Page 1

POWERTRIM

Code 407F

OWNER’S HANDBOOK

407F 310000001

Issue 10/2009

P .ON LAIRESEDOC ART NO: 111-3445 (Rev. A)

Page 2

TABLE OF CONTENTS

11

14

19

21

23

3

4

8

LIMITED WARRANTY

OPERATOR SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

TROUBLESHOOTING

SPECIFICATIONS

REPAIR PARTS

1739579

2

Page 3

LIMITED WARRANTY

Hayter Limited warrants to the original user / purchaser that this unit shall be free from defects in

material and workmanship under normal use and service for a period of three years from the

date of purchase. The manufacturers of the engine and battery pack system (where applicable)

furnish their own warranty and services are provided through their authorised network (Refer to

“Engine/Battery Pack Warranty Statement”). To qualify for the full benefit of the warranty, the warranty registration card must be returned within 60 days of purchase. Subject to the conditions and

exclusions noted in this limited warranty, we shall at our option, repair or replace any warranted

part during the applicable period. If you are in doubt or experience any difficulty, please consult a

Hayter Authorised Service Dealer for clarification..

To qualify for the extended warranty (second and third year) of the three year limited warranty, the

machine must have annual services carried out by an Authorised Hayter Service Dealer. These

chargeable services should be carried out within 12 and 24 months of the date of purchase.

Excluded from the extended warranty period are those items which are subject to normal wear

and tear e.g. tyres, wheels, cutterbars, cables, batteries and other consumable wearing parts.

All consumer machines which are fitted with a genuine Hayter friction disc as original equipment,

before use, are covered by a Lifetime Warranty against the engine crankshaft bending. Note:

friction washers, blade brake units and other such devices are not applicable. Only machines

fitted with a genuine Hayter friction disc, which are used in accordance with the recommended

operating and maintenance procedures, are covered.

This warranty does not apply to any unit that has been tampered with, altered, misused, abused

or used for hire, and will become invalid if non genuine Hayter parts are fitted. This warranty does

not cover minor mechanical adjustments unless they are due to defective materials or workmanship. Consult the Owner’s Handbook or a Hayter Authorised Service Dealer for assistance when

making these adjustments.

A warranty period of 90 days applies to machines used for commercial purposes.

To make a warranty claim, return the unit to a Hayter authorised dealer along with proof of purchase stating the machine serial number and date of purchase. The service receipt(s) or this

Owner’s Handbook with the 1st/2nd year service boxes fully completed, must be produced as

proof of entitlement to the extended warranty period. Subject to the conditions and exclusions in

this limited warranty, the authorised dealer will, at our option, repair or replace any warranted part

within the duration of the warranty period.

This limited warranty gives you specific legal rights and is in addition to any statutory rights to

which you may be entitled and your statutory rights are not affected by this warr

additional information concerning this written warranty, or assistance in obtaining services,

please write to:

HAYTER LIMITED,

Service Department,

Spellbrook,

Bishop’s Stortford,

Hertfordshire. CM23 4BU

anty. If you need

1st Year

Service

Record

Date . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . .

Signed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1739579

2nd Year

Service

Record

Date . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . .

Signed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

Page 4

OPERATOR SAFETY

OWNER’S INFORMATION

Know your product: If you understand the

unit and how the unit operates, you will get

the best performance. As you read this manual, compare the illustrations to the unit. Learn

the location and the function of the controls.

It is important that you read and understand

these original instructions thoroughly before

attempting to start or operate this equipment.

WARNING: Look for this symbol to indicate important safety precautions. This

symbol indicates: “Attention! Become

Alert! Your Safety Is At Risk.”

Responsibility Of The Owner

WARNING: This cutting machine

is capable of throwing objects.

Failure to observe the following

safety instructions could result in serious

injury to the operator or bystanders.

The responsibility of the owner is

to follow the instructions below.

SAFETY PRECAUTIONS

I. General Operation

1. Read, understand, and follow all instructions on the machine and in the manual(s). Be thoroughly familiar with the

controls and the proper use of the machine before starting.

2. Familiarize yourself with all of the safety

and operating decals on this equipment

and on any of its attachments or accessories.

3. Do not put hands or feet near or under

rotating parts.

4. Only allow responsible individuals, who

are familiar with the instructions, to operate the machine.

5. Thoroughly inspect the area where the

machine is to be used and remove all

foreign objects. Your equipment can

propel small objects at high speed causing personal injury or property damage.

Stay away from breakable objects, such

as house windows, automobiles, greenhouses, etc.

6. Keep the area of operation clear of all

persons, particularly small children, and

pets.

1739579

7. Wear appropriate clothing such as a

long−sleeved shirt or jacket. Also wear

long trousers. Do not wear shorts.

8. Do not wear loose clothing or jewelry.

They can be caught in moving parts.

9. Always wear safety goggles or safety

glasses with side shields when operating

the machine to protect your eyes from

foreign objects which can be thrown

from the unit.

10. Always wear work gloves and sturdy

footwear. Wear footwear that will improve footing on slippery surfaces. Do

not operate product when barefoot or

wearing open sandals. Leather work

shoes or short boots work well for most

people. These will protect the operator’s

ankles and shins from small sticks, splinters, and other debris.

11. It is advisable to wear protective headgear to prevent the possibility of being

struck by small flying particles, or being

struck by low hanging branches, twigs,

or other objects which may be unnoticed

by the operator.

12. Do not operate the machine without

proper guards or other safety protective

devices in place.

13. Use this

pose only.

. See manufacturer’s instructions for prop-

14

er operation and installation of accessories. Only use accessories approved by

the manufacturer.

15. Operate only in daylight or good artificial

light.

16. Do not operate product when fatigued or

under the influence of alcohol, drugs or

other medication which can cause

drowsiness or affect your ability to operate this machine safely.

17. Never operate machine in wet grass. Always be sure of your footing; keep a firm

hold on the handle and walk; never run.

