45-15263D

SERVICE KIT INSTRUCTIONS

MASTER CYLINDER REBUILD - 98/99 DH Purple, Comp,

HFX-Mag/Mag Plus

A. Lever Blade Pivot Removal

98/99 and DH Purple

1. Remove the small retaining ring on the lever pivot by prying it off with a small screwdriver. Push out the lever pin.

2. Remove the two small wave washers that fit between the sides of the lever and the body.

The Following procedures cover the installation of Hayes Disc Brakes items

purchased as an aftermarket item. When you need to install any of the disc

brake components, a qualified technician with the proper tools should do that

installation work. Improper installation could cause severe or fatal injuries.

Warning: When following any of the procedures below, be sure to keep

your hands and fingers from getting caught in the disc. Failure to do so

could result in injury.

Warning: With use, disc brake components may become very hot. Always

allow components to cool before attempting to service your bike.

HFX Comp

1. Remove the lever pivot by removing the two 4mm Allen bolts on each side of the cylinder. Slide each bolt out of the body.

HFX Mag / Mag Plus

1. Remove the lever by punching the press fit pin out of the lever and body with a hammer and small drift punch.

Hint: This is best done with the lever assembly removed from the handlebars and having the lever assembly placed over the open jaws of a vice.

2. Remove the two plastic lever pin bushings from each side of the body.

B. Master Cylinder Rebuild

The right hand and the left hand master cylinders will be rebuilt in the exact same manner. Be sure parts are ordered for the appropriate model year brake.

Although parts may look similar, they may not be interchangeable between model years.

1. Remove the master cylinder assembly from the handlebars.

2. Slide the nose cone off the fitting and down the hose.

3. With a 10mm end wrench, loosen the hose nut.

4. Pull the hose off of the end of the master cylinder.

Caution: The end of the hose will have fluid in it. Point the hose upward and do

not shake it so that you do not drip fluid onto a painted surface.

5. If there is nothing wrong with the rest of the system, leave the hose and the caliper

attached to the bicycle.

6. Remove the lever pivot pin. See above instructions for brake model.

7. Unscrew the lever and adjuster bushing off of the cartridge push rod and out of the body.

Note: 98/99 brake models use a small flat head screwdriver

Note: All 2000-2002 DH, Comp, and Mag model brakes use a 2.5mm Allen wrench

Note: All 2003 HFX-Mag/Mag Plus model brakes use a 2mm Allen Wrench

8. Begin removal of the cartridge by loosening the jam nut with a 13mm wrench and threading it all of the way off.

9. Push the cartridge and the bladder retainer out the end of the master cylinder body.

10.Slide the bladder off the end of the cartridge.

11. Remove the cartridge boot by pulling it over the threaded push rod.

12 . Remove the snap ring and washer using a snap ring tool.

Warning: Always wear safety glasses when removing a snap ring.

13 . Insert the 24-gauge wire (supplied in MC piston service kit) through the barb end of the cartridge pushing the cartridge piston out of the

master cylinder cartridge. DO NOT attempt to take the rubber seals off the mc piston. The cartridge spring and spring guide will also

come out of the cartridge.

14 . Clean and inspect the inside of the master cylinder and all parts. Replace those parts that are damaged with new service parts.

Thoroughly clean all the parts by spaying them with isopropyl alcohol and wiping them with a clean rag.

15. Begin reassembly by dropping the cartridge spring into the cartridge – make sure the spring falls directly into the center of the cartridge.

16. Drop the spring guide into the spring with the head up.

Note: 2003 model brakes do not use the spring guide.

17. Install the new master cylinder piston into the cartridge over the spring and spring guide. (See picture)

18 . Install the ball end of the threaded push rod into the master cylinder piston. Push on the push rod to assure the spring assembly is lined

up correctly.

19. Place the retaining washer over the threaded end of the push rod.

20 . Using a snap ring tool, install the snap ring into to the snap ring groove on the inside of the cartridge. Push on the threaded push rod to

assure that all parts are properly in place.

Note: Clean and inspect all of the parts and replace those that are damaged with new service parts. Thoroughly clean all of the

parts by spraying them with isopropyl alcohol and wiping them with a clean rag.

21 . Begin re-assembly by putting the cartridge boot over the push rod. Slide the push rod up through the hole in the boot - making sure that

the boot sits into the grove on the cartridge.

22. Pull the cartridge retainer all of the way down to the end of the cartridge - it will snap into place.

Hint: Align the flat on the cartridge with the top of the bladder retainer.

23. Slide the bladder over the cartridge and line up the oval profile of the bladder with the oval profile of the bladder retainer.

24. Snap the bladder onto the little ridge on the retainer.

Caution: Installing the bladder incorrectly can create a leak.

25. Install the small paper gasket onto the end of the cartridge.

Note: the paper gasket is not needed with the HFX-Comp

26. Using supplied lubricant; place a small amount of lubricant on the inside of the lever body. The lube will help all parts slide into place

and form a better seal.

