Haulotte Group Compact 2668RT, HS3388RT, Compact 12DX, Compact 3368RT, H12SXL Maintenance Book

...

Maintenance book

E

NGINE

-

POWERED

SCISSOR

LIFTS

4000014930 e10 12 EN

Maintenance book

ENGINE-POWERED SCISSOR LIFTS

Compact 10DX (Compact 2668RT)

Compact 12DX (Compact 3368RT)

H12SX (HS3388RT) - H12SXL (HS3388RTXL)

H15SX (HS4388RT) - H15SXL (HS4388RTXL)

H18SX (HS5388RT) - H18SXL (HS5388RTXL)

4000014930

e10 12

2 4000014930 e10 12 EN

Engine-powered scissor lifts

EN

3

CONTENTS

Maintenance book

CONTENTS

1 - Maintenance book. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

2 - After Sales Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

3 - Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

A

SAFETY PRECAUTIONS

1 - Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

1.1 - Maintenance book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 - Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 - Label colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 - Manufacturer's warranty . . . . . . . . . . . . . . . . . . . . . . . . .

10

2.1 - Warranty acceptance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 - Warranty period. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 - Conditions of warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 - Warranty conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 - Scope of intervention . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

4 - Instructions for intervention . . . . . . . . . . . . . . . . . . . . . .

13

B

RECOMMENDATIONS

1 - Lubrication diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15

2 - Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18

2.1 - Fuels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2 - Motor oils. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3 - Hydraulic oils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3 - Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21

3.1 - Classification plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1.1 - Red labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1.2 - Orange labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1.3 - Yellow labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.1.4 - Other labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.1.5 - Green labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.1.6 - Blue labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.2 - Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

C

MAINTENANCE

1 - General program / Recommendations . . . . . . . . . . . . . .

41

2 - Detailed program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46

3 - Maintenance sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

95

3.1 - Placing the machine in maintenance configuration. . . . . . . . . . . . . . . . 95

3.2 - Placing in operating configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

3.3 - General points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

3.3.1 - Recommendations on the conditions of maintenance . . . . . . . . 97

3.3.2 - Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

3.3.2.1 - Bolts and Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

3.3.2.2 - Pins and bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

3.3.2.3 - Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

3.3.2.4 - Brakes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

3.3.3 - Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

3.3.3.1 - Oil replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

3.3.3.2 - Replacing damaged of hoses . . . . . . . . . . . . . . . . . . . . . . . . . . 101

3.3.3.3 - Evaluation of leaks on hydraulic cylinders . . . . . . . . . . . . . . . . 102

3.3.4 - Electric . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3.3.4.1 - Replacing damaged cables . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

4

Maintenance book

E001 -

Oil tank . . . . . . . . . . . . . . . . . . . . . . . . . . . .

105

E002 -

Wheel reducer. . . . . . . . . . . . . . . . . . . . . . .

107

E003 -

Hydraulic filter cartridge . . . . . . . . . . . . . .

109

E004 -

Fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . .

111

E006 -

Wheel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

113

E007 -

Screws, bolts and nuts . . . . . . . . . . . . . . .

117

E010 -

Steering wheel pivots . . . . . . . . . . . . . . . .

119

E011 -

Guide rail. . . . . . . . . . . . . . . . . . . . . . . . . . .

121

E012 -

Cylinder hinge . . . . . . . . . . . . . . . . . . . . . .

123

E018 -

Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

125

D

DIAGNOSIS ASSISTANCE

1 - Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

129

2 - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

129

E

ELECTRIC CIRCUIT

1 - Wiring diagram-Main components . . . . . . . . . . . . . . . .

131

2 - Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

137

3 - Relays and terminals . . . . . . . . . . . . . . . . . . . . . . . . . . .

139

4 - Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

141

5 - Diagnosis assistance indicators . . . . . . . . . . . . . . . . . .

146

6 - Locations and functions of the main safety features .

148

7 - Buzzers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

153

8 - Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

154

F

HYDRAULIC CIRCUIT

1 - Hydraulic diagram-Main components. . . . . . . . . . . . . .

155

2 - Solenoid valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

155

2.1 - Hydraulic unit details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

2.2 - Pressure switches, sensors and stabilisation solenoid valves . . . . . 160

2.3 - Lifting cylinder solenoid valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

G

INTERVENTION REGISTER

1 - Intervention register. . . . . . . . . . . . . . . . . . . . . . . . . . . .

169

5

4000014930 e10 12 EN

Engine-powered scissor lifts

You have just purchased a HAULOTTE® product

and we would like to thank you for your business.

1 - Maintenance book

As indicated on the delivery slip, this maintenance book is one of the documents in our on-board case

supplied on delivery of your machine.

Person using this product must do so in accordance with the instruction provided in this manual.

We would particularly like to draw your attention to 2 essential points :

• Compliance with safety instruction (machine, use, environment).

• Use of the equipment within the performance limits.

2 - After Sales Service

Our HAULOTTE Services® After Sales Service is at your disposal throughout your machine's service

life to ensure optimal use of your HAULOTTE product..

• When contacting our After Sales Service, ensure that you provide the machine model and serial

number.

• When ordering any consumables or spare parts, please use this manual and the Haulotte Essential

catalogue to receive your genuine HAULOTTE spare parts, your only guarantee of parts

interchangeability and correct machine operation..

• If there is an equipment malfunction involving a HAULOTTE® product, then contact HAULOTTE

Services® immediately even if the malfunction does not involve material and/or bodily damage..

• HAULOTTE® must be informed in the event of an incident that either involves one of these products

or has caused bodily injury or significant deterioration of property (personal property or the product);

contact HAULOTTE Services® immediately (See : HAULOTTE Services® contact details)

6 4000014930 e10 12 EN

Engine-powered scissor lifts

3 - Compliance

We would like to remind you that HAULOTTE® complies with the provisions of any applicable

directives applicable to this type of machine.

HAULOTTE advises you that NO modifications carried out without the written permission

of HAULOTTE® will void the HAULOTTE warranty..

HAULOTTE® cannot be held liable for any changes to the technical specifications contained in this

manual.

HAULOTTE® reserves the right to alter technical specifications and to make improvements or

modifications to the machine without modifying this manual.

Certain options can modify the machine's operating characteristics and its associated safety. If your

machine was originally delivered with options fitted, replacing a safety component associated with a

particular options not require any particular precautions other than those associated with the installation

itself (static test).

Otherwise, it is essential to follow the manufacturer's recommendations below :

• Installation by authorised HAULOTTE® personnel only.

• Update the manufacturer's identification plate.

• Have stability tests carried out by a certified agency/competent person.

• Ensure label compliance.

A

B

C

D

E

F

G

H

I

7

4000014930 e10 12 EN

Engine-powered scissor lifts

A

- Safety precautions

Safety precautions

1 - Recommendations

1.1 - MAINTENANCE BOOK

The maintenance book is intended for the on-site maintenance technician.

It is the on-site maintenance technician's duty to carry out the regular maintenance work

recommended by HAULOTTE Services®.

This maintenance work is essential for correct machine operation.

If regular maintenance is not carried out, this may :

• Void the warranty.

• Cause machine malfunction.

• Reduce machine reliability and shorten its service life.

• Cause operator safety problems.

To ensure that the regular maintenance requirements are fully satisfied, contact HAULOTTE

Services®.

HAULOTTE Services® technicians are specially trained to carry out extensive repairs,

interventions or adjustments on the safety systems or elements of HAULOTTE® machines,

and carry genuine HAULOTTE spare parts and tools as required, and also provide fully

documented reports on all work completed..

