Hayward HL32950VVSP, HL26720VSP, HL23520VSP, HL32900VSP, HL23510VSP Installation Manual

Hayward Pool Products

620 Division Street, Elizabeth NJ 07207

Phone (908)-355-7995

www.hayward.com

VS Omni

Pool Automation Control

Installation Manual

HL32950VVSP HL32900VSP

HL26720VSP HL23520VSP

HL23510VSP

Contents

Before you Begin.....................3

Mounting...............................7

Plumbing................................9

Wiring...................................10

Startup................................22

Conguration........................22

092680 RevB

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

FCC Statement

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Changes or modifications not expressly approved by Hayward could void the user’s authority to

operate this equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio

or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

-- Reorient or relocate the receiving antenna.

-- Increase the separation between the equipment and receiver.

-- Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

-- Consult the dealer or an experienced radio / TV technician for help.

Industry Canada Statement

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

The term “IC” before the certification / registration number only signifies that the Industry Canada

technical specifications were met.

1

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Table of Contents

Before you Begin.......................................................................................................3

Overview..................................................................................................................4

Mounting

VS Hub.............................................................................................................7

Control Pad.......................................................................................................7

Smart Relay......................................................................................................8

Temperature Sensors........................................................................................9

Plumbing.................................................................................................................9

Electrical Wiring

High Voltage...................................................................................................11

Low Voltage....................................................................................................13

System Startup.........................................................................................................22

Configuration

Pre Programmed Configuration........................................................................25

Typical Configuration.......................................................................................25

Advanced Configuration..................................................................................27

Quick Edit..............................................................................................................42

Control Pad Mounting Template.................................................................................50

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

2

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

2

Before you Begin

What’s Included

Check that the following components have been included in your package:

• VS Omni Hub

• Control Pad

• Smart Relay

• 2 Temperature Sensors

• Variable Speed Pump (VSP)

• 15 ft, 3 conductor (red, black and bare wire) communication cable to connect Hub to VSP

• 2 Wiring Whips - 6 ft flexible conduit containing three 12AWG conductors (red, black and

green) for wiring VSP to VS Omni Hub and for Smart Relay installation). A length of white 12

AWG conductor is included to replace red for 115V Smart Relay applications

• Input Power Wiring harness and miscellaneous installation hardware

What’s NOT Included

Some of the additional items that you may need to complete an installation include:

Wire

Wire/conduit for incoming power

Wire for remote heater control and other low voltage devices

Ethernet cable (if not using wifi)

Miscellaneous

Valve actuator to automate pool functions (see page 9)

Flow switch for pump protection/flow monitoring

Mounting hardware for mounting Hub, Control Pad and Smart Relay

Cable/cord connectors to provide knockout strain relief

Wire nut connectors

USB thumbstick (to update firmware)

Tools Needed

Philips and flat screwdrivers

Wire cutters and strippers

Knife to cut conduit

Drill and drill bits (including 3/8")

Pliers

Level

Accessory Products - Order Separately

HLH485RELAY Smart Relay used for controlling additional pool equipment

FLO Flow Switch used to detect water flow

GVA-24 Valve Actuator

2PC Temperature Sensor for 3rd input

3

USE ONLY HAYWARD GENUINE REPLACEMENT PARTSUSE ONLY HAYWARD GENUINE REPLACEMENT PARTS

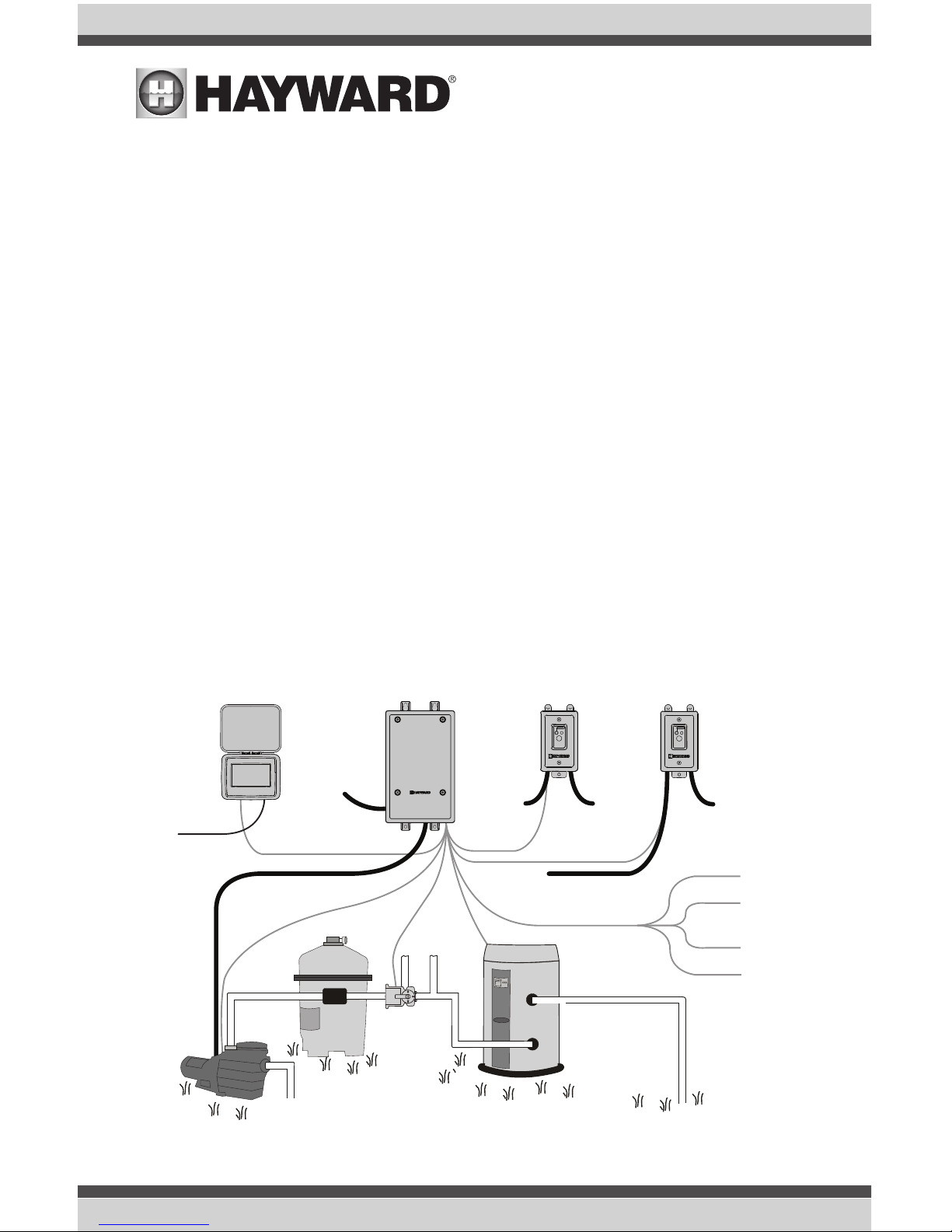

Overview

The Hayward VS Omni is a web enabled pool automation control with a convenient touchscreen

interface. Because it's packaged with a high efficiency variable speed pool filter pump, the VS Omni

is ideal for both retrofit and new pool/spa installations. Automatically and remotely control pumps, a

heater, a valve actuator, pool and yard lighting, and more. The VS Omni offers the next generation of

technology to manage pool/spa equipment, allowing communication to web connected computers

and mobile devices. You can now conveniently monitor your pool/spa and change settings anytime,

and from anywhere.

