Page 1

No. 2077650(8)

5874PB/5874PBF/VRK5874/VRK5874HF/

PBA6/ PBA7 Valve/Push Button

INSTALLATION, OPERATION

&

MAINTENANCE INSTRUCTIONS

Factory any goods, or part thereof, which shall appear to the Company upon

inspection to be of defective material or not of first class workmanship, provided that

product. Where claims for defects are made, the defective part or parts shall be

delivered to the Company, prepaid, for inspection. HAWS will not be liable for the

made by the owner or his agents, except upon written authority from HAWS,

Sparks, Nevada. HAWS will not be liable for any damages caused by defective

materials or poor workmanship, except for replacements, as provided above. Buyer

claimed to arise under the contract of sale. The drinking fountain manufactured by

HAWS is warranted to function if installation and maintenance instructions provided

also must be used for the purpose for which they were

NOTE TO INSTALLER: Please leave this information with the Maintenance Department.

SHOULD YOU EXPERIENCE DIFFICULTY WITH THE INSTALLATION OF THIS

1455 Kleppe Lane Sparks, NV 89431-6467 (775) 359-4712 Fax (775) 359-7424

E-mail: haws@hawsco.com website: www.hawsco.com

HAWS warrants that this specific product is guaranteed against defective material or

poor workmanship for a period of one year from date of shipment. HAWS liability

under this warranty shall be discharged by furnishing without charge F.O.B. HAWS

claim is made in writing to Haws within a reasonable period after receipt of the

cost of repairs, alterations or replacements, or for any expense connected therewith

agrees that HAWS shall not be liable for general, special, or consequential damages

are adhered to. The units

intended.

NO OTHER WARRANTIES EXPRESSED OR IMPLIED ARE AUTHORIZED,

PROVIDED OR GIVEN BY HAWS.

MODEL PLEASE CALL:

TECHNICAL SUPPORT: 1-800-766-5612

FOR CUSTOMER SERVICE: 1-888-640-4297

07/17 Mod el 5874 P B/58 74 PBF/VRK5874/VRK574HF/PBA6/PBA7 Page 1 of 6

LIMITED WARRANTY

Page 2

Note:

1. Be fo re removing valve, strainer or cartridge assembly, shut off water supply line.

2. This valve is pressure compensating. Be sure to remove any existing flow control

devices. (May be present in fitting or SPUD).

3. Verify that new valve will fit in place of the older 5871 and 5872 series valves. Contact

Haws technical support, if needed.

4. When retrofitting an existing fountain with a 58 74 series valve:

a) Remove any in-line strainer that may be present in the supply l ine,

b) Verify if unit requires a high flow cartridge. If so, follow notes on Page 4 of 6.

c) Valve is directional. Verify flow direction indicated on valve when installing.

d) Reconnect tubing to new valve using your existing fittings.

Caution: Valve must be protected by a 60-mesh strainer LOCATED INSIDE VALVE BODY.

WARRAN TY VOID IF 60-MESH STRAINER IS REMOVED FROM VALVE BODY.

OPERATION & MAINTENANCE OF FRONT ACCESS FEATURES

FLOW ADJUSTMENT: A 3/16” hole in the center of this button is provided for front access to the

adjustment screw found on the cartridge assembly. While pushing the button in and using a slotted

narrow blade scre wdriver, the f low may be adj usted by ins erting it into the hole and tur ning cloc kwise for

increased flow, and counterclockwise for decreased flow.

STRAINER CLEANING: Periodically clean the strainer located inside valve body. Remove front push-

button and retaining nut with the universal spanner wrench provided. Pull cartridge assembly out. Gently

remove strainer off of cartridge. Thoroughly flush away any debris from strainer. Ensure that both the

gasket on cartridge and strainer gasket are very clean with no debris whatsoever, then re-attach strainer

by aligning larger hole opening on gasket over the larger water inlet opening on the cartridge (Don’t

remove gasket that comes with cartridge). Make sure there is no debris in the valve body before inserting

the cartridge assembly back into the valve body. When inserting cartridge assembly, align strainer with

large hole in the valve body, ensure the cartridge has bottomed out by turning slightly into place. Install

retaining nut until it makes contact with the cartridge, then tighten 1 1/4 turn farther; check for leaks.

