Hayward H100ID1, ABG1001 Installation & Operation Manual

Installation, Operation & Service Procedures

Above Ground Pool Heater

Models H100ID1 & ABG1001

Unit must be installed outdoors only

and below an altitude of 2000 feet

FOR YOUR SAFETY

WARNING: If the information in these instructions is not followed exactly, a fire or explosion may result causing property damage,

personal injury, or death.

– Do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance

• Do not touch any electrical switch; do not

use any phone in your building

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas suppli-

er’s instructions.

• If you cannot reach your gas supplier, call

the fire department.

– Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

PATENT US6082993 1302507301 REV P 0811

WARNING:

The heat exchanger in your Hayward pool heater is made from the highest quality of copper materials. The premium materials

and the exacting processes used in the manufacture of the heat exchanger is state of the art in pool heater design and manu-

facture. Yet, it remains vital that the heat exchanger be protected from damaging or corrosive chemicals, insufcient water ow

or improperly balanced water chemistry. Heat exchanger damage or failure resulting from improper ow, improperly balanced

pool water or the improper addition of sanitizers into the water is NOT covered under the terms of your warranty.

The following factors are critical to heat exchanger protection. Follow these guidelines to help prevent pre-mature damage or

failure to your heater and heat exchanger.

1. WATER FLOW THROUGH HEATER

Water must be owing through the heater at the minimum rated flow rate during operation. Check that the pump is operating

and the system is lled with water and purged of all air prior to starting the heater. The minimum rated ow rate for your heater

is 20 GPM.

2. POOL/SPA WATER CHEMISTRY

The chemistry balance and mineral content of swimming pool water changes daily due to the addition of pool and sanitizing

chemicals, bather loads, rain, runoff and the amount of sun - to name a few. Improper chemistry balance and mineral content

can cause scaling and deposits to form on pool walls, in the ltration system, in the heat exchanger tubes and additionally can

promote corrosive action to all metals in the water path. Changing spa water regularly and maintaining the correct chemical

balance in your pool/spa will keep the pool/spa safe and sanitary, and will help protect the heat exchanger. Use a 4-way pool/

spa water test kit to check your water frequently (at least weekly). Use the following guidelines to help protect your heater’s

heat exchanger:

Failure to Maintain Proper Water Chemistry May Cause

Premature Heat Exchanger Damage or Failure

Recommended

Level

Chlorine

Bromine

pH

Total Alkalinity

Calcium Hardness

Salt

3. SKIMMER CHLORINATION

Placing chlorine or bromine tablets directly into the skimmer may result in high chemical concentrations owing through the

heater. DO NOT place chlorine or bromine tablets in the skimmer.

4. CHLORINATOR INSTALLATION

Chlorinators must be installed downstream of the heater, and a check valve must be installed between the heater and chlorinator to prevent high chemical concentrations from back owing into the heater.

5. BYPASS

Until water chemistry is properly balanced, and if your piping has a bypass valve installed for the heater, open the bypass so

that corrosive and potentially damaging water will not ow through the heater and therefore the heat exchanger. Close the

bypass valve once the water is properly balanced. Failure to close the bypass valve when attempting to operate the heater

will result in extensive damage to the heat exchanger. Ensure water ow through the heater is restored before operating the

heater. A bypass feature is also advantageous for service needs and for the ability to remove the heater from the water path

when not heating. Refer to Figure 2 in the installation manual for further information.

1 - 3 ppm

2 - 4 ppm

7.4 - 7.6

80 - 120 ppm

200 - 400 ppm corrosive to heat exchangerscaling of heat exchanger

2700 - ppm poor salt chlorinator performancecorrosive to heat exchanger

5000

Effect of Low Levels Effect of High Levels

hazy water, algea growth,

bacteria causing infections

corrosive to heat exchanger,

swimmer irritation

corrosive to heat exchanger,

large fluctuations in pH

swimmer irritation, bleaching of clothes/hair,

corrosive to heat exchanger

cloudy water, scaling of heat exchanger,

reduced sanitizer effectiveness

scaling of heat exchanger

2

Section I. General Information

Outdoor Installations

Top - Unobstructed Right side - 10 inches

Front - 10 inches Left side - 10 inches

Back - 10 inches Bottom - Combustible floor

Important notice:

The instructions herein are intended for the use of a

qualified technician, specifically trained and experienced

in the installation of this type of heating equipment. Some

states or provinces require that installation and service personnel performing the installation be licensed. If this is the

case in the state or province where heater is located, the

contractor must be properly licensed.

