Hayward CAT 4000 Owner's Manual

\

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

Hayward Pool Products

620 Division Street, Elizabeth NJ 07207

www.hayward.com

CAT 4000

Water Quality Controller

Owner’s Manual

092431A RevE

CAT-4000

Contents

Introduction............................................2

Installation..............................................4

Pool Chemistry........................................7

Conguration..........................................7

System Maintenance.............................24

Network Communications.....................25

Troubleshooting....................................29

Warranty...............................................34

®

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

1

IMPORTANT SAFETY INSTRUCTIONS

When using this electrical equipment, basic safety precautions should always be followed, including the following:

• READ AND FOLLOW ALL INSTRUCTIONS

• WARNING: Risk of Electric Shock. Connect controller only to a grounding type recep-

tacle protected by a ground-fault circuit interrupter (GFI). CAT Controllers recommends

installation to a dedicated GFI circuit breaker performed by a licensed electrician.

• WARNING: Disconnect power before servicing. Other than the fuses, there are no user

serviceable parts inside the controller.

• WARNING: All power cords should be inspected frequently. Any damaged power cords

must be replaced immediately to reduce the risk of electric shock. Never operate a

controller without functional flow protection.

• WARNING: Installation requires a properly located GFI protected receptacle. Never use

an extension cord for electrical connections to the controller.

• WARNING: Always mount controller in a safe area not subject to damage by moving

objects. Never bury controller power cords.

• WARNING: Any person using, adjusting, or monitoring the controller must be at least 18

years of age and be familiar with these instructions and the contents of this manual.

• WARNING: Always take and record manual water chemistry readings in conformance

with Health Department requirements. Although automated controllers are a great aid in

maintaining healthy water quality, controllers are not a substitute for manual water testing with an accurate test-kit.

• WARNING: Always read and become familiar with Material Safety Data Sheets (MSDS)

and safe handling instructions for all chemicals used with the controller.

• CAUTION: The automatic controller should not be installed where it is accessible to the

public.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

2

Introduction

Description

The CAT 4000 revolutionizes the manner in which water quality can be monitored and maintained.

A pool operator typically checks, records and adjusts pool or spa water chemistry hourly at best.

The CAT 4000 continuously samples pH and sanitizer activity, adjusting the feeding of chemicals

on a basis proportional to the demand. Hourly water quality readings are sent along with any

alarms or service requests through a wireless network to the POOLCOMM web server for remote

monitoring and management through any internet connection. NOTE: The POOLCOMM website is

a subscription based service. Monthly charges apply.

From the website, the subscriber can monitor water quality, print charts, graphs and logs, change

controller settings, and designate contacts for outbound notification via email, cell phone or PDA.

Optional digital flow and level sensors are available to monitor flow rate, chemical storage tank

levels, and even automate water level control.

The results include elimination of “human error”, accurate and reliable maintenance of chemical

levels twenty-four hours a day, compliance with Health Department operating standards, reduced

burden on operating staff, and a reduction of chemical usage and costs. The CAT 4000 controller and POOLCOMM water quality management website together provide unprecedented control,

access and documentation.

