Page 1

ISC250CF-98

OWNER’S GUIDE

INSTALLATION AND OPERATING INSTRUCTIONS

HAYWARD

®

CHEMICAL FEEDER

MODELS

C250CF, C500CF, C1100CF, C1800CF, C2400CF

Your Hayward Automatic Chemical Feeder is designed for installation next to

filter/pump system. It uses either Trichloro-S-Triazinetrione (tri-chlor) slow

dissolving chlorine or bromine sticks or tablets ONLY. No other type of

chemical should ever be used in your feeder. It should be installed to operate

by the pressure differential of the system, or a pressure-suction combination,

using the pump to provide water flow through the feeder. The amount of

sanitizer dissolved depends on the flow rate through the feeder. By

regulating the Dial Control Valve between FULL (more sanitizer) and toward

OFF (less sanitizer), you can easily adjust the rate of feed necessary to

maintain the proper residual for your pool.

DANGER—READ CAREFULLY

Always read label and carefully follow the sanitizer

manufacturer’s and dealer’s recommendations for proper

water conditioning and daily sanitizer requirements for your

particular pool. This chemical feeder is designed to use only

either Trichloro-s-Triazinetrione (tri-chlor) slow dissolving

chlorine or bromine sticks or tablets. NEVER MIX or use any

other types of chlorine sanitizer or chemicals in this feeder.

Explosion or fire may result, causing property damage,

personal injury or death.

WARNING: MISUSE MAY RESULT IN SERIOUS

PERSONAL INJURY REQUIRING HOSPITALIZATION.

RELATED COMPLICATION MAY LEAD TO DEATH.

Exercise extreme caution when opening or servicing your

feeder. Always shut off pump and available valves before

opening feeder. NEVER OPEN chemical feeder when pump

is running. Do not inhale fumes from any chemical feeder or

container. Protect your eyes, skin and clothing from

chemicals at all times with gloves and face shield. To

prevent build up of gas in chemical feeder, be sure return

line valve(s) is kept open—except when opening/servicing

unit.

WARNING: IF THESE INSTRUCTIONS ARE NOT

FOLLOWED EXACTLY, A FIRE OR EXPLOSION MAY

RESULT, CAUSING PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

For proper installation of your Chemical Feeder, see

Installation Instructions on next page.

BROMINE USE:

Before start-up of your chemical feeder, your pool should be

properly conditioned and have the recommended bromine

residual as listed below. The chemical demand for pools

varies based on use, temperature, sunlight, etc. Initially,

you’ll have to experiment to determine the proper valve

setting required for your pool and filter time cycle. As a start,

add desired quantity of bromine tablets or sticks, slow

dissolving type only, and set Dial Control Valve at 1/2. Test

water periodically and adjust Dial Control Valve setting to

maintain a proper bromine level.

Recommended Bromine Residual:

CHLORINE USE:

Before start-up of your chemical feeder, your pool should be

properly conditioned and have the recommended chlorine

residual as listed below. The chemical demand for pools

varies based on use, temperature, sunlight, etc. Initially,

you’ll have to experiment to determine the proper valve

setting required for your pool and filter time cycle. As a start,

add desired quantity of chlorine tablets or sticks, slow

dissolving type only, and set Dial Control Valve between 2

and 4. Test water periodically and adjust Dial Control Valve

setting to maintain a proper chlorine level.

Recommended Chlorine Residual:

Residential Pools: 2.0 - 3.0 PPM

Commercial Pools: 3.0 - 5.0 PPM

Residential Pools: 1.0 - 2.0 PPM

Commercial Pools: 1.0 - 2.0 PPM

C500CF

C1800CF

Page 2

SPECIFICATIONS

MODEL NO.

C250CF

C500CF

C1100CF

C1800CF

C2400CF

PIPE SIZE

3/4” FIP

3/4” FIP

1-1/2” FIP

1-1/2” FIP

1-1/2” FIP

FEEDER WIDTH FEEDER HEIGHT

MAXIMUM

WORKING PRESSURE

INCHES

10.5

10.5

13

13

13

CM

26.7

26.7

33

33

33

INCHES

17.5

27.5

33

45

56

CM

44.5

69.9

83.8

114.3

142.2

PSI

50

50

50

50

50

BAR

3.45

3.45

3.45

3.45

3.45

PERFORMANCE DATA

Model No.

C250CF

C500CF

C1100CF

C1800CF

C2400CF

Max. Chemical Capacity

Chlorine or Bromine

Max. Output Rate (1 hr.)

