haupa 21 66 01 Instruction Manual

Q

ZERTIFIKAT

DIN EN ISO 9001

… convincing solutions

Electro hydraulic crimping tool

Art. 21 66 01

INSTRUCTION MANUALHydraulic pliers

1. Technical characteristics

Application field: A compression tool for crimping electrical connectors,

suitable for copper conductors up to 400 mm2and aluminium

conductors up to 300 mm

2

.

Force developed: 120 kN

Press opening: 25 mm

Rated operating pressure: 700 bar

Oil type: ISO class viscosity 15

Voltage 14.4V

Battery: 3.0 Ah

Speed of advance: The tool moves at two speeds. A speed to move the dies

together and a slower speed for the crimping action.

The changeover from one speed to the other is automatic.

Safety: The tool is equipped with a factory-set safety valve.

Sicherheitsventil ausgestattet.

Construction: 216601 model features a built-in drive pump.

It is equipped with an 180º rotating head for easy access in

confined areas. The model 216601 is not designed to protect the

operator in hot line work.

2. Working range

Pressure: 120 kN

Crimping range: DIN cable lugs 300 mm

2

standard copper 400 mm

2

aluminium 240 mm

2

Crimping time: 6 - 12 sec.

Charging time for batteries: 20 min

Battery voltage: 14.4 V

Battery capacity: 3.0 Ah

Working pressure: 700 bar

Dimension: 335 x 310 x 75 mm

Weight: 7 kg

Weight Set: 12 kg

Germany: HAUPA GmbH & Co. KG, Königstraße 165-169, D- 42853 Remscheid.

Phone: +49 (0)2191 8418-0, Fax: +49 (0)2191 8418-840, sales@haupa.com • Errors and technical changes reserved.

… convincing solutions

english

3. Instrucctions for use

WARNING! NEVER USE THE TOOL WITHOUT FIRST INSERTING THE DIE SET.

Ensure that the dies correspond exactly to the area to be crimped and that the dies are perfectly

positioned in their corresponding holders.

FAILURE TO DO SO COULD RESULT IN SERIOUS DAMAGE OR BREAKAGES AND WOULD VOID

THE GUARANTEE.

Preparation:

• Select the correct die for the connection to be made.

• Insert the die set in the tool head. All the dies used in these models are semicircular,

regardless of the type of compression or crimping to be performed. Both die parts have

identical outside dimensions and can therefore be mounted indistinctly on either the piston

or the head. The same procedure is used for mounting the dies on both the piston and the

head.

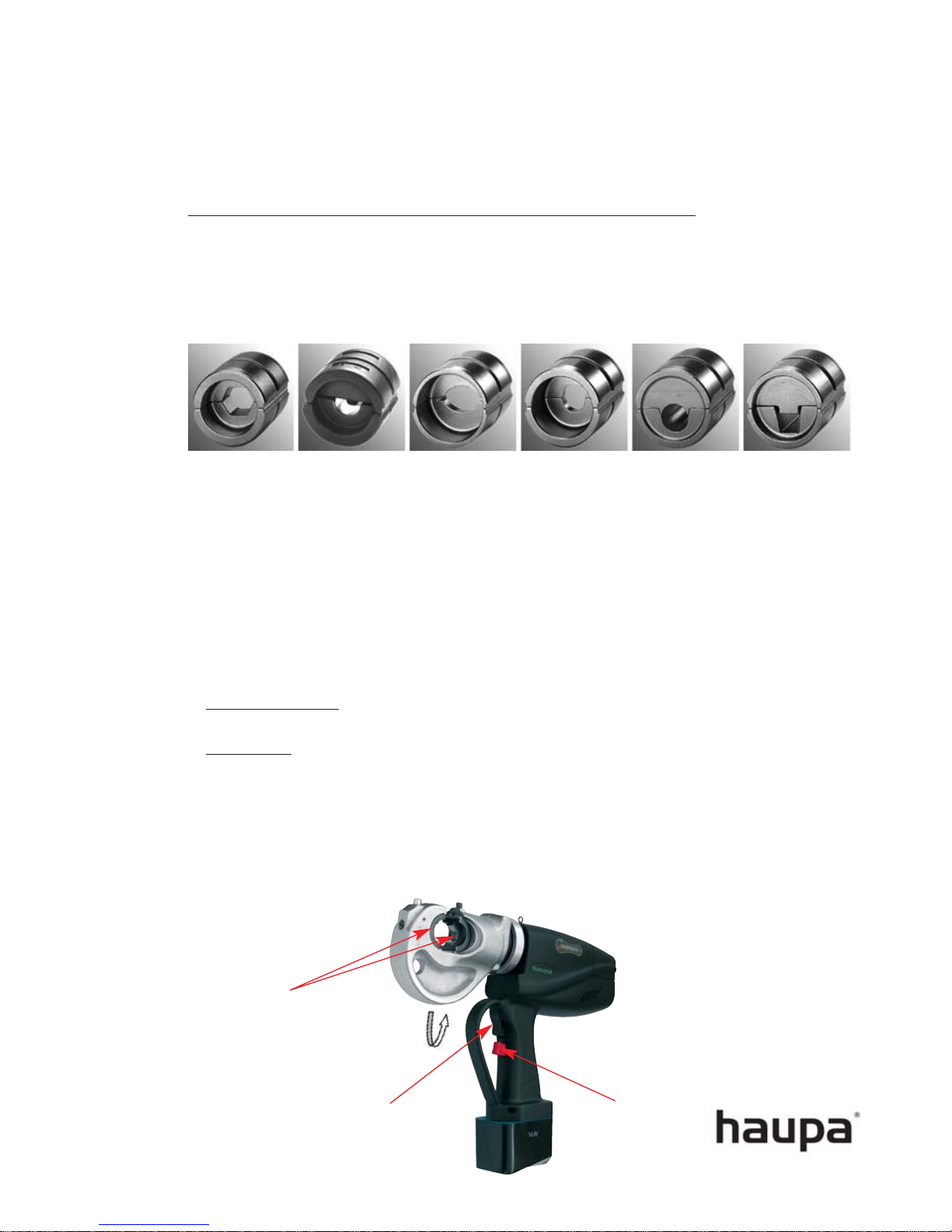

• Insert the die along the guides, until it comes to a stop against the locking pin.

• Then, remove the locking pin by pressing the release button and continue to insert the die

until it is retained in position by the pin.

• For t

he piston side: To carry out the above-mentioned operations, it is first necessary to

move the piston forward to allow access to the release button.

• Die remo

val: The procedure is also the same for both parts of the die set. Release by pres

sing the locking buttons and slide the die outwards. When removing the die from the

piston, reverse the procedure described in the previous point.

Die holder

Pushbutton

to advance

Pushbutton for

return movement

Loading...

Loading...