Page 1

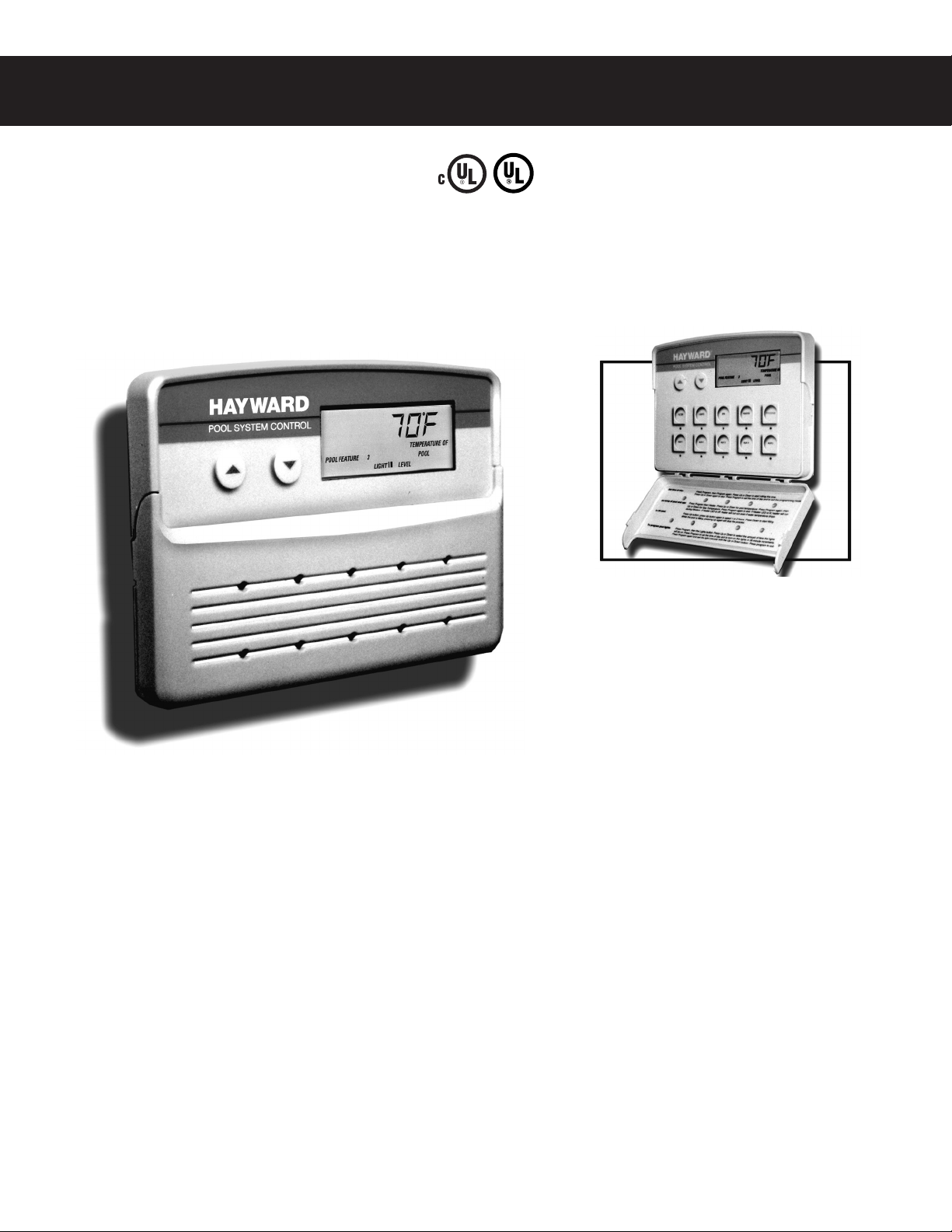

HAYWARD

®

2100 SERIES

POOL SYSTEM CONTROL

INSTALLATION AND PROGRAMMING INSTRUCTIONS

SAVE THESE INSTRUCTIONS

ISPSC2100-2

LISTED

SWIMMING POOL AND

SPA CONTROL

3Z62

Designed and engineered for today’s carefree lifestyle. The 2100 Series sets

new standards of ease of operation and performance for remote pool system

control. The easy-to-install master remote control allows you to monitor, set

and control up to 12 functions necessary for total pool system control as well

as pool environment control.

Page 2

WATER SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

ELECTRICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

ELECTRICAL SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

INSTRUCTIONS FOR OPTIONAL RF CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

PRODUCT SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

APPLICATION OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

SYSTEM OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

OPTIONAL ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

PH/ORP OPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

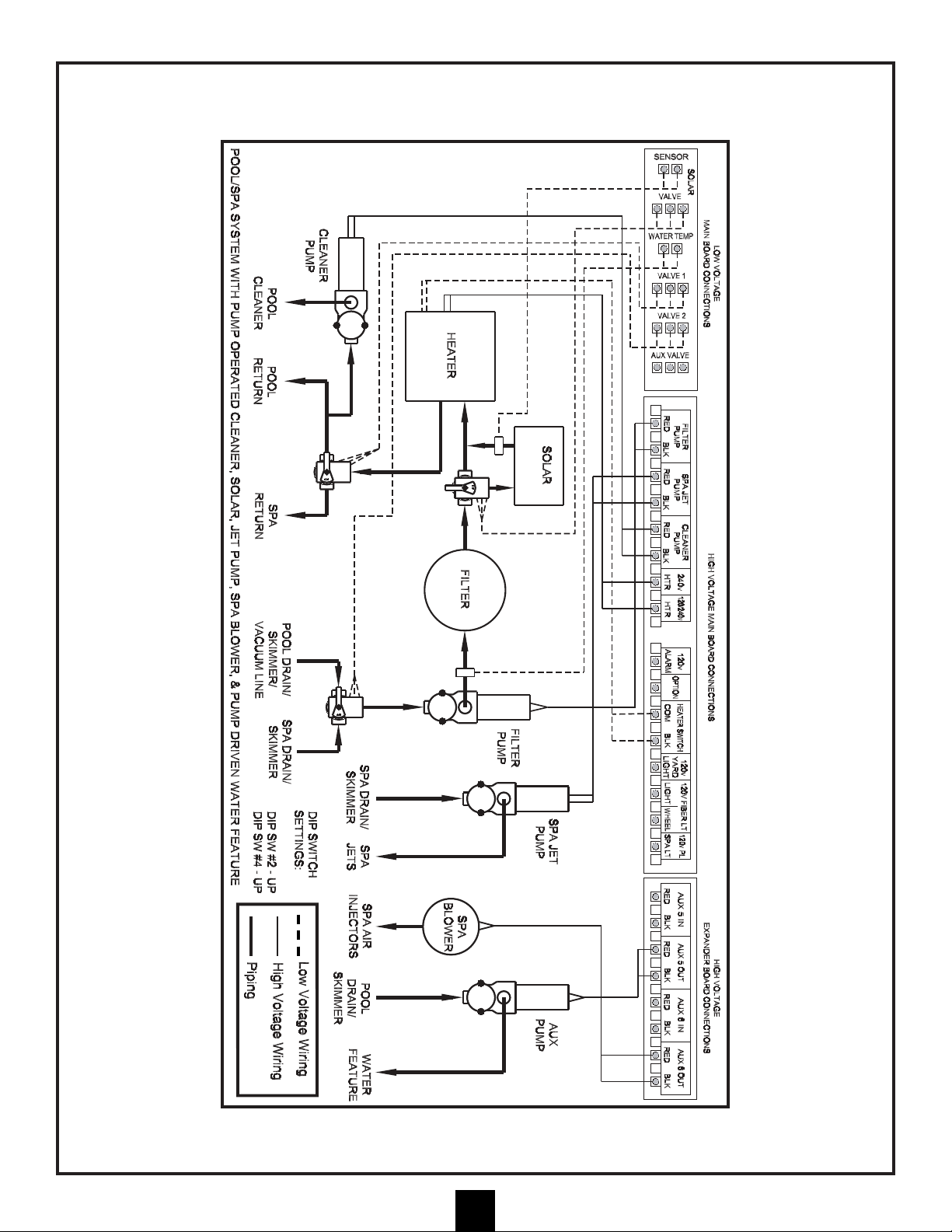

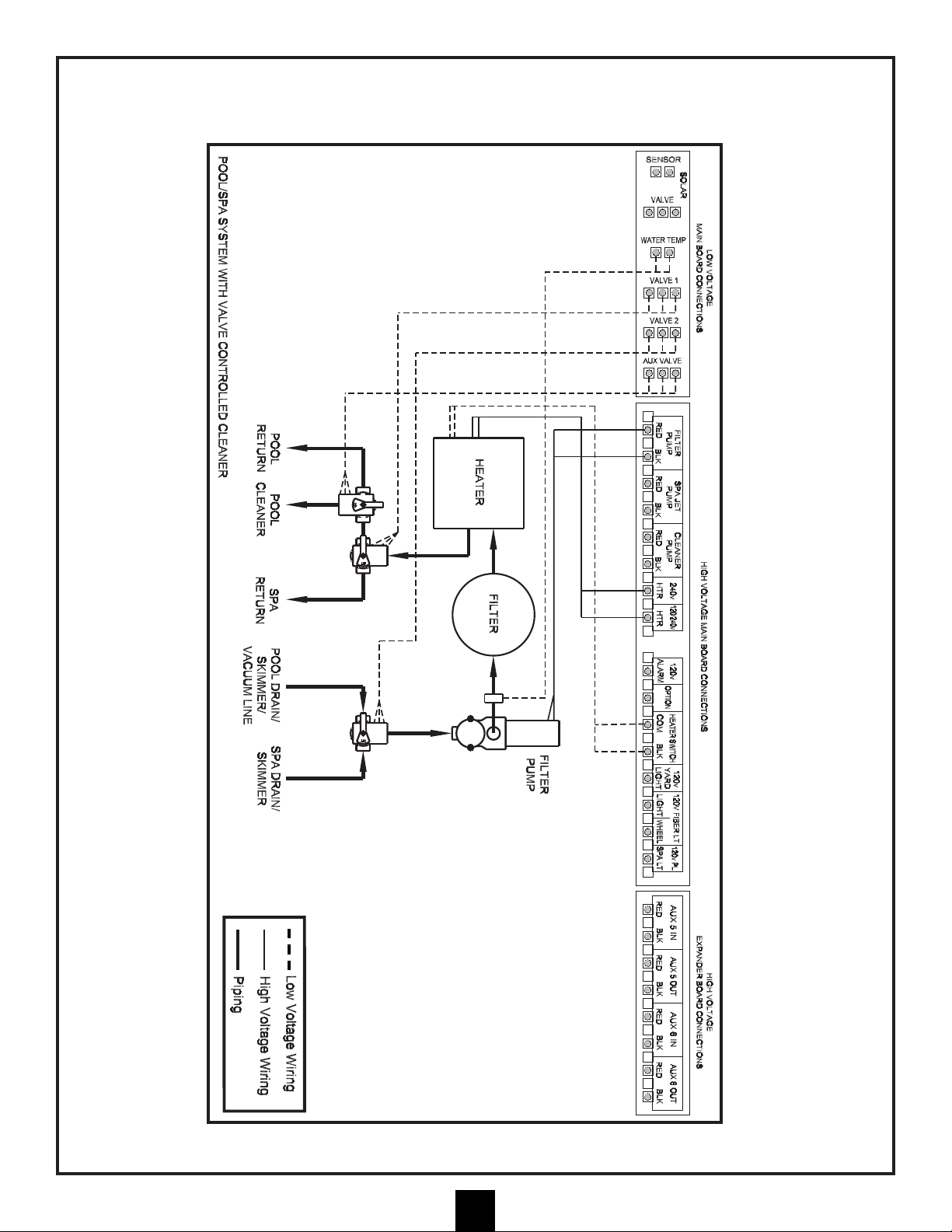

TYPICAL PLUMBING SCHEMATIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

INSTALLING THE WATER TEMPERATURE SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

INSTALLING THE AIR TEMPERATURE SENSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

LOCATING & INSTALLING MAIN CONTROL CENTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

LOCATING & INSTALLING MASTER CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

TEMPLATE FOR MASTER CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

INSTALLING OPTIONAL RF PANELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

LOCATING & INSTALLING SPA SIDE CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

CONNECTING LOW VOLTAGE COMPONENTS TO THE MAIN CONTROL CENTER . . . . . . . . . . . .33

CONNECTING HIGH VOLTAGE COMPONENTS TO THE MAIN CONTROL CENTER . . . . . . . . . . . .34

CONFIGURING THE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

CONNECTING THE POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

WIRELESS REMOTE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

BUTTON FUNCTIONS FOR MAIN CONTROL CENTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

BUTTON FUNCTIONS FOR SPA SIDE CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

BUTTON FUNCTIONS FOR SERVICE PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

TROUBLE SHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

BASIC PROGRAMMING FOR MASTER CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

2

TABLE OF CONTENTS

Page 3

STANDARD INPUTS:

Master Control Panel

Spa-Side Control Panel

Service Control Panel

Air Temperature Sensor

Water Temperature Sensor

3

IMPORTANT WATER SAFETY INSTRUCTIONS

When installing and using these Control Systems, basic safety precautions should always be followed,

including those listed below:

READ AND FOLLOW ALL INSTRUCTIONS

1. WARNING - Risk of Accidental Drowning. Extreme caution must be exercised to prevent unauthorized

access by children. To avoid accidents, ensure that children cannot use the spa or pool to which this Control

System is connected unless they are closely supervised at all times.

