Page 1

Operator ’sManual

21inHeavy-DutyWalk-BehindRotaryMower

Code455E

SerialNo.310000001

ManualPartNo.3364-824RevA

Page 2

Contents

Introduction

Thisrotary-blade,walk-behindlawnmoweris

intendedtobeusedbyresidentialhomeowners

orprofessional,hiredoperators.Itisdesigned

primarilyforcuttinggrassonwell-maintainedlawns

onresidentialorcommercialproperties.Itisnot

designedforcuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

Wheneveryouneedservice,genuineparts,oradditional

information,contactanAuthorizedServiceDealerand

havethemodelandserialnumbersofyourproduct

ready.Figure1identiesthelocationofthemodeland

serialnumbersontheproduct.

Figure1

1.Modelandserialnumberlocation

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Introduction.................................................................2

Safety...........................................................................3

GeneralLawnMowerSafety.................................3

SoundPressure.....................................................5

SoundPower........................................................5

Vibration,Hand/arm...........................................5

SafetyandInstructionalDecals.............................6

Setup............................................................................7

1InstallingtheHandle..........................................7

2InstallingtheFuelTankandtheFuel

Line..................................................................7

3FillingtheCrankcasewithOil.............................8

ProductOverview........................................................9

Controls...............................................................9

Specications.......................................................9

Operation...................................................................10

CheckingtheEngineOilLevel............................10

FillingtheFuelTank...........................................11

StartingtheEngine.............................................12

StoppingtheEngine...........................................12

OperatingtheBlade............................................12

OperatingtheTractionDrive..............................13

CheckingtheBladeBrakeClutch........................13

AdjustingtheCuttingHeight..............................13

UsingtheGrassBag...........................................14

OperatingTips...................................................15

Maintenance...............................................................17

RecommendedMaintenanceSchedule(s)................17

Lubrication.............................................................17

LubricatingthePivotArms.................................17

LubricatingtheGearCase...................................18

EngineMaintenance...............................................18

ServicingtheAirFilter........................................18

ChangingtheEngineOil....................................19

ChangingtheOilFilter.......................................19

ServicingtheSparkPlug.....................................20

FuelSystemMaintenance.......................................21

EmptyingtheFuelTankandCleaningthe

FuelFilter.......................................................21

DriveSystemMaintenance.....................................21

AdjustingtheSelf-propelDrive...........................21

ServicingtheWheels..........................................22

ControlsSystemMaintenance.................................23

AdjustingtheBladeBrakeCable.........................23

BladeMaintenance.................................................25

MaintainingtheCuttingBlade.............................25

Cleaning.................................................................26

CleaningundertheMowerHousing....................26

CleaningtheBladeBrakeClutchShield...............27

Storage.......................................................................28

PreparingtheFuelSystem...................................28

©2009—HayterLimited

PrintedintheUSA

2

AllRightsReserved

Page 3

PreparingtheEngine..........................................28

GeneralInformation..........................................28

RemovingtheLawnMowerfromStorage............28

Troubleshooting.........................................................29

Safety

Improperlyusingormaintainingthismowercan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructions.

Thismowerwasdesignedandtestedforreasonablysafe

service;however,failuretocomplywiththefollowing

instructionsmayresultinpersonalinjury.

Toensuremaximumsafety,bestperformance,and

togainknowledgeoftheproduct,itisessential

thatyouandanyotheroperatorofthemowerread

andunderstandthecontentsofthismanualbefore

theengineiseverstarted.Payparticularattention

tothesafetyalertsymbol(Figure2)whichmeans

Caution,Warning,orDanger—“personalsafety

instruction.”Readandunderstandtheinstruction

becauseithastodowithsafety.Failuretocomply

withtheinstructionmayresultinpersonalinjury.

GeneralLawnMowerSafety

Thefollowinginstructionshavebeenadaptedfrom

CENstandardEN836:1997.

Thiscuttingmachineiscapableofamputatinghands

andfeetandthrowingobjects.Failuretoobservethe

followingsafetyinstructionscouldresultinserious

injuryordeath.

Training

•Readtheinstructionscarefully.Befamiliarwiththe

controlsandtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethemower.Localregulationscan

restricttheageoftheoperator.

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Understandexplanationsforallpictogramsusedon

themowerorintheinstructions.

Petrol

WARNING-Petrolishighlyammable.Takethe

followingprecautions.

•Storefuelincontainersspecicallydesignedforthis

purpose.

•Refueloutdoorsonlyanddonotsmokewhile

refueling.

•Addfuelbeforestartingtheengine.Neverremove

thecapofthefueltankoradpetrolwhiletheengine

isrunningorwhentheengineishot.

3

Page 4

•Ifpetrolisspilled,donotattempttostarttheengine

butmovethemowerawayfromtheareaofspillage

andavoidcreatinganysourceofignitionuntilpetrol

vaporshavedissipated.

•Replaceallfueltankandcontainercapssecurely .

–Donotmowexcessivelysteepslopes.

–Exerciseextremecautionwhenonslopes.

–Mowacrossthefaceofslopes,neverupand

downandexerciseextremecautionwhen

changingdirectiononslopes.

Preparation

•Whilemowing,alwayswearsubstantialfootwearand

longtrousers.Donotoperatetheequipmentwhen

barefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentis

tobeusedandremoveallstones,sticks,wires,bones

andotherforeignobjects.

•Beforeusing,alwaysvisuallyinspecttoseethat

guards,andsafetydevices,suchasdeectorsand/or

grassbags,areinplaceandworkingcorrectly.

•Beforeusing,alwaysvisuallyinspecttoseethatthe

blades,bladeboltsandcutterassemblyarenotworn

ordamaged.Replacewornordamagedbladesand

boltsinsetstopreservebalance.

Starting

•Disengageallbladeanddriveclutchesandputinto

neutralbeforestartingtheengine.

•Donottiltmowerwhenstartingtheengineunless

themowerhastobetiltedforstarting.Inthiscase,

donottiltitmorethanabsolutelynecessaryandlift

onlythepart,whichisawayfromtheoperator.

•Starttheengineorswitchonthemotorcarefully

accordingtoinstructionsandwithfeetwellaway

fromtheblade(s)andnotinfrontofthedischarge

chute.

Operation

•Nevermowwhilepeople,especiallychildren,orpets

arenearby.

•Mowonlyindaylightoringoodarticiallight.

•Avoidoperatingthelawnmowerinwetgrass,where

feasible.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Neverpickuporcarryalawnmowerwhilethe

engineisrunning.

•Useextremecautionwhenreversingorpullinga

pedestriancontrolledlawnmowertowardsyou.

•Walk,neverrun.

•Slopes:

–Alwaysbesureofyourfootingonslopes.

•Uselowthrottlesettingswhenengagingthe

traction-clutch,especiallyinhighgears.Reduce

speedonslopesandinsharpturnstoprevent

overturningorlossofcontrol.

•Stopthebladeifthelawnmowerhastobetiltedfor

transportationwhencrossingsurfacesotherthan

grassandwhentransportingthelawnmowertoand

fromtheareatobemowed.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Stoptheengine

–wheneveryouleavethelawnmower.

–beforerefueling.

–beforeremovingthegrassbag.

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator’s

position.

•Stoptheengineanddisconnectthespark-plugwire.

–beforeclearingblockagesoruncloggingchute.

–beforechecking,cleaningorworkingonthelawn

mower.

–afterstrikingaforeignobject,inspectthelawn

mowerfordamageandmakerepairsbefore

restartingandoperatingthelawnmower.

–iflawnmowerstartstovibrateabnormally(check

immediately).

•Reducethethrottlesettingduringengineshutdown,

andclosethefuelvalveattheconclusionofmowing.

•Lightningcancausesevereinjuryordeath.Ifyousee

lightningorhearthunderinthearea,donotoperate

themachine;seekshelter.

•Watchoutfortrafcwhencrossingornearroadways.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Donotusepressurecleaningequipmentonmachine.

•Neverstoretheequipmentwithpetrolinthetank

andinsideabuildingwherefumescanreachanopen

ameorspark.

4

Page 5

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,silencer,

batterycompartmentandpetrolstoragearefreeof

grass,leaves,orexcessivegrease.

•Checkgrassbagcomponentsandthedischarge

guardfrequentlyandreplacewithmanufacturer’s

recommendedparts,whennecessary.

•Replacewornordamagedpartsforsafety.

•Replacefaultysilencers.

•Ifthefueltankhastobedrained,dothisout-doors.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatinganengineat

excessivespeedcanincreasethehazardofpersonal

injury.

•Becarefulduringadjustmentofthelawnmowerto

prevententrapmentofthengersbetweenmoving

bladesandxedpartsofthelawnmower.

•Toensurethebestperformanceandsafety,

purchaseonlygenuineHayterreplacement

partsandaccessories.Donotuse

andaccessories;theymaycauseasafetyhazard.

will t

parts

SoundPressure

Thisunithasasoundpressurelevelattheoperator’s

earof87dBA,whichincludesanUncertaintyValue(K)

of1dBA.Thesoundpressurelevelwasdetermined

accordingtotheproceduresoutlinedinEN836.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof98dBA,

whichincludesanUncertaintyValue(K)of1dBA.The

soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

Vibration,Hand/arm

Thisunitdoesnotexceedhand/armvibrationlevelsof

2.5m/s

hand,eachincludinganUncertaintyValue(K)of1.3

m/s

totheproceduresoutlinedinEN836.