18. Before each use, inspect the throttle

control lever and cable. Make sure that

the cable is free and that the lever is not

damaged. Also check the cable linkage

running to the carburetor for kinks, loose

fittings, and obstructions. Verify that the

control bail is working properly.

19. Stop the rotating trimmer head when

crossing gravel drives, walks, or roads.

Wait for the cutting lines to stop rotating.

20. Watch for traffic when operating near, or

when crossing roads.

4

equipment for its intended pur-

Page 5

OPERATOR SAFETY

21. Stop the engine whenever you leave the

equipment, before cleaning repairing or

inspecting the unit, be sure the trimmer

head and all moving parts have stopped.

Let the engine cool, disconnect the

spark plug wire and move it away from

the spark plug.

22. If the equipment should start to vibrate

abnormally, stop the engine, disconnect

the spark plug wire and prevent it from

touching the spark plug. Check immediately for the cause. Vibration is generally

a warning of trouble.

23. After striking a foreign object, stop the

engine. Remove the wire from the spark

plug. Inspect the machine for damage. If

damaged, repair before starting and operating the machine.

24. Never leave the machine unattended

when the engine is running. Remove

the wire from the spark plug.

25. Regularly inspect the machine. Make

sure parts are not bent, damaged or

loose.

26. Allow muffler and engine areas to cool

before touching. Never pick up or carry

the trimmer while the engine is running.

27. Prolonged exposure to noise and vibration

from petrol engine powered equipment

should be avoided. Take intermittent

breaks and/or wear ear protection from

engine noise as well as heavy work

gloves to reduce vibration in the hands.

II. Slope Operation

Slopes are a major factor related to slip and

fall accidents which can result in severe injury. All slopes require extra caution. If you feel

uneasy on a slope, do not trim it.

Do trim across the face of slopes; never up

and down. Do not trim excessively steep

slopes (maximum 15 degrees) or areas

where the ground is very rough. Exercise extreme caution when changing direction on

slopes.

Do remove objects such as rocks, tree limbs,

etc.

Do watch for holes, ruts, or bumps. Tall grass

can hide obstacles.

Do not trim near drop

bankments. The operator could lose footing

or balance.

1739579

−offs, ditches, or em-

Do not trim on wet grass. Reduced footing

could cause slipping.

III. Children

Tragic accidents can occur if the operator is

not alert to the presence of children. Children

are often attracted to the machine and the

trimming activity. Never assume that children

will remain where you last saw them.

1. Keep children out of the trimming area

and under the watchful care of a responsible adult.

2. Be alert and turn machine off if children

enter the area.

3. Before and while moving backwards,

look behind and down for small children.

4. Never allow children to operate the machine.

5. Use extra care when approaching blind

corners, shrubs, trees, or other objects

that may obscure vision.

IV. Service

1. Use extra care in handling petrol and

other fuels. They are flammable and vapors are explosive.

a. Use only an approved container.

b. Never remove gas cap or add fuel

with the engine running. Allow engine to cool before refueling. Do not

smoke.

c. Fill fuel tank outdoors with extreme

care. Never fill fuel tank indoors or

near appliances with pilot lights,

heaters, or other ignition sources.

Replace fuel tank cap securely. If

fuel is spilled, do not start the

engine but move product and fuel

container from area. Clean up

spilled fuel and allow to evaporate.

d. Never store the machine or fuel

container inside where there is an

open flame (such as a water

hea

ter), or other ignition source.

e. If the fuel tank has to be drained,

this should be done outdoors. The

drained fuel should be stored in a

container specifically designed for

fuel storage or it should be dis-

5

posed of carefully.

Page 6

OPERATOR SAFETY

2. Never run the engine indoors or inside a

closed area. The exhaust fumes are

dangerous, containing CARBON MONOXIDE, an ODORLESS and DEADLY

gas.

3. Never make adjustments or repairs with

the engine running. Disconnect the

spark plug wire, and keep the wire away

from the plug to prevent accidental starting. Always wear eye protection when

you make adjustments or repairs.

4. Check the trimmer head and engine

mounting bolts at frequent intervals for

proper tightness.

5. Keep all nuts and bolts tight and keep

equipment in good condition. Check

mounting hardware on trimmer head every time you change trimmer line and

prior to each use.

6. Never tamper with safety devices.

Check their proper operation regularly.

7. When servicing or repairing the machine, do not tip the machine over or up

unless specifically instructed to do so in

this Manual. Service and repair procedures can be done with the machine in

an upright position. Some procedures

will be easier if the machine is lifted on a

raised platform or working surface.

8. To reduce fire hazard, keep machine

free of grass, leaves, or other debris

build−up. Clean up oil or fuel spillage.

Allow machine to cool before storing.

9. Stop and inspect the equipment if you

strike an object. Repair, if necessary, before restarting.

10. Always disconnect spark plug wire before cleaning, repairing, or adjusting.

11. Do not change the engine governor setting or over−speed the engine.

12. Clean and replace safety and instruction

decals as necessary.

13. To guard against engine over−heating,

always have engine debris filter

mounted and clean.

14. Inspect trimmer before storage. When

not in use, disconnect spark plug lead

and store product indoors in a dry place

locked or otherwise inaccessible to children.

