Hayward HRCK2A, HRCK2B, HRCK2R, HRSN3A, HRCK2S Installation, Operation And Maintenance Instructions

...

INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

LCS Products Supplement

to HRSN2 through HRSN6 Series

Low Voltage and Single Phase Products

TO PREVENT POTENTIAL INJURY OR DAMAGE TO PROPERTY, READ THIS MANUAL CAREFULLY AND COMPLETELY.

Back to TOC

Hayward Flow Control

1-888-HAY-INDL (1-888-429-4635)

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

www.haywardowcontrol.com

HRSLCSSPLMNTIOM Rev A

Page 1 of 42

IMPORTANT SAFETY INSTRUCTIONS

Basic safety precautions should always be followed, including the following: Failure to follow instructions

can cause severe injury and/or death.

This is the safety-alert symbol. When you see this symbol on your equipment or in this manual, look

for one of the following signal words and be alert to the potential for personal injury.

WARNING warns about hazards that could cause serious personal injury, death or major property

damage and if ignored presents a potential hazard.

CAUTION warns about hazards that will or can cause minor or moderate personal injury and/or

property damage and if ignored presents a potential hazard. It can also make consumers aware of

actions that are unpredictable and unsafe.

Notice:

A notice indicates special instructions that are important but not related to hazards.

WARNING - Read and follow all instructions in this IOM manual and on the equipment. Failure

to follow instructions can cause severe injury and/or death.

WARNING – Risk of Electric Shock. All electrical wiring MUST be in conformance with applicable

local codes, regulations, and the National Electric Code (NEC). Hazardous voltage can shock, burn,

and cause death or serious property damage. To reduce the risk of electric shock, do NOT use an

extension cord to connect unit to electric supply. Provide a properly located electrical receptacle.

Before working on any electrical equipment, turn off power supply to the equipment.

WARNING – To reduce the risk of electric shock replace damaged wiring immediately.

WARNING – Ground all electrical equipment before connecting to electrical power supply.

Failure to ground all electrical equipment can cause serious or fatal electrical shock hazard.

WARNING – Do NOT ground to a gas supply line.

WARNING – To avoid dangerous or fatal electrical shock, turn OFF power to all electrical

equipment before working on electrical connections.

WARNING – Failure to bond all electrical equipment to system structure will increase risk for

electrocution and could result in injury or death. To reduce the risk of electric shock, see installation

instructions and consult a professional electrician on how to bond all electrical equipment. Also,

contact a licensed electrician for information on local electrical codes for bonding requirements.

CAUTION – Potential pinch point. Equipment connected to or driven by this device may start

unexpectedly and may cause personal injury or entrapment in linkage systems.

Back to TOC

Hayward Flow Control

1-888-HAY-INDL (1-888-429-4635)

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

www.haywardowcontrol.com

HRSLCSSPLMNTIOM Rev A

Page 2 of 42

TABLE OF CONTENTS

HR2~6 LVHV LCS Series

Important Safety Instructions .....................2

Table of Contents ...............................3

LCS Supplement to HRS Series Actuators ..........4

Conventions Used in this Manual ..................5

Theory of Operation .............................6

HRCK, HRCP On/Off Control ..................6

HRCK, HRCP Proportional Control .............. 7

HRCL, HRCD On/Off Control ..................8

HRCL, HRCD Proportional Control ..............9

CK Series LCS Operation .......................10

CP Series LCS Operation .......................11

CL Series LCS Operation .......................12

CD Series LCS Operation .......................13

LCS Calibration and Commissioning ..............14

HRCK On/Off Control .......................14

HRCK Proportional Control ................... 16

HRCP On/Off Control .......................18

HRCP Proportional Control ................... 20

HRCL On/Off Control .......................22

HRCL Proportional Control ................... 24

HRCD On/Off Control .......................26

HRCD Proportional Control ...................28

Notes ....................................31

Mechanical Data ..............................32

HRCK2A~2S Exploded View ..................32

HRCK2A~2S Dimensional Data ..............33

HRCK, HRCP 3A~4F Exploded View ...........34

HRCK, HRCP 3A~4F Dimensional Data ........35

HRCK, HRCP 5A~6A Exploded View ...........36

HRCK, HRCP 5A~6A Dimensional Data ........37

HRCL, HRCD 3A~4F Exploded View ...........38

HRCL, HRCD 3A~4F Dimensional Data ........39

HRCL, HRCD 5A~6A Exploded View ...........40

HRCL, HRCD 5A~6A Dimensional Data ........41

Notice: HRCK, HRCP, HRCL & HRCD Series actuators are fully assembled, calibrated and tested prior to

leaving our factory. In most cases, after you have mounted the actuator to your device, you should be able to

operate the actuator from fully CLOSED (CW) to fully OPEN (CCW) and back again, and nd that no adjustments

are needed. The assembly can be put into service immediately.

If, however, it should be necessary to make adjustments to the end-of-travel positions to overcome any device

related issues (i.e. valve shaft incorrectly timed to the drive stem), the procedures outlined in the Installation,

Operation and Maintenance Instructions (IOM) for each unit should be followed to put the assembly into

service. Note that there is a maximum adjustment range of +/- 3° at each end of travel.

CAUTION – For any 3 Phase products (i.e. HRCK4AR8), refer to the IOM for the respective 3 Phase unit.

These instructions are specic to low voltage and single phase products only.

Back to TOC

Hayward Flow Control

1-888-HAY-INDL (1-888-429-4635)

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

www.haywardowcontrol.com

HRSLCSSPLMNTIOM Rev A

Page 3 of 42

LCS SUPPLEMENT TO HRS SERIES ACTUATORS

Local Control Stations (LCS) provide a means to select Local or Remote control of a valve or damper actuator.

There are four different types of LCS offered on the HRS series actuators. Each of these four types provide unique

capabilities and human-machine interface.

This supplemental Guide is to be utilized in conjunction with the

actuator IOM. This document differs from the actuator IOM.

This guide will provide necessary wiring diagrams which will differ

from those provided in the actuator IOM itself. You MUST utilize the

wiring diagrams provided in this supplement.

Dimensional Data will differ from that provided in the actuator IOM.