2

fortherighthandand2.0m/s

2

.Themeasuredvaluesweredeterminedaccording

2

fortheleft

5

Page 6

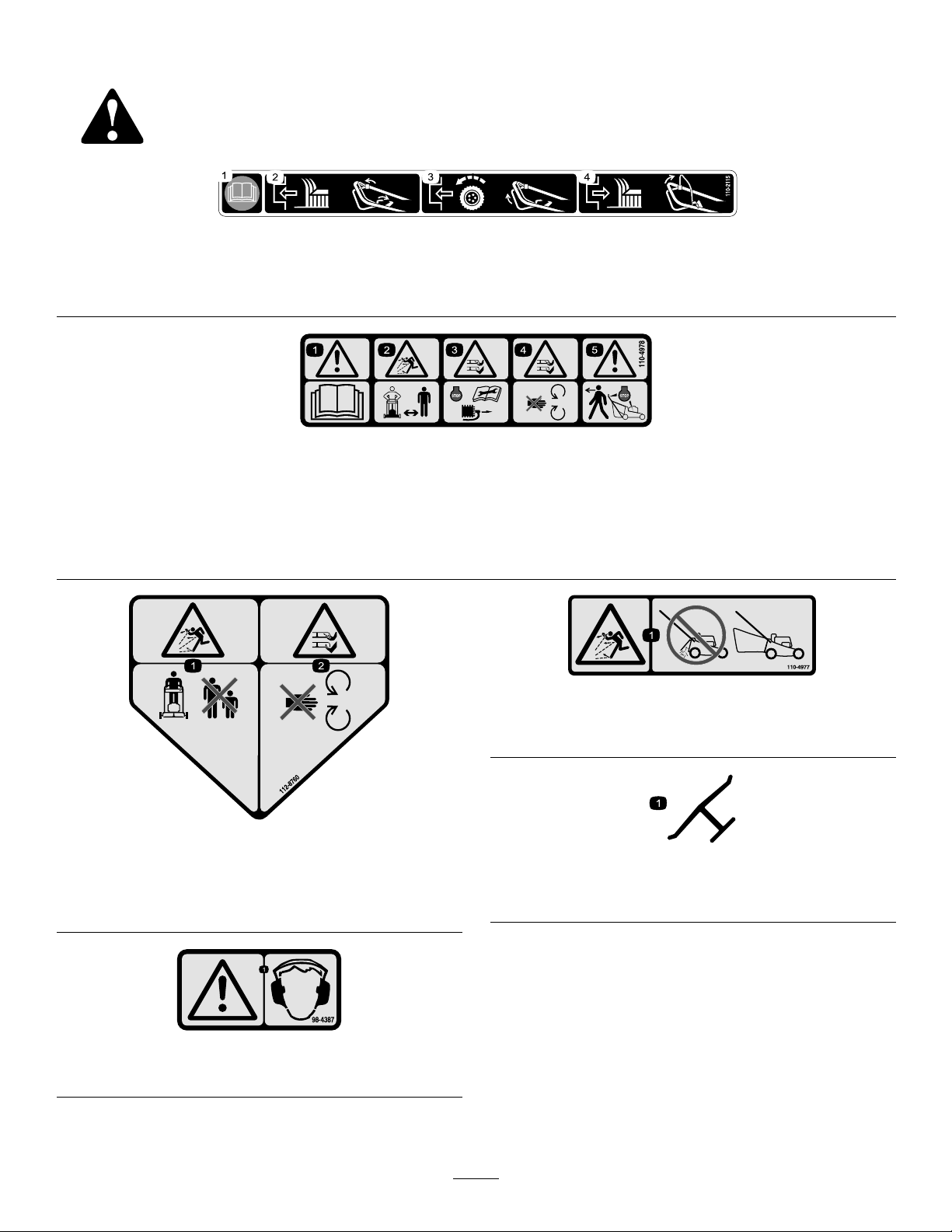

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

110-2115

1.ReadtheOperator’sManual.3.Toengagethetractioncontrol,liftthelowerbailupward.

2.Toengagetheblade,rstmovethesafetylatchforwardand

thenpulltheupperbailtotherear.

1.Warning—readtheOperator’sManual.

2.Thrownobjecthazard—keepbystandersasafedistancefromthemachine.

3.Cutting,dismembermenthazardofhandorfoot—stoptheengineandremovethesparkplugwirebeforeperformingany

maintenanceonthemachine.

4.Cutting,dismembermenthazardofhandorfoot—stayawayfrommovingparts.

5.Warning—stoptheenginebeforeleavingthemachine.

4.Todisengagetheblade,releasetheupperbail.

110-4978

112-8760

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

98-4387

1.Warning—wearhearingprotection.

110-4977

1.Thrownobjecthazard—donotoperatethemowerwithout

abaginplace.

Manufacturer’sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

6

Page 7

Setup

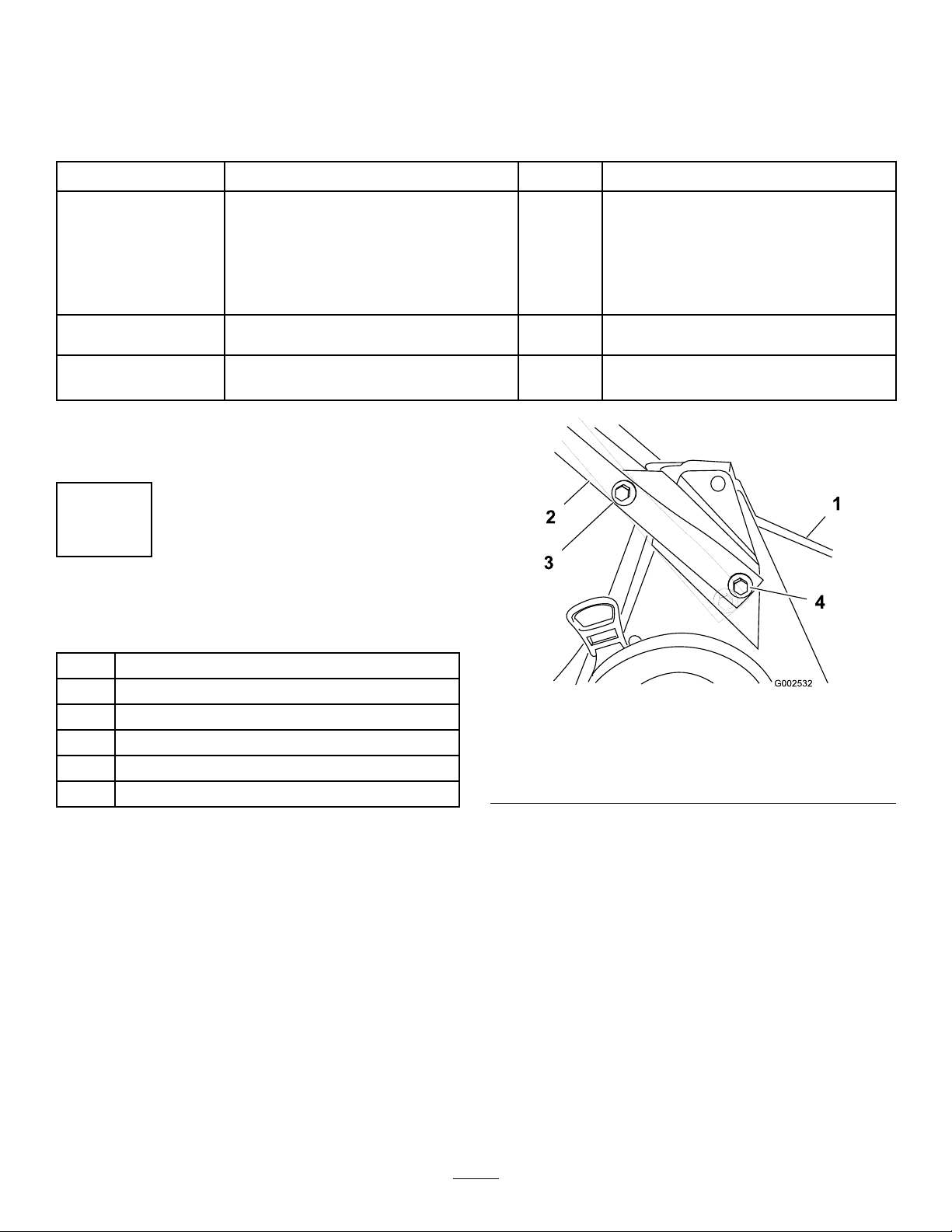

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Handle1

Bolt(5/16x7/8inch)

Bolt(5/16x1-1/2inches)

1

2

3

Washer4

Locknut(5/16inch)

Cabletie

Self-tappingscrew

Fueltank1

Nopartsrequired

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

InstallingtheHandle

Qty.