15. Use only original equipment or authorized replacement parts.

16. Never replace the cutting lines with metal parts.

1739579

6

Page 7

OPERATOR SAFETY

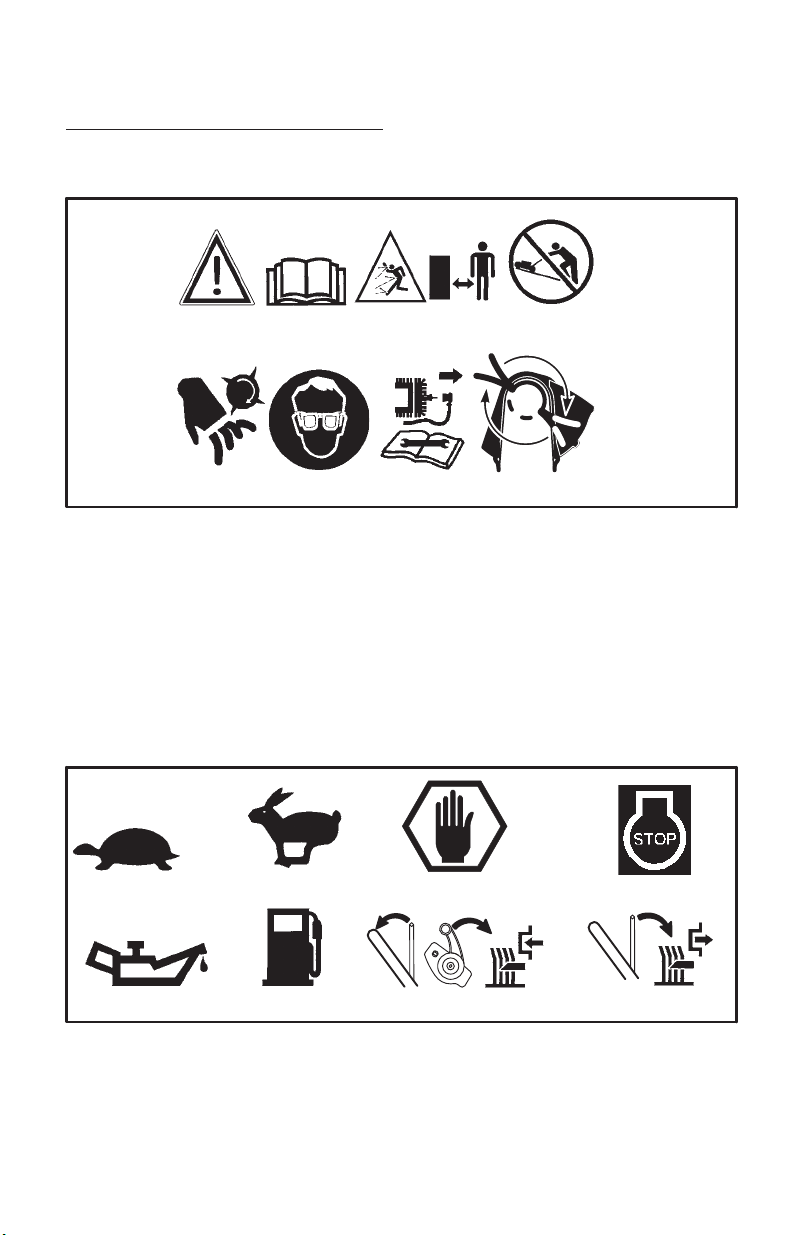

INTERNATIONAL PICTORIALS

IMPORTANT: The following pictorials are located on your unit or on literature supplied

with the product. Before you operate the unit, learn and understand the purpose for

each pictorial.

1 2

5

Safety Warning Pictorials

1 WARNING

2 IMPORTANT: Read Owner’s Manual

Before Operating This Machine.

3 WARNING: Thrown Objects. Keep

Bystanders Away. Read User

Instructions Before Operating This

Machine.

4 Do Not Trim Up And Down Slopes. Trim

Across Slopes.

1

6 7

2

3

4

8

5 WARNING: Rotating Parts. Stop Engine.

Disconnect Spark Plug Wire Before

Making Adjustments.

6 WARNING: Wear Eye Protection

7 DANGER: Disconnect Spark Plug Wire

Before Servicing Unit.

8 Direction of Rotating Line.

3

4

5

6

Control And Operating Pictorials

1 Slow

2 Fast

3 Engine Stop

4 Engine Stop

1739579

7

5 Oil

6 Fuel

7 Engage

8 Disengage

7

8

Page 8

ASSEMBLY

CONTENTS OF LITERATURE PACK

1 - Operator’s Manual

1 - Engine Manual

1 - Document of Conformity

1 - Warranty Card

1 - Safety Glasses

1 - Trimmer Line (2 Sets)

1 - Bag (4 Screws)

WARNING: Always wear safety

glasses or eye shields while assembling the machine.

TOOLS REQUIRED

1 − Knife to cut carton.

1 − Phillips Screwdriver.