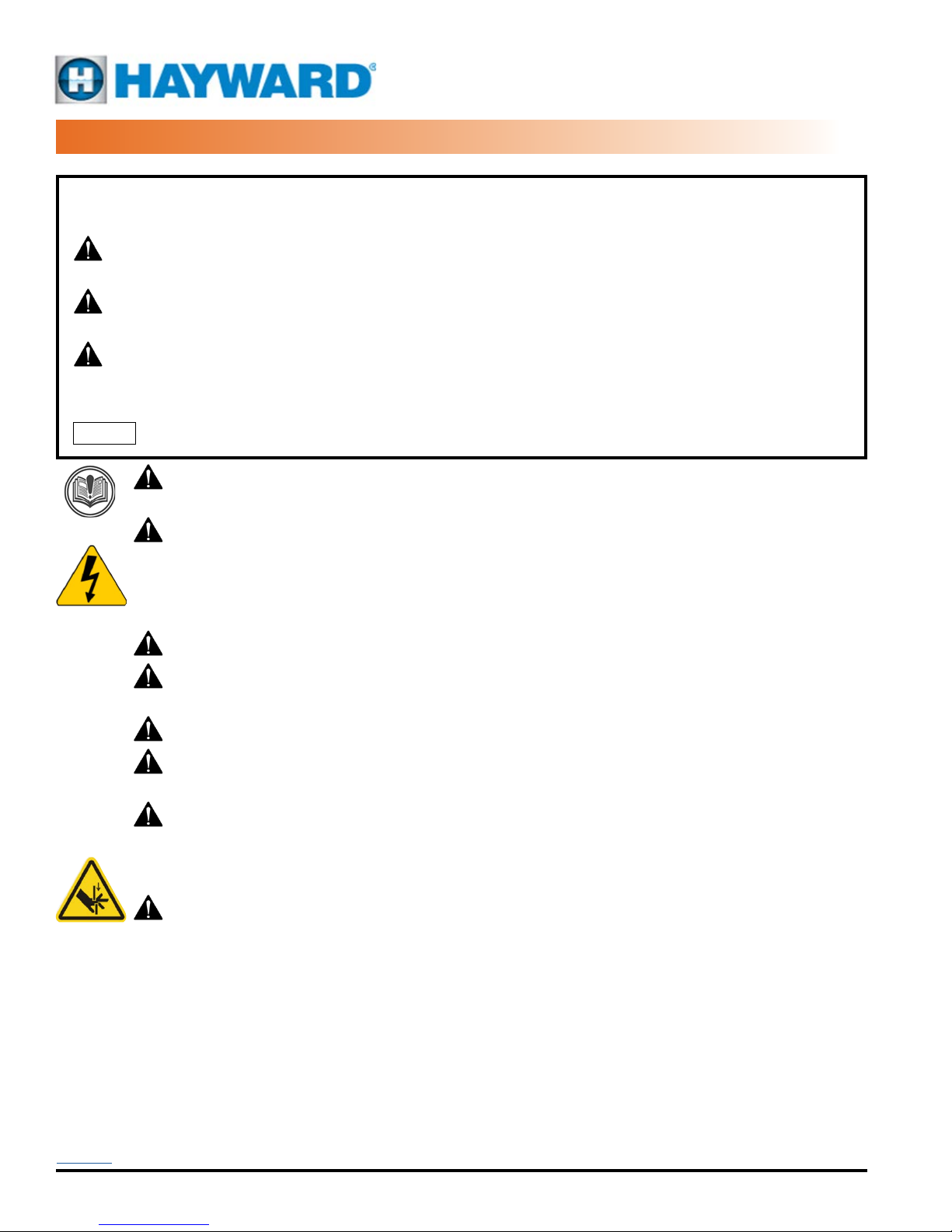

Type CK – Key/Knob type. This is an IP65 type round enclosure that is integral to

the actuator housing. It employs a key switch for the Mode select, a knob switch

for Move commands, and three LED indicators indicating Power, Open and Closed

positions. This version is available on HRSN2 thru HRSN6 Series 24v, 120v & 230v On/

Off actuators.

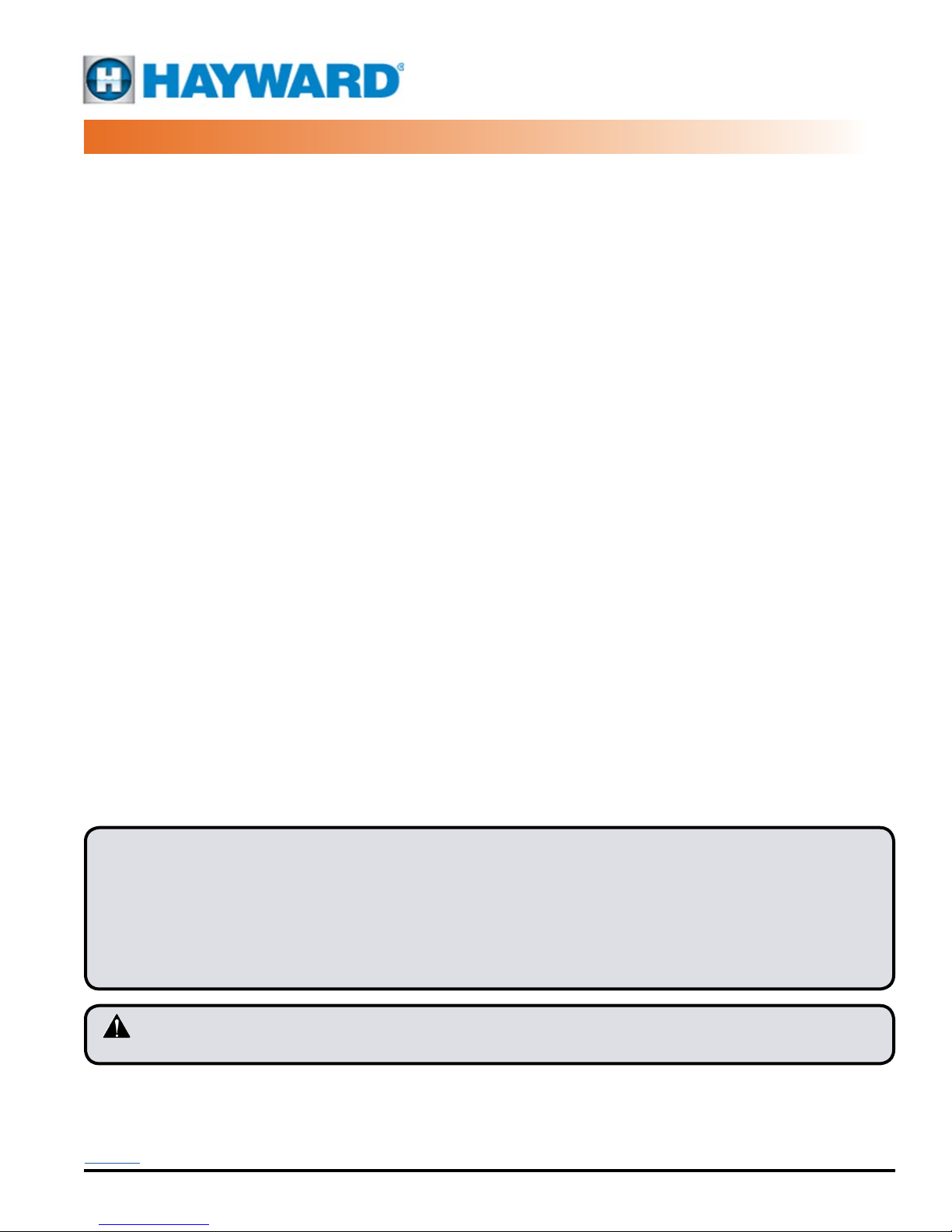

Type CP – Push Button type. This is an IP67 type round enclosure that is integral to

the actuator housing. This model utilizes push buttons (press-press) to select Remote/

Local Mode, Open/Stop/Close Mode, and LED indicators to show Power, Running

Open and Fully Open, Running Closed and Fully Closed positions. This version is

available on HRSN3 thru HRSN6 Series 24v, 120v & 230v On/Off and Proportional

Control actuators.

