Havis C-HDM-410, C-HDM-412, C-HDM-401, C-HDM-403, C-HDM-409 Installation Instructions Manual

...Page 1

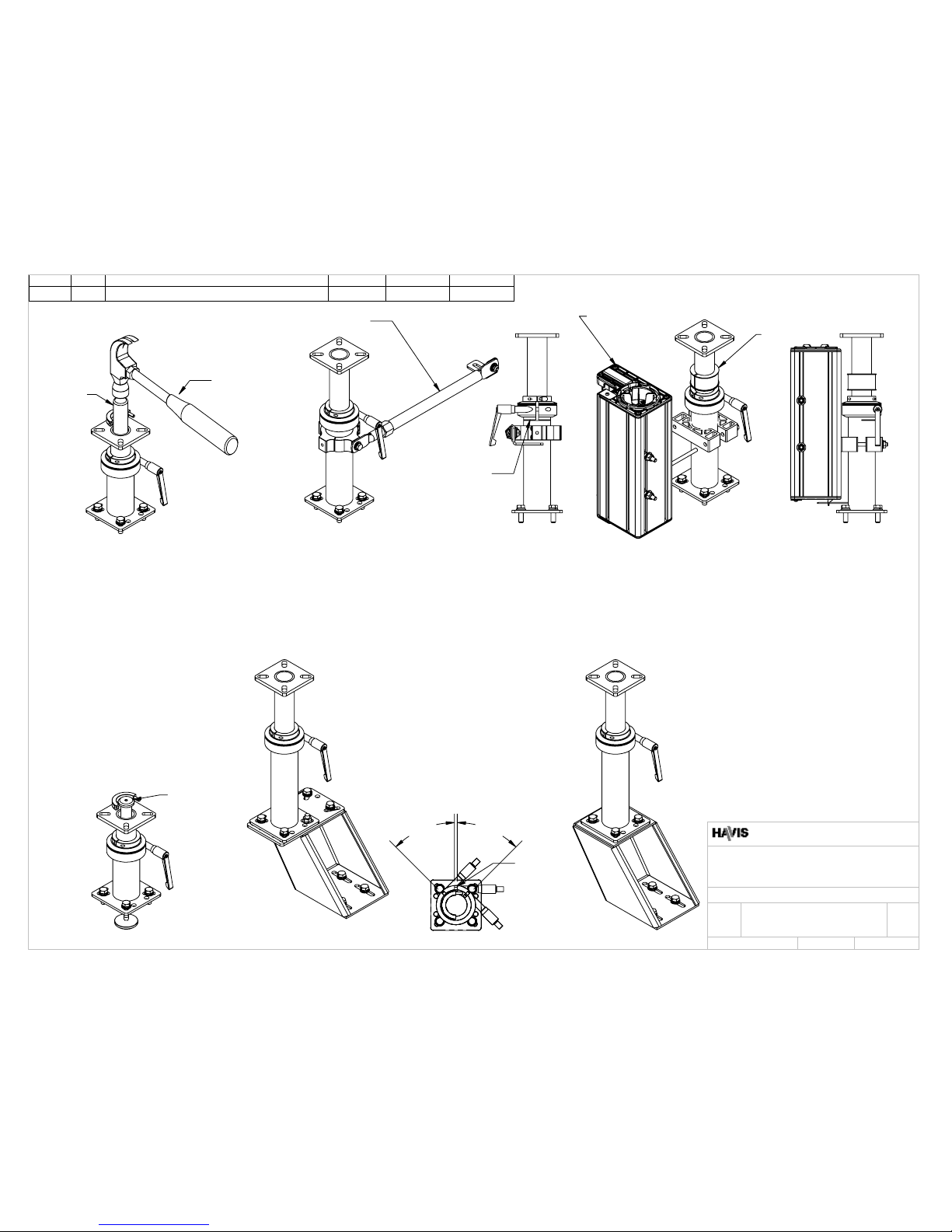

A-

GUIDE RING BUSHING REMOVAL

WE STRONGLY RECOMMEND NOT TO REMOVE THE

GUIDE RING BUSHING, BUT IF REMOVAL OF INNER POLE

IS DESIRED - FOLLOW THIS SIMPLE REMOVAL

INSTRUCTION

INSERT MAXIMUM 1" DIAMETER OBJECT WITH

1.