Reassemble push button per Steps 5, 6, 7 & 10 of installation instructions on Pages 5 & 6.

CARTRIDGE ASSEMBLY REPLACEMENT: Remove front push-button and retaining nut with the

universal spanner wrench provided. Pull cartridge assembly out. Gently remove strainer off of old

cartridge and reassemble on new cartridg e (Don’t remove gask et that comes with c artridge) (See strainer

reattachment instructi ons above). Insert cartr idge assembl y into valve body by aligning sc reen into large

opening inside bottom of valve body. Ensure cartr idge has bottomed out, by tur ning slightly into place.

Install retaining nut until it makes contact with the cartridge, then tighten 1 1/4 turn farther; check for

leaks. Reassemble push button per Steps 5, 6, 7 & 10 of installation instructions on Pages 5 & 6.

STRAINER GASKET REPLACEMENT: Remove front push button and retai ning nut w ith the un iver sal

spanner wrench provided. Pull cartridge assembly out. Gently remove strainer off of cartridge. Ensure

that the gasket on the cartridge is very clean with no debris. Attach new strainer gasket to cartridge (Don’t

remove gasket that comes with cartridge) by aligning larger hole opening on gasket over the larger water

inlet opening on the cartridge. Make sure there is no foreign matter in the valve body before inserting the

cartridge assembly back into the valve body. When inserting cartridge assembly, align strainer with large

hole in the valve body. Ensure the cartridge has bottomed out by turning slightly into place. Install

retaining nut until it makes contact with the cartridge, then tighten 1 1/4 turn farther.

CAUTION: When replacing strainer or cartridge assembly, damage can occur if not

properly re-installed. Read instructions carefully.

PUSH BUTTON ASSEMBLY/REASSEMBLY

Must apply 1 Dot of Loctite 222MS Threadlocker o n fema le threads of push-button. Carefully

follow Steps 5, 6, 7 & 10 on installation drawing (Pages 5 & 6) to ensure proper assembly

procedure.

07/17 Mod el 5874 P B/58 74 PBF/VRK5874/VRK574HF/PBA6/PBA7 Page 2 of 6

Page 3

TROUBLESHOOTING

PROBLEM

REPAIR CHECKLIST

1.

Insufficient water flow.

1a.

Check that the inlet screwdriver stop is in wide open position.

b.

Verify that correct valve cartridge is being utilized for your

c.

Adjust bubbler stream height. See Flow Adjustment

d.

Verify flow direction indicated on valve.

e.

Verify that wave washer is in place and that push button is

f.

Shut off screwdriver stop (not supplied), clean the fine mesh

g.

Verify minimum 30 psi flowing supply pressure.

h.

Shut off screwdriver stop and replace cartridge assembly. See

2.

Water flow too high.

2a.

See steps 1b, 1c or 1e above.

3.

Valve won’t shut off

3a.

Cycle the cartridge assembly by pushing the push-button 5

3b.

Shut off screwdriver stop. Replace cartridge assembly. See

4.

No flow out of valve.

4a.

Check that the inlet screwdriver stop is in wide open position.

b.

Verify flow direction indicated on valve.

c.

Check strainer for possible clogging (see 1f above).

5.

Inconsistent bubbler

stream height.

5a.

See 1f above

6.

Button is loose

6a.

Refer to Installation Drawing Steps 5, 6, 7 & 10 on Pages 5 & 6

7.

Water is leaking out of

7a.

Remove push button with spanner wrench ( P/N 000 69 83506)

b.

