Page 1

INSTALL INSTRUCTIONS KK-100-03 & KK-120-03

KWIK-KIT PRISONER TRANSPORT INSERT

FORD and CHEVY VAN PRISONER TRANSPORT

TOOLS REQUIRED:

¼” & 3/8” Ratcheting Wrenches

¼” & 3/8”Air Ratchets (recommended)

3/8” Impact Guns (recommended)

¼” & 3/8” Standard Socket Sets

Powered Drill

Powered Screwdriver (recommended)

Drill Bit Set

Tape Measure

Screwdriver Set

HARDWARE - 60” or 80” COMPARTMENT: Some hardware not used in all application:

QTY DESCRIPTION PART # USED FOR:

80 ¼” Serrated nut GSM30023

60 ¼” x ¾” Carriage bolt GSM32000

50 #10 x 1” Phillips pan head sheet metal screw GSM33196 Floor/wall to ceiling

8 #8 x 3/8” Phillips flat head screw GSM33179 Vent plates/dome lights

32 ¼” x ¾” Phillips flat head machine screw GSM33078 Wall/Bench extension

25 ¼” x ¾” Hex head bolt GSM33001 3rd divider, 3rd ceiling

25 ¼” Flat washer GSM31005 3rd divider, 3rd ceiling

15 ½” Flat washer GSM31009 Grab straps/seat belts

15 ½” Lock washer GSM31030 Grab straps/seat belts

15 ½” x 1 ¼” Socket button head bolt GSM33310 Grab straps/seat belts

4 3/8” x 2” Hex head bolt GSM33032-1 Bulkheads

4 3/8” Hex nut GSM30008 Bulkheads

4 3/8” Lock washer GSM31028 Bulkheads

4 3/8” x 2” Fender washer GSM31022 Bulkheads

2 White Silicone tube PRM97343 Seams & Gaps

4 Lock key PRM97660-1 Doors

4 Vent block off plate KKM0403-004 Ceiling (vent adapter kit)

2 A/C vent plate KKM0403-001 Ceiling (vent adapter kit)

2 Dome light KK-DOME-2 Ceiling

HARDWARE - 40” COMPARTMENT:

QTY DESCRIPTION PART # USED FOR:

90 ¼” x ¾” Carriage bolt GSM32000

90 ¼” Serrated nut GSM30023

Awe or Scribe

Pry-bar

Wire Crimping tool

Wire Stripping tool

Wire Cutter

Circular Saw (for plywood)

Utility knife

Caulking gun

Page 2

40” COMPARTMENT (cont):

QTY DESCRIPTION PART # USED FOR:

40 #10 x 1” Phillips pan head sheet metal screw GSM33196 Floor, wall to ceiling

25 #8 x 3/8” Phillips flat head screw GSM33179 Vent plates/dome lights

5 ½” Flat washer GSM31009 Grab straps/seat belts

5 ½” Lock washer GSM31030 Grab straps/seat belts

5 ½” x 1 ¼” Socket button head bolt GSM33310 Grab straps/seat belts

5 3/8” x 2” Hex head bolt GSM33032-1 Bulkheads

5 3/8” Hex nut GSM30008 Bulkheads

5 3/8” Lock washer GSM31028 Bulkheads

5 3/8” x 2” Fender washer GSM31022 Bulkheads

2 A/C Vent plate KKM0403-001 Ceiling (vent adapter kit)

1 Dome light KK-DOME-2 Ceiling

HARDWARE – DIVIDER:

QTY DESCRIPTION PART # USED FOR:

28 ¼” x 1 ½” Hex head lag bolt GSM33062 Divider to floor

14 ¼” x 5/8” Stainless socket button head bolt GSM33308 Divider

7 ¼” x ¾” Stainless socket button head bolt GSM33309 Divider

14 ¼” Stainless flat washer GSM31048 Divider

10 #10 x ½” Phillips flat head machine screw GSM33072 Door frame to divider

10 #10 Thin nylock nut GSM330015-1 Door frame to divider

Always!

Read all instructions before installing any Havis-Shields Equipment Corp products.

Check for obstructions (Wire, brake lines, fuel tank, etc.) before drilling any holes!

Use hardware provided with install kit

For product support, visit the Install Instructions Section of our website at

http://havis.com/Installation/Installation.html, email technicalsupport@havis.com or call 1-800-

524-9900.