Type CK

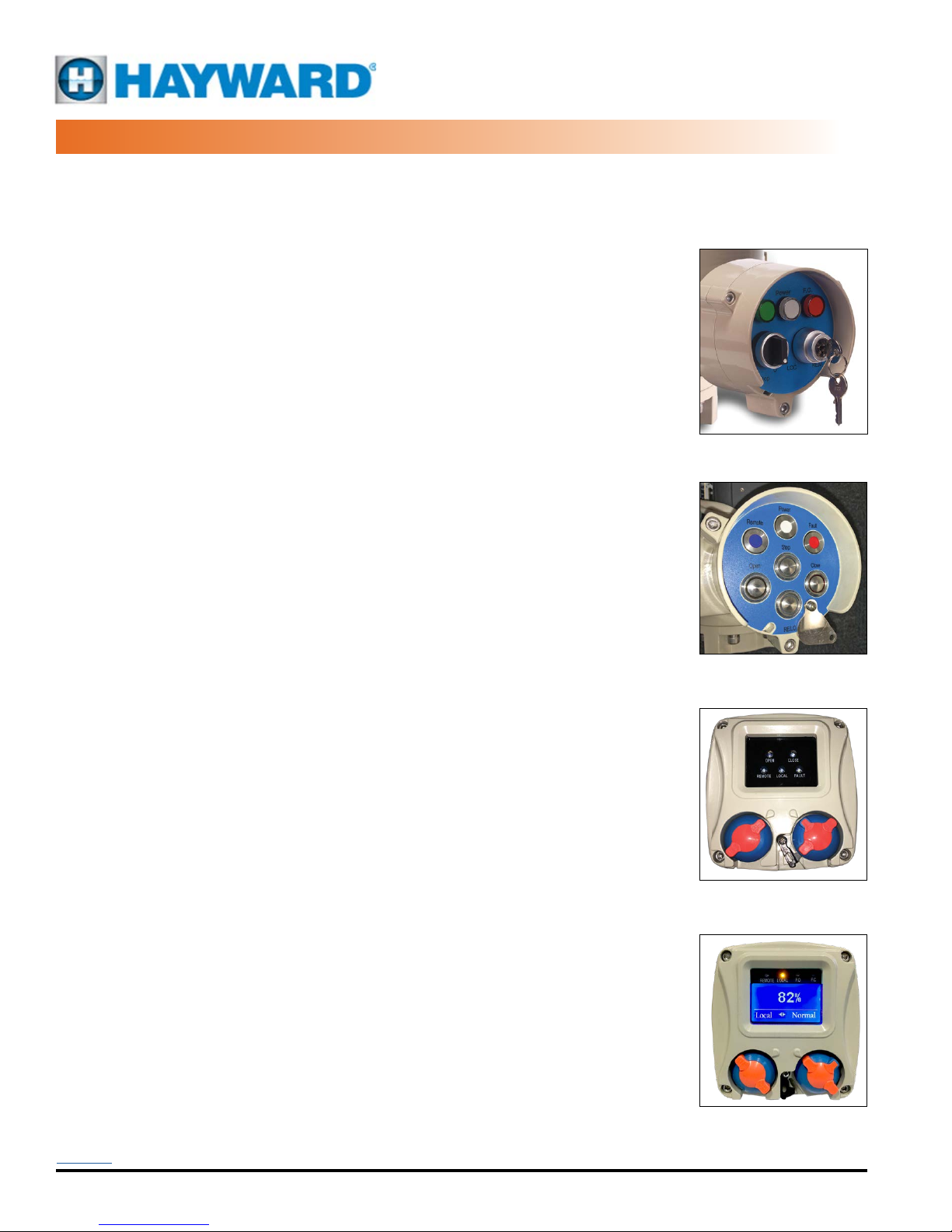

Type CL – LED type. This is an IP67 rectangular enclosure integral with the actuator

housing. This model has non-intrusive magnetic type knob switches for Mode and

Position control. This version also employs an LED panel mounted behind glass with

indicators for Open, Close, Remote, Local and Fault. This version is available on HRSN3

thru HRSN6 Series 24v, 120v & 230v On/Off and Proportional Control actuators.

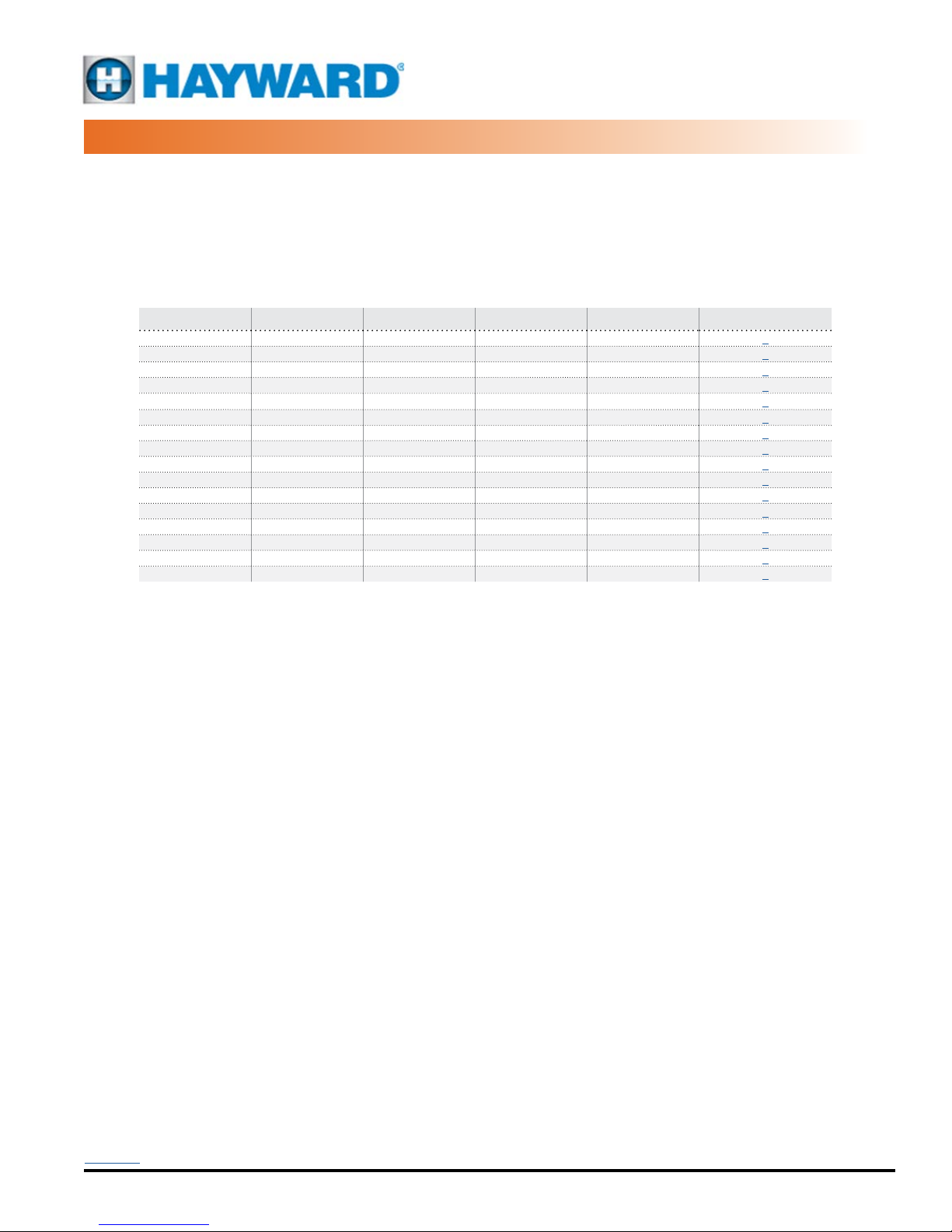

Type CD – LCD type. This is an IP67 rectangular enclosure integral with the actuator

housing. This model has non-intrusive magnetic type knob switches for Mode and

Position control. This version utilizes a monochrome (blue) LCD panel that provides

graphic information regarding the status of the actuator. Its main feature is a large

% display in the center of the screen which shows the position of the actuator as a

function of % of full OPEN. The numeric display ashes when the actuator is moving.

There are UP and DN arrows showing direction of travel.

The lower line of text in the display shows mode of operation, normal status, fault

status, and torque switch trips in their respective directions. There are also LED

indicators above the screen that show Local, Remote, Open and Closed functions.

This version is available on HRSN3 thru HRSN6 Series 24v, 120v & 230v On/Off and

Proportional Control actuators

Type CP

Type CL

Back to TOC

Hayward Flow Control

1-888-HAY-INDL (1-888-429-4635)

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

www.haywardowcontrol.com

Type CD

HRSLCSSPLMNTIOM Rev A

Page 4 of 42

CONVENTIONS USED IN THIS MANUAL

Below are Terms and Denitions used throughout this manual.