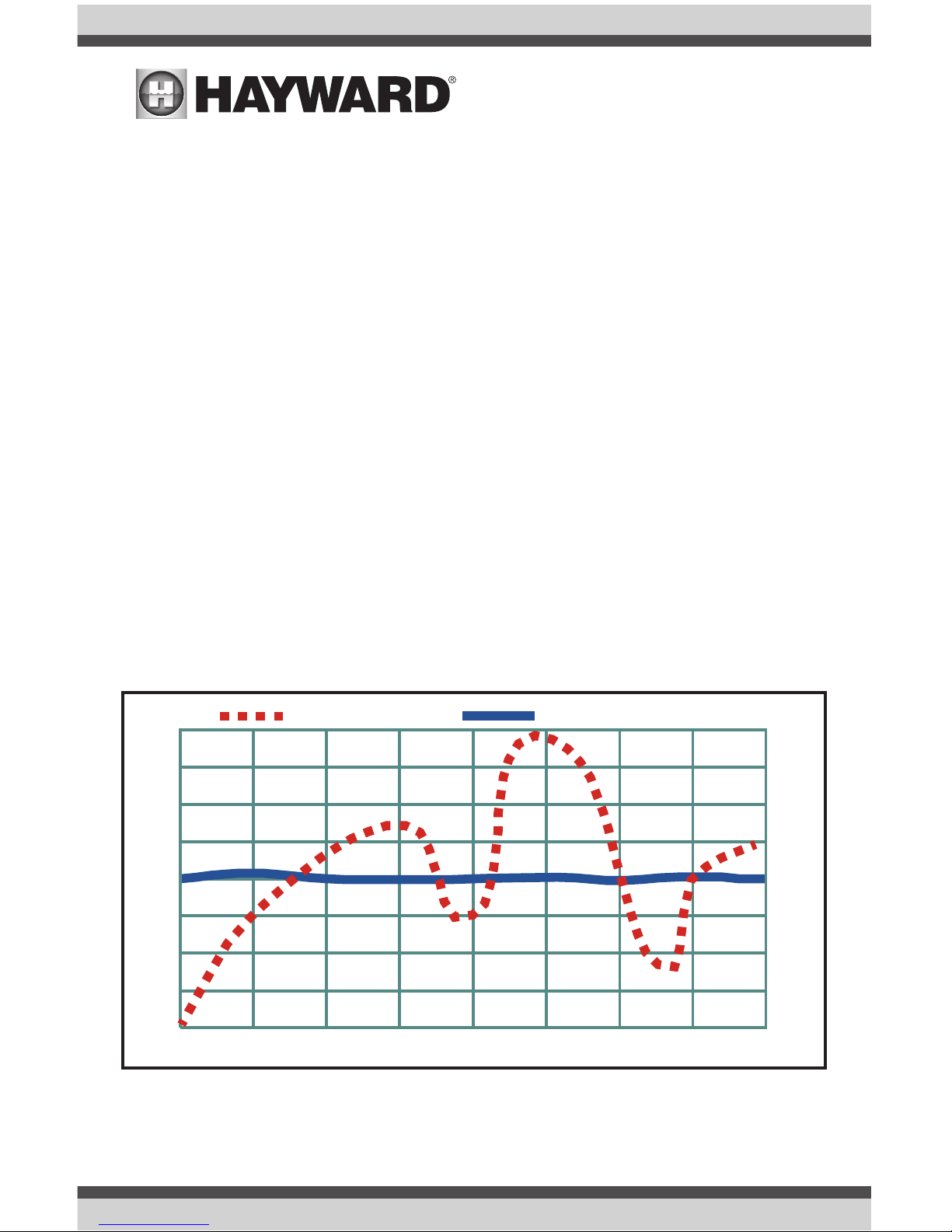

The following graph compares typical chlorine levels when chemistry is adjusted manually versus

automatically with the CAT 4000 controller:

Manual Control

HCC Automated Control

CL2

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0.0

10:00 11:00

12:00

1:00 2:00

3:00

4:00

5:00

Time

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

3

What’s Included

Description

The following is a description of the components incorporated in a typical CAT 4000 wireless water

quality control system:

The Professional-Series pH Sensor samples water from the filtration system and sends signals to

the controller indicating the acidity of the water. The ideal pH range for pools and spas is 7.4 - 7.6.

The CAT 4000 controller is preset from the factory to maintain pH 7.5. If pH is maintained below

7.4 (too acidic), eye irritation, corrosion of equipment, and damage to the pool or spa surface can

occur. If pH is maintained above 7.6 (too alkaline), sanitizer activity is reduced, water may become

cloudy, and eye irritation may result.