8 4000014930 e10 12 EN

Engine-powered scissor lifts

A

- Safety precautions

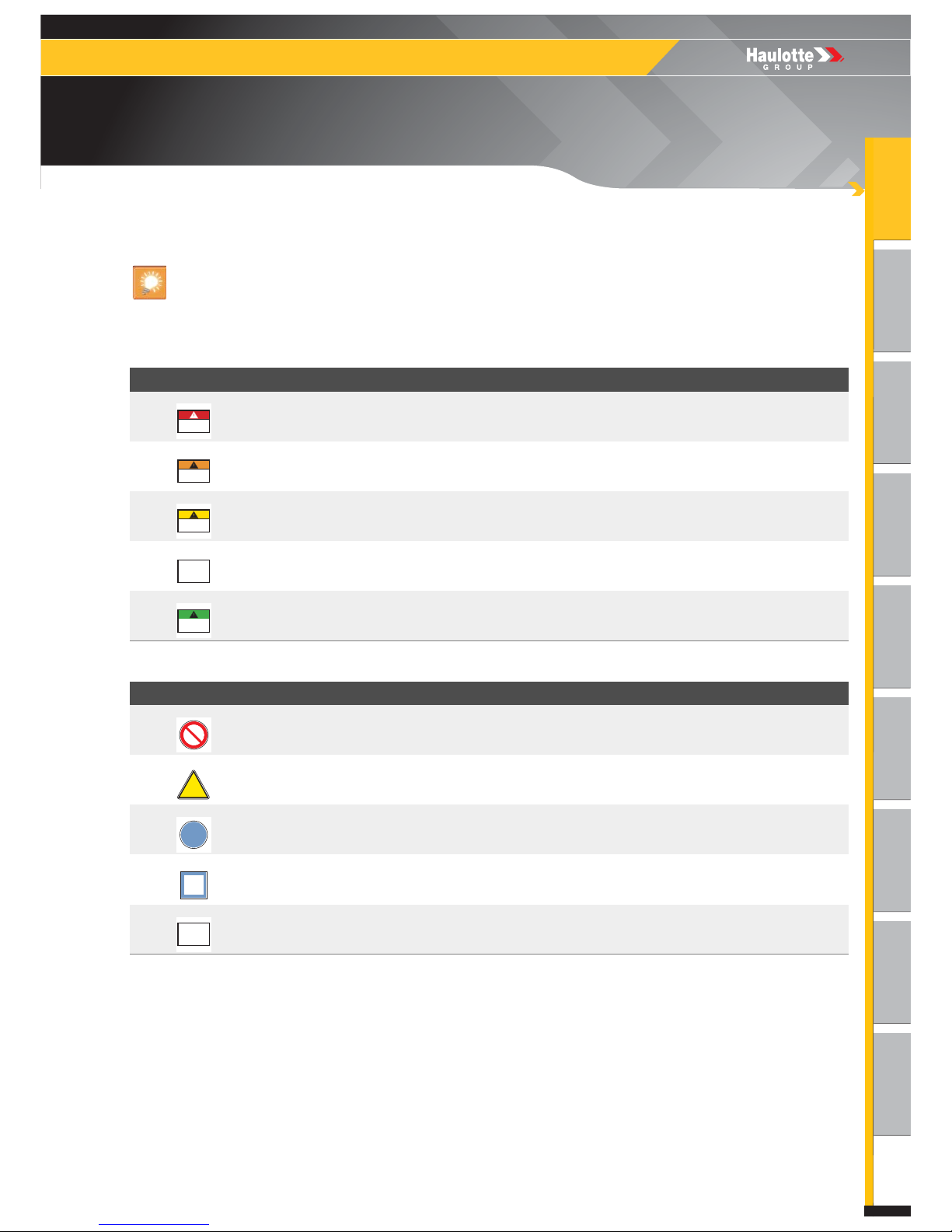

1.2 - SYMBOLS USED

Symbols are used to alert the operator to safety precautions or to highlight practical

information.

Symbol meanings

Symbol Meaning

Danger : Risk of injury or death (work safety)

Caution : Risk of material damage (work quality)

Prohibition relating to work safety and quality

Reminder : No identified risk, but a reminder of the need for common

sense, good practice or pre-action prerequisites

Cross-reference to another part of the manual (see section or sheet)

Cross-reference to another manual (see manual)

Cross-reference to repairs (contact HAULOTTE Services®)

Maintenance sheet

Time required for intervention

Recommended tools

Recommended part

Safety

N.B. : Additional technical information

A

B

C

D

E

F

G

H

I

9

4000014930 e10 12 EN

Engine-powered scissor lifts

A

- Safety precautions

1.3 - LABEL COLORS

The potential dangers and any specific regulations are indicated around the product by labels

and identification plates.

Familiarize yourself with the labels and their respective color codes.

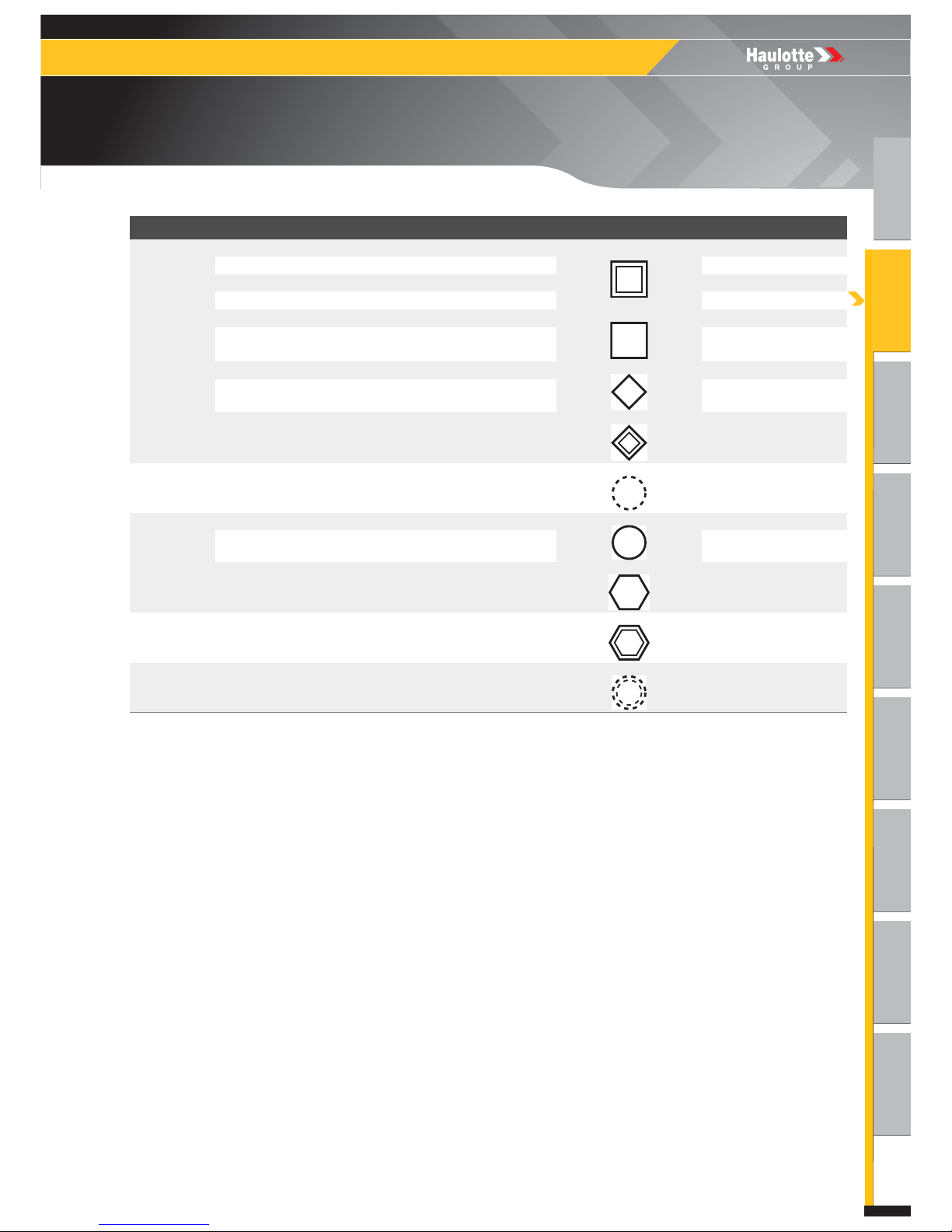

Label color code

Label color code-For Russia and the Ukraine only

The labels must be kept in good condition. Additional labels can be obtained from HAULOTTE Services®.

