OWNER’S MANUAL

Installation, Operation and Service

HEAT PUMP STYLE

POOL / SPA

HEATERS

TA2267

Jan. 2004

Owner’s

Manual

I. Operating Principles

• How a heat pump works…………...………………………………………………….2

• Get familiar with your heat pump ………………………………………………...….3

Temperature control systems for each model……………………….………...……4-9

•

II. Installation Specifications and Procedures

•

eceipt inspection of unit……………………………………………………...……10

R

• Determining optimum location…………………………………………………..….10

Clearance…………………………………………………………….………….11

o

o

Placement………………………………………………………………………..11

o

Drainage…………………………………………………………………………11

Other Precautions………………………………………………………………..12

o

III. Application Guidelines and Maintenance

• Climate Conditions……………………………………………………...……….…..12

• Pool Cleaning Systems………………………………………………………………12

• Efficient Practices

o

Using a pool cover…………………………………………..…………………..13

Water flow………………………………………………………………………13

o

o

Chlorine content…………………………………………………………………13

• Cleaning Procedures………………………………………………………..………..14

• At the beginning of each season………………………………………….………….14

• Occasional / Weekend Use…………………………………………….…………….15

• Summertime Shutdown…………………………………………….………………..15

At the end of each season………………………………………...………………….15

•

IV. Service Procedures

• Before you call for service……………………………………………..………..16, 38

Troubleshooting guide…………………………………………………………...16-18

•

V.

Warranty

……….……………………..……………………………….………...19

VI. Installation Guide

……………………………………………………...…20-40

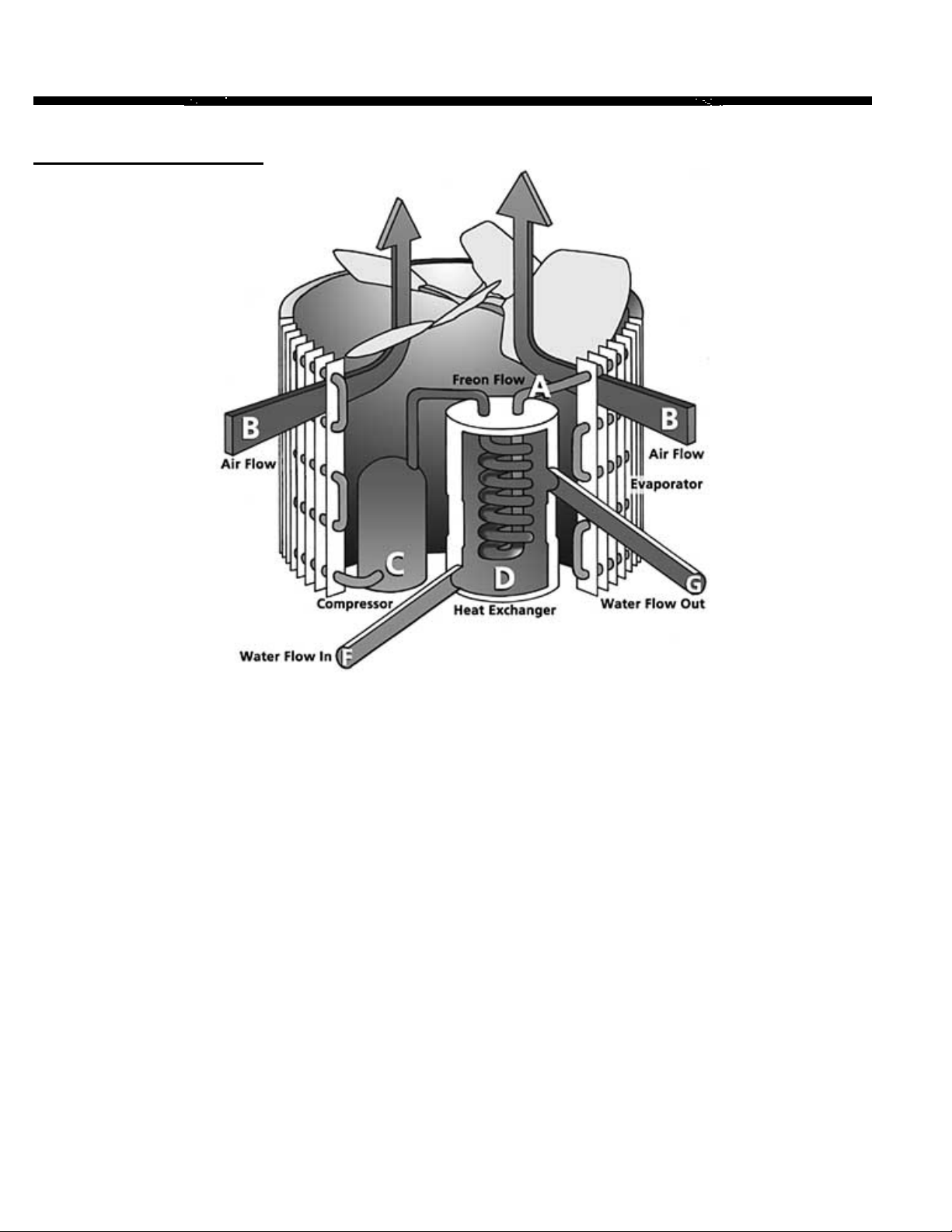

How a Heat Pump Works

Hayward Heat Pumps take heat from the environment and use it to heat your pool

water. During heat pump operation, liquid freon from inside the unit is pumped

through the system (A) and is turned into a heated gas. This happens when heat is

taken from the surrounding air (B) as it is drawn through the evaporator by the fan.