The Professional-Series ORP Sensor samples water from the filtration system and sends signals

to the controller indicating the oxidation-reduction potential (redox) of the water. ORP is an actual

measure of sanitizer activity (chlorine, bromine, ozone, etc.) and bacteriological water quality rather

than an expression of chemical residual levels. The CAT 4000 controller is preset from the factory

to maintain ORP at 650 millivolts.

The Flow Sensor monitors the rate of flow across the pH and ORP sensors and signals the controller to disable automated chemical feeding during periods when the filtration system is off or low

recirculation flow is detected.

The Flow Cell provides a convenient location for mounting the pH, ORP and Flow sensors while

ensuring ideal hydraulic conditions to maximize sensor performance and life.

The CAT 4000 Controller scans and interprets the signals from the pH, ORP, flow, and optional

digital flow-rate and level sensors, displays water quality readings and alarms in alphanumeric

format, and activates chemical feeders in proportion to demand to maintain pH and ORP setpoint

levels.

The controller incorporates audible and visual safeguard alarms for out of range conditions and

menu-driven control of setpoints, alarms, and a host of advanced features. The CAT 4000 controller also features an internal transceiver for wireless transmission of data between the controller

and POOLCOMM website.

The Level Sensors (optional) provide signals to the controller indicating low pH chemical tank level,

low ORP tank level, and low water level.

The Digital Flow Sensor (optional) provides a flow rate to be displayed by the controller and an

alarm indication when filter maintenance is required.

Package Contents:

(1) CAT 4000 Wireless Water Quality Controller

(1) PVC Backboard with Mounting Holes and Stainless Hardware

(1) Professional Series pH Sensor with 24” Cable and BNC Connector

(1) Professional Series ORP Sensor with 24” Cable and BNC Connector

(2) Sensor Storage Containers

(1) Injection Molded Flow Cell

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

4

(3) 1/4” NPT x 3/8” Tubing True-Seal Ball Valve

(1) Flow Switch with 24” Cable and Specialty Connector

(2) BNC Connector Protective Covers (Remove to Connect Sensors)

(1) 30’ Roll, Blue Poly Installation Tubing (3/8” OD)

(2) 1/4” NPT x 3/8” Tubing True-Seal Connectors

(1) CAT 4000 Quick Reference Guide

NOTE: Before commencing installation, please confirm that items listed above have been included.

Please report any shortages immediately to the factory.

What You Will Need

The following tools are recommended for installation:

• Drill (Cordless preferred)

• 3/8” Drill Bit

• 1/4” NPT (National Pipe Tapered) Tap

• Masonry Drill Bit & Anchors (if required)

• 13/16” Wrench or Channel-Lock Pliers

Installation

Installation Procedure

The key to a successful flow cell installation is in the plumbing. A pressure differential is required to

allow clean, untreated water to pass through the cell and across the sensors. We recommend using

the enclosed tubing and fittings to create a pressure-suction “loop” line.

