Page 1

Harrier

48

CODE 485T

(Blade Brake Clutch - Auto Drive)

OWNER’S HANDBOOK

English Version

FROM SERIAL NO: 485T001001 HANDBOOK: 485101 (rev.0.)

Issue : 21.09.99

Page 2

CERTIFICATE OF CONFORMITY

I, the undersigned M.A. Wright, of:

HAYTER LIMITED, Spellbrook, Bishop’s Stortford

Herts CM23 4BU

ENGLAND

certify that the lawnmowers:

1. Machine Type No. CODE 485T

2. Category. Combustion Engine

3. Make. Hayter

4. Type. Rotary

5. Engine - Manufacturer. Briggs & Stratton

- Type. 12G882-1512-21

- Speed of rotation during test. 2950 rpm

Conforms to the specifications of Directive 84/538/EEC as adapted to technical

progress by Directive 87/252/EEC and amended by Directive 88/180/EEC.

Guaranteed maximum sound power level. 96 dB(A)

- Type of cutting device Cutterbar

- Width of cutting device 48 cm

- Speed of rotation of the cutting device 2950 rpm

TESTED AT SUDBURY, SUFFOLK, ENGLAND 25.03.98

Signed

M.A. Wright

(Technical Director)

EC DECLARATION OFCONFORMITY

Company Name HAYTER LIMITED

Company Address Spellbrook

Machine Type No.. CODE 485T

Models Harrier 48 BBC

Directives complied with:

93/68/EEC Essential. Health & Safety Requirements Relating to the Design & Construction of Machinery

and Safety Components.

84/538/EEC amended by 87/252/EEC and 88/180EEC Permissible Sound Power Levels of Lawn Mowers

89/336/EEC amended by 92/31/EEC Electromagnetic Compatibility

Standards Used: EN292, EN836, ENISO14982

I declare on behalf of Hayter Limited that these machines conform to the EC Essential Health & Safety

Requirements.

Bishop’s Stortford

Herts. CM23 4BU

ENGLAND

Signed

M.A. Wright

(Technical Director)

Date:21.09.99

VIBRATIONINFORMATION

Lawnmower vibration information. RMS acceleration measured in 3 - axes at operators contact position on the

CODE 485T = 6 ms

handlebars.

-2

Page 3

1.1

CONTENTS Page No.

INTRODUCTION 1.3

WARRANTY 1.4

SAFETY PRECAUTIONS 1.5 - 1.9

Decals 1.9

SPECIFICATIONS 1.10

ASSEMBLY INSTRUCTIONS 1.11 - 1.13

General Assembly 1.11

Assembling the Mower for the First Time 1.12- 1.13

STARTING THE ENGINE 1.14 - 1.16

Before Starting the Engine 1.14 - 1.15

To Start the Engine 1.16

STOPPING THE ENGINE 1.17

OPERATINGTHE MOWER 1.18 - 1.23

Safety Notice 1.18

Height of Cut 1.18

Travel 1.19

Turning the Mower 1.19

Mowing with Grass Collection 1.20

Mowing without Grass Collection 1.21

Heavy Growth 1.21

Moving the Mower across Non-Grassed Areas 1.21

Cutterbar Operation 1.22

Mowing and Grass Care Tips 1.23 - 1.24

CONTENTS

1.1

MAINTENANCE 1.25 - 1.33

Engine 1.25

Throttle Cable Adjustment 1.25

Carburettor Adjustments 1.26

Oil Service 1.26

Air Cleaner Service 1.27

Spark Plug Service 1.27

Keeping the Engine Clean 1.28

Grassbag 1.28

Deck Housing 1.28

485101MT210999A

Page 4

1.2

CONTENTS Page No.

MAINTENANCE Continued.

Securing Nuts and Bolts 1.29

Lubrication 1.29

Clutch Cable Adjustment 1.29

Cutterbar 1.30 - 1.31

Maintenance Schedule 1.32 - 1.33

- After First 5 Hours 1.32

- Every 5 Hours or Daily 1.32

- Every 25 Hours or Every Season 1.32

- Every 50 Hours or Every Season 1.33

- Every 100 Hours or Every Season 1.33

PREPARINGTHE MOWER FOR STORAGE 1.34

FAULT FINDING 1.35 - 1.37

485T PARTS LIST 2.1 - 2.3

485T PARTS DIAGRAM 2.4

ENGINE ANCILLARY PARTS 2.5

CONTENTS

1.2

WARRANTY ENGINE 2.6

NOTES 2.7

CUSTOMER INFORMATION 2.8

485101MT210999A

Page 5

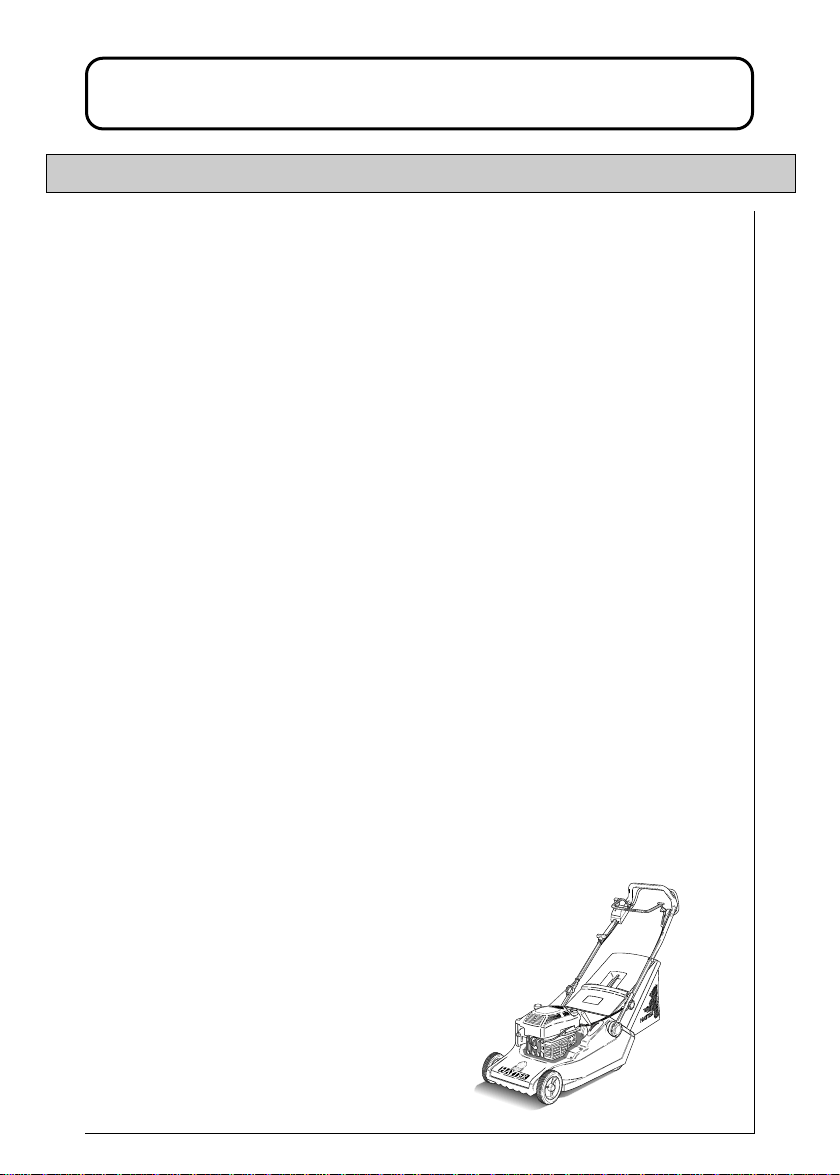

1.3

INTRODUCTION

1.3

INTRODUCTION

Thank you for purchasing a Hayter mower. The following pages are designed to help you

gain safe and efficient service from your machine.

IMPORTANT: This ‘Owners Handbook’ should be regarded as part of the machine as it

gives essential information regarding machine safety, operation, maintenance and

specifications. Read and understand this handbook prior to operating your machine for the

first time. Make sure you are familiar with all the controls and points of regular maintenance.

If you have any doubts, consult your Hayter authorised dealer who will be pleased to give

you assistance.

IMPORTANT: This machine is designed solely for use in a domestic grass cutting

environment. Use in any other way is considered as contrary to the intended use. Compliance

with and strict adherence to the conditions of operation, service and repair as specified in this

handbook also constitute essential elements of the intended use.

This machine should be operated, serviced and repaired only by persons who are familiar with

its particular characteristics and who are acquainted with the relevant safety procedures.

The safety precautions listed here in and all other generally recognised regulations on safety

must be observed at all times.

Any arbitrary modifications carried out to this machine may relieve Hayter Limited of

liability for any resulting damage or injury.

All Hayter mowers are robustly constructed and designed for efficient economical

performance under normal mowing conditions. Correct operation and maintenance will

ensure a long and satisfactory service life. Prior to despatch from our factory every effort is

made to ensure your machine arrives in perfect condition. Your dealer will carry out a predelivery inspection to ensure that there has been no transit damage prior to installation.

Please allow your dealer to familiarise you with the controls and safety features of the

machine during installation.

