Page 1

Model 2000SMS/2000SMSN

Bottle Filler with Lifecycle Control

INSTALLATION GUIDE

NOTE: A Class A ground-fault circuit interrupter

supplying power to this unit.

CAUTION! Prior to making any electrical

from the service panel is off.

SHOULD YOU EXPERIENCE DIFFICULTY WITH THE INSTALLATION OF THIS

PARTS LIST: 1 Bottle Filler, 1 filter cartridge, 1 plastic drain basin, 1 hex key, 1 grommet.

1455 Kleppe Lane Sparks, NV 89431-6467 (888) 909-4297

website: www.Hawsco.com

No. 0510000664 (2)

(GFCI) shall be installed in the branch-circuit

connections, verify with a voltm eter that power

MODEL, OR REQUIRE REPLACEMENT PARTS, PLEASE CALL:

TECHNICAL SUPPORT:

1-800-766-5612

HOURS OF OPERATION: MON-THURS 7:00a.m. - 4:30p.m PT, FRI 7:00a.m.- 11:00a.m. PT

QUICK START REFERENCE

RECOMMENDED TOOLS: Phillips screwdrivers, level.

REQUIRED PARTS (NOT SUPPLIED): 1/2” screwdriver stop, 3/8” tubing (to be used for water

supply inlet), 6 1/8” x 3” zinc-plated steel toggle bolts, 6 zinc-plated steel 1/8” fender washers.

PRODUCT INSTALLATION: When installing this product, local, state or federal codes should be

adhered to. This unit is certified for indoor use only.

SUPPLY LINE: Minimum recommended line size is 1/2" IPS with 30-90 PSI (2-6 ATM) flowing

pressure; supply water is to be cold water supply. Intended for municipal water only.

PLUMBING CONNECTIONS: Inlet is 3/8” O.D. push-in type fitting. If a waste is desired, the Haws

6470 retrofit 1-1/4” O.D. waste kit may be used.

E

LECTRICAL CONNECTIONS: 115VAC, 60HZ , appr ox . 0.1 4A. Unit is equipped with a standard

115VAC plug.

RATED SERVICE FLOW: 0.5 GPM (2725L/day)

OPERATING TEMPERATURE: 35–100

OPERATING PRESSURE: 30-90 PSI

FILTER CAPACITY: 2500 gallons (9460L) or 1 year

REPLACEMENT FILTER CARTRIDGE: Electronic Lifecycle Control Filter Model 6423

°

F (1.7–37.8°C)

©

2017 Haws

HAWS

08/17 Model 2000SMS/2000SMSN Page 1 of 5

®

Corporation – All Rights Reserved

®

and other trademarks used in these materials are the exclusive property of Haws Corporation.

Page 2

INSTALLATION PROCEDURE

Tube Sizes

O.D. Tolerance

Insertion Depth

1/4”

±.005”

11/16”

3/8”

±.005”

3/4”

1/2”

±.005”

7/8”

WARNING: Filter is not intended to withstand operating pressures greater than 100 PSI (6.8

WARNING: Make ce rtain power is discon nected before installation to redu ce risk of electrical