The compressor (C) receives this warmer gas and compresses it to a higher

pressure, resulting in the freon reaching even higher temperatures. As the unit

sends the heated gas through the heat exchanger, the gas gives up its heat to the

surrounding water (D). The freon reverts to a liquid state as it gives up the heat to

the pool water, which completes the cycle (A). The water (F), which is being

forced through the heat exchanger (D) by your pool pump, is heated by three to

five degrees as it passes through and returned to your pool as heated water. (G)

This process can also be reversed to remove heat from pool water.

A heat pump can transform 4 to 6 units of heat energy (BTU’s) for every 1

equivalent unit of electrical energy it consumes. This results in a coefficient of

performance between 4 and 6. The specific performance coefficient depends on

your heater model, ambient air temperature and climatic conditions, as well as

incoming pool water temperatures.

2

Get Familiar with Your Heat Pump

Safety Features

Hayward heat pumps are equipped with safeguards that will stop operation to protect your unit in case

of the following events:

High / Low Refrigerant Pressure Switches

• The high-pressure switch senses the refrigerant pressure in the sealed refrigeration system

and shuts the heater down in the event unsafe operating pressures are reached. The heat pump

will automatically reset after the system pressure drops back to normal operating pressures. When

this switch is tripped, digital displays will read “HP”

• The low-pressure switch senses the refrigerant pressure in the sealed refrigeration system to

protect against certain conditions that could be detrimental to compressor life. The switch shuts

the unit down in the event of loss of refrigerant, fan motor failure, evaporator freeze-up and

airflow blockage. The switch automatically resets when the pressure rises to normal operating

pressures. The display will show “LP” if this switch is tripped.

Heat Pump Pool / Spa Heater Owner’s Manual

• Excessively high refrigerant pressure

• Excessively high water temperature

• Loss of refrigerant

• Fan Motor Failure

• Evaporator Freeze-up

• Low Ambient Temperature

Refrigerant line blockage or overcharging

•

Evaporator Freezing

The low-pressure switch will shut the heat pump down when the evaporator starts to freeze.

When the unit starts to freeze the low-pressure switch will be tripped, causing the display to read

“LP” This will prevent the evaporator from becoming damaged or deformed.

Water Pressure Switch

The water pressure switch contacts close when pressure is applied as pool water flows through

the heat exchanger. Low flow rates as well as no flow will let these contacts open and this will

cause the unit to shut down. The display will read “PS” if the water pressure is not sufficient.

Time Delay

All models use a 5-minute time delay to prevent repeated tripping of the compressor thermal

overload, which is caused by attempting startup before system pressures are equalized. Any

interruptions, outside of power loss, will result in a 5-minute time delay.

Low Ambient Temperature

If the air outside the heat pump is not warm enough to produce heat, the system will shut down.

The actual point at which your unit will shut down due to low temperature varies depending on

which model you purchased, current weather conditions, and the amount of sunlight reaching the

heat pump. The shutdown can occur anywhere within a wide range of temperatures, usually

45≡F-55≡F. This is not a “fixed” range. We stress that climate conditions, sunlight, and various

models respond quite differently to low ambient temperature. A shutdown occurs because low

temperatures will activate the systems low-pressure safeguard switch (digital thermostats will

display a code “LP”.) The unit will start up again when the temperature has raised enough to reset

this switch. Note: Low ambient temperature does not necessarily affect the Chiller models

or the cooling cycle of the heat/cool units.

