haupa HS-8 Instruction Manual

… convincing solutions

Hydraulic hand-punching tool „HS-8“

Art. 217604

INSTRUCTION MANUALHydraulic punching tools

2

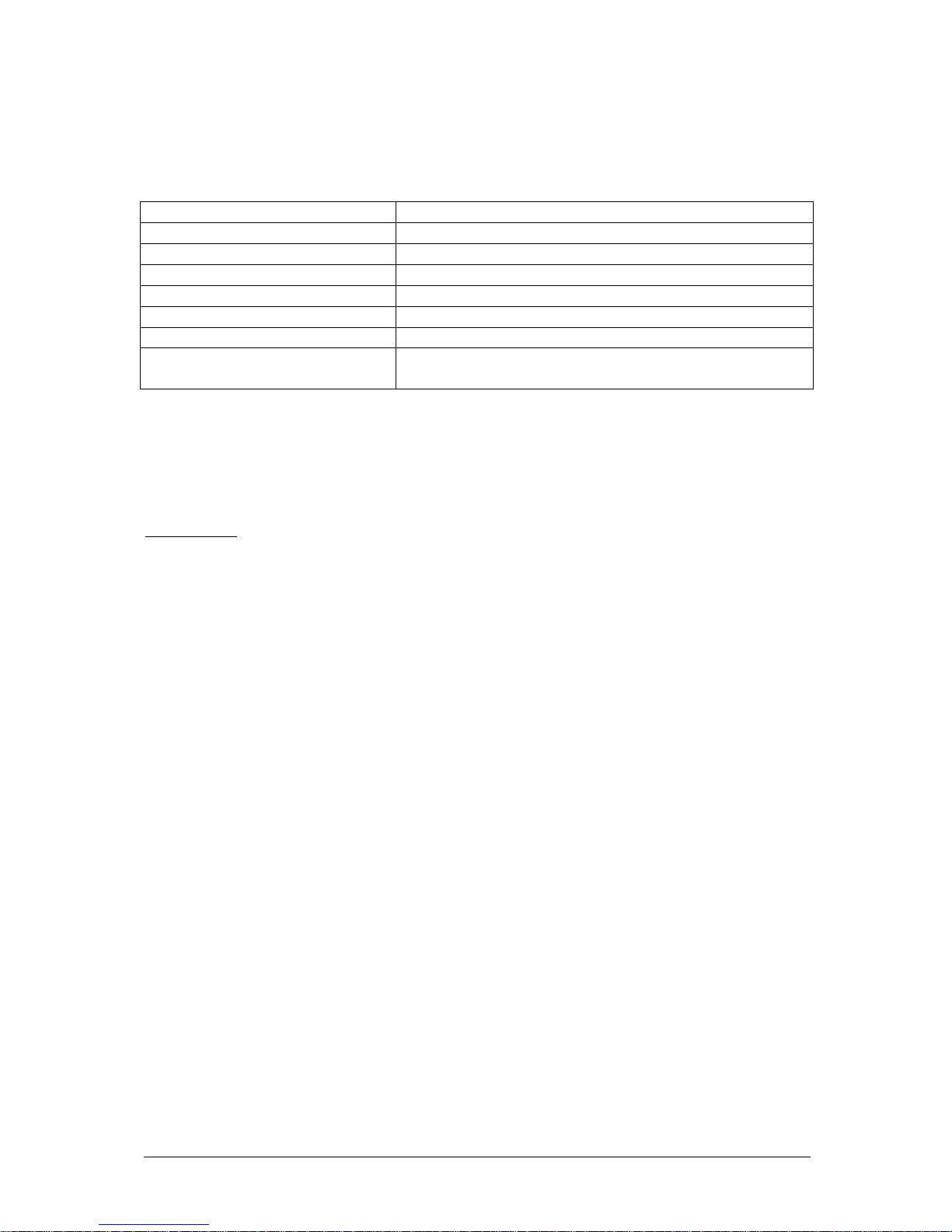

1 Technical Data

Hydraulic plate puncher HS-8

Punching power

Approx. 80 kN

Cutting material

Steel plates up to max. 3 mm strength

Lift

22 mm

Manual exertion

Approx. 350 N

Lever transmission

1:10

Length

308 mm

Weight

2,4 kg

Oil specification

Hydraulic oil GW ISO 7

Use only water and acid free oil!!!

2 Safety Instructions

Attention: Before using the tool please read all safety instructions. Always keep

these safety instructions together with the tool and ensure the instructions are

heeded at all times. HAUPA cannot legally be held responsible for any damage or

injury sustained which is related to incorrect usage of the tool or as a result of poor

maintenance. Should there be any further questions regarding use of the product or

any aspect safety measures, please contact HAUPA.

1. Keep your workplace clean and free from foreign bodies and always take care

that there is sufficient lighting.

2. Always wear protective clothes and spectacles.

3. Make sure that the tool is protected from external damage e.g. the effects of

excessive heat, open fires, sharp edges, moving pieces of machinery,

corrosive chemicals and damp.

4. Avoid high pressure on the tool! Use the cutter only according to technical

data regarding cutting material and cutting capacity.

5. Do not try to extend the handles beyond their normal length!

6. Only allow authorized personnel to carry out repair and maintenance work to

the tool. Any maintenance / repair work carried out by unauthorized personnel

will invalidate the guarantee.

7. Make sure that the matrix is concordant with the cutting edge concerning the

diameter.

3

8. Check the oil level on occasion. While re-filling pay attention to outermost

cleanness. Use only oil according oil specification (s. Technical Data).

9. Keep children, pets and unauthorized persons away from the workplace.

10. Keep the safety instructions with the tool.

3 Tool – Operation

HS-8 is a tool for punching plates according cutting material (s. Technical Data).

Please consider the following constructions to ensure an operation without any

problems.

.

Operation:

1- Pre-drill with ! 10, 5 after marking out and 2- screw rod (thread entirely) in.

marking the centre. .

3- Fit distance bushing and matrix. 4-Insert rod into drill-hole and

screw cutting edge on.

Loading...

Loading...