Throughout this handbook all references to left hand and right hand are as viewed from

behind the handlebar, facing in the direction of

forward travel.

This handbook is based on information

available at the time of publication.

HAYTER LIMITED reserve the right to make

changes at any time without notice.

1D485

485101MT210999A

Page 6

1.4 1.4

LIMITED WARRANTY

Hayter Limited warrants to the original user/purchaser that this unit shall be free from defects

in material and workmanship under normal use and service for a period of three years from the

date of purchase. The manufacturers of the engine and battery pack system (where applicable)

furnish their own warranty and services are provided through their authorised network (Refer to

"Engine/Battery Pack Warranty Statement"). To qualify for the full benefit of the warranty, the

warranty registration card must be returned within 60 days of purchase. Subject to the conditions

and exclusions noted in this limited warranty, we shall at our option, repair or replace any

warranted part during the applicable period. If you are in doubt or experience any difficulty,

please consult a Hayter Authorised Service Dealer for clarification.

To qualify for the extended warranty (second and third year) of the three year limited warranty

the machine must have annual services carried out by an Authorised Hayter Service Dealer.

These chargeable services should be carried out within 12 and 24 months of the date of purchase.

Excluded from the extended warranty period are those items which are subject to normal wear

and tear e.g. tyres, wheels, cutterbars, cables, batteries and other consumable wearing parts.

All consumer machines which are fitted with a genuine Hayter friction disc as original

equipment before use, are covered by a Lifetime Warranty against the engine crankshaft

bending. Note: friction washers, blade brake units and other such devices are not applicable.

Only machines fitted with a genuine Hayter friction disc, which are used in accordance with the

recommended operating and maintenance procedures, are covered.

This warranty does not apply to any unit that has been tampered with, altered, misused, abused or

used for hire, and will become invalid if non genuine Hayter parts are fitted. This warranty does

not cover minor mechanical adjustments unless they are due to defective material or

workmanship. Consult the Owner's Handbook or a Hayter Authorised Service Dealer for

assistance when making these adjustments.

A warranty period of 90 days applies to machines used for commercial purposes.

To make a warranty claim, return the unit to a Hayter authorised dealer along with proof of

purchase stating the machine serial number and date of purchase. The service receipt(s) or this

Owners Handbook with the 1st/2nd year service boxes fully completed, must be produced as

proof of entitlement to the extended warranty period. Subject to the conditions and exclusions in

this limited warranty, the authorised dealer will, at our option, repair or replace any warranted

part within the duration of the warranty period.

This limited warranty gives you specific legal rights and is in addition to any statutory rights to

which you may be entitled and your statutory rights are not affected by this warranty. If you need

additional information concerning this written warranty, or assistance in obtaining services,

please write to : HAYTER LIMITED, Service Department, Spellbrook, Bishop's Stortford,

Hertfordshire CM23 4BU

UK ONLY: Details of your local Hayter authorised dealer are contained in Yellow Pages or

contact:- Freephone 0800 616298.

Date.................................................................... Date.............................................................

Signed................................................................ Signed..........................................................

Issue: 09.12.97

DEALER STAMP

DEALER STAMP

1st Year

Service

Record

2nd Year

Service

Record

WARRANTY

485141EB201198A

Page 7

1.5

SAFETY PRECAUTIONS

THIS SYMBOL MEANS BE ALERT! YOUR SAFETY IS INVOLVED.

WHEN YOU SEE THIS SYMBOL BE ALERT TO THE POSSIBILITY

OF INJURY. CAREFULLY READ THE MESSAGE THAT FOLLOWS

AND INFORM OTHERS.

EXERCISE GREATCARE AND FOLLOW THE ADVICE GIVEN TO

AVOID POTENTIALLYHAZARDOUS SITUATIONS.

The Harrier 48 is perfectly safe if used correctly. Failure to observe the

following simple precautions may result in serious injury.

Training:

Read the instructions carefully. Ensure that you are familiar with the controls and the

proper use of the equipment. Learn how to stop the mower quickly in an emergency.

Never allow children or people unfamiliar with these instructions to use the mower.

Never mow while people, especially children, or pets are nearby.

Keep in mind that the user is responsible for accidents or hazards occurring to other people

or their property.

Preparation:

SAFETY PRECAUTIONS

1.5

While mowing, always wear substantial footwear and long trousers. Do not operate the

equipment when barefoot or wearing sandals.

Thoroughly inspect the area where the mower is to be used and remove all objects which may

be thrown by the machine.

WARNING: Petrol is highly flammable.

- Store fuel in containers specifically designed for this purpose.

- Refuel outdoors only and do not smoke while refuelling.

- Add fuel before starting the engine. Never remove the cap from the fuel tank or add petrol

while the engine is running or when the engine is hot. Allow the engine to cool for at least 2

minutes before refuelling.

- Do not attempt to start the engine if petrol is spilled or a smell of petrol is present. Move

the mower away from the area of spillage and avoid creating any source of ignition until

petrol vapours have dissipated.

- Always use fresh fuel. Stale fuel can block the carburettor and cause leakage.

485101MT210999A

Page 8

1.6

SAFETY PRECAUTIONS

1.6

SAFETY PRECAUTIONS

- Replace fuel tank and container caps securely.

- Replace faulty exhaust mufflers.

Always ensure that the mower is in a safe operating condition. Frequently check all nuts,

bolts and screws for tightness. Use only genuine Hayter replacement parts.

A damaged cutterbar or loose fixing screws are major hazards. Before use, visually inspect

the cutting mechanism to ensure that it is in good condition. A damaged cutterbar must be

replaced immediately with a genuine Hayter replacement part. Acutterbar which is slightly

worn can be re-sharpened. Ensure that both cutting edges are re-sharpened equally to maintain balance. An unbalanced cutterbar may cause serious damage to your machine.

Refer to “Maintenance”.

Operation:

Do not operate the engine in a confined space where dangerous carbon monoxide fumes can

collect.

Always pull the starter cord slowly until resistance is felt. Then pull the cord rapidly to avoid

kickback and prevent hand or arm injury.

Mow only in daylight or good artificial light.

Continued.

Avoid using the mower on wet grass, where feasible.

Always be sure of your footing on slopes.

Walk, never run.

Mow across the face of slopes, never up and down.

Exercise extreme caution when changing direction on slopes.

Do not mow excessively steep slopes.

Use extreme caution when reversing or pulling the mower towards you.

Stop the engine if the mower has to be tilted for transportation when crossing surfaces other

than grass and when transporting the mower to and from the area to be mowed.

Never operate the mower unless the guards are securely in position and in good condition.

485101MT210999A

Page 9

1.7

SAFETY PRECAUTIONS

1.7

SAFETY PRECAUTIONS

Do not change the engine governor settings or overspeed the engine.

Disengage the rear roller drive clutch before starting the engine.

Start the engine carefully, with feet well away from the cutterbar.

Do not tilt the mower when starting the engine.

Do not put hands or feet near or under rotating parts.

Never pick up or carry a mower while the engine is running.

Stop the engine and disconnect the spark plug lead:

- Before clearing blockages or unclogging the discharge chute.

- Before cleaning / checking or working on the mower.

- After striking a foreign object. Inspect the mower for damage and make repairs

before restarting and operating the mower.

- If the mower starts to vibrate abnormally (check immediately).

Stop the engine:

Continued.

- Whenever you leave the mower.

- Before refuelling.

Never lift the deflector plate whilst the mower is in operation.

Never touch the engine muffler / muffler guard or cooling fins when the engine is hot.

WARNING: THE CUTTERBAR CAN CONTINUE TO ROTATE

AFTER THE ENGINE IS SWITCHED OFF

485101MT210999A

Page 10

1.8

SAFETY PRECAUTIONS

1.8

SAFETY PRECAUTIONS

Maintenance and Storage:

Keep all nuts, bolts and screws tight to ensure that the equipment is in safe operating

condition.

Frequently check fuel lines and fittings for cracks or leaks and replace if necessary.

Never check for a spark with the spark plug removed. (Use an approved tester).

Never crank the engine with the spark plug removed. If the engine is flooded, move the

throttle to the ‘fast’ position and crank the engine until it starts.

Never strike the flywheel with a hammer or hard object as this may cause the flywheel to

shatter in operation. Always use the correct tools to service the engine.

Never operate the engine without a muffler guard. Inspect the muffler periodically and

replace if worn or leaking.

Never start the engine with the air-cleaner or air-cleaner cover removed.

Never store the mower with petrol in the tank within an enclosed area where fumes may reach

an open flame or spark.

Allow the engine to cool before storing in any enclosure.

To reduce the fire hazard, keep the engine, muffler, cooling fins and petrol storage area free

of grass, leaves, or excessive grease.

Continued.

Check the grassbag frequently for wear or deterioration.

Replace worn or damaged parts for safety.

If the fuel tank has to be drained, it is essential that this be done outdoors.

