4000.12 Tank Shower

Picture 1: Cover picture

Project name: Tag No.: Project No. Haws: Order No.: -

Manufacturer: Haws AG

Bachweg 3

CH-3401 Burgdorf

Switzerland

Tel.: +41 (0)34 420 60 00

Fax: +41 (0)34 420 60 01

Mail: info@haws.ch

www.haws.ch

Document version: 140556 v1

Date of issue: 08.08.2014

Before starting all tasks, read the operating instructions!

4000.12_V1 2014.08.08 Autor: tara

©Haws AG Switzerland Confidential Page 1

TABLE OF CONTENTS

1 GENERAL INFORMATION .......................................................................................................................................... 3

1.1 STANDARDS: ................................................................................................................................................................................. 3

1.2 SCHEDULE .................................................................................................................................................................................... 3

1.3 INFORMATION CONCERNING THIS DOCUMENTATION ................................................................................................................ 3

1.4 SYMBOL EXPLANATION ................................................................................................................................................................ 4

1.5 DISCLAIMER .................................................................................................................................................................................. 5

1.6 WARRANTY CONDITIONS ............................................................................................................................................................. 5

1.7 CUSTOMER SERVICE AND PRODUCT MONITORING ..................................................................................................................... 5

2 SAFETY INFORMATION ............................................................................................................................................. 6

3 DESCRIPTION ............................................................................................................................................................ 6

3.1 CORRECT USE TO THE INTENDED PURPOSE ................................................................................................................................. 6

3.2 NAME PLATE ................................................................................................................................................................................ 7

3.3 OVER HEAD TANK SHOWER ......................................................................................................................................................... 7

3.1 DELIVERY INCLUDES ..................................................................................................................................................................... 9

4 GENERAL ARRANGEMENT ....................................................................................................................................... 10

5 P & ID PROCESSSCHEMASTICS ................................................................................................................................ 11

6 CONTROLS .............................................................................................................................................................. 12

7 SPARE PARTS .......................................................................................................................................................... 13

7.1 SPARE PART LIST ......................................................................................................................................................................... 14

7.2 RECOMMENDED SPARES FOR 2 YEARS CONTINUOUS OPERATION ............................................................................................ 15

7.3 MATERIAL OF CONSTRUCTION ................................................................................................................................................... 16

8 WIRING DRAWING .................................................................................................................................................. 17

9 INSTALLATION AND ERECTION INSTRUCTION ......................................................................................................... 18

9.1 CONDITIONS ............................................................................................................................................................................... 18

9.2 ASSEMBLY INSTRUCTION ........................................................................................................................................................... 19

9.3 CONNECTION LIST ...................................................................................................................................................................... 25

9.4 CHECKLIST AFTER ERRECTING / YEARLY CHECKUP ..................................................................................................................... 25

9.4.1 PRE-COMMISSIONING PROCEDURE ................................................................................................................................ 26

9.4.2 COMMISSIONING PROCEDURE ........................................................................................................................................ 26

9.5 BRIEFING OF PERSONNEL AND ORGANISATION OF MAINTENANCE .......................................................................................... 27

10 SITE ACCEPTANCE PROTOCOL ................................................................................................................................. 28

11 MAINTENANCE ....................................................................................................................................................... 30

11.1 MAINTENANCE SCHEDULE ......................................................................................................................................................... 30

11.2 MAINTENANCE REPORT ............................................................................................................................................................. 31

11.3 TROUBLE SHOOTING .................................................................................................................................................................. 33

12 MANUALS / DRAWINGS & CERTIFICATES OF COMPONENTS ................................................................................... 34

12.1 HEATING CABLE GM 2X .............................................................................................................................................................. 34

12.2 END SEAL KIT E-150 .................................................................................................................................................................... 34

12.3 POWER CONNECTION KIT C-150-E ............................................................................................................................................. 34

12.4 JUNCTION BOX GIFAS TYPE 3020 ............................................................................................................................................... 34

12.5 THERMOSTAT RAYSTAT CONTROL 10 ......................................................................................................................................... 34

12.6 INDUCTIVE SENSOR IS M12 ........................................................................................................................................................ 34

12.7 BIMETAL THERMOMETER Model 52 .......................................................................................................................................... 34

13 CERTIFICATION HAWS............................................................................................................................................. 35