Please read through this manual thoroughly before attempting to install, configure or operate this

unit. A Quick Start guide is also included to offer concise information to experienced installers.

Features

The standard Hayward VS Omni offers the following functionality:

• controls up to 2 variable speed pumps for pool/spa filtration and water features

• controls up to 2 Smart Relays to turn on/off single speed pumps, pool lights, yard lights, water

features, chemical dispensers and more

• controls up to two valve actuators allowing you to manage two bodies of water (both pool and

spa) or can be used for water features, cleaners, solar heating, etc. (currently requires Hub to be

powered by 230 VAC)

• controls one conventional heater (electric heatpump or gas) and optional solar heater (for single

body of water applications only)

• inputs for up to 3 temperature sensors or external input devices

• built-in wireless to connect to the home’s router/access point (ethernet port provided for optional

wired connection)

• optional flow switch used to protect pool equipment by detecting water flow

Optional accessories (page 3) can expand the functionality of the VS Omni. Determine your needs

and select the necessary accessories before you begin the installation.

Equipment

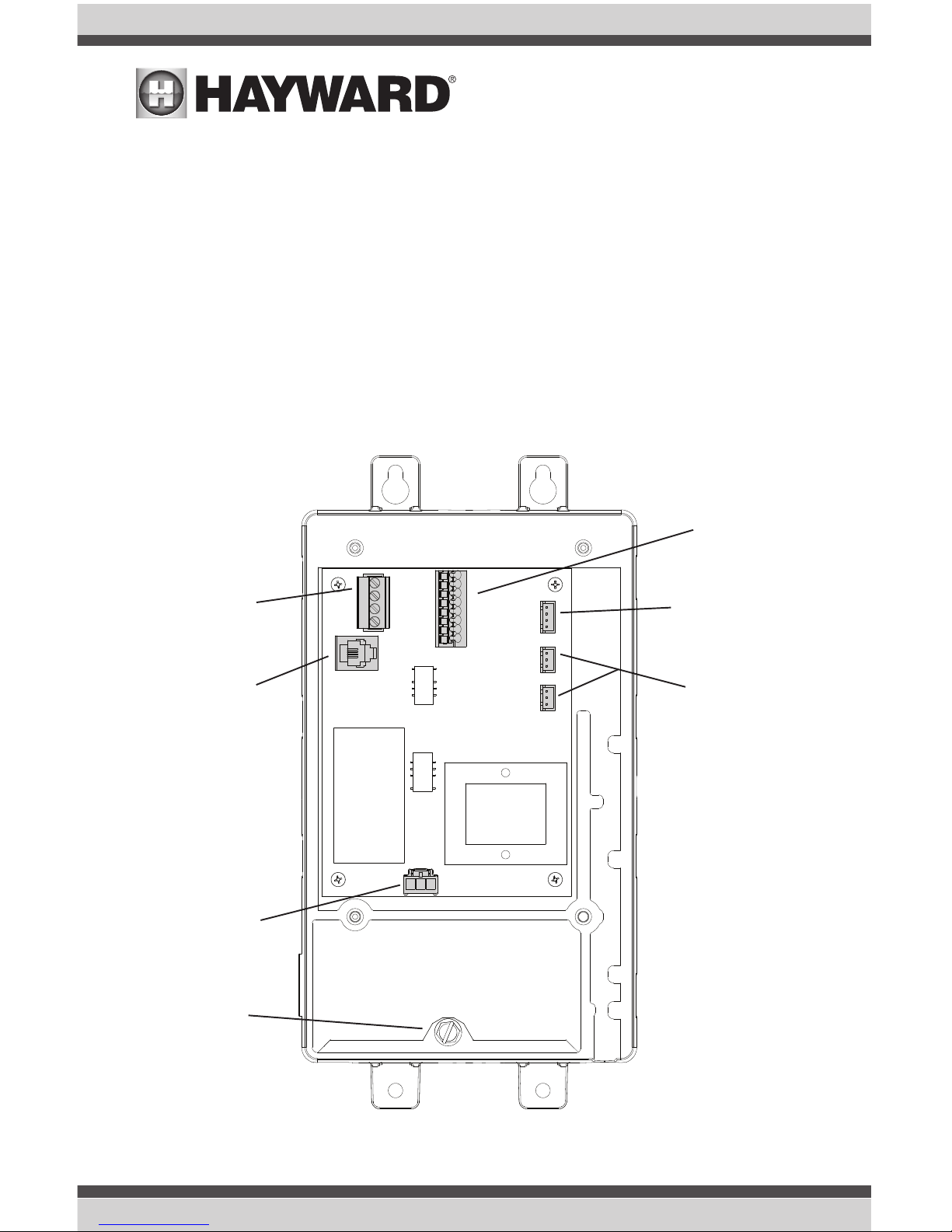

VS Omni Hub

All incoming/outgoing wiring will be connected to the Hub. The VS Omni Hub can be powered by

either 115 VAC or 230 VAC. Input power should be constant, not from a timer. If a timer must be

used, set the timer to power the Hub continuously. For convenience, a 6ft Wiring Whip is included

with the VS Omni. This whip is intended to connect the Hub's input power to the variable speed

pump if using 230 VAC. This connection should be made inside of the Hub and will ensure that both

the Hub and pump are powered continuously.

The remaining connections, including the Control Pad, are all low voltage. Depending on your installation, these connections could be to a heater, Smart Relays, temperature sensors, actuator and a

flow switch.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

4

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Control Pad

The Control Pad is weather resistant and comes with a 15 ft cord. Its resistive touch screen with

flip down cover is designed to function year round directly in the elements. Because it plugs into the

Hub, it should be mounted close by, but in a location that is convenient for the user to periodically

view and change pool/spa settings.

The Control Pad features a USB connector for firmware updates and an Ethernet connector for an

optional direct connection to your router (if wifi won't be used).

Smart Relay

Smart Relays have 15 ft cable that wire to the Hub. They're used to control high voltage 115 or 230

VAC pool equipment like lights, water features, pumps and more. Power to the intended load must

be supplied separately and run through the Smart Relay. Smart Relays are rated for up to 20 amps

at 230 volts.

