Page 1

Solar Mower

Workshop Manual

101 88 90-26

Page 2

LIST OF CONTENTS

!

!

!

!

WARNING!

This tool can be dangerous if used incorrectly.

Warnings and safety instructions in this

Workshop Manual must be followed carefully

for the tool to be used safely and efficiently.

WARNING!

Keep hands and feet away from the rotating

blades.

Never place your hands or feet close to, or

under the cutting deck’s cover before you

have checked that the power switch is off and

that the motor has stopped.

WARNING!

Do not permit anyone who does not know how

the lawn mower works or behaves to carry out

repairs on the lawn mower.

WARNING!

Under no circumstances may the lawn mower’s original design be modified without the

permission of the manufacturer. Always use

genuine spare parts. Non authorised modifications and/or components can result in serious

disruptions and the risk of personal injury.

List of Contents

Safety instructions

User safety .......................................................................... 2

Tool safety ........................................................................... 2

Working safety..................................................................... 2

Technical data

Technical data ..................................................................... 3

What is what?...................................................................... 3

Trouble shooting

General trouble shooting tips .............................................. 4

Solar panels ........................................................................ 4

Motor and cutting disc ......................................................... 5

Drive motors ........................................................................ 6

Sensors ............................................................................... 6

Moisture sensor................................................................... 6

Microswitches (Collision detectors) ..................................... 7

Cables ................................................................................. 7

Batteries .............................................................................. 7

Keyboard ............................................................................. 8

Generator and loop cable.................................................... 8

Circuitboard with CPU ......................................................... 9

Buzzer ................................................................................. 9

Main power switch............................................................... 9

Magnetic switch................................................................... 9

Start-up sequence ............................................................. 10

Trouble shooting chart....................................................... 11

Circuit diagram

Circuit diagrams ................................................................ 13

IMPORTANT!

Read through the Workshop Manual carefully and understand the contents before

starting to carry out any repairs. Follow all

directions.

English – 1

Page 3

SAFETY INSTRUCTIONS

User safety

• Read carefully through this Workshop Manual to understand

all the repair directions.

• Check that there are no stones, twigs, tools or other objects,

which can damage the blades, on the lawn to be used as a

test surface.

• Those not familiar with how the lawn mower works or behaves

should not be allowed to repair the tool. They should not be

allowed to be within the vicinity of, or in the lawn mowers

working area when the mower is activated.

• Never permitted anyone to touch the lawn mower when in use.

• Never use the lawn mower

with damaged panels,

covers or cables.

• Never use the lawn

mower if the power

switch does not work.

Working safety

WARNING! Always switch off the lawn mower

using the power switch before inspecting,

!

• Never move the lawn mower with the rear panels folded down.

Switch off the lawn mower using the power switch when

moving outside of the cutting area or if maintenance shall be

carried out.

• Always wait until the blades have stopped. Carry it by using

the handle and with the rear panels folded up.

• When moving over short distances the lawn mower can be

switched off by folding up the rear solar panel and waiting until

the blades have stopped. Carry it by using the handle and with

the rear panel folded up.

• Never use the lawn mower with defective covers, screws, nuts

or cables.

• Start the lawn mower according to the instructions. Keep

hands and feet away from the rotating blades. Never place

your hands or feet under the solar panels.

• Do not stand in front of the lawn mower when you start it, also

ensure than no one else is standing in front of the lawn

mower.

cleaning or carrying out repairs.

Tool safety

WARNING!

Always switch off the lawn mower using the

!

• Replace damaged parts. Check especially that the blades and

cutting disc are not damaged. Change all the blades at the

same time so that rotating parts are balanced.

• The lawn mower contains environmentally hazardous batteries. In accordance with applicable laws regarding spent

batteries: These must not be thrown in household waste or

mixed with industrial waste. Those who professionally sell

batteries or such equipment where such batteries are included, are obliged to accept spent batteries and thereafter

leave then to an approved authority for disposal.

power switch before inspecting, cleaning or

carrying out repairs. The batteries should

always be disconnected when carrying out

maintenance or repairs to the lawn mower’s

internal components. The only exception is

when current or voltage needs to be measured. Extra care should then be exercised.