SUFFICIENT LENGTH AND DROP INSIDE INNER POLE.

MAKE SURE NOTHING PREVENTS GUIDE RING

2.

BUSHING FROM BEING EJECTED UNDERNEATH. HIT

WITH A HAMMER TO FORCE THE GUIDE RING

BUSHING OUT.

7/8" - 1"

DIAMETER

OBJECT

SUPPORT ARM

(OPTIONAL)

B -

INSTALL SPIDER COLLAR (OPTIONAL

COMES WITH C-HDM-401 & 403)

IF MOUNTING THE SPIDER COLLAR TO THE INNER

1.

POLE USE CM003406 REDUCING BUSHING. SPREAD

AND SNAP OVER THE INNER POLE.

LOOSELY ATTACH SPIDER COLLAR TO THE OUTER

2.

POLE OR CM003406. DO NOT MOUNT SPIDER

COLLAR ABOVE OUTER POLE HORIZONTAL CUT.

SPIDER MUST BE

BELOW THIS SLOT

ON THE OUTER POLE

C -

INSTALL OPTIONAL C-HDM-416

IF MOUNTING C-HDM-416 TO THE INNER POLE USE

1.

CM003406. SPREAD THE PIECE AND IT SHOULD SNAP

OVER THE INNER POLE.

ATTACH C-PM-101 TO CLAMP ASSEMBLY USING

2.

LONG CARRIAGE BOLTS INSERTED THROUGH THE

PRINTER AND ONE PIECE OF EXTRUSION.

ATTACH POLE CLAMP TO THE OUTER POLE OR

3.

CM003406. AFFIX SECOND PIECE OF EXTRUSION

AROUND POLE AND LOOSELY TIGHTEN THE

HARDWARE. DO NOT MOUNT CLAMP ABOVE

OUTER POLE HORIZONTAL CUT.

CM003406 REDUCING

BUSHING IS NECESSARY

IF MOUNTING TO

THE INNER POLE.

(USE ONLY ON FIXED

HEIGHT POLES)

C-PM-101

SOLD SEPARATELY

D-

INSTALL GAS SHOCK (OPTIONAL)

(SKIP IF GAS SHOCK IS NOT IN USE)

1.

UNSCREW SMALL PLASTIC DISC FROM SHOCK

2.

INSERT GAS SHOCK ASSEMBLY UPWARD FROM

THE BOTTOM OF HDM POLE ASSEMBLY WITH GAS

SHOCK'S ROD FACING DOWNWARD. GAS

SHOCK WILL SANDWICH BETWEEN MOUNTING

BASE C-HDM-100 SERIES (NOT SHOWN) AND

ACTION ADAPTER C-HDM-300 SERIES (NOT

SHOWN).

ONCE GAS SHOCK SITS PROUD OF THE INNER

3.

POLE REATTACH SMALL PLASTIC DISC

GAS SHOCK

(OPTIONAL)

E -

INSTALL C-HDM-409 OPTIONAL

& COLLAR CLAMP ALIGNMENT

THIS CAN BE DONE EITHER AT THIS POINT OR ONCE

1.

THE C-HDM-100 SERIES BASE IS ALREADY IN THE

VEHICLE. YOU WILL NEED THE OFFSET THAT WAS

WIITH THE C-HDM-100 BASE IF APPLICABLE.

DECIDE ON THE ORIENTATION OF THE C-HDM-409.

2.

ENSURING THAT IF THE HANDLE VERSION OF THE

POLE IS BEING USED THE TWO SLOTS ARE NO MORE

THAN 45 DEG APART IF THIS IS THE CASE ROTATE THE

POLE TO THE CORRECT POSITION.

IF NO HANDLE IS BEING USED ENSURE THE OUTER

3.

POLE SLOT AND THE CLAMP COLLAR SLOT LINE UP.

TIGHTEN ALL THE HARDWARE.

4.

F -

INSTALL C-HDM-410-412 OPTIONAL

THIS CAN BE DONE EITHER AT THIS POINT OR ONCE

1.

THE C-HDM-100 SERIES BASE IS ALREADY IN THE

VEHICLE. YOU WILL NEED THE OFFSET THAT WAS

WIITH THE C-HDM-100 BASE IF APPLICABLE.

DECIDE ON THE ORIENTATION OF THE OFFSET.

2.