If leak persist, shut off screwdriver stop and replace cartridge

application. Models 1920/1920HPS/1920W 1025/1025G

3300/3300G (equipped with a pop-up bubbler head Model

5725) & any models that feature a cuspidor (i.e. 2406, etc.)

require a high flow cartridge (P/N 0001632151) to ensure

proper flow stream height. All other models utilize a standard

flow cartridge.

instructions in Front Access Feature Box.

properly adjusted per Steps 5 & 7 of installation drawing

(Pages 5 & 6).

strainer found inside the 5874 series valve. See Strainer

Cleaning instructions in Front Access Feature Box.

completely

push button assembly.

Cartridge Assembly Replacement instructions in Front Access

Feature Box.

times to clear any foreign matter (if any is present) from the

valve seat.

Cartridge Assembly Replacement instructions in Front Access

Feature Box.

for proper application of Threadlocker 222MS and assembly

procedure.

and tighten retaining nut using same spanner wrench.

assembly. See Cartridge Assembly Replacement instructions

in Front Access Feature Box.

For more information about Haws products, see our website: www.hawsco.com

© 2017 Haws® Corporation – All Rights Reserved

HAWS

07/17 Mod el 5874 P B/58 74 PBF/VRK5874/VRK574HF/PBA6/PBA7 Page 3 of 6

®

and other trademarks used in these materials are the exclusive property of Haws Corporation.