WARNING: Failure to comply with the appliance

installation instructions and service instructions in this

manual may result in equipment damage, fire, asphyxiation, or carbon monoxide poisoning. Exposure to products of incomplete combustion (carbon monoxide) can

cause cancer and birth defects or other reproductive

harm.

Conformance with codes:

The heater shall be installed in accordance with all local

and state codes. The heater installation must conform to

the latest edition of the National Fuel Gas Code American

National Standard (ANSI) Z223.1 and with the requirements

of the authority having jurisdiction. Design Certification in

the United States is in compliance with ANSI Z21.56 (latest

edition).

For Canadian installations, the heater must be installed

in accordance with standards CAN/CGA B149.1 and

B149.2 – INSTALLATION CODES FOR GAS BURNING

APPLIANCES AND EQUIPMENT and/or local codes,

and if applicable, Standard CSA C22.1 – CANADIAN

ELECTRICAL CODE, Part 1.

Location of heater:

Locate the heater in an area where a leaking heat

exchanger or connection leak will not result in damage to

the area adjacent to the heater or structure.

This heater must be installed at least five feet from

the wall of an above-ground pool.

The heater shall not be installed with the top of the vent

assembly within 10 feet below or to either side of any opening into the building.

Outdoor installation only:

The following installation and service clearances must be

maintained from surfaces to provide adequate air flow to the

heater.

Figure 1

An A.G.A. Certified main gas valve shutoff must be

installed outside of the cabinet and within 6 feet of the

heater. Gas shutoff valve must have an inside diameter

large enough to supply the proper amount of gas volume to

the heater.

NOTE: Do not use flexible appliance connectors on

any gas connections unless the connector is A.G.A.

approved for outdoor Installation, Is marked with the

BTUH capacity (which must be equal to or greater than

100,000 BTUH), and the type of gas (Natural or LP) to be

used.

Propane Gas:

All Propane gas tanks must be located outdoors away

from the pool and in accordance with the standard for stor-

age and handling of propane gas, ANSI/NFPA 58 (latest

edition) and applicable local codes. If propane gas tank is

installed underground, the discharge of the regulator vent

must be above the highest probable water level.

Propane tanks must have sufficient capacity to provide

adequate vaporization for the full capacity of the equipment

at the lowest expected temperatures. Consult a propane

company expert for correct sizing.

Water piping:

This heater is designed for use with pool and spa/hot

tub water only, as furnished by municipal water distribution

systems. The warranty does not cover heater use with mineral water, sea, salt, or other non-potable waters.

Do not install any restriction in the water pipe between a

heater outlet and the pool/spa with the exception of a three-

way switching valve and associated check valve. Blockage

of water flow from heater return to pool may result in fire or

explosion causing property damage, personal injury, or loss

of life.