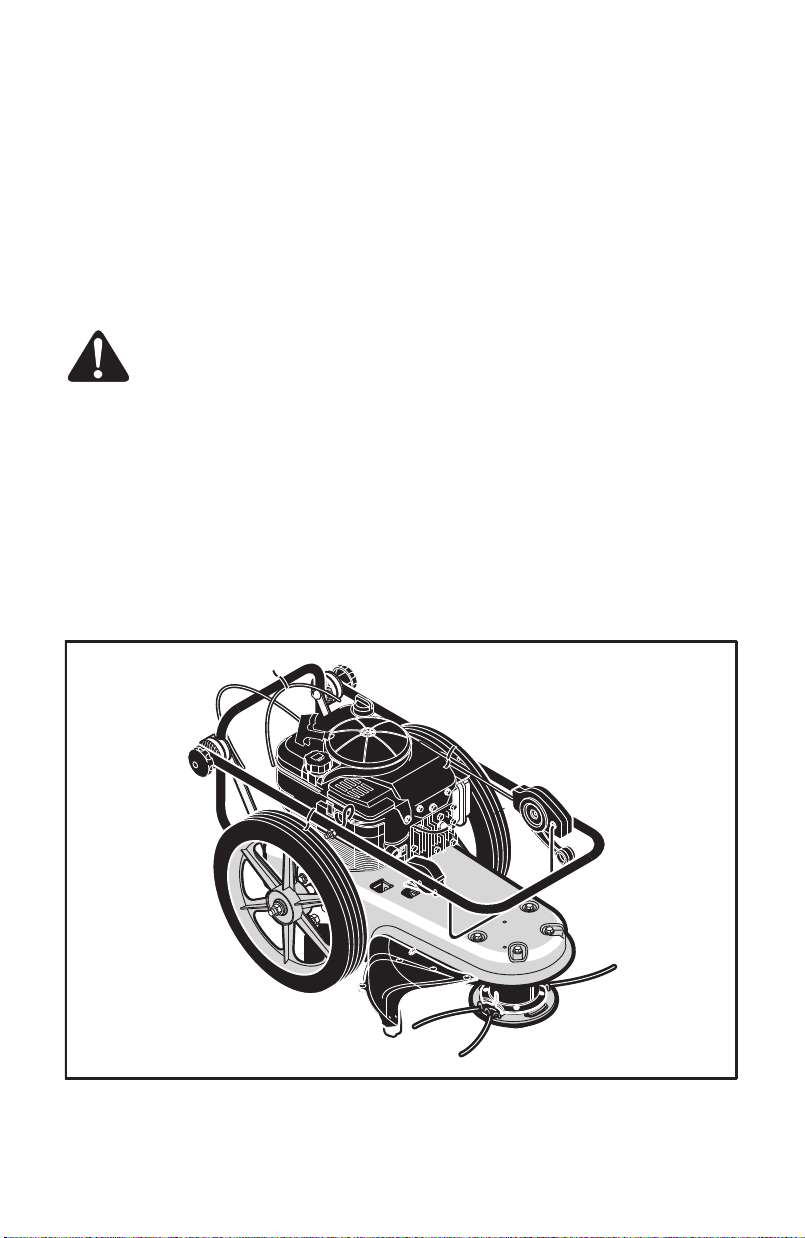

Figure 1 shows the machine completely assembled and positioned in the carton for shipment.

References to the right or left hand side of the

machine are from the viewpoint of the operator’s position behind the unit.

REMOVE THE TRIMMER

FROM CARTON

1. Remove the parts bag and any loose parts

from carton.

2. Remove the packing material positioned

around the unit.

3. Cut down all four corners of the carton and

lay the side panels flat.

4. Pull the trimmer out of the carton and off

the base pad.

5. Remove packing material from around the

trimmer head.

6. Remove protective plastic from front of

frame.

1739581

Figure 1

8

Page 9

ASSEMBLY

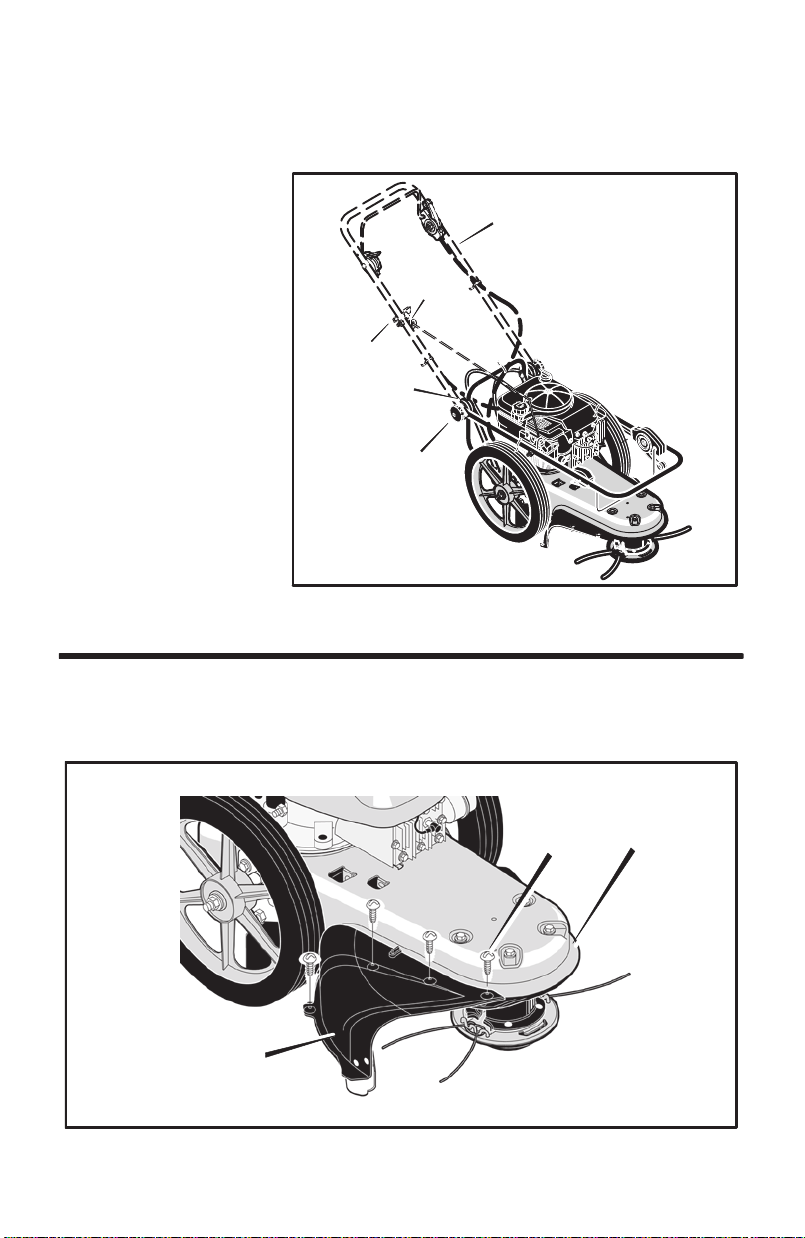

RAISE THE HANDLE

1. Hold the handle with one hand and loosen both handle adjustment knobs until the ratchet

teeth are disengaged. Do not remove the handle adjustment knobs. See Figure 2.

2. Raise the handle to the

operating position.

3. Stand in the operator’s

position behind the machine. Put the handle in

a comfortable position.

Make sure both sides of

the handle are level.

NOTE: Make sure the

cables are not caught

between the upper and

lower handle.

4. Tighten the handle adjustment knobs. Make

sure the handle pivots

are locked in place.

NOTE: The handlebar

height is adjustable.

