Haydon 758P, 958, 958-2, 958-3, 958-4 User Manual

...

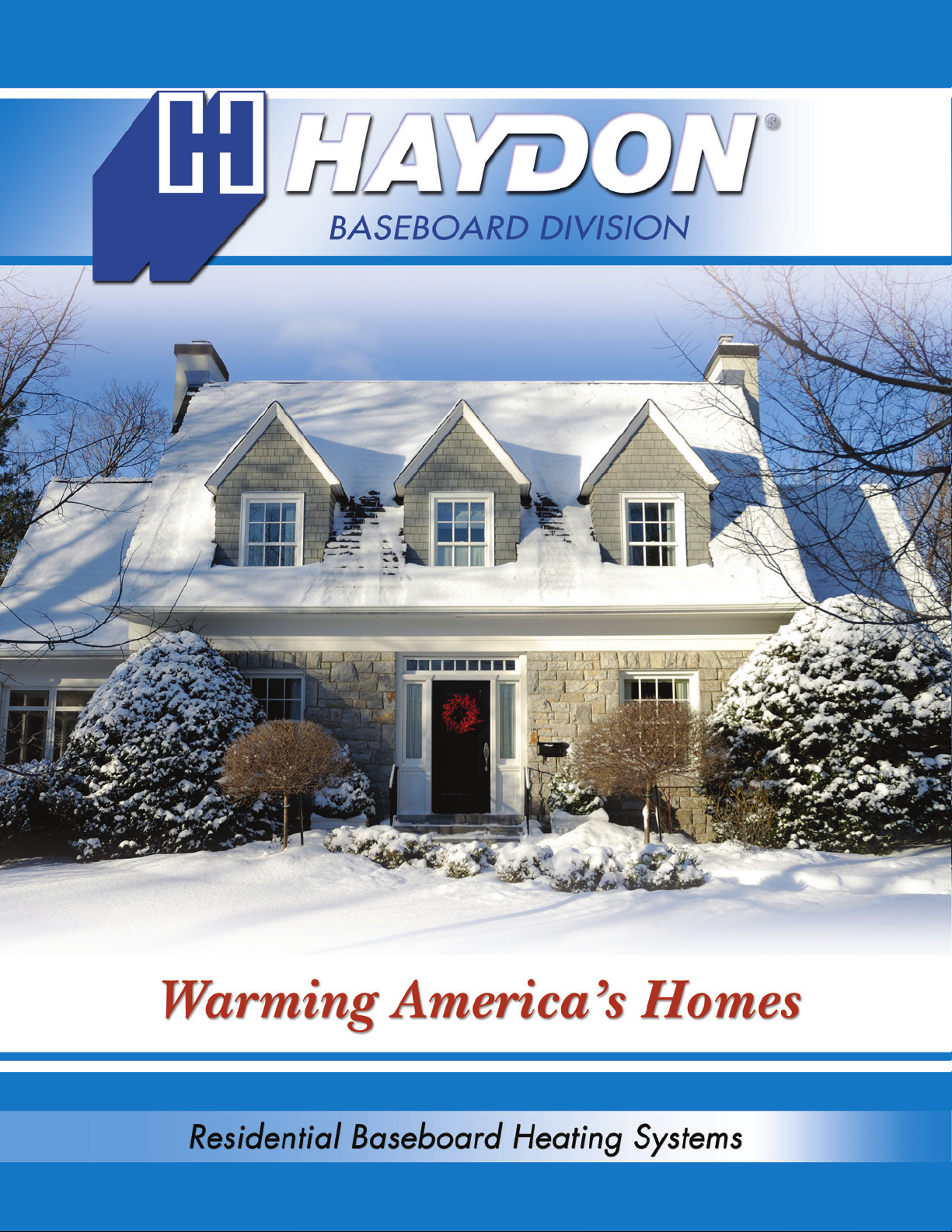

...A COMPANY YOU CAN COUNT ON

Haydon Corporation, now in its fifth decade of growth, is one of the east

coast’s leading Roll Forming and Metal Fabricating companies producing

numerous tube and roll-formed products to be found in a wide variety of

consumer and commercial products.

Facilities consist of over 80,000 square feet of manufacturing space

containing state-of-the-art equipment, plus a design and development

engineering division ensuring that Haydon products live up to the enviable

reputation they have established in the industry.

This reputation for quality and service is personified in Haydon’s Hydronic

Baseboard Heating Division...

All Products are Made In The USA!