• Never lift up the lawn mower or carry it around when it is

running.

• Always switch off the lawn mower using the power switch

before inspecting or cleaning the underside or carrying out

repairs.

Care and storage safety

• Store the lawn mower in an area that is dry but not too warm,

otherwise damage can be caused to the solar panels and

batteries.

• During the winter the lawn mower should be stored in a dry

place, preferably in the original packaging or parked on all four

wheels, with the power switch off and the batteries disconnected.

Transport safety

• Fold up the rear section of the solar panel and switch off the

power switch when transporting the lawn mower. Use the

original packaging when transporting the lawn mower over

longer distances.

2 – English

Page 4

TECHNICAL DATA

Technical data

Batteries NiCd

Cutting system Cutting disc with three flexible blades

Wheels Front wheels with stainless steel bearings

Height control Variable, 30 - 60 mm

Weight 6.5 kg

Length/Width/Height 105cm/63cm/22cm

2

Working capacity 1200 m

+- 20%

7

18

2

3

1

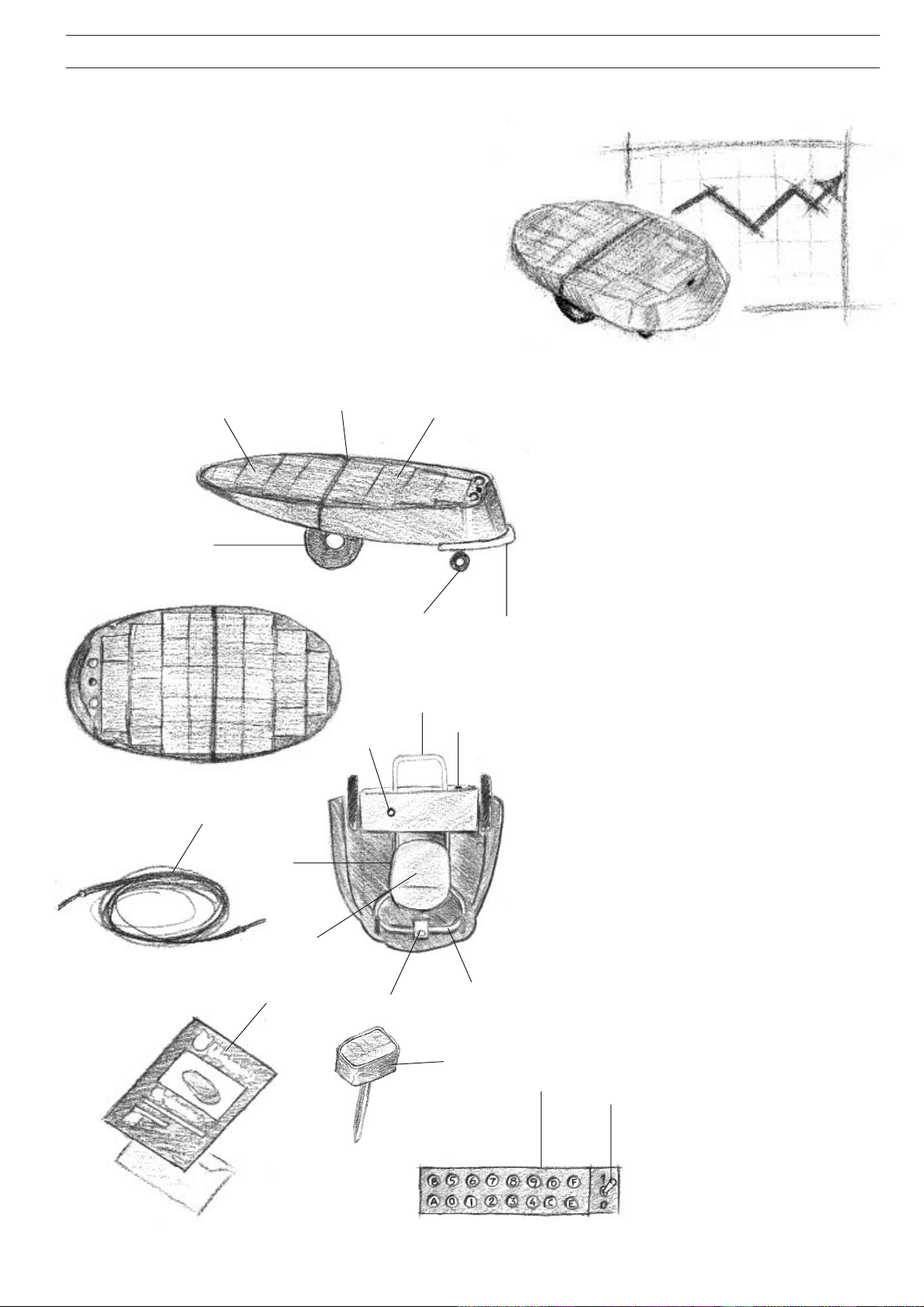

What is what?

1. Front solar panel

2. Rear solar panel

3. Hinge

4. Bumper

5

8

10

9

4

5. Front wheels

6. Cutting disc

7. Drive wheel

8. Handle and rear panel support

9. Moisture sensor

10. Electronic controller with microprocessor

11. Protective plate

12. Frame

6

17

11

15

13. Keyboard

14. Power switch

15. Sensor

16. Generator

17. Operator’s Manual with code

12

18. Loop cable

16

13

14

English – 3

Page 5

TROUBLE SHOOTING

General trouble shooting tips

The dealer should have a test lawn of a least 5 x 5 m, surrounded by a loop cable and generator. This test lawn can be

used in those cases where the customer has a problem with

the lawn mower not detecting signals from the loop cable.

Thereby making it possible to determine whether the operating

disruptions are due to metal objects or electrical power lines in

the customer's garden.

So called “islands“ (see the diagram below), which are formed

with a loop around flowerbeds, fountains, etc. should be routed

in the loop cable’s direction and have a diameter of at least 2 m

(see the Operator’s Manual) to ensure its function. If the

commands F1-9 are changed to increase sensitivity then

smaller “islands“ can also be made, carry out tests before

burying the loop cable.

Solar panels

A number of solar panels connected together transform daylight