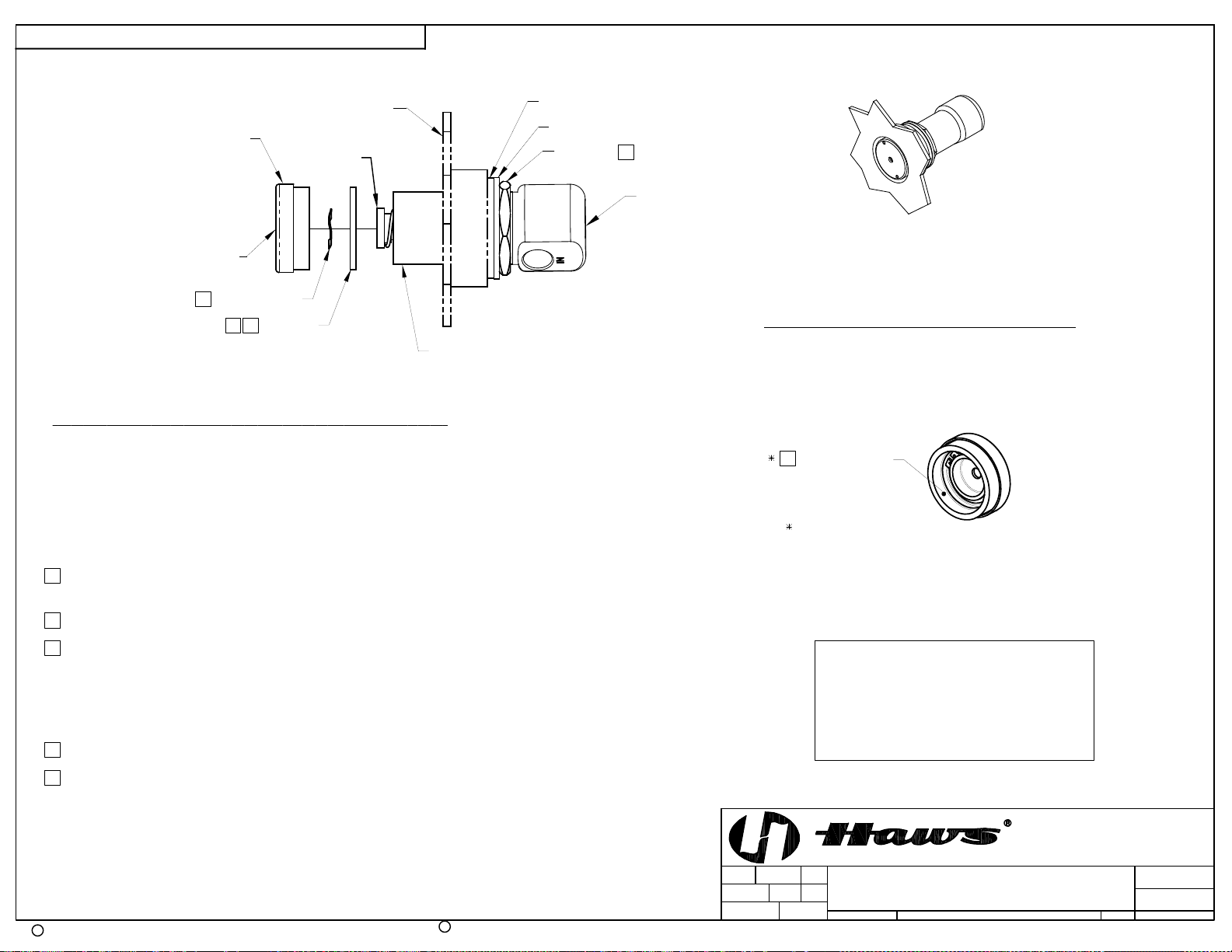

Page 4

THIS DOCUMENT IS TRUE AND CORRECT AT TIME OF PUBLICATION. CONTINUED PRODUCT IMPROVEMENTS

MAKE SPECIFICATIONS AND MEASUREMENTS SUBJECT TO CHANGE WITHOUT NOTICE.

OPTIONAL PCP

***

WASHER FOR

PARTS BREAKDOWN

FLUSH MOUNT

SURFACES (SEE

NOTE BELOW)

5874PB

41

POLISHED CHROME PLATED PUSH BUTTON WITH VALVE

FOR BOTH RECESSED AND FLUSH MOUNT SURFACES.

(ALSO USED FOR REPLACEMENT OF OLDER VALVE

MODELS 5871, 5872, AND 5872HF - SEE NOTE 4.)

5874PBF

1

POLISH CHROME PLATED FLANGE

PUSH BUTTON WITH VALVE FOR

FLUSH MOUNT SURFACES ONLY.

0006983506

SPANNER WRENCH

(ONLY INCLUDED WITH MODELS:

5874PB & 5874PBF)

VRK5874

1

VALVE REPAIR KIT

(STANDARD FLOW)

DO NOT REMOVE

GASKET WHICH COMES

WITH CARTRIDGE.

2

VRK5874HF

VALVE CARTRIDGE

DO NOT REMOVE

GASKET WHICH COMES

WITH CARTRIDGE.

5

2

3

(HIGH FLOW)

PBA6

POLISHED CHROME PLATED

FLANGED PUSH BUTTON FOR

FLUSH MOUNT SURFACES ONLY.

IF NEEDED, USE 1-3/4" O.D. X .050 THICK PCP

***

WASHER PN 0006729529 (NOT SUPPLIED) IN

POLISHED CHROME PLATED PUSH

BUTTON FOR BOTH RECESSED

AND FLUSH MOUNT SURFACES.

PBA7

SITUATIONS WHERE THE PUSH BUTTON HOLE IS

SLIGHTLY OVERSIZED FOR THE 5874PB RING NUT.

NOTES:

1 MODELS 5874PB, 5874PBF, AND VRK5874 ARE EQUIPPED WITH A STANDARD FLOW CARTRIDGE.

ORDER THESE MODELS WHEN REPLACING/REPAIRING VALVES WITH A STANDARD FLOW APPLICATION.

DO NOT USE ON ANY MODELS THAT FEATURE A CUSPIDOR OR HAVE A HIGH FLOW APPLICATION

WITHOUT IMPLEMENTING ADDITIONAL REQUIRED STEPS (SEE NOTES 2 AND 3).

0003244389

THREADLOCKER TO

SECURE PUSH BUTTON

(ONLY INCLUDED W/PB SERIES)

0002568123

3

GASKET W/SCREEN

0006626653

WAVE WASHER FOR USE WITH

BOTH RECESSED AND FLANGED

STYLE PUSH BUTTON ASSEMBLIES.