Labels Color Meaning

Red Potentially fatal danger

Orange Risk of serious injury

Yellow Risk of material damage and/or minor injury

Other Additional technical information

Green Maintenance operation or information

Labels Color Meaning

Red Prohibitions - Danger

Yellow Warning : Risk of material damage and/or minor injury

Blue Precaution

Blue Information

Other Additional technical information

10 4000014930 e10 12 EN

Engine-powered scissor lifts

A

- Safety precautions

2 - Manufacturer's warranty

2.1 - WARRANTY ACCEPTANCE

On reception of his machine, the owner or rental company must check the machine's condition

and fill out the machine reception slip provided.

2.2 - WARRANTY PERIOD

The present warranty is granted for a period of 12 months or a limit of 1000 operating hours

for lifting and handling equipment and 2000 operating hours for public works machinery, to run

from delivery and terminating with the first period to be reached.

Spare parts are covered by a 6 month warranty.

2.3 - CONDITIONS OF WARRANTY

HAULOTTE® guarantees its products against defects, faults or manufacturing defects when

the owner or rental company has informed HAULOTTE® of the defect.

The warranty does not cover the consequences of normal wear, nor any defects, failure or

damage resulting from poor maintenance or abnormal usage, in particular overloading, impact

by an external source, faulty installation or any modification made to products marketed

by HAULOTTE® and performed by the owner or rental company.

In case of operation or use which does not comply with the instructions or recommendations

in this maintenance book, claims will not be accepted.

The machine utilisation period must be recorded by reading the engine hour meter whenever

an intervention is made. The engine hour meter must be maintained in good working order to

guarantee maximum working life and to justify maintenance at the recommended time.

Warranty obligations for the time period stated above will cease immediately in situations

where the defect is due to the following reasons :

• Use of spare parts that are not HAULOTTE® originals.

• If elements or products other than those recommended by the manufacturer are used.

• If the HAULOTTE® name, serial numbers or identification marks are removed or altered.

• After an unreasonably long delay before reporting a manufacturing problem.

• If the owner or rental company continues to use the machine despite problems.

• If damage is caused by modifications that do not comply with HAULOTTE® specifications.

• If lubricants, hydraulic oils or fuels that do not comply with HAULOTTE® recommendations are used.

• If the machine is incorrectly repaired or used by the customer or in case of an accident caused by a

third party.

If no particular agreement has been made, any claims made after the previously established

warranty period has expired will be refused..

A

B

C

D

E

F

G

H

I

11

4000014930 e10 12 EN

Engine-powered scissor lifts

A

- Safety precautions

The present warranty does not cover damage that may result directly or indirectly from any

flaws or defects covered by the latter :

• Consumables : No claims will be accepted for objects or parts replaced in the context of normal

machine usage.

• Settings : Adjustments of all sorts may become necessary at any time. Therefore adjustments are

considered a part of normal machine usage conditions and are not covered by the warranty.

• Hydraulic and fuel circuit contamination : Every possible precaution is taken to ensure that fuel and

hydraulic liquid delivered is clean. On the other hand, in certain cases it is possible to contaminate fuel

and hydraulic circuits, especially when fuel and lubricants are stored on the work site. Moreover,

irregular or poor cleaning of the decanting device may also cause fuel/hydraulic circuit contamination

and therefore damage the parts in direct contact with these liquids. HAULOTTE® will not accept any

claims concerning cleaning of the fuel circuit, filter, injection pump or any other equipment in direct

contact with fuel or lubricants.

• Wearing parts (pads, bearings, tyres, connections, etc.) : These parts are, by definition, subject to

deterioration during the period of operation. Wearing parts will therefore not be covered by the

warranty agreement.

2.4 - WARRANTY CONDITIONS

To benefit from the present warranty, the owner or rental company must inform the nearest

HAULOTTE® branch or the branch that delivered the machine (the only dealer authorised to

carry out an intervention under the manufacturer's warranty agreement) of the defect in writing

as quickly as possible.

The branch will decide whether to repair or replace the part that proves to be faulty.

The owner or rental company must present the duly completed maintenance book supplied

with the machine as proof that the maintenance operations recommended by the manufacturer

have been carried out.

The owner or rental company must ensure that the defect covered by the HAULOTTE®

warranty is reported to and acknowledged by the HAULOTTE® branch (the only dealer

authorised to carry out work covered by the warranty) as rapidly as possible or must report the

defect in writing.

Work carried out under the HAULOTTE® warranty will be performed by the branch which

participated in delivery of the machine, wherever possible.

12 4000014930 e10 12 EN

Engine-powered scissor lifts

A

- Safety precautions

3 - Scope of intervention

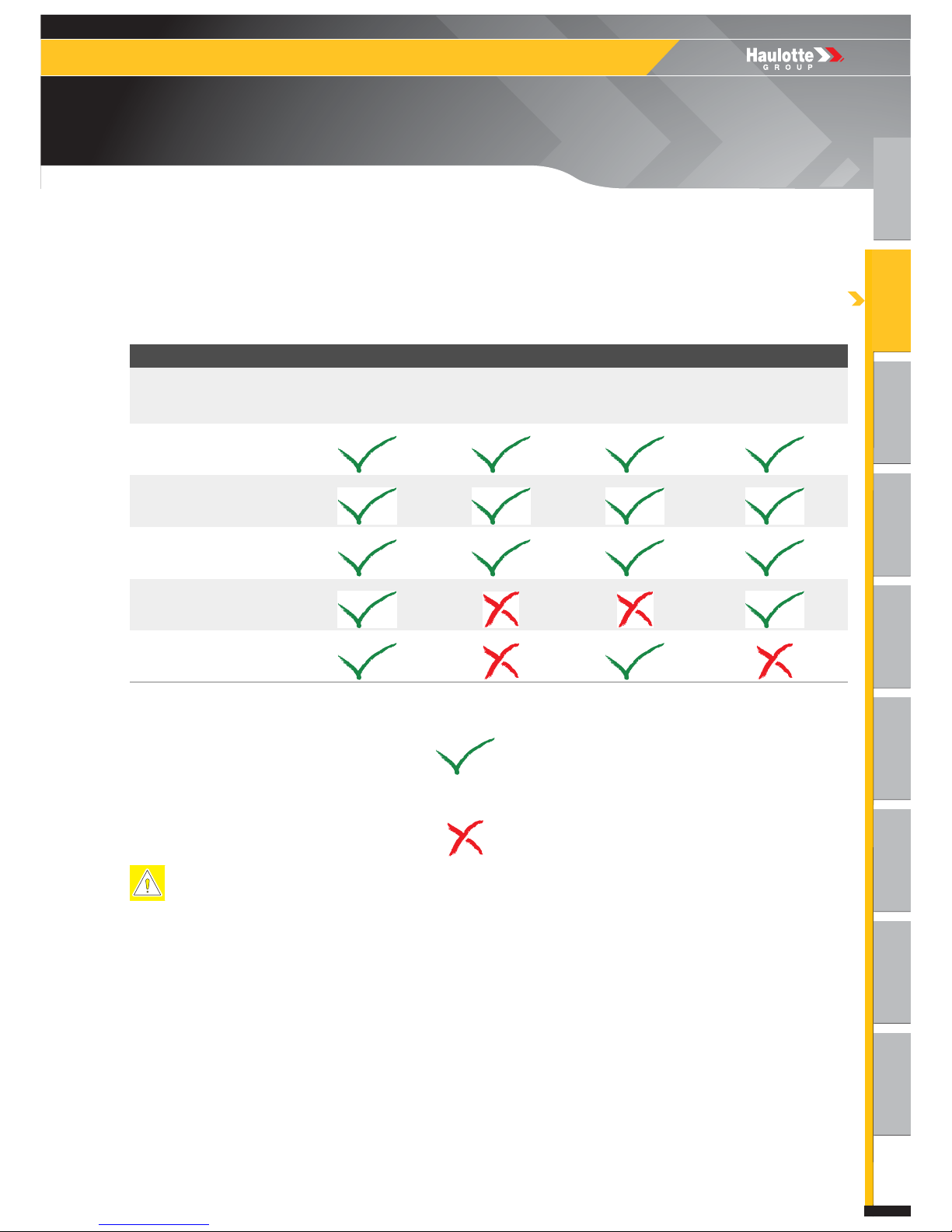

The inspection and maintenance table below, identifies the role and the responsibilities of each party

in periodical machine maintenance..