14 DECLARATION OF CONFORMITY HAWS .................................................................................................................. 36

15 LIST OF FIGURES ..................................................................................................................................................... 37

4000.12_V1 2014.08.08 Autor: tara

©Haws AG Switzerland Confidential Page 2

1 GENERAL INFORMATION

1.1 STANDARDS:

- EN ISO 12100-1:2011

- EN 15154-3:2009

- EN 15154-4:2009

- EN 60204-1:2006

- EN10244:2005

- ANSI Z358.1

1.2 SCHEDULE

Purchase Order: PO and clarification of all technical aspects Delivery date:

02.06.2014 30.07.2014 12.08.2014

1.3 INFORMATION CONCERNING THIS DOCUMENTATION

Use of documentation This documentation serves as a guideline for normal course of

trouble-free operations with safety showers model 4000.

Targed group This documentation is designed for:

Installation designers/Planners

Installers

Operators

Tester

Repairmen

Requisition to read this documentation This documentation must be read carefully by any person who

is or will be responsible for using, maintaining or repairing this

equipment. Please contact the manufacturer / supplier if you

are uncertain or have any questions.

Storage location of this documentation This documentation is an integral part of the Safety

equipement and should be accessable for all persons in

charge.

Reselling products In case the product should be passed on to a successive user

then the operating and maintenance instructions must also be

included.

Concomitant regulations,

guidelines and norms Besides the advices in this opearting instruction, please also

regard the advices and signs on the safety-equipement.

Furthermore, the local accident prevention regulations and

general safety conditions for the application of the

Safetyequipement are also applicable.

Illustrations in this documentation The illustrations in this guide are for the purpose of

explanation and may differ from the actual design of your

safety shower.

4000.12_V1 2014.08.08 Autor: tara

©Haws AG Switzerland Confidential Page 3

1.4 SYMBOL EXPLANATION

In these instructions, safety instructions are designated by symbols. The safety instructions are initiated by key

words that express the extent of the hazard. It is imperative to adhere to safety instructions and act with

caution in order to prevent accidents, personal injury and material damage.

DANGER !

… points to an immediately dangerous situation, which will lead to death or serious injuries if it is not avoided

_____________________________________________

WARNING !

… points to a potentially dangerous situation, which will lead to death or serious injuries if it is not avoided

_____________________________________________

CAUTION !

… points to a potentially dangerous situation, which may lead to minor or light injuries if it is not avoided

_____________________________________________

ATTENTION !

… points to a potentially dangerous situation, which may lead to property damage if it is not avoided.

_____________________________________________

NOTICE !

… emphasizes useful hints and recommendations as well as information for efficient and trouble-free

operation.

_____________________________________________

4000.12_V1 2014.08.08 Autor: tara

©Haws AG Switzerland Confidential Page 4

1.5 DISCLAIMER

Information in this documentation All information and notes in this manual were compiled under

consideration of valid standards and regulations, the present

status of technology and our years of knowledge and

experience. The actual scope of delivery can, by special

designs, deviate from the explanations and presentations

given here, because of the utilization of additional order

options, or because of the most recent technical changes.

Shipment The responsibilities agreed in the delivery contract, the

General Terms and Conditions as well as the delivery

conditions of the manufacturer and the statutory regulations

valid at the time of the conclusion of the contract are

effective.

Technical modifications The manufacturer reserves the right to make technical

modifications according to legal regulations stipulating the

continual improvement of product features and safety.

exclusion of liability The manufacturer will not guarantee against any accident

caused by caused by the following:

Use not according to regulations

On non-observance of this operating manual and its

operating instructions

Work or handle on this safetyepuipement by non-qualified

personnel

Use of spare parts other than those from the original

manufacturers

Alterations, additions or maintenance without the written

approval of manufacturer

use of unsuitable operating equipment

1.6 WARRANTY CONDITIONS

Reference The guarantee conditions shall be as stipulated in the sales

contract and General Terms of Business of the manufacturer.

General It will be up to the manufacturer to decide on the warranty

claim. The event of any action that falls under warranty the

original warranty period will not be prolonged and no new

warranty will be given.

If repairs during the warranty period are carried out by

operator or third partys without the manufacturers written

permission, the warranty will expire immediately.