(MUST BE IN PLACE FOR PROPER

PUSH BUTTON OPERATION)

2 MODELS 1025/G AND 3300/G EQUIPPED WITH A POP-UP BUBBLER HEAD (MODEL 5725) AND MODEL

VRK5874HF, 2406 (EQUIPPED WITH A CUSPIDOR) AND 1920 SERIES BOTTLE FILLER MODELS ALL

UTILIZE A HIGH FLOW CARTRIDGE TO ENSURE PROPER FLOW.

3 WHEN REPLACING A HIGH FLOW CARTRIDGE ASSEMBLY, DO NOT USE VRK5874; USE VRK5874HF.

4 FOR VALVE REPLACEMENT ON UNITS WITH OLDER 5871, 5872 (STANDARD FLOW) AND 5872HF (HIGH FLOW) VALVES:

CONTACT HAWS TECHNICAL SUPPORT.

5 VRK5874HF IS ALSO USED ON 1920 SERIES BOTTLE FILLER MODELS (SEE NOTE 2).

ECN:

5216

DATE

06/08/16

DATE

BYECN NO.

CHKD

07/25/17

MODEL(S)

JP

JP

SCALE:

5874PB/5874PBF/VRK5874/VRK5874HF/

NA

PBA6/PBA7.

DRAWING TYPE: SIZE: A

PARTS BREAKDOWN

REVISED PER

4250

DRAWN

WHEN ORDERING PARTS PLEASE SPECIFY MODEL NUMBER.

C

2017

Haws Corporation - All Rights Reserved

HAWS and other trademarks used in these materials are the exclusive property of Haws Corporation.

R

LM

APPROVED

FV

1455 KLEPPE LANE

SPARKS, NEVADA 89431

(775) 359-4712 FAX (775) 359-7424

E-MAIL: HAWS@HAWSCO.COM

WEBSITE: WWW.HAWSCO.COM

PAGE

PART NUMBER

0002077650

REVISION

8

SHEET OF

11

4 OF 6

Page 5

THIS DOCUMENT IS TRUE AND CORRECT AT TIM E OF PUB L ICATION. CONTINUED PRODUCT IMPROVEME NTS

MAKE SPECIFICATIONS AND MEASUREMENTS SUBJECT TO CHANGE WITHOUT NOTICE.

(FRONT OF FOUNTAIN)

FLANGED

PUSH BUTTON

CARTRIDGE

RUBBER WASHER

FIBER WASHER

LOCK NUT

CARTRIDGE ***

(DO NOT REMOVE GASKET

THAT COMES WITH CARTRIDGE)

9

5 OF 6

VALVE BODY

FRONT ADJUST

SCREW ACCESS

2X 1/4" IPS CONNECTION

5

*** WAVE WASHER

(FITTINGS NOT SUPPLIED)

GASKET W/SCREEN ***

LARGE RING NUT

4

8

VALVE SHOWN MOVED

FORWARD ABOUT 1" (STEP 3).

*** MODEL VRK5874 & VRK5874HF- VALVE REPAIR KITS INCLUDE THESE ITEMS

INSTALLATION INSTRUCTIONS FOR 5874PBF.

1) FOLLOW INSTRUCTIONS CAREFULLY ON O&M MANUAL (PAGE 2 OF 6) WHEN REMOVING

OLD VALVE. NOTE: SEE PARTS BREAKDOWN (PAGE 4 OF 6) FOR ADDITIONAL NOTES.

2) VERIFY THAT LOCK NUT, FIBER, AND RUBBER WASHERS ARE POSITIONED SLIGHTLY

PAST MIDWAY OF THREADS ON NEW VALVE BODY.

3) INSERT VALVE INTO BRACKET FROM INSI DE AND PUSH FORWARD ABOUT 1".