Inspections and maintenance

If the machine is operated in a hostile environment or intensively, increase the frequency of maintenance.

Type of

intervention

Frequency Person-in-charge Intervenor

Reference

document

Pre-delivery

inspection

Before each delivery

of sold, hired or

resold equipment

Owner (or hirer)

Qualified HAULOTTE

Services® technician

Operator's manual

Pre-operation

inspection

Before operation or

when the operator

changes

Operator Operator Operator's manual

Periodical

preventive

maintenance

At the specified

intervals (250 hours

or 1 year)

Owner (or hirer)

On-site technician or

qualified HAULOTTE

Services® technician

Maintenance book

Periodical visit

2 times a year or at

the latest 6 months

after the last

periodic visit, and

according to the

local regulations

Owner (or hirer)

Organization or

technician approved by

the employer or by the

intermediary

of HAULOTTE

Services® in

accordance with

the HAULOTTE

Services® contract

Maintenance book

A

B

C

D

E

F

G

H

I

13

4000014930 e10 12 EN

Engine-powered scissor lifts

A

- Safety precautions

4 - Instructions for intervention

N.B.-:-Acid is neutralised with sodium bicarbonate and water.

Do not use the machine during while maintenance work is being completed on it.

For any intervention on the power sources, wear glasses and protective clothes (acid spray).

Do not operate the product in the following situations :

• Do not work in an explosive or flammable atmosphere (spark, flame, etc.).

• Do not touch the hot parts of the hydraulic power source (engine, filters, etc.).

• Do not bridge the battery terminals with metallic objects.

• Do not service the battery close to a spark, naked flame, glowing tobacco (emissions of gas).

• Never expose the batteries or electrical components to water (pressure cleaner, rain).

• Never disable the safety devices.

• Do not climb onto the covers.

• Do not fill up the fuel tank, when the engine is running and/or close to a naked (open) flame.

Use an oil collection pan to avoid polluting the environment.

14 4000014930 e10 12 EN

Engine-powered scissor lifts

A

- Safety precautions

A

B

C

D

E

F

G

H

I

15

4000014930 e10 12 EN

Engine-powered scissor lifts

B

- Recommendations

Recommendations

1 - Lubrication diagram

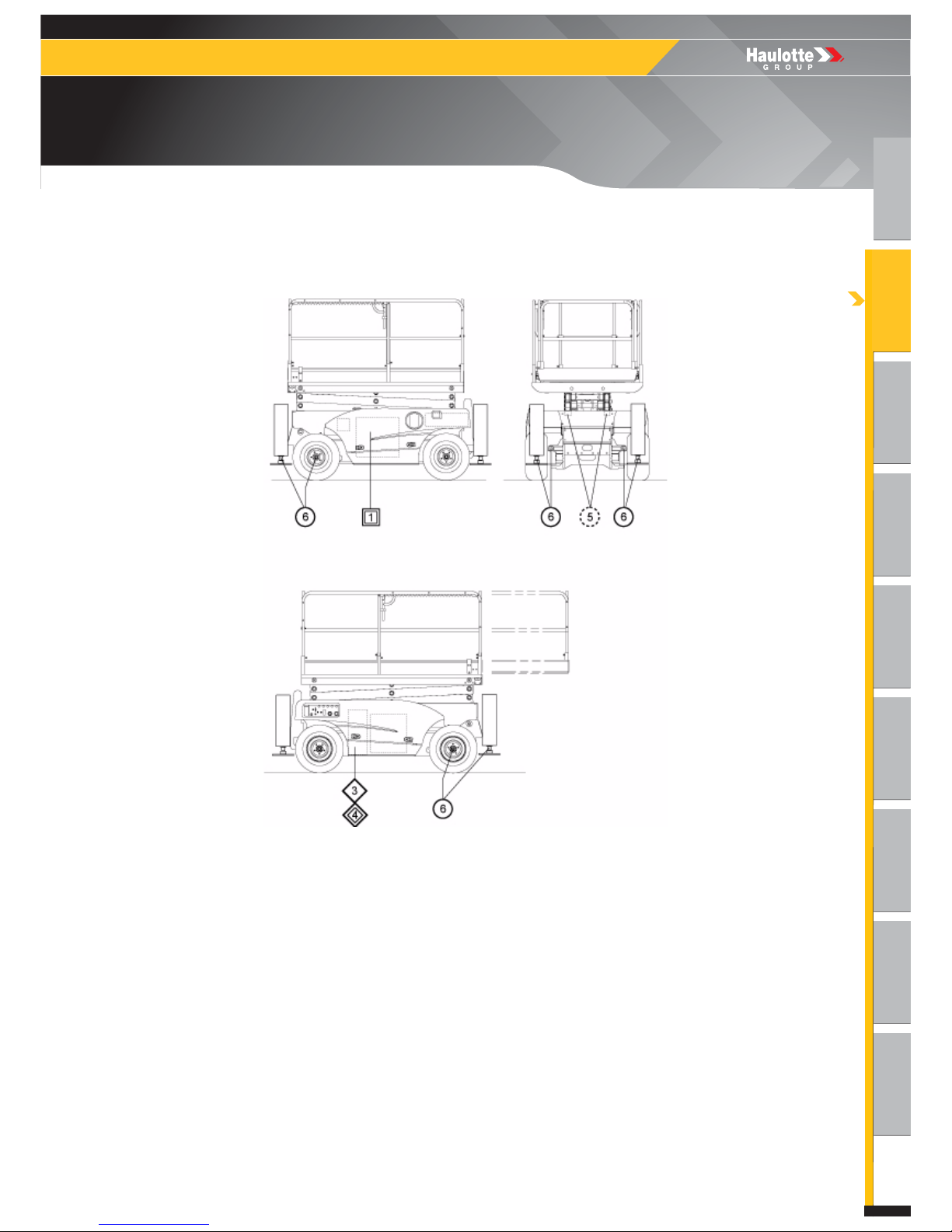

Diagram Compact 10/12DX (Compact 2668/3368RT)

16 4000014930 e10 12 EN

Engine-powered scissor lifts

B

- Recommendations

Diagram H12/15/18SX(L) (HS3388/4388/5388RT(XL))

2

22

2

5

5

3

4

6 6

2

2 2

6

6

1

A

B

C

D

E

F

G

H

I

17

4000014930 e10 12 EN

Engine-powered scissor lifts

B

- Recommendations

List of ingredients

Marking Ingredient Symbol HAULOTTE® code

1

Engine oil - Can 20 l(5,3 gal US) 2420801360

Engine oil - Barrel 209 l(55,2 gal US) 2420801350

Engine oil (+30° / - 20° ) 2820305670

Engine oil (Winter option) 4000010660

2

Box oil - Can 20 l(5,3 gal US) 2420801370

Box oil - Barrel 209 l(55,2 gal US) 2420801380

3

Hydraulic oil (Standard) - Barrel 209 l(55,2 gal US) 2420801310

Hydraulic oil (Winter option) 2505002640

4 Biological hydraulic oil - Barrel 209 l(55,2 gal US) 2820304310

5 Extreme-pressure lithium grease 2820304320

6

Lead-free grease - Aerosol 0,4 l(0.1 gal US) 2820304330

Lead-free grease - Can 5 l(1,32 gal US) 2820304340

7 Molybdenum grease

8 Oil

9 High-pressure lubricant

18 4000014930 e10 12 EN

Engine-powered scissor lifts

B

- Recommendations

2 - Consumables

List of consumables

Consumable HAULOTTE® code Applicability

Hydraulic filter cartridge

2427002940

• COMPACT 10DX (COMPACT 2668RT)

• COMPACT 12DX (COMPACT 3368RT)

2427002910

• H12SX (HS3388RT)

• H12SXL (HS3388RTXL)

• H15SX (HS4388RT)

• H15SXL (HS4388RT)

• H18SX (HS5388RT)

• H18SXL (HS5388RTXL)

Air filter (system)