into electrical energy. This electrical energy drives the lawn

mower and charges the batteries.

When the lawn mower is in the sun its rays are sufficient to

drive the lawn mower and charge the batteries.

The microprocessor is also used to measure the voltage levels

from the solar panels, and thereby determine whether the lawn

mower has gone into the shade or whether dusk is approaching.

In the evening, when the light intensity is too low, the lawn

mower stops and signals with 1 beep every 10 seconds. This

indicates the night mode.

All trouble shooting should be preceded by at least 1 hour of

charging (with the switch in the off position) outdoors in the

middle of the day, to eliminate the fault being badly charged

batteries.

Read through the entire Workshop Manual and the Operator’s

Manual to determine whether the fault is easily rectified via the

keyboard or with the main power switch.

If the lawn mower avoids the shade during the day, it is because the batteries at the present time do not have sufficient

capacity and to also ensure a long operating time. Large

amounts of sun (sunny weather) allow the mower to charge fully

before it starts to move, while small amounts of sun (cloudy)

means that it charges a little and then moves hoping to find a

sunnier part of the lawn.

If the lawn mower frequently stops to charge in the shadow, this

is a sign that the batteries are deficient.

To check the operation of the solar panels the jointing sleeves

535 03 86-01 should be dismantled and the current from the

front and rear solar panels should be measured.

535 03 86-01

The panel's connection cables should be connected as follows:

The red cable from the box to the red cable from the front of the

body (suitable length 85 mm).

The black cable from the box to the black cable from the rear of

the body (suitable length 55 mm).

The black cable from the front of the body to the red cable from

the rear of the body (suitable length 70 mm).

4 – English

When the panels are connected together (in series) the cable

runs to the box and is connected to the connector X1 at terminals

6 (black) and 7 (red). See the circuit diagram on the last page.

As the light intensity can vary a great deal it is difficult to specify

an exact current, however, if a different current is measured from

the front and rear solar panels at the same time, you may

presume that the panel that generates the lowest current is faulty.