2. DANGER - To reduce the risk of drowning from hair or body entrapment, assure that the suction fittings,

skimmers and main drains in the spa or pool connected to this Control System are approved for the

application.

3. DANGER - To reduce the risk of injury, do not remove the suction fittings or main drain covers. Never operate

the spa or pool if these covers are broken or missing.

4. WARNING - To reduce the risk of injury:

A. The water in a spa to which the Control System is connected should never exceed 104°F (40°C). Water

temperatures between 100°F (38°C) and 104°F (40°C) are considered safe for a healthy adult. Lower

water temperatures are recommended for young children and when spa use exceeds 10 minutes.

B. Since excessive water temperatures have high potential for causing fetal damage during the early months

of pregnancy, pregnant or possibly pregnant women should limit spa water temperatures to 100°F (38°C).

C. Before entering a spa, the user should measure the water temperature with an accurate thermometer

since the tolerance of water temperature-regulating devices vary.

D. Prolonged immersion in water hotter than 104°F (40°C) may cause hyperthermia. Hyperthermia occurs

when the internal body temperature reaches a level several degrees above normal body temperature of

98.6°F (37°C). The symptoms of hyperthermia include dizziness, fainting, drowsiness, lethargy, and an

increase in the internal temperature of the body. The effects of hyperthermia include:

E. The use of alcohol, drugs, or medication can greatly increase the risk of fatal hyperthermia.

F. Leave the spa immediately if nausea, dizziness or headaches occur. Immediately cool the body by taking

a cool shower or by applying cold towels or ice packs. If the symptoms persist, seek medical attention.

G. The use of alcohol, drugs, or medication before or during spa use may lead to unconsciousness with the

possibility of drowning.

H. Obese persons and persons with a history of heart disease, low or high blood pressure, circulatory system

problems, or diabetes should consult a physician before using a spa.

I. Persons using medication should consult a physician before using a spa since some medication may

induce drowsiness or may affect heart rate, blood pressure, and circulation.

5. Occasional users of the spa should be made aware of these important Safety Instructions.

6. WARNING - People with infectious diseases should not use a spa or pool.

7. WARNING - To avoid injury, exercise care when entering and exiting a spa or pool.

8. WARNING - Do not use a spa immediately following strenuous exercise.

9. CAUTION - Maintain water chemistry to provide safe bathing environment.

SAVE THESE INSTRUCTIONS

1. Unawareness of impending hazard.

2. Failure to perceive heat.

3. Failure to recognize the need to exit

the spa.

4. Physical inability to exit the spa.

5. Fetal damage in pregnant women.

6. Unconsciousness resulting in a danger of

drowning.

ELECTRICAL SPECIFICATIONS

POWER SUPPLY:

BASIC 50A MAX.

SYSTEM:

-240 vac, 3 wire plus

ground, 20-50A max.

EXPANDER

CIRCUIT BOARDS:

-120 vac and/or 240

vac, 2 wire plus

ground

Power Supply must be

60Hz.

OPTIONAL INPUTS:

2nd Master Control Panel

pH Sensor

ORP Sensor

Solar Sensor (future)

R.F. Remote Control Panels

for Pool and Spa

OUTPUTS:

BASIC 20-50A MAX. SYSTEM

4 - Motorized Diverter Valves- 24 vac

1 - Gas Heater - 120/240 vac, max amperage 1.5A

1 - Filter Pump - 240 vac, max amperage 14.8A

1 - Cleaner Pump - 240 vac, max amperage 6.2A

1 - Spa Jet Pump - 240 vac, max amperage 11.8A

1 - Pool Lighting Option - 120 vac, max amperage 1.6A

1 - Underwater Lighting System- 120 vac, max

amperage 10.3A

1 - Aux. Lighting System - yard lights,120 vac, max

amperage 10.3A

1 - Fill Valve 24 vac, max amperage 0.3A

EXPANDER CIRCUIT BOARD:

2 - Auxiliary Circuits -120/240 vac, max amperage 16A

each circuit

Page 4

4

IMPORTANT ELECTRICAL SAFETY INSTRUCTIONS

When installing and using these Control Systems, basic safety precautions should always be followed, including

those listed below:

READ AND FOLLOW ALL INSTRUCTIONS

1. DANGER - Risk of electric shock. Before making any electrical connections, make certain that the Main Power

breaker from the house breaker box has been turned off.

2. DANGER - Risk of Electric Shock. Do not permit any electric appliance, such as a light, telephone, radio, or

television within 5' (1.5m) of a pool or spa.

3. All electrical work must be performed by a qualified electrician and must conform to all national, state, and local

codes.

4. Do not install or service this equipment if precipitation is present or imminent.

5. Install the Main Control Center in an area that is not prone to flooding.

6. Install the Main Control Center and all other high voltage components at least 5' (1.5m) from the inside wall of the

pool or spa. Canadian installations must be installed at least 3 meters from the inside wall of the pool or spa.

7. A terminal marked “GROUND” is provided within the Main Control Center enclosure. To reduce the risk of electrical

shock, connect this terminal to the grounding terminal of the electric supply panel with a continuous green insulated

copper wire equivalent in size to the circuit conductors supplying this equipment, but no smaller than #12 AWG.

8. A bonding wire connector is provided on the outside of the Main Control Center to accommodate the connection of

a min #8 AWG solid copper conductor (#6 AWG in Canada) between this unit and the local common bonding grid

in the spa and pool area. Additionally, any metal equipment, metal ladders, metal enclosure of electrical equipment,

metal water pipe, or conduit within 5' of the unit or within 5' of the pool (3 meters in Canada) must be connected to

the bonding wire connector.

9. The electrical supply circuit connected to the Main Control Center must be equipped with a suitably rated

disconnect device - a circuit breaker, a GFCI circuit breaker, switch or other device capable of opening all

ungrounded conductors in the supply circuit. This disconnect must be installed at least 5' from the pool or spa, but

be within sight of and readily accessible to the user.

10. This Control System is intended to supply the high voltage (120-240 vac) to a gas heater, and is intended to

override the thermostat in the control circuit of all the heaters. This Control System is intended to control gas

heaters that provide a safety circuit that include high temperature limit switch(s).

11. A suitably rated circuit breaker or a GFCI circuit breaker, must be installed in the electrical supply circuit connected

to the main control center. This circuit breaker may also provide the disconnect function referenced in item 9 if it

meets the sight and accessibility criteria.

12. This control system is provided with an Integral Ground-Fault Circuit Interrupter for the underwater lighting circuit. It

is located on the right side of the control enclosure under a Weather-Tite cover.

This GFCI must be tested before each use of the pool or spa. To test the GFCI, follow the following steps:

1. Turn on the underwater pool lighting circuit.

2. Press the ‘RESET’ button fully.

3. Check the underwater lights to be sure they are illuminated.

4. Press the ‘TEST’ button in order to trip the GFCI. The ‘RESET’ button will pop out and the underwater lights

will go out.

5. Press the ‘RESET’ again and the underwater lights will again be illuminated.

If this GFCI fails to operate in this manner there is a ground current flowing indicating the possibility of an

electric shock. Disconnect the power until the fault has been identified and corrected.

SAVE THESE INSTRUCTIONS

INSTRUCTIONS FOR OPTIONAL RF CONTROLS

Units which include the optional RF Antenna, RF Master Control, and RF Infrared Control shall include these

additional instructions:

1. RF Antenna and RF Master Control shall be installed at least 5 feet from the inside wall of a pool or spa.

2. The RF Antenna, RF Master Control, and the RF Infrared Remote are optional accessories for use with

Listed Controls, Models PC-XXXXXX-DCA and BPC-XXXXXX-DCA.

3. The RF Antenna and the RF Master Control must be installed in accordance to NEC regulations.

Page 5

5

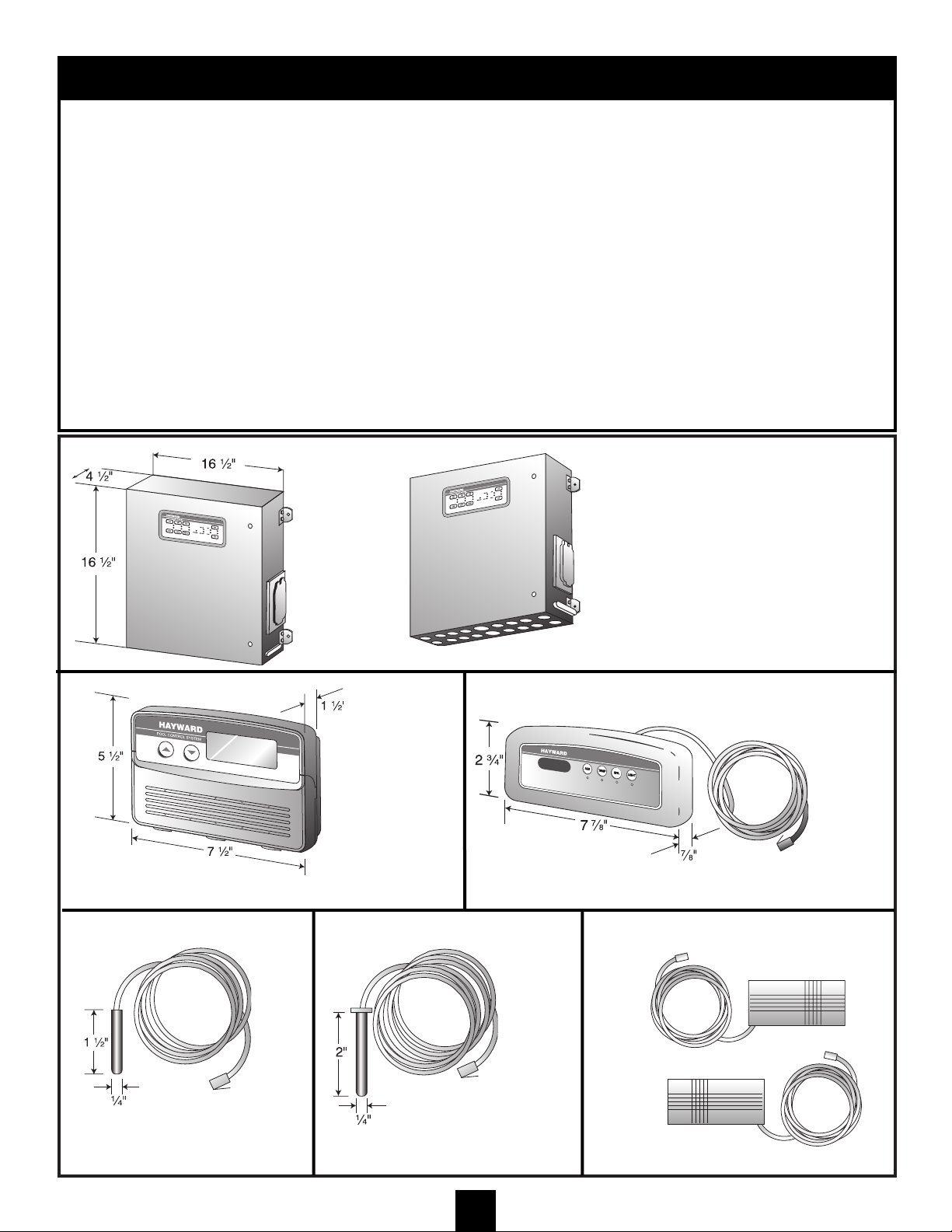

PRODUCT SPECIFICATIONS

POOL/SPA CONTROL - PSC2104

ITEMS INCLUDED

PSC2002 MAIN CONTROL CENTER WITH KNOCKOUTS

PSC2001 MASTER CONTROL PANEL

PSC2023 AIR TEMPERATURE SENSOR

PSC2022 WATER TEMPERATURE SENSOR

PSC2005 SPA SIDE CONTROL WITH 100’ OF CABLE INCL.

VALVE ACTUATORS (2 SUPPLIED)

POOL CONTROL - PSC2105

ITEMS INCLUDED

PSC2002 MAIN CONTROL CENTER WITH KNOCKOUTS

PSC2001 MASTER CONTROL PANEL

PSC2023 AIR TEMPERATURE SENSOR

PSC2022 WATER TEMPERATURE SENSOR

OPTION

PSC 2003 SPA SIDE CONTROL WITH 100’ CABLE INCLUDED.