1. XTS/TS product manufactured without/with Torque Switches.

2. LCS product manufactured with attached Local Control Station.

Depending on the options required you can efciently select the level of actuator and wiring diagram you require.

ACTUATOR OPTIONS

Control Voltage Actuator Range* Torque Switches** Local Control Wiring Diagram Page

On/Off 24VDC/VAC HRCK2A~6A XTS/TS LCS CK

On/Off 120/230VAC HRCK2A~6A XTS/TS LCS CK

On/Off 24VDC/VAC HRCP3A~6A XTS/TS LCS CP

On/Off 120/230VAC HRCP3A~6A XTS/TS LCS CP

Mod 24VDC/VAC HRCK2A~6A XTS/TS LCS CK

Mod 120/230VAC HRCK2A~6A XTS/TS LCS CK

Mod 24VDC/VAC HRCP3A~6A XTS/TS LCS CP

Mod 120/230VAC HRCP3A~6A XTS/TS LCS CP

On/Off 24VDC/VAC HRCL3A~6A XTS/TS LCS CL

On/Off 120/230VAC HRCL3A~6A XTS/TS LCS CL 8

On/Off 24VDC/VAC HRCD3A~6A XTS/TS LCS CD 8

On/Off 120/230VAC HRCD3A~6A XTS/TS LCS CD 8

Mod 24VDC/VAC HRCL3A~6A XTS/TS LCS CL 9

Mod 120/230VAC HRCL3A~6A XTS/TS LCS CL 9

Mod 24VDC/VAC HRCD3A~6A XTS/TS LCS CD 9

Mod 120/230VAC HRCD3A~6A XTS/TS LCS CD

6

6

6

6

7

7

7

7

8

9

* The only LCS available in the HRSN2A~2S range is the LCS CK.

** Some frame sizes are available only with TS (no XTS option).

Back to TOC

Hayward Flow Control

1-888-HAY-INDL (1-888-429-4635)

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

www.haywardowcontrol.com

HRSLCSSPLMNTIOM Rev A

Page 5 of 42

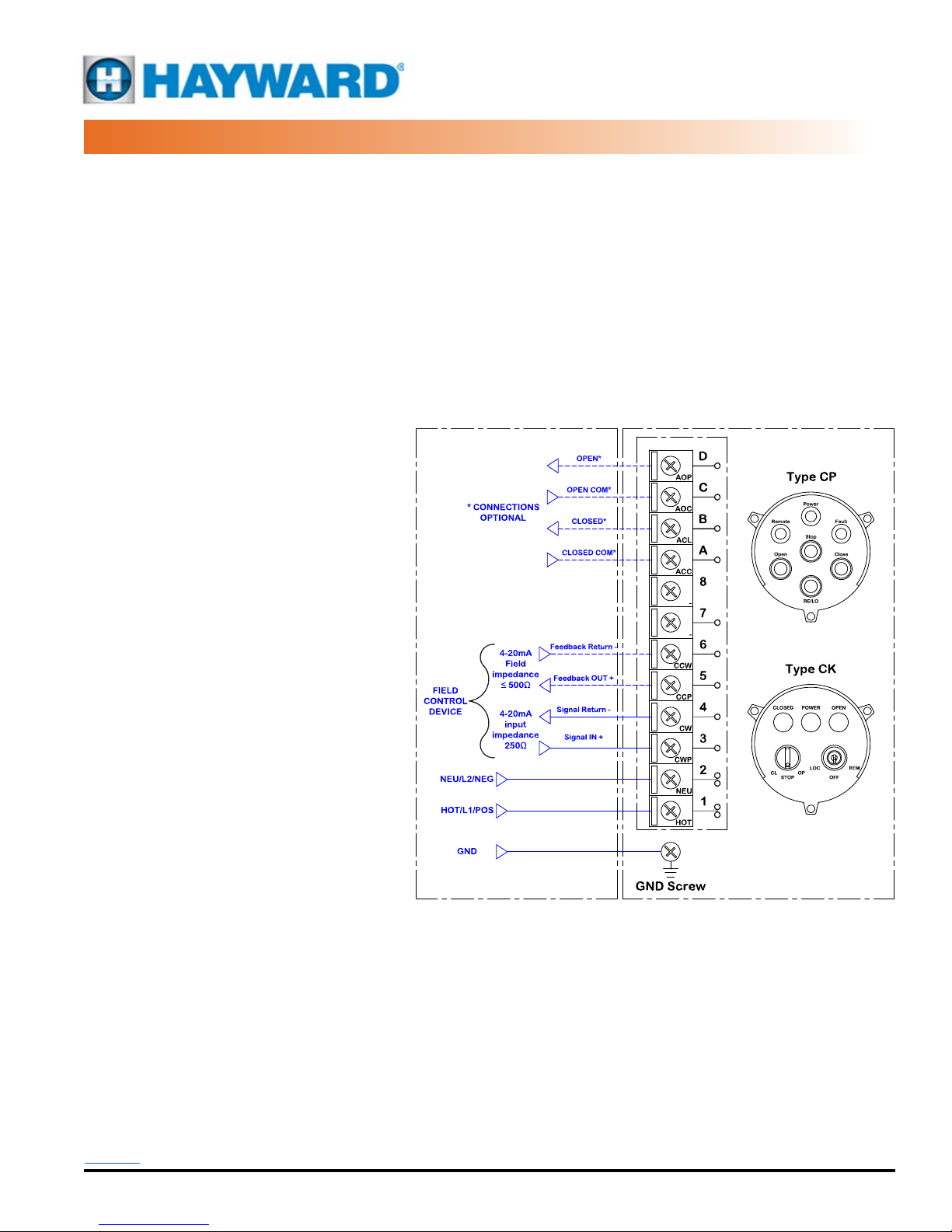

HRCK, HRCP 2A~6A

24V~230V On/Off Control

LCS, XTS/TS

THEORY OF OPERATION

HRCK and HRCP advanced stand-alone actuators are designed to be installed in new contruction sites or existing

sites where there are NO existing local control capabilities. These single phase and low voltage actuators have

several versions that continue to add more features and options than the standard actuator range.

Moreover, these units incorporate a Local Control Station (LCS) to facilitate operating the actuator. Having this

feature allows operation of the actuator WITHOUT having an existing PLC or BAS based analog controller while also

providing operability with existing external controls.

Inside the actuator/LCS package, you will nd:

1. Integral Local Control Device. This series is designed to operate in Local mode (control knobs or buttons located

on the face of the LCS, which is an integral part of the actuator) or in Remote mode, which utilizes commands from

a PLC, BAS or other volt-free contact (dry contact) automation device.

A. While in Remote mode, the Remote

devices must have volt-free contacts

(dry contacts) which will switch the

actuator’s internal 24vac power

supply to generate commands to

drive CW or CCW.

B. While in Local mode, the actuator

responds to the position of the

controls located on the face of the

integral LCS.

C. The Mode switch (CK Series) is operated

by a removable key which, when

removed, will prevent unauthorized

changes in the operating mode

(Local, Off or Remote).

D. The Mode button (CP Series) is

protected by a lockable cover

plate which, when locked, will

prevent unauthorized changes in

the operating mode (Local, Off or

Remote).

Apply no external power

Back to TOC

Hayward Flow Control

1-888-HAY-INDL (1-888-429-4635)

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

www.haywardowcontrol.com

WD75TS

HRSLCSSPLMNTIOM Rev A

Page 6 of 42

HRCK, HRCP 3A~6A

24V~230V Proportional Control

LCS, TS

THEORY OF OPERATION

HRCK and HRCP advanced stand-alone actuators are designed to be installed in new contruction sites or existing

sites where there are NO existing local control capabilities. These single phase and low voltage actuators have

several versions that continue to add more features and options than the standard actuator range.