Page 6

TROUBLE SHOOTING

The panel can still work despite one of the segments being

damaged, but then gives a lower capacity. This can mean that

the machine frequently stands still and charges, even on very

sunny days. Or the lawn mower can stand still and beep once

every 10 seconds, which is the night mode signal, despite it

being the middle of the day.

No objects should be placed on top the panels for these to give

maximum electrical energy. Panels should be cleaned using a

damp sponge and a soap solution/hand washing up detergent

when surfaces are dusty or dirty and during the pollen season

or with similar daily soiling.

Motor and cutting disc

A 12V AC motor with controlled speed (max 2500 r/min) is used

as the cutting motor. The cables from the motor are connected

to connector X1 on the terminals 1-5 on the circuitboard in the

box. Registration of the motor speed is made by using a

tachometer which sends signals to the microprocessor on the

circuitboard in the box.

The speed measurement is made to “measure“ the length of the

grass (mowing resistance).

If the mowing resistance momentary exceeds the mean value

for the last few minutes the lawn mower can move in a spiral

pattern, to mow areas that have longer grass than average.

When the lower mower senses a drastic reduction in the

mowing resistance, or if an obstacle comes in its way, it returns

to its normal movement pattern.

Great care should be exercised when handling the panels due

to their low weight and fragility. This is especially important

when the lawn mower is turned upside down, e.g. when the

cutting height needs to be adjusted (see the diagram below).

WARNING!

!

The blades are extremely sharp. Always wear

protective gloves when working with the

blades or cutting disc.

The cutting height can be adjusted variably between 30-60 mm.

Adjust the height by loosening the orange coloured knob and

move the entire cutting unit upwards or downwards in its

mountings.

The cutting disc is bolted to the cutting motor’s shaft and holds

3 blades thrown out by centrifugal force.

These blades are mounted in blade holders (coloured red) to

allow them to be easily attached to or dismantled from the

cutting disc. The design of the blade holders ensures that the

blades are well secured if a collision with small objects, e.g.

twigs on the lawn, should occur.

English – 5

Page 7

TROUBLE SHOOTING

Drive motors

Two, 12 V DC motors with reversible direction of rotation are

used to drive the lawn mower forwards. The two drive motors

can rotate in different directions at the same time to give the

lawn mower a tight turning circle and increase manoeuvrability.

A gearbox is engaged after the drive motors to give the lawn

mower increased traction. The speed is registered by a tachometer which is connected to the motors. The speed of the motors

is then governed by the microprocessor.

The cables from the drive motors are connected to the connector X9 (left) and X8 (right) on the circuitboard in the box. The

voltage to the drive motors should be 12 V.

Red cable (+) and black cable (-) are the supply cables. These

can be fed with 12 V for test driving. The other three cables are

used to control the motor.

Supply cable

The sensor is sensitive to moisture and dirt. If, for example,

grass sticks between the sensor's pins this will cause signal

leakage and the lawn mower will possibly signal that it cannot

sense a signal from the loop cable (3 beeps/second). The

unused (smaller) pin can be cut off and insulated using silicon if

the problem frequently recurs.

The part of the cable harness that runs from the sensor is

connected to terminals 15 and 16 on the connector X1 on the

circuitboard. (Arbitrary pole reversal.)

Sensors

A sensor (coil) is mounted on top of the front bracket between

the front wheels, see the diagram below, so that the lawn

mower can sense the electromagnetic field emitted by the loop

cable.

Sensor

The lawn mower uses two different systems to sense the

electromagnetic field:

1. The lawn mower should, with a loop length of 300 m – at a

distance of max. 35 meters from the loop cable (see

diagram) sense that the loop cable is generating an

electromagnetic field, see diagram, (with a 500m loop

length - max 25 m). If it does not sense the electromagnetic

field an error signal, 3 beeps/sec. is sounded.

Moisture sensor

Using the keyboard (press C0) you can activate the moisture

sensor which is located under the box so that the lawn mower

can determine whether the grass is too moist to give an acceptable mowing result.

A copper rivet and a zinc plate form a galvanic element that

when wet generates a voltage of 0.7V, which can be measured

on the cables on the inside.

The moisture sensor only measures moisture in long grass, that

is, it will not react to short, moist grass.