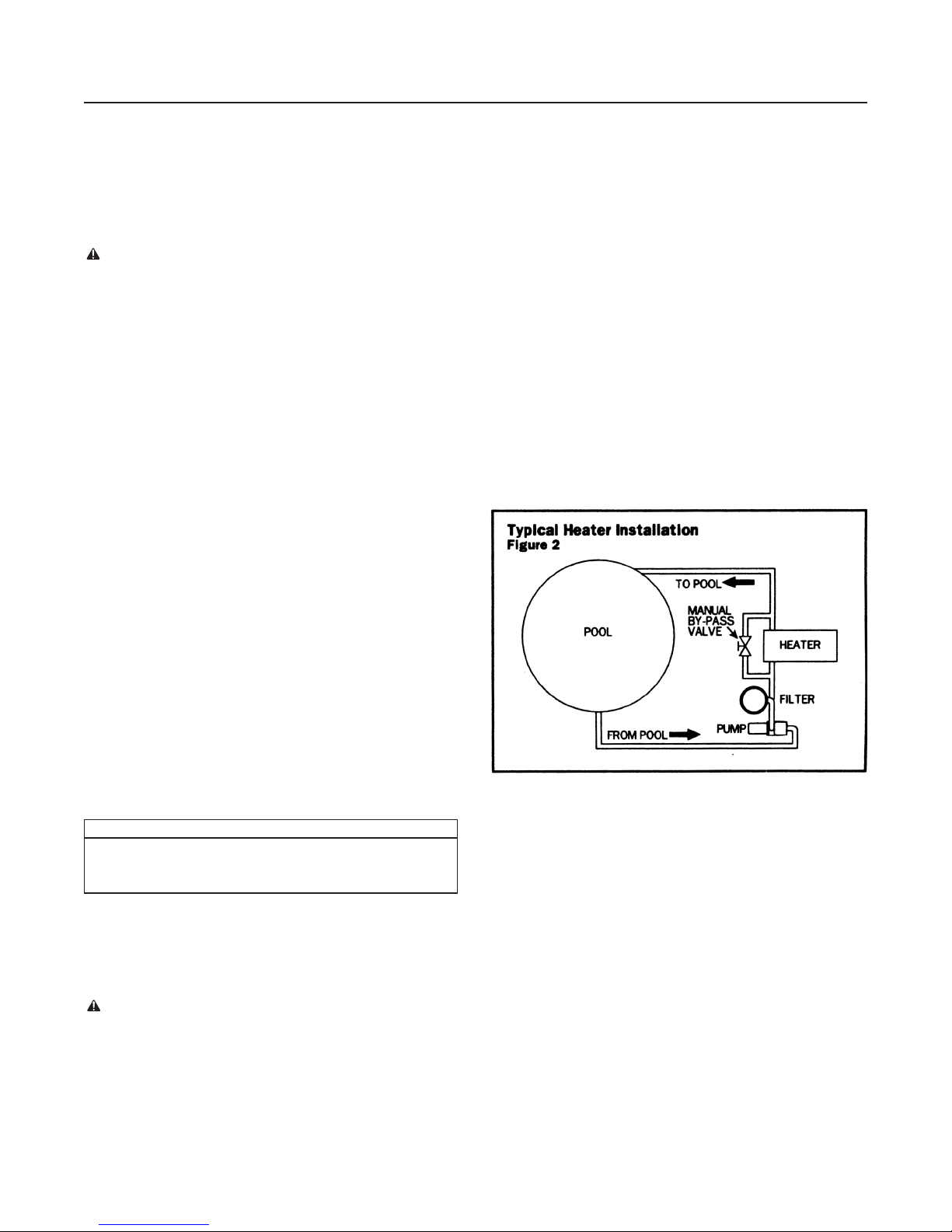

Plumbing connections:

Water flow rate to the pool must be between 20 and 70

gpm. If flow rate exceeds 70 gpm an external by-pass valve

must be installed. Figure 2 shows a typical heater installation.

Electrical system:

This heater is equipped with a standard 3-prong 120 volt

cordset. The plug must be inserted into a GFI protected,

watertight, outdoor receptacle rated for at least 10 amps.

The heater must be electrically grounded and bonded in

accordance with local codes, or in the absence of local

codes, with the National Electrical Code ANSI/AFPA 70.

If the heater must be hard wired, open the junction box

and disconnect the cord. Remove the cord and strain relief

and wire the heater in accordance with local codes or the

National Electrical Code.

The ignition system used to light the burners is a direct

spark system which requires 120 volt AC current as does

the blower motor. The system amp draw is 2 amps.

It is strongly recommended that the heater be supplied with a constant power source. If remote operation is

required, the heater should be controlled through the thermostat only.

