PT32

PT32, PT33

— Pulse Timers

• Solid State Electronics

• Timer Range: 1-1270 seconds

• Low Voltage, low current

• Nema 4 enclosure

• Single Timer (PT32)

• Dual Timer (PT33)

PT33

SPECIAL FEATURES

• Simple Installation and Operation. The PT32 and PT33 are easy to install and operate. Hays

controller are designed to eliminate expensive installation.

• Safe Power Switching with Pulse Meter. For safety, the meter sensor loop is low voltage, low

curent and transformer isolated

• Compatable with all Hays Meters. This gives the ability to match control requirements to the

pulse timer.

• Power, Input and Output Lights. At a glance, you are able to determine process in action.

4-23

• Precise Setting. Digital setting eliminates the trial and error settings of a rotary dial.

4-24

PT32, PT33

TYPICAL APPLICATIONS

• Water treatment

• Proportional feed of chemicals

• Fertilizer injection

• Cooling tower bleed

HOW TO ORDER

Specify: model number and ordering option

• PT32 - Single TImer

• PT33 - Dual Timer

Ordering Options:

• Conduit connection (not output receptacle)

• Sequential timers (PT33 only)

• Third power receptacle (unswitched)(PT33 only)

— Pulse Timers

Example:

Order: PT32 with conduit connection

Single Timer with Nema 4 Rating

SPECIFICATIONS

Power: 115 VAC, 50-60 Hz

Timer Ranges: 1-1270 seconds (21 minutes)

Enclosure: Glass-reinforced polycarbonate

Relay Contact Rating:

5 A resistive at 115 VAC

1/4 Hp inductive at 115 VAC

Sensor: 5 mA at 15 V max.

Shipping Weight:

PT32 - 2 lbs.

PT33 - 4 lbs.

PT32, PT33

— Pulse Timers

INSTALLATION

CAUTION: When this timer is used to control equipment where personal injury or property

damage might occur as a result of timer malfunction, install safeguards which would protect persons and/or equipment in the event of any unexpected operation or failure of the

equipment.

1. Mount the timer to a solid surface as follows: PT32—Gain access to the screw holes by

removing the front cover. Insert a screw through each of the four corner holes and tighten. PT33—

Three screws are required. Drive the center first, before lifting the unit into place. Leave the head of

the screw extending out slightly. Slide the mounting lug in the center of the back over this screw.

Remove the terminal cover to expose the other two screw holes. Insert screws through these holes

and tighten.

2. Connect meter to the timer. Standard units have a built-in meter connector. The mating

connector on the end of the meter cable can be plugged in and secured by a threaded locking ring.

If additional cable to the meter is necessary, two-conductor 24 AWG is recommended. Shielded

cable is not necessary.

3. Connect load to the timer. On the standard PT32, this can be accomplished by plugging a

power cord from the load into the receptacle on the underside of the unit. The PT33 has dual output

receptacles on the lower terminal cover. The receptacle on the left corresponds to the timer on the

left (Timer 1), and the receptacle on the right serves the timer on the right (Timer 2).

4. Connect power to the timer. The cord from standard units may be plugged into any grounded

115 V receptacle.

CAUTION: Always remove power from the unit before making any terminal connections or

removing the faceplate!

SETTING

1. Determine proper output time(s). For best results, the output time should be no longer than

the shortest expected interval between meter pulses. This interval, in seconds, can be calculated:

60

Max. flow (GPM x Pulse Rate (Pulses/Gallon)

If the output time is set longer than this interval, the output will be on continuously as flow nears its

maximum, and proportional output will be lost in the upper part of the flow range.

2. With the front clear cover opened, set the desired output time(s). As the front panel states,

“Total output time equals sum of the switches turned on.” Note that any time between 1 and 1024

seconds can be set by combining switches. For example, to set 43 seconds, first set the 32 sec.

switch on, followed by the 8, and the 2 and 1 (32 + 8 + 2 + 1 = 43). The advantage of this method

soon becomes apparent. Whatever time is set will be the precise output time. It is not necessary to

time the output with a stopwatch and make adjustments.

4-25

4-26

PT32, PT33

— Pulse Timers

OPERATION

1. Turn the power switch “ON.” The power indicator should light.

2. Press the TEST button. The TIMER indicator(s) should light, and stay on for whatever time is

set.

3. When the meter is operating, the INPUT indicator should light periodically, followed by operation of the timer(s). A TIMER light indicates that the timer output relay is on. The PT33 has two

TIMER indicator lights marked “TIMER 1” and “TIMER 2.” Note that at low flows or low pulse rates

(100 G/P) there may be a considerable interval between inputs. Also, at low flow rates, the INPUT

indicator may remain on for some time.

4. Be sure to replace the front cover and tighten screws before leaving the unit in operation.

The PT32/PT33 pulse timer is designed for use with a HAYS MR or ME pulse meter. It can be

used to control a metering pump or valve in a variety of proportional feed or bleed applications. The

timer’s solid-state one-shot logic cycles once for each contact from the meter. Output time is

digitally set at the front of the control, and is very precise across the entire time range of 1-1024

seconds. This elminates the need for trial and error settings using a rotary dial.