3

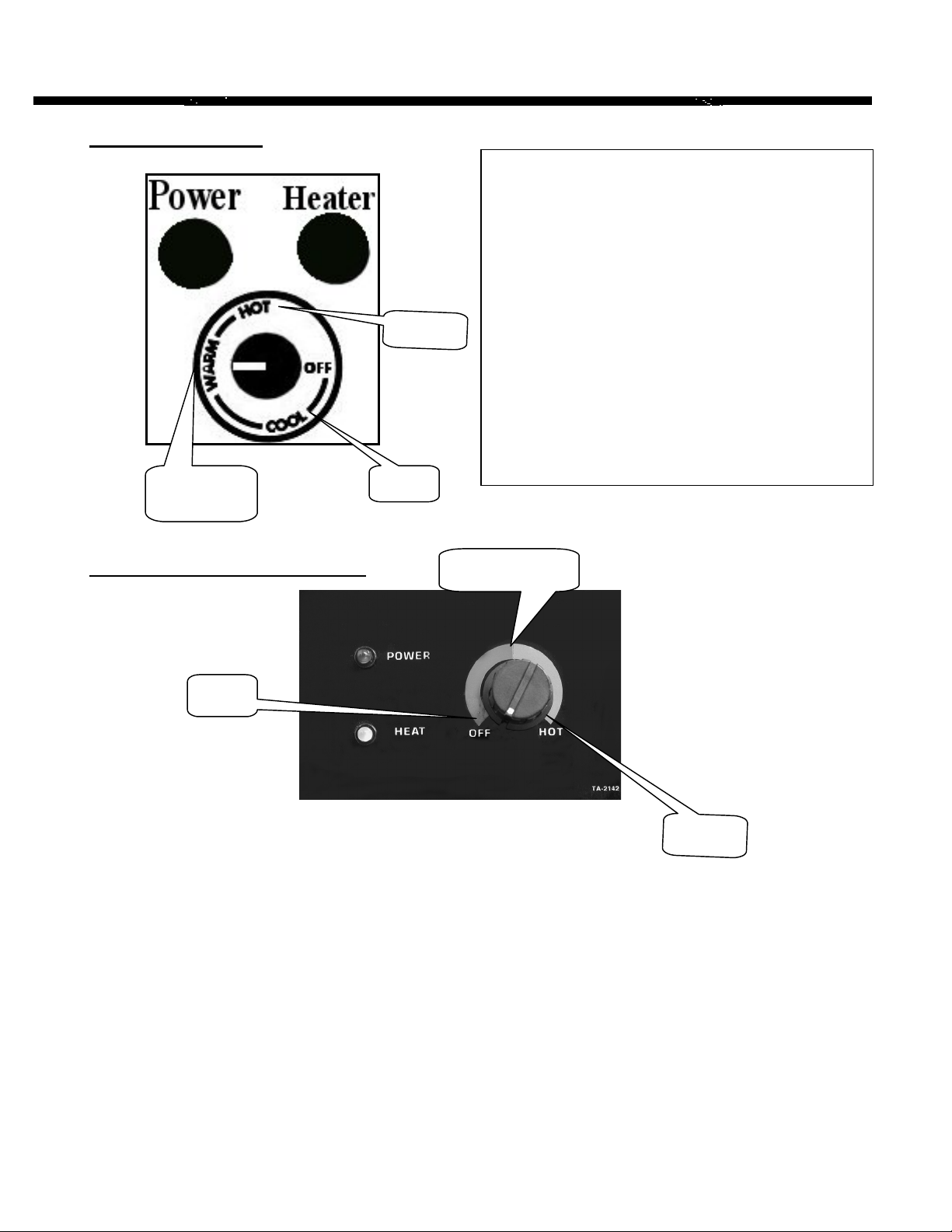

Analog Thermostat

Approx.

83°F

105°F

60°F

Power Indicator Light: Shows that proper power is

supplied.

Heater Indicator Light: Shows the unit is operating

normally and the thermostat is making a demand for

heat.

Temperature Control Knob: Adjust knob to desired

range, using the diagram on the left as a guide. The

thermostat has a temperature range from 60°F –

105°F(approx. ± 5° at the mid point.) Once you have

the dial is set to the preferred temperature, the unit

will achieve and maintain this temperature.

For help with this type of control, refer to the

troubleshooting guide

.

Single Mechanical Thermostat

60°F

Power Indicator Light: Shows that power is supplied.

Approx. 83°F

105°F

Heat Indicator Light: Shows the unit is operating normally and the thermostat is making a demand for heat.

Temperature Control Knob: Adjust knob to desired range, using the diagram above as a guide. The

thermostat has a temperature range from 60°F – 105°F. Once the dial is set to a preferred temperature, the

unit will achieve and maintain this temperature.

** The Single Mechanical Thermostat models do not turn off under 60 degrees F. This model was designed

to come on automatically if your water temperature is below 60 degrees to prevent the pool from becoming

excessively cool and creating long recovery times. If your application dictates the need to turn the heater off

for extended periods of time, use the circuit breaker.

For help with this type of control, refer to

Control

in the back of the owner’s manual.

Troubleshooting Guide for

MECHANICAL

Thermostat

4

Heat Pump Pool / Spa Heater Owner’s Manual

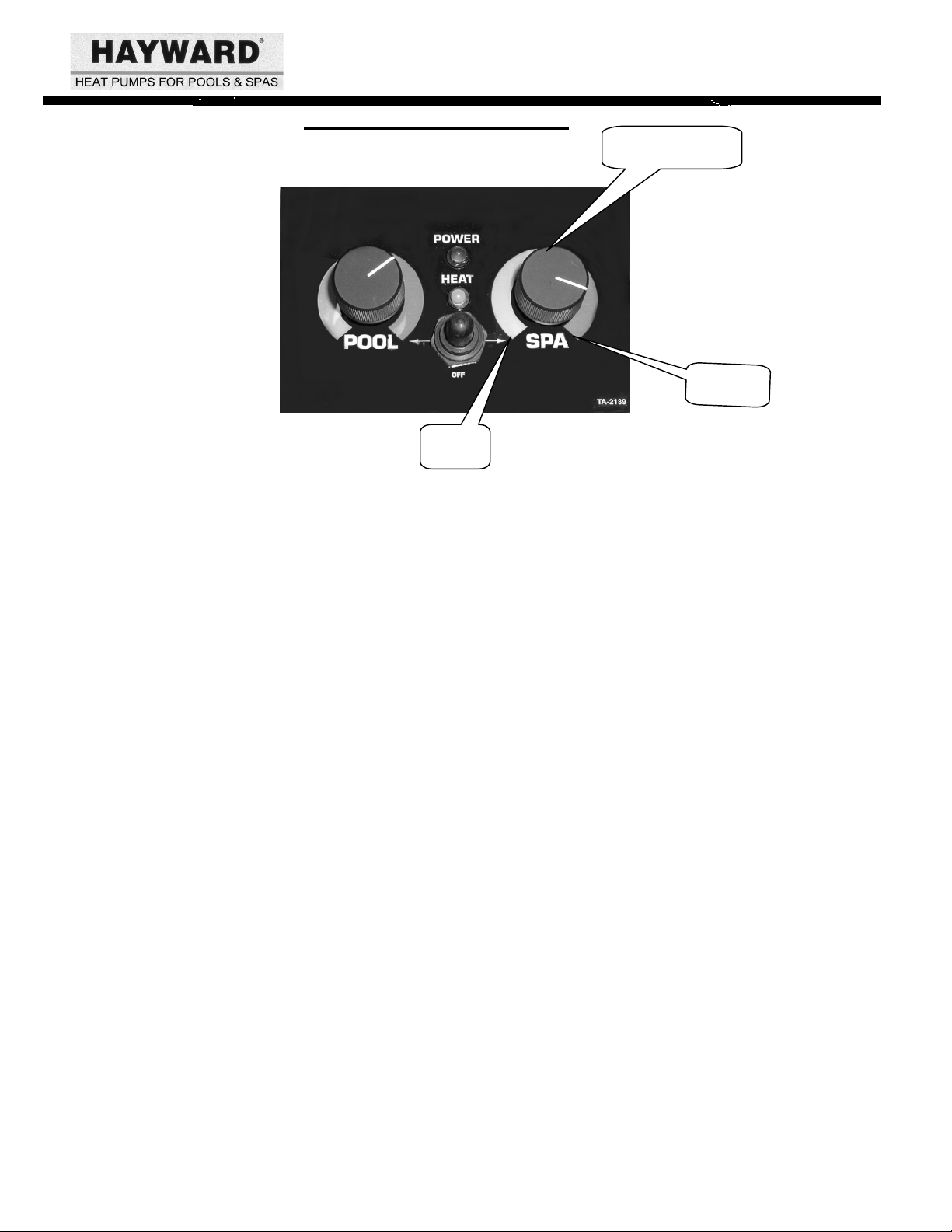

Dual Mechanical Thermostat

60°F

Power Indicator Light: Shows that power is supplied.