LOW VOLTAGE

COMPARTMENT

KNOCKOUTS

(2) 1/2” KNOCKOUTS

LEFT SIDE

(2) 1/2” KNOCKOUTS

RIGHT SIDE

SPA SIDE CONTROL PANEL

MAIN

CONTROL

CENTER

WIDTH-16 1/2”

HEIGHT-16 1/2”

DEPTH-4 1/2”

MASTER

CONTROL

PANEL

WIDTH-7 1/2”

HEIGHT-5 1/2”

DEPTH-1 1/2”

WIDTH-5 7/8”

HEIGHT-2 3/4”

DEPTH-7/8”

PSC2003 100’ or 200’ OF CABLE (SPECIFY)

CABLE LENGTH AVAILABLE

50’, 100’, 200’ (NOT INCLUDED)

DIAMETER-1/4”

LENGTH-1 1/2”

10’ OF CABLE INCLUDED

DIAMETER-1/4”

LENGTH-2”

25’ OF CABLE INCLUDED

POWER CABLE LENGTH- 10’

AIR TEMPERATURE SENSOR WATER TEMPERATURE SENSOR VALVE ACTUATORS

(MODEL 2100 ONLY)

ITEM #-PSC2002

ITEM #-PSC2023 ITEM #-PSC2022

ITEM #-PSC2001

HIGH VOLTAGE

COMPARTMENT

KNOCKOUTS

(6) 1/2” KNOCKOUTS

LEFT SIDE

(7) 3/4” KNOCKOUTS

RIGHT SIDE

(1) 1” KNOCKOUTS

CONDUIT KNOCKOUTS

POOL/SPA CONTROL W/WIRELESS REMOTE

- PSC2106

ITEMS INCLUDED

PSC2002 MAIN CONTROL CENTER WITH KNOCKOUTS

PSC2001 MASTER CONTROL PANEL

PSC2023 AIR TEMPERATURE SENSOR

PSC2022 WATER TEMPERATURE SENSOR

PSC2108 RF WIRELESS SPA REMOTE UPGRADE KIT

VALVE ACTUATORS (2 SUPPLIED)

POOL CONTROL W/WIRELESS REMOTE & WIRELESS

MASTER PANEL

- PSC2109

ITEMS INCLUDED

PSC2002 MAIN CONTROL CENTER WITH KNOCKOUTS

PSC2001 MASTER CONTROL PANEL

PSC2023 AIR TEMPERATURE SENSOR

PSC2022 WATER TEMPERATURE SENSOR

PSC2108 RF WIRELESS SPA REMOTE UPGRADE KIT

PSC2107 RF WIRELESS MASTER PANEL UPGRADE KIT

VALVE ACTUATORS (2 SUPPLIED)

ITEM #-PSA24

Page 6

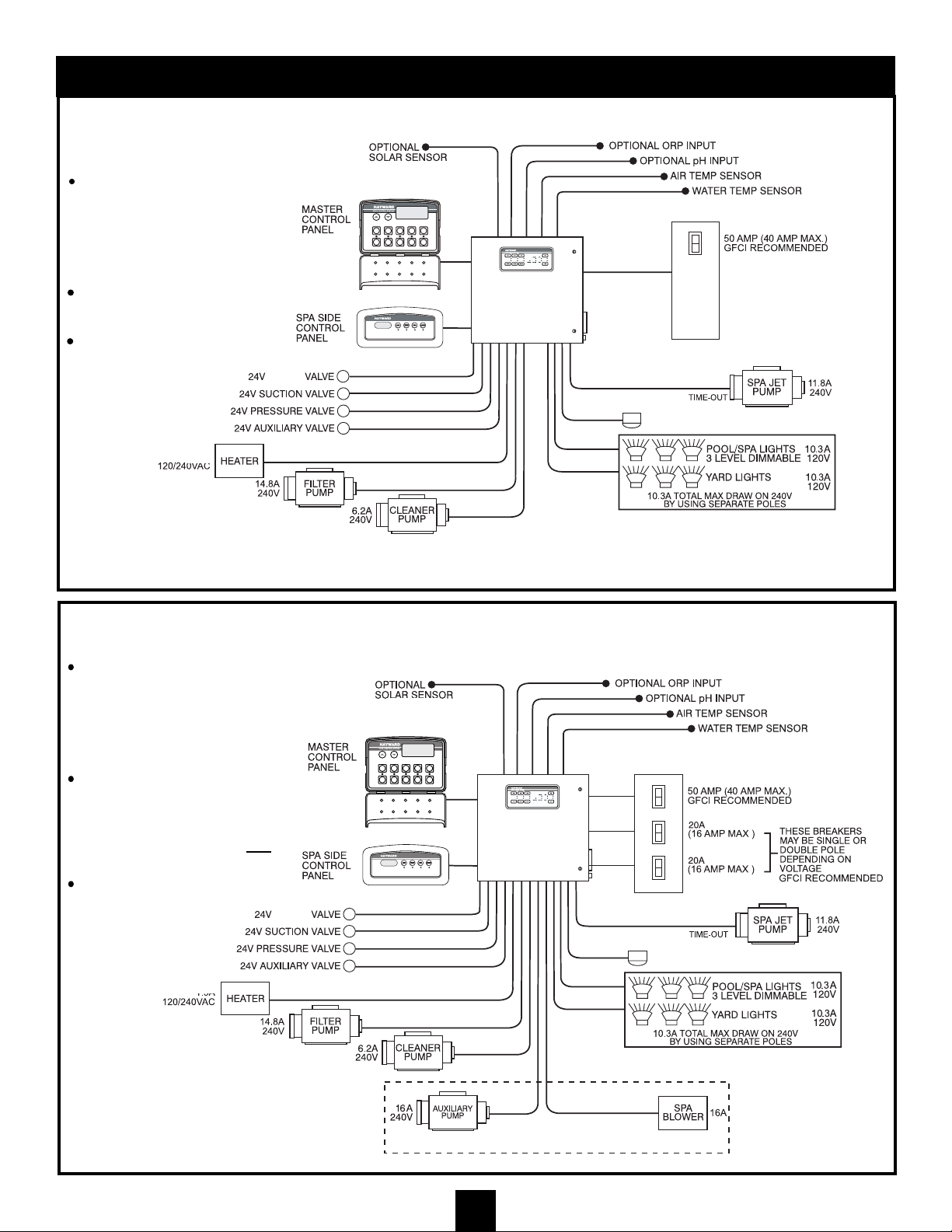

SOLAR

Notes:

Additional local disconnect

may be required if main

breakers DO NOT meet the

requirements of a local

disconnect.

See IMPORTANT

ELECTRICAL SAFETY

INSTRUCTIONS

Maximum Amp draw for

basic 50 Amp system is

40 Amps.

Cleaner Pump disabled

when Jet Pump is on.

Jet Pump disabled when

Cleaner Pump is on.

6

APPLICATION OVERVIEW

SOLAR

BASIC 20-50 AMP MAX SYSTEM (Without Expander Board Use)

BASIC SYSTEM WITH 20A X 20A (MAX) EXPANDER CIRCUIT BOARD

Notes:

Additional local disconnect

may be required if main

breakers DO NOT meet the

requirements of a local

disconnect.

See IMPORTANT

ELECTRICAL SAFETY

INSTRUCTIONS

Max Amp draw for the Basic

50 Amp System and

Expander Board

Basic 50 Amp System- 40A

Expander Board Circuit #1- 16A

Expander Board Circuit #2- 16A

Total 72A

Cleaner Pump disabled

when Jet Pump is on.

Jet Pump disabled when

Cleaner Pump is on.

20 X 20 EXPANDER BOARD

MAIN POWER PANEL

MAIN POWER PANEL

TWO HOUR

LIGHTING OPTION 1.6A

LIGHTING OPTION 1.6A

TWO HOUR

(future)

may be

2-speed

may be

2-speed

may be

2-speed

may be

2-speed

(future)

1.5A

1.5A

Page 7

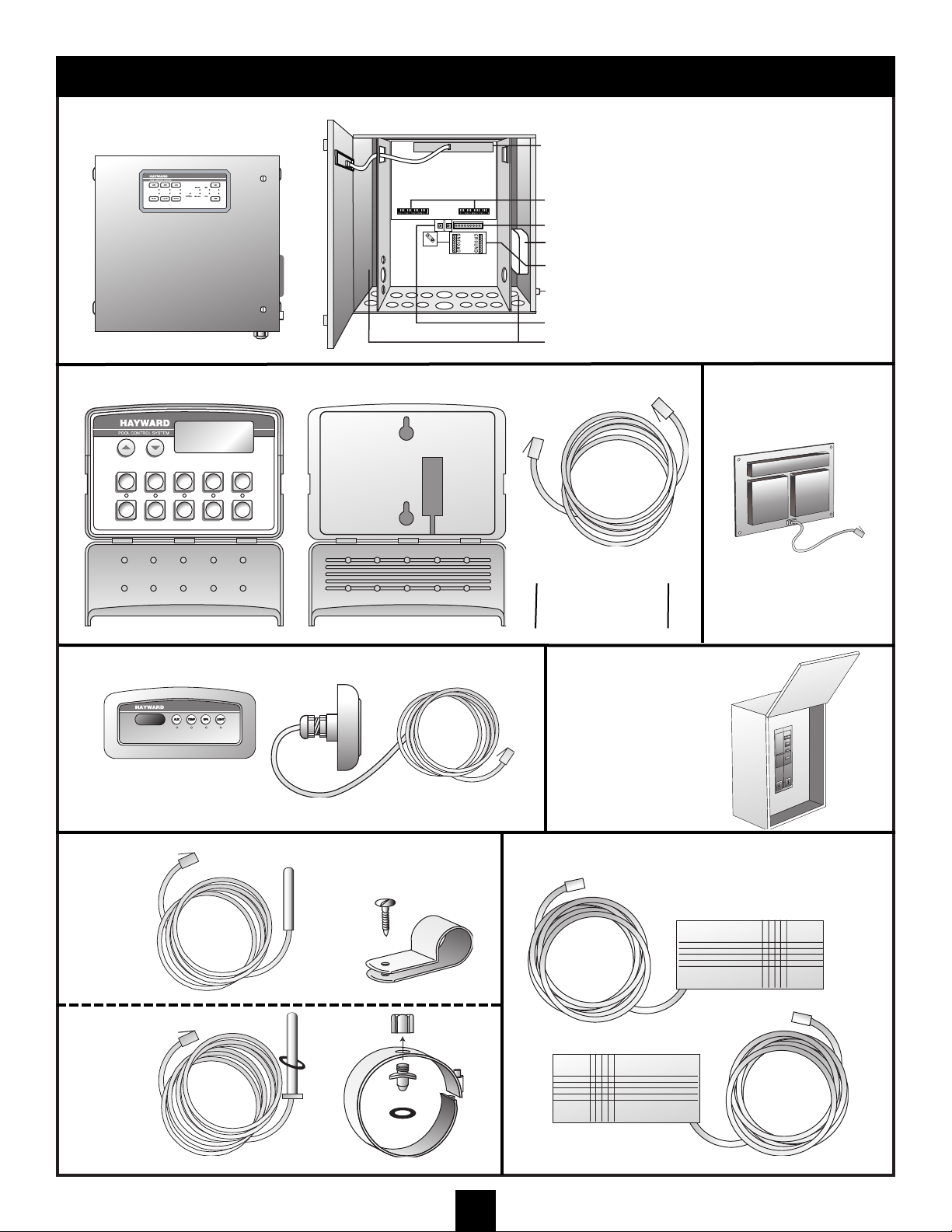

50’, 100’, 200’

PANEL CONNECTING

CABLES OPTIONAL

7

SYSTEM OVERVIEW

MAIN CONTROL CENTER

MASTER CONTROL PANEL

SPA SIDE CONTROL PANEL

INPUT SENSORS VALVE ACTUATORS

AIR TEMP

SENSOR

LOW VOLTAGE CONNECTIONS

EQUIPMENT OUTPUT CONNECTIONS

LINE NEUTRAL LUG NEUTRAL FOR 120V EQUIPMENT

BONDING LUGS FOR EQUIPMENT

WATER

TEMP

SENSOR

25’ CABLE

TWO SUPPLIED WITH POOL/SPA SERIES

SENSOR

MOUNT

MASTER CONTROL CABLE

Spa-side panels are available

on certain systems and have

100’ or 200’ cables.