ENSURING THAT IF THE HANDLE VERSION OF THE

POLE IS BEING USED THE TWO SLOTS ARE NO MORE

THAN 45 DEG APART IF THIS IS THE CASE ROTATE THE

POLE TO THE CORRECT POSITION.

IF NO HANDLE IS BEING USED ENSURE THE OUTER

3.

POLE SLOT AND THE CLAMP COLLAR SLOT LINE UP.

TIGHTEN ALL THE HARDWARE.

4.

45°

MAX

45°

MAX

SLOTS IN TUBE

AND CLAMP

ALIGNED

HAMMER

PROJECT #

REV.

DESCRIPTION

DATE

BY

CHECKED BY

1765

3-13

REVISION DATE CORRECTED TO PT895 DOCUMENTED CHANGE.

NO OTHER CHANGES

8/5/2014

KDAVIS

75 JACKSONVILLE RD,

WARMINSTER, PA. 18974

1-800-524-9900

SIZE

SCALE: 1:8

SHEET 1 OF 4

DO NOT SCALE DRAWING

WEIGHT (LB): 12.634

TITLE:

DWG. NO.

C-HDM_INST

REV

A

3-13

HAVIS, INC.

INSTALLATION INSTRUCTIONS, C-

HDM MOUNTING BASES

Page 2

C-HDM-204 SHOWN

STANDARD FLAT SURFACE

MOUNTING

F

OR FLAT SURFACE MOUNTING OF C-HDM204, 205, 212, 213, 214, 215, 216 AND 217

(INCLUDING HAVIS CONSOLES WHICH DO

NOT HAVE HOLES PRE-DRILLED)

POSITION POLE MOUNT IN DESIRED

1.

LOCATION

MARK AND DRILL 1/4" HOLES INTO THE

2.

MOUNTING SURFACE (SEE NOTES FOR

DRILLING)

THROUGH-BOLT USING 1/4" HARDWARE

3.

PROVIDED WITH THE MOUNT OR

EQUIVALENT HARDWARE IF NECESSARY.

C-HDM-204 SHOWN

STANDARD CONSOLE SIDE

MOUNTING

FOR CONSOLE SIDE MOUNTING OF CHDM-204, 205, 212, 213, 214, 215, 216 AND

217 (WHERE CONSOLE HAS PRE-INSTALLED

NUTS IN CONSOLE RAIL)

TO ATTACH C-HDM-204, 205, 214, 215

1.

LOOSEN THE RETAINING SET SCREW TO

2.

ALLOW THE NUTS TO BE POSITIONED AS

DESIRED IN THE TRACK.

LINE UP THE MOUNT WITH THE NUTS IN

3.

THE CONSOLE,

ATTACH USING HARDWARE

4.

PROVIDED WITH THE MOUNT, OR

EQUIVALENT 1/4-20 X 1/2" LONG

(MAX.) BOLTS AND FLAT WASHERS.

C-HDM-204 SHOWN

PRE-DRILL;ED CONSOLE SIDE

MOUNTING

FOR CONSOLE SIDE MOUNTING OF CHDM-204, 205, 212, 213, 214, 215, 216 AND

217 (WHERE CONSOLE HAS PRE-INSTALLED

NUTS IN CONSOLE RAIL)

TO ATTACH C-HDM-204, 205, 214, 215

1.

LINE UP THE MOUNT WITH THE

2.

PREDRILLED HOLES IN THE CONSOLE,

ATTACH USING HARDWARE PROVIDED

3.

WITH THE MOUNT, OR EQUIVALENT 1/420 BOLTS.

DEPENDING ON THE DESIRED POSITION,

4.

HOLES MAY NEED TO BE DRILLED, OR

ONE (1) BOLT CAN USE THE NUT TRACK

WITH A 1/4-20 X 1/2" LONG BOLT.

FOR VEHICLE MOUNTING THAT REQUIRES DRILLING

INSPECT ALL AREAS BEFORE DOING ANY DRILLING

1.

ENSURE NO SERIOUS DAMAGE HAPPENS TO THE

VEHICLE.

SECURE THE MOUNT WITH SUPPLIED HARDWARE KIT.

2.

NOTE:

MOST C-VS (VEHICLE SPECIFIC)

SERIES CONSOLES HAVE HOLES FOR

AN HDM-204 OR 214 PRE-DRILLED.