Temperature Sensors

Depending on your installation, up to 3 temperature sensors may be used. The VS Omni requires

a water temperature sensor for heater operation. If freeze protection is desired, an air temperature

sensor is also required. For solar heating systems, a solar sensor is necessary. Even if your installation doesn't require the use of temperature sensors, installing water and air sensors provides a

convenience to the user, especially during remote use.

Flow Switch (not included)

An optional flow switch can be used to detect leaks or clogs in the pool/spa plumbing.

Input Power or

Existing Timeclock

Wiring Hub

(Optional)

Smart Relay 2

To Feature,

Accessory,

Lights, etc.

Variable

Speed Pump

Filter

Valve

Actuator

Heater

TO

POOL

FROM

POOL

Power

to VSP

Input Power to

Smart Relay 1

Comm. to Smart

Relay 1 (15’)

Comm. to

Heater

Comm. to

Valve Actuator

Comm.

to VSP

To Solar

REMOTE

RELAY

OFFLINE:

ON/OFF

Smart Relay 1

Input

Power

Comm. to Smart

Relay 2 (15’)

Control Pad

To Feature,

Accessory,

Lights, etc.

Wireless

Connection

OR

Ethernet to

Router

Comm. to

Controller (15’)

Sensor 1

(Water Temp.)

Sensor 2

(Air Temp.)

Sensor 3 (Solar OR

External Input)

(Optional)

Flow Switch

REMOTE

RELAY

OFFLINE:

ON/OFF

Wiring Whip

5

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Installation

Installation Steps

DANGER of Death, Injury or Property Damage if procedure not followed. Power wiring must

be shut off before attempting to install the VS Omni.

The VS Omni is designed to be mounted outdoors at the pool pad. Both the Hub and the Control

Pad are water resistant and can be left out for the winter. Details on each installation step are

shown below:

1. Mounting the equipment (page 7)

VS Omni Hub

Control Pad

Smart Relay

Temperature sensors

Valve actuators (if applicable)

2. Plumbing (page 9)

General Pool Equipment

Flow Switch

3. Electrical Wiring (page 10)

Hub power

Grounding

Low voltage wiring (Pool Pump Communication, Heater, Smart Relays, Temperature Sensors,

Flow Switch, etc.)

5. System Startup and Firmware Upgrade (page 22)

The most common installation technique is described in the included Quick Start Guide. Use this

guide if possible. If the Guide can not be applied to your particular installation, refer to the additional