GROUND LUGS

LOW VOLTAGE RACEWAYS

POWER INPUT LUGS

GFCI

10’ CABLE10’ CABLE

PSC2038

MOUNTING

CLIP

INTEGRATED

40 AMP

EXPANDER BOARD

-Can be wired for 120 VAC or

240 VAC, 2 wire plus ground

-Can be wired for 120 VAC and

240 VAC, 2 wire plus ground

ITEM #-PSC2004

CIRCUIT BREAKER

WITH ENCLOSURE

50 A MAX. GFCI

ITEM #-PSC2021

Page 8

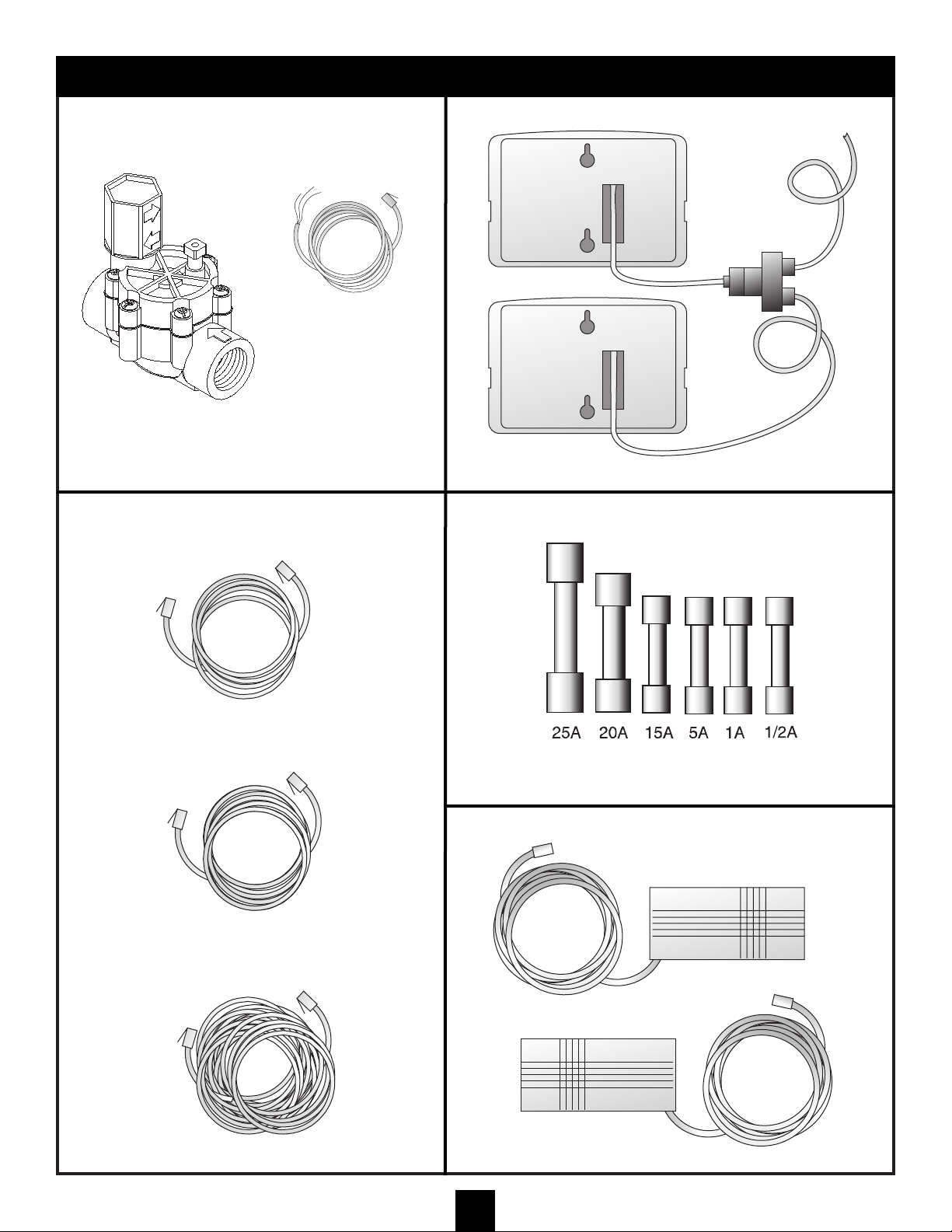

8

OPTIONAL ACCESSORIES

MASTER CONTROL PANEL

EXTENSION CABLES

2-1 CABLE

CONNECTOR

OPTIONAL FILL VALVE KIT

W/CONNECTOR CABLE

25’

50’

100’

200’

MASTER

CONTROL

PANEL

AUXILIARY

MASTER

PANEL

OPTIONAL ACTUATORS

ITEM #-PSC2020

ITEM #-PSC2014

ITEM#-PS2025

ITEM #-PSC2012

ITEM #-PSC2013

SPARE FUSES

Fuses are sized for maximum permissible output on each load circuit, in

certain applications it may be necessary to install lower rated fuses to comply

with the National Electrical Code.

ITEM#-PSA24

ITEM#-PS2036

Page 9

9

PH/ORP OPTION

CALIBRATION

CALIBRATION PROCEDURE

1. Test the pool water with a test kit (pH 7.2-7.8; Orp 500-750mV)

2. If the ph/Orp sensors readings are not correct, use a small flat head screwdriver to adjust the potentiometer

(R11) on the pH circuit board. Very slowly adjust the potentiometer until the display on the panel shows the

correct reading.

Note: Wait until the display reads a constant correct setting before moving to next step.

3. Calibration is completed.

4. The display on the panel will show the actual pH reading in the spa. Add any necessary chemicals to insure that

the pH sensor reading remains between 7.2 and 7.8 pH.

5. Requirement: Use a test kit no less than once a month to verify calibration and optimal Orp reading.

Note: ORP readings are affected by the following factors: water temperature, total dissolved solids,

cyanuric acid, and alkalinity.

INSTALLATION

1. Splice in a 1 1/2" x 1 1/2" x 1/2" or 2" x 2" x 1/2" reducer tee (depending upon size of pipe configuration).

Position the 1/2” female pipe thread on the tee at approximately 45°.

2. Press the two stand-offs into the digital control board.

3. Remove the pH jumper from the 4-pin connector (J20 for circuit board #25500 or J11 for circuit board #25501) on

the control board.

4. Install the pH board onto the control board. Important! The pH board must be installed component side up.

Make sure that J20 or J11 and the two stand-offs snap fit into the pH board.

Note: All sensors are shipped with the measuring end covered with a wetting cap.

5. Remove the wetting cap by twisting it counter-clockwise and gently easing it off. It is recommended that this cap

be retained for future long-term storage and winterization.

Note: Hand tighten sensors in place. Do not use a wrench to install the sensor as this could cause breakage.

Use a wrench to remove the sensor only if unable to do so by hand.

6. Install the pH sensor into the 1/2" NPT tee by turning the sensor clockwise. Hand tighten only.

7. Feed the BNC connector (from the outside of the control box) through a hole on the bottom LEFT side of the box

for a horizontally-mounted system. Pass the BNC connector through a hole on the bottom RIGHT side of the

control box for a vertically-mounted system.

8. Connect the BNC connector to the pH board. First align it with its mated connector, then press them together

and then twist to lock them into place.

9. Turn the system power on.

CARE AND MAINTENANCE

UNPACKING

Remove the electrode from its package and check that it is undamaged. If damaged, contact your supplier for

replacement. Most electrodes are rugged in design, but some are fragile. Care should be taken when unpacking

and handling all electrodes.

PREPARATIONS FOR USE

All electrodes are shipped with a wetting cap covering the measuring end. This cap contains a solution of pH 4

buffer saturated with potassium chloride for single-junction combination electrodes, and solution of potassium nitrate

in pH 4 buffer for double-junction electrodes. Mono-measuring electrodes, pH and ORP, are shipped in pH 4 buffer.

Page 10

Gently remove the wetting cap from the electrode by unscrewing the bottle form the cap and then sliding the cap

and o-ring off of the electrode body. Save the cap for future long-term storage. Some electrodes are shipped with

slide-on caps sealed with teflon tape, these caps are simply pulled off.

During shipping, the air space inside the pH glass internal may have moved into the bulb. Grasp the electrode near

the cable end and gently swing it through an arc to force the internal electrolyte into the pH bulb.

ELECTRODE CLEANING

Slow response and large offsets may indicate the electrode has become coated. The nature of the coating will

dictate the type of cleaning technique that should be used.

Soft coatings, like foodstuffs or bacterial films are best removed using a squirt bottle or the water jet from a faucet. If

this is not successful, then wiping with a soft, wet cloth is the best choice.

Hard coatings, like calcium or lime scale are best removed with a solvent appropriate for the particular coating. A

5% solution of HCI would be a good choice for the calcium scale. If unsure of the proper solvent to remove a hard

mineral coating, alternate between a 5% HCI and a 4% NaOH for 10 minutes each. After treating the electrode with

these strong acids or bases, rinse the electrode with water and soak it in pH 4 buffer for at least 1/2 hour.

Greasy and oil coatings are best removed with a detergent solution or a solvent that will not attack the electrodes

body. Methanol and isopropyl alcohol are good choices for solvents. Acetone, MEK, THF, or trichloroethane will

irreparably harm the electrode. A soft toothbrush can be used with the detergent in removing stubborn coatings.

The platinum or gold sensing tip of an ORP electrode should be cleaned just like a pH electrode. The surface can

also be cleaned with an abrasive as a last resort. Gently scour the platinum with a 600 grit wet emery cloth or

preferably a 1-3 micron alumina polishing powder.

Important: Good laboratory practices should be used and protective gloves and safety glasses should be worn while

handling any solvents or chemicals. If you are unsure of the proper technique for handling a chemical or of its

hazardous properties, it is best to discard the electrode, eliminating the risk of danger.

INTERPRETING PH/ORP READINGS

1. To check the measured pH and/or ORP readings, run the filter pump for at least 5 minutes. Press the DOWN

arrow button on the master panel until the desired reading is displayed. The DOWN button will toggle the display

through the available chemical sensor readings.

2. Adjust water chemistry as close to these suggested readings as possible:

Alkalinity: 100 ppm

Total Dissolved Solids (TDS): 500 ppm

PH: 7.2 - 7.8

3. Once water chemistry has been adjusted as per #1, note ORP reading (mV). This reading can be used to

indicate proper water chemistry in your installation. If the ORP reading changes dramatically, adjust the water

chemistry accordingly.

4. Millivolt reading should fall between 500-750 mV.

5. If ORP reading falls outside of suggested range, adjust water chemistry accordingly.

Note: ORP readings are affected by the following factors: water temperature, total dissolved solids,

cyanuric acid, and alkalinity.

WINTERIZATION

1. Disconnect the sensor connector from the PCB board located in the power center.

2. Carefully remove the sensors from the plumbing.

3. Reinsert the electrode into the wetting cap and fill cap with pool water.

4. Store at room temperature.

5. When reinstalling the probe, refer back to the Preparation for Use section of the Care and Maintenance

instructions.

10

PH/ORP OPTION (continued)

Page 11

11

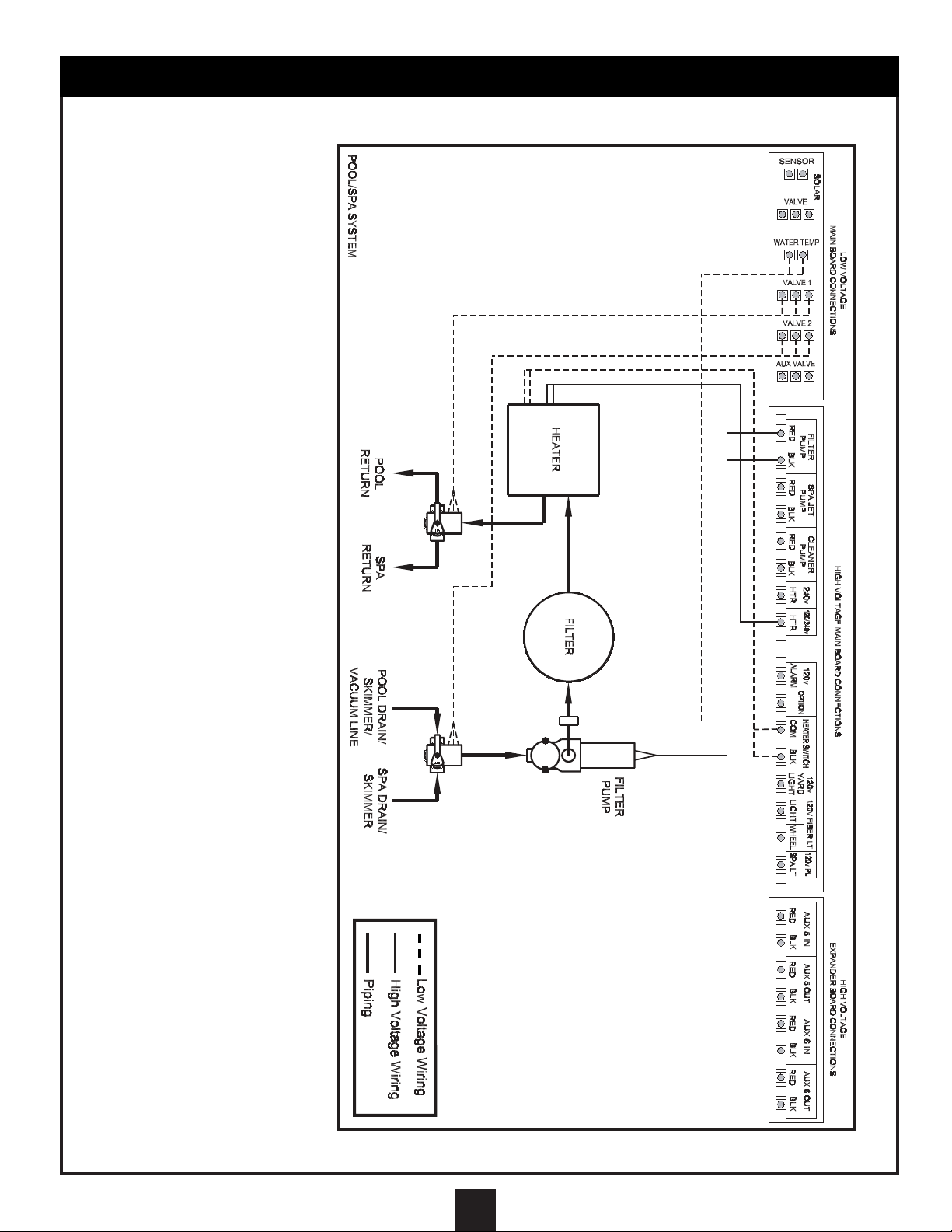

TYPICAL PLUMBING SCHEMATIC

1. Reverse the polarity of

the wiring to the valve

diverter motor that is out

of synchronization. The

best way to accomplish

this is to reverse the red

and white wires inside

the valve diverter motor

enclosure.