27. Install the cartridge into the master cylinder body. Line up the bladder retainer with the slot in the top of the master cylinder body and

the end of the cartridge with the flat in the master cylinder body. Grab the end of the cartridge and pull it in place making sure that the

flat on the cartridge aligns with the flat on the master cylinder body.

Note: 2000-2003 Comp, HFX-Mag, and Mag Plus model brake have a flat machined on the threaded end of the aluminum cartridge.

98/99 and DH model brakes DO NOT have a flat machined across the threaded end of the cartridge.

28 . With a 13mm wrench, thread the jam nut onto the end of the cartridge and torque the nut to 50 in-lbs +/- 5 in-lbs.

29. Put the adjuster bushing into the hole in the lever blade and thread the push rod of the cartridge through the hole in the bushing.

30. Reinstall lever blade. See above instructions for brake model.

31. Put the completed master cylinder back onto the handlebars.

32. Reinstall the hose and bleed the system.

Note: Bleed Instructions are included in Hayes bleed kit or on the web at www.hayesdiscbrake.com

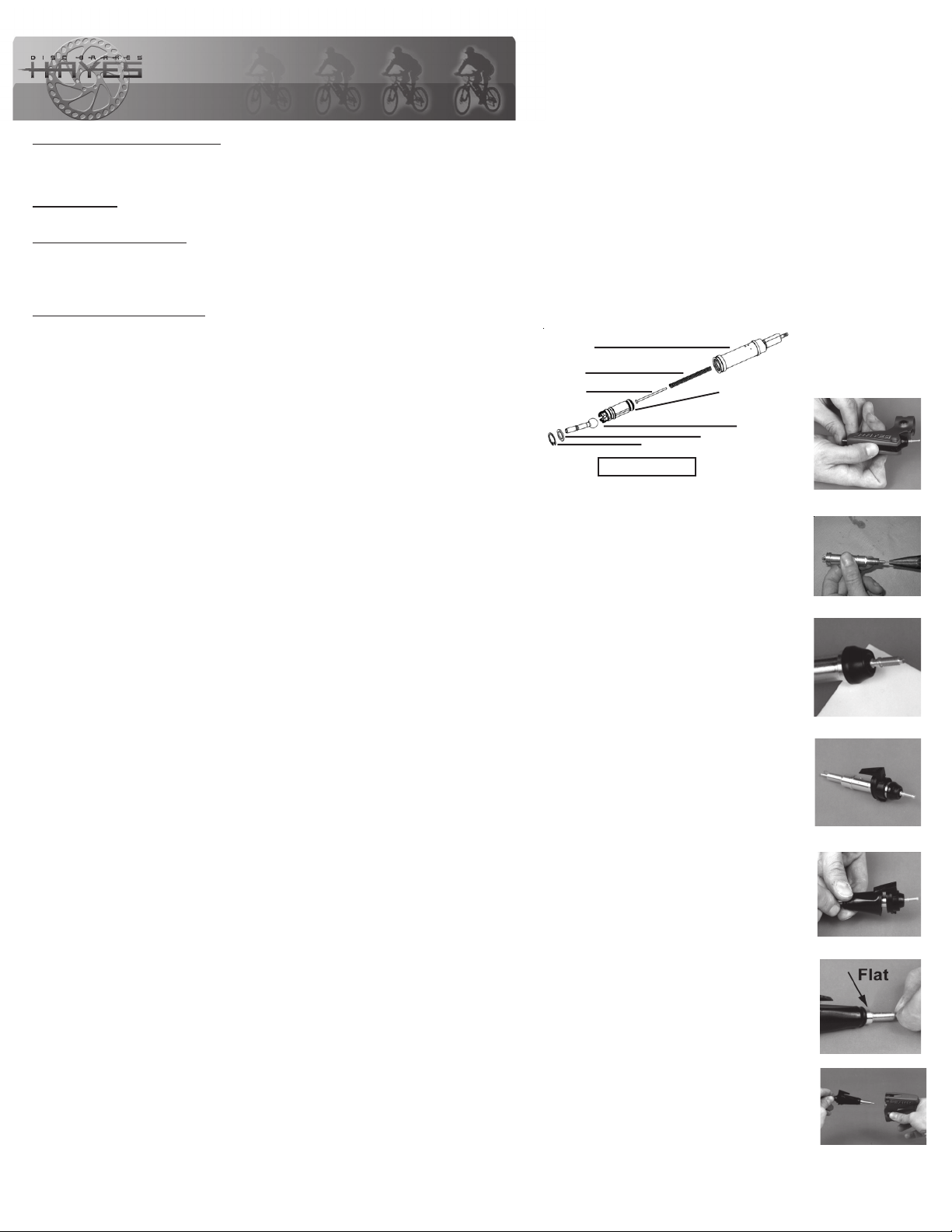

cartridge

spring

spring guide

snap ring

Kit Components

piston with primary and

secondary cups

push rod

retaining washer

Step B-9

Step B-13

Step B-21

Step B-22

Step B-24

Step B-27

Step B-27

Hayes Brake Inc. 5800 W. Donges Bay Rd., Mequon, WI 53092

Technical Assistance Phone Line 1-888-686-3472

www.hayesdiscbrake.com

Loading...

Loading...