1.7 CUSTOMER SERVICE AND PRODUCT MONITORING

Customer service If any problems are encountered during installation or

operation which cannot be resolved with the aid of the

installation and maintenance instructions, please contact the

supplier or manufacturer for more information.

Product monitoring The common aim is to continuously improve our safety

products, processes and services for customers. Furthermore,

our employees are always interested in new information and

experience arising from use and which can be valuable for the

improvement of our products.

4000.12_V1 2014.08.08 Autor: tara

©Haws AG Switzerland Confidential Page 5

2 SAFETY INFORMATION

WARNING !

Faulty installation.

Negligent maintenance.

Tripping hazards and barriers on your way to the safety

shower.

Mortal danger!

Risk of loss of eyesight!

Danger of permanent damage to health!

This safety shower shall safe life and eye sight:

Do not risk the effectiveness of the safety shower by

unprofessional installation.

Check weekly the function of the safety shower and

provide immediate troubleshooting.

Please ensure at all time that there are no tripping hazards

and barrieres on the way to the safety shower.

_____________________________________________

Personal Protective Equipement • Wear personal safety equipment in accordance with the

relevant local regulations.

3 DESCRIPTION

3.1 CORRECT USE TO THE INTENDED PURPOSE

The safety shower

- 4000.12 combination unit

Is a

- Body shower with water and additive inlet connection at

storage tank.

In combination with an

- Integrated eyewash with water supply connection to

storage tank.

and meets the requirements of

- Non plumbed-in body showers according to

EN 15154-3:2009

and

- Non plumbed-in eyewash units according to

EN 15154-4:2009

Any other use is not according to the directives

NOTICE !

Use for the intended purpose also includes observation of the appropriate INSTALLATION AND ERECTION

INSTRUCTION instruction Page 18 including compliance with the CONDITIONS Page 18 and regular

MAINTENANCE Page 30.

_____________________________________________

4000.12_V1 2014.08.08 Autor: tara

©Haws AG Switzerland Confidential Page 6

3.2 NAME PLATE

Picture 2: Name plate

3.3 OVER HEAD TANK SHOWER

HAWS Integrated model 4000.12 is a self contained combination shower with a 1200 liter over head tank.

The shower is driven by gravitiy of the water column.

Optional: The water tank can be ordered heat traced and insulated for

outdoor application. With this option the water temperature

can be set between 25-28°C.

The HAWS Integrated model 4000.12 is designet according ANSI Z358.1. However the gravity fed tank shower

do not meet ANSI Z358.1 because the flow performance is not constant for the entire flushing time of 15

minutes.

The tank capacity lasts for at least 15 minutes flushing time of body shower and eyewash. The stainless steel

tank incorporates a water level indicator and a temperature gauge.

The cabin offers enough space for two people.

Frame, side walls and roof are made of stainless steel.

The frame can be anchored to the ground. The tank comes with lifting lugs for easy erection.

The body shower has an average capacity of approx. 60l/min. The flow decreases due to the static height of

water level decreases.

The eyewash has a capacity of 6l/min and lasts for at least 9 minutes during simultaneous operation with the

body shower.

The combination shower signs are according to ISO 3864-1 & ANSI Z358.1 standard. In addition a green-white

tape around the cabin is included.

4000.12_V1 2014.08.08 Autor: tara

©Haws AG Switzerland Confidential Page 7

One bottle of water preservative is included in the scope of supply.

OPTIONAL:

- An inductive alarm sensor is connected to the level

indicator. The sensor will be activated if the water level

drops below the set point.

- Tank is insulated and heat traced. The water temperature

will be controlled by Thermostat and scald valve.

4000.12_V1 2014.08.08 Autor: tara

©Haws AG Switzerland Confidential Page 8

3.1 DELIVERY INCLUDES

The Tank shower Model 4000.12 will be tailored to include the following:

- 1x 1200lt Tank (stainless steel). Heat traced and insulated.

(25-28°C)

- 1x Eye wash, mounted inside (Stainless steel).

Activated by foot treadle (Stainless steel). Capacity of

approx. 6l/min

- 1x Body shower (Stainless steel) Capacety of approx.

60l/min.

- 1x tank case (Stainless steel) including green/yellow

marking

- 6x Frame elements (Stainless steel)

- 1x Set of Eye wash and shower sign in jumbo size.