2. Remove the motor

enclosure cover, remove

the wire nuts, switch

the red and white wires,

reconnect the wires

with wire nuts, and

reinstall cover.

BASIC POOL/SPA PLUMBING:

These schematics show the

necessary plumbing required

to operate a pool and a spa

that share common pumps,

filters, and heaters. The

Motorized Diverter Valves

will change position when spa

use is desired.

IMPORTANT:

Be sure the valves are

synchronized to move

simultaneously from pool

suction and pool return to

the spa suction and spa

return. If they are not

synchronized, please follow

the instructions below:

NOTE:

The polarity of the wiring to

the valve motor that is out of

synchronization can also be

reversed by changing the

position of the toggle switch

to the reverse position.

If you select this method to

reverse polarity, be sure to

change the sticker at the rear

of the motor enclosure from

the black (Auto-Off-Reverse)

sticker to the white (ReverseOff- Auto) sticker.

You must change the sticker

so that users and service

personnel know the correct

auto position for the valve.

Page 12

12

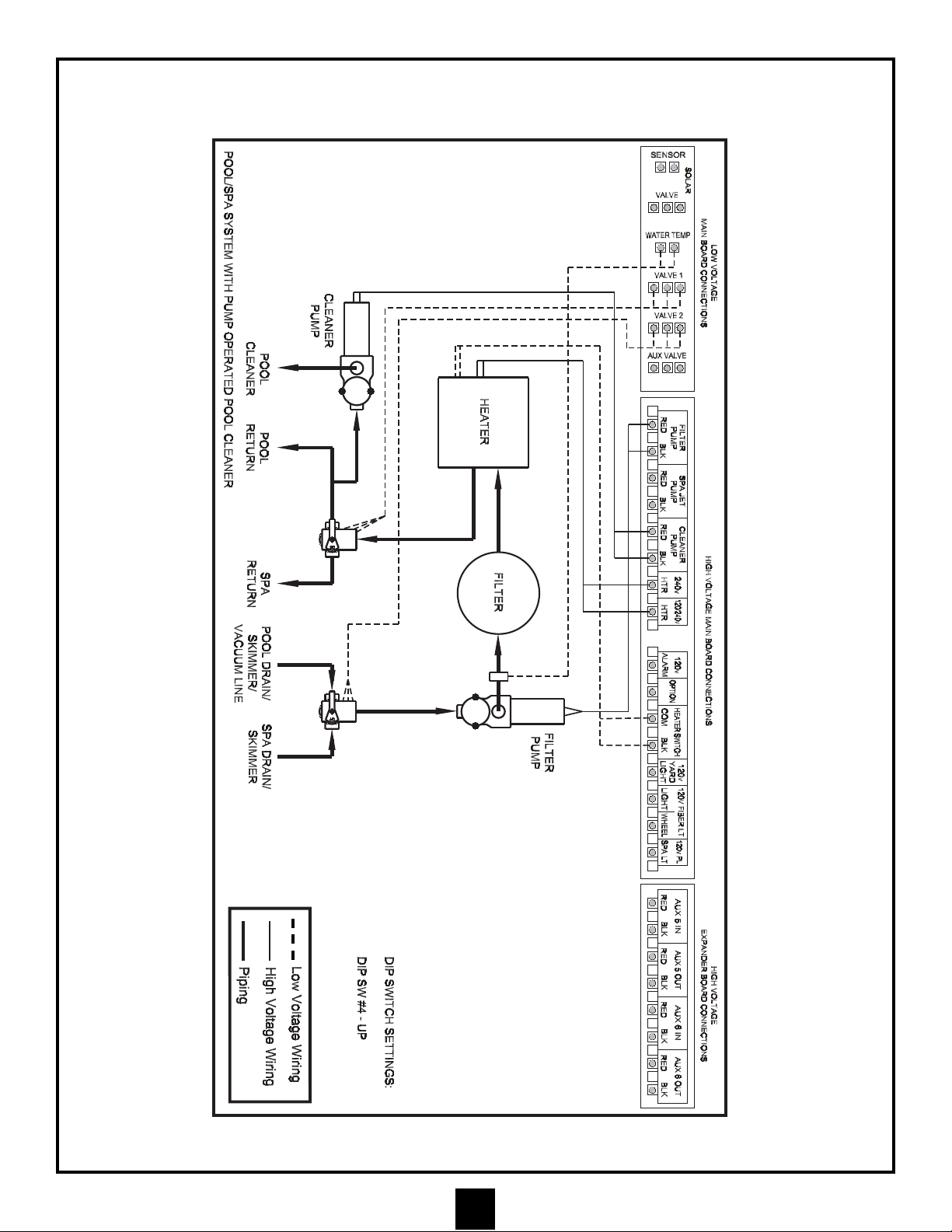

TYPICAL PLUMBING SCHEMATIC (continued)

Page 13

TYPICAL PLUMBING SCHEMATIC (continued)

13

Page 14

TYPICAL PLUMBING SCHEMATIC (continued)

14

Page 15

TYPICAL PLUMBING SCHEMATIC (continued)

15

Page 16

TYPICAL PLUMBING SCHEMATIC (continued)

16

Page 17

TYPICAL PLUMBING SCHEMATIC (continued)

17

Page 18

TYPICAL PLUMBING SCHEMATIC (continued)

18

Page 19

TYPICAL PLUMBING SCHEMATIC (continued)

19

Page 20

TYPICAL PLUMBING SCHEMATIC (continued)

20

Page 21

21

INSTALLING TEMPERATURE SENSORS

ATTENTION: The air temperature sensor is 10’ long and the water

temperature sensor is 25’ long. Consider the sensor mounting locations

BEFORE mounting the Main Control Center.

TO INSTALL THE WATER TEMPERATURE SENSOR

1. ATTENTION: Before connecting the temperature sensor wire to the

Main Control Center circuit board, the sensor wire must be inserted

through the sensor retaining nut. Insert the sensor wire through the

nut and slide the nut to a position adjacent to the sensing bulb.

2. Locate the Water Temperature Sensor in the discharge (pressure)

line of the filter pump as shown in the Basic Plumbing Schematic.

Drill a .390" (25/64") hole in the pipe and install the sensor mount

on the pipe by tightening the sensor mount clamp.

3. Install the O-ring onto the water temperature sensor. Slide the Oring onto the water temperature sensor so that it is positioned

against the plastic flange on the water temperature sensor. With

the retaining nut and O-ring installed on the water temperature

sensor, insert the water temperature sensor into the sensor mount

and tighten the nut, hand tight only. DO NOT OVER TIGHTEN.

FREEZE PROTECTION FEATURE

ONLY ACTIVE WHEN VALVES ARE IN POOL MODE

When the system senses air temperature of 35°F or lower, the valves

will turn to Pool and the filter pump, Aux 1, Aux 3, and Aux 5 will turn

on for 30 minutes. After 30 minutes, these devices will turn off, and the

valves will turn to Spa. At that time the Spa Aux, Filter Pump and

Blower will run for 30 minutes. After 30 minutes the system will again

turn off and the valves will turn to Pool again. The cycle will repeat if

the system still senses air temperature of 35°F or lower.

Note: This feature is designed to protect the pool equipment in

the event of unforeseen or unseasonal freezing conditions. It is

not intended to take the place of proper winterizing procedures.

Freeze protection disabled in Spa Mode.

TO INSTALL THE AIR TEMPERATURE SENSOR

OUTSIDE BUILDING LOCATION OPTION

1. Locate the Air Temperature Sensor so that it will be exposed to the

outside ambient temperature.

2. If the Main Control Center is installed inside a building and is

adjacent to heat generating devices such as heaters and pumps,

route the Air Temperature Sensor Cable through the wall of the

building securing the cable neatly and then secure the Air

Temperature Sensor with the clip and screw provided. Avoid

attaching the Air Temperature Sensor to any surface that will get

hotter than the ambient air temperature.

MAIN CONTROL CENTER LOCATION OPTION

3. If the Main Control Center is not installed in a building and there is

no benefit to installing the air sensor remotely, position the sensor

in a Liquid-Tite connector installed in one of the knock outs

beneath the low voltage raceways as shown in illustration.

RETAINING NUT

WATER TEMPERATURE

SENSOR

O-RING

SENSOR

FITTING

WASHER

PUMP

DISCHARGE

LINE

.390” HOLE

SENSOR

MOUNT

CLAMP

OUTSIDE BUILDING

LOCATION OPTION

MAIN CONTROL CENTER LOCATION

MOUNT OPTION

AIR

TEMPERATURE

SENSOR

WATER TEMPERATURE

SENSOR LINE

LOW VOLTAGE

KNOCK OUTS IN MAIN

CONTROL CENTER

Page 22

The Main Control Center should be located as close as possible to the pumps, heater, valves, and sensors that are

required to be connected to it. Preferably, the system should mount inside a pool equipment house or other

enclosure. However, the system can be mounted outside. It should mount on a flat vertical wall and be positioned

so that the conduit knockouts are located at the bottom of the enclosure. Remember to consider the length of the

wires & valve wires when selecting the final location.

ATTENTION: POSITIONING THE ENCLOSURE WITH THE CONDUIT KNOCKOUTS

LOCATED AT THE SIDE OR THE TOP OF THE ENCLOSURE MAY ALLOW WATER TO

ENTER THE SYSTEM AND CAUSE DAMAGE TO THE SYSTEM AND/OR CREATE AN

ELECTRICAL SHOCK HAZARD.

Be sure that the system and all other electrical components are at least 5' from the edge of the pool or spa. When

selecting the mounting position, plan how the 1" rigid PVC conduit carrying the power to the Main Control Center

will be routed. Also plan for the routing of the flexible conduit that will be run to the pumps and heater. You should

also keep in mind that the cable length on the Air Temperature Sensor is 10’ long and the Water Temperature

Sensor is 25’ long. They must reach connector receptacles located inside the system. Additionally, the location

selected should provide clear access in front of the system to permit the owner or service personnel to stand in

front of the Main Control Center unobstructed by other equipment.

ATTENTION: BE SURE THE LOCATION CHOSEN FOR THE MAIN CONTROL CENTER

ALLOWS UNOBSTRUCTED ACCESS TO THE GFCI PROTECTING THE UNDERWATER

LIGHT CIRCUIT.

INSTALLATION:

After the location has been selected follow these easy steps to mount the Main Control Center:

1. If the mounting substrate will allow, mount the Main Control

Center by driving mounting screws through the holes

provided in the back of the enclosure and into the wall. If

wall anchors must be used, hold the Main Control Center

enclosure in position and mark the hole pattern on the wall.

Drill and set the anchors; fasten the enclosure with screws.

Be sure to position the Main Control Center level and

square for a neat installation.

2. Run electrical PVC conduit from the Power Supply Panel to

the Main Control Center. Determine the number of conduit

runs and the size of the conduit needed for the installation

based on the wire size being run, the number of conductors

within the conduit, and the number of circuits needed.

Typically, if the Main Power Panel is 100' or less from the

Main Control Center the 50A max. breaker will require

4- #6 AWG conductors, one each of red, black, white and

green. These conductors will require a 1" conduit run.

(The enclosure has been provided with 1" conduit

knockouts that are adjacent to the line terminals in the

Main Control Center.)

A. If the installation requires the use of additional circuits or an Expander Circuit Board is being used, you may elect to

run separate conduit runs for each expander circuit, or you may elect to run the expander circuit in a common

conduit, or you may elect to run it inside the 1" conduit with the 50A max. circuit. If the runs are 100' or less in

length the expander circuit board will require 3- #12 AWG conductors. If the loads on this circuit are 240 vac, the

colors of the conductors should be red, black and green. If the loads on this circuit are 120 vac, the colors should

be black, white, and green. These wires can be run in 1/2" or 3/4" conduit. Be sure to follow all codes in effect

regarding the number and size of conductors that can be installed in various sizes of conduit.