IF ANOTHER LOCATION IS DESIRED,

HOLES MAY NEED TO BE DRILLED

75 JACKSONVILLE RD,

WARMINSTER, PA. 18974

1-800-524-9900

SIZE

SCALE: 1:8

SHEET 2 OF 4

DO NOT SCALE DRAWING

WEIGHT (LB): 0.00

TITLE:

DWG. NO.

C-HDM_INST

REV

A

3-13

HAVIS, INC.

INSTALLATION INSTRUCTIONS, C-

HDM MOUNTING BASES

Page 3

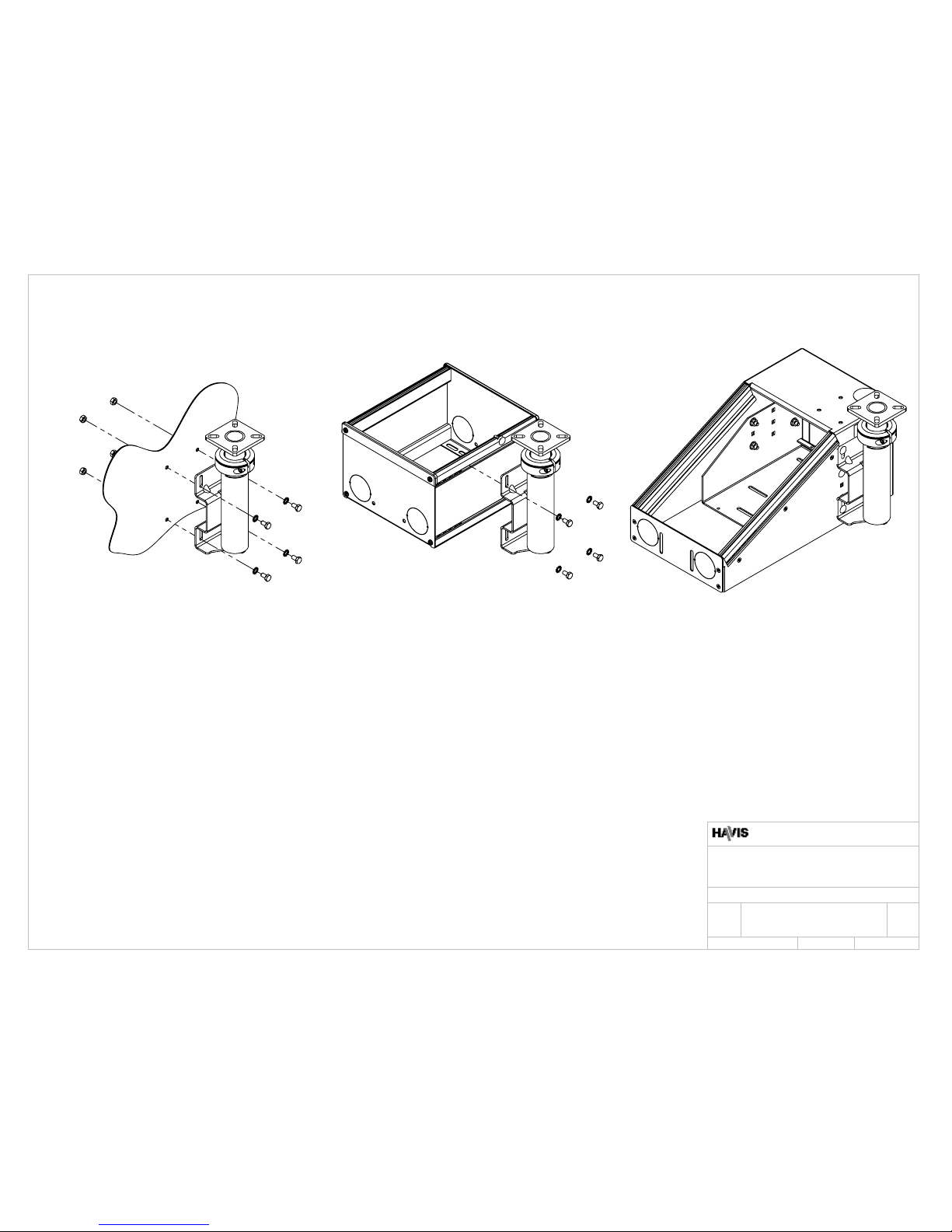

D-

C-HDM-417 VERTICAL

PRINTER MOUNT SHOWN

WITH C-PM-101 ATTACHED

F-

EXAMPLE OF A FINISHED ASSEMBLY

THE ABOVE ASSEMBLY INCLUDES A C-HDM-102, C-

1.