The cables connected to the rivet are connected to connector

X5 on the circuitboard.

NOTE! The maximum cutting area to achieve a good

cutting result is approx. 1200m

2. The lawn mower should sense the increase in the electromagnetic field as it approaches the loop cable and because

of this turns just in front of the loop cable.

2

.

6 – English

Cable

Page 8

TROUBLE SHOOTING

Microswitches (Collision detectors)

The front panel’s rear edge is suspended in two, spring-loaded

aluminium levers.

These levers in turn activate two microswitches which are

integrated in the “housings“ (see the diagram below) that

connect the front panel with the box.

The microswitches are activated when the bumper on the front

of the lawn mower hits an obstacle. These give a signal to the

microprocessor that tells the lawn mower to back away. The

lawn mower determines whether to reverse straight back and

then turn to the left or right depending on whether the righthand, left-hand or both microswitches are activated.

If you wish to check whether the microswitches are functioning

proceed as follows:

1. Check that the microswitches ”click” when the levers are

pressed back.

Cables

The cables are used to connect all the electrical components on

the lawn mower that concern, propulsion, charging, communication and mowing.

When checking whether a cable break has occurred all connections must be removed before each individual cable is resistance measured using a multimeter.

For operations to be good, bearing in mind the short cable

lengths in question, the resistance in the cables should be 0

ohm.

Batteries

Two, series connected 6V Nickel-Cadmium batteries are used

in the lawn mower. One, 2.4V Nickel-Cadmium battery is used

in the generator.

2. Dismantle the black cover plates on the sides of the

microswitches.

3. Check that the levers (535 03 29-01) are not bent and that

they run parallel to the side of the microswitch housing.

4. Check that the microswitch’s arm can move freely in the

hole against lever.

5. Measure the voltage (the main power switch in position “1“)

between the earth (the box) and one of the cables on the

microswitch. The voltage should be 5.0-5.1 V on one pin

and 0 V on the other.

Press the lever backwards, the voltage should be between

5.0 - 5.1 V between the earth and the connected cables. If

a voltage value lower than 5 V is obtained then the

microswitch is defective and should be replaced (presupposes charged batteries).

Microswitch

535 03 29-01

The batteries are used in the lawn mower to power the “computer“, i.e. the circuitboard with microprocessor, even at night to

ensure that the theft alarm works. The batteries also act as a

buffer when the lawn mower is mowing in the shade or during a

cloudy or a partially sunny day. This is why the lawn mower can

still mow for short periods on cloudy days.

In the generator, the battery ensures that the loop is generating

an electromagnetic field even when the sun is not shining

sufficiently to power the generator. It is important that the

generator is placed where it is well lit.

If the lawn mower requires long charging times on very sunny

days and, despite this, only has a short operating time, it’s

reasonable to suspect that the batteries need to be replaced.

The batteries in the lawn mower should be changed in pairs to

guarantee operations, as a new battery with a relatively old

battery will reduce capacity and in some cases completely

destroy the new battery. If changing the batteries does not help,

check whether the solar panels are functioning correctly.

Another sign that the batteries are discharged is when the lawn

mover frequently stops in the shade to charge.

6. Also check that the cables from the microswitch are

correctly made in terminals 8-11 on connector X1 on the

circuitboard. Right 8 (+) 9 (-) and left 10 (+) 11(-).

If the lawn mower has difficulties in sensing the electromagnetic

field from the loop cable when it’s cloudy, at daybreak or dusk,

the battery in the generator may need to be replaced, see page

2. Thereafter check that the cables outside and inside the

generator are in working order, and that there are no loose

connections.

The lawn mower stands in the charging mode (2 beeps/10

seconds) for a maximum of 40 minutes, irrespective of whether

the batteries are fully charged or not.

English – 7

Page 9

TROUBLE SHOOTING

Keyboard

The keyboard is used to deactivate the theft alarm and to enter

the security code and to change limit values for a number of the

lawn mower’s parameters.

If the keyboard ceases to beep when the keys are pressed this

can be due to, in addition to a discharged battery and/or

insufficient light, bad contact between the cables and the

connectors on the circuitboard.