The Haydon Hydronic Baseboard Division

Haydon’s Hydronic Baseboard Systems with

Silent Glide™ have rapidly become the first

choice of consumers and contractors alike.

Meticulously manufactured and assembled

to exacting specifications using specially

designed custom built equipment, the Haydon

hot water baseboard product line offers BTU

ratings to suit all conditions – from residential,

hot water fed, to large demand commercial

steam-fed systems.

All Haydon baseboard heating systems are

IBR rated – the industry standard – and

are manufactured to provide many years of

trouble-free, safe, silent, and economical heat

distribution.

Haydon’s Hot Water Baseboard is found

wherever good looks, ease of installation, and

superior heating capability are paramount.

Enduring Comfort and Livability...

Hallmarks of Haydon Systems

Day-in, day out reliability, the kind that allows homeowners the

freedom to forget about their heating system and simply enjoy

“all the comforts of home” - without messy maintenance, irritating

temperature fluctuations, aggravating noises and unwarranted costs

– these are the reasons to choose Haydon hydronic heating systems.

By virtually every standard of comparison, hot water baseboard is the

superior heating system. And Haydon is the superior manufacturer.

Precision manufactured components are incorporated into Haydon’s

advanced design hydronic heating units – Heat Base 750, HI Output

958, Supr-heat 1000 and Slope-Top 1200 – providing the ultimate

performance in...

COMFORT. Hot water baseboard systems generate naturally

convected heat that rises gently, warming walls and blocking drafts,

providing uniform heat throughout a home’s entire perimeter. By

contrast, hot air ducted heat operates with surges of hot air that are

warmer at the ceiling, cooler at floor level. Blown air stirs up dust,

aggravates allergies, creates drafts.

SILENCE. Hot water baseboards operate smoothly, silently. With

hot air, you constantly hear and feel “fan on, heat on, draft, fan off,

heat off.”