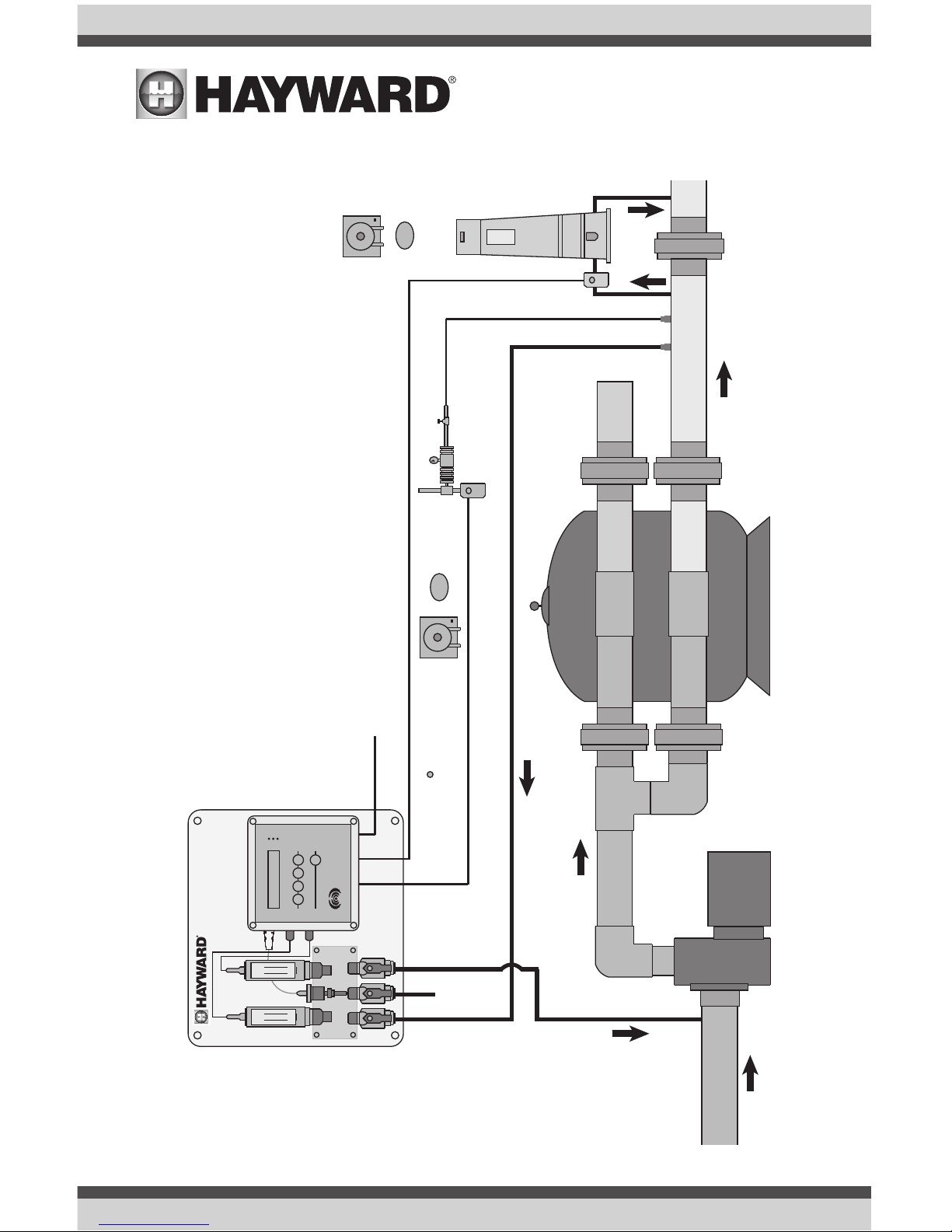

Follow the directions below for installation and refer to the Installation Diagram on page 6.

1. Turn off heater, chemical feeders, pump, and any other related equipment. Relieve pressure

from filtration system.

2. Select a convenient mounting location for the controller unit which will meet the following

criteria:

• Facilitates a combined (influent and effluent) maximum tubing run of 30’

• Located a minimum of ten feet from pool or spa

• GFI protected power source available

• Easily accessible to pool or spa operator

• Away from corrosive materials and physical hazards

3. Securely mount PVC Backboard on vertical wall.

4. Drill and tap a 1/4” NPT port at a location just downstream of the filter, but upstream from

any chemical injection point. Install a tubing connector, and run flex tubing to the influent

flow cell port.

5. Drill and tap a 1/4” NPT port at a location subject to vacuum or reduced pressure. Install the

remaining tubing connector and run flex tubing to the effluent flow cell port.

6. Cut a 3” length of flex tubing and insert into the sample stream port.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

5

7. Remove pH and ORP sensors from the plastic storage bottles and save bottles and storage

fluid for future use. Thread sensors into flow cell.

