Page 1

INSTALLATION INSTRUCTIONS KK-K9-F12-K

2000-2006 FORD EXCURSION

TOOLS REQUIRED:

Power Drill

Standard & Metric Socket Sets

Phillips Screw Driver

7/16” Wrench

Wire Cutters / Crimping tool

HARDWARE: Some of this hardware is already attached.

QTY:

28 ¼-20 X ½” Stainless carriage bolts GSM 32022

30 ¼-20 X ¾” Stainless carriage bolts GSM 32024

64 ¼-20 Serrated nuts GSM 30023

6 ¼-20 X ¾” Hex head Cap Screw Zinc GSM33001

14 ¼” X 1 ½” Hex head lag screw GSM 33062

36 #12 X ¾” Stainless sheet metal screws GSM 34177

24 #10 X ¾” Stainless sheet metal screws GSM 34170

22 #10 X ½” Stainless sheet metal screws GSM 34169

6 #10 X ¾” Sheet metal screws GSM 33195

20 #10 X ½” Sheet metal screws GSM33194

1 Tube Silver Caulk PRM 97343

1 46” X 45 1/2” Rubber Mat KNM01029-SUV

11 1/2 feet Adhesive Molding

SUB ASSEMBLY:

INSTALLATION:

DESCRIPTION: PART #:

• Dome light with wire

• Tunnel edge molding

• Install exhaust fans (Optional). If locating in custom

location drill 4 ½” hole into desired location of K-9

housing. Mark and drill 3/16” mounting holes to

attach fan using (4) 10/32” X ½” machine screws and

10/32” keps nuts. Then mark and drill 3/16” holes to

mount fan guard using 10/32” X ½” machine screws

and 10/32” keps nuts.