These units accept analog control signals (4-20mA or 2-10vdc) and process these incoming signals to position the

actuator as a function of the incoming signal. Additionally, these units generate an analog feedback signal proportional

to the position of the actuator and not directly related to the incoming signal. This feedback signal is designed to be

used by automation devices or displays external to the actuator.

Moreover, these units incorporate a Local Control Station (LCS) to facilitate operating the actuator locally. Having this

feature allows operation of the actuator WITHOUT having an existing PLC or BAS based analog controller while also

providing operability with existing external controls.

Inside the actuator/LCS package, you will nd:

1. Integral Local Control Device. This

series is designed to operate in Local

mode (control knobs located on the

face of the LCS which is an integral

part of the actuator) or in Remote

mode, which utilizes commands from

a PLC, BAS or other volt-free contact

(dry contact) automation device.

A. While in Local mode, the actuator

responds to the position of the

controls located on the face of the

integral LCS.

B. The Mode switch is operated by

a removable key which, when

removed, will prevent unauthorized

changes in the operating mode

(Local, Off or Remote).

2. Proportional Controller. When the unit is

in Remote Mode, this analog processing

Printed Circuit Board (PCB) accepts

4-20mA or 2-10vdc from the eld and

positions the actuator accordingly,

utilizing the internal reversing motor

starter. A 4-20mA or 2-10vdc feedback

signal is internally generated to provide

remote reading of the position of the

actuator.

Back to TOC

Hayward Flow Control

1-888-HAY-INDL (1-888-429-4635)

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

www.haywardowcontrol.com

WD76TS

HRSLCSSPLMNTIOM Rev A

Page 7 of 42

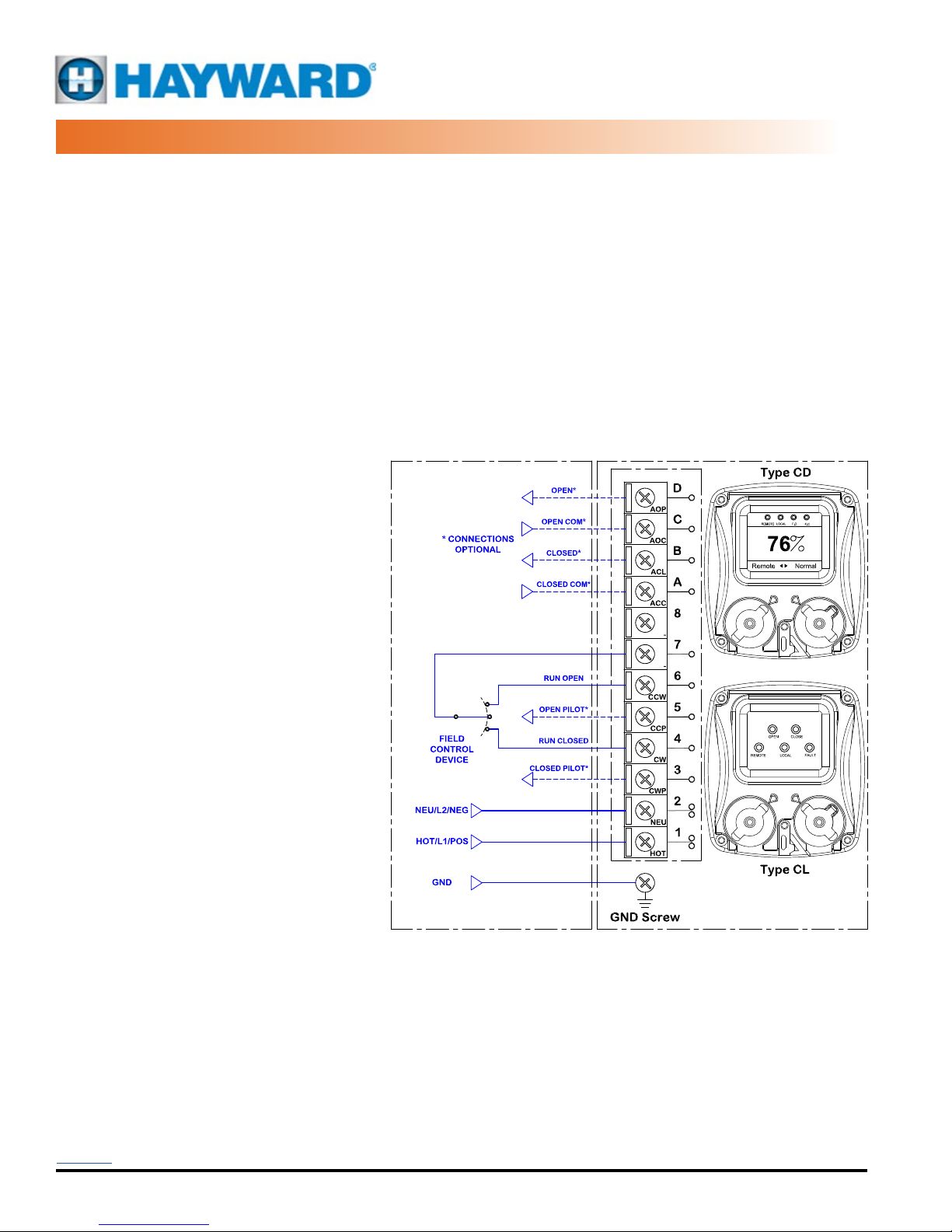

HRCL, HRCD 3A~6A

24V~230V On/Off Control

LCS, XTS/TS

THEORY OF OPERATION

HRCL and HRCD advanced stand-alone actuators are designed to be installed in new contruction sites or existing

sites where there are NO existing local control capabilities. These single phase and low voltage proportional control

actuators have several versions that continue to add more features and options than the standard actuator range.

These actuators generate a 24V control output that is connected to a remote PLC or BAS to control the actuator. This

24v output also serves as a status of the power connections and actuator operability. Any internal faults will disable

the 24v control output. Moreover, these units incorporate a Local Control Station (LCS) to facilitate operating the

actuator locally. Having this feature allows operation of the actuator WITHOUT having an existing PLC or BAS based

analog controller while also providing operability with existing external controls.

Inside the actuator/LCS package, you will nd:

1. Integral Local Control Device. This series is designed to operate in Local mode (control knobs located on the face

of the LCS which is an integral part of the actuator) or in Remote mode, which utilizes commands from a PLC, BAS

or other volt-free contact (dry contact) automation device.

A. While in Local mode, the actuator

responds to the position of the

controls located on the face of the

integral LCS.

B. The Mode switch (CL and CD

Series) employs a padlockable

lever that locks the Mode switch

in any of its three positions,

preventing unauthorized changes

in the operating mode (Local, Off or

Remote).

Apply no external power

Back to TOC

Hayward Flow Control

1-888-HAY-INDL (1-888-429-4635)

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

www.haywardowcontrol.com

WD135TS

WD165TS

HRSLCSSPLMNTIOM Rev A

Page 8 of 42

HRCL, HRCD 3A~6A

24V~230V Proportional Control

LCS, TS

THEORY OF OPERATION

HRCL and HRCD advanced stand-alone actuators are designed to be installed in new contruction sites or existing

sites where there are NO existing local control capabilities. These single phase and low voltage proportional control

actuators have several versions that continue to add more features and options than the standard actuator range.

These units accept analog control signals (4-20mA or 2-10vdc) and process these incoming signals to position the

actuator as a function of the incoming signal. Additionally, these units generate an analog feedback signal proportional

to the position of the actuator and not directly related to the incoming signal. This feedback signal is designed to be

used by automation devices or displays external to the actuator.