485101MT210999A

Page 11

1.9

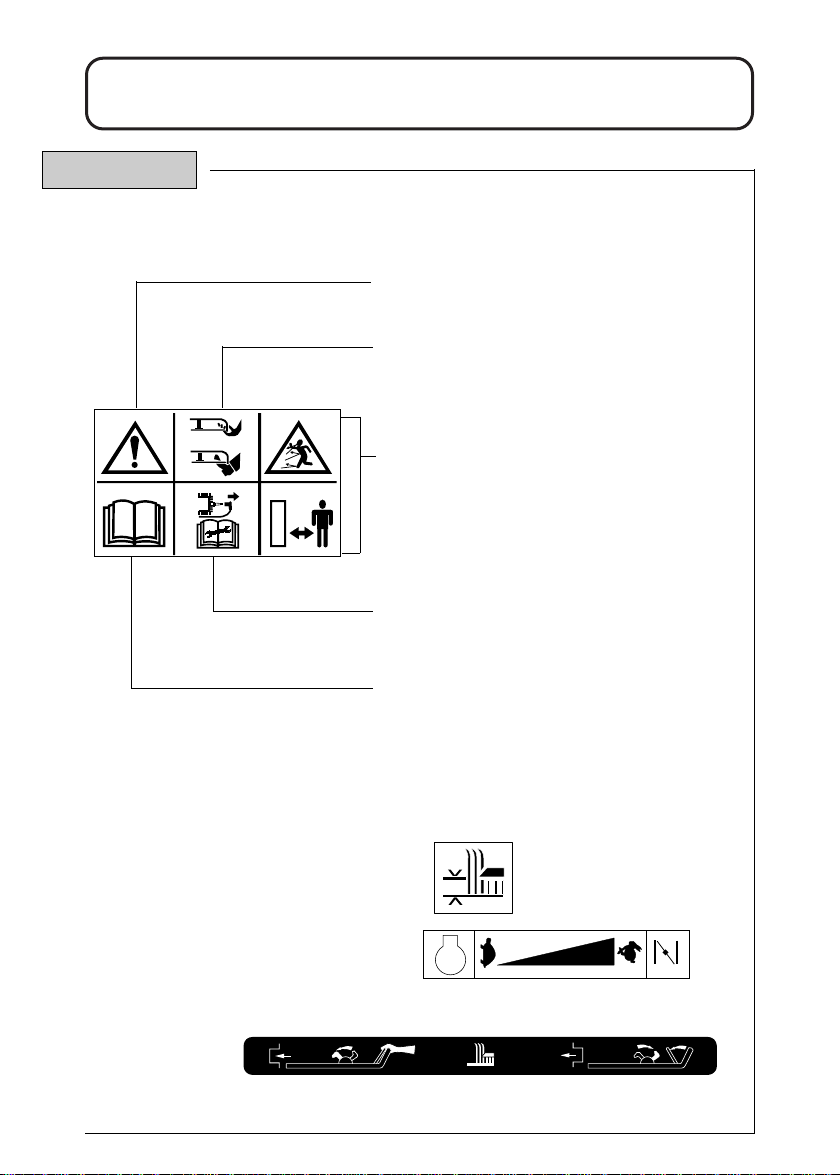

DECALS

WARNING DECAL

SAFETY PRECAUTIONS

WARNING - RISK OF DANGER - SAFETY

ALERT.

DANGER OF SEVERING TOES OR

FINGERS IN CUTTING MECHANISM.

DANGER OF BEING HIT BY THROWN

OBJECTS. KEEP BYSTANDERS ATA SAFE

DISTANCE FROM THE MACHINE.

STOP ENGINE AND REMOVE SPARK PLUG

LEAD BEFORE PERFORMING MAINTENANCE OR REPAIR WORK.

CAREFULLY READ THE OWNERS HANDBOOK BEFORE USING THE MACHINE.

1.9

CUT HEIGHT ADJUSTMENT:

THROTTLE CONTROL:

BLADE BRAKE CLUTCH DECAL:

Part No. 343019

343019 REV(0)

21 12

305113

STOP

485101MT210999A

Page 12

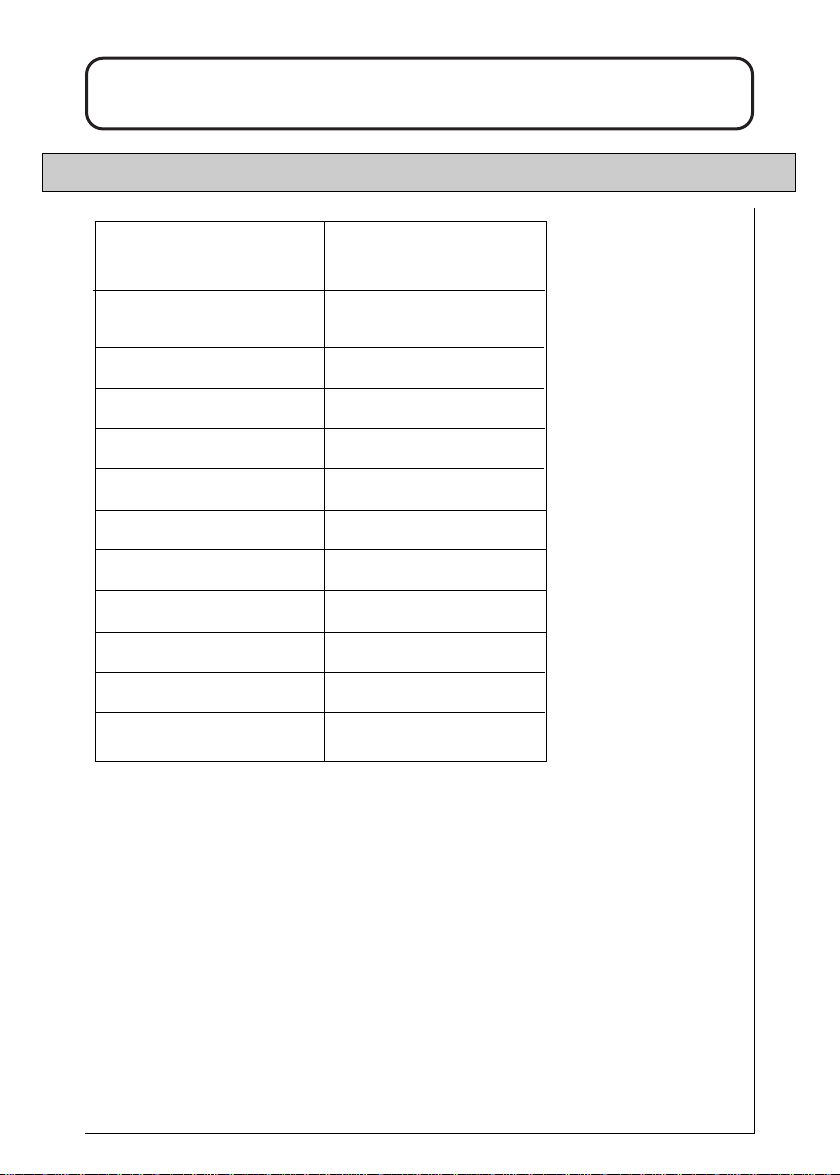

1.10

SPECIFICATIONS

MODELS CODE 485T

Engine Briggs & Stratton

Engine Type 12G882-1512-21

Engine / Cutterbar Speed 2950 rpm

Fuel Type Unleaded Petrol

Fuel Capacity 1.5 litres

Oil Type SAE 30 engine oil

Oil Sump Capacity 0.6 litres

Cutting Width 480mm

Cutting Height 12 - 65mm

SPECIFICATIONS

Blade Brake Clutch - Auto Drive

Diamond XTL-45

1.10

Overall Dimensions 1040 x 514 x 1377mm

Dry Weight 49 Kg

485101MT210999A

Page 13

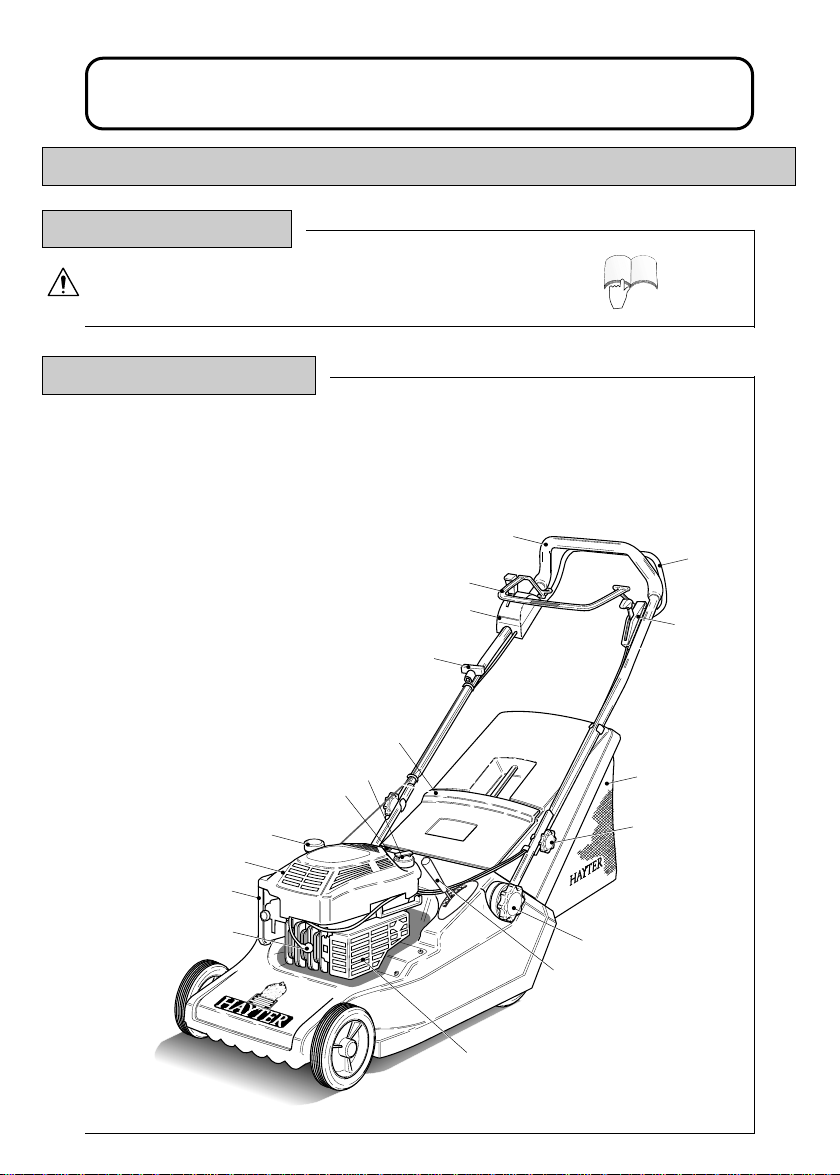

1.11

ASSEMBLY INSTRUCTIONS

ASSEMBLY INSTRUCTIONS

SAFETY NOTICE

Before using the mower, read the owner’s handbook carefully.

Pay particular attention to the safety precautions.

GENERALASSEMBLY

1. Spark Plug Lead

2. Air Cleaner

3. Engine Cover

4. Fuel Cap

5. Serial Number Label

6. Oil Filler & Dipstick

11

7. Rear Deflector

8. Engine Start Grip

9. Throttle Control

10. Cutterbar Stop Lever

10

9

11. Handlebar

12. Ground Drive Clutch Lever

8

13. Blade Brake Clutch Lever

14. Grassbag Assembly

15. Handlebar Securing Knob

16. Handlebar Height Adjust Knob

17. Height of Cut Lever

18. Muffler Guard

7

6

5

1.11

MS001

12

13

14

4

3

2

1

17

18

1D485S

15

16

485101MT210999A

Page 14

1.12

ASSEMBLY INSTRUCTIONS

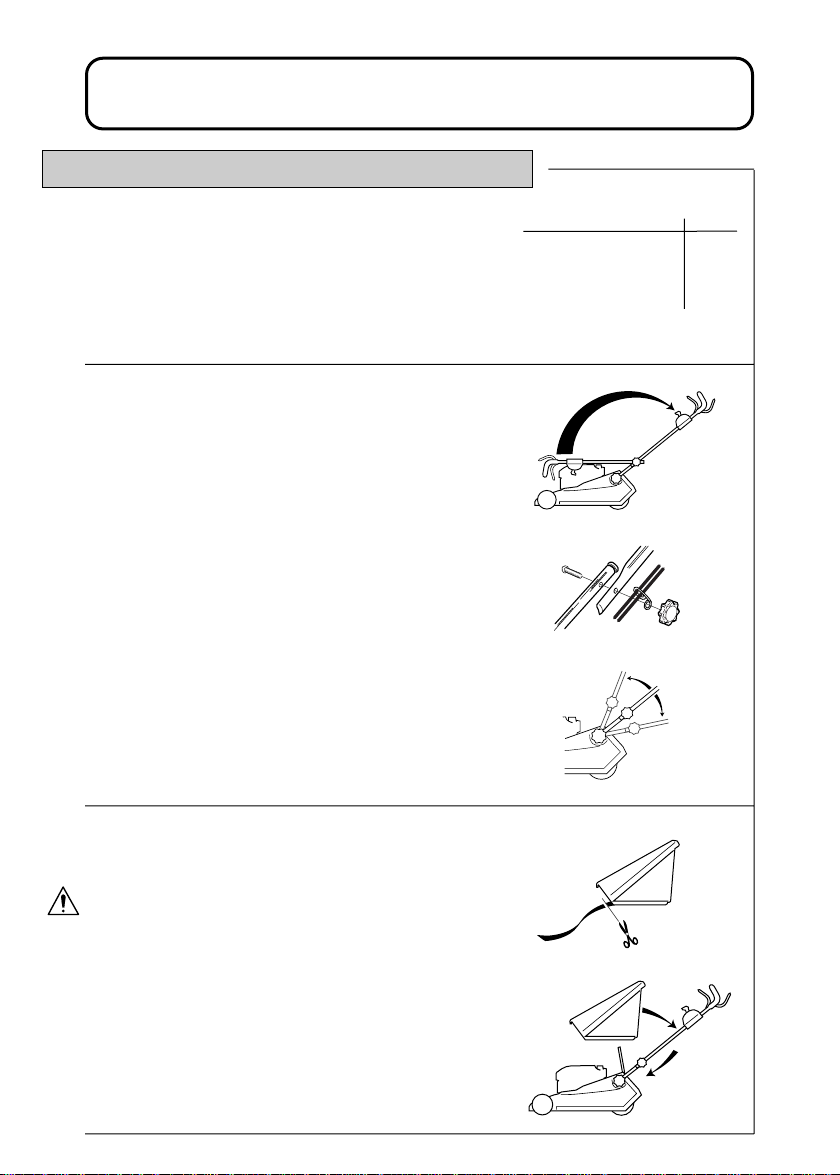

ASSEMBLING THE MOWER FOR THE FIRST TIME

Check that parts are delivered correctly: Remove the

mower from the packaging and check that all loose items

have been supplied correctly. Refer to the delivery checklist opposite and the general assembly. If any items are

missing contact, your local Hayter dealer.

Assemble the handlebar: Unscrew the handlebar securing

knobs sufficiently to allow the handlebar to be pivoted.

Move the engine stop lever away from the engine to avoid

damage and unfold the handlebar to its operating position.

Ensure that both Knobs are on the outside of the handlebar

and the cable guide is positioned as shown. Tighten to

secure handlebar in position.

IMPORTANT - PREVENT DAMAGE : When unfolding the handlebar, take care to ensure that the controls

and cables do not become damaged. Always replace

damaged controls and cables before using the mower.

Adjust height of handlebar: Unscrew the two larger

Knobs at base of handlebar sufficiently to allow it to be

moved to the upper, middle or lower position. Secure in

best position for comfort. Ensure that both sides are set to

the same height.

1.12

DELIVERY CHECKLIST

Description Quantity

Grassbag

Owner’s Handbook

Warranty Registration Card

CS005

CS072

CS006

1

1

1

Assemble the grassbag: Remove the long ribbon label by

cutting it off close to the grassbag. Discard the ribbon label.

WARNING - AVOID ENTANGLEMENT : Completely

remove this ribbon before using the mower

Grassbag attachment: Raise the rear deflector. Lower the

grassbag through the handlebar and hook in position behind

the deflector springs. Lower the grassbag to rest against the

rear of the mower. Finally, lower the rear deflector to rest

against the top of the grassbag.