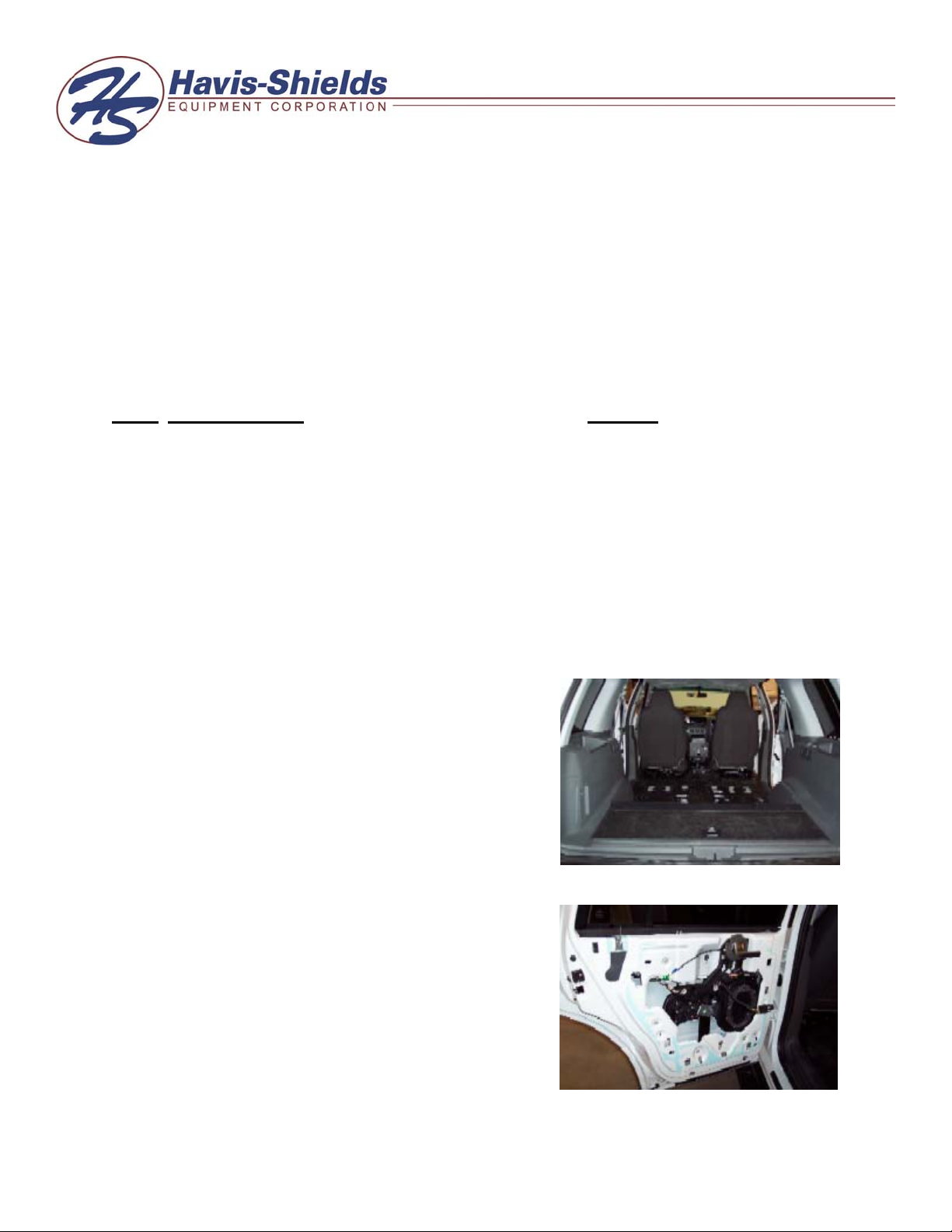

1. Remove interior:

• Remove rear seats

• Remove rear seat belt assembly

• Remove top, and bottom plastic rear trim caps

Ratchet Wrench With 6” Extension

Torx Bit Set

4 ½” Hole Saw (Exhaust Fan Option)