8. Remove BNC protective covers from left side of controller unit and store for future use.

These covers protect the controller unit from electrostatic discharge (ESD) and should be

used whenever handling or transporting the controller unit.

9. Connect the pH, ORP and Flow sensor cables to the controller unit as labeled. Sensor cables

are constructed from a specialized material - never cut or splice.

10. If new or additional chemical feeders are to be used with the controller, install according to

manufacturer’s instructions at this time.

11. Connect chemical feeders to the controller as labeled (See diagram on following page).

12. Check all electrical and mechanical connections. Resume filtration system operation and

check for any leaks.

Working with Tru-Seal Fluid Connections for a Fast, Professional Installation (See diagram below).

Body

Collet

TubingO-Ring

Prepare Tubing: Insert Tubing

To Release Tubing:

Cut tubing squarely

and remove any

burrs. Mark tubing

3/4” from end. This

is the insertion mark.

Insert tubing straight

into fitting until it

bottoms out and

insertion mark is no

longer visible.

Push collet toward

fitting body and pull

on tubing to release.

Repeat steps 1 and 2

to reuse fitting.

Influent

Sample

Stream

Effluent

pH Feed

ORP Feed

Power

Supply

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

6

Typical Cat 4000 Installation Diagram

Flow

Main Drain

and Skimmer

Flow

Flow

Flow

Flow Cell / Flow Sensor Bypass Line

Solenoid

Flow

Pressure

Differential

Solenoid

CAT CO2

pH Control

Erosion

Feeder

or

or

Chemical

Pump

Chemical

Pump

pH Feed Output

Power Cord

ORP Feed Output

Influent

(to Return Line)

Effluent

(to Suction)

CAT 4000

SYSTEM

CAT Controllers

SUCTION LINE

PUMP

FILTER

WASTE

RETURN LINE

Sample

Stream

MENU UP DOWN ENTER

TRANSMIT

CAT 4000

POOLCOMM

ENABLED

pH

Cl/Br

FEED

FEED

ALARM

WATER QUALITY CONTROLLER

CAT PRO25

ORP

Sensor

CAT PRO15

pH

Sensor

pH

ORP

Flow

pH

ORP

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

7

Pool Chemistry

Now that your new controller has been physically installed, water chemistry should be tested and

adjusted prior to initiating automated control of the pool or spa. Confirm that your pool or spa water

conforms to the following ranges before powering on and setting up the CAT 4000.