CS009

CS007

485101MT210999A

Page 15

1.13

ASSEMBLY INSTRUCTIONS

1.13

ASSEMBLING THE MOWER FOR THE FIRST TIME

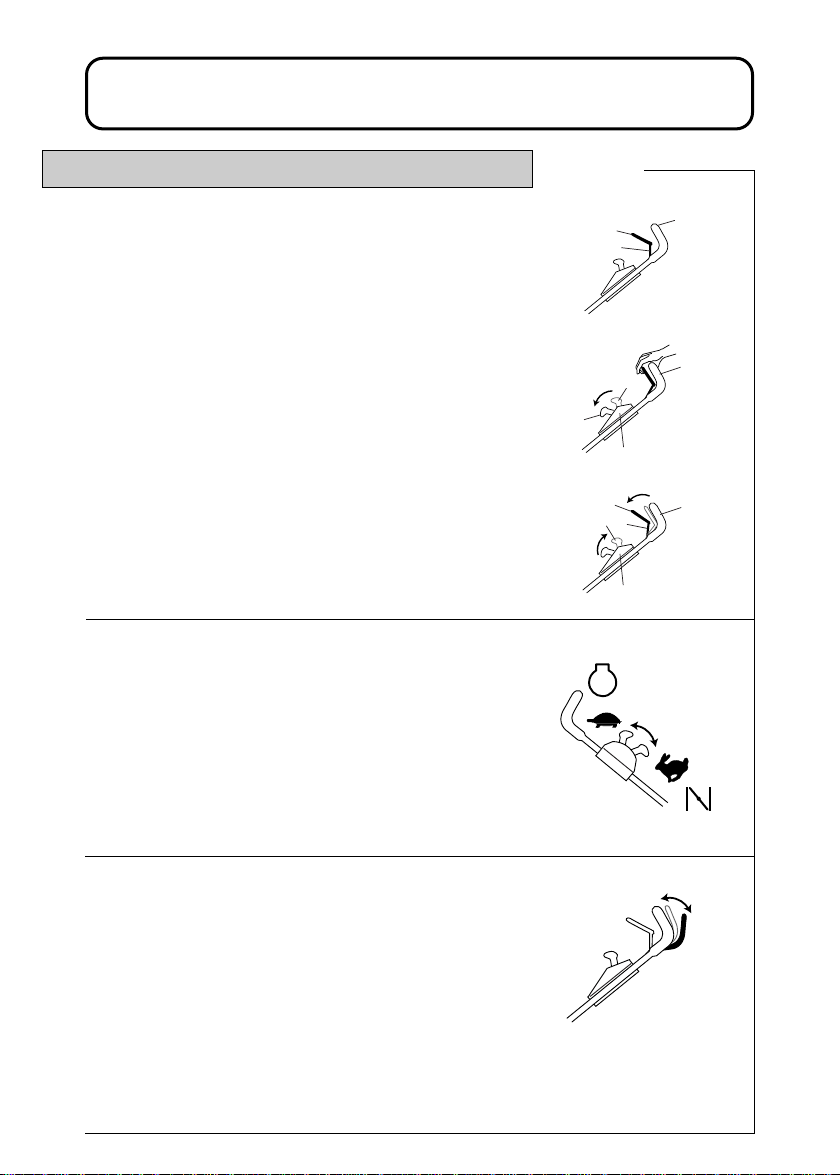

Check blade brake / clutch controls: Operate the blade

stop lever (A) several times, to ensure the lever moves

freely. Hold the lever against the handlebar in position (1)

and check that it returns to position (2) when released.

Use the right hand to hold the blade stop lever against the

handlebar (1) and use the left hand to push the blade clutch

lever (B) to the ‘engaged’ position (3). Remove the left

hand and the blade clutch lever should return to position (4),

leaving the blade drive clutch engaged.

Remove the right hand and check that the blade stop lever

automatically returns to position (2). There should be an

audible ‘clunk’ to indicate that the blade drive clutch has

disengaged.

Check throttle lever operation: Operate the throttle lever

several times and ensure that the cable moves freely whilst

operating the engine throttle mechanism. Slight resistance

should be felt when the lever moves to the ‘choke’ position.

Continued.

2

3

2

4

STOP

1

A

CS047

1

4

CS048

B

A

1

CS049

B

Check ground drive clutch lever operation: Operate the

clutch lever several times and ensure that the cable moves

freely.

CS050

CS051

485101MT210999A

Page 16

1.14

STARTING THE ENGINE

BEFORE STARTING THE ENGINE

IMPORTANT - PREVENT ENGINE DAMAGE: The

engine is shipped without oil or petrol. The engine must

be filled with the correct grade of oil and petrol before

starting the engine.

Oil recommendations: Always use high quality detergent

oil classified “For service SE, SF, SG” SAE 30 oil. Never

use additives with recommended oils.

SAE 10W-30 multigrade oil may be used, but this will result

in higher engine operating temperatures with consequential

high oil consumption. It is imperative that the oil level is

checked more frequently if this grade of oil is used in order

to guard against serious engine damage.

Check oil level: Clean around the oil filler cap before

removing. With the mower on a level surface, unscrew and

remove the oil filler - dipstick. Wipe oil from it with a clean

cloth. Screw the oil filler - dipstick back in place, then

unscrew and remove it to check the oil level.

The oil level is correct when it is at the full mark on the dipstick. DO NOT OVERFILL.

Slowly fill with engine oil as necessary and replace the oil

filler - dipstick.

IMPORTANT: The oil filler dipstick must be secured to

prevent oil leakage during operation.

0.15

Litres

1.14

CS024

FULL

{

ADD

CS028

485101MT210999A

Page 17

1.15

STARTING THE ENGINE

1.15

BEFORE STARTING THE ENGINE

Continued.

Fuel Recommendations: Always use clean, fresh unleaded

petrol. Purchase fuel in quantities which can be used within 30 days. Never mix oil with petrol. For added engine

protection Briggs & Stratton recommend the use of their

fuel additive which is available from an authorised Briggs &

Stratton service dealer.

Check fuel level: Clean around the fuel filler cap before

removing and fill the fuel tank with clean unleaded petrol.

Do not overfill the fuel tank. Allow 6mm minimum of tank

space for fuel expansion.

IMPORTANT: The fuel filler cap must be secured to

prevent fuel leakage during operation.

WARNING - PREVENT ACCIDENTS: The cutterbar

rotates when the engine is operating.

ALWAYS operate the engine stop lever several times and

ensure the engine stop cable moves freely before starting the

engine.

6mm

minimum

CS036

ALWAYS position the mower on a level stone free grass

surface before starting the engine. Ensure that the cutterbar

is set above grass height before the cutterbar drive is

engaged to prevent the engine being subjected to excessive

load.

CS037

485101MT210999A

Page 18

1.16

STARTING THE ENGINE

TO START THE ENGINE

Operate the throttle control lever: Push the lever to

‘choke’ position before starting a cold engine. It should

only be necessary to push the lever to the ‘fast’ position

before starting a warm engine.

Operate the engine start - grip: Stand behind the mower

and maintain a firm hold on the handlebar to prevent the

mower moving towards you. Use your right hand to hold

the engine start - grip and pull slowly until resistance is felt,

then pull rapidly to crank the engine. When the engine

starts carefully return the engine start - grip to the storage

position. If the engine does not start after 5 attempts - refer

to “Fault Finding”.

Allow the engine to warm up and return the throttle lever to

the ‘fast’ position after starting a cold engine.

IMPORTANT - PREVENT ENGINE DAMAGE: Never

pull the engine start - grip when the engine is running.

1.16

CS052

CS053

485101MT210999A

Page 19

1.17

STOPPING THE ENGINE

STOPPING THE ENGINE

Stopping the engine: Push the lever to the rearmost position.

Emergency stop: If the engine stop lever fails, move the

throttle lever to the ‘slow’ position and disconnect the spark

plug lead to stop the engine.

1.17

STOP

CS054

1

2

CS034

3

1. Engine

2. Spark Plug Lead

3. Spark plug

485101MT210999A

STOP

Page 20

1.18

OPERATING THE MOWER

SAFETY NOTICE

WARNING - PREVENT ACCIDENTAL STARTING :

Always stop the engine and disconnect the spark plug

lead before cleaning, inspecting or working on the

machine.

1. Engine

2. Spark Plug Lead

3. Spark plug

SAFETY NOTICE

WARNING - PREVENT ACCIDENTS: Before mowing,

thoroughly inspect the area where the mower is to be

used and remove all objects which when contacted by

the mower cutterbar could become dangerous projectiles.

Inspect the area for hidden obstructions which when

contacted by the cutterbar could risk health and safety.

Remember the location of these obstructions and ensure

that you mow around them.

2

CS034

CS031

1.18

1

STOP

3

IMPORTANT - PREVENT ENGINE DAMAGE : DO

NOT use the mower on a slope greater than 20 degrees.

HEIGHT OF CUT

To adjust the height of cut: Grip the lever and pull side-

ways to disengage it from the locking notch, then push forwards to lower or pull backwards to raise the height of cut.

Finally release the lever at the required position and ensure

it locks firmly into one of the seven notch settings.

Always select a height of cut to suit operating conditions.

Aim to prevent engine overloading and blockages by avoiding low cuts in long grass conditions. Be prepared to make

two cuts when the grass is long.

20omax.

485101MT210999A

CS030

CS211

Page 21

1.19

OPERATING THE MOWER

TRAVEL

Forward travel: Hold the handlebar and operate the clutch

lever to power the mower in a forward direction.

Travel speed is controlled by engine speed. Use the throttle

control to increase forward travel speed.

Release the clutch lever to stop the mower from travelling in

a forward direction.

When the clutch lever is disengaged the mower can be operated as a push model. This feature is useful when mowing

in confined areas.

Reverse travel: Release the clutch lever. Hold and pull

against the handlebar with both hands to reverse the mower

towards you.

WARNING - PREVENT ACCIDENTS: Always reverse

the mower carefully towards you. Always disengage the

cutterbar drive before walking backwards with the

mower.

1.19

CS061

CS051

TURNING THE MOWER

To make a wide turn: Steer the mower with the handlebar

in the direction required.

To make a tight turn: Stop and apply downward pressure

on the handlebar to raise the front wheels of the mower just

above ground level and steer the mower using the handlebar

in the required direction.

WARNING - PREVENT ACCIDENTS: DO NOT raise

the front of the mower excessively when making a turn.

NEVER raise the rear of the mower when the engine is

running.

485101MT210999A

Page 22

1.20

OPERATING THE MOWER

MOWING WITH GRASS COLLECTION

The grassbag is designed to collect grass clippings.

For optimum performance, mow in dry conditions with the

throttle control set at ‘fast’.

WARNING - PREVENT ACCIDENTS: ALWAYS check

the condition of the grassbag for signs of damage and

ensure the reardeflector is positioned correctly on top of

the grassbag. Replace a damaged grassbag immediately.

DO NOT operate the mower with a damaged grassbag.

ALWAYS stop the engine and disconnect the spark plug

lead before attempting to remove a grass blockage.

Ensure the rear grass deflector is sitting on the grassbag

correctly.