Use

2

2

4

3

2

–

Installthehandle.

Installthefueltankandfuelline.

Fillthecrankcasewithoil.

Partsneededforthisprocedure:

1Handle

2

Bolt(5/16x7/8inch)

2

Bolt(5/16x1-1/2inches)

4Washer

4

Locknut(5/16inch)

3

Cabletie

Procedure

1.Mountthehandletothemowerhousingwith2bolts

(5/16x7/8inch),2bolts(5/16x1-1/2inches),4

washers,and4locknuts(Figure3).

Figure3

1.Housing

2.Handle

3.Bolt(5/16x1-1/2inches),

washer,andlocknut

4.Bolt(5/16x7/8inch),

washer,andlocknut

Note:Installthewasherswiththecupsidefacing

thehandle.

Note:Youcanadjustthehandleheightformore

comfortableoperation.Securingthelowerhandle

endintheupperholelowersthehandle;securingthe

lowerhandleendinthelowerholeraisesthehandle.

2.Usethecabletiesprovidedtosecurethecontrol

cablestothehandle.

7

Page 8

2

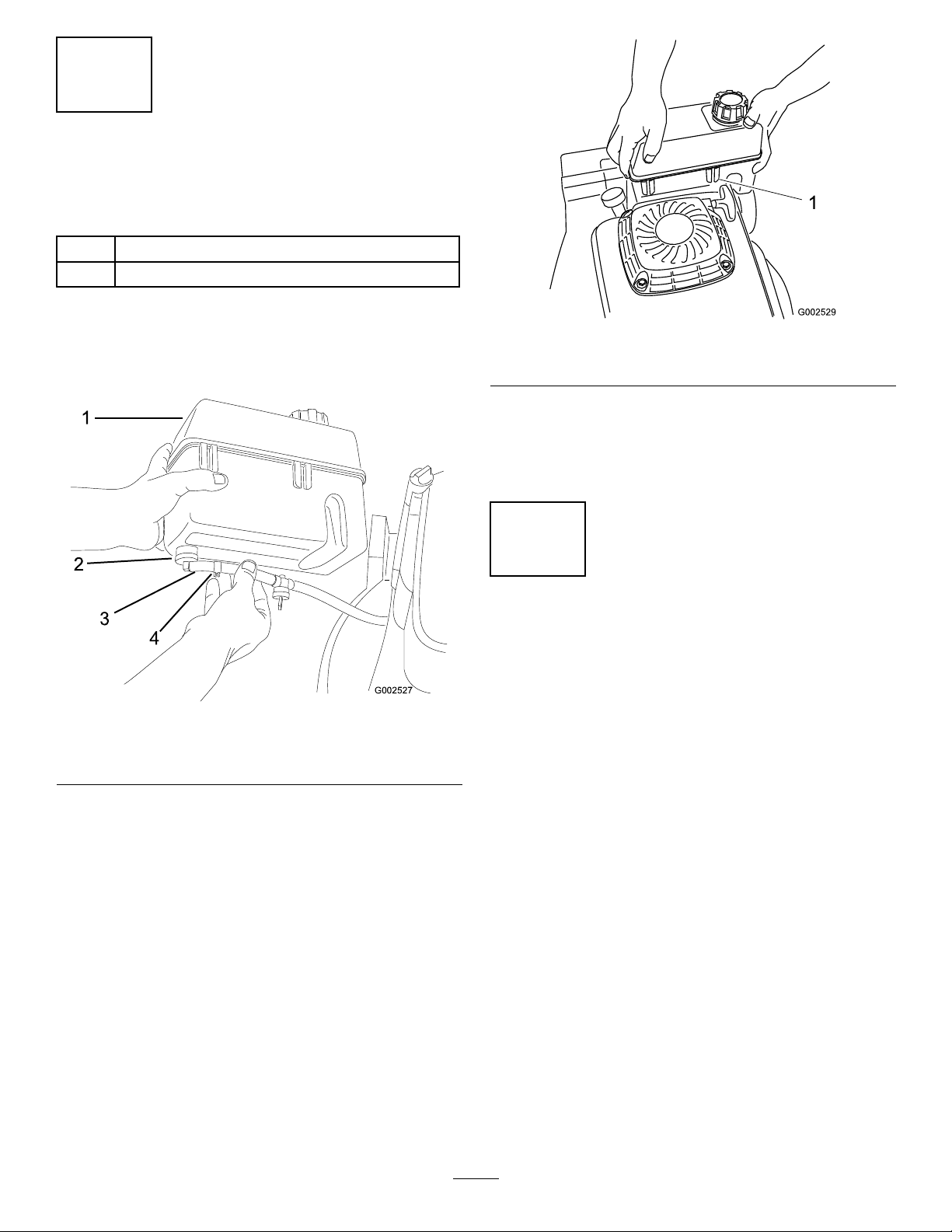

G002527

1

2

3

4

InstallingtheFuelTankand

theFuelLine

Partsneededforthisprocedure:

2

Self-tappingscrew

1Fueltank

Procedure

1.Slidetheendofthefuellineontotheelbowtting

(Figure4).

Figure4

1.Fueltank3.Fuelline

2.Elbowtting

2.Securethefuellineinplacewiththefuellineclamp

(Figure4).

4.Fuellineclamp

Figure5

1.Plasticclip(2)

4.Securethebottomofthefueltanktothefueltank

bracketbyinstallingtheself-tappingscrewsfromthe

bottom.Torquethescrewsto40to50in-lb(4.5

to5.6N-m).Donotovertightenthescrews.

3

FillingtheCrankcasewithOil

NoPartsRequired

Procedure

Theenginecrankcaseisshippedwithoutoil.Youmust

llitwithapproximately30oz.(0.88L)ofoilbefore

startingtheengine.RefertoCheckingtheEngineOil

LevelintheOperationsectionforoilspecicationsand

instructions.

3.Slidetheplasticclipsonthefrontofthefueltank

ontothefueltankmount(Figure5).

8

Page 9

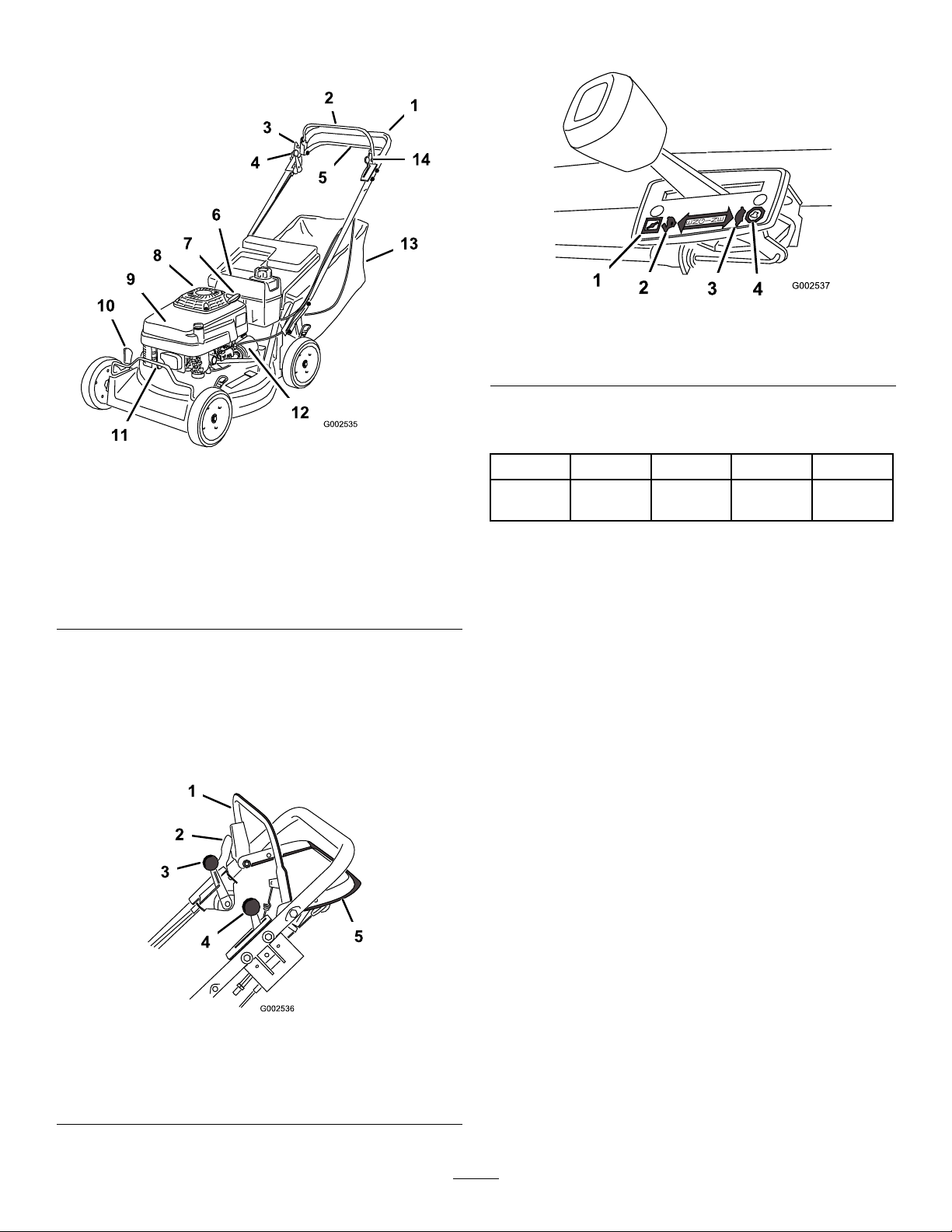

ProductOverview

Figure6

1.Handle

2.Bladecontrolbar

3.Controlbarlock10.Cuttingheightlever

4.Groundspeedcontrol

lever

5.Tractioncontrolbar

6.Fueltank

7.Starterhandle

8.Oilll/dipstick(notshown)

9.Airlter

11.Sparkplug

12.Oillter

13.Grassbag

14.Throttlecontrollever

ThethrottlesettingsareshowninFigure8.