If this is your first time installing a Havis Shields Equipment Corp Prisoner Transport, please

contact the factory for tips and suggestions that will ease the installation.

VEHICLE PREPERATION:

1. STEPS, HVAC, VAK, OPTIONS, ETC:

••••

Refer to the specific install instructions. Installing the steps prior to installing the Kwik Kit will

ease installation and must be done on Chevy side step.

••••

Installing options may be necessary prior to installing the kit.

2. SOUND DEADENING & FLOORING:

••••

OPTION #1: KK-RFM A self-adhesive rubber sound deadening floor mat is sold separately

and will help deaden road noise.

••••

Install optional rubber flooring onto van floor. Rubber floor mat should go under OEM floor

mat in drivers compartment to cover sheet metal floor.

••••

Excess material can be placed onto walls of the van, around the wheel wells, inside door

panels, etc. This will also help deaden the echo in the vehicle.

••••

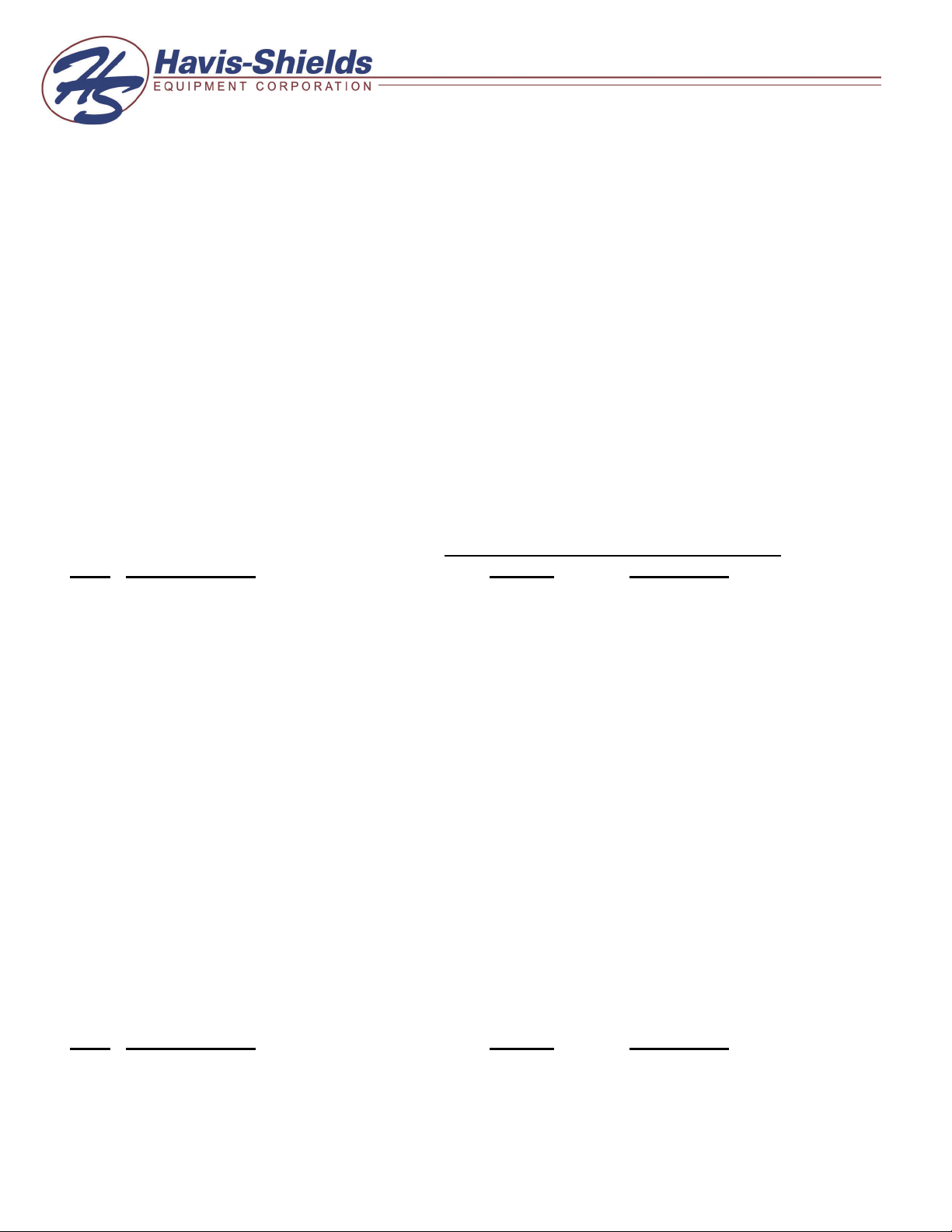

OPTION #2: 3/8” to ½” plywood can also be used as an alternative solution. Cover the entire

cargo floor of the van. (1 ½) – 48” x 96” sheets of plywood are needed. Havis Shields

Equipment Corp does not supply plywood floor kit. Draw a line on the rubber/wood floor from

rear doorframe as shown on the following page. This will be the starting point of the kit.