Grassbag attachment: Raise the rear deflector. Lower the

grassbag through the handlebar and hook in position behind

the deflector springs. Lower the grassbag to rest against the

rear of the mower. Finally, lower the rear deflector to rest

against the top of the grassbag.

1.20

CS017

CS007

Grassbag removal: Raise the rear deflector and lift the

grassbag through the handlebar. Finally lower the rear

deflector to rest against the rear of the mower.

Grassbag emptying: To empty the grassbag, pour out the

grass clippings and shake the grassbag vigorously to clean

the airways. Good grass collection depends on good air

flow through the grassbag. When collecting grass clippings

it is important that the grassbag is emptied regularly to prevent blockages and engine overloading.

CS010

485101MT210999A

Page 23

1.21

OPERATING THE MOWER

MOWING WITHOUT GRASS COLLECTION

To mow without collecting the grass clippings, remove the

grassbag and operate the mower with the rear deflector in its

lowest position.

WARNING - PREVENT ACCIDENTS: ALWAYS check

the condition of the rear deflector for signs of damage

and ensure it is positioned correctly on the rear of the

mainframe. Replace a damaged rear deflector immediately. never operate the mower with a damaged rear

deflector.

HEAVY GROWTH

Areas of heavy growth should be mown without grass collection. If grass collection is required, first mow the area

without grass collection at the maximum height of cut setting. Allow the grass clippings to dry out and then mow the

area at the maximum height of cut setting with the grassbag

fitted. Reduce the height of cut and mow the area again as

necessary until the required finish is obtained.

1.21

CS029

MOVING THE MOWER ACROSS NON-GRASSED AREAS

Set the mower to its maximum height of cut to protect the

cutting mechanism when moving the mower over surfaces

other than grass.

WARNING - PREVENT ACCIDENTS : ALWAYS

disengage the cutterbar drive and push the mower

carefully at slow walking speed when moving the mower

over non-grassed areas.

485101MT210999A

Page 24

1.22

CUTTERBAR OPERATION

OPERATING THE MOWER

1.22

General information: The cutterbar is driven by the engine

1

via a brake/clutch device (1) which enables the

cutterbar to be engaged/disengaged using control levers

whilst the engine is running. The cutterbar will stop

CS120

within three seconds of releasing the blade stop lever.

WARNING - PREVENT ACCIDENTS: DO NOT operate the mower if the cutterbar

fails to stop within three seconds. Return the mower to your Hayter dealer for

examination and repair.

A friction device in the blade brake/clutch helps prevent

damage occurring to the cutting mechanism when a hidden

obstruction or overload is encountered. When the

obstruction or overload is removed, the friction device will

automatically reset.

CS208

WARNING - PREVENT ACCIDENTS: ALWAYS disengage the cutterbar drive and

stop the engine when a hidden obstruction or excessive vibration is encountered.

Disconnect the spark plug lead and examine the cutting mechanism. ALWAYS replace

a damaged cutterbar - refer to “Maintenance”.

Engaging cutterbar drive: Use the right hand to hold the

blade stop lever against the handlebar (1) and use the left

4

1

hand to push the clutch lever (2) to the ‘engaged’ position

(3). Remove the left hand and the blade clutch lever should

return to position (4).

3

CS058

2

Disengage cutterbar drive: Release the blade stop lever to

2

disengage cutterbar drive. Check that the blade stop lever

automatically returns to position (2).

Emergency stop: If the cutterbar drive mechanism fails,

CS059

stop the engine.

WARNING - PREVENT ACCIDENTS: Do not operate the mower with a faulty

cutterbar drive mechanism.

485101MT210999A

Page 25

1.23

MOWING AND GRASS CARE TIPS

In dry weather conditions leave the grass long to help retain ground moisture.

Aerate the lawn to stimulate soil organisms and root growth. In spring and late summer

remove dead grass and aerate the lawn by raking or similar means.

Keep the cutterbar sharp. A blunt cutterbar will tear the grass and cause the tips to turn

brown.

Prevent scalping. Plan your direction of travel to mow across hollows and humps.

Prevent grass damage. Take care when turning the mower.

Prevent grass damage. DO NOT mow in wet conditions.

Brush the lawn surface to disperse worm casts before mowing.

Spike compacted lawn areas with a fork. Fill the holes with sand to improve aeration and

drainage.

Mow lawns in a different direction to the previous cut.

As a general rule the grass clippings should be removed each time you mow. If weather

conditions are dry and hot and the grass is weed free, leave the clippings on the lawn to help

maintain ground moisture.

OPERATING THE MOWER

1.23

Mow lawns twice a week when the grass is growing vigorously in the summer.

Mow lawns once a week in spring, autumn and during prolonged dry weather in the summer.

Prevent grass damage - DO NOT remove more than one third of the grass height in one

cut.

485101MT210999A

Page 26

1.24

OPERATING THE MOWER

1.24

MOWING AND GRASS CARE TIPS

Recommended grass heights for lawns :

DANGER Coarse grasses dominate fine grasses. 38mm

General lawn in spring, autumn or prolonged dry period. 32mm

General lawn in summer. 25mm

Luxury lawn in spring, autumn or prolonged dry period. 19mm

Luxury lawn in summer. 12mm

DANGER Grass strength is reduced. 6mm

Continued.

485101MT210999A

Page 27

1.25

MAINTENANCE

MAINTENANCE

WARNING - PREVENT ACCIDENTS: Stop the engine

and disconnect the spark plug lead before attempting to

carry out maintenance procedures on the mower.

ENGINE

Engine Cowl

1.

Carburettor

2.

Spark Plug / Lead

3.

Muffler Guard

4.

Muffler

5.

Oil filler Cap/ Dipstick

6.

Start Grip

7.

Fuel Cap

8.

Finger Guard

9.

Air Cleaner

10.

1.25

THROTTLE CABLE ADJUSTMENT

Remove two screws securing the engine cowl and remove

the cowl to expose the throttle mechanism on the front of the

engine. Loosen the outer cable clamp screw (1) and move

the governor control lever (2) to the left as far as possible.

Insert a large, flat blade screw driver (3) into the slot in the

engine control bracket (4) at the angle shown. Push the governor control lever to the right until it just touches the screw

driver blade. Move the throttle control lever to the ‘fast’

position (not the ‘choke’ position) and re-tighten the outer

cable clamp screw. Replace the engine cowl.

2

CS039

3

485101MT210999A

1

4

Page 28

1.26

MAINTENANCE

1.26

CARBURETTOR ADJUSTMENTS

Carburettor adjustments should only be made by an authorised Briggs & Stratton dealer.

Under no circumstances should the engine be adjusted to run at a speed in excess of

3,000 r.p.m.

OIL SERVICE

Refer to the Maintenance Schedule at the end of this section and ensure that the recommendations are followed. More frequent service is required when operating in adverse conditions.

- Check the oil level every 5 hours or daily and ensure that the correct oil level is main

tained. Refer to-‘Before Starting the Engine Oil Recommendations’ for oil checking

procedure and filling instructions.

- Drain the engine oil after the first 5 hours of operation and thereafter at the end of

every grass cutting season.

- Change the oil while the engine is warm. Refill with fresh clean oil of the recommended SAE viscosity grade. Refer to -‘Before Starting the Engine : Oil Recommendations’.

WARNING - PREVENT ACCIDENTS: Drain fuel by running the engine until the fuel

tank is empty and the engine stops before attempting to tip the mower for oil draining

purposes.

- Remove the spark plug lead and allow the engine to cool. Tip

1

the mower over on to its left hand side thus ensuring that the air

cleaner is kept uppermost to prevent engine damage. Remove

2

the oil filler dipstick and drain the oil into a suitable container.

STOP

CS034

1. Engine

2. Spark Plug Lead

3. Spark plug

3

485101MT210999A

Page 29

1.27

DUAL ELEMENT AIR CLEANER SERVICE

Refer to the Maintenance Schedule at the end of this section

and ensure that the recommendations are followed. More

frequent service is required when operating in adverse conditions.

MAINTENANCE

1.27

- Gain access to the pre-cleaner (4) and cartridge (3)

by loosening screw (1) and tilting cover (2).

- To service the pre-cleaner, carefully remove and

wash in a solution of liquid detergent and water.

Allow to air dry thoroughly before replacing.

- Clean the cartridge by tapping gently on a flat surface. If very dirty, replace or wash in a solution of

non-foaming detergent and warm water. Rinse thoroughly with running water from the mesh side until

the water is clear. Allow the cartridge to stand and air

dry thoroughly before replacing. Do not use petroleum solvents during cleaning as this will cause the cartridge to deteriorate. Do not use pressurised air as this

may damage the cartridge. Do not oil the cartridge.

- After servicing, install the pre-cleaner and cartridge

in the cover. Insert the tabs on the bottom of the cover

into the slots in the bottom of the base (5). Tilt the

cover upwards and securely tighten the screw to the

base.

SPARK PLUG SERVICE

Use only Briggs & Stratton spark tester (1) to check for a

spark as shown in the diagram.

4

5

1. Screw

2. Tilting Cover

3. Cartridge

4. Pre-cleaner

5. Base Cover

Replace the spark plug every 100 hours or every season,

which ever occurs first. A spark plug wrench is available

from any authorised Briggs & Stratton service dealer.

