking) water sanitiza-

tion.

• DANGER - ULTRAVIOLET RADIATION. Disconnect Power Before Replacing Lamp .

• This device contains an ultraviolet lamp that can cause discomfort, irritation and damage to the eyes if viewing oc-

curs while device is in operation. Prolonged exposure to the eyes can cause serious injury to the eyes, including

blindness. DO NOT VIEW UV LAMP WHILE THE DEVICE IS IN OPERATION.

• SAVE THESE INSTRUCTIONS

1

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Before you Begin

The Hayward HydroRiteTM HYD-UVO is designed for use in residential swimming pools and spas; it must not be used in potable (drinking) water installations. Use

of this product in applications other than swimming pools and spas will void your warranty and could be harmful to your health or the health of others.

How the Hayward HydroRite Works

The Hayward HydroRite contains a high intensity electrically operated Ultraviolet (UV) lamp which is located inside the unit’s wet chamber. The UV lamp emits

light at two separate wavelengths within the UV spectrum; 254 nm and 185 nm. The 254 nm wavelength is called the “germicidal” wavelength. This wavelength

is capable of inactivating a wide array of microorganisms such as bacteria, viruses, protozoa (e.g. Cryptosporidium and Giardia), algae spores and other single

vesseled waterborne microbes. The 254 nm UV light alters the DNA and RNA of the microorganisms rendering them incapable of infection. The 185 nm wavelength, on the other hand, is called the “ozone generating” wavelength and is responsible for converting oxygen contained in the quartz sleeve area, into ozone.

The ozone so created is introduced into the water stream using a venturi. Ozone, a strong oxidizer and bactericide, works together with the UV to oxidize bather

waste and inactivate microorganisms utilizing a process known as “advanced-oxidation”.

When the HydroRite is creating Ozone, bubbles will appear within the HydroRite vessel and may also be seen at the return jets in the pool. At flow rates below

35 gpm, Ozone creation will stop and the bubbles will disappear. Although low flow rates will prevent the creation of ozone, the longer exposure time to UV

light within the vessel will increase the efficiency and efficacy of the UV sanitization process. Consider these factors when setting run times and pump speeds.

Specifications

HYD-UVO

Plumbing diameter: 2 inch

Input Power: 120VAC, 60Hz

Power Consumption: 0.8A

Maximum Operating Pressure: 50 psi

Operating Flow Range: 10-75 gpm

Minimum Flow Rate of Venturi (necessary for the creation of ozone): 35gpm

Maximum Flow Rate: 75 gpm

Number of bulbs: 1

Volume of Vessel: 0.75 gallon

Sizing

The HydroRite HYD-UVO is capable of sanitizing residential pools up to 60,000 gallons. For larger installations, more than one HydroRite can be used. When

using multiple HydroRites, plumb vessels in parallel.

WARNING: Determine that the flow rate of your pool does not exceed the maximum specified.

What’s Included

The HydroRite system contains the following components:

• HydroRite Controller

• Vessel

• 2” Venturi Manifold

• Venturi Hose Kit with check valves and fittings

• Ozone Producing UV Lamp

• Gloves for handling the UV Lamp

• 2” Flow Switch

• 2” 3-Way Valve

• Valve Actuator

Tools Needed

• Saw or PVC pipe cutter

• PVC glue

• 6 mounting screws/bolts for fastening HydroRite controller to mounting surface

• 4 mounting screws/bolts for fastening HydroRite vessel to mounting surface

• Screwdriver/Nutdriver for mounting fasteners

• Philips head screwdriver for vessel cap

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

2

POOL

3ft

venturi

tube

NOTE: Leave at least 12

inches of straight path

before (upstream) the flow

switch.

Cell

Vessel

FROM

POOL

TO

POOL

Filter

Heater

GFCI

Outlet

15 ft

ballast

cable

interlock

cable

flow

switch

cable

6 ft

9 ft

9 ft

120

VAC

Check

Valve

Bypass

NOTE: A check valve is not

necessary for salt chlorination

systems but must be installed

when using chlorine erosion

feeders. Chlorination must take

place “downstream of the Cell

Vessel.

