Haws 3600, 3610, 3611, 3612, 3620 Installation, Operation & Maintenance Instructions Manual

...

INSTALLATION, OPERATION

&

MAINTENANCE INSTRUCTIONS

NOTE TO INSTALLER: Please leave this information with the Maintenance Department.

SHOULD YOU EXPERIENCE DIFFICULTY WITH THE INSTALLATION OF THIS

1455 Kleppe Lane Sparks, NV 89431-6467 (775) 359-4712 Fax (775) 359-7424

E-mail: haws@hawsco.com website: www.hawsco.com

MODELS 3600/3601/3602/3603/3610/3611/3612/3620/3621/3630/3601FR/

HAWS warrants that this specific product is guaranteed against defective material or

poor workmanship for a period of one year from date of shipment. HAWS liability

under this warranty shall be discharged by furnishing without charge F.O.B. HAWS

Factory any goods, or part thereof, which shall appear to the Company upon

inspection to be of defective material or not of first class workmanship, provided that

claim is made in writing to Haws within a reasonable period after receipt of the

product. Where claims for defects are made, the defective part or parts shall be

delivered to the Company, prepaid, for inspection. HAWS will not be liable for the

cost of repairs, alterations or replacements, or for any expense connected therewith

made by the owner or his agents, except upon written authority from HAWS, Sparks,

Nevada. HAWS will not be liable for any damages caused by defective materials or

poor workmanship, except for replacements, as provided above. Buyer agrees that

HAWS shall not be liable for general, special, or consequential damages claimed to

arise under the contract of sale. The drinking fountain manufactured by HAWS is

warranted to function if installation and maintenance instructions provided are

adhered to. The units also must be used for the purpose for which they were

intended.

NO OTHER WARRANTIES EXPRESSED OR IMPLIED ARE AUTHORIZED,

PROVIDED OR GIVEN BY HAWS.

MODEL PLEASE CALL:

TECHNICAL SUPPORT: 1-800-766-5612

FOR CUSTOMER SERVICE: 1-888-640-4297

Modular Outdoor Fountain System

3602FR/3603FR/3610FR/3611FR/3612FR/3620FR/3621FR/3630FR

LIMITED WARRANTY

No. 0510000704 (2)

02/19 Models 3600/3601/3602/3603/3610/3611/3612/3620/3621/3630/3601FR/ Page 1 of 10

3602FR/3603FR/3610FR/3611FR/3612FR/3620FR/3621FR/3630FR

O.D.

1/4”

±.005”

11/16”

3/8”

±.005”

3/4”

1/2”

±.005”

7/8”

5/8”

±.005”

1-1/8”

RECOMMENDED TOOLS: Hack saw, PVC solvent weld glue, screwdriver, level, 12"

adjustable wrench, 10" pipe wrench, 1/8” or 5/32” tamper-resistant hex key wrench (supplied),

9/16”, 1/2", 7/16” socket wrench or open- end wrench.

LOCATION OF UNIT: The Model 36XX/36XXFR Modular Fountain System can be assembled

to be wheelchair accessible. When the pedestal arm is installed in the high orientation, the

height dimensions shown on the model specification sheet meet current ADA requirements.

When installing this unit, local, state or federal codes should be adhered to. If height other

than shown is required, then dimensions must be adjusted accordingly.

SUPPLY LINE: The minimum recommended line size is 1/2“IPS with 30-90 psi (2-6 ATM)

flowing pressure. Where sediment or mineral content is a problem, an inlet filter is

recommended.

PLUMBING CONNECTIONS: Inlet is 3/8“O.D. quick-connect fitti n g. Waste outlet is female 11/2” PVC pipe. Plumbing connections vary depending on how the unit is configured during

assembly. The pedestal (3674/3675) is supplied with various fittings and PVC pipe for a top

waste connection. The arm (3671/3673) is supplied with various fittings, waste tee, and elbow

for a side arm waste connection. If two arms are attached to the pedestal at the same height,

a 1-1/2” PVC cross is required (not supplied) for connecting the waste lines.

MAINTENANCE:

For 36XX models- Periodically clean the pushbutton strainer. Refer to 5874 Series Valve

Operation and Maintenance Sheet for more information.

For 36XXFR models- Refer to 6518 Operation and Maintenance Sheet for more information.

INSTALLATION PROCEDURE

The 36XX Modular Outdoor Drinking Fountain is a system in interchangeable components that

can be installed in the configuration best suited to the installation site. The fountain can reconfigured after installation as desired. Follow the installation procedures outlined in the

installation diagram. 36XXFR versions must be connected to 6518 series freeze resistant bury

valve. See 6518 installation manual for instructions.

GENERAL NOTES:

1. For all plastic push-in type fitting connections, only connect NSF-61 copper or

plastic tubing. Stainless steel or glass tubing is not recommended. The

following assembly instructions must be followed to ensure a watertight

connection:

a. Cut tubing square and clean.

b. Mark from end of tube the length of insertion (See table below).

c. Push tube into the fitting until it bottoms out.

d. To remove, depress collet and pull tubing out.