Moreover, these units incorporate a Local Control Station (LCS) to facilitate operating the actuator locally. Having this

feature allows operation of the actuator WITHOUT having an existing PLC or BAS based analog controller while also

providing operability with existing external controls.

Inside the actuator/LCS package, you will

nd:

1. Integral Local Control Device. This

series is designed to operate in Local

mode (control knobs located on the face

of the LCS which is an integral part of

the actuator) or in Remote mode, which

utilizes commands from a PLC, BAS

or other volt-free contact (dry contact)

automation device.

A. While in Local mode, the actuator

responds to the position of the

controls located on the face of the

integral LCS.

B. The Mode switch employs a

padlockable lever that locks the

Mode switch in any of its three

positions, preventing unauthorized

changes in the operating mode

(Local, Off or Remote).

2. Proportional Controller. When the unit is

in Remote Mode, this analog processing

Printed Circuit Board (PCB) accepts

4-20mA or 2-10vdc from the eld and

positions the actuator accordingly, utilizing

the internal reversing motor starter. A

4-20mA or 2-10vdc feedback signal is

internally generated to provide remote

reading of the position of the actuator.

Back to TOC

Hayward Flow Control

1-888-HAY-INDL (1-888-429-4635)

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

www.haywardowcontrol.com

WD136TS

WD166TS

HRSLCSSPLMNTIOM Rev A

Page 9 of 42

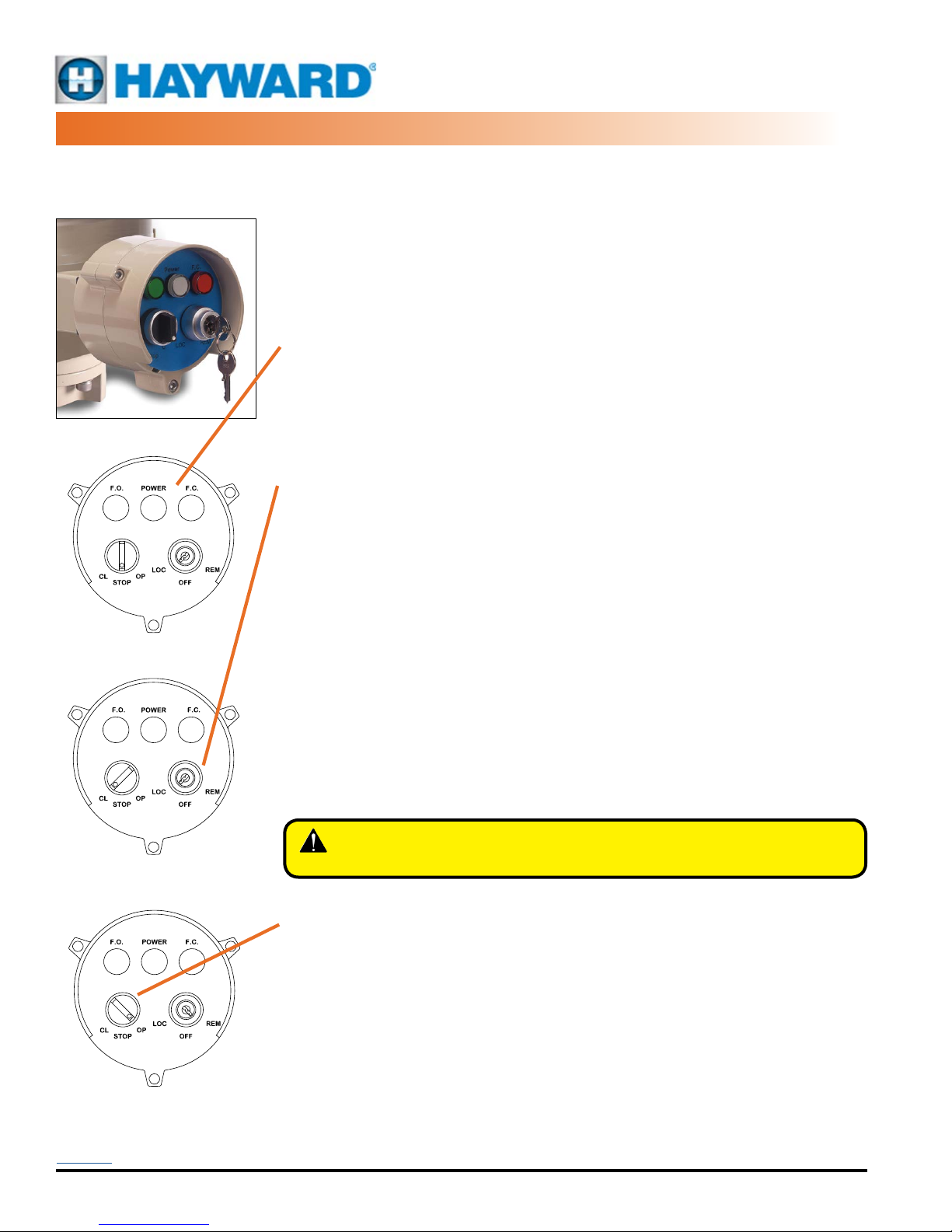

CK SERIES LCS OPERATION

ROUND LCS, KEYED

Operating the

Local Control Station

Panel Indicators

This round NEMA 4X/IP65 enclosure houses two rotary control knobs that provide the user with

the ability to operate the actuator in a normal (REMOTE) mode where the actuator responds

to control signals from a building automation system or a PLC or other control device (by

others). Or the user can elect to operate the actuator in LOCAL mode where one can control

the positioning of the actuator while standing AT the device. This allows opening and closing

the actuator (valve) to test for operation, perform maintenance or other function without relying

on radio communication to command the automation system to position the actuator.

A Key is provided for lockout and secured access to the MODE control switch of the

actuator. With the key removed (from any of the three positions), the MODE switch cannot

be changed.

The Position Indicators (top).

POWER (POWER indicator, all actuators): The Power LED is illuminated whenever power is

present at the unit, regardless of MODE position.

The panel also contains two colored LED indicators to provide visual indication of the position

and status of the actuator. The green Fully Open LED corresponds to the OPEN actuator

position. The red Fully Closed LED corresponds to the CLOSED actuator position. Both remain

steady ON when their respective end of travel is reached.

The MODE switch (right hand side) has three positions.

• REM (REMOTE, On/Off actuators): sets the actuator to respond to eld generated

control signals. In this mode the POSITION KNOB has NO affect on the positioning

of the actuator. All actuator movement is controlled by the external signal device.

The manual handwheel may be used to reposition the actuator while in this mode;

however, if an active external signal is present, the actuator WILL reposition as a

function of that control signal. The indicators are active in this mode.

• REM (REMOTE, Proportional Control actuators): The actuator follows the incoming

4-20mA(2-10vdc) control signal, and generates a 4-20mA(2-10vdc) feedback signal

OUT which corresponds to the position of the actuator.

• LOC (LOCAL, On/Off actuators): sets the actuator to respond to the POSITION KNOB.

The indicators are active in this mode.

• LOC (LOCAL, Proportional Control actuators): The actuator responds to the function

of the POSITION knob AND generates a 4-20mA(2-10vdc) feedback signal OUT

which corresponds to the position of the actuator.

• OFF (all models) In the OFF position, electronic movement of the actuator is disabled.

The actuator will NOT respond to any incoming remote or local signals. The actuator MAY

be operated manually using the handwheel and the unit will STAY in its desired position.

Panel shown in the

Local Mode

The POSITION switch (left hand side) has three positions.

When power is present in the unit, the mode switch is operational.

• STOP (center position) removes any ability to reposition the actuator electrically.

• STOP with Proportional Control actuators: The actuator generates a 4-20mA (2-10vdc)

• OP (OPEN) set the POSITION switch to OP to drive the actuator to the full CCW position.