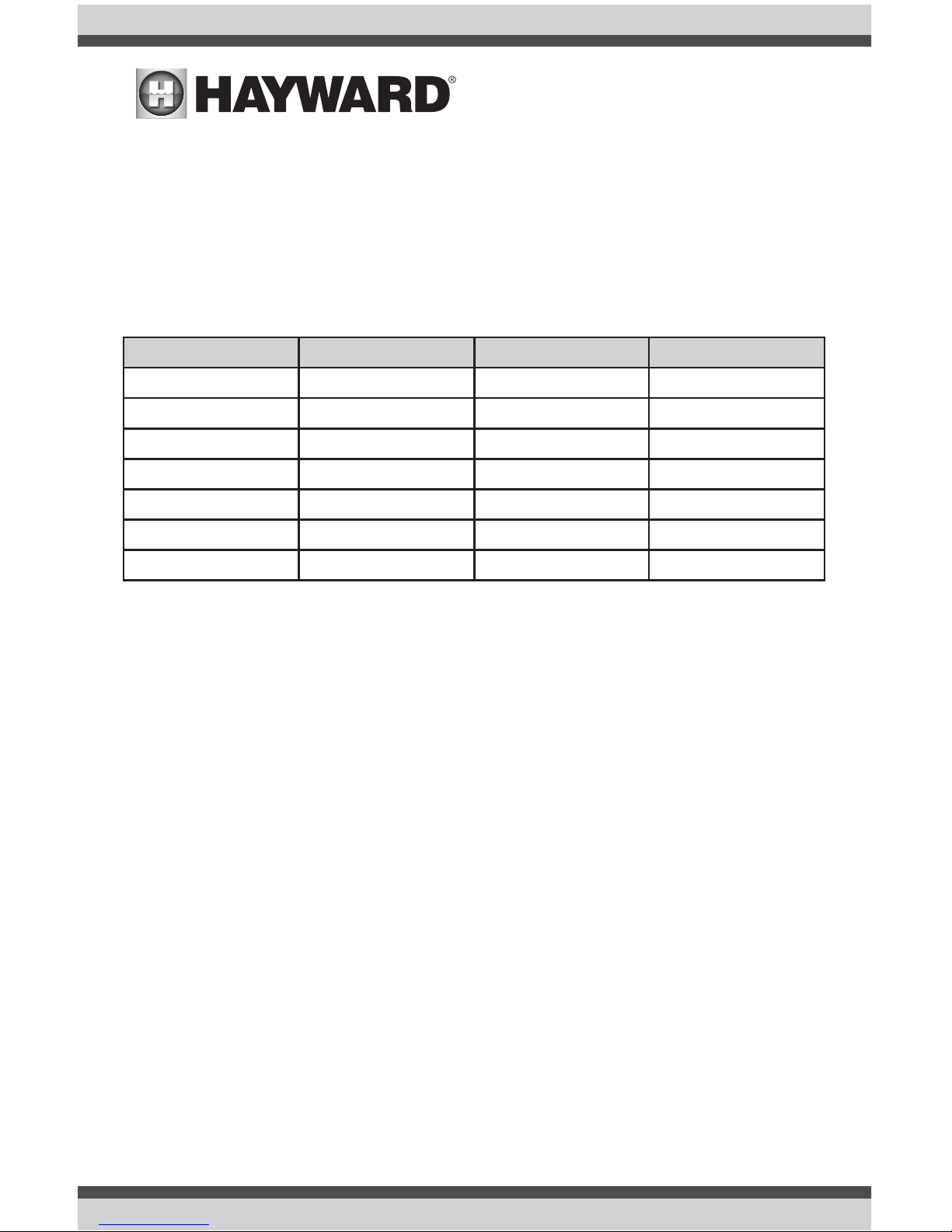

The table below indicates generally accepted guidelines. Always maintain water chemistry according to standards set by your local or State Health Department.

Test Minimum Ideal Maximum

pH 7.2 7.5 7.8

Free Chlorine (PPM) 1 2 3

Bromine (PPM) 2 3 4

Cyanuric Acid (PPM) 0 - 100

ORP (mV) 650 - -

Total Alkalinity 80 - 120

Calcium Hardness 200 - 400

All CAT water quality controllers maintain sanitizer levels (chlorine, bromine, ozone, etc.) based

on ORP. Although ORP is a superior index of water quality compared to part per million sanitizer

residual levels, factors such as pH, cyanuric acid concentration and total dissolved solids can affect

sanitizer residual readings relative to ORP.

CAT Controllers recommends establishing desired pH, sanitizer residual, calcium hardness, total

alkalinity, temperature and cyanuric acid levels prior to initiating automated control of the pool or

spa. The ORP setpoint will need to be changed periodically as described later in this section if the

goal is to provide consistent sanitizer residual levels rather than consistent control of ORP.