2

KK-XXX-03_INST_10-07

Page 3

similar in Ford and Chevy Vans.

step)

After plastic trim is cut and back in

parts

Note: With OEM rear AC/Heat,

The kit will be shifted to passenger

1997-2008 Chevrolet G-Series Van

Rear OEM Trim modifications

Installation of Kwik Kit is very

All kits start with a

measurement at the rear floor.

The rear plastic floor trim on

Chevy vans must be cut straight

across as shown in photo.

Measure seven inches (7 1/4”)

from rear center of trim and cut

straight-line full width.

(Jig saw works well for this

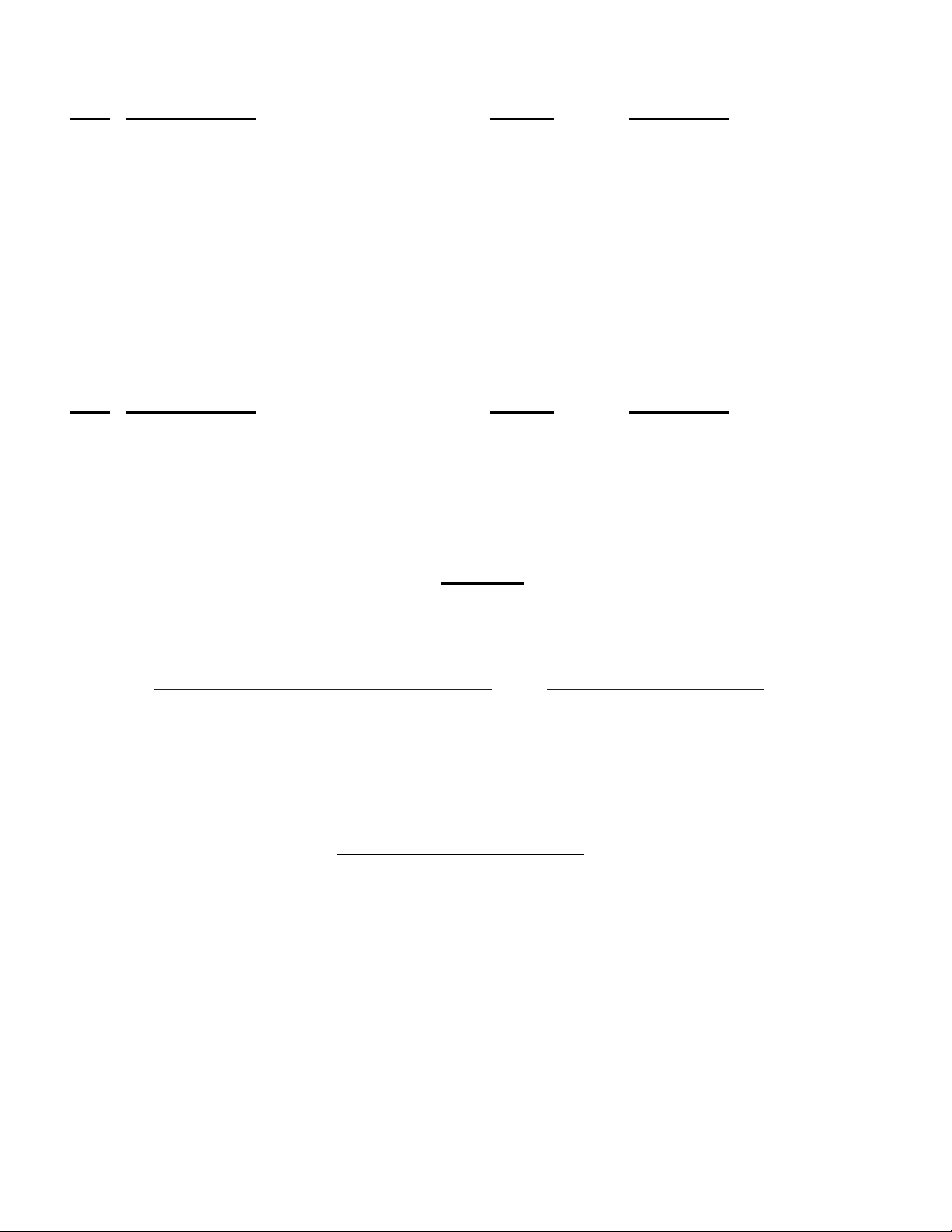

it’s original location, you must

measure 7” inches forward on both