• CL (CLOSE) set the POSITION switch to CL to drive the actuator to the full CW position.

• The position switch can be used to “bump” or “jog” the actuator incrementally in

Panel shown in the

Remote Mode driving OPEN

Back to TOC

Hayward Flow Control

1-888-HAY-INDL (1-888-429-4635)

WARNING – Being in the OFF mode does NOT serve as a power disconnect.

Live voltage will still be present inside the actuator.

feedback signal OUT which corresponds to the position of the actuator.

either direction as well.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

www.haywardowcontrol.com

HRSLCSSPLMNTIOM Rev A

Page 10 of 42

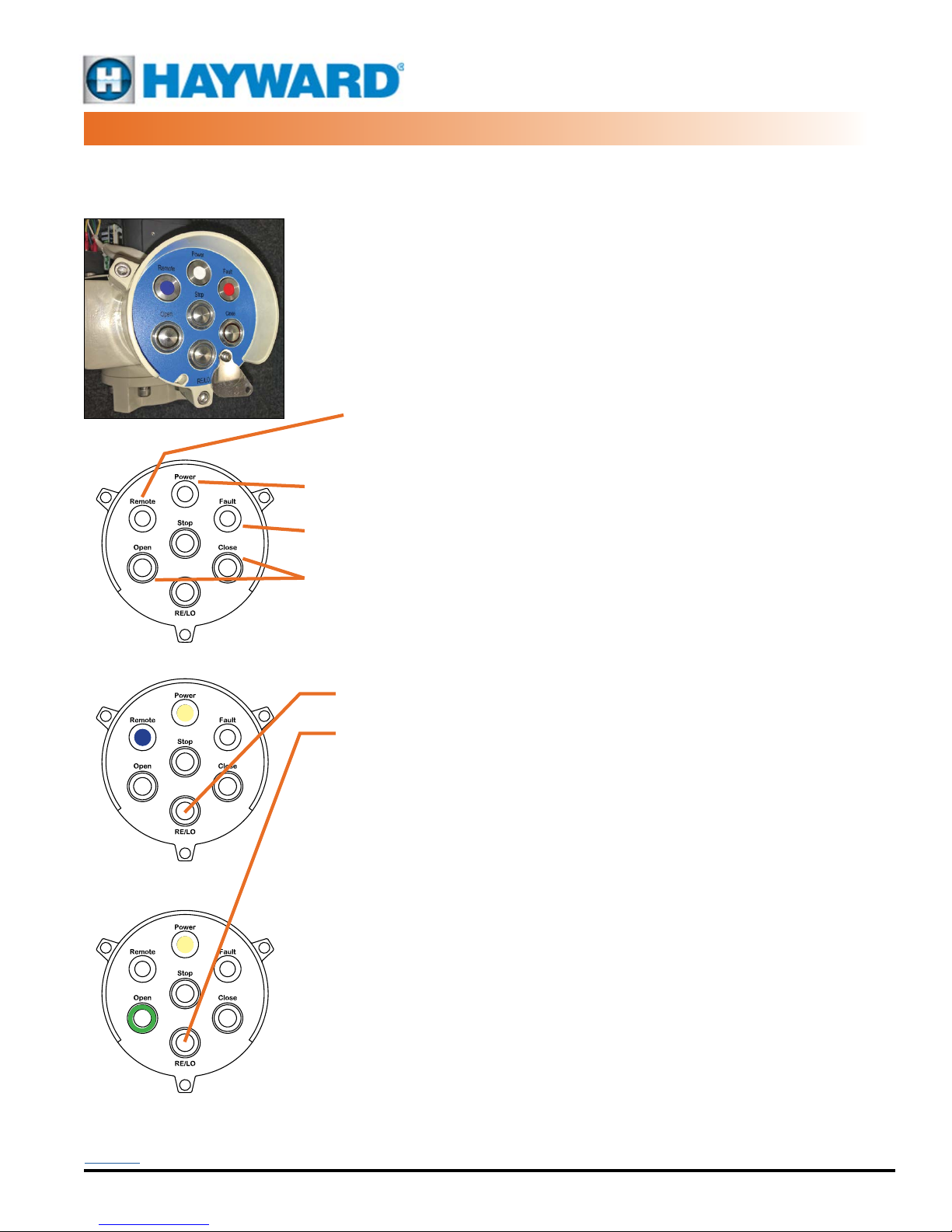

CP SERIES LCS OPERATION

ROUND LCS, PUSHBUTTON

Operating the

Local Control Station

This round NEMA 4X/IP67 enclosure houses four pushbutton control switches that provide the

user with the ability to operate the actuator in a normal (REMOTE) mode where the actuator

responds to control signals from a building automation system or a PLC or other control device

(by others). Or the user can elect to operate the actuator in LOCAL mode where one can

control the positioning of the actuator while standing AT the device. This allows opening and

closing the actuator (valve) to test for operation, perform maintenance or other function without

relying on radio communication to command the automation system to position the actuator.

The panel houses three status LED’s that indicate Power, Remote operation, and a Fault

indicator. There are also four push button switches (non-latching, push/push) two of which

also have ring surround LEDs providing the operational status of the actuator. Whenever power

is present at the unit, regardless of MODE position, the Power LED is illuminated.

REMOTE (REMOTE MODE indicator, all actuators):

• The RE/LO mode switches from Local to Remote and back with each

successive press of the push button (see below).

• When the unit is in Remote mode, the Blue Remote LED will be illuminated.

• When the unit is in Local mode, the Remote LED will be OFF.

POWER (POWER indicator, all actuators): The Power LED is illuminated whenever power is

present at the unit, regardless of MODE position.

FAULT (FAULT indicator, all actuators): The Fault LED is illuminated whenever there is a fault

detected in the actuator.

OPEN/CLOSE (OPEN and CLOSE indicators, all actuators): Regardless of the Mode of

operation (other than powered OFF), the Open and Close push buttons have internal LED

rings which ash Red (Closing) or Green (Opening). When end of travel is reached, the LED

indicators remain constant ON.

Panel shown with NO POWER

Panel shown in the

Remote Mode

Panel shown in the

Local Mode, actuator fully OPEN

RE/LO (REMOTE/LOCAL, all actuators): When the RE/LO push button is pressed, the mode

switches from Local to Remote and back with each successive press of the push button.

• REMOTE: When the unit is in Remote mode, the three Move push

buttons are disabled and have no effect on the operation of the actuator.

• LOCAL: When the unit is in Local mode (Blue LED OFF), the three Move

push buttons are enabled and one can control the position of the actuator

using the push buttons.

OPEN: Pressing the Open push button drives the actuator CCW until it reaches the end of

travel determined by the internal CCW travel cam settings.When pressed (momentary switch),

the unit will start and continue to drive until it reaches its full CCW position UNLESS the Stop

push button is pressed. This will arrest the CCW travel of the actuator and it will stay in its

current position UNLESS the manual handwheel is utilized.

CLOSE: Pressing the Close push button drives the actuator CW until it reaches its CW end of

travel limit switch.

STOP: Pressing the Stop push button stops the actuator in position.

Using the manual handwheel. In Remote mode with an active control signal present,

repositioning the actuator with the handwheel will result in the unit driving to maintain the

control signal command. i.e. if in Remote mode with a drive CW active control signal, if the

handwheel is utilized to reposition the actuator to mid-stroke, the motor will immediately drive

the actuator to its full CW position. While in Local Mode, the manual handwheel can be used

to reposition the actuator to any desired position AFTER the unit has reached its intended end

of travel position and the associated ring LED is illuminated.

This Control system employs a pad-lockable security plate that can be positioned over the

MODE push button and locked in place. This prevents changing the mode of operation. The lock

plate must be unlocked and swung out of the way to gain access to the mode switch function.