information in this manual.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

6

Mounting the Equipment

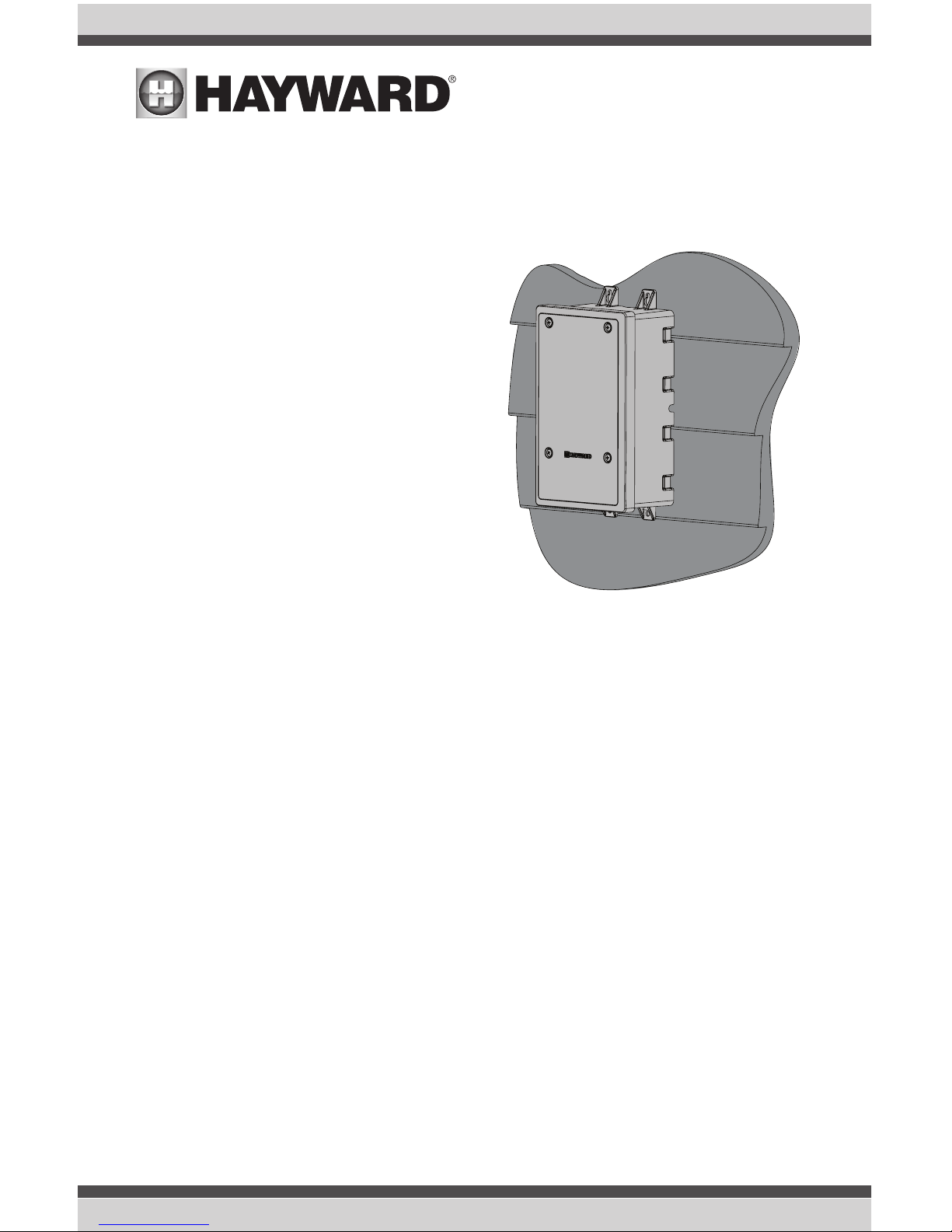

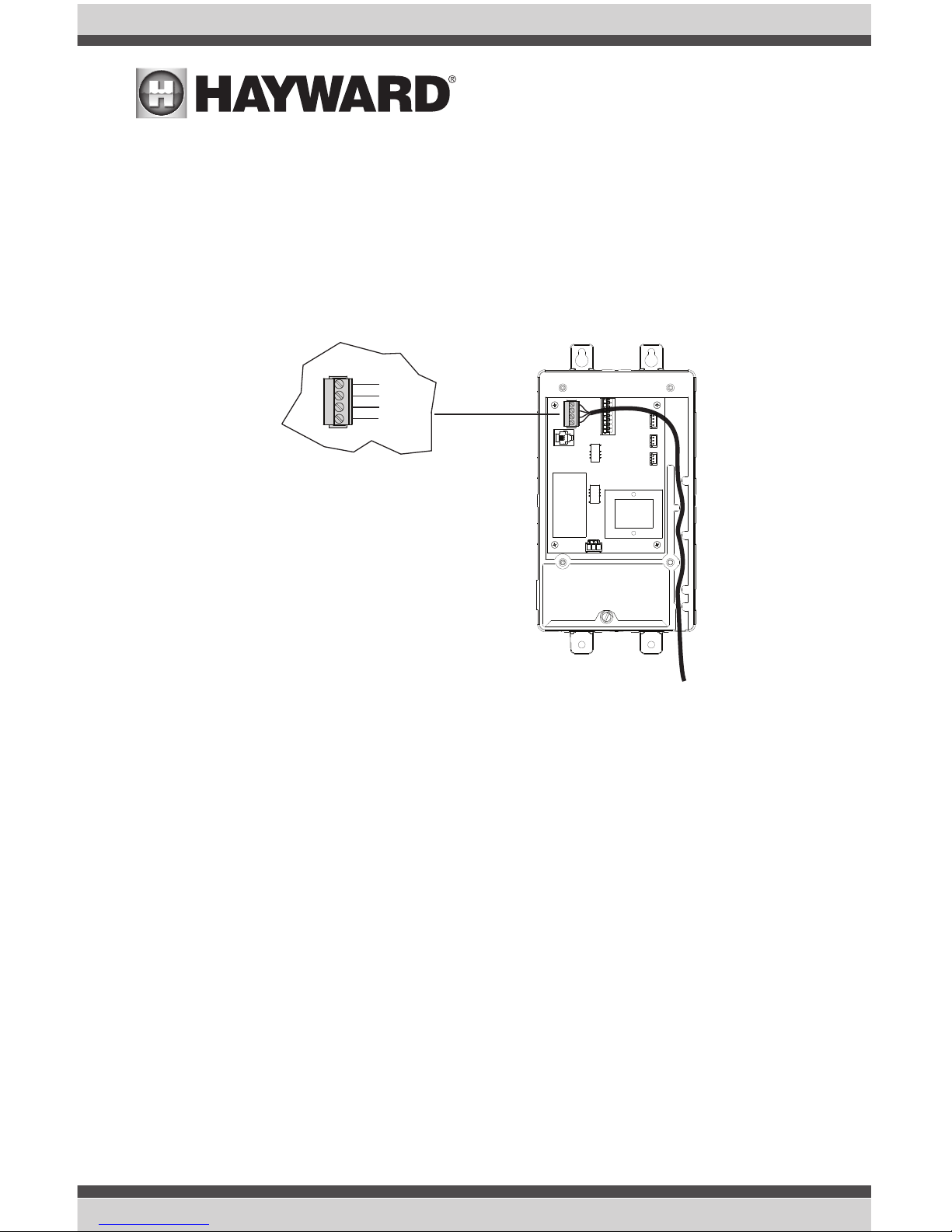

VS Omni Hub

The Hub is contained in a raintight enclosure

that is suitable for outdoor mounting. It must

be mounted a minimum of 6 ft (2 meters) horizontal distance from the pool/spa (or more, if

local codes require). The Hub is designed to

mount vertically with the knockouts facing

downward. Do not mount the Hub inside a

panel or tightly enclosed area.

When selecting a location, note that the standard cables supplied with the optional flow

switch, temperature sensors, and actuators

are all 15 ft (5m) long. Additional low voltage connections will have to be made to the

pump and/or heater. 115 VAC or 230 VAC input power must also be run to the Hub. Try to

mount the Hub in a location where incoming/

outgoing wiring will be easily accessible.

Mount the Hub on a wall or flat surface. Select

mounting hardware that is appropriate for the

mounting surface and material. The Hub has two keyhole type mounting tabs on the top and bottom

of the enclosure requiring a total of 4 fasteners.