Figure8

1.Choke3.Slow

2.Fast

4.Stop

Specications

ModelWeightLengthWidthHeight

455E124lb

(56kg)

59in

(149cm)

23in

(57cm)

38in

(97cm)

Controls

Thebladecontrolbar,controlbarlock,groundspeed

controllever,throttlecontrollever,andtractioncontrol

barareontheupperhandleasshowninFigure7.

Figure7

1.Bladecontrolbar4.Throttlecontrollever

2.Controlbarlock

3.Groundspeedcontrol

lever

5.Tractioncontrolbar

9

Page 10

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Note:Whenthecrankcaseisempty,pourabout3/4

ofthecrankcasecapacityofoilinthecrankcase,then

followtheprocedureinthissection.

1.Movethelawnmowertoalevelsurface.

Eachtimebeforeyoumow,makesurethatthe

self-propeldriveandthebladecontrolbaroperate

properly.Whenyoureleasethebladecontrolbar,the

bladeshouldstop.Ifitdoesnot,contactanAuthorized

ServiceDealer.

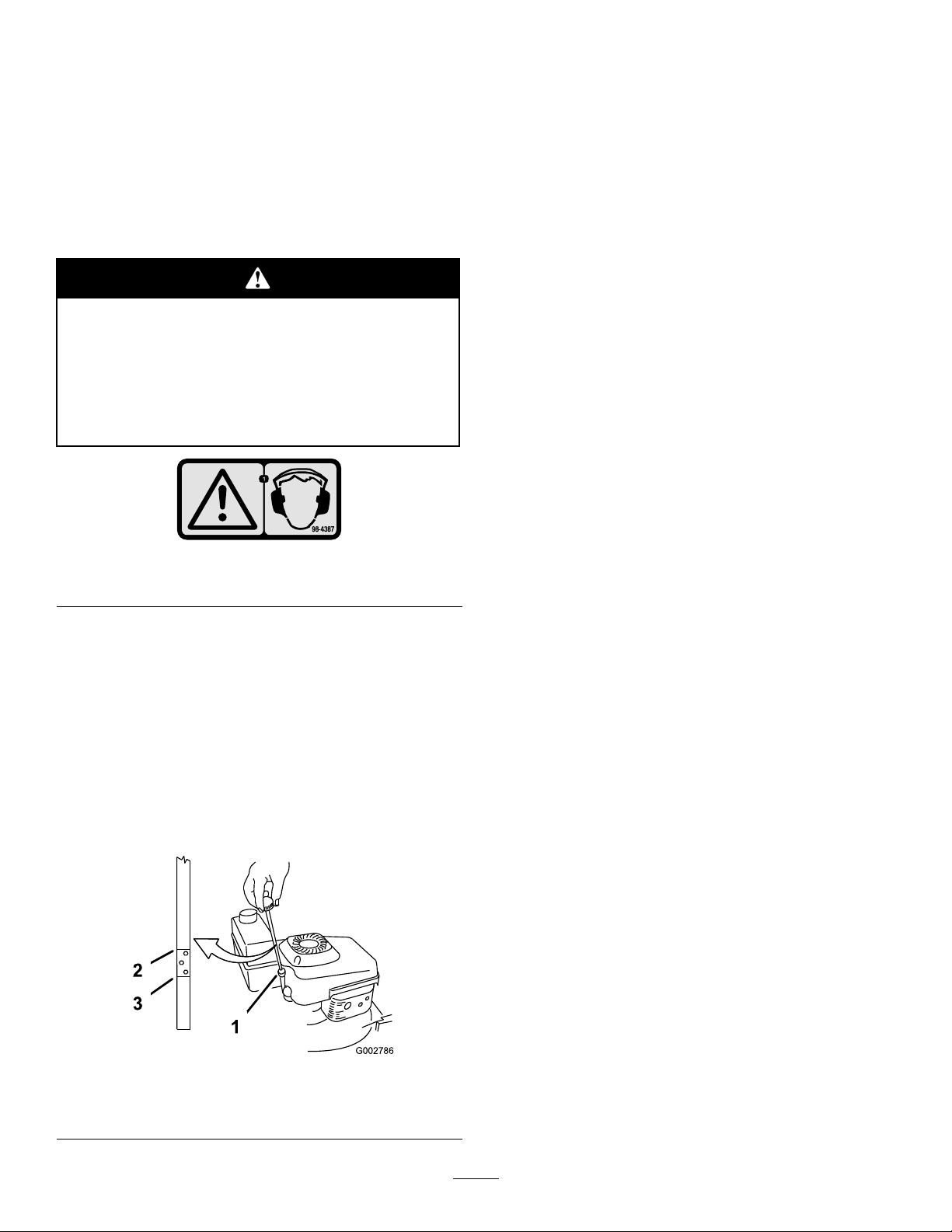

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

Figure9

1.Warning—wearhearingprotection.

2.Cleanaroundthedipstick(Figure10).

3.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

4.Wipethedipstickcleanwithacleancloth.

5.Insertthedipstickintothellerneck,butdonot

screwitin.

6.Removethedipstickandreadtheoillevelonthe

dipstick(Figure10).

7.IftheoillevelreadingisbelowtheAddmarkon

thedipstick,slowlypouronlyenoughoilintothe

llerholetoraisetheoilleveltotheFullmarkon

thedipstick.

Important:Donotoverllthecrankcasewith

oilandruntheengine;enginedamagewill

result.Draintheexcessoiluntiltheoillevelon

thedipstickreadsFull.

8.Insertthedipstickintothellerneckandrotatethe

capclockwiseuntilitistight.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Initially,llthecrankcasewith30ounces(0.88liters)

ofoil.Useonlyhigh-qualitySAE30orSAE10W30

weightdetergentoilthathastheAmericanPetroleum

Institute(API)serviceclassicationSF,SG,SH,orSJ .

Beforeeachuse,ensurethattheoillevelisbetweenthe

AddandFullmarksonthedipstick(Figure10).

Figure10

1.Dipstick3.Add

2.Full

10

Page 11

FillingtheFuelTank

Forbestresults,useclean,fresh,lead-freepetrolwith

anoctaneratingof87orhigher.Toensurefreshness,

purchaseonlythequantityofpetrolthatyouexpectto

usein30days.Usingunleadedpetrolresultsinfewer

combustiondepositsandlongerenginelife.Youmay

useleadedpetrolifunleadedpetrolisnotavailable.

Important:Donotaddoiltothepetrol.

Important:Donotusepetrolthathasbeenstored

sincethelastmowingseasonorlonger.

Whenfueling,undercertaincircumstances,a

staticchargecandevelop,ignitingthepetrol.A

reorexplosionfrompetrolcanburnyouand

othersanddamageproperty.

•Alwaysplacepetrolcontainersonthe

groundandawayfromyourvehiclebefore

lling.

•Donotllpetrolcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

Incertainconditions,petrolisextremely

ammableandhighlyexplosive.Areor

explosionfrompetrolcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

andwhentheengineiscold.Wipeupany

petrolthatspills.

•Donotllthefueltankcompletelyfull.Add

petroltothefueltankuntilthelevelis1/4

to1/2in.(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsthepetroltoexpand.

•Neversmokewhenhandlingpetrol,andstay

awayfromanopenameorwhereaspark

mayignitethepetrolfumes.

•Storepetrolinanapprovedfuelcontainer

andkeepitoutofthereachofchildren.

•Neverbuymorethana30-daysupplyof

petrol.

1.Cleanaroundthefueltankcap(Figure11).

•Whenpractical,removepetrol-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

round.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfrom

aportablecontainer,notfromapetrol

dispensernozzle.

•Ifyoumustuseapetroldispensernozzle,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

Useafuelstabilizer/conditionerregularlyduring

operationandstorage.Astabilizer/conditionercleans

theengineduringoperationandpreventsgum-like

varnishdepositsfromformingintheengineduring

periodsofstorage.

Important:Donotusefueladditivesotherthan

afuelstabilizer/conditioner.Donotusefuel

stabilizerswithanalcoholbasesuchasethanol,

methanol,orisopropanol.