HDM-202, C-MD-102, C-HDM-403, C-HDM-404(2X)

B-

C-HDM-401 SUPPORT ARM

LOOSELY ATTACH SPIDER (CLAMP) COLLAR TO

1.

POLE WITH HARDWARE SUPPLIED (IF NOT ALREADY

ATTACHED). POSITION AS DESIRED AND TIGHTEN

HARDWARE.

LOOSELY ATTACH C-HDM-401 USING HARDWARE

2.

PROVIDED.

FIND A SUITABLE LOCATION TO ATTACH THE OTHER

3.

END OF THE SUPPORT ARM. SOME VEHICLES HAVE

HOLES UNDER THE DASH OR OEM HARDWARE THAT

CAN BE UTILISED. LOOSELY ATTACH TAB PROVIDED.

EXTEND THE ARM ATTACHING THE TAB TO THE

4.

SUPPORT ARM WITH THE HARDWARE PROVIDED.

TIGHTEN ALL HARDWARE.

5.

A-

C-HDM-403 HORIZONTAL PRINTER

MOUNT

LOOSELY ATTACH SPIDER (CLAMP) COLLAR TO

1.

POLE WITH HARDWARE SUPPLIED (IF NOT

ALREADY ATTACHED). POSITION AS DESIRED

AND TIGHTEN HARDWARE.

ATTACH C-HDM-403 PLATE USING HARDWARE

2.

PROVIDED. AVOID TIGHTENING SCREWS IF AN

OFFSET ARM IS TO BE ADDED.

ATTACH DESIRED ITEM TO SHELF BRACKET.

3.

THE C-HDM-403 WORKS VERY WELL IF THERE IS

4.

NO CENTER CONSOLE. SPACE IS VERY LIMITED

AND WILL CAUSE LACK OF LEG ROOM IF THE

VEHICLE DOES HAVE A CENTER CONSOLE.

C-

C-HDM-404 SUPPORT ARM

THE C-HDM-404 IS PRIMARILY USED FOR UNIVERSAL

1.

FLOOR MOUNTS WHEN PREMIUM STRENGTH / 3

POINT MOUNTING IS NECESSARY.

COMPLETE SECTION B.

2.

LOOSELY ATTACH C-HDM-404 USING HARDWARE

3.

PROVIDED.

THE MAJORITY OF HAVIS BASES HAVE AN EXTRA PEM

4.

IN ORDER TO ATTACH TO THE SUPPORT ARM. IF NOT

FIND ANOTHER LOCATION OR DRILL AND THROUGH

BOLT THE TAB BRACKET.

EXTEND THE SUPPORT ARM AND ATTACH WITH

5.

SUPPLIED HARDWARE.

TIGHTEN ALL HARDWARE.

6.

D-

C-HDM-417 VERTICAL PRINTER MOUNT

COMPLETE SECTION B.

1.

LOOSELY ATTACH C-HDM-417 BRACKET USING THE

2.

HARDWARE PROVIDED.

SLIDE TWO CARRIAGE BOLTS IN THE C-PM-101 SLOTS.

3.

LOCATE THE TWO HOLES IN THE C-HDM-417

4.

BRACKET PUSH THE CARRIAGE BOLTS THROUGH THE

HOLES AND FINGER TIGHTEN THE SERRATED NUTS

PROVIDED.

SLIDE THE PRINTER TO THE RIGHT POSITION AND

5.

TIGHTEN ALL HARDWARE.

E-

ATTACHING THE SHAFT STOP

COLLAR THAT COMES WITH

TELESCOPING POLE WITH HANDLE

SLIDE THE INNER POLE TO THE DESIRED HEIGHT.

1.

ATTACH THE SHAFT COLLAR USING THE HARDWARE

2.

PROVIDED.

INNER POLE SHOULD NOW SPIN FREELY WHILE

3.

MAINTAINING THE DESIRED HEIGHT.

75 JACKSONVILLE RD,

WARMINSTER, PA. 18974

1-800-524-9900

SIZE

SCALE: 1:8

SHEET 3 OF 4

DO NOT SCALE DRAWING

WEIGHT (LB): 19.41

TITLE:

DWG. NO.