See “How To Adjust

The Height Of The Handlebar” in the Maintenance section.

5. To attach the recoil start handle to the rope guide, twist the rope through

the rope guide mounted on the right side of the handlebar.

Recoil Start

Handle

Handle Adjustment

Handle

Pivot

Knob

Rope

Guide

Handle

Figure 2

ATTACH THE GUARD

1. Attach the guard to the machine with the

four fasteners as shown. See Figure 3.

Guard

1739579

Fastener

9

Trimmer

Figure 3

Page 10

ASSEMBLY

ENGINE PREPARATION

Note: Engine does not contain OIL or

PETROL.

WARNING: Follow the engine

manufacturer’s instructions for

the type of petrol and oil to use.

Always use a safety petrol container. Do

not smoke when adding petrol to the engine. When inside an enclosure, do not

fill with petrol. Before you add petrol,

stop the engine. Let the engine cool for

several minutes.

See the engine manufacturer’s instructions

for the type of petrol and oil to use. Before

you use the unit, read the information on

safety, operation, maintenance, and storage.

Note: Actual sustained horsepower will

likely be lower due to operating limitations and environmental factors.

Fill Crankcase With Oil

1. Remove the oil fill cap/dipstick shown in

Figure 4. Fill the crankcase to the FULL

line on oil fill cap/dipstick. DO NOT OVER-

FILL.

2. Install the oil fill cap/dipstick and tighten

securely.

Fill Fuel Tank With Petrol

See the engine manufacturer’s instructions for

the type of petrol to use.

Oil Fill

Cap/Dipstick

Fuel

Cap

Figure 4

CHECKLIST

For the best performance and satisfaction

from this quality product, please review the following checklist before you operate the machine:

All assembly instructions have been

completed.

Check carton. Make sure no loose parts

remain in the carton.

1739579

As you learn how to use the machine, pay extra attention to the following important items:

Engine oil is at correct level.

Fuel tank is filled with fresh, clean, regular unleaded petrol.

Become familiar and understand the

function of all controls. Before you start

the engine, operate all controls.

10

Page 11

OPERATION

KNOW YOUR POWERTRIM

READ THE OWNER’S HANDBOOK AND ALL SAFETY RULES BEFORE YOU OPERATE the

machine. To familiarise yourself with the location of the controls, compare the illustrations with your

machine. Save this handbook for future reference.

Control Bail

Upper Handle

Throttle Control Lever

Recoil Starter Handle

Handle Adjustment Knob

Fuel Cap

Shield Edge Guard

Trimmer Head Drive Lever

Trimmer Head Drive Lever − Engages

the rotation of the trimmer head.

Control Bail − Release to stop the rotation

of the trimmer head.

Dipstick

Debris Screen

Trimmer Head

Trimmer Line

Figure 5

Throttle Control Lever − Controls the

speed or stops the engine.

Recoil Starter Handle − The engine is

equipped with an easy pull recoil starter.

EYE PROTECTION

WARNING: Debris thrown from

the machine can result in

foreign objects being thrown

into the eyes, which can cause severe

eye damage. Always wear safety

glasses or eye shields when operating

the machine.

Always wear safety glasses. If you wear eye

glasses, put a Wide Vision Safety Mask over

your eye glasses.

1739579

STOP THE TRIMMER HEAD

1. Release the control bail. It will return to its

open position and disengage the trimmer

head.

STOP THE ENGINE

WARNING: The trimmer head will

continue to rotate for several seconds after the engine has

stopped

1. Move the throttle control lever completely back to the STOP position.

11

Page 12

OPERATION

USE THE TRIMMER HEAD

DRIVE LEVER

1. To engage the trimmer head, hold the control bail against the handle. Move the

trimmer head drive lever forward to en-

gage the trimmer head. See Figure 6. The

faster the engine runs, the faster the trimmer head will rotate.

2. Once the trimmer head is rotating, push

the machine forward to trim.

USE THE THROTTLE CONTROL

1. During normal use, set the throttle control lever in the FAST position to run the

engine at full speed.

2. Pull the throttle control lever back to decrease engine speed. Push the throttle

control lever forward to increase engine

speed.

Control Bail

Handlebar

Trimmer Head

Drive Lever

Figure 6

3. To stop the engine, pull the throttle con-

trol lever completely back to the STOP

position.

USE THE PRIMER BUTTON

1. Push the primer button. See Figure 8 for

location. For the number of times to push

the primer button, see the primer button

decal located on the engine or follow the

directions in the Engine Manual. Wait

approximately two seconds between each

push.

NOTE: Do not use the primer button to restart a warm engine after a short shutdown.

1739579

12

Throttle Control

Lever

Figure 7

Primer

Button

Figure 8

Page 13

OPERATION

START THE ENGINE

NOTE: DO NOT BE ALARMED, your engine

will smoke the first time it is started. It is

burning off the protective coating that is on

the internal engine parts.

WARNING: Never leave the machine unattended while the engine is running. Wait for the trimmer lines to stop rotation.

1. Before each use, remove debris from the

debris screen shown in Figure 5. Debris

can cause the engine to overheat. Wipe

the debris screen with a cloth or paper

towel.

2. Move the throttle control lever forward to

the START or FAST position.

3. To start a cold engine, push the primer button five times. Wait two seconds between

each push of the primer button.

NOTE: Do not use the primer to start a

warm engine.

4. Firmly hold the recoil starter handle with

your right hand. See Figure 9.

5. Pull back sharply on the recoil starter

handle. DO NOT allow the starter rope to

snap back. Let the starter rope slowly rewind as you hold the recoil starter handle.

NOTE: If engine fails to start after three

pulls, push the primer button two times and

again pull the recoil starter handle.

WARNING: Never run the engine

indoors or in a poorly ventilated

area. Engine exhaust contains

carbon monoxide, an odorless

and deadly gas. Keep hands,

feet, hair and loose clothing

away from the machine and any

moving parts on the engine.