4000007200-4000007210

• COMPACT 10DX (COMPACT 2668RT)

• COMPACT 12DX (COMPACT 3368RT)

2427002750

• H12SX (HS3388RT)

• H12SXL (HS3388RTXL)

• H15SX (HS4388RT)

• H15SXL (HS4388RT)

• H18SX (HS5388RT)

• H18SXL (HS5388RTXL)

Diesel pre-filter 2427005110

• H12SX (HS3388RT)

• H12SXL (HS3388RTXL)

• H15SX (HS4388RT)

• H15SXL (HS4388RT)

• H18SX (HS5388RT)

• H18SXL (HS5388RTXL)

Diesel filter

4000007230

• COMPACT 10DX (COMPACT 2668RT)

• COMPACT 12DX (COMPACT 3368RT)

2427002820

• H12SX (HS3388RT)

• H12SXL (HS3388RTXL)

• H15SX (HS4388RT)

• H15SXL (HS4388RT)

• H18SX (HS5388RT)

• H18SXL (HS5388RTXL)

Engine oil filter

4000007250

• COMPACT 10DX (COMPACT 2668RT)

• COMPACT 12DX (COMPACT 3368RT)

2427002480

• H12SX (HS3388RT)

• H12SXL (HS3388RTXL)

• H15SX (HS4388RT)

• H15SXL (HS4388RT)

• H18SX (HS5388RT)

• H18SXL (HS5388RTXL)

Filter pack

(1)

(1.) hydraulic filter cartridge + air filter + diesel pre-filter + diesel filter + engine oil filter

KKIT250H-COMPDK

• COMPACT 10DX (COMPACT 2668RT)

• COMPACT 12DX (COMPACT 3368RT)

KKIT250H-3M99

• H12SX (HS3388RT)

• H12SXL (HS3388RTXL)

• H15SX (HS4388RT)

• H15SXL (HS4388RT)

• H18SX (HS5388RT)

• H18SXL (HS5388RTXL)

A

B

C

D

E

F

G

H

I

19

4000014930 e10 12 EN

Engine-powered scissor lifts

B

- Recommendations

2.1 - FUELS

These fuels can be used on any type of mechanical injection engine. Please see machine

configuration.

N.B.-:-The fuel to be used is regulated by national laws; refer to these requirements and to the table

below to define the appropriate fuel.

Table of technically permitted fuels

Compliant

Not compliant

Engines Fuels

Hydraulic filter cartridge

European gas oil

according to

EN590

European fuel oil

according to

BS2869 class 2

American gas oil

according to

ASTMD975-07b

Japanese gas oil

according to

NATO F54

HATZ 41C

DEUTZ 2011/2012

PERKINS 403/804/1104

LOMBARDINI LDW 1404

KUBOTA D1105-W1

Other fuels :

• Biofuels : According to EN14214 (EU) and ASTM D6751-07a (USA) biofuels are allowed on some

engines and under certain conditions. For more information, please contact HAULOTTE Services®.

• Jet engine fuels (kerosene) : F34 and F35 types under OTAN designation are possible on some

engines and under certain conditions. For more information, please contact HAULOTTE Services®.

The use of vegetable oils is forbidden.

20 4000014930 e10 12 EN

Engine-powered scissor lifts

B

- Recommendations

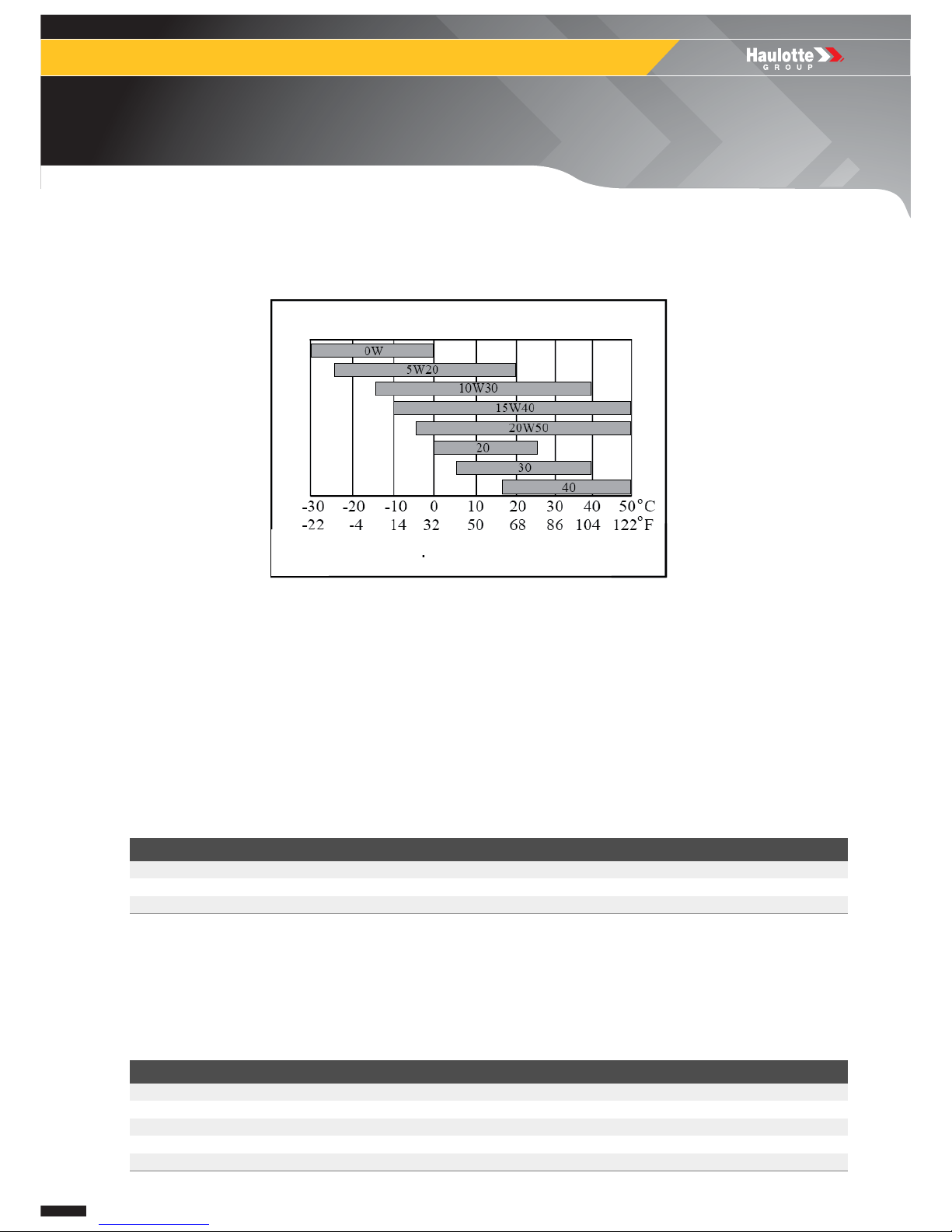

2.2 - MOTOR OILS

In order to ensure that the engine will run properly, it is recommended to use the following oils

Viscosity table

2.3 - HYDRAULIC OILS

Hydraulic oils must comply with the following requirements :

• Oil filterability must be compatible with absolute filters .

• Have properties such as :

• Antifoam and deaeration.

• Anti-wear, anti-shear and antioxydant.

• Rust and corrosion inhibitors (copper).

The recommended viscosity grades depending on the environmental conditions are as follows

:

Biodegradable oils may be used if they comply with the following requirements :

• Ambient operating temperature between -15 °C(-9 °F) and + 40 °C(+ 104 °F) .

• HEES type biodegradable oil only according to standards ISO 15380 and VDMA 24568.