sides from newly cut trim to place

rear Kwik Kit bulkhead.

This is the starting position so

fit into the correct locations.

side.

.

*** Ford Van does NOT require

rear trim modification***

3

KK-XXX-03_INST_10-07

Page 4

all rear trim and headliner as this will aid in sound deadening & insulation

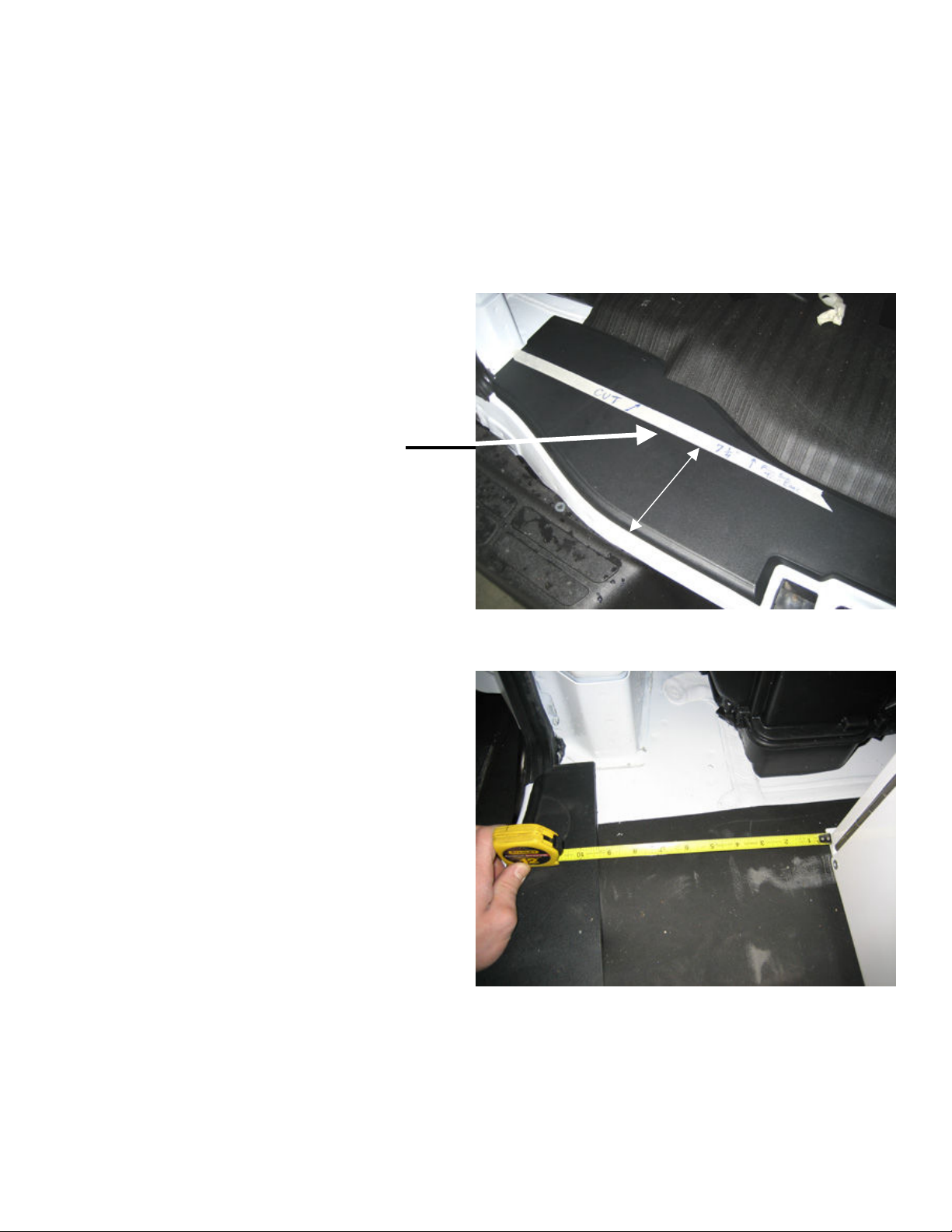

Ford Driver-Side rear

Ford Passenger-Side rear

8”inches

3. PASSENGER WINDOW VAN PREPARATIONS:

8” inches

***Kwik kits are designed for cargo vans with no rear OEM trim, however they can be installed

into passenger window vans. Some rear trim removal or modification is required. Do not remove