Approx. 83°F

105°F

Heat Indicator Light: Shows that the unit is operating normally and the thermostat is making a

demand for heat.

Temperature Control: Adjust knob pool or spa to desired range, using the diagram

above as a guide. The thermostat has a temperature range

from 60°F – 105°F. Once the dial is set to a preferred

temperature, the unit will achieve and maintain this

temperature.

Mode Toggle Switch: Off: Middle position, sets the unit to a “no-heating” mode.

Pool: Flip the switch toward the pool control knob (left). This sets the

unit into pool mode. The unit will maintain the preferred

temperature set point for your pool.

Spa: Flip the toggle switch toward the spa control knob (right). The unit

will maintain the preferred temperature set point for your spa.

For help with this type of control, refer to Troubleshooting Guide for MECHANICAL

Thermostat Control in the back of the owner’s manual.

5

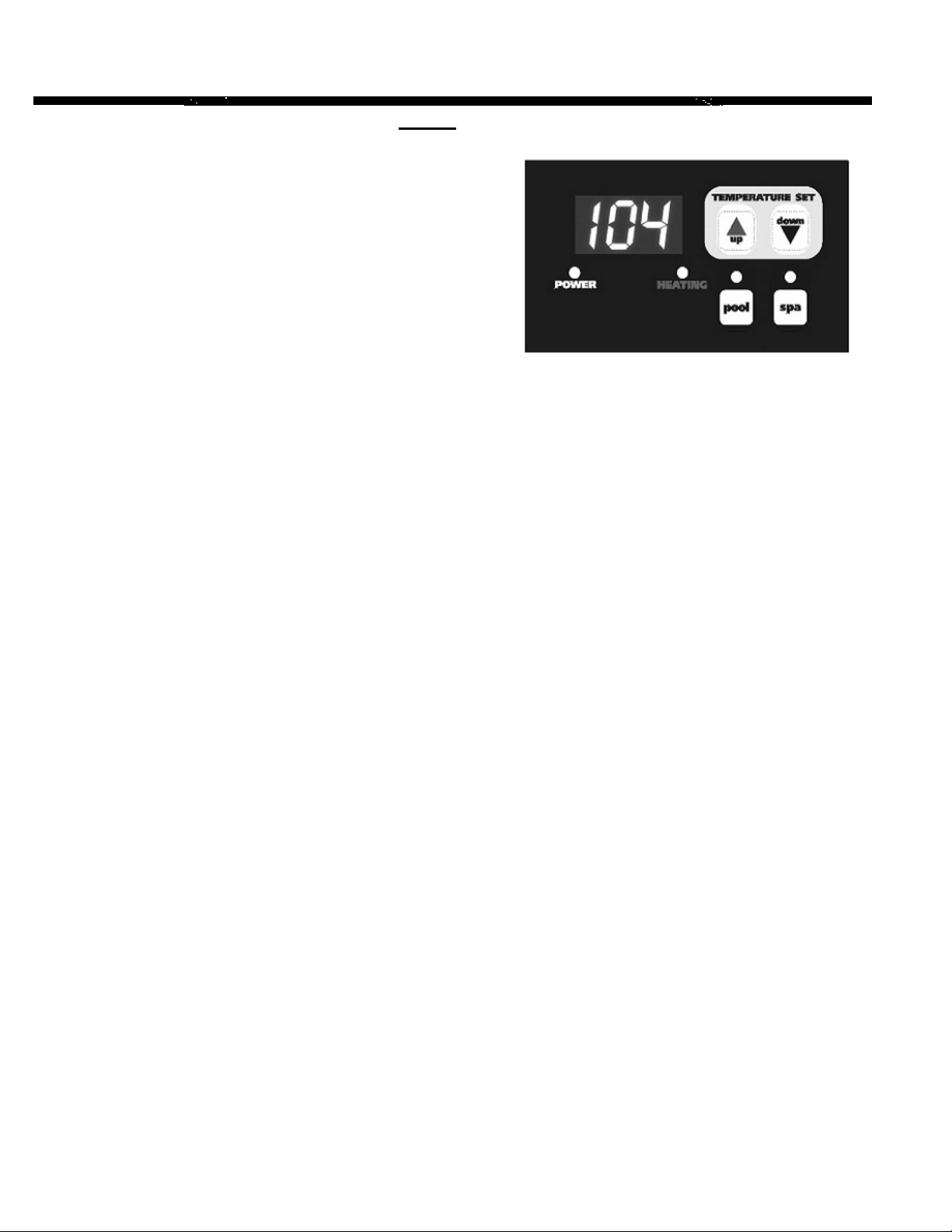

PST-1

Power Indicator Light: Indicates that power is

supplied to the heat pump

but does not indicate that

the unit is in operation.

Heating Indicator Light: Shows the unit is operating

normally and the thermostat

is making a demand for

heat.

Display: When power is supplied to

the unit, the display will

either show temperature,

diagnostic code (such as “PS”), or rolling dots.