Figure11

1.Oilll/dipstick

2.Fueltankcap

3.Aircleaner

2.Removethecapfromthetank.

3.Fillthefueltankwithunleadedpetroltowithin1/4

to1/2inch(6to13mm)fromthetopofthetank.

Donotllintothellerneck.

11

Page 12

Important:Donotllthetankmorethan1/4

inch(6mm)fromthetopofthetankbecause

thepetrolmusthaveroomtoexpand.

4.Installthefueltankcapandwipeupanyspilled

petrol.

OperatingtheBlade

EngagingtheBlade

Whenyoustartyourengine,thebladedoesnotturn.

Youmustengagethebladetomow .

StartingtheEngine

1.Connectthewiretothesparkplug(Figure12).

Figure12

1.Spark-plugwire

2.Openthefuelvalve(Figure13)

1.Pushthecontrolbarlockforward(Figure14).

Figure14

2.Pullthebladecontrolbartothehandleandhold

it(Figure15).

Figure13

1.Fuelvalve

3.MovethethrottlecontrollevertotheChoke

position(Figure8).

4.MovethegroundspeedcontrollevertotheNeutral

(N)position.

5.Pullthestarterhandlelightlyuntilyoufeel

resistance,thenpullitsharply.

6.Regulatethethrottleandthegroundspeedcontrol

asdesiredwhentheenginestarts.

Note:Iftheenginefailstostartafter3pulls,repeat

steps3through6.

StoppingtheEngine

1.MovethethrottlecontroltotheStopposition.

2.Disconnectthewirefromthesparkplugifyoudo

notusethelawnmowerorleaveitunattended.

Figure15

12

Page 13

DisengagingtheBlade

DisengagingtheTractionDrive

Releasethebladecontrolbar.

Important:Whenyoureleasethebladecontrol

bar,thebladeshouldstopwithin3seconds.Ifit

doesnotstopproperly,stopusingyourmower

immediatelyandcontactanAuthorizedService

Dealer.

OperatingtheTractionDrive

EngagingtheTractionDrive

1.Releasethetractioncontrolbar(Figure16).

Releasethetractioncontrolbar.

CheckingtheBladeBrake

Clutch

Checkthebladecontrolbarbeforeeachusetoensure

thatthebladebrakeclutchsystemisoperatingproperly.

Youcanusethegrassbagtoperformanadditionaltest

tocheckthebladebrakeclutchmechanism:

1.Installtheemptygrassbagonthedischargetunnel.

2.Starttheengine.

3.Pullthebladecontrolbartothenormalblade

engagedposition.Thebagshouldbegintoinate,

indicatingthatthebladeisengagedandrotating.

4.Releasethebladecontrolbail.Ifthebagdoesnot

immediatelydeate,itindicatesthatthebladeisstill

rotating.Thebladebrakeclutchmechanismmay

bedeteriorating,and,ifignored,couldresultinan

unsafeoperatingcondition.Havethelawnmower

inspectedandservicedbyanAuthorizedService

Dealer.

Figure16

2.Movethegroundspeedcontrollevertothedesired

gearposition.

3.Squeezethetractioncontrolbaragainstthehandle

(Figure17).

Figure17

Ifthebladebrakeclutchsystemisinoperative,

thebladewillcontinuetorotatewhenyou

releasethebladecontrolbail.Contactwith

bladecouldoccur,causingseriousinjury.

•Checkthebladebrakeclutchoperation

beforeeachuse.

•Neveruseamowerequippedwithablade

brakeclutchthathasaninoperativesafety

system.

•TakeyourmowertoanAuthorizedService

Dealerforrepairifthesafetysystemfailsto

operateproperly.

AdjustingtheCuttingHeight

Eachwheelisadjustedindividuallywithawheelheight

adjustmentlever.Cuttingheightsare1inch(25mm),

1-1/2inches(38mm),2inches(51mm),2-1/2inches

(64mm),3inches(76mm),and3-1/2inches(89mm),

and4inches(102mm).

13

Page 14

Adjustingthecuttingheightleverscouldbring

yourhandsintocontactwithamovingblade

andresultinseriousinjury.

•Stoptheengineandwaitforallmovement

tostopbeforeadjustingthecuttingheight.

•Donotputyourngersunderthehousing

whenadjustingthecuttingheight.

1.Pullthewheelheightadjustmentlevertowardthe

wheel(Figure18)andmoveittothedesiredsetting.

Figure19

1.Reardoor

3.Installthebagonthebagmountingposts

(Figure20).

Figure18

1.Wheelheightadjustmentlever

2.Releasethewheelheightadjustmentleverandseat

itsecurelyinthenotch.

3.Adjustallthewheelstothesamecuttingheight

setting.

UsingtheGrassBag

InstallingtheGrassBag

1.Waitforallmovingpartstostop.

2.Raiseandholdupthereardoor(Figure19).

Figure20

1.Bagmountingposts

4.Lowerthereardoor.

RemovingtheGrassBag

Toremovethebag,reversethestepsabove.

Themowercanthrowgrassclippingsandother

objectsthroughanopendischargetunnel.

Objectsthrownwithenoughforcecouldcause

seriouspersonalinjuryordeathtotheoperator

orbystander.

Donotoperatethemowerwithoutagrassbag

installed.

14

Page 15

MowingwiththeGrassBag

Aworngrassbagcouldallowsmallstones

andothersimilardebristobethrowninthe

operator’sorbystander’sdirectionandresultin

seriouspersonalinjuryordeathtotheoperator

orbystanders.

Checkthegrassbagfrequently.Ifitisdamaged,

installanewHayterreplacementbag.

OperatingTips

Operatingamowerwithitsenginerunningat

aspeedgreaterthanthefactorysettingcan

causethemowertothrowapartofthebladeor

engineintotheoperator’sorbystander’sarea

andresultinseriouspersonalinjuryordeath.

–Donotchangetheenginespeedsetting.

–Ifyoususpecttheenginespeedisfaster

thannormal,contactanAuthorizedService

Dealer.

•Cleantheairlterfrequently.Mulchingstirsup

moreclippingsanddustwhichclogstheairlter

andreducesengineperformance.

GeneralTips

•Maintainasharpbladethroughoutthecutting

season.Periodicallyledownnicksontheblade.

•Replacethebladewhennecessarywithanoriginal

Hayterreplacementblade.

•Mowonlydrygrassorleaves.Wetgrassandleaves

canbuildupandcloginthechuteorcausethe

enginetostall.

Wetgrassorleavescancauseseriousinjuryif

youslipandcontacttheblade.

Mowonlyindryconditions.

•Cleanunderthemowerhousingaftereachmowing.

SeeCleaningundertheMowerHousing.

•Keeptheengineingoodrunningcondition.

•Settheenginespeedtothefastestpositionforthe

bestcuttingresults.

CuttingGrass

•Grassgrowsatdifferentratesatdifferenttimes

oftheyear.Inthesummerheat,itisbesttocut

grassatthe2-1/2inch(64mm),3inch(76mm),

or3-1/2inch(89mm)cuttingheightsettings.Cut

onlyaboutathirdofthegrassbladeatatime.Do

notcutbelowthe2-1/2inch(64mm)settingunless

thegrassissparseoritislatefallwhengrassgrowth

beginstoslowdown.

•Whencuttinggrassover6inches(15cm)tall,rst

mowatthehighestcuttingheightsettingandwalk

slower;thenmowagainatalowersettingforthe

bestlawnappearance.Ifthegrassistoolongand

theleavesclumpontopofthelawn,themowermay

clogandcausetheenginetostall.

•Alternatethemowingdirection.Thishelpsdisperse

theclippingsoverthelawnforevenfertilization.

Ifthenishedlawnappearanceisunsatisfactory,try

oneormoreofthefollowing:

•Sharpentheblade.

•Walkataslowerpacewhilemowing.

•Raisethecuttingheightonyourmower.

•Cutthegrassmorefrequently.

•Overlapcuttingswathsinsteadofcuttingafull

swathwitheachpass.

•Setthecuttingheightonthefrontwheelsonenotch

lowerthantherearwheels.Forexample,setthe

frontwheelsat2-1/2inches(64mm)andtherear

wheelsat3inches(76mm).

CuttingLeaves

•Aftercuttingthelawn,ensurethathalfofthelawn

showsthroughthecutleafcover.Youmayneedto

makemorethanonepassovertheleaves.

15

Page 16

•Forlightleafcoverage,setallthewheelsatthesame

cuttingheightsetting.

•Iftherearemorethan5inches(12.7cm)ofleaves

onthelawn,setthefrontcuttingheight1or2

notcheshigherthantherearcuttingheight.This

makesiteasiertofeedtheleavesunderthemower

housing.

•Slowdownyourmowingspeedifthemowerdoes

notcuttheleavesnelyenough.

•Ifyoumowoveroakleaves,youcanaddlimeto

thegrassinthespringtoreducetheacidityofthe

oakleaves.

16

Page 17

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every300hours

Yearly

Important:Refertoyour

MaintenanceProcedure

•Changetheengineoil.

•Checktheengineoillevel.