- 1x Inductive alarm sensor

- 1x thermostat Raystat control 10

- 1x scald valve

- 1x heating cable

- Voltage: 230V/ 50Hz.

- 1x Water connection 1 1/4" BSP male

- 1x temperature sensor PT-100

Weight of this unit: ca. 370kg

Dimensions: 1.05m x 1.13m x 3.56m (Length x Width x Height)

4000.12_V1 2014.08.08 Autor: tara

©Haws AG Switzerland Confidential Page 9

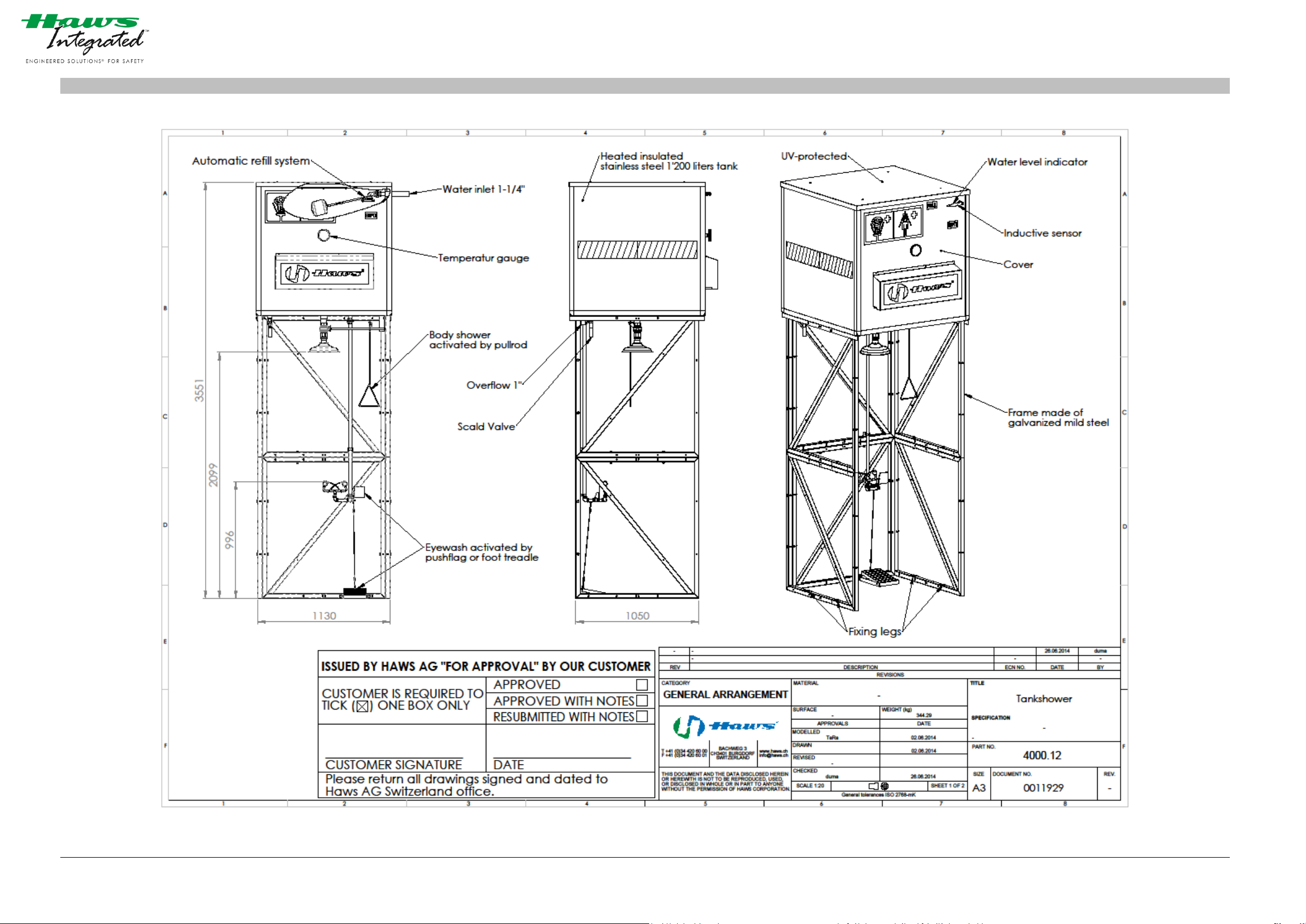

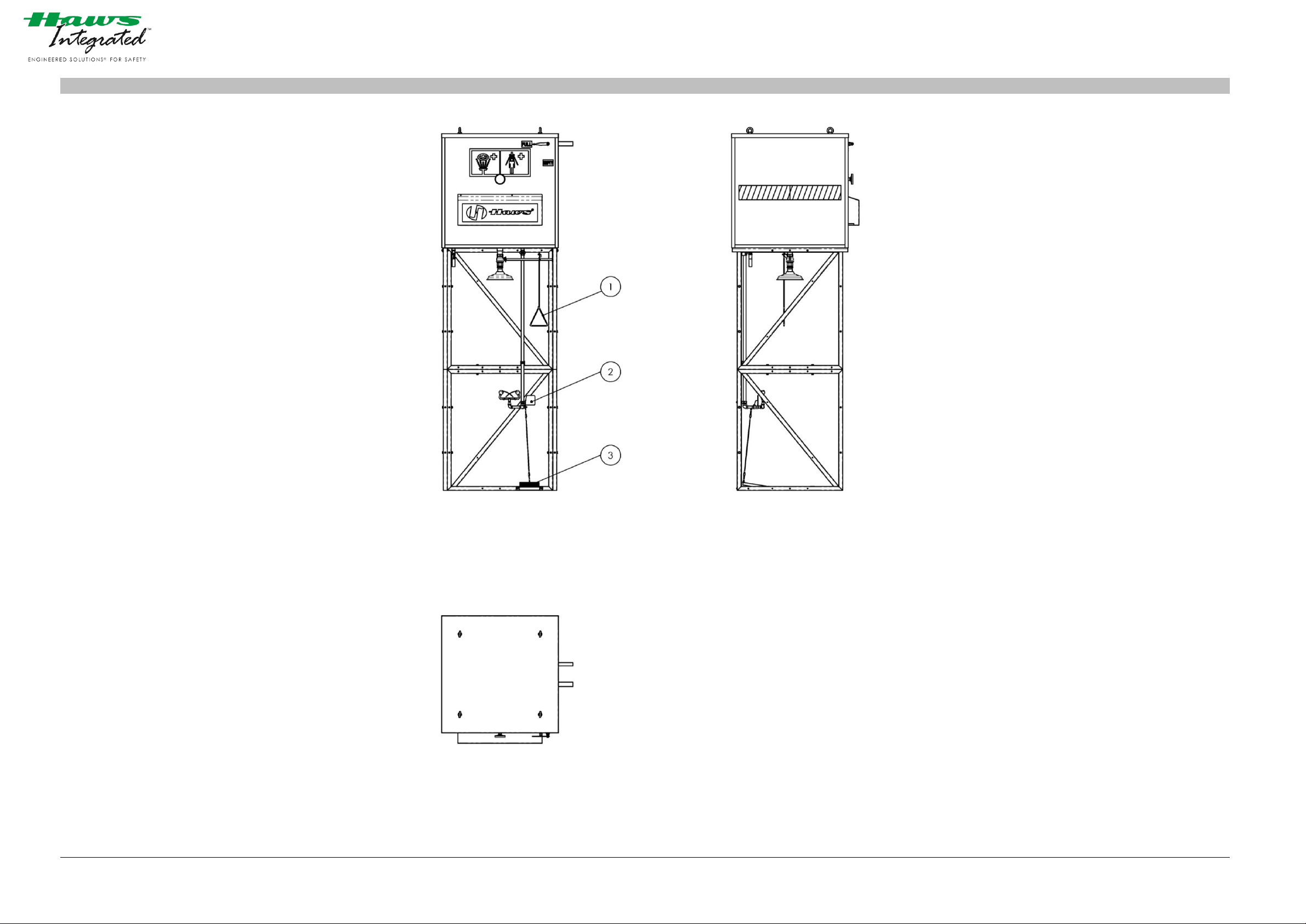

4 GENERAL ARRANGEMENT

Picture 3: Drawing of GA Haws

4000.12_V1 2014.08.08 Autor: tara

©Haws AG Switzerland Confidential Page 10

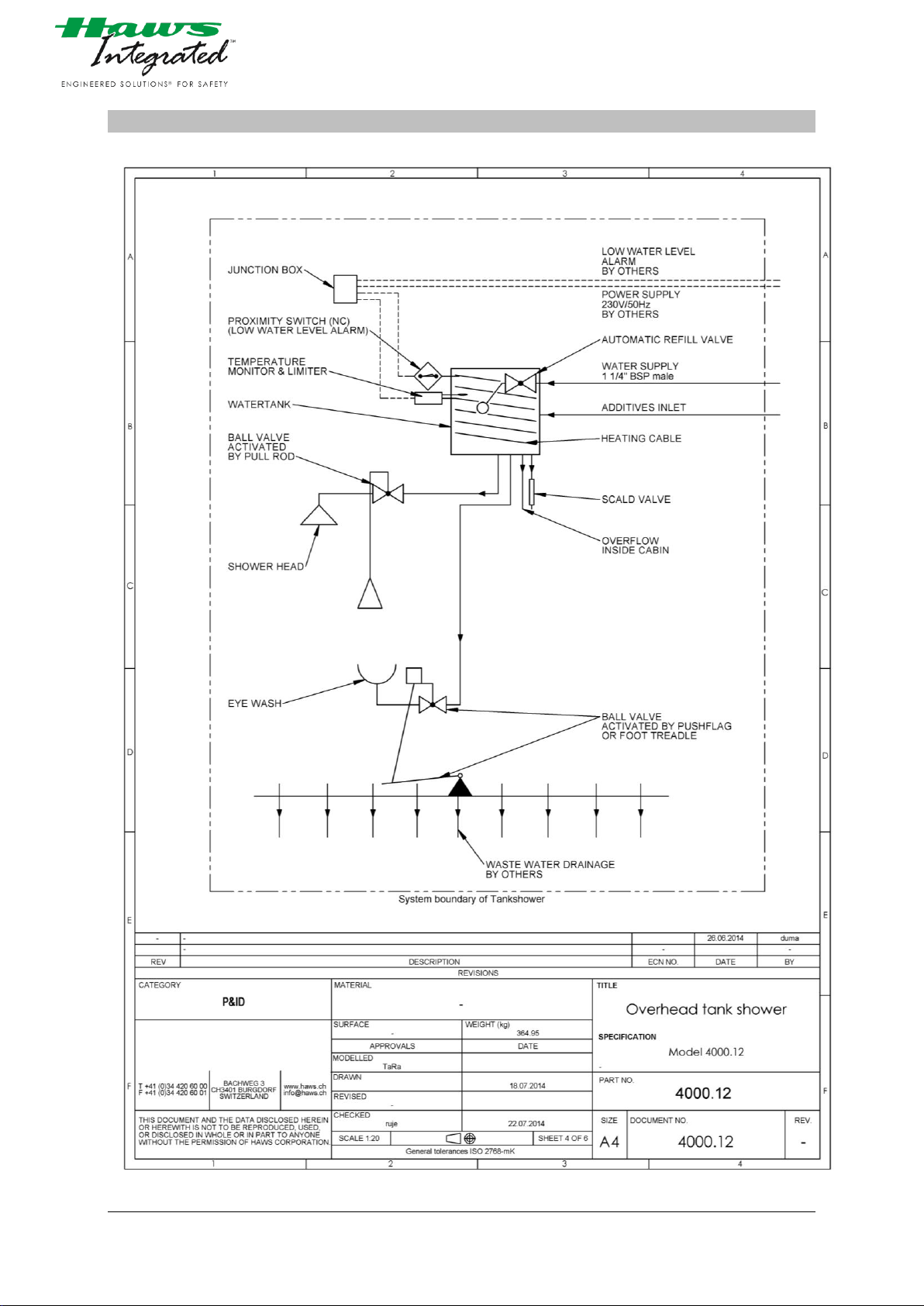

5 P & ID PROCESSSCHEMASTICS

Picture 4: P&ID Drawing

4000.12_V1 2014.08.08 Autor: tara

©Haws AG Switzerland Confidential Page 11

Picture 5: controls

1. Pull rod

To activate: pull down

To turn off: pull up

2. Push flag

To activate: Push down

To turn off: Pull up

3. Grate

To activate: step on.

To turn off: step off and pull the pushflag up [2.]

6 CONTROLS

4000.12_V1 2014.08.08 Autor: tara

©Haws AG Switzerland Confidential Page 12

Loading...

Loading...