22

LOCATING AND INSTALLING THE MAIN CONTROL CENTER

Amperage to Maximum Breaker Copper Wire

Wire Gauge Ratios System Loads Rating Gauge

40A System 40A 50A 6 AWG

32A System 32A 40A 8AWG

24A System 24A 30A 10AWG

Page 23

23

LOCATING AND INSTALLING THE MAIN CONTROL CENTER (continued)

LOW VOLTAGE

(AUX, BOARD CONTROL

PH, ORP SENSORS)

CONTROL PANELS

ETC..

LOW VOLTAGE

AIR & WATER

TEMPERATURE SENSORS,

MOTORIZED

DIVERTER VALVES ETC..

POWER

INPUT

HIGH

VOLTAGE

OUTPUT

WIRING DIAGRAM

HIGH

VOLTAGE

OUTPUT

B. GFCI RECOMMENDATIONS

A Ground Fault Circuit Interrupter (GFCI) is recommended to be

installed in the electrical supply circuit connected to these products.

GFCI’s are ultrasensitive switching devices, providing the ultimate in

safety. The most common style of GFCI also provides high-current

protection as a circuit breaker, and may be required by code in

certain installations. Breaker must be sized in accordance with

applicable code.

A 50A max GFCI circuit breaker is the best method to obtain complete

system protection. An additional enclosure containing the 50A max

GFCI may need to be installed between the main power supply

(50A max breaker) and the pool control. This must be done in cases

where a 50A max GFCI circuit breaker cannot be found to fit the

existing electrical service. Additionally, it can meet the requirements of

a local disconnect if it is located properly.

SEE IMPORTANT ELECTRICAL SAFETY INSTRUCTIONS. PAGE 3

C. The Expander Circuit Board will require separate circuits for each relay

and consequently 2- 20A circuit breakers, single pole for 120V or

double pole for 240V. For a 120 vac circuit, use 3- #12 AWG

conductors; one each of black, white, and green. For a 240 vac circuit,

use 3- #12 AWG conductors; one each of red, black, and green. These

wires can be run in 1/2" or 3/4" conduit. The enclosure has been

provided with 1/2" or 3/4", and 1" conduit knockouts that are adjacent to

the line terminals in the Main Control Center.

D. If the conduit run is long or has numerous bends, use watertight pulling

fittings positioned in the middle of the run. If this is necessary, it is

advisable to elevate the pulling fitting at least 6" above finished grade of

the surrounding area to avoid potential flooding. Remember to complete

the installation of the conduit before concrete is poured that might

obstruct a direct route from the Power Supply Panel to the Main Control

Center. Be sure that underground conduit is positioned in well

compacted soil. Also use care when making the glue joint to be sure

they are watertight.

3. Pull the required conductors as outlined in #2 above and

connect the power supply conductors to the line terminals of the

Main Control Center, and if required to the line terminals at the

Expander Circuit Board.

4. DO NOT HOOK UP THE CONDUCTORS TO THE POWER

SUPPLY PANEL UNTIL ALL ELECTRICAL CONNECTIONS FOR

ALL LOADS (MOTORIZED VALVES, HEATER, PUMPS, LIGHTS,

ETC.) HAVE BEEN COMPLETED. This will assure that all conductors

are not energized while completing the installation.

NOTE: All of the electrical wiring methods and materials used to complete

the electrical installation of the Pool/Spa Control System must be

in accordance with the National Electrical Code or the Canadian

Electric Code, as well as any local electrical codes in effect at the

time of installation.

The selection of electrical materials required to accomplish this

installation and the installation of the Hayward Pool Control System

must be accomplished by, or be under the direct supervision of a

qualified electrician.

TO LINE NEUTRAL

CONNECTION OR

NEUTRAL BAR

INPUT/OUTPUT

LOAD NEUTRAL

TERMINAL TO

POWER SYSTEM

EXPANDER BOARD

STAND-OFFS IN MAIN

CONTROL CENTER

Page 24

24

LOCATING AND INSTALLING THE MASTER CONTROL PANEL

For maximum convenience the Master Control Panel should be installed inside the home of the user.

However, it can be installed outside if desired. It must be mounted on a vertical surface such as a wall and be

located at eye level for the user. While choosing the location, plan for the routing of the control cable from the

Main Control Center to the Master Control Panel.

TO INSTALL:

1. If the pool and spa equipment room housing the Main Control Center is attached to the main dwelling where

the Master Panel will be located, simply route the cable through attics and hollow walls securing the cable as

needed for a neat installation. Store excess cable in the attic or between walls.

2. If the pool and spa equipment room housing the Main Control Center is in a separate building from the main

dwelling where the Master Control Panel will be located, 1/2" or 3/4" conduit should be installed from the Main

Control Center conduit knockouts entering the low voltage compartment and extend at the other end of the

conduit to a point within the main dwelling. Route the cable through the conduit, and through attics and hollow

walls, securing the cable as needed for a neat installation. Store excess cable in the attic or between walls.

3. Next, drill a hole in the hollow wall at a location that will permit the cable to extend through the wall directly

behind the Master Panel. Pull the cable through the hole storing any excess cable in the attic or inside the

hollow wall. Install hollow wall anchors as needed on the Master Control Panel vertical centerline and 3" apart.

Install pan head screws into the anchors and adjust them so that the Master Control Panel rests snugly

against the wall when it is installed on the screws. Plug the control cable into the receptacle at the rear of the

panel and install on the wall anchor screws.

4. If the Master Control Panel is mounted outside, be sure to route the control cable so that it approaches the

panel from the bottom and enters below the panel vertically. Secure the cable to the wall to maintain this cable

orientation. This will prevent water from running down the cable connectors and into the Master Control Panel.

5. An Additional Master Control Panel can be added to the system by connecting a 2-1 cable connector to the

end of the cable coming from the Main Control Center. This provides 2 outputs for 2 Master Control Panels.

Connector cables are then run between the 2-1 cable connector and the Master Control Panels. The additional

Master Control Panels will perform the same functions and all panels will indicate system status

simultaneously. Master Control Panels and connecting cables are available as an option.

ATTENTION: IF A CABLE IS NOT LONG ENOUGH TO REACH FROM THE MASTER PANEL TO THE

MAIN CONTROL CENTER, DO NOT ADD LENGTH TO THE CABLE BY SPLICING ADDITIONAL CABLE

ONTO THE CABLE; OBTAIN A CABLE THAT IS LONG ENOUGH TO REACH. A CABLE THAT IS TOO

LONG MAY BE SHORTENED BY CUTTING OFF THE EXCESS AND REINSTALLING A NEW

CONNECTOR AT THE DESIRED LENGTH.

SEE TEMPLATE ON PAGE 17

CONTROL CABLE

PLUGS IN HERE

HOLLOW WALL ANCHORS

PANEL

POSITION

CONTROL

CABLE

KEY SLOTS

FOR HANGING

3”

Page 25

LOCATING AND INSTALLING THE MASTER CONTROL PANEL (continued)

USE THIS FULL SIZED TEMPLATE FOR

CORRECT POSITIONING OF MASTER

CONTROL PANEL ON WALL

25

3”

Page 26

INSTALLING OPTIONAL RF PANELS

26

Under ideal conditions, the Hayward RF Spa Remote Kit allows a user to position the spa remote controller

anywhere within 100 ft. of the Main Control Center without a hard-wired connection. The range for an

improperly installed unit can be as low as 25 ft.

Certain physical or architectural structures may interfere with the performance of the unit, so

care must be given to the installation (See instructions on page 27). While a hard-wired

Master Panel can be installed outdoors, the RF Master Panel is not suitable for outdoor

installation and should be stored indoors when not in use.

WARNING: ALL POWER MUST BE SHUT OFF

BEFORE INSTALLATION. DO NOT ATTEMPT TO

WORK INSIDE THE HAYWARD POOL SYSTEM

CONTROL WITH ANY LIVE ELECTRICAL PARTS.

Begin the installation by turning off the main

power (50 Amp Max) to the Hayward Pool

System Control at the house breaker box.

If there is an expander board installed

(Aux 5 and/or spa blower), turn off the

power to the two individual circuits

(20 Amp Max each) that may be

installed to the expander board.

INST

ALL HAYWARD RF MASTER

RECEIVER AND CONNECT IT T

O THE

MAIN CONTROL CENTER:

Once all power has been shut off to the

control, open the door on the Control

System enclosure. If there is a wired

connection for a Master Panel installed on

the circuit board, disconnect it from the board and coil it near the bottom of the low voltage raceway through which

it enters the central area of the enclosure (probably the left side). If the control supports a spa, do not disconnect

the spa control panel cable at this time.

NOTE: The Master Panel MUST be RF ready to be compatible with the RF Kit. You may, however, hard wire an

RF-ready panel if you choose. If you are not sure that you have an RF-ready panel, note the serial number on

the label located on the bottom of the panel and call your Hayward service center for verification.

Next, feed the wire from the RF Master Panel receiver module through an appropriate knockout in the bottom of

the main control center. You should choose from the knockouts below the low voltage raceways for this purpose.

Continue to feed the cord that is attached to the RF Master Panel module through the hole in the raceway barrier

and over to the main circuit board. Plug it into an available phone-type socket on the top of the board. If there was

a hard-wired master panel installed, as mentioned above, use the same socket for the new RF connection.

If you would like to use a hard-wired panel and an RF panel, install an optional 2-1 cable connector inside the

system enclosure. This will allow connection of the hard-wired Master Panel cable and the RF Master Panel

receiver cable. This installation is similar to instruction 5 on page 23.

Mount the Receiver Module in a convenient location that maximizes the range of the RF Master Panel. (See

instructions on page 27.)

INST

ALL HAYWARD RF SPA RECEIVER AND CONNECT IT TO THE MAIN CONTROL CENTER:

Under ideal conditions, the Hayward RF Spa Remote Kit allows a user to position the spa remote controller

anywhere within 100 ft of the Main Control Center without a hard-wired connection.

Follow the same procedures to mount the RF Spa Control Receiver Module. (See instructions on page 27.) With

an optional extended cable, the effective range of the RF components can also be enhanced.

This completes the installation in the system box. Secure the Control System door and power up the System.

NOTE: Make sure RF Circuit Board connection is separate from the hard-wired connection;

use 2 to 1 connector as needed.

SPA

PANEL

Page 27

27

INSTALLING OPTIONAL RF PANELS (continued)

Installing RF Panels to Optimize Range:

1. Position both receivers away from any cables (such as power lines, extension cords, cable lines, and

phone lines).

2. Mount far away from large metallic objects (such as fences, aluminum siding, metal piping, and rain gutters).

3. Be sure there are no metal objects between the spa receiver and the spa.

4. Position the receiver so that the antenna is pointing upwards, perpendicular to the ground.

5. Position as high off the ground as possible:

When using both receivers, place the spa unit as high off the ground as possible while placing the master panel

unit lower and at least 5-6 feet to one side.

When only using one receiver, place it as high as possible.

Make sure the master panel system gives you the proper range before mounting it permanently.

The closer it is mounted to the ground, the less range it will have.

While the master panel tends to be stationary and more predictable, the spa transmitter moves around and

should receive the highest mounting position possible.

6. IMPORTANT: Line of sight between the receiver and the spa provides the best range.

CAUTION: PLEASE READ THE FOLLOWING INSTRUCTIONS BEFORE INSTALLATION.

7. CAUTION: With all above noted tips in mind, experiment by placing receiver(s) in different places to find the best

range before permanently mounting the receiver(s) to the wall.

Page 28

SETTING DIP SWITCH IN CASE OF 2 HA

YWARD POOL SYSTEM CONTROLS INSTALLED NEAR ONE ANOTHER:

Note: There are DIP switches on the circuit board,

inside the Receiver Modules, that are always

shipped in the OPEN position. In the event that two

Hayward wireless control systems are installed near

one another, these switches can be used to create a

unique "code" that your control will communicate

under. This will minimize the possibility of any

"crosstalk" between systems.

IMPORTANT: THE SWITCHES MUST BE SET THE

SAME WAY IN BOTH THE RECEIVER MODULE AND

THE MASTER PANEL RF CRADLE.

INST

ALL RF MASTER PANEL CRADLE:

The RF Master Panel Cradle is battery operated and is

ready to operate once the existing "RF-ready" Master Panel is

installed in it. The unit is supplied with the internal DIP switches set to OPEN so it is compatible with

the RF board described above. The RF Master Panel will turn on when either the Up or Down button

is pressed once. When it is on, it should behave just as if it were hard-wired. If a button is not pressed

for 3 minutes, the panel will "sleep" to preserve battery life.

USING A TRANSFORMER FOR RF MASTER P

ANEL CRADLE:

A plug-in transformer option is available that allows the panel to be "awake" at all times and display pool functions

without the need to activate the panel first. The plug in connector for the transformer can be used by removing the

battery cover and plugging the transformer wire into the circuit board and then routing the wire out of the battery

compartment through an upper or lower opening.

INST

ALL RF MASTER PANEL INTO CRADLE:

To install an RF-ready Master Panel in the RF Cradle, first turn the Master Panel over and remove the upper right

and lower left screws that are obvious on the back of the panel. These screws will be replaced by the longer screws

included with the RF Cradle. Plug the phone-type wire from the RF Cradle into the Master Panel. Carefully lay the

Master Panel into the RF Cradle and install the new, longer screws through the RF Cradle and into the Master

Panel, being careful not to overtighten.