Back to TOC

Hayward Flow Control

1-888-HAY-INDL (1-888-429-4635)

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

www.haywardowcontrol.com

HRSLCSSPLMNTIOM Rev A

Page 11 of 42

CL SERIES LCS OPERATION

RECTANGULAR LCS, LED

Operating the

Local Control Station

Panel shown in the STOP Mode

Panel shown in the Remote Mode

Panel shown in the Local Mode

driving CLOSED

Panel shown in the Local Mode

driving OPEN

There is a padlockable lever that engages with the MODE

knob to lock the operation of the MODE switch in position.

It provides restricted access in any of the three positions.

Back to TOC

Hayward Flow Control

1-888-HAY-INDL (1-888-429-4635)

This rectangular NEMA 4X/IP67 (Optional IP68) enclosure houses two non-intrusive

(magnetic) rotary control knobs that provide the user with the ability to operate the

actuator in a normal (REMOTE) mode where the actuator responds to control signals

from a building automation system or a PLC or other control device (by others). Or

the user can elect to operate the actuator in LOCAL mode where one can control

the positioning of the actuator while standing AT the device. This allows opening

and closing the actuator (valve) to test for operation, perform maintenance or other

function without relying on radio communication to command the automation system

to position the actuator.

The panel also contains ve bright LED’s to provide visual indication of the position

and status of the actuator. OPEN (green) and CLOSE (red) ash when the actuator

is MOVING open (CCW) or closed (CW), and they remain steady ON when end of

travel is reached.

The MODE switch (right hand side) has three positions.

• STOP (STOP, On/Off actuators): STOP (center position) removes any ability

to reposition the actuatorelectrically. Power is still present in the unit, and

the OPEN and CLOSE LED indicators are operational. If the unit is fully

CLOSED (CW), then the REDLED will be steady ON. Due to its epicyclic

gear train, the manual handwheelCAN be used to position the actuator. The

actuator will remain in position lastdetermined by the use of the handwheel.

• STOP (STOP, Proportional Control actuators): The actuator generates

a4-20mA(2-10vdc) feedback signal OUT which corresponds to the position

of theactuator.

• REM (REMOTE, On/Off actuators): Sets the actuator to respond to eld

generated control signals. In this mode the POSITION KNOB (left side)

has NO affect on the positioning of the actuator. All actuator movement

is controlled by the external signal device.The manual handwheel may be

used to reposition the actuator while in this mode; however, if an active

external signal is present, the actuator WILLreposition as a function of that

control signal. The LED indicators are activein this mode.

• REM (REMOTE, Proportional Control actuators): The actuator follows

theincoming 4-20mA(2-10vdc) control signal, and generates a 4-20mA(2-10vdc)

feedback signal OUT which corresponds to the position of the actuator.

• LOC (LOCAL, On/Off actuators): Sets the actuator to respond to the

POSITION KNOB (see below).

• The LED indicators are active in this mode.

• All external eld signals are ignored and have no affect on the

positioning of theactuator.

• LOC (LOCAL, Proportional Control actuators): The actuator responds tothe

function of the POSITION knob (see below) AND generates a 4-20mA(210vdc)feedback signal OUT which corresponds to the position of the actuator.

The POSITION switch (left hand side) has three positions.

When in the LOC mode, the actuator has been set to respond to the POSITION

KNOB (left side).

• OPE (OPEN, all models): When the POSITION knob is set to OPE, the

actuator will drive to the full CCWposition.

• CLO (CLOSE, all models): When the POSITION knob is set to CLO, the

actuator will drive tothe full CW position.

• There is an unmarked HOLD position detente in theknob (see red dot at

left) that allows the actuator to maintain position at somepoint away from

full travel endstops. In this mode, the manual handwheelmay be used to

reposition the actuator and it will remain in position whilePOSITION knob

is in HOLD. The LED indicators are active in this mode. Allexternal eld

signals are ignored and have no affect on the positioning of theactuator.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

www.haywardowcontrol.com

HRSLCSSPLMNTIOM Rev A

Page 12 of 42

CD SERIES LCS OPERATION

RECTANGULAR LCS, LCD

Operating the

Local Control Station

Panel shown in the STOP Mode

Panel shown in the Remote Mode

Panel shown in the Local Mode

driving CLOSED

Panel shown in the Local Mode

driving OPEN

There is a padlockable lever that engages with the MODE

knob to lock the operation of the MODE switch in position.

It provides restricted access in any of the three positions.

Back to TOC

Hayward Flow Control

1-888-HAY-INDL (1-888-429-4635)

This rectangular NEMA 4X/IP67 (Optional IP68) enclosure houses two nonintrusive

(magnetic) rotary control knobs that provide the user with the ability to operate the

actuator in a normal (REMOTE) mode where the actuator responds to control signals

from a building automation system or a PLC or other control device (by others). Or

the user can elect to operate the actuator in LOCAL mode where one can control

the positioning of the actuator while standing AT the device. This allows opening

and closing the actuator (valve) to test for operation, perform maintenance or other

function without relying on radio communication to command the automation system

to position the actuator.

The panel houses a monochrome LCD screen that shows percentage of full OPEN

position as a default. There are individual LED’s to show Remote, Local, F.O. (Fully

Open) and F.C. (Fully Closed) operational status.

The MODE switch (right hand side) has three positions.

• STOP (STOP, On/Off actuators): STOP (center position) removes any ability

to reposition the actuatorelectrically. Power is still present in the unit, and

the OPEN and CLOSE LED indicators are operational. If the unit is fully

CLOSED (CW), then the REDLED will be steady ON. Due to its epicyclic

gear train, the manual handwheelCAN be used to position the actuator. The

actuator will remain in position lastdetermined by the use of the handwheel.

• STOP (STOP, Proportional Control actuators): The actuator generates

a4-20mA(2-10vdc) feedback signal OUT which corresponds to the position

of theactuator.

• REM (REMOTE, On/Off actuators): Sets the actuator to respond to eld

generated control signals. In this mode the POSITION KNOB (left side)

has NO affect on the positioning of the actuator. All actuator movement

is controlled by the external signal device.The manual handwheel may be

used to reposition the actuator while in this mode; however, if an active

external signal is present, the actuator WILLreposition as a function of that

control signal. The LED indicators are activein this mode.

• REM (REMOTE, Proportional Control actuators): The actuator follows

theincoming 4-20mA(2-10vdc) control signal, and generates a 4-20mA(2-10vdc)

feedback signal OUT which corresponds to the position of the actuator.

• LOC (LOCAL, On/Off actuators): Sets the actuator to respond to the

POSITION KNOB (see below).

• The LED indicators are active in this mode.

• All external eld signals are ignored and have no affect on the

positioning of theactuator.

• LOC (LOCAL, Proportional Control actuators): The actuator responds tothe

function of the POSITION knob (see below) AND generates a 4-20mA(210vdc)feedback signal OUT which corresponds to the position of the actuator.

The POSITION switch (left hand side) has three positions.

When in the LOC mode, the actuator has been set to respond to the POSITION

KNOB (left side).

• OPE (OPEN, all models): When the POSITION knob is set to OPE, the

actuator will drive to the full CCWposition.

• CLO (CLOSE, all models): When the POSITION knob is set to CLO, the

actuator will drive tothe full CW position.

• There is an unmarked HOLD position detente in theknob (see red dot at

left) that allows the actuator to maintain position at somepoint away from

full travel endstops. In this mode, the manual handwheelmay be used to

reposition the actuator and it will remain in position whilePOSITION knob

is in HOLD. The LED indicators are active in this mode. Allexternal eld

signals are ignored and have no affect on the positioning of theactuator.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

www.haywardowcontrol.com

HRSLCSSPLMNTIOM Rev A

Page 13 of 42

Loading...

Loading...