Configuration

Overview

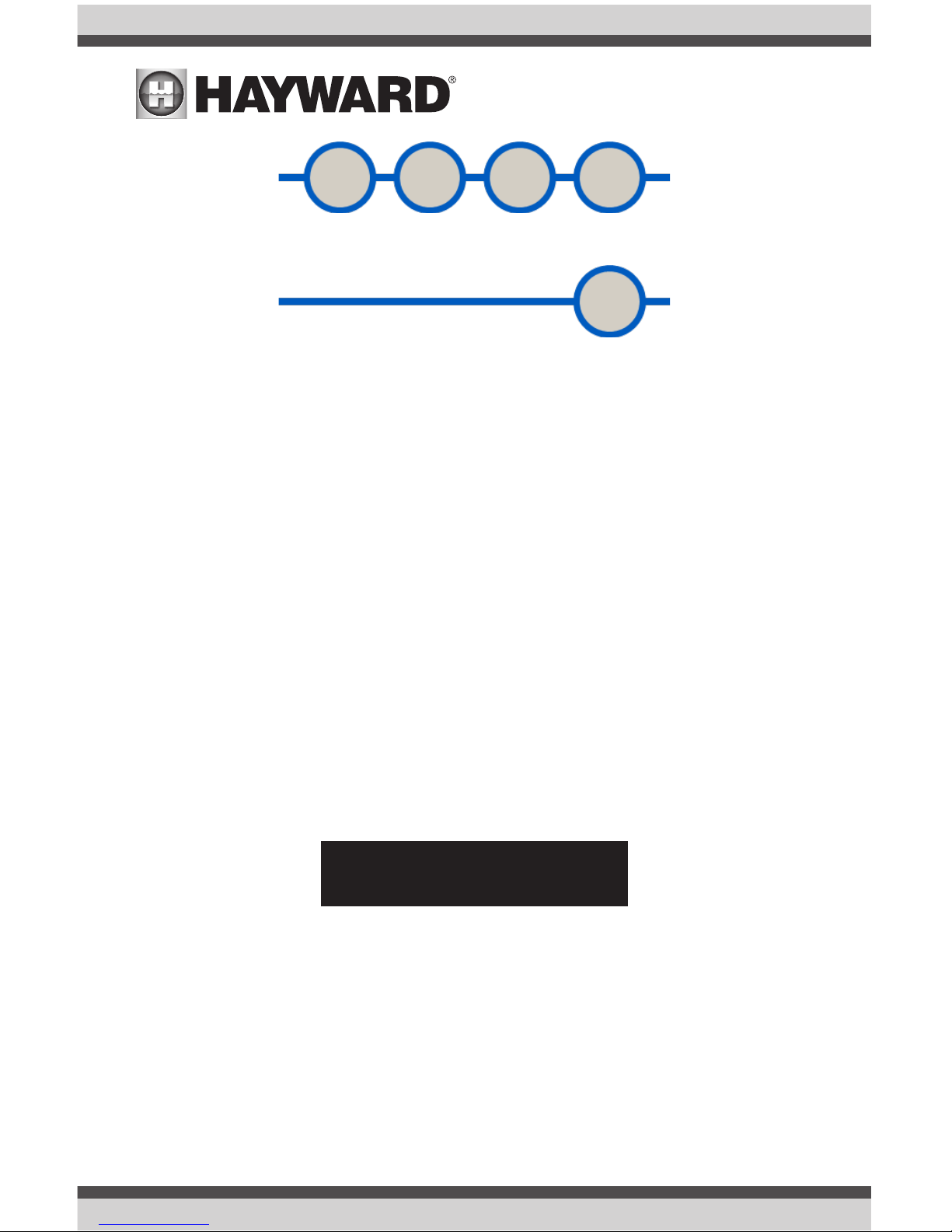

The CAT 4000 features a bright, menu-driven vacuum-fluorescent display which makes setup and

programming simple in any lighting conditions. The menu structure is divided into two sections; the

Operating Menu is intended for the end user to manage settings which are accessed on a frequent

basis, while the Configuration Menu is used to set up advanced features which truly customize the

controller to meet the individual requirements of the application.

The keypad provides intuitive access to the controller functionality as described on the following

page.

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

8

MENU: Used to enter menu mode and to navigate back within the menu structure.

UP: Used to increase values and to navigate vertically up within the menu structure.

DOWN: Used to decrease values and to navigate down within the menu structure.

ENTER: Used to select or confirm a menu item.