Inlet

3-Way

Valve

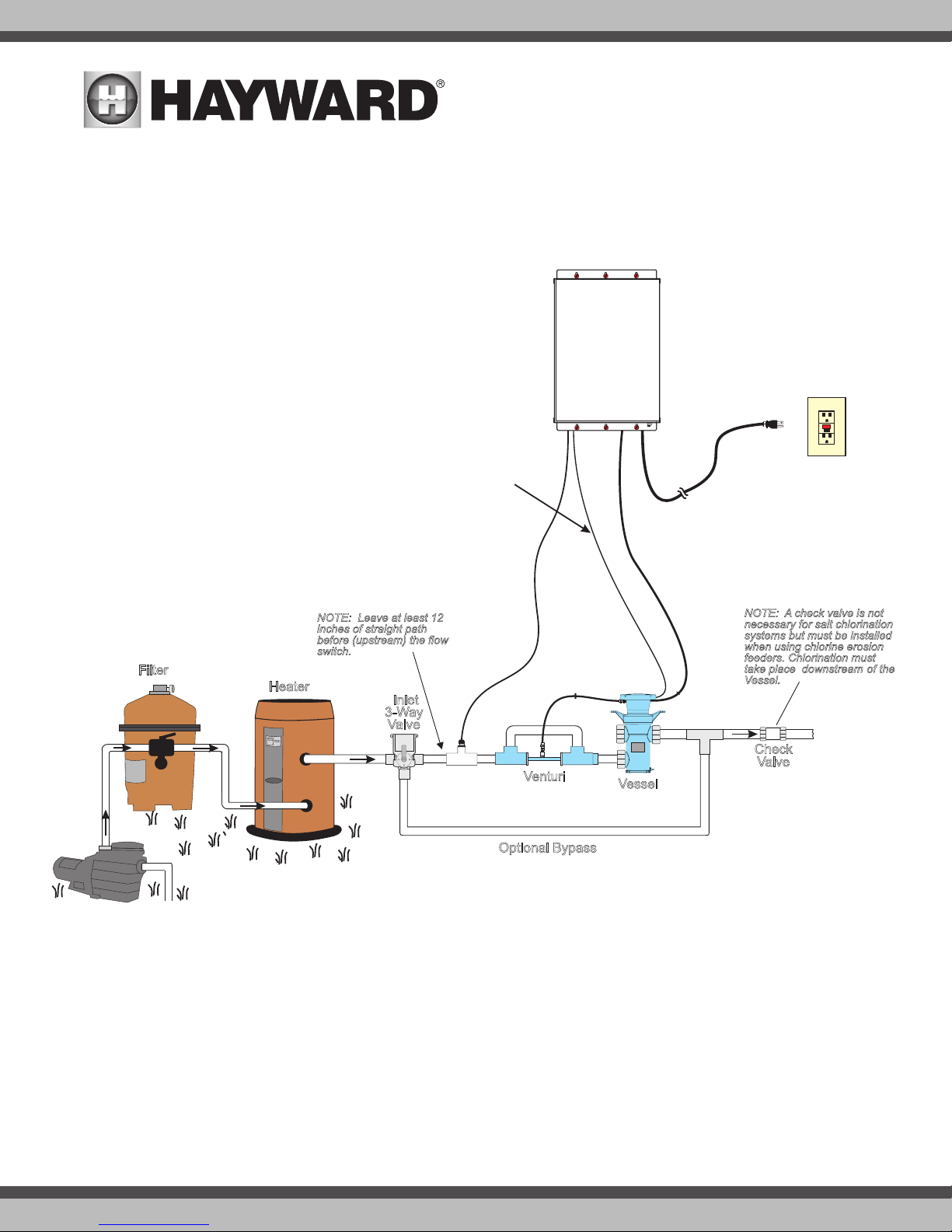

Installation

Before starting your installation, you MUST read this manual in its entirety in order to install your unit in a safe manner. Note that a few moments spent becoming

familiar with the HydroRite unit and its installation may save a great deal of time (and expense) later. If you have any questions that are unanswered when you

have completed the reading of this manual, contact your supplier or Hayward.

Overview

Filter

NOTE: In-line Chemical feeders and chlorinators should be

plumbed AFTER the HydroRite

system

Heater

Inlet

3-Way

Valve

interlock

cable

9ft

15 ft

flow

switch

cable

Venturi

Vessel

9ft

ballast

cable

6ft

NOTE: A check valve is not

necessary for salt chlorination

systems but must be installed

when using chlorine erosion

feeders. Chlorination must

take place downstream of the

Vessel.