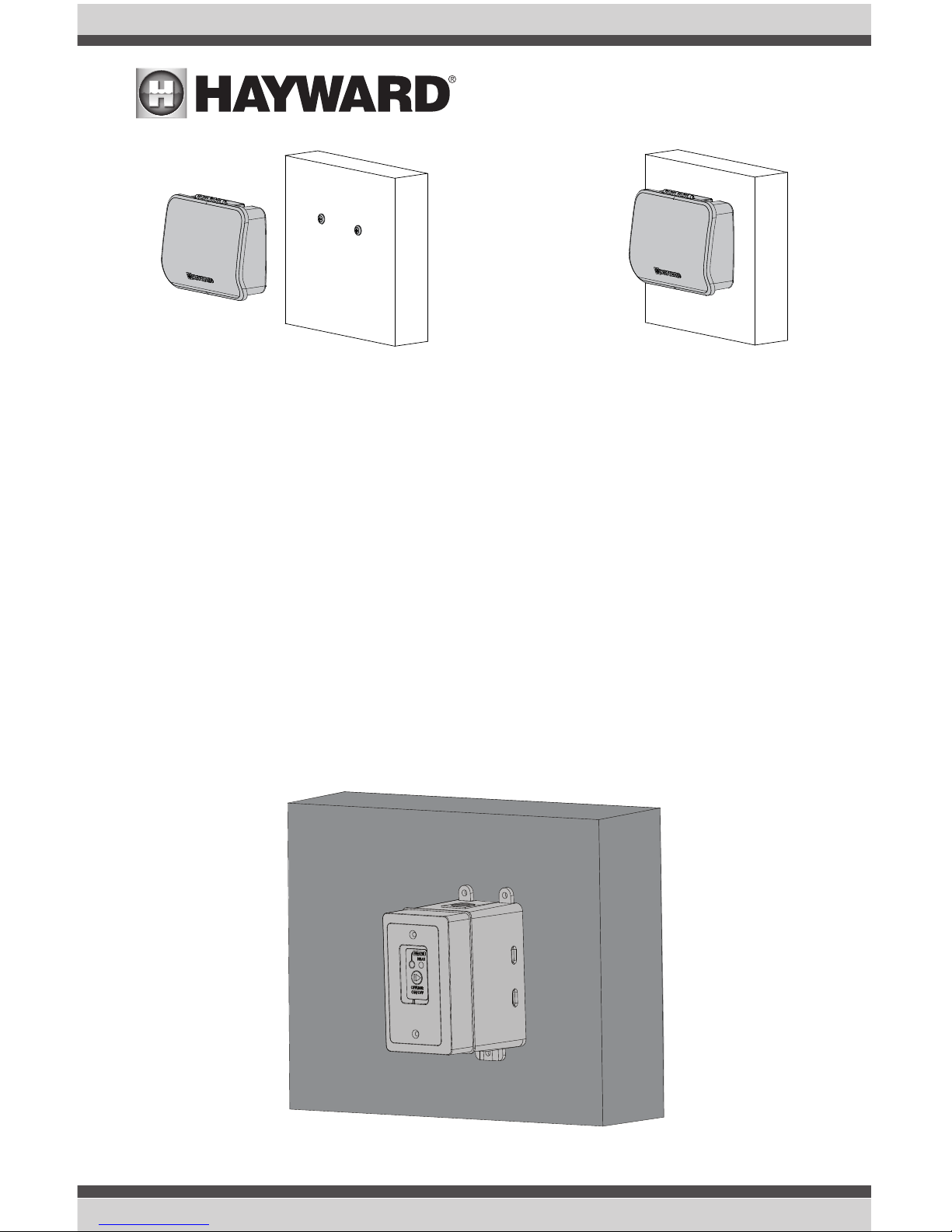

Control Pad

The Control Pad comes with a 15 ft cord and plugs into the Hub. It should be mounted in a location

that is convenient for the user to view and change pool/spa settings. When considering the mounting location, make sure there is enough clearance above the enclosure so that the flip door will be

able to be opened fully. Also be sure to allow enough clearance below the Control Pad to access

the USB and Ethernet connectors. For best viewing results, position the Control Pad where it won't

be subjected to direct sunlight.

The Control Pad has two keyhole cutouts on the back of its enclosure. To mount, screw the two

provided fasteners into the mounting surface at the desired location using the template found on

page 54 . Tighten until the bottom of the screw heads are 1/8" off the mounting surface. Position

the Control Pad cutouts over the screw and slide the unit downward. You may have to tighten or

loosen the screws slightly to fully engage the screw heads to get a snug fit.

7

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Smart Relay

The Smart Relay is packaged with a single gang electrical box but can also be used with any existing

comparable standard electrical box with a minimum volume of 16.2 in3. If using 115 VAC, make

sure that there is a Neutral line inside the box before installation. If not, you must run a separate

Neutral wire to power the Smart Relay. This is not a concern if using 230 VAC. Note that conduit and

connections to the included plastic box must be non-metallic.

Find a location within 15 ft of the Hub with convenient access to the pool equipment that you intend

to control with the Smart Relay. Three threaded 1/2" NPT knockouts are provided for high voltage

power coming into the relay and for power out to the pool equipment. A Wiring Whip is included to

aid installation.

The Smart Relay has a manual On/Off button that can be used if communication is lost with the Hub.

Although this button is not functional during normal operation, mount the Smart Relay in an accessible location to use this feature in case of communication loss.

Mount the Smart Relay to a wall or other flat surface using the mounting holes which are designed

to accommodate #8 screws.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

8

Temperature Sensors

Water Sensor

This sensor is used to measure the pool/spa temperature and is installed in the filtration plumbing

after the filter but before either the solar or conventionally fueled heaters.

1. Drill a 3/8” (10mm) diameter hole in the PVC piping and remove all chips and burrs.

2. Insert sensor until O-ring collar sits flush on the hole.

3. Position hose clamp over the sensor and gently tighten until O-ring makes an adequate seal.

Do not overtighten.

Air Sensor

Mount the air sensor outdoors. IMPORTANT: The air sensor must not be mounted in direct sunlight.

Solar Sensor

For solar applications, mount the sensor near the solar collector array so that it is exposed to the

same sunlight as the collectors. Use additional cable (20 AWG) if necessary.

Optional Valve Actuators

Currently, using an Hayward GVA-24 actuator or equivalent requires that the Hub be powered with

230 VAC. If powering the VS Omni Hub with 115 VAC, an actuator can't be used. For installation,

refer to the mounting instructions included with the unit. After configuring and first operating the

valve, note that the internal cams in the actuator may have to be adjusted depending on the way the

actuator is mounted on the valve and the desired valve action.

Plumbing

Optional Flow Switch

Only applicable if leak/clog detection is desired. The flow switch should be plumbed on the return

side at the very end of the pool pad plumbing. This will ensure that if a leak occurs anywhere at the

pool pad, the VS Omni will be able to detect it. Understand that if a leak occurs after the flow switch

(downstream), the VS Omni will not sense a no flow condition.

IMPORTANT: There must be at least a 12” (30cm) straight pipe run before (upstream) the flow switch.

IMPORTANT: To ensure proper operation, verify that the arrow on the flow switch points in the direction of water flow.

Variable Speed Pump

Refer to the included VS Omni Pump manual for plumbing information.

9

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Electrical Wiring

The Hub requires both high and low voltage connections. Always:

- Ensure that Power is disconnected prior to performing any wiring

- Follow all local and NEC (CEC if applicable) codes

- Use copper conductors only

A dedicated channel on the right side of the Hub has been provided for all low voltage wiring. All low

voltage wires should run through this channel to exit the Hub. A weather resistant gasket is provided

(see page 21) to seal this exit.