Installation above or below water level:

This heater is supplied with a pressure switch factory set

at 3.0 psi. If the heater does not operate and the pressure

switch is at fault, the following procedure is recommended

to adjust the switch:

3

1. Clean filter thoroughly.

2. Set heater thermostat to highest setting.

3. Start filter pump. Make sure all air is out of water

lines and complete system is full of water.

4. Place a 5/64” allen head wrench in the adjusting

socket on the front of the switch and turn it

Section II. Installer

clockwise to increase the pressure required to close

the switch (this may be required if the heater is

installed more than 4 feet below water level).

5. To check operation, turn the pump on and off several

times. The heater should shut off immediately when

the pump is shut off.

Gas line testing:

The appliance and its gas connection shall be leak tested before placing in operation. The heater and its individual

shutoff valve must be disconnected from the gas supply

piping system during any pressure testing of that system

at test pressures in excess of 1⁄2 psig. The heater must be

isolated from the gas supply piping system by closing its

individual manual shutoff valve during any pressure testing

of the gas supply piping system at test pressure equal to or

less than 1⁄2 psig.

The gas supply line must be capped when not connected. After pressure testing, reconnect the gas piping to the

gas valve. Turn gas supply on and test all pipe and pilot tub-

ing joints for leaks. Use a soap and water solution. Bubbles

forming indicate a leak. Never use a open flame (match,

lighter, torch, etc.) as a leak could cause an explosion

or injury. Shut off gas and fix even the smallest leak imme-

diately. Be sure to leak test the main burner fittings using

the above procedure once the heater is in operation.

Gas pipe size:

Follow local gas codes for proper gas line material selection (copper, iron or plastic etc.)