On/Off: This control does not have a true on/off feature. The unit uses standby mode

instead. Rolling dots in the display indicate standby. Standby mode serves two

functions. (1) It serves as an “off” mode, which keeps the heat pump from

transferring heat into your pool water. (2) Standby allows a pool owner with

remote controlling systems, such as Jandy or ComPool, to maintain pool and

spa temperatures via their remote.

To enter standby mode: If pool mode is active (indicated by the green led over the pool button), press

the pool button once. Rolling dots should appear on the display.

If spa mode is active (indicated by the green led over the spa button), press the

spa button once. Rolling dots should appear on the display.

To exit standby mode: Press either the pool or spa mode button.

Mode Selection: Selecting the desired mode of operation (spa or pool) is accomplished using the

POOL / SPA buttons. A green LED above buttons designates the active mode.

When the pool mode is active, any displays or adjustments apply only to the

pool mode. Adjustments for spa mode must be made while the spa button is

activated. A user can switch between modes without turning the control to

standby first.

Temperature

Setpoint: Pool mode range is 70-98°F (21-37°C).

Spa mode range is 70-105°F (21- 41°C).

Adjust the setpoint: Continuing to hold the up or down button will scroll the setpoint value until

the desired setpoint is reached. When the desired value has been reached, release the button. The

new setpoint will flash to indicate a new value has been recognized and the display will revert

back to water temperature as indicated by a steady display.

Note

: The temperature reading displayed when the unit is in operation (heating indicator light is present)

displays the current water temperature.

To display the setpoint

setpoint for 3 seconds.

: Press and release the Temperature Set up or down button once will display the current

For help troubleshooting this type of control, refer to the Troubleshooting

Guide for

DIGITAL Thermostat Control in the back of this manual.

6

Heat Pump Pool / Spa Heater Owner’s Manual

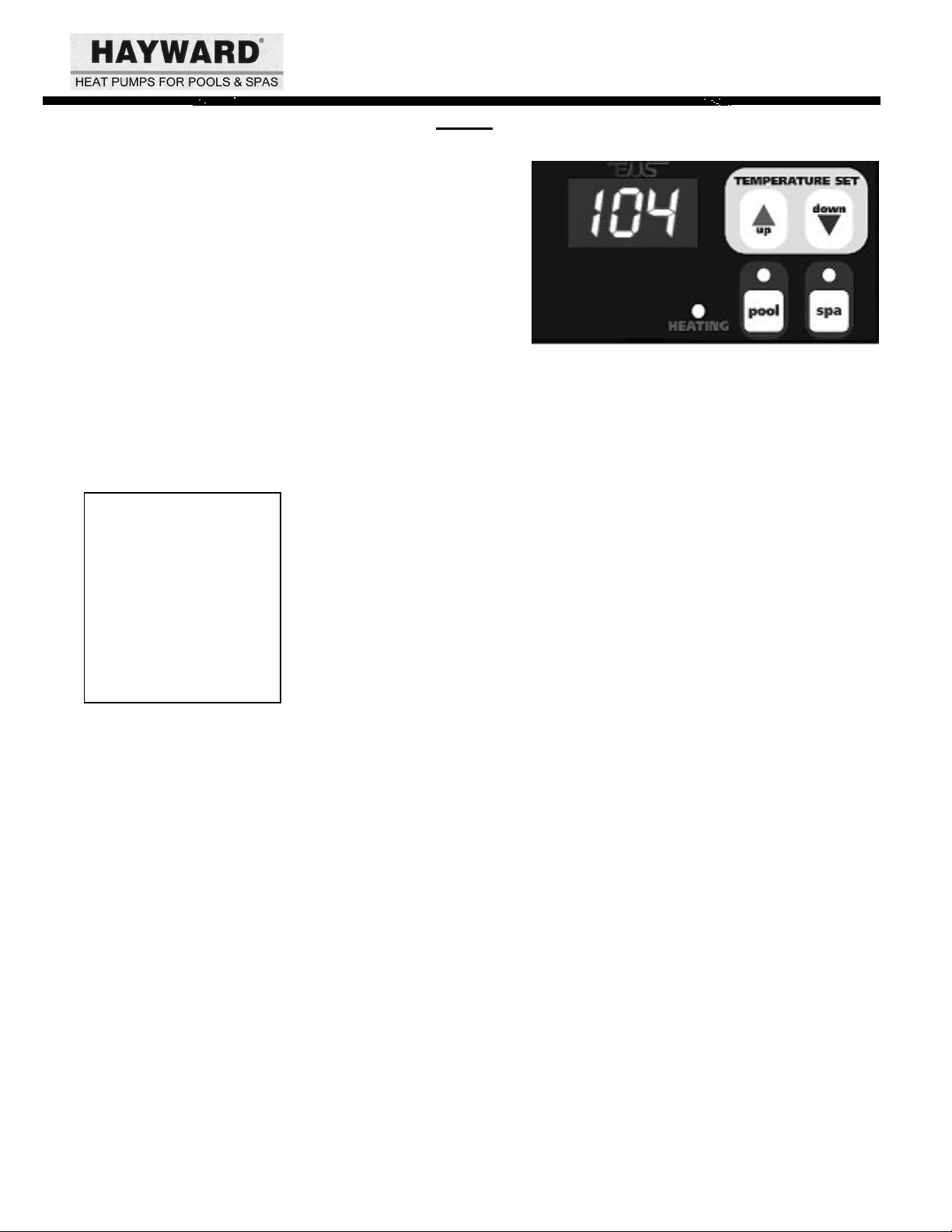

PST-4

The PST-4 temperature control is similar to the PST-1

shown above, with two differences. (1) The PST-4 has

a Time Clock Override. (2) The PST-4 has no power

indicator light.

Please read the data for the PST-1 on the previous page before continuing. It will provide you with

descriptions of button functions and setpoint programming.

Time Clock Override: This feature must be connected by an electrician. TCO provides a method of

maintaining the pool temperature when a time clock has the pool filter pump

turned off. TCO function then controls the pool filter pump via the PST-4.