Note: Kwik Kits are recommended for Cargo Vans. The installer must determine modifications

to the interior of a window van.

1. Remove all rear bench seats from the vehicle.

2. Modify / remove interior parts as needed.

3. Remove floor mat/carpet and replace with ½” plywood or sound deadening material.

(Recommended).

4. If installing KK-F-VAK, (OEM air conditioning adapter) cut or remove all plastic trim around

the rear OEM system.

UNPACKING AND INSTALLATION:

***Refer to exploded view drawing on page 22 to identify parts ***

4

KK-XXX-03_INST_10-07

Page 5

wrap covering the

prisoner transport

assembly.

2. This is the rear 40/60/or

80 section of the kit.

3. Remove all black

hardware, wood panels

and brackets holding

wood panels.

4. Remove bolts

holding the kit to the

wood pallet.

5. With all hardware

removed the remaining

sections should match

the sub-assemblies on

the following pages

1. Remove clear shrink-

1. Remove clear shrink-wrap covering from

prisoner transport assembly.

2. This is the 3rd compartment, 40 section

3. Remove all black hardware, wood fillers,

and brackets holding assemblies.

4. Remove bolts holding the kit to the wood

pallet.

5. With all hardware removed the remaining

sections should match the sub-assemblies on

the following pages

5

KK-XXX-03_INST_10-07

Page 6

Remove all black hardware from assembled unit. This will give you the

subassemblies as they are shown on the following pages.

6

KK-XXX-03_INST_10-07

Page 7

VERY IMPORTANT:

Be sure that all Auxiliary lighting, video systems, Kwik kit options, and

Run all wiring for dome lights, power

done prior to installing Kwik Kit

Be sure to tape harnesses to roof in

the different model kits.

VAK

for wiring

wiring are complete. Access is severely limited after kit is installed.

Notch trim

If optional rear load light(s)

(KK-RLL) was ordered, install at

this time.

See KK-RLL install instructions

approximate locations that

accessories are being installed in

Kwik kit. This will vary between

vents, video system, HVAC, etc. at

this time. Tie to existing OEM harness

At this time go to the KK- (x)-

install instructions. This must be

installed prior to Kwik Kit.

“B” Pillar

For neatness of wiring, route all

cables down driver-side “B” pillar.

If going under hood for power to

console, drill hole at location above.

If optional Power Vent(s)

(KK-PVENT) was ordered, see

those instructions at this time for

necessary prep work that must be

1 ½” Hole

7

KK-XXX-03_INST_10-07

Page 8

Driver

-

side Bench/Wall

Item #1

install

Passenger

-

side

assembly into van so

Emergency

Exit Hatch

Emergency Exit Hatch

Front Bulkhead

Front Bulkhead

Item #2

Place

assembly into van so bench rests

on wheel well

Place

Bench/Wall

bench rests on wheel well

Item #3

Remove steel support bracket for

Emergency Exit Hatch pin. Re-

when attaching Front Bulkhead to

Item #3

Remove

from Front Bulkhead to ease

installation

Bench/Wall assemblies

Item #3

Place

vehicle

into

Item #3

Attach

Driver-side Bench/Wall

assembly

Item #3

to

View of

support bracket assembled.

8

KK-XXX-03_INST_10-07

Page 9

Place Center Divider into vehicle.

prior to divider

.

Driver

-

side

Center Divider

Diamond Plate Floors

the floor to avoid scratching the bench.

KK

-

Note: Vent hose will be tight in spots. If hose are crushed to an oval

shape the airflow will still be good. Avoid completely crushing hoses.

nches

Item #4 & #13

Be careful that exposed wires are not touching metal and optional

x-VAK hoses are not completely crushed

Item #5

Item #3

Item #4

The floor(s) will square the be

and bulkheads to the kit.