•Inspectthemowerbladesforwearordamage.

•Cleanunderthemowerhousing.

•Cleanthefoampre-cleaner(morefrequentlyindustyconditions).

•Changetheengineoil(moreoftenindustyconditions).

•Cleanthebladebrakeclutchshield.

•Lubricatethegearcase.

•Changetheoillter.

•Checkthesparkplug.

•Replacethepaperairlter(morefrequentlyindustyconditions).

•Cleanthefuellter.

Engine Operator’ s Man ual

foradditionalmaintenanceprocedures.

Ifyouleavethewireonthesparkplug,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Disconnectthewirefromthesparkplugbeforeyoudoanymaintenance.Setthewireasidesothatit

doesnotaccidentlycontactthesparkplug.

Lubrication

LubricatingthePivotArms

Afterevery50operatinghoursorwhentheseasonends,

lubricatethepivotarms.

1.Movetherearwheelcuttingheightleverstothe

centersetting.

2.Wipethegreasettingswithacleanrag(Figure21).

3.Installagreasegunontothettingandgentlyapply2

or3pumpsof#2multi-purposelithiumbasegrease.

Important:Excessivegreasepressuremay

damagetheseals.

Figure21

17

Page 18

LubricatingtheGearCase

ServiceInterval:Every100hours

Afterevery100operatinghours,greasethegearcase.

1.Removethegrassbag.

2.Installagreasegunontothettingthroughthebelt

coveropening(Figure22).

Figure22

EngineMaintenance

ServicingtheAirFilter

ServiceInterval:Every25hours—Cleanthefoam

pre-cleaner(morefrequentlyindusty

conditions).

Every300hours—Replacethepaper

airlter(morefrequentlyindusty

conditions).

Important:Donotoperatetheenginewithoutthe

airlterassembly;extremeenginedamagewill

occur.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug(Figure12).

3.Removethescrewthatsecurestheaircleanercover

(Figure23).

3.Gentlyapplyoneto2pumpsof#2multi-purpose

lithium-basegrease.

4.Installthegrassbag.

Figure23

1.Screw3.Paperairlter

2.Cover

4.Removethecoverandcleanitthoroughly(Figure23).

5.Removethepaperairlteranddiscardit(Figure24).

18

Figure24

1.Paperairlter

Important:Donottrytocleanapaperlter.

2.Foampre-cleaner

Page 19

6.Removethefoampre-cleanerandwashitwitha

milddetergentandwater,thenblotitdry.

10.FillthecrankcasetotheFulllineonthedipstickwith

freshoil.RefertotheFillingtheCrankcasewithOil.

7.Saturatethepre-cleanerwithoil,thensqueezeit(do

nottwist)toremovetheexcessoil.

8.Installthefoampre-cleaner.

9.Installthenewpaperairlter.

10.Installthecoverandsecureitwiththescrew.

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours

Every50hours

OilCapacity

Withoillter29ounces(0.85liters)

Withoutoillter22ounces(0.65liters)

Note:Theoilcapacitiesinthetableaboveaccount

fortheemptycrankcasetocontainasmallamountof

residualoil.

1.Runtheenginetowarmtheengineoil.

Note:Warmoilowsbetterandcarriesmore

contaminants.

11.Wipeupanyspilledoil.

ChangingtheOilFilter

ServiceInterval:Every100hours

Replacetheoillter(Figure25)afterevery100operating

hoursoryearly,whichevercomesrst.

Figure25

1.Oillter

1.Runtheenginetowarmtheoil.

2.Fuelline

Oilmaybehotafterenginehasbeenrun,and

contactwithhotoilcancauseseverepersonal

injury.

Avoidcontactingthehotengineoilwhenyou

drainit.

2.Stoptheengineandwaitforallmovingpartstostop.

3.Disconnectthewirefromthesparkplug(Figure12).

4.Placeasuitabledrainpanundertherightsideof

themower.

5.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

6.Tipthemowerontoitsrightsidetodraintheoil

intothedrainpan.

Note:Youcanalsoremovetheoilfromthe

crankcaseusinganoilextractor.

7.Returnthemowertoitsoperatingposition.

Oilmaybehotaftertheenginehasbeenrun,

andcontactwithhotoilcancausesevere

personalinjury.

Avoidcontactingthehotengineoilwhenyou

drainit.

2.Stoptheengineandwaitforallmovingpartstostop.

3.Disconnectthewirefromthesparkplug.

4.Draintheengineoil;refertoChangingtheEngine

Oil.

5.Placearagundertheoilltertocatchanyoilthat

mayleakoutasyouremovethelter.

6.Removetheoillter.

7.Useyourngertocoatthegasketonthenewlter

withoil(Figure26).

8.Insertthedipstickintothellerneckandrotatethe

capclockwiseuntilitistight.

9.Recycletheusedoilaccordingtolocalcodes.

19

Page 20

Figure27

Figure26

1.Gasket

1.Centerelectrodeinsulator

2.Sideelectrode

3.Airgap(nottoscale)

8.Installthenewlterandhandtightenit2/3turn

only.

9.FillthecrankcasetotheFulllineonthedipstickwith

freshoilRefertoFillingtheCrankcasewithOil.

10.Connectthewiretothesparkplug.

11.Runtheengineforabout3minutes.

12.Stoptheengine,waitforallmovingpartstostop,

andcheckforoilleakagearoundthelter.

13.Addoiltocompensatefortheoilintheoillter.

RefertoCheckingtheEngineOilLevel.

14.Recycletheusedoillteraccordingtolocalcodes.

ServicingtheSparkPlug

ServiceInterval:Every100hours—Checkthespark

plug.

UseanNGKBPR5ESsparkplugorequivalent.

1.Stoptheengineandwaitforallmovingpartstostop.

6.Installthesparkplugandthegasketseal.

7.Torquetheplugto17ft-lb(23N-m).

8.Connectthewiretothesparkplug.

2.Disconnectthewirefromthesparkplug(Figure12).

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotcleantheelectrodes

becausegritenteringthecylindercandamage

theengine.

5.Setthegapontheplugto0.030in.(0.76mm)

(Figure27).

20

Page 21

FuelSystem

DriveSystem

Maintenance

EmptyingtheFuelTankand

CleaningtheFuelFilter

ServiceInterval:Yearly

Thefuellter(screen)elementislocatedinsidethefuel

tank.Cleanthefuellterelementyearly .

1.Stoptheengineandwaitforittocooldown.

Note:Drainpetrolfromacoldengineonly.

2.Disconnectthewirefromthesparkplug.

3.Disconnectthefuellinebylooseningthetubeclamp

atthecarburetor.

4.Openthefuelvalve.

5.Drainthepetrolcompletelyfromthetankandfuel

lineintoanapprovedfuelcontainer.

6.Removethefueltankfromthemower.

Maintenance

AdjustingtheSelf-propelDrive

Ifthemowerdoesnotself-propelorhasatendencyto

creepforwardwhenthecontrolbarismorethan1-1/2

inches(3.8cm)fromthehandle,adjusttheself-propel

drive.

1.Loosenthenutthatsecurestheadjuster(Figure28).

7.Pourasmallamountoffuelinthefueltank,move

thefuelaroundinthetank,andpouritoutintoan

approvedfuelcontainer.

8.Installthefueltankandfuelline;refertoInstalling

theFuelTankandtheFuelLine.

Figure28

1.Adjuster

2.Nut

2.Turntheadjusteruntilyouremovetheslackinthe

exposedcable(Figure28).

3.Tightenthenut.

Note:Tochecktheadjustment,slowlypullthe

mowerbackwardwhileyougraduallymovethe

controlbartowardthehandle.Theadjustmentis

correctwhentherearwheelsstopturningandthe

topofthecontrolbarisabout1-1/2inches(3.8cm)

fromthebottomofthehandle.

Note:Iftheadjusterisfullyextendedandthe

mowerdoesnotself-propelwhenthebladecontrol

baris1-1/2inches(3.8cm)fromthehandle,you

willneedtoadjusttheloweranchorbracket.Refer

tosteps4to9.

3.Cable

4.1-1/2inches(3.8cm)

4.Movetheadjustertoobtainthemaximumslackin

thecable.

5.Removethefueltank.

Note:Youdonotneedtodisconnectthefuelline

fromthefueltank.

6.Removetheupperbeltcover(Figure29).

21

Page 22

G012156

1

8.Movetheloweranchorbracketuponehole

(Figure30).

9.Repeatsteps1through3toadjustthecontrolbar.

Note:Whenyouinstallanewbelt,movethelower

anchorbrackettoitsoriginalfactoryposition,which

isindicatedbythenotchesnexttotheholesinthe

bracket(Figure30).

ServicingtheWheels

Figure29

1.Upperbeltcover

7.Removethescrewsfromtheloweranchorbracket

(Figure30).

RemovingtheWheels

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug(Figure12).

3.Removethebolt,thewheelspacer,andthelocknut

mountingthewheeltothepivotarm(Figure31).

4.Separatethewheelhalvesfromthetyrebyremoving

4capscrewsand4locknuts(Figure31).