The keyboard is attached to the box using self-adhesive tape,

which is why care should be exercised when the keyboard is

replaced and must be removed. All remaining adhesive should

be removed using acetone or a similar solvent but not white

spirit, to ensure the new keyboard is correctly attached.

WARNING! The box must not be washed while

!

electronic equipment is fitted.

Generator and loop cable

The generator is used together with the loop cable to form an

electromagnetic enclosure that the lawn mower senses and

keeps within.

The lawn mower gives a signal of 3 beeps/sec. if it does not

sense the electromagnetic field emitted by the loop cable.

The problem can be due to the sensor under the front of the

lawn mower being faulty, or the generator and/or loop cable

also being faulty. If the cable has been routed in the wrong

direction around "islands" then this will extinguish the electromagnetic field.

Metal objects and electrical cables on the lawn can weaken the

loop cable's electromagnetic field. If the lawn mower only

signals 3 beeps/second in certain areas of the garden this can

mean that it's experiencing a disturbance in just this area. Try

moving the loop cable. Sharp bends (90 degrees) in the loop

cable bring about a weakened electromagnetic field and this

can result in the lawn mower escaping (see diagram).

If the loop cable is correctly connected a signal should be given

when the momentary switch on the generator makes. If the

generator does not give a signal, start by bridging the generator

using a piece of cable and make the generator's switch again. If

a signal is now heard then the loop cable is not correctly

connected or there is a break in the loop cable. Start by checking the cable's connection to the generator. If the cable is

corroded, cut and strip it so that a good contact is obtained.

Measurement of the loop cable's resistance is carried out with

the cable disconnected from the generator. The resistance

should be max. 2 ohm/100m per loop cable (max. loop cable

length is 500 m).

If a cable break is established, (R=infinity), start by checking the

joints and the transition between ground and air. (For damp and

oxide-proof joints use jointing sleeves 535 04 43-01.) Use only

original loop cables from Husqvarna.

535 04 43-01

The easiest way to check the operation of the generator is to

measure the current flow in series with a functioning loop cable.

There is a risk, with a measurement value under 7mA AC, that

the electromagnetic field will be too weak.

Check that the cables and connections inside of the generator

are correct. Another quick check is to test using a new battery

(allow to charge in daylight).

8 – English

Sharp cable bends = risk

of escaping.

Gentle bends give a

stronger electromagnetic field.

A

> 7mA AC

Page 10

TROUBLE SHOOTING

Circuitboard with CPU

The circuitboard together with the CPU (microprocessor) are

the lawn mower’s “brain“ and handle all functions, commands

and path selections the lawn mower decides on, based on the

input data provided by the keyboard, sensors, solar panels,

microswitches (collision detectors) and the batteries charge

status.

To check whether an operating disruption is due to an error in

the microprocessor start by resetting it 3 times (preceded by

charging in daylight for at least 1 hour). That is, remove and

reconnect one of the batteries connectors 3 times, allowing 5

seconds to elapse in between.

Also check that the fuses on the circuitboard have not blown

and that they make good contact in the fuse holders. Replace

fuses carefully.

The voltage between the fuses and the earth can also be

measured and should be the same as the actual battery

voltage. (The main power switch in position “1“.)

I

f this does not solve the problem you can try replacing the

microprocessor with a microprocessor that you know functions

correctly. The processor must be lifted out using the processor

tool, otherwise there is a large risk of damaging the processor

pins.

Main power switch

The main power switch ensures that the lawn mower does not

start when it is switched off. The code must be entered in the

lawn mower every time the main power switch has been

switched off, even some commands are reset (see the Operator's Manual). Note that the switch does not cut the voltage from

the batteries and solar cells. Accordingly, the batteries' connection cables should be disconnected when working inside the

box and during the winter storage period.

The main power switch can be checked by measuring its

resistance. The resistance should be 0 ohm respective infinite

resistance depending on the position of the switch.

Magnetic switch

The magnetic switch is located by the hinge between the front

and rear solar panel halves and ensures that the lawn mower

does not start until the rear solar panel has been lowered.