Input Power

Flow Switch

Smart Relays

&

Variable Speed Pump

Communication

Temperature Sensors,

External Input

& Heater

Control Pad

Valve Actuators

(Hub must be powered by

230 VAC)

Wiring Channel

Low Voltage

Ground Screw

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

10

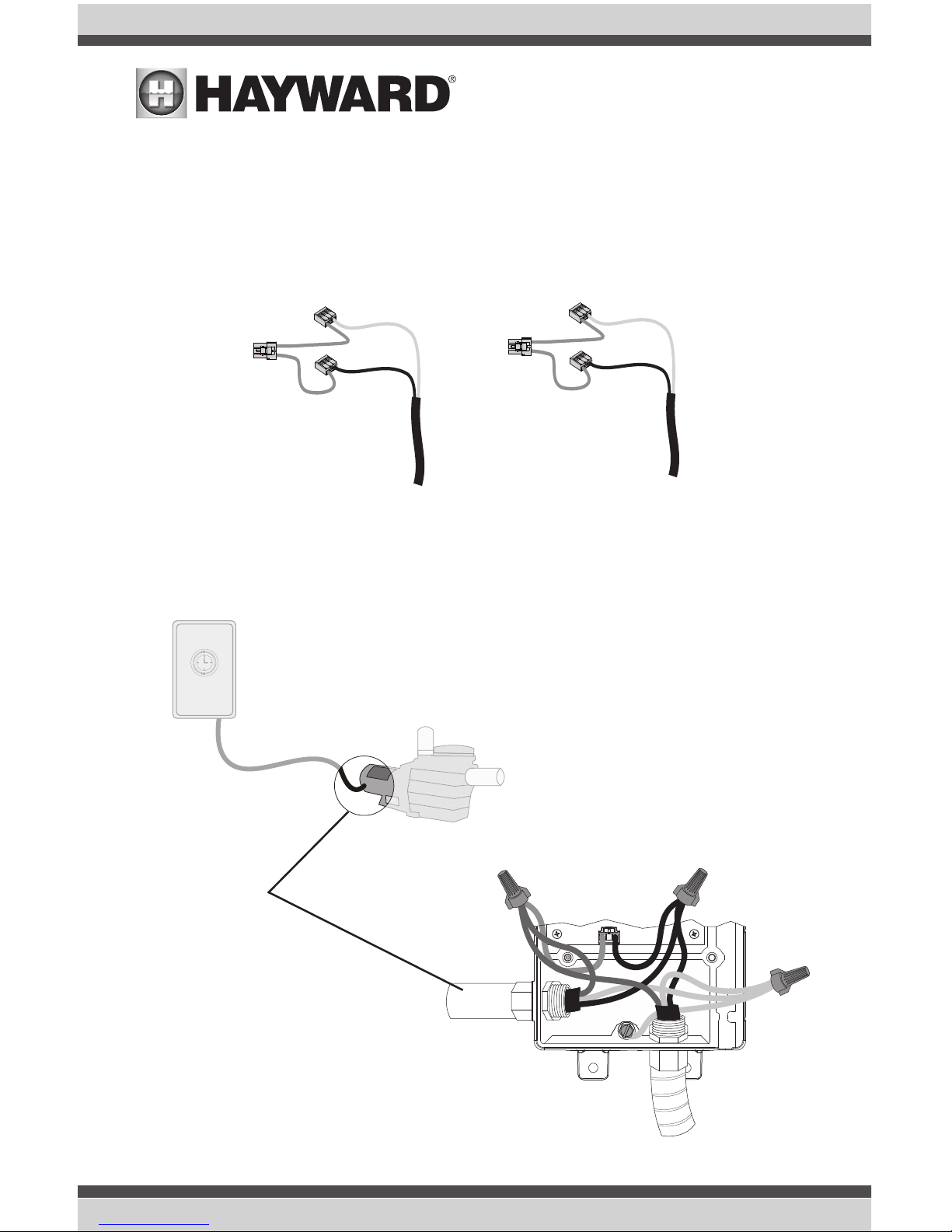

High Voltage Wiring

Hub Input Power

The Hub requires a constant 115 VAC or 230 VAC input power to operate. A wiring harness is included and will plug into the input power connector shown on page 10. Wire the harness according

to the diagram below.

For easy installation, if replacing an existing 230 VAC pump, disconnect power at the pump and use

that connection to provide power to both the Hub and the new variable speed pump (VSP). Use the

included Wiring Whip to aid in this connection. The diagram below shows an existing timeclock used

to power the old pump. This configuration can be easily modified to power the VS Omni and the new

VSP. Refer to the diagrams below.

115 VAC

L1

N

230 VAC

L1

L2

Connect to Hub and

new Variable Speed

Pump (VSP)

L1

L2

Ground

Disconnect from existing

230 VAC pump

Wiring Whip to

VSP

230 VAC

Existing Timeclock

11

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

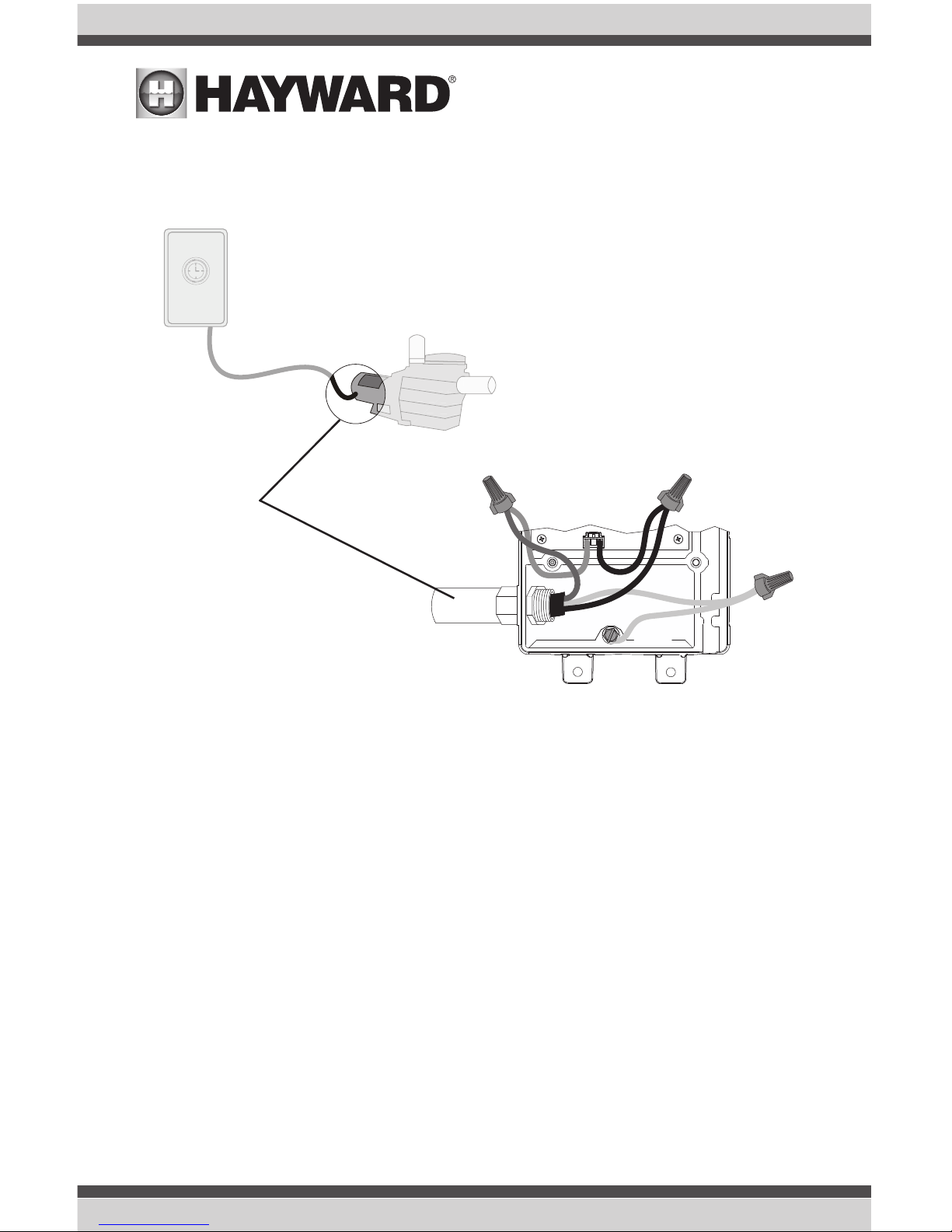

If replacing a 115 VAC pump, you can disconnect power at the pump and use it to power the Hub

only. The new variable speed pump however, requires 230 VAC which will have to be run separately.