4 THREAD LARGE RING NUT ONTO VALVE BODY, A PPROXIMATELY 1" INTO VALVE.

5 PLACE WAVE WASHER INSIDE OF FLANGED PUSH BUTTON ASSEMBLY (MUST BE IN PLACE).

6 APPLY ONE (1) DOT OF LOCTITE 222MS, ON THE FEMALE THREADS OF BUTTON ASSEMBLY

LEAVING THE FIRST AND LAST THREADS FREE. (FIGURE 1). CAUTION: EXCESS LOCTITE CAN

CAUSE THREADS TO LOCK VERY TIGHTLY, MAKING REPAIRS DIFFICULT.

**7) THREAD FLANGED PUSH BUTTON ASSEMBLY ON VALVE UNTIL WAVE WASHER MAKES SLIGHT

CONTACT WITH STEM OF CARTRIDGE. CAUTION: DO NOT HAND-TIGHTEN.

ASSEMBLED 5874PBF

(FLUSH MOUNT APPLICATION)

SEE SHEET 2 OF 2 FOR RECESSED MOUNT INSTRUCTIONS.

APPLY 1 DOT OF

6

LOCTITE 222MS

(WHERE SHOWN)

THIS ALSO APPLIES

TO PBA6

FIGURE 1

NOTE!

THIS VALVE IS PRESSURE COMPENSATING.

BE SURE TO REMOVE ANY EXISTING FLOW

CONTROL DEVICES. (MAY BE PRESE NT IN

FITTING OR SPUD).

PAGE

8 UNTHREAD RING NUT FORWARD UNTIL IT STOPS FLUSH WITH PUSH BUTTON ASSEMBLY.

9 PUSH VALVE BACK TOWARD THE INSIDE OF BRACKET AND TIGHTEN LOCKNUT (SEE

ILLUSTRATION ABOVE).

10) TIGHTEN PUSH BUTTON ASSEMBLY USING UNIVERSAL SPANNER WRENCH PROVIDED.

** OVERTIGHTENING WILL PRE-ACTUATE VALVE AND CAUSE WEEPAGE, WHILE NOT ENO UGH

CONTACT BETWEEN WAVE WASHER AND STEM CAN CAUS E A LOW FLOW CONDITION.

C

2017

Haws Corporation - All Rights Reserved.

HAWS and other trademarks used in these materials are the exclusive property of Haws Corporation.

R

4250

DRAWN:

LM

APPROVED:

FV

REVISED PER

ECN:

5216

DATE:

06/08/16

DATE:

BY:ECN NO.

CHK'D.:

07/25/17

MODEL(S)

JP

GC

SCALE:

1455 KLEPPE LANE

SPARKS, NEVADA 89431

(775) 359-4712 FAX (775) 359-7424

E-MAIL: HAWS@HAWSCO.COM

WEBSITE: WWW.HAWSCO.COM

5874PB/5874PBF/VRK5874/VRK5874HF/

NA

DRAWING TYPE: SIZE: A

PBA6/PBA7

INSTALLATION

PART NUMBER

0002077650.D

REVISION

8

SHEET OF

12

Page 6

THIS DOCUMENT IS TRUE AND CORRECT AT TIM E OF PUB L ICATION. CONTINUED PRODUCT IMPROVEME NTS

MAKE SPECIFICATIONS AND MEASUREMENTS SUBJECT TO CHANGE WITHOUT NOTICE.

RUBBER WASHER

FIBER WASHER

LOCK NUT

9

CHROME RECESSED

PUSH BUTTON

(FRONT OF FOUNTAIN)

CARTRIDGE

VALVE BODY

(SEE SHEET

1 OF 2 FOR

FRONT ADJUST

DETAILS)

SCREW ACCESS

5

WAVE WASHER

84

RING NUT

VALVE SHOWN MOVED

FORWARD ALL THE WAY (STEP 3)

INSTALLATION INSTRUCTIONS FOR 5874PB.