The spark plug gap (2) should be checked with a feeler

gauge and set at 0.76mm (0.030”).

485101MT210999A

Page 30

1.28

MAINTENANCE

KEEPING THE ENGINE CLEAN

WARNING - PREVENT ACCIDENTS : Accumulation

of debris around the muffler could cause a fire. Inspect

and clean the engine after every use.

Remove all grass and debris from the engine including the

muffler / muffler guard, the air ways in the top cowl and the

surrounding deck areas on a daily basis after use.

IMPORTANT - PREVENT ENGINE DAMAGE: Never

spray the engine with water during cleaning. Water can

contaminate the fuel. Always clean with a brush orcompressed air.

NOTE: Grass and debris may clog the engine’s air cooling

system especially after prolonged operation while cutting

tall, dry grass. The internal cooling fins and surfaces may

require cleaning to prevent overheating and engine damage.

This may be achieved by cleaning all areas shown within the

black boundary line. We would recommend that this service

be carried out by an authorised Briggs & Stratton dealer.

1.28

GRASSBAG

Remove grass debris from the grassbag immediately after

use and check its condition for signs of damage.

WARNING - PREVENT ACCIDENTS: Replace a damaged grassbag immediately.

DECK HOUSING

Remove grass debris from the top and underside of the deck

housing immediately after use.

IMPORTANT - PREVENT DAMAGE: Fertilisers and

top dressings are particularly corrosive. Thoroughly

clean the mower deck immediately after use on treated

grass and store well away from corrosive materials.

CS017

485101MT210999A

Page 31

1.29

SECURING NUTS AND BOLTS

MAINTENANCE

1.29

Regularly check that all securing nuts and bolts are tight.

Replace missing or damaged items immediately.

LUBRICATION

Lubricate the wheels, pivot points and linkages with engine

oil every 25 operating hours.

Apply a good quality medium grease to the inner control

cables at the point of entry and exit from their outer casings.

CLUTCH CABLE ADJUSTMENT

Check the clutch cable operation every 25 operating hours

and adjust if necessary. The clutch cable is adjusted correctly when the belt drive just engages with the clutch lever

positioned 32-38mm (1.1/4” - 1.1/2”) from the handlebar.

CS015

CS022

32-38mm

1.1/4"-1.1/2"

Unscrew the lock nuts (1) and screw the adjuster (2) in or

out as necessary. Tighten the locknuts (1) when correctly

adjusted.

IMPORTANT - PREVENT DAMAGE: ALWAYS operate the mower with the clutch cable correctly adjusted.

ALWAYS replace damaged cables.

CS060

1

2

485101MT210999A

Page 32

1.30

MAINTENANCE

1.30

CUTTERBAR

WARNING - PREVENT ACCIDENTS: Never work on the cutterbar unless the spark

plug lead has been removed. The cutterbar has sharp edges. ALWAYS wear strong

gloves to protect your hands when working on the cutterbar. DO NOT rotate tools

towards the cutting edges to avoid the risk of injury should the tool slip. ALWAYS use

genuine Hayter replacement parts.

The condition of the cutterbar and its mounting arrangement should be checked regularly for signs of wear or damage. Ensure that the cutterbar is not bent or cracked.

A damaged cutterbar that is out of balance will vibrate excessively and may break. DO

NOT use an unbalanced cutterbar.

Regularly check that the bolt securing the cutterbar is tightened to the specified torque

of 54Nm (40 lbs ft).

Replace the cutterbar every 2 years or sooner if excessively worn or damaged.

How to remove the cutterbar: Drain the fuel by running

the engine until the fuel tank is empty and the engine stops.

Remove the spark plug lead and allow the engine to cool.

Turn the mower on its left hand side and ensure that the air

cleaner side of the engine is uppermost.

CAUTION - PREVENT INJURY: It is wise to seek

assistance when turning the mower onto its side.

Firmly grip the end of the cutterbar with the gloved hand

and remove the 2 fixing screws (1) securing the cutterbar

(2).

How to assemble the cutterbar: Assemble the cutterbar (2)

with the turned up edges facing towards the engine. Secure

the cutterbar using two new fixing screws and tighten to

40Nm torque.

WARNING - PREVENT ACCIDENTS: Never reuse the

fixing screws. Always use new cutterbar fixing screws

when refitting or replacing the cutterbar.

1

2

CS062

485101MT210999A

Page 33

1.31

MAINTENANCE

1.31

CUTTERBAR

Continued.

How to sharpen and balance the cutterbar: A slightly

worn cutterbar may be re-sharpened. Both cutting edges

must be sharpened equally to ensure balance. Sharpen the

cutterbar every 25 mowing hours or more frequently if conditions require. Remove the cutterbar from the mower and

clean using a brush and water. Inspect the cutterbar for

signs of damage.

WARNING - PREVENT ACCIDENTS : DO NOT use a

damaged or excessively worn cutterbar.

Sharpen both cutting edges with a flat file to restore the

original cutting edge.

Ensure that the cutterbar is balanced. Use a screw driver

with a round shaft to support the cutterbar through its centre

hole. Hold the cutterbar horizontal and then release. Abalanced cutterbar will remain horizontal. If the cutterbar is

not balanced the heavy end will rotate downwards. Sharpen

the heavy end until the cutterbar is correctly balanced.

30 -45

CS040

CS025

CS026

485101MT210999A

Page 34

1.32

MAINTENANCE SCHEDULE

Follow the hourly or calendar intervals, whichever occurs first. More frequent service

will be required if working for prolonged periods under dusty, dry conditions, or when

airborne debris is present or after extensive operation cutting tall, dry grass.

AFTER FIRST 5 HOURS

Change engine oil

EVERY 5 HOURS OR DAILY

Check oil level

Remove grass debris from around engine, muffler/muffler guard and air ways in the top

cowl.

Remove grass debris from top and underside of deck housing.

Remove grass debris from the grassbag and check for signs of damage.

Check condition of guards and safety devices.

Check condition of cutterbar.

MAINTENANCE

1.32

EVERY 25 HOURS OR EVERY SEASON

Change engine oil if continuously operating under heavy load or high ambient temperature.

Service the dual element air cleaner - pre cleaner.

Lubricate wheels, pivot points and linkages.

Grease inner control cables at point of entry and exit from their outer casings.

Check clutch cable adjustment.

Sharpen cutterbar.

485101MT210999A

Page 35

1.33

MAINTENANCE SCHEDULE Continued.

EVERY 50 HOURS OR EVERY SEASON

Change engine oil.

EVERY 100 HOURS OR EVERY SEASON

Clean engine cooling system. Clean more often under dusty conditions or when airborne

debris is present or after prolonged operation whilst cutting tall, dry grass.

Service the dual element air cleaner cartridge.

Replace spark plug.

MAINTENANCE

1.33

485101MT210999A

Page 36

1.34

PREPARING THE MOWER FOR STORAGE

1.34

PREPARINGTHE MOWER FOR STORAGE

Handlebar storage: To lower the handlebar unscrew the 2

small securing knobs sufficiently to allow it to be pivoted forwards to rest against the mower. Take care to ensure that the

control cables do not become snagged at the pivot point and

depress the engine stop lever to prevent it being damaged

through contact with the engine spark plug.

Storage for periods in excess of 30 days: Engines stored in

CS035

excess of 30 days need to be protected with Briggs & Stratton

fuel additive or drained of fuel to prevent gum from forming in

the fuel system or on essential carburettor parts. T o ensure your

mower is maintained in good working order it is important that

the following procedure is adopted. Refer to the Maintenance

section as necessary.

Drain fuel from the engine by operating the engine until it stops.

Disconnect the spark plug lead.

Change the engine oil.

Remove the engine spark plug and pour 15ml of engine oil into the engine cylinder and

replace the spark plug. Do not exceed the stated volume of oil as engine damage may occur

on re-starting. Do not replace the spark plug lead. Slowly pull the engine start - grip once

to crank the engine. This will distribute the oil and help prevent engine corrosion.

Clean grass and debris from the engine cylinder, cylinder head cooling fins, under top cowl,

and around and behind muffler/muffler guard.

Clean all other areas of the mower and ensure that the grassbag is clean.

Lubricate the mower.

Treat metal parts with a water repellent anti-corrosion product.

Lower the handlebar, if desired.

Rest the mower deck on wooden blocks to remove the mower from its wheels / roller.

Cover the mower with a protective sheet and store it in a dry, ventilated area.

IMPORTANT: Fertilisers and top dressing are particularly corrosive. Thoroughly

clean the mower immediately after use on treated grass and store well away from

corrosive materials.

485101MT210999A

Page 37

1.35

FAULT FINDING

PROBLEM POSSIBLE FAULT REMEDY

Engine will not turn over Engine stop lever released Operate engine stop lever

Engine smokes Excess oil level Check oil level

Engine runs then stops Fuel starvation Fill fuel tank

FAULT FINDING

Incorrect oil level Check oil level

Air cleaner cartridge oil Service air cleaner

soaked or plugged

Fuel cap vent blocked Clean fuel cap vent

1.35

485101MT210999A

Page 38

1.36

FAULT FINDING

1.36

FAULT FINDING

PROBLEM POSSIBLE FAULT REMEDY

Engine will not start Engine under load Raise height of cut

Engine runs rough Spark plug lead becoming Connect spark plug lead

Continued.