Notes:

1. An electrician must

wire the TCO

function to your pool

system before it will

work.

2. The 2-hour TCO

checking interval

cannot be adjusted.

TCO will automatically turn the pool filter pump on after 2 hours of “off

time”. It will run the filter pump for 10 minutes while monitoring the water

temperature. If there is more than a 2-degree difference between the setpoint

and the actual pool temperature the heat pump will energize and continue to

run until the setpoint is satisfied.

A user may temporarily override the TCO. An example would be that you

want to use your pool between 9:00 and 10:00 pm. The control may be

programmed to energize the filter pump, which will engage the heat pump to

maintain the pool temperature. This is a temporary measure that can be

initiated in 30-minute increments, for a period up to 3 hours.

Programming for Temporary Pump Override:

1) Push and hold up and down buttons simultaneously – Display reads P0.0

2) Release buttons.

3)

4)

Push up button – display reads P0.5 (Each time the up Arrow engages, the

display will increase by .5 increments. Each .5 increment equals 30 minutes,

3 hours is the max.).

Push down button to decrease the temporary override time.

Example of typical TCO cycle: When the time clock turns off the filter pump, a “PS” will show on

the display. A timer starts inside the controller. After 2 hours, the heater will start the filter pump to

circulate water. “PS” is removed from the display and if a demand for more heat is made, the heater

goes back to normal operation. When the water is brought back to temperature, the TCO turns off the

filter pump and the heat pump will shut-down, displaying “PS”. The 2-hour timer is reset and the cycle

will begin anew.

For help troubleshooting this type of control, refer to the

Thermostat Control

in the back of this manual.

Troubleshooting Guide for

DIGITAL

7

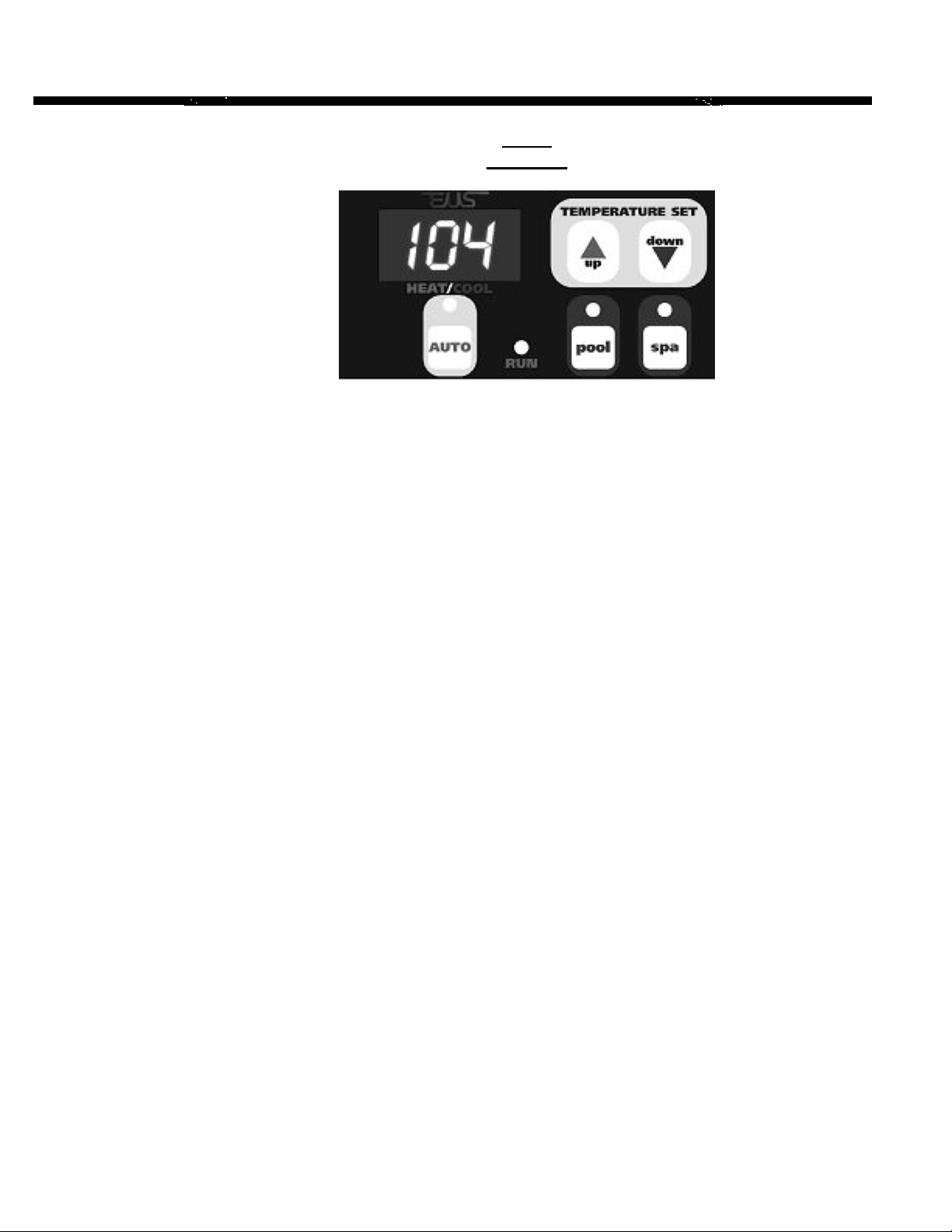

PST-5

Heat/Cool

The PST-5 is an upgrade of the PST-4 with the addition of an AUTO function. This allows the heat pump to

heat or cool the water automatically to maintain the setpoint. The PST-5 also has an optional Time Clock

Override (TCO-This feature must be connected by an electrician to operate.)