Check

Valve

GFCI

Outlet

120

VAC

TO

POOL

Filter

Pump

FROM

Optional Bypass

Determine a suitable location

Installation of HydroRite system requires mounting the controller and vessel, plumbing the vessel, venturi and flow switch (on the return side of the filter pump),

and finally, connecting the required cables. Remove power to the pool filter pump before starting this installation. Installation must be performed in accordance

with local and NEC code.

The HydroRite vessel must be mounted at least 10 ft. from the pool. The controller must be mounted a minimum of 6 ft. horizontal distance (or more, if local

codes require) from the pool and has a 6 ft. power cord that must be connected to a GFCI protected circuit. Refer to the diagram above for lengths of other cords

and the venturi tube. Note that the vessel and flow switch will be plumbed into the return plumbing after the heater and all other equipment with the exception

of chemical feeders and chlorination systems.

3

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Cell

Vessel

FROM

POOL

Filter

Heater

Filter

Pump

15 ft

ballast

cable

interlock

cable

flow

switch

cable

6 ft

9 ft

9 ft

Check

Valve

Bypass

NOTE: A check valve is not

necessary for salt chlorination

systems but must be installed

when using chlorine erosion

feeders. Chlorination must take

place “downstream of the Cell

Vessel.

Inlet

3-Way

Valve

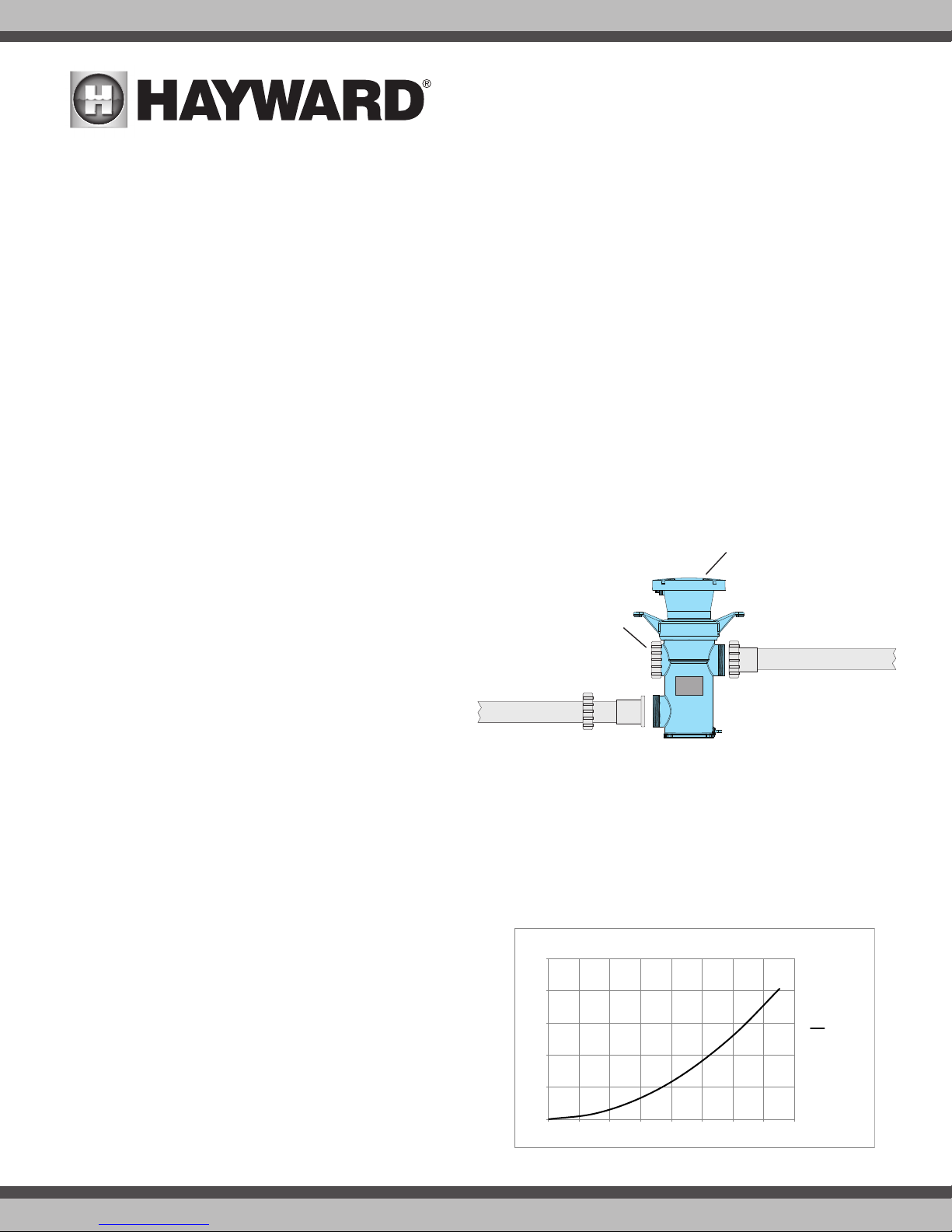

Mounting the Controller

0

5

10

15

20

25

0 10 20 30 40 50 60 70 80

Head Loss (Feet of Water)