• Necessary characteristics

Environmental conditions ISO Viscosity grade

Ambient temperature between - 15 °C(- 9 °F) and + 40 °C(+ 104 °F) HV 46

Ambient temperature between - 35 °C(- 31 °F) and + 35 °C(+ 95 °F) HV 32

Ambient temperature between 0 °C(32 °F) and + 45 °C(+ 113 °F) HV 68

Viscosity grade ISO Viscosity grade

Viscosity at + 40 °C(+ 104 °F) 46 +/- 3 mm² / s

Viscosity at + 100 °C(+ 260 °F) > 8 mm² / s

Viscosity index > 160

Flashpoint > 220° C (> 572° F)

Pour point < - 40° C (> - 104° F)

A

B

C

D

E

F

G

H

I

21

4000014930 e10 12 EN

Engine-powered scissor lifts

B

- Recommendations

3 - Labels

3.1 - CLASSIFICATION PLAN

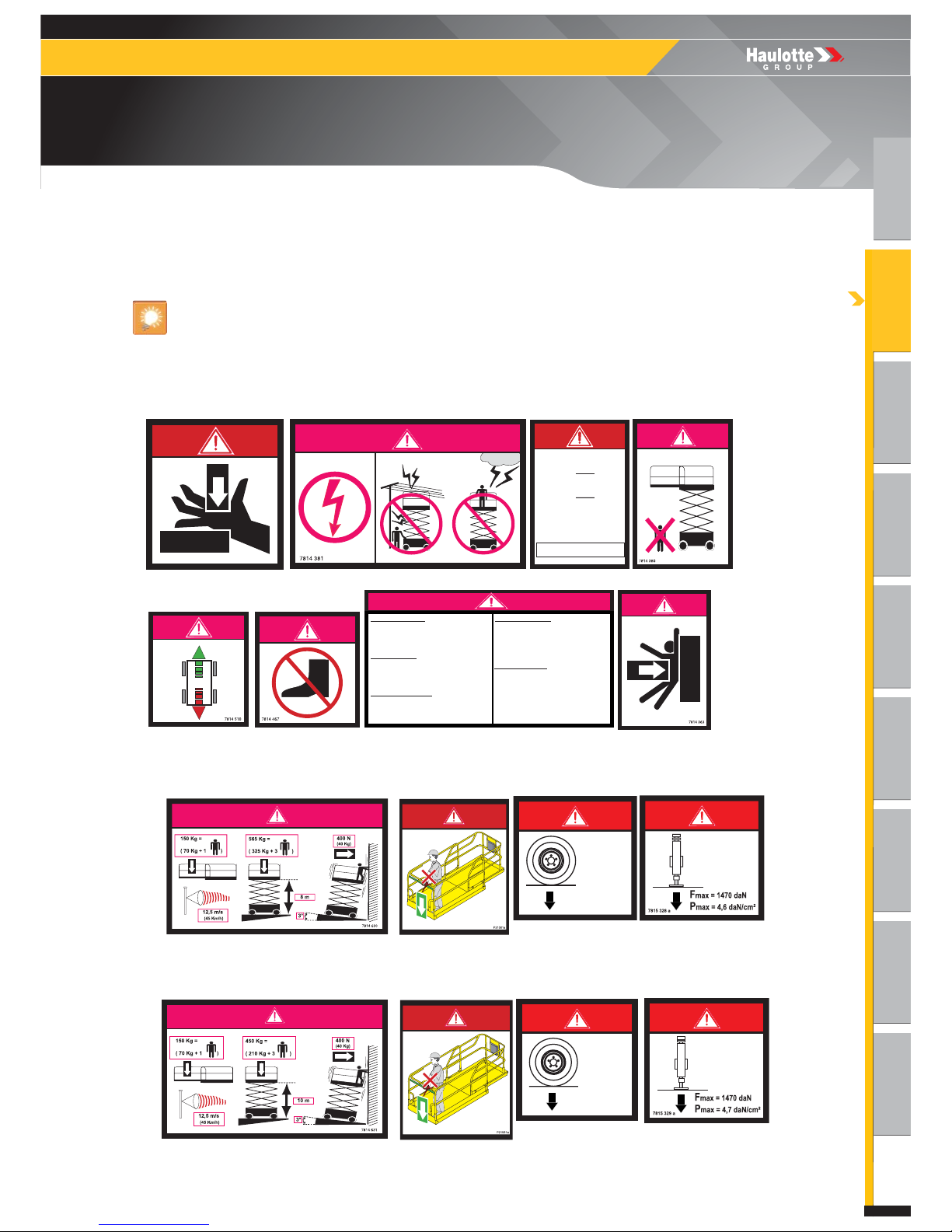

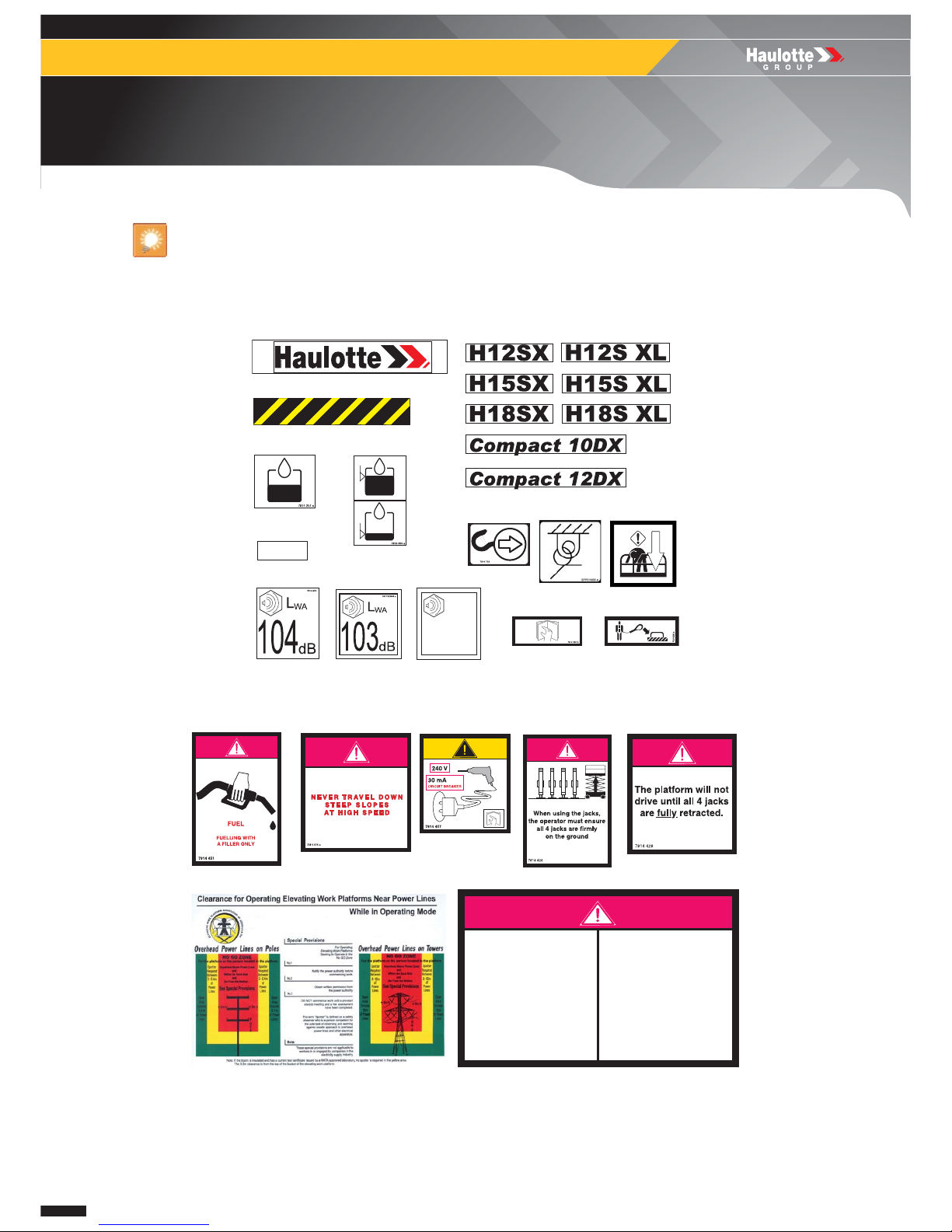

3.1.1 - Red labels

Common labels

Specific labels COMPACT 10DX (COMPACT 2668RT)

Specific labels COMPACT 12DX (COMPACT 3368RT)

The red labels indicate a potentially fatal danger.