Read the instructions for the PST-1 and PST-4 fully before continuing. . The PST-1 page will

provide you with descriptions of button functions and setpoint programming. If you have purchased

the TCO option, the PST-4 page will provide TCO functionality and programming procedures.

Run indicator light:

Serves the same function as the “heating” indicator on the PST-1

and PST-4.

Setting the

AUTO function:

will be off.)

1. Disengage the AUTO mode (the AUTO mode indicator light

2. Program your desired temperature setpoint.

3. Press the AUTO button to activate the automatic heat / cool

function. (AUTO mode indicator will light.)

4. “AC5” should show on the display (set at the factory). “AC”

indicates that the cooling function is enabled and the

“5”means that when the water temperature is 5°F above the

setpoint, the unit will energize to cool your pool or spa.

By using the up and down keys, the AC5 can be changed to

values ranging from AC3 to AC9.

Setting unit to

cool only:

Engage the AUTO mode and use the up button to scroll past “AC9”. You

will notice that after the display of “AC9” an “ACP” (AUTO Cool

Primary) will be displayed. When “ACP” is displayed, the unit will only

cool the pool and will not go into the heating mode, no matter how

cool the pool gets.

NOTE: The

light will flash during cooling cycles.

RUN

Time Clock Override: Refer to TCO information on the previous page. (PST-4)

If troubleshooting this controller, refer to the

Troubleshooting Guide for DIGITAL Thermostat Control.

8

Installation Specifications

Receipt Inspection of Unit

Inspect the heat pump pool heater carton upon receipt for possible damage in shipment. Check

the “Tip-n-Tell” indicator attached to the outside of the box. A punctured or oil-soaked area of

the carton could indicate damage to the sealed refrigeration system. If damage has been

incurred or is suspected, bring it to the immediate attention of the delivering carrier. The carton

bears specific warnings stating “DO NOT DROP OR TAILGATE”, as well as arrows indicating

the correct vertical positioning. THE POOL HEATER MUST NOT BE TIPPED OR

TRANSPORTED ON ITS SIDE AS EVAPORATOR “OIL LOGGING” MAY OCCUR.

Upon arrival at the installation site, the unit should be carefully unpacked and again inspection

for any damage that may have occurred in transit. Minor indentations to the aluminum

evaporator fins will not affect performance of the unit.

THE MANUFACTURER CANNOT ACCEPT RESPONSIBILITY FOR

DAMAGE INCURRED OR REPAIRS NECESSITATED DUE TO IMPROPER

Heat Pump Pool / Spa Heater Owner’s Manual

HANDLING OF OUR EQUIPMENT.

Determining Optimum Location

THE LOCATION OF THE HEAT PUMP POOL HEATER IS VERY IMPORTANT FOR

EFFICIENT OPERATION

In order of importance, the installer must consider the following conditions:

o The heat pump will perform more efficiently when placed in direct sunlight

o Ample air intake

o Avoidance of air recirculation

o Accessibility of service panels

o Means of draining condenser in freezing weather (such as union-style fittings)

o Means of draining condenser and rainwater. Insulation of long water lines (over 25 ft.) from

heater to pool.

The installation of the unit in a fully enclosed area (i.e. garage, shed, etc.) is not

recommended. Consult HAYWARD for indoor pool application analysis.

.

.