Fuel starvation Fill fuel tank

Engine cold Set throttle to ‘choke’ position

Incorrect/contaminated fuel Drain fuel tank and fill with

correct fuel

Spark plug lead disconnected Connect spark plug lead

Throttle setting incorrect Set throttle to ‘fast’ position

Engine brake not released Operate engine brake lever

Faulty spark plug Clean and adjust gap or replace

disconnected in use

Faulty spark plug Clean and adjust gap or replace

Air cleaner blocked Service air cleaner

Incorrect/contaminated fuel Drain fuel tank and fill with

correct fuel

Engine vibrates excessively Mounting bolts loose Tighten bolts

Cutterbar screws loose Tighten screws

Cutterbar out of balance Balance cutterbar

Bent crankshaft Consult your dealer

Cutterbar drive will not Faulty blade brake clutch Consult your dealer

engage / disengage

485101MT210999A

Page 39

1.37

FAULT FINDING

1.37

FAULT FINDING

PROBLEM POSSIBLE FAULT REMEDY

Uneven cut Undulating ground conditions Change direction of travel

Discharge chute blocks Grass is wet Mow dry grass

Mower is hard to push Cut height too low Increase cut height

Continued.

Cutterbar worn Sharpen the cutterbar

Cutterbar out of balance Balance the cutterbar

Wheels / roller damaged Inspect and replace as necessary

Cut height too low Increase cut height

Grassbag full Empty grassbag

Slow engine speed Increase engine speed

Airflow through the Clean the grassbag

grassbag is restricted

Wheels / roller damaged Inspect and lubricate or replace

as necessary

Mower will not self propel Clutch out of adjustment Adjust clutch cable

Drive belt damaged Replace drive belt

Poor grass collection Airflow through the Clean the grassbag

grassbag is restricted

Discharge chute blocked Remove blockage

Slow engine speed Increase engine speed

Wet grass Mow dry grass

Grassbag full Empty grassbag

485101MT210999A

Page 40

2.1

PARTS LIST

ITEM NO. DESCRIPTION PART NO. QTY

1 Mainframe - Casting 480010V 1

2 Plate - Location RH 480083V 1

3 Clamp - Boss Inner 480084W 2

4 Clamp - Boss Outer 480085W 2

5 Handwheel - Assy 480054 2

6 Spacer - BBC 485006 1

7 Throttle Control & OPC Cable 485026 1

8 Engine - B/S Diamond XTL50 APTO 485110 1

9 Decal - Engine 485111 1

10 Knob - Handlebar 480088 2

11 Handlebar - Lower 480089W 2

12 Bolt - Handlebar 226024 2

13 Nut - Nylon Insert 09544 3

14 Washer - Plain 09472 1

15 Guide Rope 305093 1

16 Bush Lever 226034 3

17 Decal - Operation 343019 1

18 Blade Stop Lever 319006W 1

19 Plastic Ferrule 305115 1

20 Handlebar 485008W 1

21 Lever - Clutch 219090 1

22 Plastic Nut Cap M6 343025 2

23 Cable Guide 480123 1

24 Bracket - Cable Clutch 306108 1

25 Screw - Deltite Posi Pan 09600 2

26 Cable - Clutch 480094 1

27 Grassbag Assy (includes items 28, 36,104 & 105) 480109 1

28 Frame - Grassbag 480058W 1

29 Deflector - Rear 480140 1

30 Pin - Roll 03997 1

31 Spring - Deflector RH 480131 1

32 Rod - Deflector 480062 1

33 Screw - Hex. Hd. Taptite 09758 2

34 Bolt - Coach 09549 2

35 Knob - HOC 480134 1

36 Base/Fabric - Grassbag Assy 480107 1

37 Spring - Deflector LH 480130 1

38 Plate - Location LH 480082V 1

39 Plate - Handlebar Retainer 480055 2

40 Cover - APTO 480014 1

41 Bearing - APTO 480050 1

42 Screw - Washer Hd Taptite 09575 3

485T PARTS LIST

485101MT210999A

2.1

Page 41

2.2

PARTS LIST

ITEM NO. DESCRIPTION PART NO. QTY

43 Bush 340154 2

44 Screw - Taptite 09591 3

45 Foam Strip 480119 1

46 Lever HOC 480128 1

47 HOC Moulding 480126 1

48 Throwplate - Main Body 480011 1

49 Screw - Taptite 09545 4

50 Bearing - Roller Housing 219102 2

51 Roller - Rear W/A 480151W 2

52 Spring Tension - Rear Axle 480133 2

53 Washer 09262 3

54 Screw - Taptite 09365 22

55 Bush - Oilite Roller 340129 2

56 Roller Freewheel - Rocket Band 340150 2

57 Spacer - Nylon 340149 2

58 Shroud - Freewheel 340168 1

59 Locknut 340163 1

60 Shaft - Roller 480032 1

61 Sprocket - 22 Teeth 480039 1

62 Frame - Rear Roller W/A (inc. item 114) 480159W 1

63 Key - woodruff 5321 1

64 Circlip 1428 1

65 Washer 480097 4

66 Cover - Transmission 480043 1

67 Chain 480068 1

68 Rod - Connecting 480045 1

69 Plate - Securing 219037 2

70 Filler - Throwplate 480017W 1

71 Pulley - Sprocket Fixedspeed 480095 1

72 Belt - V APTO 480063 1

73 Washer 02575 1

74 Circlip 03096 1

75 Pulley - Jockey 219156 1

76 Washer - Starlock 0201086 2

77 Bracket - Idler Assy 480115 1

78 Belt Guide 480116 1

79 Pulley - Drive APTO 480038 1

80 Spring - Torsion Idler 480066 1

81 Bush 4452 1

82 Washer - Plain 09280 1

485T PARTS LIST

2.2

485101MT210999A

Page 42

2.3

PARTS LIST

ITEM NO. DESCRIPTION PART NO. QTY

83 Nut M4 - Nylon Insert 09657 1

84 M10 x 25 Tuf-Lok Screw 09747 2

85 Blade Brake Clutch 485007 1

86 Cutterbar - BBC 485005 1

87 Cover - Throwplate Drive 480012 1

88 Support Plate Assy 319008W 1

89 Spacer 321034 3

90 Cap - Hub 219143 2

91 Nut - UNF Nyloc 4486 2

92 Wheel 5218 2

93 Axle - Front W/A 219031 1

94 Moulding - Front axle Bearing 219036 2

95 Fin - Front Insert 480013 1

96 Decal - Hayter & Royal Warrant 219186 1

97 Nut - M8 Shouldered 480086 2

98 Guide - Rope 305127 1

99 Plug - Tube 300160 2

100 Tie - Cable 3966 6

101 Setscrew 09704 1

102 Control - BBC Assy 485028 1

103 Screw Pan Hd. 09384 2

104 Grassbag Filler 480052 1

105 Grassbag Top 480107 1

106 Nipple Split 510118 1

107 Compensating Spring 319018 1

108 Spring 343011 1

109 Centre Bolt BBC 343029 1

110 Screw Soc. Shld ZIS8L030S 1

111 Screws 09634 1

112 Clip - Cable 287034 1

113 Torsion Spring HOC 480132 1

114 Bracket HOC 480157W 1

115 Rivets - 2

116 Ratchet 480156 1

117 Cover Plate 480018 1

118 Screw 09687 1

485T PARTS LIST

2.3

485101MT210999A

Page 43

2.4

7

5

4

97

1

96

90

91

92

93

94

95

87

106

107

68

94

54

54

485T PARTS DIAGRAM

9

8

6

3

2

39

40

42

43

89

88

44

44

108

44

54

85

86

102

54

10

30

32

31

100

35

33

34

41

52

70

89

54

49

54

69

110

109

78

76

82

84

81

92

80

91

90

2.4

20

100

27

5

56

57

63

117

67

66

21

13

13

24

83

105

-Grassbag Assy.

Includes Items

28,36,104,105

58

57

56

59

55

50

49

61

65

42

1D485S01D

22

26

64

19

7

15

98

29

45

39

53

48

54

79

54

99

12

11

11

100

100

47

37

116

54

111

112

52

53

118

49

65

50

51

74

73

26

72

77

75

115

17

18

103

16

102

25

14

101

13

100

100

99

12

23

28

38

52

53

54

55

60

52

71

54

76

113

114

10

104

36

3

97

4

51

62

69

49

68

46

485101MT210999A

Page 44

2.5

ENGINE ANCILLARY PAR TS

These parts are available through an authorised Briggs & Stratton dealer.

FUEL ADDITIVE

AIR CLEANER CARTRIDGE

Pre-cleaner

2.5

493537

SPARK PLUG

SPARK PLUG WRENCH

SPARK PLUG TESTER

485101MT210999A

Page 45

2.6

ENGINE WARRANTY

2.6

485101MT210999A

Page 46

2.7

NOTES

2.7

485101MT210999A

Page 47

2.8

Machine Serial No: .....................................................................................

Engine Serial No: ........................................................................................

CUSTOMER INFORMATION

2.8

485101MT210999A

Loading...

Loading...