Caulk Gun

Page 2

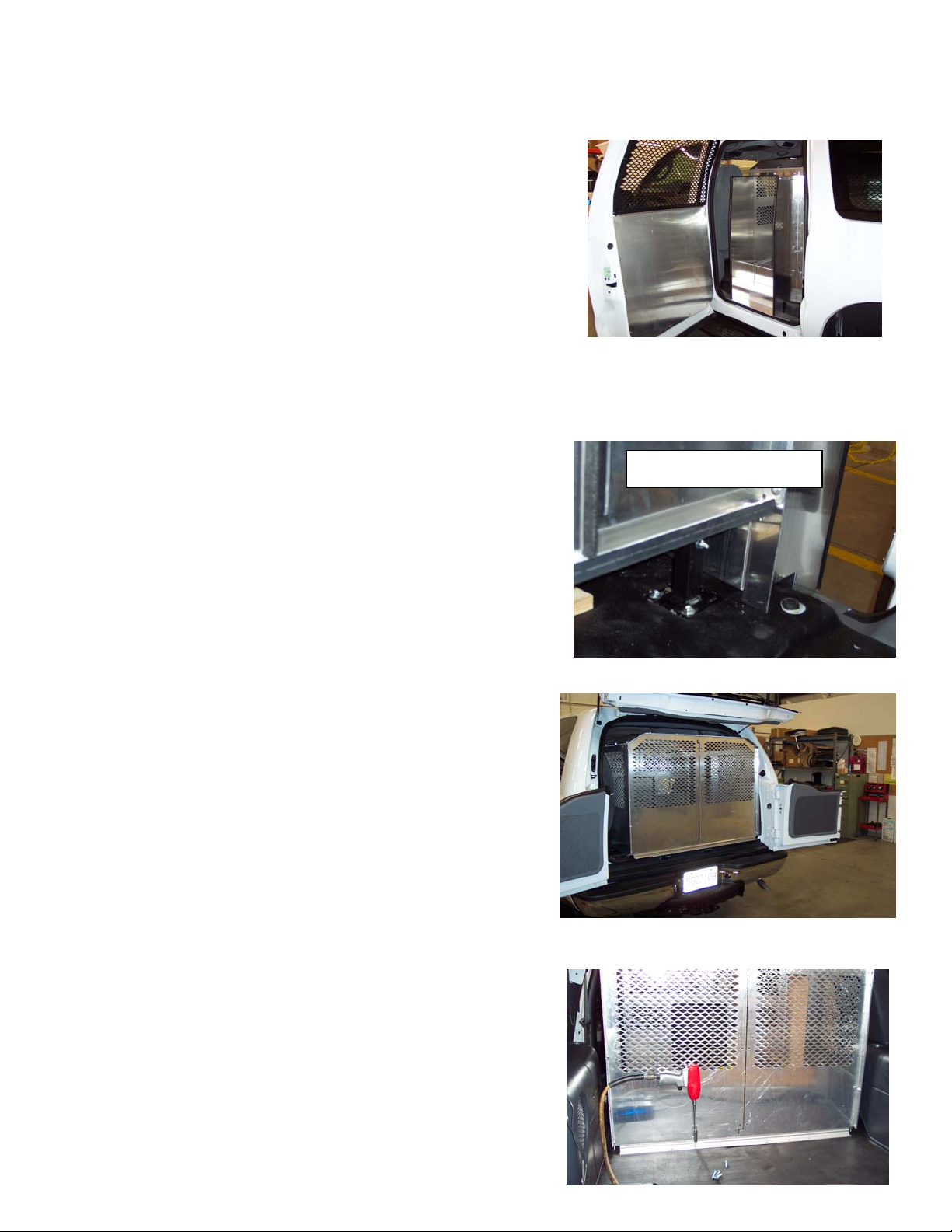

2. Remove rear OEM door panels:

• Remove speaker, door handle, and lock

• Remove switch assembly from plastic housing (leave

plug on switch)

Note: if doors have electric door switches, they must be reattached to

original plug assembly. Switch assembly must then be wired-tied

down so it does not interfere with window or door latch operations

3. Install mounting legs:

• Using ¼-20 x ¾” carriage bolts attach mounting legs

to floor of vehicle using 1/4” x 1 ½” hex head lag screws.

Note: keep nuts loose at this time. And set legs at 6 1/2” high.

4. Slide in K-9 main housing:

• Slide in main housing.

• Housing should be 48 ½” from rear plastic sill to

rear mounting flange.

• Mount legs to housing loosely, using ¼-20 x ¾”

carriage bolts.

• Mount rear support to bottom of rear housing using

(6) ¼-20 x ¾” hex head cap screw.

5. Install tunnels and fillers:

• Loosely attach side tunnels to main housing using

¼-20 x ¾” carriage bolts and ¼-20 x ½” carriage

bolts.

• Place sill plate and cover step in tunnels and

mount with #12 x ¾” stainless sheet metal screws.

6. Housing final step:

• Center housing so cover steps are even on both

sides.

• Mount rear housing to vehicle with ¼” x 1 ½” hex

head lag screw.

• Tighten all loose bolts on tunnels and legs.

Note: If 32” inch long K-9 kit is being installed, a 10”

rear floor extension must be used. (provided with 32”

kits)

Front Driver Side Leg

KK-K9-F12-K-INST-6-06

Page 2

Page 3

7. Door panels and window guards:

• Center door panels so edges do not hang over.

• Attach to door with #10 x ½” stainless sheet metal screws.

Note: window guards have holes around perimeter for permanent mounting. These holes are not used

with hinge kit! They also come flat in shipping. The guard must be pre-bent so it fits tight against the door

window frame.

• Hold window guard with pre-assembled hinge and upper bracket onto window frame.

• Make sure guard is centered on window.

• Attach hinge to lower door panel with #10 x ½” sheet metal screws.

• Mark upper aluminum bracket location on

window frame and remove from window guard.

• Attach aluminum bracket onto window frame with

#10 x ½” sheet metal screws.

• Apply adhesive molding to inner side of window

guard.

• Hinge up window guard and reattach to bracket

with #10 x ½” stainless machine screws and #10

stainless flat washers.

Note: this is for easy window cleaning.

8. Final steps:

• Mount dome light (fan if necessary) switch box as

desired. A switch box is provided so switch can

be mounted to K-9 housing in various locations.

(Topside of tunnel housing works very well).

Wire to 12-volt power source.

• Sheet metal seams and gaps need to be carefully

silicone at floor area. Proper sealing of

compartment will eliminate water from getting

under the K-9 unit.

• Allow silicone to dry overnight before placing in

rubber floor mat.

Upper Window Bracket

Adhesive Molding

KK-K9-F12-K-INST-6-06

Page 3

Loading...

Loading...