Avoid the muffler and surrounding areas. Temperatures may exceed 150

Recoil Starter Handle

F.

Figure 9

TRIMMER TIPS

WARNING: Debris such as sticks,

gravel or stones, can be thrown

with sufficient force to cause personal injury or property damage.

Set the throttle control in the FAST position. If the weeds or grass are tall and

thick, operate the machine at a slower

walking speed.

Frequently clean the underside of the machine to remove any grass build up.

For best results and longer lasting line,

use the ends of the line to do the cutting.

This is easily done by moving slowly

through very thick or heavy weeds.

If the trimmer lines become too short, it will

1739579

take longer to complete the job. If the trimmer lines are worn to less than half their

original length, change to a new trimmer

line. “See How To Change The Trimmer

Line” in the Maintenance section.

Do not trim on excessively steep slopes. If

a slope is difficult to stand on, do not trim.

Do not trim on slopes when the ground is

slippery or wet. Trim across the face of a

slope, not up and down.

Trimming may be done at slower engine

speeds especially when trimming around

flowers, shrubs, and small trees. Operating at slower speeds will also reduce engine noise and vibration at the upper

handle.

13

Page 14

SERVICE RECORDS

Fill in dates as you

complete regular service.

MAINTENANCE

Before

Each

Use

Every

5

Hours

Every

25

Hours

Every

100

Hours

As

Noted

SERVICE

DATES

Check Engine Oil Level

Check Trimmer Lines

Check Trimmer Head

Engagement

Engine/Machine Cleaning

Check Nuts and Bolts

Check Spark Plug

Change Engine Oil

Service Air Filter

Lubricate Jackshaft Assembly

Lubricate Wheel Bearings

Note 1 − When old line is half the original length, replace with new line.

Note 2 − Clean daily if used in extremely dusty or dirty conditions.

Note 3 − Change more often if used in extremely dusty or dirty conditions.

√

√

√

√

√

√

√

√

√

√

1

2

3

1739579

14

Page 15

LUBRICATION

MAINTENANCE

Lubricate the Jackshaft Assembly

A grease fitting is provided to lubricate the

jackshaft assembly. Use a grease gun with automotive type grease to lubricate the jackshaft

assembly as shown in Figure 10.

Change Engine Oil

Change the engine oil when the engine is

warm. For the proper oil capacity, see the engine manufacturer’s instructions.

1. Disconnect spark plug wire from the spark

plug.

2. Remove the oil drain plug as shown in

Figure 11.

3. Drain all the engine oil into a flat pan.

4. Install the oil drain plug. Make sure the

oil drain plug is tight.

5. Remove the dipstick.

6. Fill the engine crankcase. DO NOT

OVERFILL. For proper oil capacity, see

the engine manufacturer’s instructions.

Grease Fitting

Figure 10

7. Connect the spark plug wire to the spark

plug.

Oil Drain Plug

Figure 11

1739579

15

Page 16

MAINTENANCE

SPARK PLUG

Check the spark plug every 25 hours. Replace the spark plug if the electrodes are

pitted or burned or if the porcelain is cracked.

1. Make sure the spark plug is clean. Clean

the spark plug by carefully scraping the

electrodes (do not sand blast or use a wire

brush).

2. Check the spark plug gap with a feeler

gauge. See “Product Specifications” for

the correct spark plug gap and replacement spark plug.

3. Before installing the spark plug, coat the

threads lightly with oil for easy removal.

ADJUST THE HEIGHT OF

THE HANDLEBAR

Use the knobs, on each side of the handlebar, to adjust the height of the handlebar.

1. Hold the handlebar with one hand and

loosen both knobs until the ratchet teeth

are disengaged. Do not remove the

knobs. See Figure 13.

2. Move the handlebar up or down to the de-

sired position, then align the ratchet

teeth. Make sure both sides of the handlebar are level.

3. Tighten the knobs.

Tighten the spark plug to a torque of 15

foot−pounds.

Feeler Gauge

0.030”

Spark Plug

Figure 12

Handlebar

Ratchet

Teeth

1739579

Knob

Figure 13

16

Page 17

MAINTENANCE

SERVICE AND ADJUSTMENT

WARNING: Before you inspect, clean or service the machine, stop the engine.

Make sure that all moving parts have stopped. Disconnect the wire from the

spark plug.

PROPER CARE OF TRIMMER LINE

For the best performance, use a heavy

gauge 3.9mm (0.155” diameter) trimmer

line. Cut the length of the trimmer line to

52cm (21.5 inches). Do not allow the length

of the lines to vary more than one inch. This

is important to make sure the trimmer head

is balanced and does not vibrate.

CHANGE TRIMMER LINES

When the trimmer line becomes worn to half the original length, replace the trimmer line as

follows:

IMPORTANT: To extend the life of the trimmer line, keep the trimmer line moist. If not

kept moist, the nylon trimmer line will become dry and brittle. Keep extra trimmer

line in a can of water. The line will then stay

flexible and easy to change. A flexible line

will also last much longer.

Line

Retainer

1. Stop the engine. Wait for

all moving parts to stop.

2. Remove worn trimmer

line from line retainer.

3. First, thread the ends of

the new trimmer line

through the outside

loops.

1739579

Trimmer

Line

Line

Retainer

4. Next, take the ends of the

line, cross over the line

retainer, and thread the

ends through the centre

hole.

17

5. Then, check to make

sure that the ends of the

line are even.

Page 18

MAINTENANCE

REPLACE THE DRIVE BELT

To replace the drive belt, see an authorized service center.

STORAGE

WARNING: Do not remove petrol

while inside a building, near a

fire, or while you smoke. Petrol

fumes can cause an explosion or

a fire.

When the machine is put in storage for thirty

days or more, follow the steps below to

make sure the machine is in good condition

the following season.

Trimmer

Completely clean the machine.

Put the machine in a building that has

good ventilation.

Engine

To prevent engine damage when the machine is in storage for 30 days or more, follow the steps below:

Let the engine run until it is out of petrol.