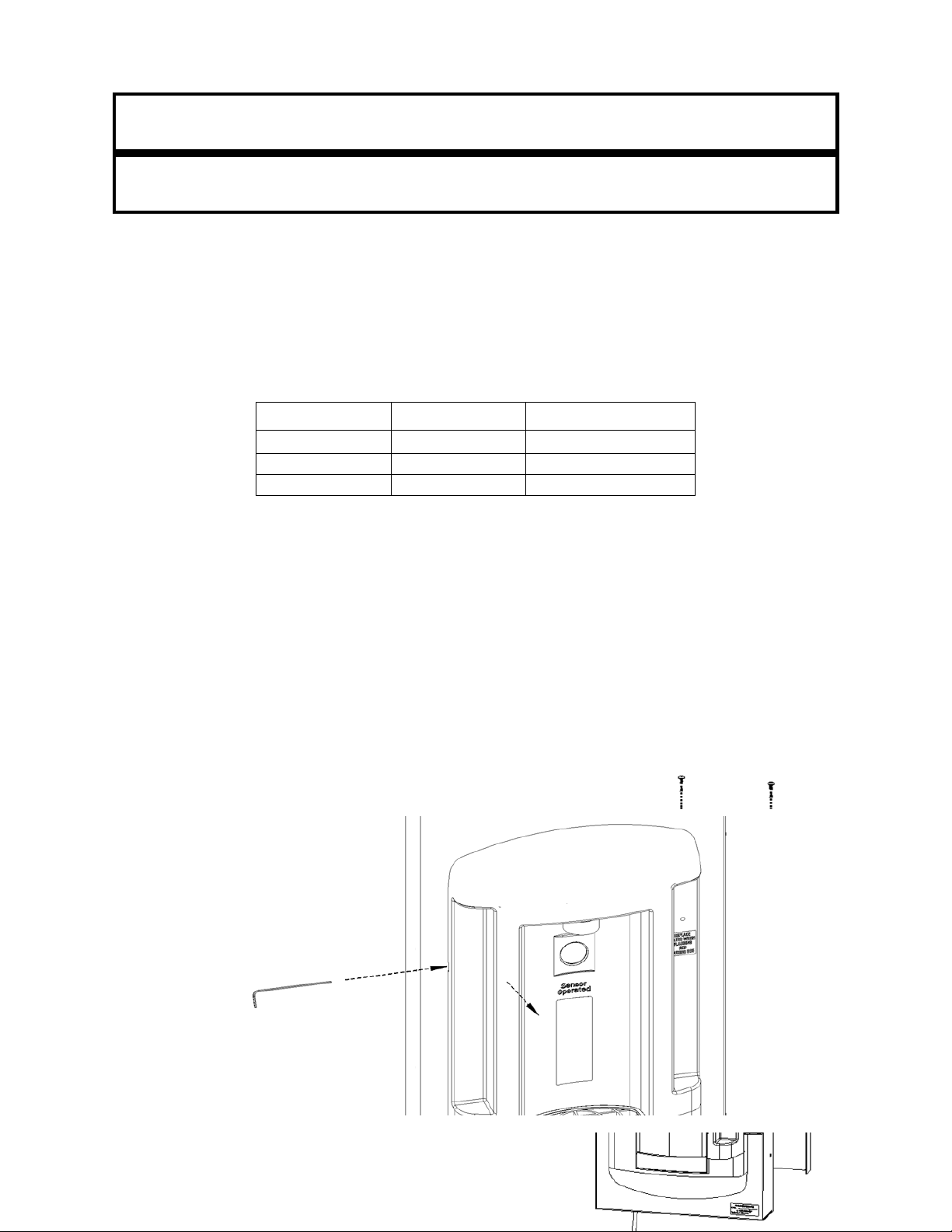

Step 1 Diagram

Step 1 Diagram

shock.

ATM). If inlet pressure is greater than this, filter must be protected with a pressure regulator.

NOTES:

1. This unit is certified for indoor use only.

2. For all plastic push-in type fitting connections, only connect NSF-61 copper or plastic

tubing. Stainless steel or glass tubing is not recommended. The following assembly

instructions must be followed to ensure a watertight connection:

a. Cut tubing square and clean.

b. Mark from end of tube the length of insertion (See table below).

c. Push tube into the fitting until it bottoms out.

d. To remove, depress collet and pull tubing out.

Step 1: To open the unit, slide the supplied hex key into the notch in the left-hand side of the hinged

Take care not to damage the stainless steel

Step 2: Remove the 4 mounting screws on the outside

2. Use NSF-61 approved pipe joint sealant on all threaded water connections.

3. Do not use with water that is microbiologically unsafe or unknown quality without

adequate disinfection before or after the system. Systems certified for cyst reduction

may be used on disinfected waters that may contain filterable cysts.

4. Use the cardboard inserts from the box to support the unit while preparing for

installation by placing unit face down on inserts.