Note:Ifyouremovethebearingsfromthe

bearing/hubassembly,removethembypressingon

thebearingspacer(Figure31).

Figure31

1.Locknuts

2.Wheelspacer7.Lug

3.Bearing/hubassembly8.Bearing(2)

4.Bearingspacer9.Bolt

5.Wheelhalf

6.Plasticcover(rearwheels

only)

Figure30

1.Loweranchorbracket2.Notches

Note:ThelowerbelthasbeenremovedinFigure30

forthepurposeforclarity.Itisnotnecessary

toremovethelowerbeltcovertoperformthis

procedure.

AssemblingtheWheels

1.Positionthetyreontoonewheelhalf,aligningthe

lugsoneach(Figure31).

2.Placethebearing/hubassemblyintothecenterhole

ofthewheelhalf.Ensurethatthelegsofthehubare

positionedovertheangeofthehole(Figure31).

3.Placetheotherwheelhalfontothebearing/hub

assembly,aligningthewheelandthetyrelugsand

themountingholes(Figure31).

4.Using2fullythreadedscrewsorbolts(1/4-20x1.50

inch)andnon-lockingnuts,looselysecurethewheel

22

Page 23

halvestogether.Mountthescrewsorboltsinthe

opposingholes(Figure31).

5.Checkthealignmentofallpartsandtightenthe

screws,alternatingfromsidetosideforauniformt,

untilthewheelhalvesaredrawntogether(Figure31).

6.Installthe2boltsand2locknutspreviouslyremoved

intheremainingholesinthewheelhalvesand

tighten.Removethe2longscrewsorboltsand

replacethemwith2boltsand2locknuts(Figure31).

ControlsSystem

Maintenance

AdjustingtheBladeBrake

Cable

Wheneveryouinstallanewbladebrakecableassembly

orreplacethebelt,adjustthebladebrakecable.

7.Installthewheeltothepivotarmwiththebolts,

aspacer,andalocknut.Ensurethatthespaceris

positionedbetweenthewheelhubandthepivotarm

(Figure31).

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug(Figure12).

3.Removethefueltankfromthetankbracket.

Note:Youdonotneedtodisconnectthefuelline

fromthefueltank.

4.Resetthecableadjusteronthehandlesothat1/4

inch(6mm)ofthethreadsshow ,thentightenthe

nut(Figure32).

Figure32

1.Adjuster

2.Nut

5.Loosenthecableclampscrewuntilthebrakecable

conduitslides(Figure33).

3.1/4inch(6mm)ofthreads

23

Page 24

Figure33

1.Spring3.Cableclampscrew

2.Brakecableconduit

6.Holdthebladecontrolbarsothattheoutsideofthe

baris5-1/2inches(14cm)fromtheoutsideofthe

handle,andpullthecabletotheremovetheslack,

butdonotputtensiononthespring(Figure34).

Donotovertightenthebladebrakecable.

Overtighteningthebladebrakecablecould

preventthebladebrakefromcontactingthe

brakedrumwhenyoureleasethecontrolbar.

Ifthebladebrakedoesnotcontactthebrake

drum,thebladewillnotstoprotating,which

couldcauseseriouspersonalinjury.

•Eachtimeyouadjustthebrakecable,ensure

thatthebrakestopsthebladein3seconds

orless.

•Ifthebladedoesnotstoprotatingin3

secondsorless,bringthemowertoan

AuthorizedServiceDealerforinspection

andrepair.

Figure34

1.5-1/2inches(14cm)

2.Handle

3.Bladecontrolbar

7.Torquethecableclampscrewto100to120in-lb(11

to14N-m)tolocktheadjustmentinplace.

24

Page 25

BladeMaintenance

MaintainingtheCuttingBlade

Alwaysmowwithasharpblade.Asharpbladecuts

cleanlyandwithouttearingorshreddingthegrassblades.

Completethefollowingprocedurebefore

inspecting,removing,orinstallingtheblade:

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug(Figure12).

3.Drainthepetrolfromthefueltank;referto

EmptyingtheFuelTankandCleaningtheFuelFilter.

4.Tipthemowerontoitsrightside(Figure35).

Figure36

1.Sail

2.Flatpartoftheblade4.Slotformed

3.Wear

Note:Forthebestperformance,installanewblade

beforethecuttingseasonbegins.Duringtheyear,le

downanysmallnickstomaintainthecuttingedge.

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrownintothe

operator’sorbystander’sarea,resultingin

seriouspersonalinjuryordeath.

Figure35

1.Blade3.Anti-scalpcup

2.Bladenuts

InspectingtheBlade

ServiceInterval:Beforeeachuseordaily

Carefullyexaminethebladeforsharpnessandwear,

especiallywheretheatandthecurvedpartsmeet

(Figure36A).Becausesandandabrasivematerialcan

wearawaythemetalthatconnectstheatandcurved

partsoftheblade,checkthebladebeforeusingthe

mower.Ifyounoticeaslotorwear(Figure36Band

Figure36C),replacetheblade;refertoRemovingthe

Blade.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

RemovingtheBlade

Grasptheendofthebladeusingaragorathickly

paddedglove.Removethebladenuts,theanti-scalpcup,

andtheblade(Figure35).

SharpeningtheBlade

Filethetopsideofthebladetomaintainitsoriginal

cuttingangle(Figure37A)andinnercuttingedgeradius

(Figure37B).Thebladewillremainbalancedifyou

removethesameamountofmaterialfrombothcutting

edges.

Figure37

1.Sharpenatthisangleonly.

2.Maintaintheoriginalradius

here.

25

Page 26

BalancingtheBlade

1.Checkthebalanceofthebladebyplacingthecenter

holeofthebladeoveranailorscrewdrivershank

clampedhorizontallyinavise(Figure38).

Figure38

Note:Youcanalsocheckthebalanceusinga

commerciallymanufacturedbladebalancer.

2.Ifeitherendofthebladerotatesdownward,lethat

end(notthecuttingedgeortheendnearthecutting

edge).Thebladeisproperlybalancedwhenneither

enddrops.

InstallingtheBlade

Cleaning

CleaningundertheMower

Housing

Toensurethebestperformance,keeptheundersideof

themowerhousingclean.

WashingMethod

ServiceInterval:Beforeeachuseordaily

1.Positionthemoweronaatconcreteorasphalt

surfacenearagardenhose.

2.Starttheengine.

3.Holdtherunninggardenhoseathandleleveland

directthewatertoowonthegroundjustinfront

oftherightreartyre(Figure39).

1.Installasharp,balancedHayterblade,theanti-scalp

cup,andthebladenuts.Thesailoftheblademust

pointtowardthetopofthemowerhousingfor

properinstallation.Torquethebladenutsto23to

27ft-lb(32to37N-m).

2.Returnthemowertoitsoperatingposition.

3.Connectthewiretothesparkplug.

Figure39

1.Rightrearwheel

Note:Thebladewilldrawinwaterandwashout

clippings.Letthewaterrununtilyounolongersee

clippingsbeingwashedoutfromunderthehousing.

4.Stoptheengineandwaitforallmovingpartstostop.

5.Turnoffthegardenhose.

6.Startthemowerandletitrunforafewminutes

todryoutthemoistureonthemowerandits

components.

ScrapingMethod

Ifwashingdoesnotremovealldebrisfromunderthe

mower,scrapeitclean.

1.Disconnectthewirefromthesparkplug(Figure12).

2.Drainthefuelfromthefueltank.RefertoEmptying

theFuelTankandCleaningtheFuelFilter.

26

Page 27

Tippingthemowermaycausethefueltoleak

fromthecarburetororthefueltank.Petrolis

extremelyammable,highlyexplosive,and,

undercertainconditions,cancausepersonal

injuryorpropertydamage.

Avoidfuelspillsbyrunningtheenginedryorby

removingthepetrolwithahandpump;never

siphon.

3.Tipthemowerontoitsrightside.

4.Removethedirtandgrassclippingswithahardwood

scraper.Avoidburrsandsharpedges.

5.Returnthemowertoitsoperatingposition.

6.Fillthefueltank.

7.Connectthewiretothesparkplug.

CleaningtheBladeBrake

ClutchShield

ServiceInterval:Every50hours

Figure40

1.Screws(4)

7.Removetheshieldandbrushorblowallthedebris

fromundertheshieldandaroundthebladebrake

clutchsystem.

8.Installtheshield.

9.Installtheblade,theanti-scalpcup,andthe2blade

nuts.

2.Bladebrakeclutchshield

Cleaninsidethebladebrakeclutchshieldwhenyou

changetheengineoiltoensurethebestperformance

andtopreventpartsfromdegradingorwhenyou

sharpenthebladebecauseyouneedtoremovetheblade

inordertoremovetheshield.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug(Figure12).

3.Drainthepetrolfromthefueltank;referto

EmptyingtheFuelTankandCleaningtheFuelFilter.

4.Tipthemoweronitsrightside.

Tippingthemowermaycausethefueltoleak

fromthecarburetororthefueltank.Petrolis

extremelyammable,highlyexplosive,and,

undercertainconditions,cancausepersonal

injuryorpropertydamage.