Place (2)

between Bench/Wall assemblies and

Front bulkhead. Place cardboard

along side of bench while positioning

Item #5

NOTE: Some installers

prefer to install ceiling

Item #5 to #3

Loosely bolt

Front Bulkhead

to

Current view of installation

9

Item #7

Carefully place

Ceiling section into vehicle.

KK-XXX-03_INST_10-07

Page 10

side Ceiling section into

Item #8

Slide the ceiling sections out of the way in order to access A/C hoses, wires, etc.

Item #8

Place Passenger-

vehicle

Do not attach any hardware at this time

Route dome light wires, HVAC

hoses, video cables, etc to their

respective locations

Item #7 & #8

Item #7 & #8

Note: These components will be hard to access once ceiling is mounted.

Remove all slack from hoses to maximize airflow.

Current view of installation

Item #9

Remove Bulkhead Emergency

Exit Hatches to ease installation.

Item #12

Item #9

Item # 10

Position Middle Bulkhead to

separate front and rear

compartments

10

Install forward compartment

driver sidewall / bench assembly.

Item 10.

Install forward compartment

ceiling assembly. Item 12.

Place rear facing bench against

front bulkhead. Item 16.

KK-XXX-03_INST_10-07

Page 11

Use under seat flange holes to mark

flange with # 10 x ¾” pan head sheet

Rear Facing bench

Attach floor flange and side seat

metal screws.

and Drill through front bulkhead

with ¼” bit. Use ¼” x ¾” bolts and

serrated to attach seat to bulkhead.

Attach seat cover plate with # 10 x

½” flat head sheet metal screws.

Drill floor flange and side seat

flange with a 5/32” drill bit.

Loosely bolt Passenger-side rear ceilings, Bench/Wall

assembly to Middle Bulkhead using ¼” x ¾” Carriage bolts

and serrated nuts

Note: An awe or scribe is recommended to help align holes.

Item #9 to #2

11

Bolt side door and door-frame

assembly using ¼” x ¾” carriage

bolts, washers and nuts.

KK-XXX-03_INST_10-07

Page 12

Rear Bulkhead

at the door hinge) to

assemblies using ¼”

3rd Compartment

Doorframe

Center

Item #6

to #5

Driver and

Rear Bulkhead

3rd Compartment Doorframe

to

Press doorframe to align with holes in

Item #6

Place

Doorframe into vehicle

Item #6 to #2

Loosely bolt

Doorframe (

Bench/Wall

x ¾” carriage bolts, washers and

serrated nuts

Item #6

Position between

Passenger-side Bench/Wall

assemblies

Note: It is recommended to put

edge molding on the OEM door

opening on the passenger side to

avoid damaging the Kwik kit

door.

Loosely attach

to

divider using #10 x 3/8” flat head

machine screws and nylock nuts

Item #11

Place the

Doorframe assembly.

Item #11

to #9

Passenger-side Bench/Wall

assembly.

12

Item #12 to #11

Align

3rd Compartment Ceiling and loosely

attach ¼” x ¾” hex head bolts, washers

and serrated nuts.

KK-XXX-03_INST_10-07

Page 13

Rear

There should be at

Position the entire unit according to the

Rear

Item #6

Item #7, #8, #12 to #3, & #6

to #5

Continue around the entire kit bolting

all Ceiling pieces to Bulkheads and

Doorframes using ¼ x ¾” carriage

bolts, washers, and serrated nuts

Cut door gasket with utility knife. Cut gasket to the length

of door acceptor frame. Attach as shown above.

An awe or scribe will help

align the holes

Tighten screws holding

Doorframe to Center Divider

Pry bar

measurements on the following page.

Note: Maneuver the kit into position.

THE FOLLOWING STEPS ARE EXTREMLY CRITICAL FOR A SUCCESFULL

INSTALLATION! PLEASE FOLLOW THESE INSTRUCTIONS CAREFULLY.