9

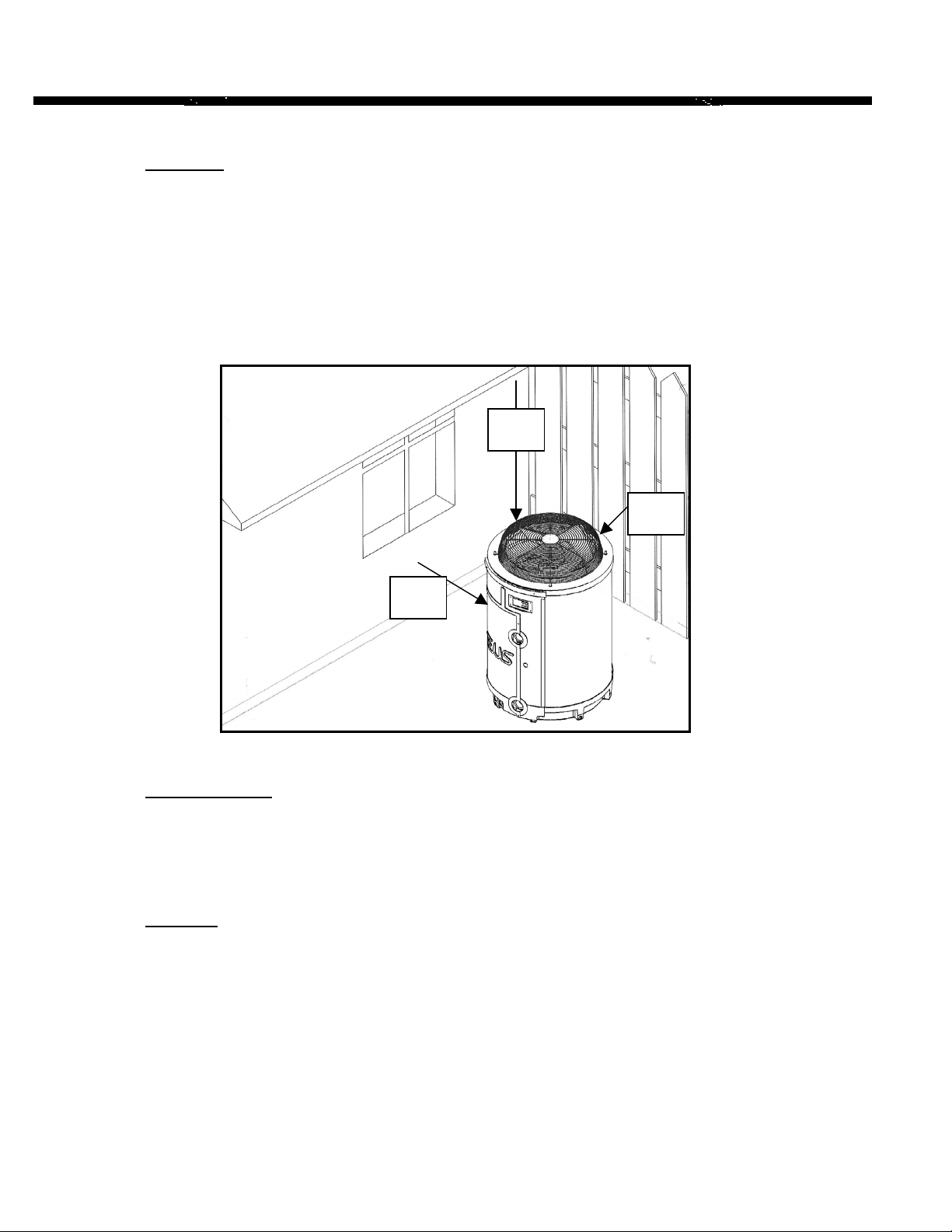

Clearance

A minimum of two feet of clearance from walls, shrubbery, equipment, etc. is required

around the entire pump circumference. This allows for ample air intake. No less than 6

feet clearance above the heat pump is required to prevent re-circulation of air. We

recommend not placing the unit underneath eaves, decks, or porches, as this causes

recirculation of discharged air.

RECIRCULATION OF DISCHARGED AIR BACK INTO THE PUMP WILL

GREATLY REDUCE ITS EFFICIENCY.

6 ft

2 ft

2 ft

Level Placement

The heater should be located on a solid, level surface. The pool heater is

exceptionally quite, but if further noise reduction is desired, the heat pump may be

placed on vibration absorbent pads, which are available from most airconditioning and refrigeration wholesalers.

Drainage

Condensation drain holes are provided in all base pans for adequate removal of

condensation and rainwater. Keep the drain holes unobstructed. Clean them

regularly (with your finger or a short stick) to remove any debris that may block

them.

HEAT PUMPS GENERATE WATER CONDENSATION DURING

NORMAL OPERATION. THIS SHOULD NOT BE MISTAKEN FOR A

LEAK IN THE UNIT.

The troubleshooting section provides recommendations should you suspect a leak.

10

Heat Pump Pool / Spa Heater Owner’s Manual

Other Precautions

The heat pump should not be placed near sprinkler systems, especially those

where fertilizer is added. This is very corrosive and, over time, will severely

damage the unit. If you live in an oceanfront area, the heat pump should be placed

out of direct spray of sand and salt. This will also clog, damage, and corrode the

unit. You may consider protecting your heat pump by planting shrubbery or a

privacy fence between the unit and the prevailing beachfront wind.

Application Guidelines and Maintenance

Climate

Weather conditions have a significant impact on pool heating. Local weather and

climate data are general conditions surrounding your pool. The microclimate

surrounding the pool must also be considered.

Lots of shade, low air temperature, relative humidity, and high wind velocity at the

pool surface negatively impact pool heating and will require an increased pool

heater output to maintain pool temperature.

Cleaning Systems

Some pools have cleaning systems attached to the filter pump intake (i.e. crawlers

and skimmers). These devices slow the flow of water entering the heat pump. As

low flow rates may damage the heat pump, built-in safeguards will automatically

shutdown the unit in instances of low water flow.

Dirty pool filters slow water flow and may cause a shutdown.

Familiarize yourself with the pool filter. Know how to check and clean or replace

it yourself. Do not completely trust a pool cleaning service to do this task for you.

11

Efficient Practices

Using A Pool Cover

POOL COVERS ARE STRONGLY RECOMMENDED.

A pool loses heat in several ways but testing shows that evaporative cooling (the cooling

effect created by water evaporating from the surface of the pool) accounts for

approximately 75% of a pool’s heat loss. However, if a pool is covered when it is not in

use, most evaporative cooling can be prevented. If the pool temperature is to be

maintained, the pool heating system must replace heat lost. Thus, the use of a pool cover

can offer dramatic savings in energy consumption. The cover’s approximate effect on

pool heat losses is illustrated in the table below:

SOURCE POOL UNCOVERED POOL COVERED

Of Heat Loss (USED 12 HRS/DAY)

Evaporative cooling 75% 30%

Convection loss to air 15% 10%

Ground loss (dry earth) (Negligible – less than 1%) (Negligible)

Re-radiation to environment 9% 9%

Make-up water 1% 1%

__________ ________________ ________________

Total 100% 50% of uncovered

pool losses

As the table shows, a pool cover that prevents evaporative cooling can reduce the

heat loss from a pool approximately 50% (which also cuts your power

consumption by 50%.)

Water Flow

To minimize heating times, make sure all water valves are open completely, that

the water level of the pool is at the correct height, and that any fountains or

waterfalls are disconnected or turned off. Maintain 30–75 gpm flow rate.

CHECK YOUR PUMP FILTER WEEKLY. REPLACE OR CLEAN AS

NECESSARY TO ENSURE PROPER FLOW RATES.

Chlorine Content

Chlorine is corrosive, along with other chemicals used in sanitizing pools.

Improperly maintained pH alkalinity levels are unhealthy for you and your pool

systems. Maintaining proper water pH levels will increase the life of all your pool

components, including your heat pump.

installed downstream of the heat pump (in the return line to the pool) and a check valve

installed in a manner that will not allow the raw chlorine to drain back to the heat pump

when the water pump is off. Do not allow pool maintenance people to pour chemicals

in skimmer.

Automatic chlorinators, if used, must be

12

Loading...

Loading...