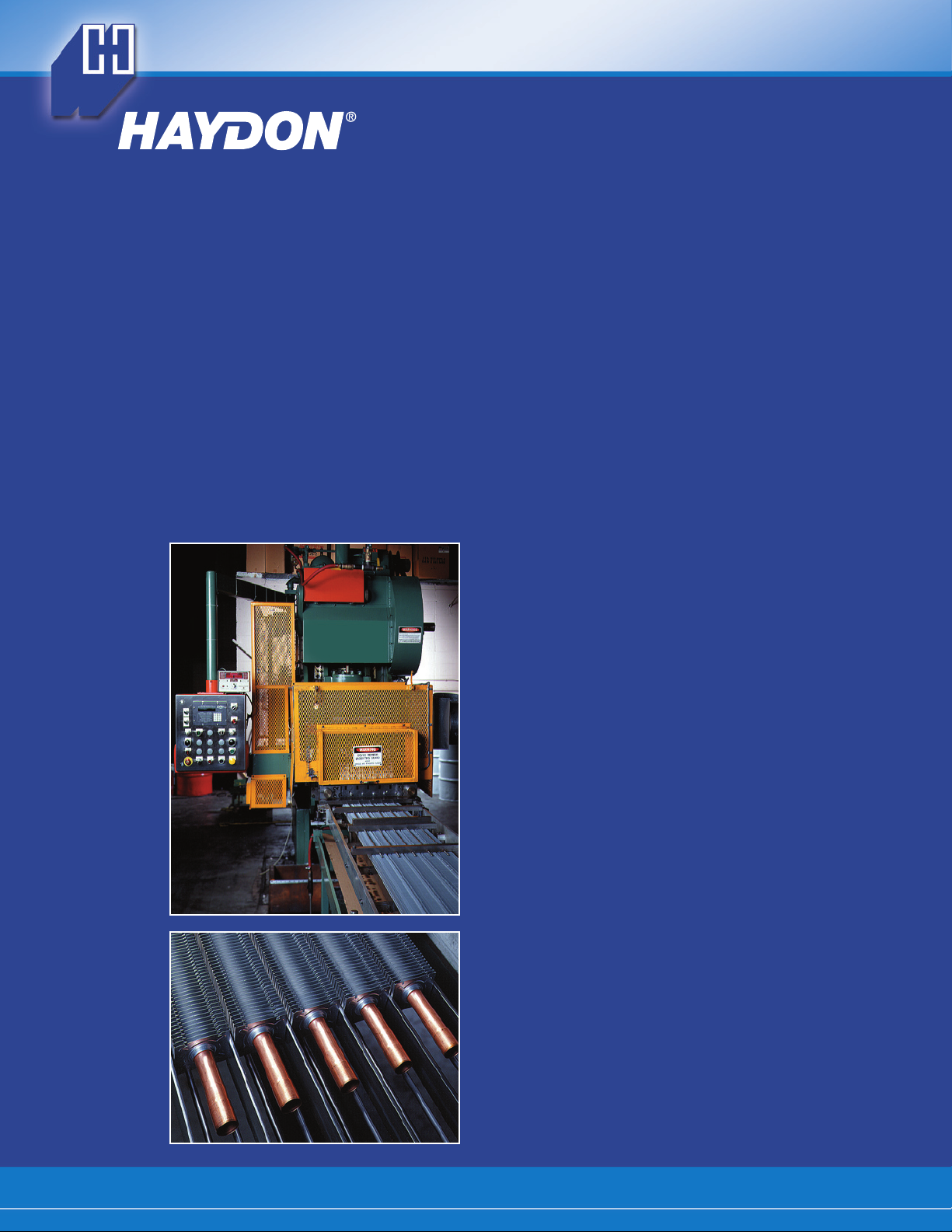

ENCLOSURE TOP-BACK PANEL: Fabricated from one

piece of sturdy pre-painted cold rolled steel designed

for efficient air flow, with uniform surfaces and no dust-

collecting cutouts.

EFFICIENCY AND VERSATILITY. Rooms with different

temperature requirements are no problem with easily zoned,

energy saving, thermostatically controlled hot water heat.

Conversely, hot air ducted heat is difficult to zone, more expensive

to install, easily unbalanced and needs adjusting every spring and

fall when air conditioning is part of the system.

CONVENIENCE AND ECONOMY. A hot water system can

supply unlimited hot water for showers, bath, laundry and kitchen,

with higher boiler operating efficiency, virtual elimination of

separate water heater costs... and it’s maintenance free.

FLEXIBILITY. Hot water heating gives you more options to

expand the system – for swimming pools, hot tubs and whirlpools,

driveway/walkway snow and ice melting – all are ways to increase

the enjoyment and value of a home.

Few things are as sacred to Americans as the comfort and

value of their homes. By scientific comparison, hot water

baseboard isthe Number One way to conduct heat.

And Haydon is the quality hydronic baseboard

system to choose.

FINGER TIP POSITIONAL DAMPER: Special hinging

mechanism allows for finger-tip control... closes shut to keep

out dust or opens wide for maximum heat output. Damper

deflects air into room, for better heating distribution.

HIGH STRENGTH BRACKETS: Die-formed from one

piece of heavy gauge steel - designed to strengthen the

enclosure and protect the heating element against damage

- special notches hold the heating element to allow for quiet

expansion... won’t break or bend, cannot pop out of place.

A turn of the wrist removes the twist slide brackets, for easy

location during installation.

RETURN BRACKET OPTION: Wire hangers allow for easy

installation of return pipe.

FRONT PANEL: Roll-formed from heavy gauge steel which

resists damage during and after installation - pre-coated

with a special rust-inhibiting white baked-on enamel paint.

Looks new year after year.

No heavier front available.

NOISELESS ELEMENT: Aluminum fins are mechanically

fastened to copper tubing to insure maximum heat transfer.

Elements have an expanded end for easy sweat connections

without coupling.

“SILENT GLIDE” EXPANSION TRACKS: Two unique

polyethylene silent glide tracks eliminate expansion and

contraction noises.