Flow Rate (GPM)

HydroRite Head Loss

HYR2CSUV-O3

Inlet Pipe

Union

Tail

Union

Nut

Do not

remove

Outlet Pipe

Vessel

Cap

The controller is designed to mount vertically on a flat surface with the cables facing downward. Because the enclosure also acts as a heat sink (disperses heat

from inside the box), it is important not to block the four sides of the controller. Do not mount the controller inside a panel or tightly enclosed area. If the supply

or a lamp cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons in order to avoid a hazard.

After ensuring that the controller’s cables can reach their destinations, mount the controller to the intended surface using proper mounting hardware given the

size and weight of the unit. The controller’s mounting brackets require a total of 6 mounting bolts to fasten the controller to the mounting surface.

Plumbing the HydroRite System

Although not required, Hayward recommends that the HydroRite system be plumbed in a dedicated loop that can be bypassed as shown on page 3. A three-way

valve and actuator are supplied for this purpose. If plumbing a bypass, a tee fitting will be required. A bypass will aid in servicing and maintaining the HydroRite.

Note that the increased head of the HydroRite system may affect the performance of water features installed in the pool’s system. A bypass will allow you to

divert water directly to water features although be aware that the HydroRite will not sanitize under these circumstances.

Installation of 3-way valves on BOTH the inlet and outlet lines attached to the vessel plumbing is mandatory if an automatic vessel cleaner is used, or if the

vessel and associated plumbing is located below the waterline. Failure to use valves where any portion of the device is below the waterline will not allow the

device to be properly drained which could lead to cracking of the unit if any retained water freezes.

Securing the Vessel

When the vessel installation location has been determined, it should be secured to a concrete or wood base. Four mounting holes are located in the mounting

base of the unit that accommodates ¼ inch diameter bolts to mount the HydroRite unit in place. FAILURE TO PROPERLY SECURE THE UNIT MAY CAUSE NOISE

DUE TO VIBRATION CAUSED BY WATER PASSING THROUGH THE WET CHAMBER. Secure the vessel using bolts and anchors (not supplied) where necessary

and appropriate for your installation.

Plumbing the Vessel

The HydroRite vessel comes with union nuts and tails pre-assembled on

the housing. Remove the Inlet and Outlet nuts and note the orientation of

the orange gaskets when removing union tails. These will need to be put

back together after gluing the union tails to the pool piping.

After cutting pipe to length, slide one union nut onto the cut pipe and

glue the gray tail piece to the pipe end. Repeat for the other pipe. Thread

the union nuts onto the vessel and handtighten both unions. DO NOT

OVERTIGHTEN. OVERTIGHTENING WILL BREAK THE UNION NUTS. To avoid

stress on the connections at the vessel, piping should be supported and

should not rest solely upon the unions.

Plumbing the Flow Switch

The flow switch is a safety device that ensures that the HydroRite is only operating when there is water passing through the vessel. The flow switch must be

plumbed in the same section of plumbing as the vessel. Failure to properly install the flow switch can result in damage to the pool’s equipment.

IMPORTANT: There must be at least a 12” (30cm) straight pipe run before (upstream) the flow switch.

IMPORTANT: To ensure proper operation, verify that the arrow on the flow switch points in the direction of water flow.

Head Loss

Refer to the adjacent table below for Head Loss information.

Venturi

The venturi assembly is pre-assembled and ready to be plumbed. A 3 ft

hose connection is made from the venturi to the ozone manifold at the vessel

as shown in the diagram on page 3. More information about the venturi tube

and connection can be found on page 5.

Chlorination Systems

Care must be taken to prevent exposure of the vessel to high concentrations of chlorine. All in-line chlorine systems must be installed AFTER (downstream) the vessel.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

HYD-UVO

4

Loading...

Loading...