Tube Sizes

02/19 Models 3600/3601/3602/3603/3610/3611/3612/3620/3621/3630/3601FR/ Page 2 of 10

3602FR/3603FR/3610FR/3611FR/3612FR/3620FR/3621FR/3630FR

Tolerance

Insertion Depth

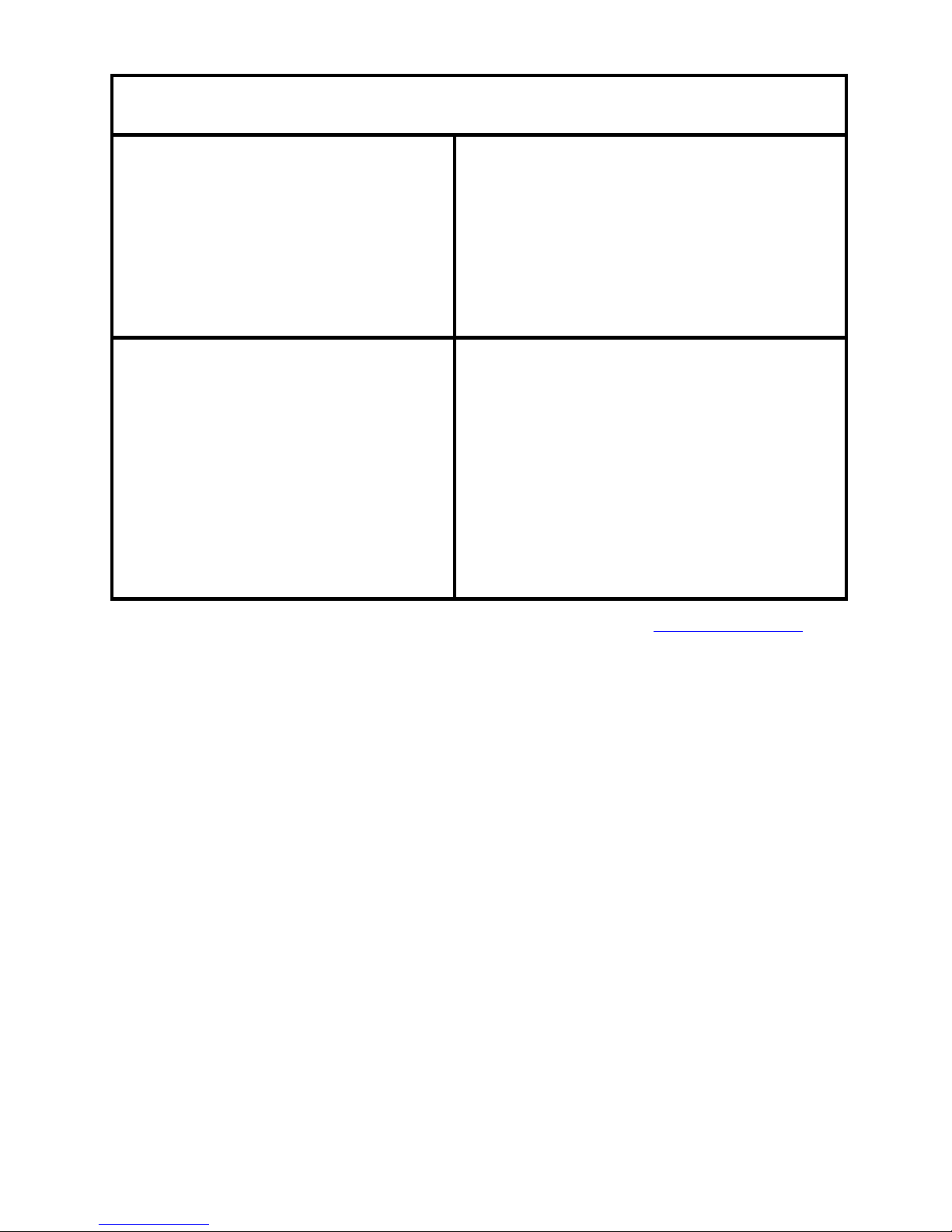

TROUBLESHOOTING

PROBLEM

REPAIR CHECKLIST

1.

Insufficient bubbler flow

1a.

Verify minimum 30 psi flow ing supply

b.

For 3680- Check that inlet screwdriver

c.

For 3680FR- Adjust valve to increase

2.

Insufficient bottl e fill er fl ow

2a.

Nozzle strainer is clogged. Use nozzle

flow. See 6518FR Manual.

(3680/3680FR Drinking Fountain)

(3690/3690FR Bottle Filler)

For more information about Haws products, see our website: www.hawsco.com

© 2019 Haws® Corporation – All Rights Reserved

HAWS

®

and other trademarks used in these materials are the exclusive property of Haws Corporation.

b.

c.

pressure.

stop valve is wide open. Clean inlet

strainer or adjust valve to increase

flow. See 5874 Series Valve Manual.

flow. See 6518FR Manual.

removal tool to remove strainer and

replace. Replacement s tr ai ners may be

ordered by calling Customer Service.

For 3690- Check that inlet screwdriver

stop valve is wide open. Clean inlet

strainer or adjust valve to increase

flow. See 5874 Series Valve Manual.

For 3690FR- Adjust valve to increase

02/19 Models 3600/3601/3602/3603/3610/3611/3612/3620/3621/3630/3601FR/ Page 3 of 10

3602FR/3603FR/3610FR/3611FR/3612FR/3620FR/3621FR/3630FR

Loading...

Loading...