1) FOLLOW INSTRUCTIONS CAREFULLY ON O&M MANUAL (PAGE 2 OF 6) WHEN REMOVING

OLD VALVE. NOTE: SEE PARTS BREAKDOWN (PAGE 4 OF 6) FOR ADDITIONAL NOTES.

2) VERIFY THAT LOCK NUT, FIBER WASHER, AND RUBBER WASHERS ARE POSITIONED TOWARD

BOTTOM END OF THREADS ON NEW VALVE BODY.

3) INSERT VALVE INTO BRACKET FROM INSIDE, AND PUSH ALL THE WAY FORWARD

(SEE ILLUSTRATION ABOVE).

4 THREAD RING NUT ONTO VALVE BODY, AS FAR IN AS POSSIBLE, TOWARD FRONT OF FOUNTAIN.

NOTE: IF REPLACING A 5871 OR 5872 SERIES VALVE, YOU MAY HAVE TO CONTACT HAWS TECHNICAL SUPPORT.

ASSEMBLED 5874PB

(RECESSED MOUNT APPLICATION)

SEE SHEET 1 OF 2 FOR FLUSH MOUNT INSTRUCTIONS.

APPLY 1 DOT OF

6

LOCTITE 222MS

(WHERE SHOWN)

THIS ALSO APPLIES

TO PBA7

FIGURE 1

6 OF 6

PAGE

5 PLACE WAVE WASHER INSIDE OF PUSH BUTTON ASSEMBLY (MUST BE IN PLACE).

6 APPLY ONE (1) DOT OF LOCTITE 222MS, ON THE FEMALE THREADS OF BU TTON ASSEMBLY

LEAVING THE FIRST AND LAST THREADS FREE. (F IGURE 1). CAUTION: EXCESS LOCTITE CAN

CAUSE THREADS TO LOCK VERY TIGHTLY, MAKING REPAIRS DIFFICULT.

**7) THREAD PUSH BUTTON ASSEMBLY ON VALVE UNTIL WAVE WASHER MAKES SLIGHT

CONTACT WITH STEM OF CARTRIDGE. CAUTION: DO NOT HAND-TIGHTEN.

8 UNTHREAD RING NUT FORWARD UNTIL IT STOPS FLUSH WITH PUSH BUTTON ASSEMBLY.

9 PUSH VALVE BACK TOWARD THE INSIDE OF BRACKET AND TIGHTEN LOCKNUT (SEE

ILLUSTRATION ABOVE).

10) TIGHTEN PUSH BUTTON ASSEMBLY USING UNIVERSAL SPANNER WRENCH PROVID ED.

** OVERTIGHTENING WILL PRE-ACTUATE VALVE AND CAUSE WEEPAGE, WHILE NOT ENOUGH

CONTACT BETWEEN WAVE WASHER AND STEM CAN CAUSE A LOW FLOW CONDITION.

C

2017

Haws Corporation - All Rights Reserved.

HAWS and other trademarks used in these materials are the exclusive property of Haws Corporation.

R

4250

DRAWN:

LM

APPROVED:

FV

REVISED PER

ECN:

5216

DATE:

06/08/16

DATE:

NOTE!

THIS VALVE IS PRESSURE COMPENSATING.

BE SURE TO REMOVE ANY EXISTING FLOW

CONTROL DEVICES. (MAY BE PRESENT IN

FITTING OR SPUD).

BY:ECN NO.

MODEL(S)

JP

CHK'D.:

07/25/17

GC

5874PB/5874PBF/VRK5874/VRK5874HF/

SCALE:

NA

DRAWING TYPE: SIZE: A

PBA6/PBA7

1455 KLEPPE LANE

SPARKS, NEVADA 89431

(775) 359-4712 FAX (775) 359-7424

E-MAIL: HAWS@HAWSCO.COM

WEBSITE: WWW.HAWSCO.COM

INSTALLATION

PART NUMBER

0002077650.D

REVISION

8

SHEET OF

22

Loading...

Loading...