TRANSMIT: Sends a Service Request alarm and current data to the POOLCOMM web server.

Basic Configuration Options

Normal Operating Mode:

During normal operating mode, the display will indicate sensed pH, ORP, Flow Rate (with optional

digital flow sensor) and a status line which alternates between:

a) “System OK” or a list of any alarm conditions

b) A graph indicating sensed pH and ORP vs- setpoint values

The following is a typical display during normal operating mode:

To Change The Brightness Of The Display:

The display intensity can be changed to accommodate comfortable viewing in a variety of lighting

circumstances. While in normal operating mode:

Press UP to increase display intensity.

Press DOWN to decrease display intensity.

MENU UP DOWN ENTER

TRANSMIT

pH 7.5 ORP 650

System OK

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

9

To Enter The Operating Menu:

The operating menu contains selections which are likely to be changed on a routine basis, and

therefore are easily accessed. While in normal operating mode:

Press MENU.

The following will be displayed:

To Change The pH Setpoint:

The CAT 4000 is programmed at the factory with a default setpoint of pH 7.5. CAT Controllers

considers this to be ideal for pool and spa applications. The following steps enable the selection of

a different setpoint. While in normal operating mode:

Press MENU.

Select pH setpoint by pressing ENTER.

The current pH setpoint will be displayed:

Press UP or DOWN to select the desired pH.

Press ENTER to save your selection.

The controller will automatically return to normal operating mode in 10 seconds.

To Calibrate pH:

The CAT 4000 is far more accurate than most liquid test standards, but pH calibration is necessary to match manual water testing results, compensate for a depleted or unclean pH sensor, and

confirm proper operation of the system. While in normal operating mode:

Press MENU.

Press DOWN to find the pH Calibrate menu item.

Press ENTER to select pH Calibrate.

The sensed pH value as currently calibrated will be displayed:

Press UP or DOWN to match your known good standard.

Press ENTER to save your selection.

The controller will automatically return to normal operating mode in 10 seconds.

pH Calibrate

7.5 pH

Operating Menu

pH Setpoint

pH Setpoint

7.5 pH

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

10

To Select pH Feed Mode:

The CAT 4000 is programmed at the factory to operate in automatic feed mode as the default setting. Other pH feed mode selections include off (disabled), and manual on for a fixed interval up to

25 minutes after which automatic feed will resume. While in normal operating mode:

Press MENU.

Press DOWN to find the pH Feed Mode menu item.

Press ENTER to select pH Feed Mode.

The current pH Feed Mode will be displayed:

Press UP or DOWN to find the desired selection.

Press ENTER to save your selection.

The controller will automatically return to normal operating mode in 10 seconds.

The “Off” (disabled) mode is useful when servicing pH feed equipment, or if pH chemical supply

has been depleted.

The “Manual On” mode allows constant chemical feed for a fixed interval of up to 25 minutes. This

feature is useful when adding extra chemicals is desired and during initial balancing of the water.

NOTE: Always disconnect chemical feeder power cords prior to performing any electrical service.

To Change The ORP Setpoint:

The CAT 4000 is programmed at the factory to maintain ORP at 650 mV by default. This is the

generally accepted world standard for safe drinking water. In order to maintain a given chlorine or

bromine residual in conformance with Health Department standards for a particular body of water,

perform the following:

Check and balance pH, calcium hardness and total alkalinity. Manually feed chlorine or

bromine to desired ppm residual. Note the displayed ORP value. This will be used as the

setpoint. While in normal operating mode:

Press MENU.

Press DOWN to find the ORP Setpoint menu item.

Press ENTER to select ORP Setpoint.

The current ORP setpoint will be displayed:

Press UP or DOWN to select the setpoint noted above.

Press ENTER to save your selection.

The controller will automatically return to normal operating mode in 10 seconds.

pH Feed Mode

Automatic Feed

ORP Setpoint

650 mV

Loading...

Loading...