5. There is an opening in the bottom of the unit to accommodate a plumbed waste. If a

plumbed waste is desired, the Haws model 6470 retrofit kit may be used.

upper plastic panel and press the key firmly in that same direction. This will disengage the

internal spring latch. Simultaneously pull open the hinged panel (see Step 1 Diagram).

panel or the spring latch in this process.

of the bottle filler with a Phillips screwdriver

08/17 Model 2000SMS/2000SMSN Page 2 of 5

Page 3

Step 2 Diagram

Step 4 Diagram (Back View )

Step 3 Diagram

Step 3 Diagram

(see Step 2 Diagram) and remove the m ounti ng brac k et from the bottle filler.

Step 3:

Remove the drai n basin, drain grate, and filter

cartridge from the small box inside the main

shipping carton. Install the drain basin with

grate into the front of the unit (see Step 3

Diagram), pushing it straight in until the snap

latches are fully engaged.

Step 4:

Firmly screw the filter cartridge into the filter

head (see Step 4 Diagram). NOTE: the bottle

filler will work only if a filter cartridge is installed

and its wiring is plugged in (see Step 7).

08/17 Model 2000SMS/2000SMSN Page 3 of 5

Page 4

Step 5: The bottle filler is supplied with a power cord. If desired, the power cord may be removed

Steps 5 & 6 Diagram

and the unit may be wired through one of the extra holes in the mounting bracket.

Install a supply line t hrough the bottom as shown in Steps 5 & 6 Diagram by removing the

plug from the port a nd installing th e supplied gromm et – f or use with 3/8” tubi ng. If desired,

one of the extra ports in the mounting bracket may be used for the supply inlet instead.

Connect the supply line with a screwdriver stop (not supplied).

Double-check supply and electrical locations.

NOTE: When installing this unit, all pertinent local, state, or federal codes should be adhered

to.

Step 6: Secure the detached mounting bracket to the wall; a number of mounting holes are provided

to fasten the bracket direct to the wall (see Step 5 & 6 Diagram for mounting hole pattern or

use the mounting bracket itself as a template).

Note that the bottle filler weighs approximately 30 pounds. As such, attach the mounting

bracket using six 1/8” x 3” zinc-plated steel toggle bolts (not supplied) in conjunction with six

appropriately-sized zinc -plated steel 1/8” fender washers (not supplied).

Use a level to verify horizontal and vertical frame mounting.

08/17 Model 2000SMS/2000SMSN Page 4 of 5

Page 5

Step 7 Diagram (Back View )

Step 9 Diagram A

Step 9 Diagram B

Step 7: Place the bottle filler onto its

mounting bracket and run 3/8” tubing (not

supplied) between the screwdriver stop (installed

in Step 5)and the bottle filler’s supply inlet

elbow in the filter head (it may help to temporarily

remove the filter cartridge – see Step 7 Diagram).

Connect the wiring coming off of the filter cartridge

to the wiring coming out of the circuit board enclosure

(see Step 7 Diagram).

Step 8: Replace the mounting screws removed

in Step 2 (see Step 2 Diagram for

details).

Provide AC power to unit.

Step 9: Activate the bottle filler by placing a bottle or cup in front of the

sensor (see Step 9 Diagram A). If water does not dispense, see

the Troubleshooting Guide in the Owner’s Manual.

The pressure regulator may need to be adjusted to better

complement the input pressure at the installation site (see Step 9

Diagram B). To do so, pull out the adjustment knob and rotate as

needed (clockwise from the front of the unit decreases flow); push

knob in when desired flow is achieved. * Flow rate is factory set to

the maximum flow rate for decreased water consumption.

Step 10: Approximately five gallons of water must be run through the system after the unit is

installed in order to remove the loose carbon particles from the filter cartridge and any air

bubbles from the system (both of these are normal occurrences after a filter change).

Check the system for leaks. Place hex key in a secure location.

08/17 Model 2000SMS/2000SMSN Page 5 of 5

Loading...

Loading...