For applications requiring a dual timer, the PT33 combines two digital setting units in one

enclosure. They are set independently for any output time from 1 to 1024 seconds.

For safety, the meter sensor loop is low voltage, low current, and fully transformer isolated. It is

designed to be used either with the solid-state sensor of the ME meter or the reed switch sensor of

the MR.

Housings for the PT32 and PT33 controls are wall-mountable non-metallic enclosures with

weathertight clear front covers. On the front panel are the timer setting switches, a power on/off

switch, and a test button which forces one output when pressed. Functions are clearly indicated by

power, input and output lights. The units are supplied standard with power cord and output receptacles—the PT32 has one output receptacle, and the PT33 has two. A conduit mounting option

preserves the NEMA 4x integrity of the enclosure, where this is required.

PT32, PT33

CONNECTION DIAGRAM

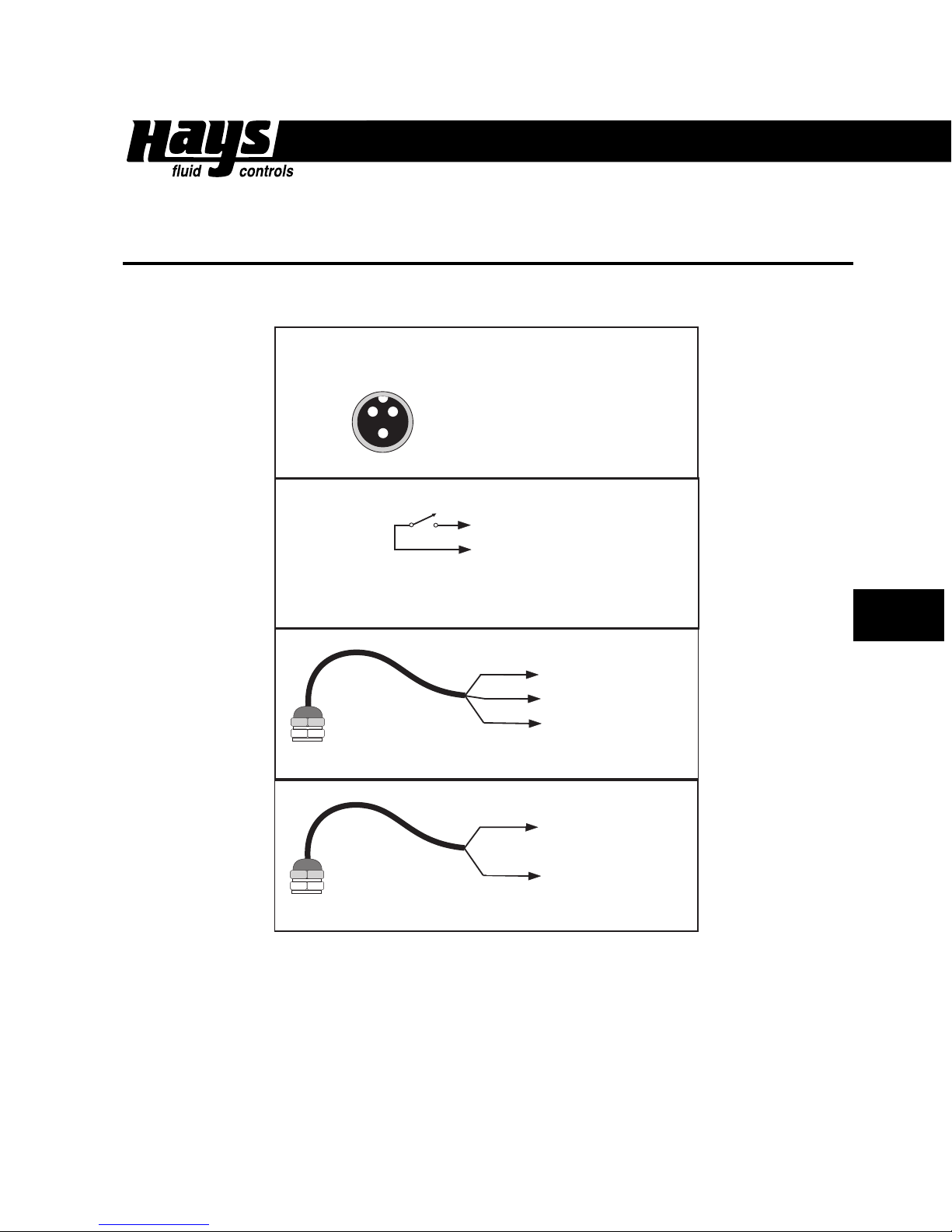

INPUT CONNECTIONS

INPUT CONNECTOR

— Pulse Timers

1

CONTACT CLOSURE

ME ELECTRONIC METER

3

2

1 POWER 2 INPUT SIGNAL

3 POWER +

TO CONNECTOR PIN 1

TO CONNECTOR PIN 2

BLACK

WHITE

RED

RED

BLACK

TO CONNECTOR PIN 1

TO CONNECTOR PIN 2

TO CONNECTOR PIN 3

TO CONNECTOR PIN 1

4-27

MT METER

MR METER

BLACK

RED

TO CONNECTOR PIN 2

Loading...

Loading...