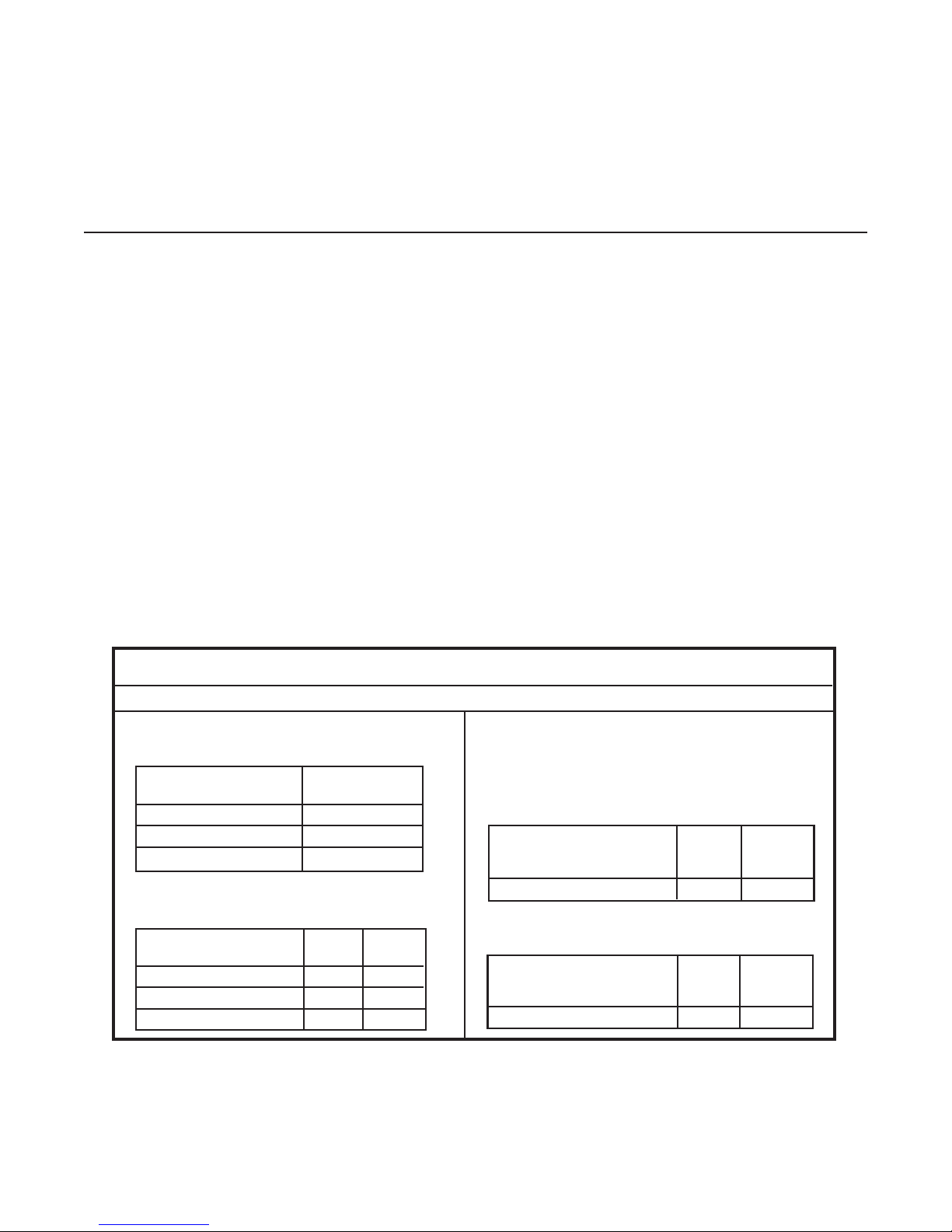

LOW PRESSURE NATURAL GAS Pipe Sizing:

(Based upon gas pressure of 0.5 psig or less and a

pressure drop of 0.5” W.C.)

Distance from Meter Iron

(Natural Gas) Pipe

0 to 25 feet 1/2”

25 to 100 feet 3/4”

100 to 200 feet 1”

LOW PRESSURE PROPANE GAS PIPE SIZING

“SINGLE STAGE”: (Based upon gas pressure of

11” W.C. inlet pressure and a 0.5” W.C. pressure drop)

Distance from Tank Iron Tubing

(propane) Pipe

0 to 25 feet 3/8” 5/8”

25 to 100 feet 1/2” 3/4”

100 to 200 feet 3/4” 7/8”

Gas pressure test procedure:

The following gas pressure adjustments are important to

proper operation of the heater. Incorrect settings can cause

improper operation.

1. Turn pump, main gas valve and heater power on. Start

heater following lighting instructions.

2. Using a manometer, determine the inlet gas pressure.

The inlet gas pressure must not exceed 10.5” W.C.

(water column pressure) for Natural gas or 13” W.C.

for Propane gas. Exposure to higher pressures can

damage the gas control valve, causing leaks or dia-

phragm rupture. This damage could result in fire, explosion or burner overfiring leading to carbon monoxide

poisoning. The inlet gas pressure must not be below 3.0”

W.C. for Natural gas and for Propane. The heater may

fail to operate at low inlet gas pressures. If the inlet gas

pressure is too high or too low, the installer must contact

the gas supplier and request that the inlet pressure to

the heater be adjusted.

3. Using a manometer, determine the gas operating pres-

sure. Manifold pressure for both natural and propane gas

is 2.0” W.C. The gas valve is preset to operate at this

pressure, no adjustment is necessary.

Figure 4

It is VERY IMPORTANT when installing a propane heater on a

two (2) stage regulation system, to follow the gas line sizing

chart below—without exception.

HIGH PRESSURE “TWO STAGE” SYSTEMS:

MGH PRESSURE PROPANE GAS PIPE SIZING

”FIRST STAGE”: (Based upon gas pressure of 10 psig inlet

pressure at a pressure drop of 1 psi.)

Distance from outlet of Iron

1st stage regulator to Pipe Tubing

inlet of 2nd stage regulator

0 to 200 feet 1/2” 1/2”

LOW PRESSURE PROPANE GAS PIPE SIZING “SECOND

STAGE” (Based upon gas pressure of 11 inches W.C. inlet

pressure at a pressure drop of 05 inch W.C.)

Distance from outlet of Iron

2nd stage regulator to Pipe Tubing

inlet of gas valve

0 to 10 feet 1/2” 1/2”

4

Loading...

Loading...