R2

R13

R26 - HSX(L)

R3

R6R5

R7

.

F

.

GB

.

D

7814 518

Composant spécifique à

cette machine.

NE PAS INTERCHANGER.

Component specific

to this machine.

DO NOT INTERCHANGE.

Komponenten nur für

diese maschine geeignet.

BITTE AUF EINE ANDERE

MASCHINE NIGHT

MONTIEREN.

N° MACHINE - MASCHINE N°

307P222890 a

before use of the nacelle.

-The user must recognize the surface on which

the nacelle will roll.

-Not toraise the platform nor to roll with the plateform

raised on inclined, irregular or movable surfaces.

V

or dem Einsatz der Maschine.

-Der Benützer muss den Untergrundkontrollieren

auf dem die Maschine fahren soll.

-Auf schrägem, unebenem oder zu weichem

Untergrund darfweder die Plattform ausgefahren

werden noch die Maschine in ausgefahrenemZustand

gefahrenwerden.

A

ntes del uso de la barquilla.

-El usuario debe reconocer la superficie sobre la cual

la barquillava a circular.

-No levantar la plataforma, ni circular con la plataforma

levantada sobre superficies inclinadas, irregulares o muebles.

P

rima dell'utilizzo della macchina.

- L'utilizzatore deve anticipatamente prendereconoscenza d

el terreno su cui la macchina deve traslare.

-Non sollevare la piattaforma o traslare su terreno inclinato,

sconnesso o non compatto.

A

vant utilisation de la nacelle.

-L’utilisateur doit reconnaître la surface sur laquelle

la nacelleva rouler.

-Ne pas relever la plateforme ni rouler avec la plateformerelevée

sur des surfaces inclinées, irrégulières ou meubles.

7814 901

R4

R1

R8

R9

R10

4000012870 a

F

max = 2760 daN

P

max = 8,42 daN/cm²

R1 R8

R9 R10

4000012880 a

F

max = 3030 daN

P

max = 6,1 daN/cm²

22 4000014930 e10 12 EN

Engine-powered scissor lifts

B

- Recommendations

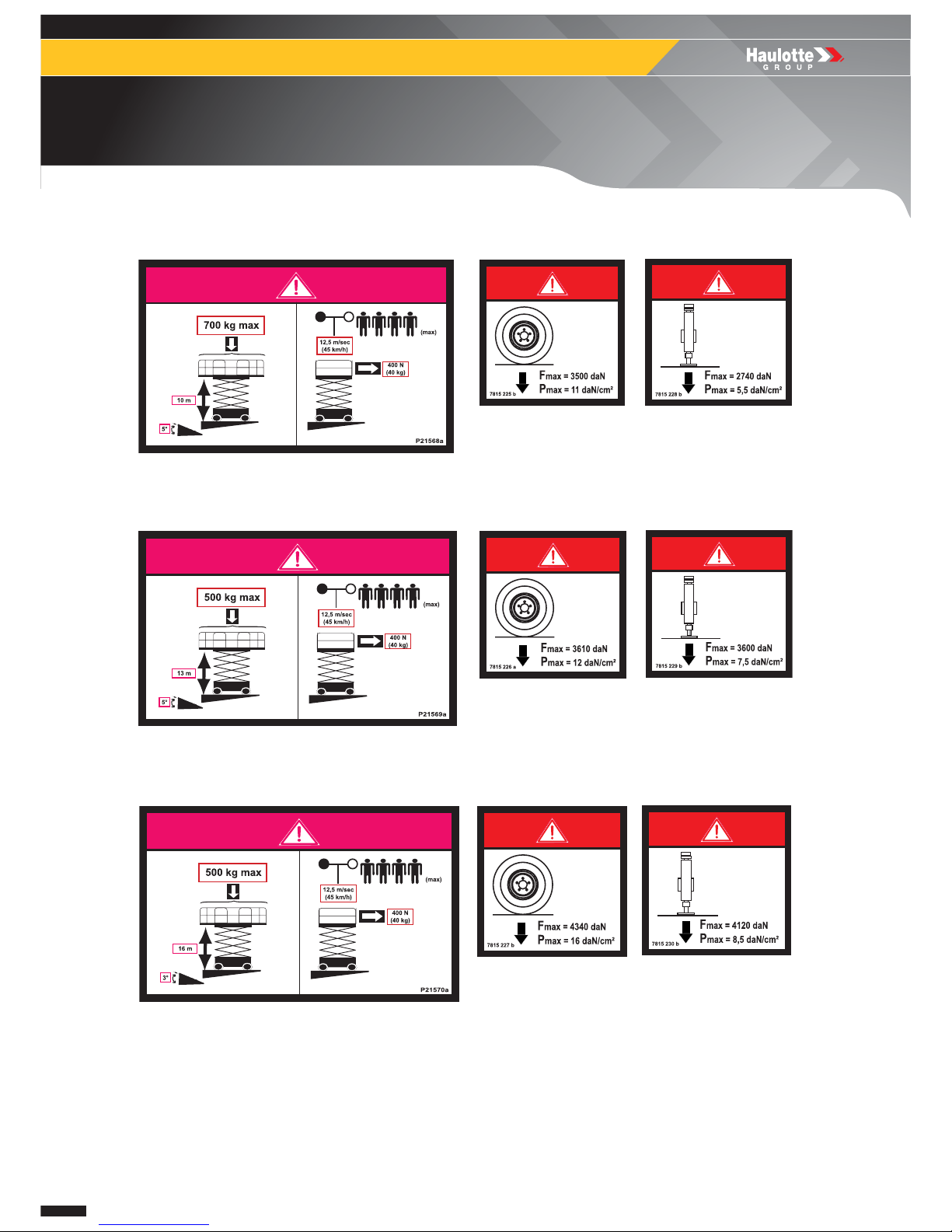

Specific labels H12SX (HS3388RT)

Specific labels H15SX (HS4388RT)

Specific labels H18SX (HS5388RT)