Item #1

Rear driver-side

doorframe wing

¼”

Position of driver-side

Doorframe when installing with

factory rear air

least ¼” of space between the

A/C blower motor and wing

Lower Driver-Side rear

8”inches

Measurement from driver-side

Rear Doorframe to vehicle

doorframe shown above

Lower Passenger-Side rear

8” inches

Measurement from passenger-side

Rear Doorframe to vehicle

doorframe shown above

13

KK-XXX-03_INST_10-07

Page 14

Driver

-

side Ceiling

in

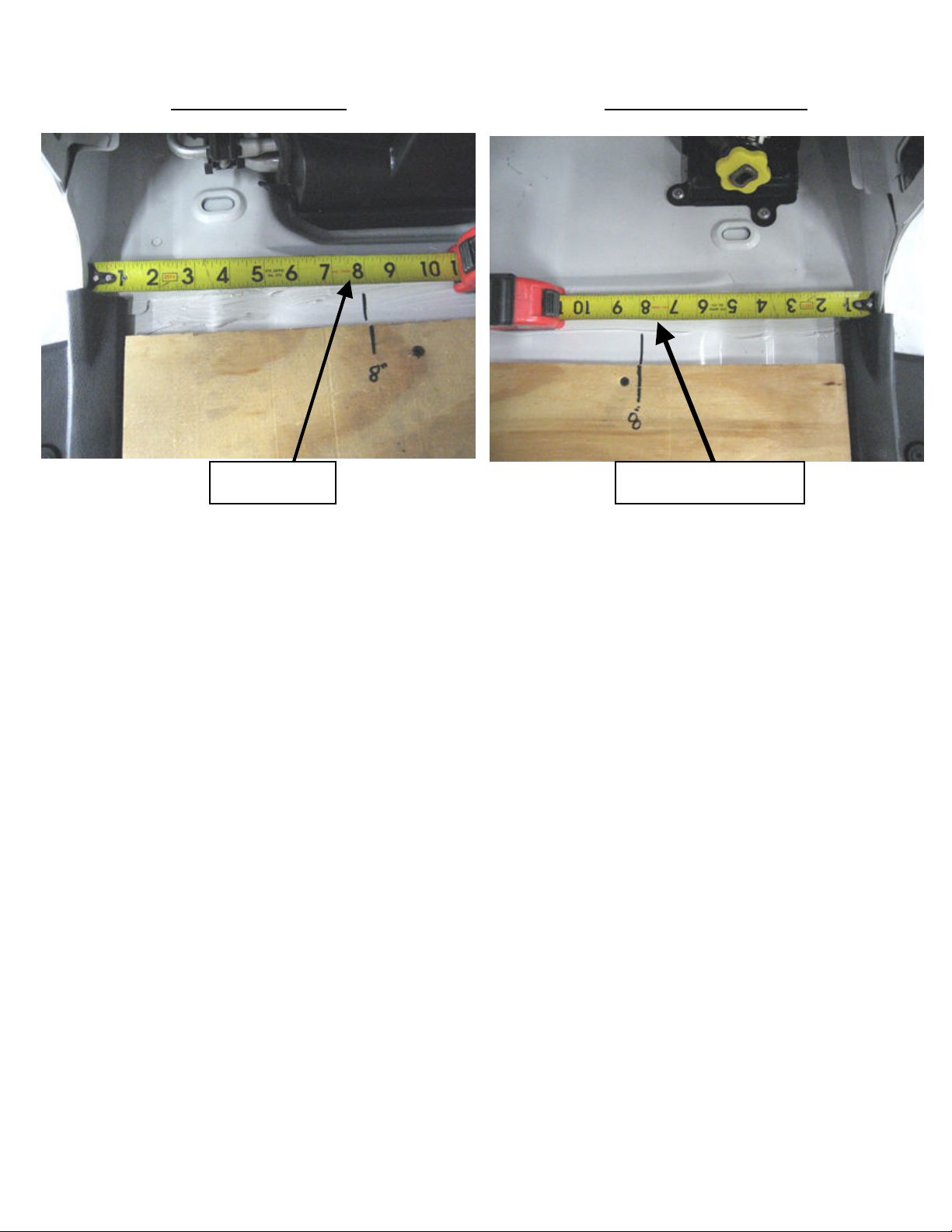

Top Driver-Side rear

Top Passenger-Side rear

Item #6

Approximately 3”inches

3” inches

Item #6

With unit positioned according to measurements on previous page, pre-

drill and attach a #10 x 1” sheet metal screw to hold the rear Bulkhead

place while assembling the remainder of the unit.

Item #6

14

Item #7 to #1

Position

mate with Bench/Wall assembly. Pre-

drill 5/32” holes into Ceiling, using

Bench/Wall assembly holes as a guide.

KK-XXX-03_INST_10-07

section to

Page 15

ALL

eing sure to align edges and bends of materials being tightened. This

Ceiling

Diam

ond plate floor.

diamond floor (only) w/ 3/16” hole and 1/8” hole through

Benches

Bulkheads.