Drain the oil from the warm engine. Fill the

engine crankcase with new oil.

Remove the spark plug from the cylinder.

Pour one ounce of oil into the cylinder.

Slowly pull the recoil starter handle so that

the oil will protect the cylinder. Install a new

spark plug in the cylinder.

Clean dirt and debris from the cylinder

cooling fins and the engine housing.

1739579

18

Page 19

TROUBLESHOOTING CHART

TROUBLE CAUSE CORRECTION

Engine does not start. Spark plug wire

disconnected.

Engine not primed. Prime engine.

Defective or incorrectly

gapped spark plug.

Fuel tank empty. Add fuel.

Dirty carburetor or fuel line. Clean carburetor or fuel line.

Dirty air filter. Replace air filter.

Carburetor out of adjustment. See authorized dealer.

Engine flooded. Wait several minutes before

Throttle control lever in

incorrect position.

Stale fuel. Drain old fuel and add

Engine runs poorly. Bad spark plug. Replace spark plug.

Dirty air filter. Replace air filter.

Carburetor out of adjustment.

Connect spark plug wire.

Inspect or replace spark

plug.

starting.

Move throttle lever to FAST

or START position.

fresh fuel.

See authorized dealer.

1739579

Stale fuel. Drain old fuel. Add fresh

fuel.

19

Page 20

TROUBLESHOOTING CHART

Engine overheats. Engine cooling system

Engine will not stop

running.

Poor trimming

performance.

Trimmer vibrates.

Trimmer head does not

retain line.

clogged.

Carburetor out of adjustment. See authorized dealer.

Oil level is low. Add oil.

Defective throttle control

lever or wire.

Trimmer line length is too

short.

Engine not set at FAST

speed.

Trimmer line lengths are

substantially different.

Loose nuts or bolts. See authorized dealer.

Broken trimmer head. See authorized dealer.

Trimmer line not properly

attached.

Broken line retainer. See authorized dealer.

Trimmer line not correct size. Use 3,9 mm (0.155 inch)

See authorized dealer.

See authorized dealer.

Correct line length is 52 cm

(21,5 inches). When less

than 1/2 this length, replace

the line.

Move engine throttle lever to

FAST position.

Adjust trimmer line to

approximately equal lengths.

Follow instructions on decal

or see Maintenance section

in this manual.

diameter trimmer line.

1739579

20

Page 21

SPECIFICATIONS

Trimmer Line Diameter 3,9 mm (0,155”)

Trimmer Line Length 520 mm (21,5”)

Height of Cut (Fixed) 76 mm (3”)

Dimensions 1400 x 555 x 1000

Engine Briggs 122T02-0188-B1

KW 2,56

Displacement 190 cc (11,57 cu in.)

Petrol Capacity 0,95 L (1,0 quarts)

Oil Capacity 0,54 - 0,59 L (18-20 oz)

Spark Plug Champion RJ−19LM

Spark Plug Gap 0,76 mm (0.030 in.)

Weight 34 kg (75 lbs)

Engine Power Rating Information

The gross power rating for individual gas engine models is labeled in accordance with

SAE (Society of Automotive Engineers) code J1940 (Small Engine Power & Torque Rating

Procedure), and rating performance has been obtained and corrected in accordance with

SAE J1995 (Revision 2002-05). Torque values are derived at 3060 RPM; horsepower values

are derived at 3600 RPM. Actual gross engine power will be lower and is aected by,

among other things, ambient operating conditions and engine-to-engine variability.

Given both the wide array of products on which engines are placed and the variety of

environmental issues applicable to operating the equipment, the gas engine will not

develop the rated gross power when used in a given piece of power equipment (actual

"on-site" or net power). This dierence is due to a variety of factors including, but not

limited to, accessories (air cleaner, exhaust, charging, cooling, carburetor, fuel pump,

etc.), application limitations, ambient operating conditions (temperature, humidity,

altitude), and engine-to-engine variability. Due to manufacturing and capacity

limitations, Briggs & Stratton may substitute an engine of higher rated power for

this Series engine.

1739579

21

Page 22

Order Replacement Parts

Replacement parts, except for the engine, transmission, transaxle or differential,

are available from your local Hayter authorised dealer, the store where the

mower was purchased or a service shop recommended by the store.

If you are unable to obtain parts or service in the manner outlined above, then

contact:

HAYTER LIMITED,

Service Department,

Spellbrook,

Bishop’s Stortford,

Hertfordshire. CM23 4BU

1739579 22

Page 23

Repair Parts

PTS - 1

Page 24

Handle And Wheels

PTS - 2

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

POWERTRIM Code 407F

Page 25

Handle And Wheels

PTS - 3

PART NO. DESCRIPTIONREF NO QTY.

POWERTRIM Code 407F

LEVER, Stop 1 MU740198E701MA

BOLT 2 MU323035MA

CABLE, Control Latching 3 MU740193MA

TIE, Cable 4 MU071372MA

HANDLEBAR 5 MU740196E701MA

NUT 6 MU15X116MA

CONTROL, Throttle 7 MU1601039MA

GUIDE, Rope 8 MU672510MA

KNOB, Handlebar 9 MU740202MA

WASHER 10 MU783000MA

WASHER, Spring 11 MU711936MA

BOLT 12 MU711937MA

PIVOT, Handlebar 14 MU740158MA

HANDLEBAR, Lower 15 MU740195E701MA

WHEEL & TIRE 16 MU740185MA

NUT, Axle 17 MU015X84MA

WASHER 18 MU0020X3MA

SPACER 19 MU740190MA

ASSEMBLY, Axle & Bracket 20 MU740188MA

SCREW 21 MU26X274MA

BOLT, Carriage 22 MU711935MA

DECK 23 MU740150E701MA

BOLT 24 MU0025X6MA

SHIELD, Trailing 25 MU740192MA

BOLT 26 MU001X45MA

SCREW 27 MU26X267MA

ENGINE (Engine Model: 122T02-0188-B1) 28 122T02-0188-B1

PROTECTION, Eye 29 MU711890MA

NUT 30 MU015X88MA

SUPPORT, Handle 31 MU1601040MA

SCREW 32 MU26X268MA

CLAMP, Throttle 33 MU690798

DECAL, Engine Stop 34 MU712409MA

DECAL, Powertrim (Not shown) -- MU407002YP

DECAL, Hayter (Not Illustrated) -- MU410087YP

DECAL, Warning (Not shown) -- MU713006MA

DECAL, Control Instructions (Not shown) -- MU712409MA

INSTRUCTION BOOK & PARTS LIST -- MU1739579

Footnotes

Page 26

Cutting Head And Shield

PTS - 4

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

POWERTRIM Code 407F

Page 27

Cutting Head And Shield

PTS - 5

PART NO. DESCRIPTIONREF NO QTY.