The magnetic switch can be checked by putting the power

switch in the “on” position and then lowering the rear solar

panel. When this is done a click should be heard from the relay

on the circuit board and the machine indicates “start-up” (1

beep/second) for 10 seconds. If you hear this the magnetic

switch functions correctly.

NOTE! All work on or in connection with the circuitboard

must take place with the batteries disconnected to avoid

short circuiting. Static electricity can also damage the

microprocessor.

When trouble shooting, a microprocessor with the article

number 535 04 90-01 can be used, all have the code “A 00000

B“. This microprocessor shall only be used for trouble shooting

and repair work.

All other trouble shooting (in addition to replacing the

circuitboard) consists of checking that connectors and cables

are connected correctly on the circuitboard, even dampness

and dust can result in faults, which is why cleaning with a dry

brush and drying indoors can solve basic problems with short

circuiting. Ocular inspection can also reveal the reason for a

fault.

Buzzer

The lawn mower has a buzzer on the outside of the box that

generates a beep, which the machine uses to interact with the

user. The buzzer's volume can be adjusted using B0 - B9,

where B9 gives a louder signal and B0 mutes the buzzer. If

these setting have no effect on the volume, try replacing the

buzzer. Connect 12 V DC to the buzzer to check whether it

functions; it should sound.

If the “start-up” does not start, temporarily strap the connection

screws on the magnetic switch. If the “start-up” now starts the

magnetic switch is defective.

For information on how to replace the magnetic switch refer to

service notice tab 5, 96.016.

There is also a buzzer on the circuit board, which has a fixed

volume. If you wish the machine to be completely silent this

must be blocked. This is done by pressing silicon into the hole

on the top of the buzzer. Note this will also mute the beep heard

when pressing the keys.

English – 9

Page 11

Start-up sequence

Charge 60 min

Switch in "off" position.

TROUBLE SHOOTING

Switch on the power switch

Long beep

The batteries have enough power to

run the electronics.

Wait 1 minute and then

enter the code

A short beep should be heard when

pressing every button.

No sound

Battery level too low.

Code not accepted

A long beep when pressing "B" indicates that the mower has not registered

the code, but will run for 2 minutes and

then stop, probably signalling "no code"

(2 beeps/second).

Code accepted

Mower starts

2 beeps / 10 seconds

This indicates that the batteries are

charging. The mower will start automatically when charged.

Mower starts backwards

When stopping it will signal "trapped"

(1 beep/second). This indicates that the

microswitches are jammed. Other

failures when signalling "trapped" might

be blocked wheels or cutting disc.

Mower starts and then

stops almost immediately

The mower will signal 2 beeps/second.

There is not enough power to run the

mower properly. Charge another 60

minutes. If this is not enough, replace

the batteries.

10 – English

Page 12

Trouble shooting chart

TROUBLE SHOOTING

Observation

3 beep/second

Possible cause

The lawn mower does not sense the

signal from the loop.

If this occurs in isolated areas it can be

caused by disturbances from metal

objects (fencing, reinforcement) or by

underground cables in the vicinity.

If it occurs in the vicinity of an “island”, it

can be due to the loop cable be routed in

the wrong direction around the “island”

and thereby extinguishing the signal.

Action

Check that the cable is not broken (by

using the operating test on the generator).

Check the sensor, wipe off any grass or

moisture on the cable connections. Ensure

the cover is fitted. If the problem frequently

recurs cut off the unused pin and insulate

using silicon (see service notice tab 5,

96.018).

Measure the current in the loop cable.

There is a risk that the electromagnetic

field is too weak with values under 7 mA

AC.

Try moving the loop cable.

Check that the loop cable has been laid

according to the instructions in the Installation guide.

The lawn mower jerks

forwards and backwards

and swings quickly.

If it only occurs in the morning it can be

caused by the battery in the generator

being discharged.

The electronics were started at too low

voltage.

The microswitches switch too easily,

e.g. at corners or over bumps.

Play on the drive motors' contact

connections.

Faulty gearbox on a drive motor or

faulty tachometer (hall element) on a

drive motor.

Electronic fault.

Replace the generator battery.

Reset the processor by disconnecting and

reconnecting one of the batteries 3 times.

Check that the microswitches do not

switch before a tractive force of approx.