Be careful when pre-

Note: Ceiling is behind wall

drilling not to hit

hoses, wires, etc…

Item #8 to #2

Pre-drill ceiling with 5/32” drill bit and attach #10 x

1” Phillips pan head sheet metal screws to hold

Ceiling to Bench/Wall assembly. Repeat these steps

on the Passenger-side Ceiling section

Item #5 through #8 into #7

Pre-drill through

sections, (using

Item #4 through #1 into van floor

Divider as a template), with 3/16” drill

bit and attach using ¼” x 1 ½” hex head

lag bolts

Be Sure Floor Is Square To

Attach Divider to vehicle. Pre-drill through floor(s)

using 3/16” drill bit and attach using ¼” x 1 ½” hex

Attach remainder of

floor of vehicle

Item #5 & #4 to van floor

&

head lag bolts

Item 4 through #1 into van floor

Pre-drill

Through Item #4, #1, & van floor

Attach to wood floor or rubber

floor mat using #10 x 1” Phillips

Begin to tighten

b

pan head sheet metal screws

15

loose hardware on the remainder of the unit,

will square the unit to itself.

KK-XXX-03_INST_10-07

Page 16

Rear doorframe

sheet metal screws installed earlier. Drill

head bolts, washers, fender washers, lock

3rd Compartment Doorframe

Rear Doorframe.

Front Bulkhead

lywood, and floor of vehicle Attach using

3/8” x 2” hex head bolt, flat washer, fender

Item #11 to van floor

Item #6 to van floor

3/8” x 2” Hex head

bolt, washers, and nut

On the

, remove the

3/8” holes through the doorframe, floor,

and vehicle. Attach using 3/8” x 2” hex

washers, and hex nuts.

On

repeat the same steps done on

is used and must be located just to the left of the doors hinge as shown above.

3/8” x 2” hex head bolt, flat washer,

fender washer, lock washer, and nut

Item #11

Attach the doorframe to the vehicle

using #10 x 1” Phillips pan head sheet

Item #3 to van floor

Secure the

per-side) 3/8” holes through the frame, ½”

p

metal screws

Item #11 to van floor

Only one bolt

. Drill (2- one

16

washer, and nut.

KK-XXX-03_INST_10-07

Page 17

In the upper corner of each side

Item #11

Place trim panels as shown above

drill through trim panel (only)

Socket

Pin

Item #14 to doors and frames

Attach Ball & Socket Style Doorstop.

1st Attach “Pin” portion of assembly. Attach to threaded hole on the door using a ¼” x 1” Hex

head bolt.

2nd Attach the “Socket” and bracket portion. Attach to doorframe using #8 x ¾” Phillips machine

screws and keps nuts.

of the 3rd Compartment

Doorframe are small filler

panels that need to be installed.

Attach using ¼” x ¾” carriage

bolts, washers, and serrated

Item #15

Pre-

with 3/16”. Pre-drill the vehicle

w/ 1/8” hole and attach panels

using #10 x 1” sheet metal screws

Silicone all seems

and joints. This will

allow the unit to be

hosed out.

17

KK-XXX-03_INST_10-07

Page 18

FINAL INSTALLATION PHOTOS

ge Compartment

Forward Compartment for models

KK-100-03, KK-100-04, KK-120-03 and KK-120-04

18

Optional Stora

(Sold Separately)

KK-XXX-03_INST_10-07

Page 19

KK-RLL

KR-CCL

-

1

KK-PVENT

PRISONER TRANSPORT OPTIONS – (All

KR-DL

SOLD SEPERATLEY)

C-VS-1800-ECO w/

C-TCB-7 & C-3090-7

PT-VIDEO-X

19

KK-XXX-03_INST_10-07

Page 20

Item 10

1 Driver-side Bench/Wall

2 Passenger-side Bench/Wall

3 Front Bulkhead

4 Diamond-plate Floor

5 Divider

6 Rear Bulkhead/ Doorframe

7 Driver-side Rear Ceiling

8 Passenger-side Rear Ceiling

9 Separator Bulkhead

10 Front Compartment “L” Bench

11 Front Compartment Doorframe

12 Front Compartment Ceiling

13 Front Compartment Floor

14 (2) Door Stops

15 Diamond-plate floor filler panel

ITEM DESCRIPTION

Loading...

Loading...