Refer to the included pump manual for input power wiring.

If using an existing timeclock to power the Omni VS Hub, set it to run constantly. If the VS Omni Hub

will be connected to a panel or switch, the power will have to be left on continuously.

Grounding

Connect a ground wire from the primary electrical panel to the Hub's ground connection as shown in

the previous diagrams. Also ground each piece of high voltage equipment that is connected through

the Hub or Smart Relay.

Variable Speed Pump Input Power

The VS Omni pump requires a constant 230 VAC, 60Hz input power whether from the VS Omni Hub

using the Wiring Whip or directly from a service panel/switch. Refer to the VS Omni Pump manual for

the location of the wiring terminals as well as other related high voltage wiring information.

Connect 115 VAC to Hub

only and run 230 VAC

separately to the new

VSP

Neutral

Disconnect from existing

115 VAC pump

L1

Ground

115 VAC

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

12

Smart Relay Load Wiring

A Smart Relay can be used to control either 115 or 230 VAC pool equipment. The relay is double pole

(makes/breaks both “legs” of 230V circuits or one "leg" of 115V circuits). Refer to the diagram below

for wire connections. Use the included Wiring Whip if the supplied electrical box will be mounted

within 6 ft of the power source. Red, black and green conductors are included for 230 VAC and a

white conductor is supplied if using 115 VAC input power. Use the included wire nuts for wiring connections. Use proper threaded strain relief fittings for conduit attached to knockouts. After wiring is

complete, carefully insert the cover with connections into the box and secure.

Low Voltage Wiring

Note: There is a low voltage channel on the right side of the Hub's enclosure labeled on page 10

and shown on page 21. All low voltage wiring that exits the Hub must run through this channel. The

included foam gasket (page 21) should be used to seal the channels's exit after wiring is complete.

Do not run low voltage wiring through a knockout or with any high voltage wiring.

Hayward Variable Speed Pump (VSP) Wiring

A separate VSP pump manual has been included with the VS Omni. For low voltage communication

wiring information, refer to the pump manual.

Gray

Black

Black/White

Red

Red/White

Red

Red/White

Black

Black/White

Gray

Neutral

Load out

No Connection

No Connection

115 VAC

Load 2 out

Load 1 out

Line 1 in

230 VAC

Line in

Connect Gray &

Red to Line 2 in

Smart Relay

Wire Colors

13

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Smart Relays

Like VSPs, Smart Relays rely on communication from the Hub. Their 4 conductor cable is wired to

the same connector as a VSP. Wire the cable as shown below. Up to two Smart Relays can be controlled by the VS Omni. In addition to communication wiring, the Smart Relay will be wired to high

voltage pool equipment shown on page 13.

Valve Actuators

When wired for 230 VAC, the VS Omni can control up to two valve actuators which allow automated

control of pool/spa, water features, cleaners or solar heating. The VS Omni is compatible with standard valve actuators manufactured by Hayward, Pentair/Compool, and Jandy. Actuators have 15 ft

cables that are terminated with connectors that plug directly into the Hub as shown on page 10.

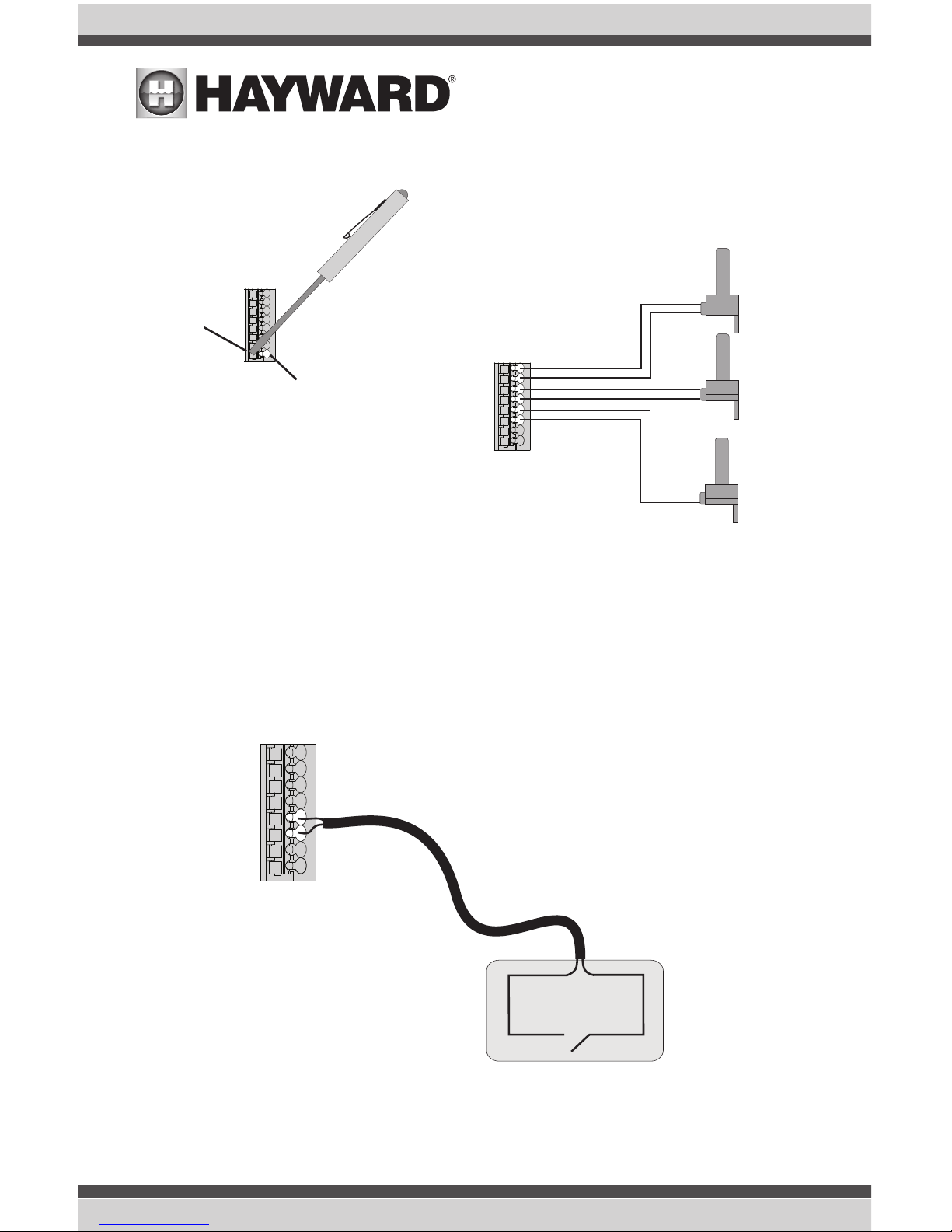

Temperature Sensors

The Hub utilizes 10K ohm thermistor type sensors with 15 ft cable. If a longer cable is required, contact the Hayward service dept. (908-355-7995) for information on suitable cable types and splices.