Chlorine Bromine

lbs.

1.50

1.75

3.75

4.00

4.75

lbs.

0.07

0.10

0.30

0.35

0.40

Kilogram

7.2

13.5

22.7

31.8

40.9

lbs.

16

30

50

70

90

Kilogram

0.68

0.79

1.70

1.81

2.15

Kilogram

0.03

0.05

0.14

0.16

0.18

Gallons

20,000

40,000

75,000

100,000

150,000

Gallons

70,000

140,000

262,500

350,000

525,000

Kiloliter

265

530

994

1325

1987

Kiloliter

76

151

284

379

568

Maximum Pool Size

Chlorine Bromine

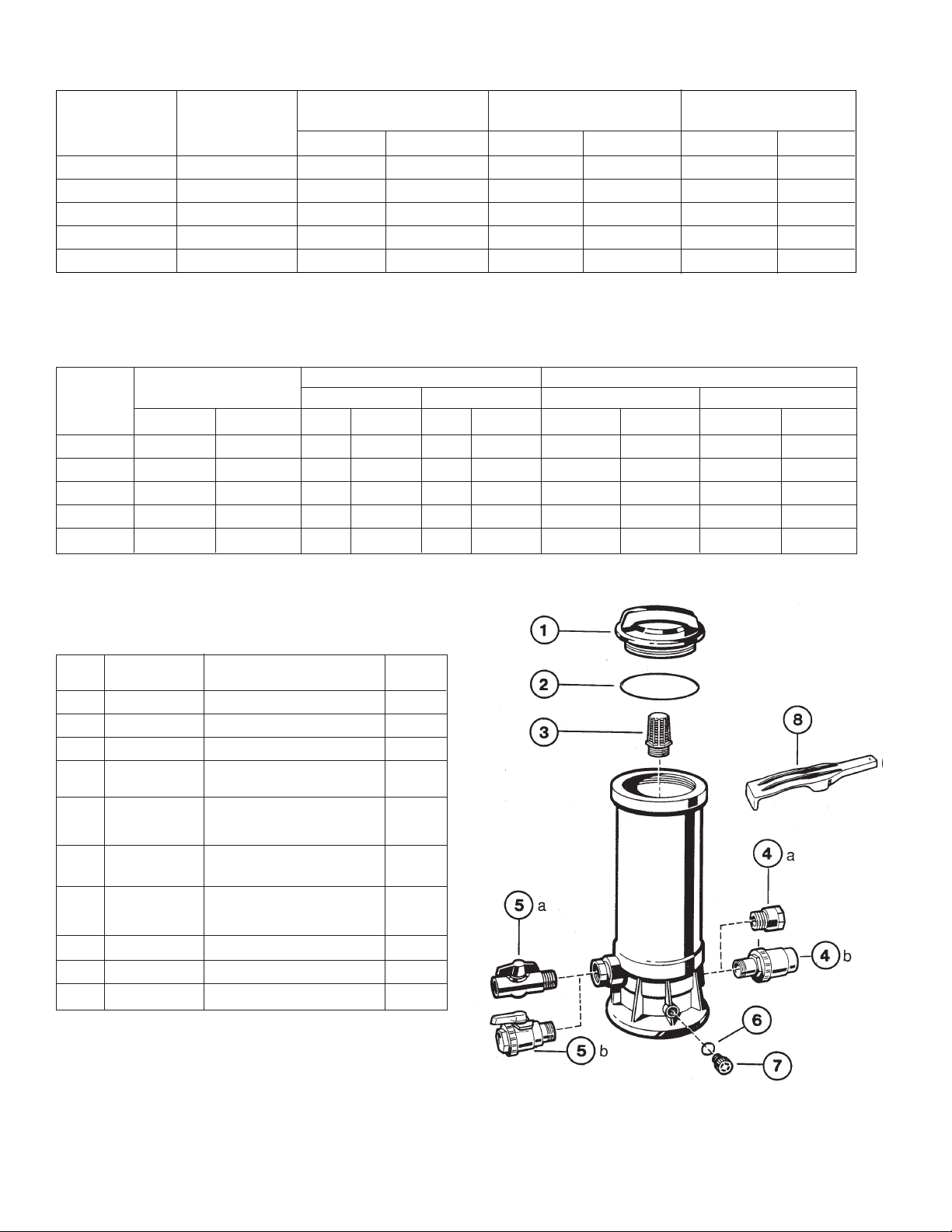

PARTS

REF.

NO.

1

2

3

4a

4b

5a

5b

6

7

8

NO.