10N is applied.

Check the drive motors' circuit board

connection.

Try by replacing one drive motor at a time.

Replace the circuit board.

The lawn mower stops

frequently to charge when

in the shade.

The batteries have discharged.

Replace the batteries.

English – 11

Page 13

TROUBLE SHOOTING

The lawn mower

escapes.

The code must be

enter frequently.

The signal from the loop is not strong

enough.

If this occurs in isolated areas it can be

caused by disturbances from metal

objects (fencing, reinforcement) or by

underground cables in the vicinity.

The loop cable is bent sharply

(90 degrees).

Loop cable is too deep.

The electronics have temporarily lost its

voltage, and interprets this as if the lawn

mower has been switched off.

Check the sensor, wipe off any grass or

moisture on the cable connections.

Ensure the cover is fitted. If the problem

frequently recurs cut off the unused lug

and insulate using silicon (see service

notice tab 5, 96.018).

Measure the current in the loop cable.

There is a risk that the electromagnetic field

is too weak with values under 7 mA AC.

Try moving the loop cable.

Lay the loop cable so that the bend is

gradual.

Move the loop cable.

Check the battery connection the circuit

board.

1 beep/second

The cutting disc is blocked.

The drive wheel is blocked.

The lawn mower starts to reverse when

it is switched on.

Check that the disc can rotate freely.

Check whether something is blocking the

drive wheel.

A microswitch has jammed. Check and

rectify.

12 – English

Page 14

Front body

Rear body

CIRCUIT DIAGRAM

Black

Red

Black

Black

Red

Red

Magnetic switch

Cutting motor

English – 13

Page 15

We hope you find the links below useful. For further gardening information visit

www.GardenResources.co.uk

Blower Vacs Brush cutters Brushcutters Chainsaws Chain saws

Cultivators Cylinder lawn

mowers

Electric

chainsaws

Garden tractors Garden vacuums Hayter lawn

Hover mowers Husqvarna

Lawn scarifiers Lawn tractors Leaf blowers Leaf vacuums Petrol chainsaws

Petrol hedge

cutters

Ryobi strimmers Scarifiers Strimmers Westwood lawn

Westwood

tractors

Chainsaws Cultivators Cylinder Lawn

Electric

Chainsaws

Garden

Shredders

Hedgecutters Hover Mowers Husqvarna

Lawn Mowers Scarifiers Lawn Tractors Leaf Blowers Leaf Vacuums

Petrol Chainsaws Petrol Hedge

Rotovators Ryobi Strimmers Garden Patio

Patio Heaters Patio Heater

Gas Greenhouse

Heaters

Christmas

Gardening Gifts

Fertiliser

spreaders

chainsaws

Ride on lawn

mowers

Brush Cutters

Fertiliser

Spreaders

Garden Tractors

Cutters

Covers

Stainless Steel

Patio Heaters

Garden Tractors Ride on Lawn

Brushcutters Blower Vacs Chain Saws

Cylinder mowers Echo chainsaws Echo Strimmers

Garden blowers Garden rollers Garden shredders

Hedge cutters

mowers

Kawasaki brush

cutters

Ride on mowers Rotary mowers Rotavators

Mowers

Garden Blowers Garden Rollers Lawn Rollers

Garden Vacuums Hayter Lawn

Chainsaws

Ride on Lawn

Mowers

Heaters

Garden Heaters

Table Top Patio

Heaters

Mowers

Kawasaki

strimmers

tractors

Echo Chainsaws Echo Strimmers

Mowers

Kawasaki Brush

Cutters

Ride on Mowers

Outdoor Patio

Heaters

Greenhouse

Heaters

Patio Heaters UK

Ride on Mowers

Hedgecutters

Lawn mowers

Westwood ride on

mowers

Hedge Cutters

Kawasaki

Strimmers

Rotary Mowers

Gas Patio Heaters

Green House

Heaters

Patio Heaters with

Covers

Also See

Gardening Tools Direct, for lawn mowers, brush cutters, chainsaws

Gardening Supply for patio heaters, lawn mowers, chainsaws

Garden Tractor, for lawn tractors and ride on mowers

Loading...

Loading...