C-HDM_INST

REV

A

3-13

HAVIS, INC.

INSTALLATION INSTRUCTIONS, C-

HDM MOUNTING BASES

Page 4

1/4-20 NYLOCK NUT (2X)

1/4-20 FEMALE HANDLE

C-HDM-301

INCL WITH

C-HDM-302,

303, 304.

GENERAL C-HDM-300's INSTALL INSTRUCTIONS

ALIGN 4 MOUNTING STUDS OF MOUNTING DEVICE C-HDM-

1.

300's INTO THE HDM-200's SERIES MOUNTING SLOTS.

BOLT THE MOUNT TOGETHER USING SPECIFIED AND SUPPLIED

2.

HARDWARE.

TORQUE THE 5/16 HARDWARE TO INDUSTRY STANDARDS .

3.

1/4-20 FEMALE HANDLE CAN BE SUBSTITUTED FOR 1/4-20

4.

NYLOCK NUT.

IF THE C-HDM-300 IS TO BE STATIONARY BOLT DIRECTLY TO

5.

THE POLE USING 5/16-18 HARDWARE.

VISIT US AT www.havis.com TO SEE PICTURES OF

6.

INDIVIDUALLY INSTALLED PRODUCTS.

1/4-20 THIN

NYLOCK NUT (4X)

SECTION REMOVED FOR CLARITY

C-HDM-402 (OPTIONAL) SAFETY LOCK

WITH C-HDM-305

FOLLOW GENERAL C-HDM-300's INSTALL

1.

INSTRUCTIONS IN "HOW TO ATTACH C-HDM-402

INTO UPPER POLE".

MOUNT C-HDM-305 (SLIDE) TO SAFETY LOCK (C-

2.

HDM-402) USING SHOWN HARDWARE AND

FOLLOWING THE HARDWARE ARRANGEMENT.

THE TOP PLATE CAN BE REMOVED IF NECESSARY

TIGHTEN HARDWARE AND REATTACH TOP PLATE.

3.

C-HDM-402

TOP PLATE

C-HDM-305

1/4-20 X 3/4" HEX HEAD BOLT (4X)

1/4" SPLIT LOCK WASHER, (4X)

1/4" SAE FLAT WASHER, (8X)

C-HDM-301 TO C-MD-200 SERIES

ALIGN 4 MOUNTING STUDS OF MOUNTING DEVICE C-HDM-

1.

300's INTO THE C-HDM-200's SERIES MOUNTING SLOTS.

BOLT THE C-MD-200 TO THE C-HDM-301 PLATE USING THE

2.

SAME HARDWARE CONFIGURATION FOR THE C-HDM-300

SERIES.

TIGHTEN HARDWARE.

3.

C-MKM-100 SERIES TO C-HDM-200

SERIES

NUT AND BOLT TOGETHER UTILIZING C-HDM-

1.

301 AS SHOWN ABOVE.

C-MD-100 SERIES

PLACE C-MD-100 SERIES MOTION DEVICE ON

1.

TOP OF POLE MOUNTING SURFACE.

LINE UP THE 4 TAPPED HOLES WITH THE UPPER

2.

POLE MOUNTING SLOTS.

ATTACH THE FOUR 1/4-20 HEX BOLTS & LOCK

3.

WASHERS AND FLAT WASHER AS SHOWN

THROUGH THE THREADED HOLES OF THE

MOTION DEVICE.

TIGHTEN HARDWARE.

4.

C-HDM-200's SERIES

(NOT INCLUDED)

5/16-18

HEX NUT(4X)

5/16" SPLIT LOCK

WASHER(4X)

5/16" STEEL

FLAT WASHER (4X)

1/4" PLASTIC

FLAT WASHER (3X)

1/4" STEEL

FLAT WASHER (3X)

75 JACKSONVILLE RD,

WARMINSTER, PA. 18974

1-800-524-9900

SIZE

SCALE: 1:8

SHEET 4 OF 4

DO NOT SCALE DRAWING

WEIGHT (LB): N/A

TITLE:

DWG. NO.

C-HDM_INST

REV

A

3-13

HAVIS, INC.

INSTALLATION INSTRUCTIONS, C-

HDM MOUNTING BASES

Loading...

Loading...