TM

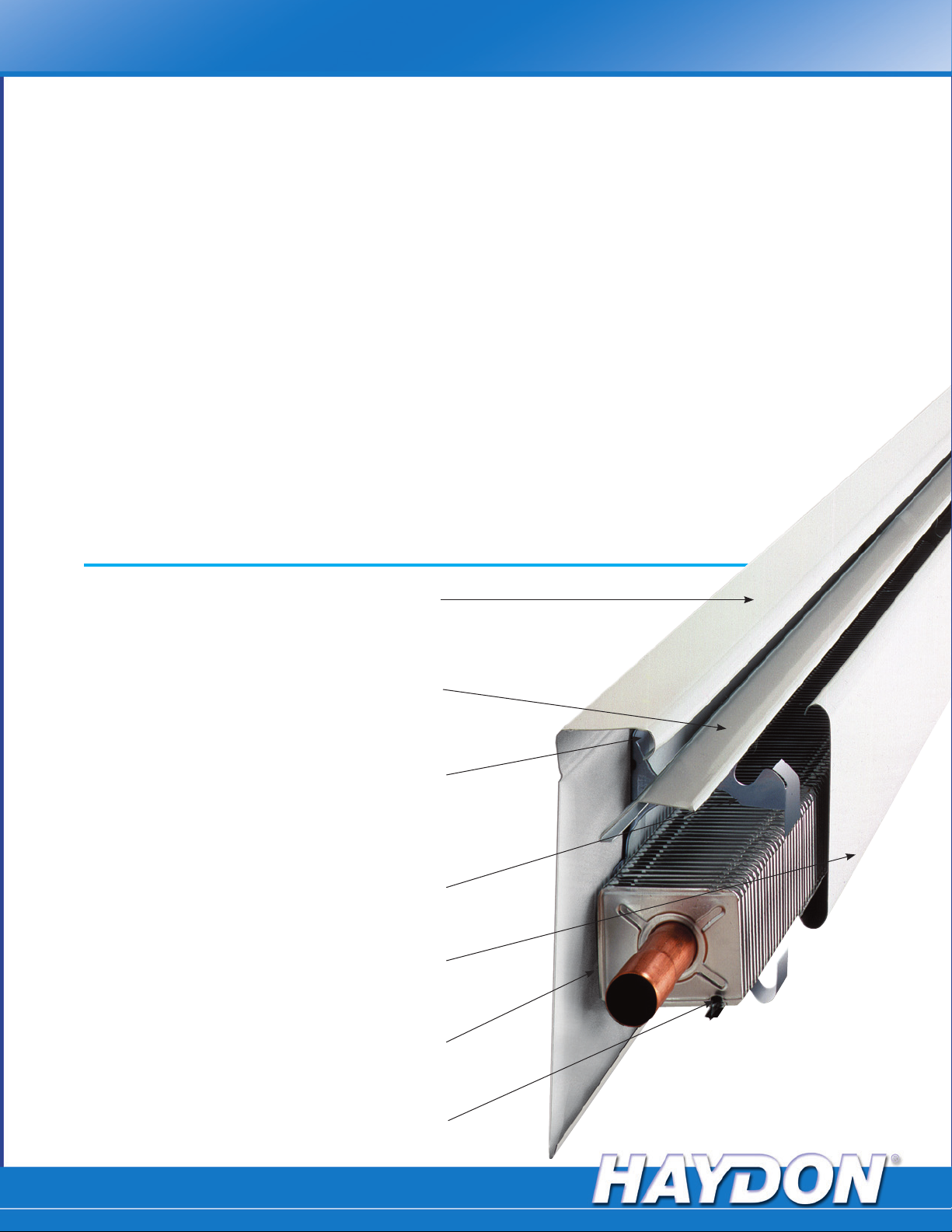

Residential

Slim and unobtrusive, the low profile Model 750’s BTU output

is ideal for efficient, economical residential installations.*

Standard 22 gauge front cover and optional heavy duty 18

gauge front cover (Model 758).