Temperature sensors are wired to the 8 position connector shown on page 10 and on the following page. To unlock, push on the corresponding lever with a small tool as shown. When pushed,

the connector will be open and able to receive the wire lead. For best results, strip back leads 1/8"

before inserting. After the wire is fully inserted, release the lever and the wire will lock in place.

Green

White

Black

Red

Smart Relay Connection

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

14

External Input Switch

If solar heating won't be used, a SPST external switch/device can be connected to this input. This

normally open or normally closed on/off external device provides a means to turn the filter pump or

other pool equipment on or off when certain conditions exists. Connect the external switch as shown

below. After properly configuring the VS Omni (see Configuration Wizard), the filter pump and/or

desired pool equipment will be forced on or off when the external device is activated.

SPST External Switch

Either Normally Open or Normally Closed

Push on lever

Insert wire here

Pool/Spa Sensor

Air

Sensor

Optional Solar Sensor or

External Input Switch

15

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Control Pad

The Control Pad has a 15 ft cable with a connector that plugs directly into the Hub as shown on

page 10.

Note that there are rubber plugs covering USB port and Ethernet port on the bottom of the Control

Pad. The ethernet port is available for those that desire a wired connection to their access point,

rather than using the VS Omni's built-in wifi (see page 21). The USB port is only used for firmware

upgrades.

Optional Flow Switch

The 15 ft flow switch cable plugs into the flow switch connector shown on page 10. Ensure that the

connector catch “snaps” in order to provide a reliable connection.

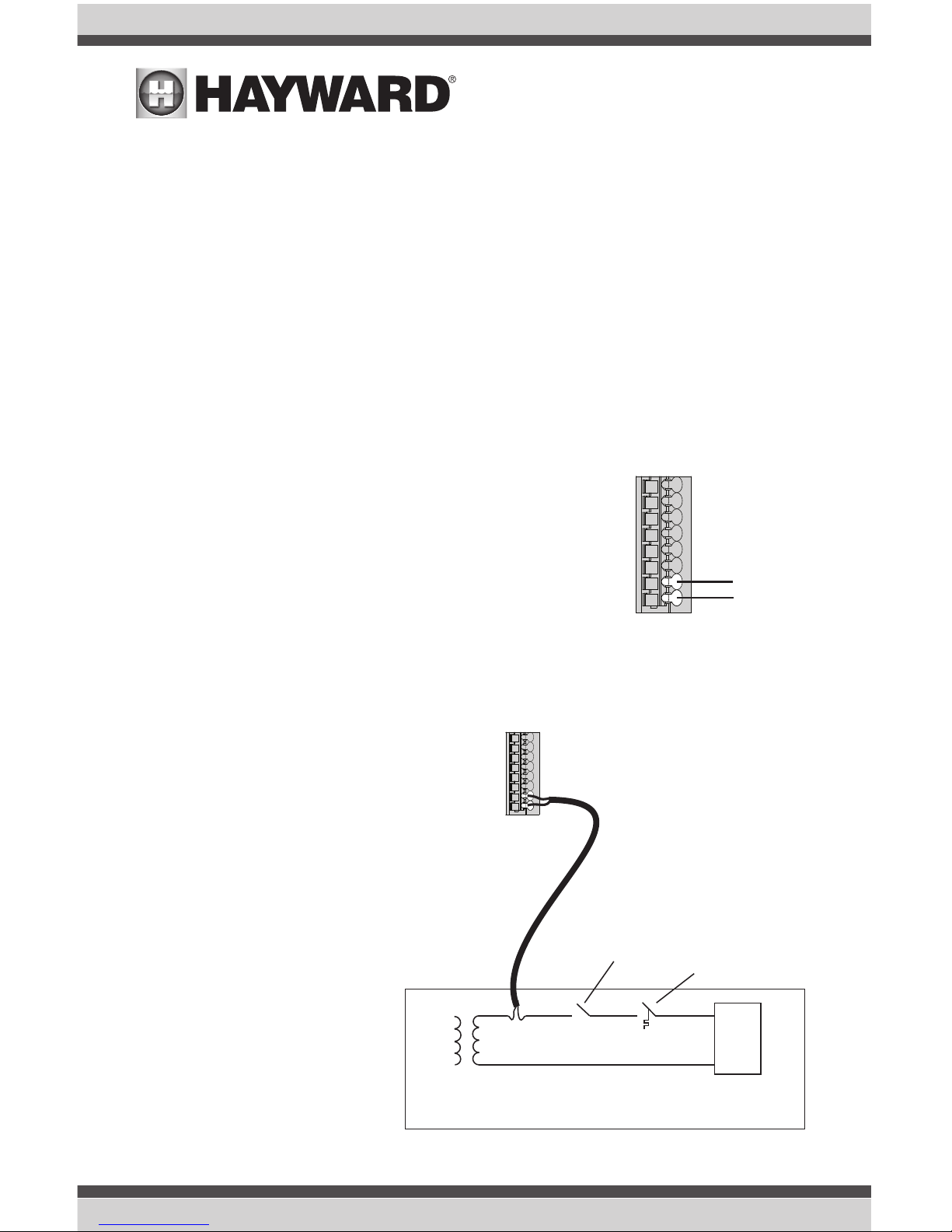

Heater

Ignition/Valve

Heater

Kill Switch

Thermostat

Heaters

The manuals supplied with most heaters also include specific wiring

instructions for connecting the heater to an external control (usually

identified as “2-wire” remote control). For millivolt or line voltage

heaters, contact Hayward Tech support, 908-355-7995. Refer to

the information on the following pages for more details on the connection to several popular heaters. Refer to the diagram below for

the location of heater connections at the Hub.

Generic Heaters

1. Wire heater to 115/230V power source per the instructions in the heater manual. The Hub

does NOT control the power going to the

heater.

2. Wire the Hub dry contact heater output

per the diagram below. Many internal

parts of the heater can get very hot--see

the heater manufacturer’s recommendations on the minimum temperature

rating for wires. If no guidance is given,

use 105°C rated wire.

3. Set any ON/OFF switch on the heater to

ON.

4. Set the thermostat(s) on the heater to

the maximum (hottest) setting.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

16

Loading...

Loading...