INST

ALL BATTERY INTO CRADLE:

Open the battery compartment by removing the cover screws and tilting the door away from the RF Cradle. Install 4

AA batteries in the battery holder and plug the battery holder into the circuit board. (At this time, the optional

transformer can be installed if desired, in which case batteries are not required.) The installation is now complete.

The antenna is able to rotate on the side of the RF Cradle and should be in a vertical orientation when the panel is

in use.

MOUNT RF MASTER CONTROLLER (CRADLE WITH MASTER P

ANEL) ON WALL:

If you intend to mount the RF panel on a wall, mark the locations of the mounting holes BEFORE the Master Panel

is installed in the Cradle. You may wish to choose a location close to a wall outlet so that the optional wall

transformer can be used to power the unit.

BACKSIDE OF

MASTER PANEL CRADLE

BACKSIDE OF

MASTER PANEL

DIP SWITCHES

MUST MATCH

INSTALLING OPTIONAL RF PANELS (continued)

28

Page 29

29

TO INSTALL SPA SIDE CONTROL PANEL:

1. DETERMINE THE EXACT LOCATION OF THE PANEL.

The Panel can be located on the deck next to the spa or on a vertical wall of the spa.

Important: Position the Panel so that it can not be submerged. Occasional splashing is permissible so long as

the water can drain off the Panel. While the Panel is designed to get wet, constant water contact must be

avoided.

2. PROVIDE AN UNOBSTRUCTED FLAT SURFACE

Be sure the location selected provides an unobstructed flat surface that is at least 4" high X 8" wide upon which

the Panel can be mounted. The 1' conduit that receives the Panel will protrude from the middle of the area.

This provision needs to be deliberately planned during the placement of the concrete/gunite and during the

installation of tile and coping stone, etc. This is the area required on the final finished surface for mounting

the Panel.

3. PROVIDE A 1" CONDUIT.

Provide a 1" conduit through the concrete/gunite at the location selected for the Panel. The Panel will extend

into the inside diameter of the conduit and the cable will be routed through it.

A. FOR INSTALLATIONS THROUGH A VERTICAL WALL:

Before concrete/gunite is placed, securely fasten the 1" conduit so that it will remain in position during the

placement of the concrete/gunite. The conduit should be long enough to extend at least 6" beyond the

finished inside surface and 6" beyond the rough outside surface of the concrete/gunite. This will allow the

conduit to be cut flush with the final finished surface on the inside and extend beyond the rough outside

surface.

Important: The 1" conduit must be positioned and adequately fastened so that it will be

perpendicular both horizontally and vertically to the finished surface. This is extremely important

for a successful installation of the Panel. Additional conduit will be added to the 1" stub-out to

reach the Main Control Center.

B. FOR INSTALLATIONS THROUGH A DECK:

Before concrete is placed, glue together enough conduit to extend from the Panel location to the edge of

the pour. Install a sweep 90 degree elbow at the Panel end of the conduit. To the elbow, install a reducing

bushing and a 1" coupling to adapt to 1" conduit. Install at least 12" of 1" conduit to the 1" coupling.

Position the conduit assembly in a trench so that the 1" conduit extends vertically and so that there is at

least 8" of 1" conduit below the finish grade of the concrete. Important: Secure the 1" conduit so that it is

perpendicular to the finish grade of the concrete and remains in that position during the placement of the

concrete. This is extremely important for a successful installation of the Panel. Fill and compact the trench

to help hold the conduit in place. After the concrete has been placed and all finishing operations have been

completed, the 1" conduit will be cut flush with the final finished surface.

ATTENTION: IF THE CABLE ON THE SPA PANEL IS NOT LONG ENOUGH TO REACH THE MAIN CONTROL

CENTER, DO NOT ADD LENGTH TO THE CABLE BY SPLICING ADDITIONAL CABLE ONTO THE CABLE;

OBTAIN A SPA PANEL WITH A CABLE THAT IS LONG ENOUGH TO REACH. A CABLE THAT IS TOO LONG

MAY BE SHORTENED BY CUTTING OFF THE EXCESS AND RE-INSTALLING A NEW CONNECTOR AT THE

DESIRED LENGTH.

LOCATION GUIDELINES: The Spa-Side Control Panel hereafter referred to as the “Panel" should be installed

during the initial pool/spa construction. This will allow for important steps to be completed before the concrete or

gunite is placed. The specific Panel location needs to be determined and planned for and the PVC conduit along

with any pulling elbow or junction boxes as required to route the Panel cable to the Main Control Center needs to be

in place. If the Panel is installed after the pool/spa construction has been completed, the installation must fulfill the

intent of these instructions.

LOCATING AND INSTALLING THE SPA SIDE CONTROL PANEL

Page 30

HORIZONTAL

LOCATION

VERTICAL

LOCATION

1/2" PVC

CONDUIT

PVC

CONDUIT

DECK

DECK

SWEEP

FINISHED

SPA WALL

1" PVC

CONDUIT

1" PVC

CONDUIT

MUST BE ENOUGH

DISTANCE TO

PREVENT

CONTINUOUS

WATER CONTACT

WITH THE PANEL

1" COUPLING

1" X 1/2" REDUCING

BUSHING

1. WARNING: IT IS IMPORTANT TO POSITION THE PANEL SO THAT IT CANNOT BE

SUBMERGED AT ANY TIME!

Occasional splashing is permissible so long as the water can drain off the Panel. While the Panel is designed to get

wet, constant water contact MUST be avoided.

2. CAUTION: ANTICIPATE WHAT THE WATER LEVEL WILL BE WHEN PLANNING INSTALLATION

Water level can rise by as much as 6 inches, depending upon the size and shape of the spa, as well as the number

of people in the spa at any given time.

The Panel can be located on the deck next to the spa or on a vertical wall of the spa. Provide an unobstructed flat

surface that is at least 4" high X 8" wide upon which the Panel can be mounted. The 1" conduit that receives the

Panel will protrude from the middle of this area.

Acceptable Locations

Position at

eye level

Installations Through a Vertical Wall

Installations Through a Deck

Remember: The water level in a spill-over type spa will depend upon which direction the valves are facing.

3. PROVIDE A 1" CONDUIT

Provide a 1" conduit through the concrete/gunite at the location selected for the Panel. The Panel will extend into the

inside diameter of the conduit and the cable will be routed through it. (See detailed installation instructions on page

27 of the Hayward 2100 Series Pool System Control Installation and Programming Instructions.)

ATTENTION: If the cable

on the spa panel is not long

enough to reach the Main

Control Center, do not add

length to the cable by

splicing additional cable

onto the cable; obtain a spa

panel with a cable that is

long enough to reach. A

cable that is too long may

be shortened by cutting off

the excess and re-installing

a new connector at the

desired length.

30

LOCATING AND INSTALLING THE SPA SIDE CONTROL PANEL (cont.)

Page 31

31

LOCATING AND INSTALLING THE SPA SIDE CONTROL PANEL (continued)

4. COMPLETE THE INSTALLATION OF THE CONDUIT.

A. Before additional concrete is placed over the route of the conduit to the Main Control Center, complete the

installation of the conduit.

B. Be sure that all underground conduit is positioned in well compacted soil below the concrete. Also use care

when making the glue joints to be sure that they are watertight. Additionally, do not use more than two 90

degree sweeps in a single pull. Doing so may make pulling the cable difficult.

C. For long conduit runs (over 100') it may be advisable to use a watertight pulling fitting positioned in the middle of

the conduit run. If this is necessary, it is advisable to elevate the pulling fitting at least 6" above the finish grade

from the surrounding area to avoid potential flooding. Important: Do not cut the cable at the pulling fitting. Use

the pulling fitting as an intermediate pulling point only.

5. CUT THE EXCESS 1" CONDUIT FLUSH WITH THE FINAL FINISHED SURFACE.

After all finish work has been completed (plaster, tile, coping stone, deck finished, etc.), cut the 1" conduit flush with

the finished surface. Sawing the conduit will not produce a flush surface, so grind, sand, or file as necessary. After

cutting flush, deburr the inside diameter of the conduit.

6. PULL THE PANEL CABLE THROUGH THE CONDUIT.

An electrician's wire pulling snake is required for this job. For long pulls, wire lubricant is also a great aid.

Push the snake from the Main Control Center to the Panel location. After the snake has exited the conduit at the

Panel location, fasten the cable to the snake.

TAKE CARE TO PROTECT THE CABLE CONNECTOR FROM DAMAGE WHILE PULLING THE CABLE.

With one person pulling the cable and one person at the Panel location assuring that no kinks or knots occur, pull

the cable through the conduit and into the low voltage compartment of the Main Control Center. Neatly coil any

extra cable and store in the low voltage compartment. Route the cable to the top of the printed circuit board to be

sure there is enough cable to install the phone connector into J20.

ATTENTION: IF THE CABLE ON THE SPA PANEL IS NOT LONG ENOUGH TO REACH TO THE MAIN

CONTROL CENTER, DO NOT ADD LENGTH TO THE CABLE BY SPLICING ADDITIONAL CABLE

ONTO THE CABLE; OBTAIN SPA PANEL WITH A CABLE THAT IS LONG ENOUGH TO REACH. A

CABLE THAT IS TOO LONG MAY BE SHORTENED BY CUTTING OFF THE EXCESS AND

REINSTALLING A NEW CONNECTOR AT THE DESIRED LENGTH. TOOLS AND CONNECTORS FOR

THIS PURPOSE ARE READILY AVAILABLE IN MOST HOME CENTERS.

1 - Blank

2 - Blank

3 - Brown

4 - Yellow

5 - Green

6 - Red

7 - Black

8 - Orange

WIRING PATTERN FOR MASTER & SPA-SIDE CONTROL CABLES

*Termination of Master Panel cable should be identical on both ends

crimp area

gold contacts

cable

release clip on opposite side

Page 32

IMPORTANT: WHEN PULLING THE PANEL CABLE THROUGH THE CONDUIT ALWAYS LEAVE

6" TO 8" OF EXCESS CABLE AT THE PANEL END. THE EXCESS CABLE IS THEN PUSHED

INTO THE 1" CONDUIT AS THE PANEL IS INSTALLED. THIS ALLOWS THE SPA PANEL TO BE

REMOVED FROM THE SPA WALL OR DECK FAR ENOUGH TO GAIN ACCESS TO THE CABLE

SO THAT IT CAN BE GRASPED AND PULLED FROM THE CONDUIT SHOULD THE PANEL

NEED TO BE REMOVED. IMPORTANT: WHEN REMOVING THE PANEL, DO NOT PULL ON THE

PANEL TO PULL THE CABLE OUT OF THE CONDUIT. ALWAYS PULL ON THE CABLE ITSELF.

7. MAKE THE FINAL CONNECTION

Route the cable through the low voltage compartment and to the top of the printed circuit board of the Main

Control Center. Push the connector on the end of the cable into the receptacle labeled J-20.

8. MOUNT THE PANEL.

Dry fit the Panel against the mounting surface to be sure there are no high points that need to be removed.

Clean the mating surfaces and then apply a bead of silicone adhesive. Remove the masking from the

double sided adhesive strips. Carefully push the extra 6" to 8" of cable into the conduit as you position the

Panel. Seat the Panel into the silicone, being sure it is level or square or parallel with surrounding surfaces.

Peel backing off adhesive strips. Push the Panel firmly against the mounting surface so that the adhesive

strips grasp firmly to the mounting surface. The adhesive strips will hold the Panel in position while the

silicone cures.

1” PVC CONDUIT

LOCATING AND INSTALLING THE SPA SIDE CONTROL (continued)

ADHESIVE STRIPS

ADHESIVE STRIPS

SILICONE

SEALANT

HERE

32

Page 33

33

CONNECTING LOW VOLTAGE COMPONENTS TO THE MAIN CONTROL CENTER

CONNECTING AIR AND WATER

TEMPERATURE SENSORS

(ALSO OPTIONAL SENSORS)

1. Route the sensor cables through the

opening provided on the bottom right

of the Main Control Center through

the low voltage compartment and over

the top of the low voltage

compartment partition.

2. Insert the connectors at the end of

the cables into the marked

receptacles along the top of the

printed circuit board.

3. Store any excess cable in the low

voltage raceway.

NOTE

: AIR TEMPERATURE

SENSOR MUST BE INSTALLED IN

A PLACE THAT WILL NOT BE

AFFECTED BY DIRECT SUN

EXPOSURE.

THE SENSOR IS DESIGNED TO

SENSE AND DISPLAY AMBIENT

AIR TEMPERATURE. ROUTE THE

CABLE ACCORDINGLY.

CONNECTING MOTORIZED DIVERTER VALVES (ALSO OPTIONAL POOL FILL VALVE)

1. Route the cables along the pipes that support the Motorized Diverter Valves as directly as possible to the

nearest wall. Use tie-wraps to secure the cable to the plumbing. Continue to route the cable to the Main

Control Center by neatly securing the cable to the wall and through the opening provided on the bottom

right of the Main Control Center.