REQ’D.

1

1

1

1

1

1

1

1

1

1

SPX3100D

SPX3000SV

CX500J

CX500CV

CX1100CV

CX500BV

CX1100BV

SP605Z2V

C250Z14

SP3100T

Cover

Cover O-Ring, Viton

®

Strainer

3/4” Check Valve

(C250CF & C500CF)

1-1/2” Check Valve

(C1100CF, C1800CF &

C2400CF)

3/4” Control Valve

(C250CF & C500CF)

1-1/2” Control Valve

(C1100CF, C1800CF &

C2400CF)

Drain Plug O-Ring, Viton

®

1/2” Drain Plug

Cover Opening Tool

A single body assembly is shown for ease of illustration. Models vary in overall height and appearance.

To be N.S.F. Listed, a flow rate indicator must be installed on chemical feeder inlet line.

PART NO.

DESCRIPTION

Page 3

TO OPEN CHEMICAL FEEDER:

Shut off pump and turn Dial Control Valve to OFF. Wait

1 minute. (If outlet is below water level, close any other

in-line valves to prevent possible water back flow.)

Turn Cover Cap counter-clockwise to open. Use

SP3100T cover opening tool if necessary. Caution: Do

not inhale fumes from feeder. Allow water in tank to

drain automatically to pool. If chemical feeder is installed

below water level, open the Drain Valve and allow the

tank to drain in a safe manner. Draining the tank should

make adding sanitizer easier and safer.

TO REFILL CHEMICAL FEEDER:

Add desired quantity of either Trichloro-S-Triazinetrione

(tri-chlor) slow dissolving chlorine or bromine tablets or

sticks. NEVER mix chemicals together or use any other type

of chlorine sanitizer in this feeder. Explosion or fire may

result causing property damage, personal injury or death.

TO CLOSE CHEMICAL FEEDER:

Be sure cover O-Ring is in place. Engage cover threads

and turn clockwise to secure. Hand tighten only.

Place Dial Control Valve to desired setting. Open in-line

valves and re-start pump per manufacturer’s

instructions.

PRESSURE - PRESSURE INSTALLATION

This uses system pressure differential to divert water

through the chemical feeder into the return-to-pool piping

after the filter/heater. The inlet of the chemical feeder is

connected to the discharge side of the pump (before the

filter) and the outlet is connected after the filter (and heater

if installed). This creates a pressure-pressure piping circuit

through the feeder. If a heater is installed, a check valve

must be installed between the heater outlet and the

chemical feeder return. This will prevent a high

concentration of the sanitizing agent from back flowing into

the heater. This back flow can occur from a pressure

differential when the pump is shut off. If a high concentration

of sanitizer flows into the heater, it will cause the copper heat

exchanger to deteriorate and possibly leak. If this

happens, a fire or explosion may result causing property

damage, personal injury or death.

PRESSURE - SUCTION INSTALLATION

With this method, the inlet pipe of the chemical feeder is

connected to the discharge side of the pump (before the

filter); and the outlet is connected back to the suction

side of the pump (before the pump). This creates a

pressure-suction piping circuit through the feeder. Do not

use this installation method if a heater is installed in the

system. This method of installation allows too high of

concentration of sanitizer to pass through the system than is

safe for the copper heat exchanger of a heater. This

installation may cause the heat exchanger to deteriorate and

possibly leak. If this happens, a fire or explosion may result,

causing property damage, personal injury or death.

1.

2.

1.

2.

GENERAL INFORMATION:

Turn Dial Control Valve to OFF when vacuuming,

backwashing, or adding D.E. to filter, and when adding any

other chemical in concentrated form. Never use petroleum

type lubricants on cover O-ring. If lubrication becomes

necessary, use non-petroleum based lubricants such as

Jack’s No. 327 lube or Ivory®bar soap.

Flush tank once a week by opening Dial Control V alve to full.

Run for approximately 1 minute. Reset Dial Control Valve to

desired setting.

Close feeder Dial Control Valve when vacuuming,

backwashing or adding D.E. to filter, and when adding other

chemicals to your pool.

WINTERIZING:

Where freezing temperatures can be expected, drain all

water from feeder. Carefully remove any undissolved, damp

tri-chlor or bromine tablets or sticks. Rinse out chemical

feeder thoroughly with water. Replace Cover and engage

1-1/2 turns. Keep unit covered all winter to prevent entrance

or rain or snow.

Page 4

©1998 Hayward Printed in U.S.A.Rev. 11/98

Loading...

Loading...