POWERTRIM Code 407F

NUT 1 MU015X84MA

SCREW 2 MU025X11MA

FRAME, Trimmer 3 MU740150E701MA

SCREW 4 MU26X256MA

BRACKET, Idler Assembly 5 MU740232MA

BOLT 6 MU009X48MA

SPRING 7 MU712403MA

SPACER 8 MU740292MA

NUT 9 MU15X119MA

WASHER 10 M710083MA

PULLEY, Cutting Head 11 MU740171MA

SPACER 12 MU740173MA

BELT 13 MU711933MA

PULLEY, Idler 14 MU740244MA

PULLEY, Engine 15 MU740179MA

PULLEY, Idler 16 MU740183MA

LOCKWASHER 17 MU018X31MA

BOLT 18 MU001X20MA

SCREW 19 MU26X235MA

GUARD ASSEMBLY 20 MU770070MA

GUARD 22 MU740206MA

SCREW 23 MU26X294MA

JACKSHAFT HOUSING ASSEMBLY 24 MU1001049MA

SHAFT, Cutting 25 MU740300MA

WRAP, Upper Head 26 MU740163MA

SCREW 27 MU712126MA

CUTTING DISC ASSEMBLY 29 MU770037MA

SCREW, Set 30 MU712127MA

LINE, Cutting 31 MU740165MA

GUIDE ASSEMBLY, Metal Height 33 MU740299MA

Footnotes

Page 28

Hex Head Capscrew

Hex Nut

Lockwasher

Washer

Carriage Bolt

Hardware Identification & Torque Specifications

Screw, 1/2 x 2

Body

Diameter

Body

Length

Inside

Diameter

Nut, 1/2”

3/8” Bolt or Nut

Wrench—9/16”

3/8

5/16” Bolt or Nut

Wrench—1/2”

5/16

1/4” Bolt or Nut

Wrench—7/16”

1/4

1/2” Bolt or Nut

Wrench—3/4”

1/2

DIA.

7/16

DIA.

7/16” Bolt or Nut

Wrench (Bolt)—5/8”

Wrench (Nut)—11/16”

Wrench & Fastener Size Guide

0

1/4 3/4

1/2

1

1/4 3/4

1/2

2

1/4 3/4

1/2

3

1/4 3/4

1/2

4

PTS - 6

Common Hardware Types

Standard Hardware Sizing

When a washer or nut is identified as 1/2”, this is the

Nominal size

second number is present it represent the

When bolt or capscrew is identified as 1/2 - 16 x 2”, this

means the

second number represents the

example, and the final number is the

bolt or screw (in this example 2 inches long).

The guides and ruler furnished below are designed to

help you select the appropriate hardware and tools.

, meaning the

Nominal size

, or

inside diameter

body diameter

threads per inch

body length

is 1/2 inch; if a

threads per inch

is 1/2 inch; the

(16 in this

of the

Torque Specification Chart

FOR STANDARD MACHINE HARDWARE (Tolerance ± 20%)

Hardware

Grade

Size Of

Hardware ft/lbs Nm. ft/lbs Nm. ft/lbs Nm.

8-32

8-36

10-24

10-32

1/4-20

1/4-28

5/16-18 11 15.0 17 23.1 25 34.0

5/16-24 12 16.3 19 25.8 27 34.0

3/8-16 20 27.2 30 40.8 45 61.2

3/8-24 23 31.3 35 47.6 50 68.0

7/16-14 30 40.8 50 68.0 70 95.2

7/16-20 35 47.6 55 74.8 80 108.8

1/2-13 50 68.0 75 102.0 110 149.6

1/2-20 55 74.8 90 122.4 120 163.2

9/16-12 65 88.4 110 149.6 150 204.0

9/16-18 75 102.0 120 163.2 170 231.2

5/8-11 90 122.4 150 204.0 220 299.2

5/8-18 100 136 180 244.8 240 326.4

3/4-10 160 217.6 260 353.6 386 525.0

3/4-16 180 244.8 300 408.0

7/8-9 140 190.4 400 544.0 600 816.0

7/8-14 155 210.8 440 598.4 660 897.6

1-8 220 299.2 580 788.8 900 1,244.0

1-12 240 326.4 640 870.4 1,000 1,360.0

1. These torque values are to be used for all hardware

excluding: locknuts, self-tapping screws, thread forming

screws, sheet metal screws and socket head setscrews.

2. Recommended seating torque values for locknuts:

a. for prevailing torque locknuts - use 65% of grade 5

b. for flange whizlock nuts and screws - use 135% of

3. Unless otherwise noted on assembly drawings, all torque

values must meet this specification.

No

Marks

SAE Grade 2 SAE Grade 5 SAE Grade 8

in/lbs in/lbs

19

2.1

30

20

27

31

66

76

torques.

grade 5 torques.

2.3

3.1

3.5

7.6 8 10.9 12 16.3

8.6 10 13.6 14 19.0

NOTES

3.4

31

3.5

43

4.9

49

5.5

in/lbs

41

43

60

68

420 571.2

4.6

4.9

6.8

7.7

P

Page 29

Page 30

Loading...

Loading...