2. Continue the cable through the low voltage compartment and over the top of the low voltage

compartment partition.

3. Insert the connectors at the ends of the cables into the marked receptacles along the top of the printed

circuit board.

4. Store any excess cable in the low voltage compartment. Remember to check the synchronization of the

valves as outlined in the basic plumbing schematic when the system is powered up. See pages 10-19 for

valve installation locations.

CONNECTING MASTER CONTROL PANEL AND SPA-SIDE CONTROL PANEL

1. Route the cables through the opening provided on the bottom left of the Main Control Center, through the

low voltage compartment and over the top of the low voltage compartment partition.

2. Insert the connectors on the ends of the cable into the marked receptacles along the top of the printed

circuit board. There should be little or no excess cable from the Master Panel or the Spa-Side Panel to

store in the low voltage compartment.

3. Excess cable from the Master Control Panel should be stored in the attic or between walls.

LOW VOLTAGE

CONNECTOR

RECEPTACLE

AIR AND WATER

TEMPERATURE

SENSORS,

MOTORIZED

DIVERTER VALVES

MASTER CONTROL PANEL,

SPA SIDE CONTROL PANEL

Page 34

34

CONNECTING HIGH VOLTAGE COMPONENTS TO THE MAIN CONTROL CENTER

HEATER CONNECTION GUIDELINES

ATTENTION: THE MAIN CONTROL CENTER PROVIDES A MEANS FOR CONTROLLING HEATERS

THAT UTILIZE MILLIVOLT CONTROL SYSTEMS AS WELL AS 24V CONTROL SYSTEMS. THE

HEATER MUST BE WIRED PROPERLY TO MATCH THE HEATER CONTROL SYSTEM AND BE IN

ACCORDANCE WITH HEATER MANUFACTURER'S INSTRUCTIONS BEFORE POWER-UP.

CONNECTING HEATER WITH MILLIVOLT CONTROL SYSTEM

NOTE:DO NOT CONNECT MILLIVOLT CONTROL CIRCUITS TO HIGH VOLTAGE. DOING SO WILL

DAMAGE THE HEATER CONTROL CIRCUIT.

1. Follow the directions below to connect the control system for a Millivolt Heater in series with a relay that is located

on the Main Control Center printed circuit board. This relay is controlled by the temperature sensing circuit on the

board and will close when heating is required. It will not provide output voltage.

2. Using #22 AWG (2 conductor, sheathed cable or cable as directed by the heater manufacturer) interrupt the

control circuit in the heater and connect each conductor in the cable to each open end of the control circuit. The

heater manufacturer may have specific terminals designated for this purpose.

3. Neatly route this cable to the main control center, through one of the low voltage raceways and after cutting and

stripping the insulation from the conductors, connect them to the 2 terminals marked “HEATER SWITCH”.

CONNECTING HEATER WITH 24V CONTROL SYSTEM

NOTE: DO NOT CONNECT 24V CONTROL CIRCUITS TO HIGH VOLTAGE; DOING SO WILL DAMAGE

THE HEATER CONTROL CIRCUIT. THIS TYPE OF HEATER REQUIRES A CONTINUOUS 120V OR

240V POWER SOURCE.

1. Install flexible conduit from a knockout that enters the high voltage compartment of the Main Control Center to the

knockout that enters the high voltage field wiring compartment of the heater.

2. For 120V heaters, pull 3- #14 AWG conductors, one each of black, white, and green with a temperature rating of

105°C or higher through the Seal-tite.

3. For 240V heaters, pull 3- #14 AWG conductors, one each of red, black, and green with a temperature rating of

105°C or higher through the flexible conduit. Leave enough wire at each end to make the required connections.

4. At the Main Control Center, cut the wires to length and strip 1/2" of insulation from the ends of the wires.

5. For 120V heaters, connect the black wire to the terminal marked “120/240 HEATER” and tighten. Connect the

white wire to the “LOAD NEUTRAL (WHT)” bar and tighten.

6. For 240V heaters, connect the red wire to the terminal marked “240V HEATER” and tighten. Connect the black

wire to the terminal marked “120/240V HEATER” and tighten.

7. For both 120V and 240V applications, connect the green wire to the ground terminal strip and tighten.

At the heater end, locate the 120V on the 240V field wiring connections and connect according to the

manufacturer's instructions.

8. After connecting the power to the heater as described above, connect the 24V control system in series with a

relay that is located on the Main Control Center printed circuit board. This relay is controlled by the temperature

sensing circuit on the board and will close when heating is required. It will not provide output voltage.

9. Using #22 AWG, 2 conductor, sheathed cable or cable as directed by the heater manufacturer, interrupt the 24V

control circuit in the heater and connect each conductor in the cable to each open end of the control circuit. The

heater manufacturer may have specific terminals designated for this purpose. Neatly route this cable to the lowvoltage raceways and after cutting and stripping the insulation from the conductors, connect them to the two

terminals marked “HEATER SWITCH.”

FOR BOTH TYPES OF HEATERS – MILLIVOLT CONTROL SYSTEM AND 24V CONTROL SYSTEM PLEASE

NOTE THE FOLLOWING:

After the heater hook-up has been made, turn all thermostats to maximum position and move thermostat selector

switches to any on position. This will enable all control switches in the Heater Control Circuit and allow the heater

to fire when the Main Control Center temperature sensing circuit calls for heat.

Page 35

35

CONNECTING HIGH VOLTAGE COMPONENTS TO THE MAIN CONTROL CENTER (continued)

CONNECTING PUMPS

1. Install flexible conduit from a knockout that enters the high voltage compartment of the Main Control Center to the

field connector fitting of each pump.

2. Pull 3- #12 AWG conductors, one each of red, black and green with a temperature rating of 60°C or higher through

the flexible conduit, leaving enough wire at each end to make the required connections.

3. At the Main Control Center, cut the wires to length and strip 1/8" of insulation from the ends of the wires. Insert the

red and black wires into the terminals marked for the pump being wired (filter pump, cleaner pump, spa jet pump, or

auxiliary outputs being used for water feature pumps) and tighten.

4. Connect the green wire to the ground terminal strip and tighten.

5. At the pump end, make the connections to the pump according to the manufacturer's instructions

CONNECTING UNDERWATER LIGHTS

ATTENTION: A DEDICATED CIRCUIT LABELED “UNDERWATER LIGHT CIRCUIT” HAS BEEN

PROVIDED TO ENABLE THE CONNECTION OF UNDERWATER LIGHTS. THIS CIRCUIT PROVIDES

GFCI PROTECTION FOR THE UNDERWATER LIGHT CIRCUIT AS REQUIRED BY THE NATIONAL

ELECTRICAL CODE. DO NOT USE ANY OTHER CIRCUIT TO ENERGIZE UNDERWATER LIGHTING.

NOTE: WHEN INSTALLING 120V LIGHTS, THE DIP SWITCH SHOULD BE IN THE “120V” POSITION. THIS

WILL ENABLE A LIGHT DIMMING CIRCUIT AND PROVIDE 3 SELECTABLE LIGHTING INTENSITIES. WHEN

INSTALLING 12V POOL LIGHTS, THE DIP SWITCH MUST BE IN THE 12V POSITION. THIS WILL DISABLE

THE LIGHT DIMMING CIRCUIT AND PROVIDE A SINGLE LIGHTING INTENSITY. THE SYSTEM WILL STILL

DELIVER 120V TO THE 12V LIGHT TRANSFORMER. (THE PRIMARY WINDING OF THIS TRANSFORMER

MUST BE SUPPLIED WITH 120V. THIS VOLTAGE CAN NOT BE ATTENUATED FOR THE PURPOSE OF

DIMMING THE LIGHT. SEE ILLUSTRATION PG. 21)

1. Install PVC conduit from a knockout that enters the high voltage compartment of the Main Control Center to the deck

box(s) that are connected to the conduit coming from the light fixture(s).

2. Pull 3 properly sized (#14GA minimum) conductors, one each of black, white and green with a temperature rating of

60°C or higher through the conduit, leaving enough wire at each end to make the required connections.

3. At the Main Control Center, cut the wires to length and strip 1/2" of insulation from the ends of the wires. Connect the

black wire to the black wire labeled “Underwater Light Circuit” using the wire nut provided.

4. Connect white wire to the white wire labeled “Underwater Light Circuit” using the wire nut provided.

5. Connect the green wire to the ground terminal strip and tighten. At the deck box end, make the connections inside

the deck box using correctly sized wire nuts. Be sure to connect black to black, white to white, and green to green.

NOTE: CHECK WITH LOCAL CODES REGARDING THE APPROVED CONNECTION METHOD FOR

GROUND WIRES.

CONNECTING AUXILIARY YARD LIGHTS

ATTENTION: THIS IS A 120 VAC LIGHTING CIRCUIT.

1. Install PVC conduit from a knockout that enters the high voltage compartment of the Main Control Center.

2. Pull 3 properly sized (#14GA minimum) conductors, one each of black, white and green with a temperature rating of

60°C or higher through the conduit, leaving enough wire at each end to make the required connections.

3. At the Main Control Center, cut the wires to length and strip 1/8" of insulation from the ends of the wires.

4. Insert the black wire into the terminal marked “YARD LT” and tighten.

5. Connect the white wire to the “LOAD NEUTRAL (WHT)” bar. Connect the green wire to the ground terminal strip and

tighten.

6. Make the necessary connections at the light fixtures with wire n

uts or with approved connectors as required.

CONNECTING POOL LIGHTING OPTION (GFCI PROTECTED)

ATTENTION: THIS IS A 120 VAC LIGHTING CIRCUIT - 5 AMP MAX

1. Install PVC conduit from a knockout that enters the high voltage compartment of the Main Control Center to the

optional light source as required.

2. Pull properly sized (#14GA minimum) conductors, one each of black (light), red (Aux 4 option), white, and green with

a temperature rating of 60°C or higher through the conduit, leaving enough wire at each end to make the required

connections.

3. At the Main Control Center, cut the wires to length and strip 1/8" of insulation from the ends of the wires. Insert the

black wire into the terminal marked “AUX 4” above “LIGHT.”

4. Insert the red wire into the terminal marked “AUX 4” above “OPTION.”

5. Connect the white wire to the “LOAD NEUTRAL (WHT)” bar. Connect the green wire to the ground terminal strip and

tighten.

6. Make the necessary connections at the light fixtures with wire nuts or with approved connectors as required.

Page 36

36

CONFIGURING THE SYSTEM

The circuit board in the Main Control Center is equipped with dip switches and a jumper. This allows the

system to be configured to specific output configurations. Be sure to review these switch and jumper

positions before power-up so that the system will respond properly to your configuration.

DIP SWITCH POSITIONS

1. DOWN- position is for 120V dimmable pool/spa light.

UP- will still deliver 120V, but will not be

dimmable.

(12V pool lights still require 120V to the

light transformer) see page 19.

2. DOWN- sets the spa aux for jet pump only.

UP- will cycle between jet pump and blower

with the spa aux button.

3. DOWN- disables spillover option.

UP- enables spillover option.

4. DOWN- (6A max) Will not activate filter pump

when Aux 1 is operating.

UP- enables cleaner pump option with filter

pump (when Aux 1 is on).

5. DOWN- is for a 1-speed filter pump.

UP- allows use of 2-speed filter pump.

6. DOWN- allows the reading from an aux ORP

sensor to be displayed.

UP- only allows PH to be displayed when a

PH/ORP daughter board and sensors are

installed.

S1

DIP SWITCH

UP

DOWN

C54

U8

RP4

RP2

"OFF"

"ON"

+

MEMORY RESET "ON"

MEMORY ACTIVE "OFF"

K1

C 2000

BALBOA PN 27105 REV:5

C42

BAR CODE

R48

RP3

RP1

+++

C5

C8

R43

R42

R45

C20

C29

Y16

U3

S2

C10

"120/240 HEATER" + "240V HEATER"

HEATER "120/240 HEATER" + "NEUTRAL" SUPPLIES 120V TO

J26

1

R23

X2

C36

R36

R8

F8

20A

CLASS G

FILTER PUMP

RED BLK BLK

RED

FILTER PUMP

SPA JET PUMP

20+20

J17

PH/ORP

J22

U15

+

U5

D4

R25

R14

R20

C31

C12

R47

C11

C52

C16

U1

C13

R46

R6

R1

R38

K2

C43

SUPPLIES 240V TO

20A

F6

CLASS G

SPA JET PUMP

RED

CLEANER PUMP

J29

BOARDEXPANDER

C51

EVCM

U11

R44

R13

Z2

C53

K3

R12

C44

HEATER

10A

F9

CLASS G

CLEANER PUMP

BLK

120/240

240V

HEATER

HEATER

C24

J30

C6

Q5

D9

D7

D6

C49

D3

D2

10A

F4

HEATER

8

RED AC

R18

C7

+

D5

U4

+

C9

R17

LINE 1

J1

R2