Avoidfuelspillsbyemptyingthefueltankas

directed;neversiphon.

10.Returnthemowertoitsoperatingposition.

11.Connectthewiretothesparkplug.

5.Remove2bladenuts,theanti-scalpcup,andthe

blade(Figure35).

6.Loosenthe4screwsthatholdtheshieldinplace

(Figure40)..

27

Page 28

Storage

2.Cleananydirtandchafffromthecylinder,cylinder

headns,andblowerhousing.

Topreparethemowerforoff-seasonstorage,perform

therecommendedmaintenanceprocedures.Referto

Maintenance.

Storethemowerinacool,clean,dryplace.Coverthe

mowertokeepitcleanandprotected.

PreparingtheFuelSystem

Petrolcanvaporizeifyoustoreitoverlong

periodsoftimeandexplodeifitcomesinto

contactwithanopename.

•Donotstorepetroloverlongperiodsoftime.

•Donotstorethemowerwithpetrolinthe

fueltankorthecarburettorinanenclosure

withanopename.(Forexample,afurnace

orawaterheaterpilotlight.)

•Allowtheenginetocoolbeforestoringitin

anyenclosure.

Emptythefueltankwhenmowingthelasttimebefore

storingthemower.

1.Runthemoweruntiltheenginestopsfromrunning

outoffuel.

2.Primetheengineandstartitagain.

3.Allowtheenginetorununtilitstops.Whenyoucan

nolongerstarttheengine,itissufcientlydry.

3.Removegrassclippings,dirt,andgrimefromthe

externalpartsoftheengine,theshrouding,andthe

topofthemowerhousing.

4.Checktheconditionoftheblade.Referto

MaintainingtheCuttingBlade.

5.CleantheBBCshield;refertoCleaningtheBlade

BrakeClutchShield.

6.Servicetheairlter;refertoServicingtheAirFilter.

7.Lubricatethepivotarms;refertoLubricatingthe

PivotArms.

8.Tightenallnuts,bolts,andscrews.

9.Touchupallrustedorchippedpaintsurfaceswith

paintavailablefromanAuthorizedServiceDealer.

RemovingtheLawnMower

fromStorage

1.Checkandtightenallfasteners.

2.Removethesparkplugandspintheenginerapidly

usingthestartertoblowexcessoilfromthecylinder.

3.Cleanthesparkplugorreplaceitifitiscracked,

broken,oriftheelectrodesareworn.

4.Installthesparkplugandtorqueitto17ft-lb(23

N-m).

5.Performanyneededmaintenanceprocedures;refer

toMaintenance.

6.Fillthefuelinthefueltankwithfreshpetrol.

PreparingtheEngine

1.Whiletheengineisstillwarm,changetheoilfrom

thecrankcase.RefertoChangingtheEngineOil.

2.Removethesparkplug.

3.Usinganoilcan,addaboutonetablespoonofoilto

thecrankcasethroughthesparkplughole.

4.Slowlyrotatetheengineseveraltimes,usingthe

starterrope,todistributetheoil.

5.Installthesparkplugbutdonotconnectthewireto

thesparkplug.

GeneralInformation

1.Cleanthemowerhousing.RefertoCleaningunder

theMowerHousing.

7.Checktheengineoillevel.

8.Connectthewiretothesparkplug.

28

Page 29

Troubleshooting

Problem

Enginedoesnotstart

Enginestartshardorlosespower

Enginerunsrough

PossibleCauseCorrectiveAction

1.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

2.ThethrottleleverisnotintheChoke

position.

3.Thewireisnotconnectedtothespark

plug.

4.Thesparkplugispitted,fouled,orthe

gapisincorrect.

1.Thefueltankcontainsstalefuel.1.Drainandllthefueltankwithfresh

2.Thefuelcapventholeisplugged.2.Cleanthefuelcapventholeorreplace

3.Theairlterelementisdirtyandis

restrictingtheairow.

4.Theundersideofthemowerhousing

containsclippingsanddebris.

5.Thesparkplugispitted,fouled,orthe

gapisincorrect.

6.Theengineoillevelislowortheoilis

dirty.

1.Thewireisnotconnectedtothespark

plug.

2.Thesparkplugispitted,fouled,orthe

gapisincorrect.

3.ThethrottleleverisnotintheFast

position.

4.Theairlterelementisdirtyandis

restrictingtheairow.

1.Drainand/orllthefueltankwithfresh

petrol.Iftheproblempersists,contact

anAuthorizedServiceDealer .

2.MovethethrottlelevertotheChoke

position.

3.Connectthewiretothesparkplug.

4.Checkthesparkplugandadjustthe

gapifnecessary.Replacethespark

plugifitispitted,fouled,orcracked.

petrol.

thefuelcap.

3.Cleantheairlterpre-cleanerand/or

replacethepaperairlter.

4.Cleanunderthemowerhousing.

5.Checkthesparkplugandadjustthe

gapifnecessary.Replacethespark

plugifitispitted,fouled,orcracked.

6.Checktheengineoil.Changetheoilif

itisdirtyoraddoilifitislow

1.Connectthewiretothesparkplug.

2.Checkthesparkplugandadjustthe

gapifnecessary.Replacethespark

plugifitispitted,fouled,orcracked.

3.MovethethrottlelevertotheFast

position.

4.Cleantheairlterpre-cleanerand/or

replacethepaperairlter.

Lawnmowerorenginevibrates

excessively

Unevencuttingpattern

Mowerdoesnotself-propel

1.Thebladeisbentorisoutofbalance.1.Balancetheblade.Ifthebladeisbent,

2.Theblademountingnutsareloose.2.Tightentheblademountingnuts.

3.Theundersideofthemowerhousing

containsclippingsanddebris.

4.Theenginemountingboltsareloose.4.Tightentheenginemountingbolts.

1.All4wheelsarenotatthesameheight.1.Placeall4wheelsatthesameheight.

2.Thebladeisdull.

3.Youaremowinginthesamepattern

repeatedly.

4.Theundersideofthemowerhousing

containsclippingsanddebris.

1.Theself-propeldrivecableisoutof

adjustmentorisdamaged.

2.Thereisdebrisunderthebeltcover.

replaceit.

3.Cleanunderthemowerhousing.

2.Sharpenandbalancetheblade.

3.Changethemowingpattern.

4.Cleanunderthemowerhousing.

1.Adjusttheself-propeldrivecable.

Replacethecableifnecessary.

2.Cleanthedebrisfromunderthebelt

cover.

29

Page 30

Notes:

30

Page 31

LIMITED WARRANTY

Hayter Limited warrants to the original user/purchaser that this unit shall be free from defects in

material and workmanship under normal use and service for a period of one year from the date

of purchase. The manufacturers of the engine furnish their own warranty and services are

provided through their authorised network (Refer to "Engine Warranty Statement"). To qualify

for the full benefit of the warranty, the Warranty Registration Card must be returned to Hayter

Limited within 14 days of purchase. If the selling dealer has not returned the Warranty

Registration Card which is attached to the rear of the Owners Handbook please complete and

return. Subject to the conditions and exclusions noted in this limited warranty, we shall at our

option, repair or replace any warranted part during the applicable period. If you are in doubt or

experience any difficulty, please consult a Hayter Authorised Service Dealer for clarification.

A 90 day warranty period applies to those items which are subject to normal wear and tear e.g.

wheels, cutterbars, cables, grassbags and other consumable wearing parts.

All machines which are fitted with a genuine Hayter Friction Disc or Crankshaft Support

Bearing as original equipment before use, are covered by a Lifetime Warranty against the

engine crankshaft bending. Note: friction washers, Blade Brake Clutch (B.B.C.) units and other

such devices are not applicable. Only machines fitted with a genuine Hayter friction disc or

crankshaft support bearing, which are used in accordance with the recommended operating and

maintenance procedures, are covered.

This warranty does not apply to any unit that has been tampered with, altered, misused, abused or

used for hire, and will become invalid if non genuine Hayter parts are fitted. This warranty does

not cover for minor mechanical adjustments unless they are due to defective material or

workmanship. Consult the Owner's Handbook or a Hayter Authorised Service Dealer for

assistance when making these adjustments.

To make a warranty claim, return the unit to a Hayter Authorised Service Dealer along with proof

of purchase stating the machine serial number and date of purchase. Subject to the conditions and

exclusions in this limited warranty, the authorised dealer will, at our option, repair or replace any

warranted part within the duration of the warranty period.

This limited warranty gives you specific legal rights and is in addition to any statutory rights to

which you may be entitled and your statutory rights are not affected by this warranty. If you need

additional information concerning this written warranty, or assistance in obtaining services,

please write to : HAYTER LIMITED, Service Department, Spellbrook, Bishop's Stortford,

Hertfordshire CM23 4BU

UK ONLY: Details of your local Hayter authorised dealer are contained in Yellow Pages and the

Hayter Website www.hayter.co.uk or contact:- Freephone 0800 616298.

Issue: 26.03.99

Warranty 070199 (Harrier)

Page 32

Date of Sale:Your Local Dealer:-

Code Serial No.

Loading...

Loading...