*Available with

1

⁄2" Copper

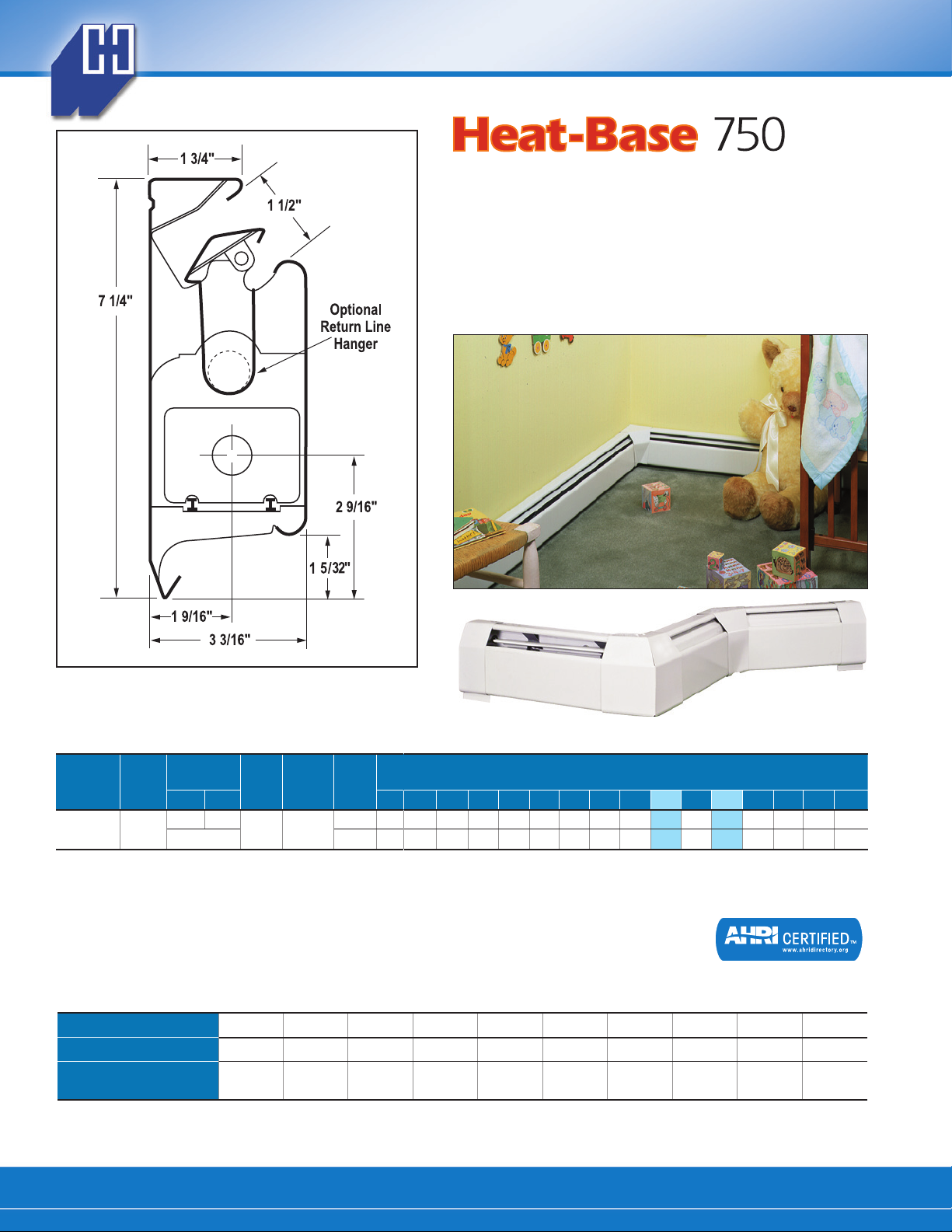

Table 1 — HEATING CAPACITIES, BTU PER HR PER LIN. FT. 65° ENTERING AIR TEMPERATURE I-B-R APPROVED

Nom.

Model

HEAT-BASE

750-1B

* Ratings at 140° F and lower temperatures determined by multiplying 150°F rating by the applicable factor specified in Table E in

the I=B=R Testing and Rating Standard for Baseboard Radiation

All the above I-B-R Ratings are based on active length, which is 3" less than total length, and includes a 15% addition for heating effect.

Ratings: Heating capacities are listed in Table 1 for two flow rates: 1 GPM and 4 GPM. The use of I-B-R Ratings

at 4 GPM is limited to installations where the water flow rate through the baseboard unit is equal to or greater than

4 GPM. Where the water flow rate through the baseboard is not known, the I-B-R Ratings at the standard flow rate

of 1 GPM must be used.

Copper

Alum. Fin

Dimensions

Tube

Size

H W

1

3

2

⁄8" 21⁄2"

⁄4"

Natural Finish 1 70* 110* 160* 210* 270* 330* 390 450 520 580 650 720 780 850 920 980

Thick-

ness

0.008 54.5

Fin

Spacing

Fins/Ft.

Water

Rate

GPM

90° 100° 110° 120° 130° 140° 150° 160° 170° 180° 190° 200° 210° 220° 230° 240°

4 70* 110* 170* 230* 280* 340* 410 480 550 610 690 760 820 900 970 1,040

HOT WATER RATINGS

AVERAGE WATER TEMPERATURE °F

Table 2 — FACTORS FOR RATINGS AT FLOW OTHER THAN STANDARD AND PRESSURE DROP VALUES

Rate of Flow GPM

Factor

Pressure Drop 3⁄4" Tube

Mill inches per ft.

Note: If the calculated water flow rate through a baseboard unit in a completely designed hot water heating system is greater than the standard

flow rate (1 GPM), the rating of that unit may be increased by multiplying the standard I-B-R Rating at 1 GPM by the factor shown for the

calculated flow rate.

1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 6.0

1.000 1.016 1.028 1.038 1.045 1.051 1.057 1.062 1.067 1.074

47 96 157 230 320 420 525 650 775 1,060

Loading...

Loading...