R1 R10R9

R1 R10R9

R1 R10R9

A

B

C

D

E

F

G

H

I

23

4000014930 e10 12 EN

Engine-powered scissor lifts

B

- Recommendations

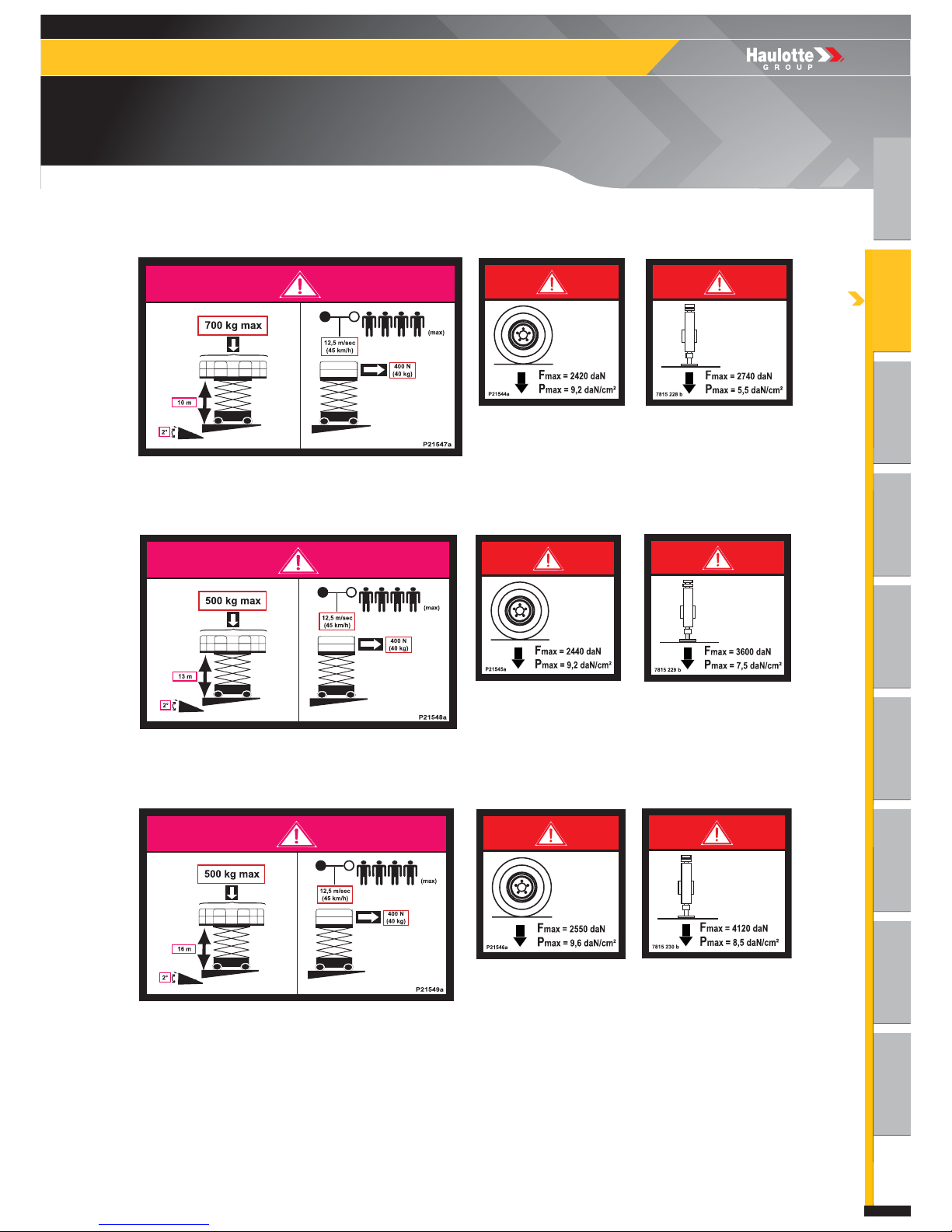

Specific labels H12SXL (HS3388RTXL)

Specific labels H15SXL (HS4388RTXL)

Specific labels H18SXL (HS5388RTXL)

R1 R10R9

R1 R10R9

R1 R10R9

24 4000014930 e10 12 EN

Engine-powered scissor lifts

B

- Recommendations

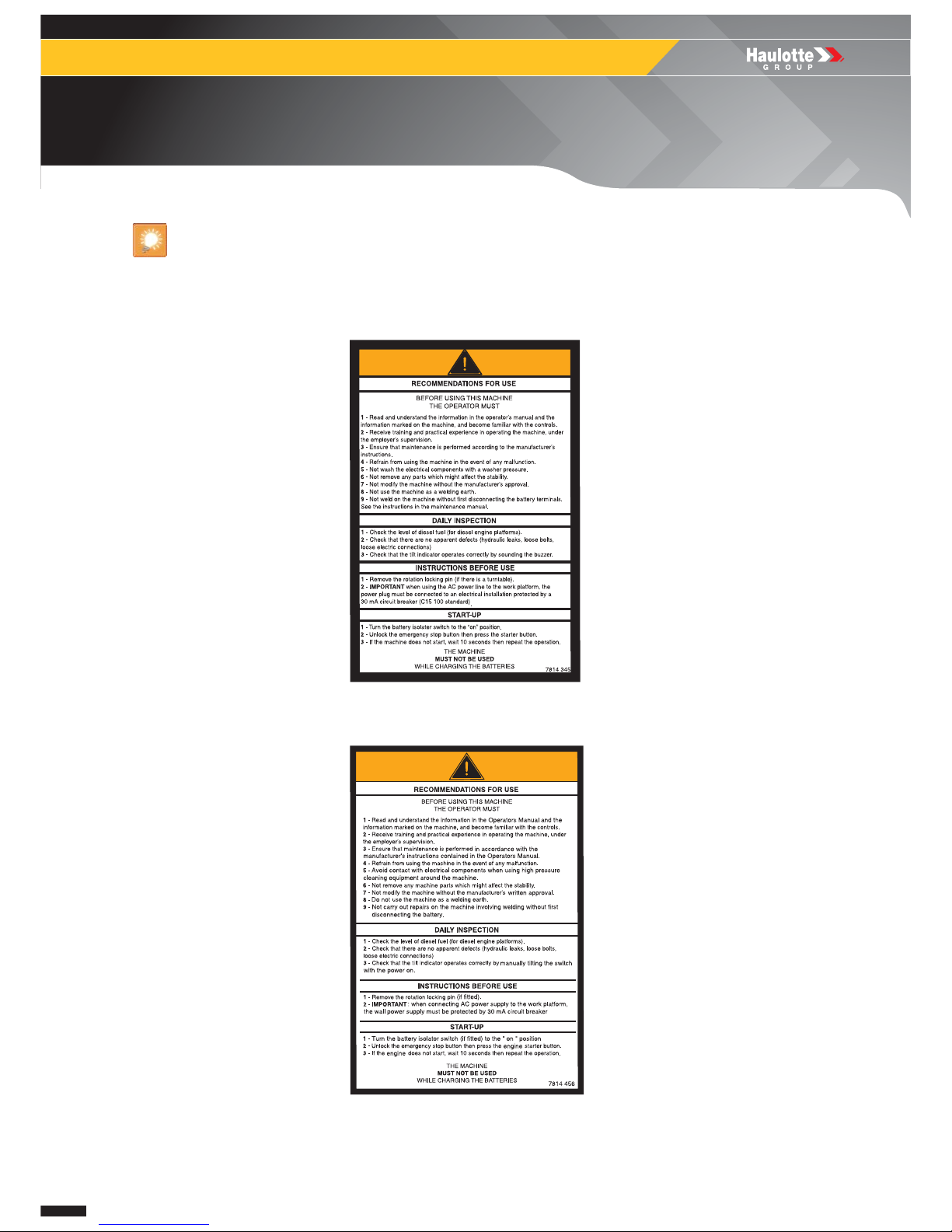

3.1.2 - Orange labels

Common labels - CE

Common labels - AS

The orange labels indicate a risk of serious injury.

O1

O1

A

B

C

D

E

F

G

H

I

25

4000014930 e10 12 EN

Engine-powered scissor lifts

B

- Recommendations

Common labels - ANSI - CSA

O1

7814 705 b

WARNING

THIS MACHINE MUST NOT BE USED UNTIL IT IS INSPECTED

AND OPERATING PROPERLY.

DO NOT operate this machine unless you have been properly trained as

described in the HAULOTTE Operation and Safety Manual by a qualified person

and authorized to operate this machine. Your training includes reading and

understanding the safety, operating and maintenance instructions in

manufacturer's manuals, knowing your employers work rules and applicable

governmental regulations.

Follow the instructions in the Operating Manual and sections 6, 7 and 8 of

ANSI A92.5-2006 for daily, frequent and annual inspections. These may be obtained

from your authorized HAULOTTE, Inc. equipment dealer or HAULOTTE, Inc.

DO NOT replace items (i.e., batteries, tires, counterweight, etc.) with items of

different weight or specification because this will affect the stability of the

machine.

DO NOT modify or change this machine without written approval from the

manufacturer.

Operate this machine with extreme caution. STOP all operation if a malfunction

occurs.

Test foot switch for proper operation.

RECOMMENDATIONS FOR USE

DAILY INSPECTION

INSTRUCTION BEFORE USE

Test high engine and high drive cut out switches for proper operation.

DO NOT wash the electrical components with a washer pressure.

DO NOT use the machine as a welding earth.

DO NOT weld on the machine without first disconnecting the battery terminals.

Check the level of diesel fuel (for diesel engine platform).

Check that there are no apparent defects (hydraulic leaks, loose bolts,

loose electric connections).

Check that the tilt indicator operates correctly by sounding the buzzer

(when machine is raised).

Remove the rotation locking pin (if there is a turntable).

IMPORTANT when using the AC power line to the work platform, the power plug

must be connected to an electrical installation protected by a circuit breaker.

START-UP

Turn the battery isolater switch to the "ON" position.

Unlock the emergency stop button then press the starter button

(for diesel engine platform).

If the machine does not start, wait 10 seconds then repeat the operation.

The machine must not be used while charging the batteries (on electrical machine)

Improper use of this machine could cause death or serious injury.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

26 4000014930 e10 12 EN

Engine-powered scissor lifts

B

- Recommendations

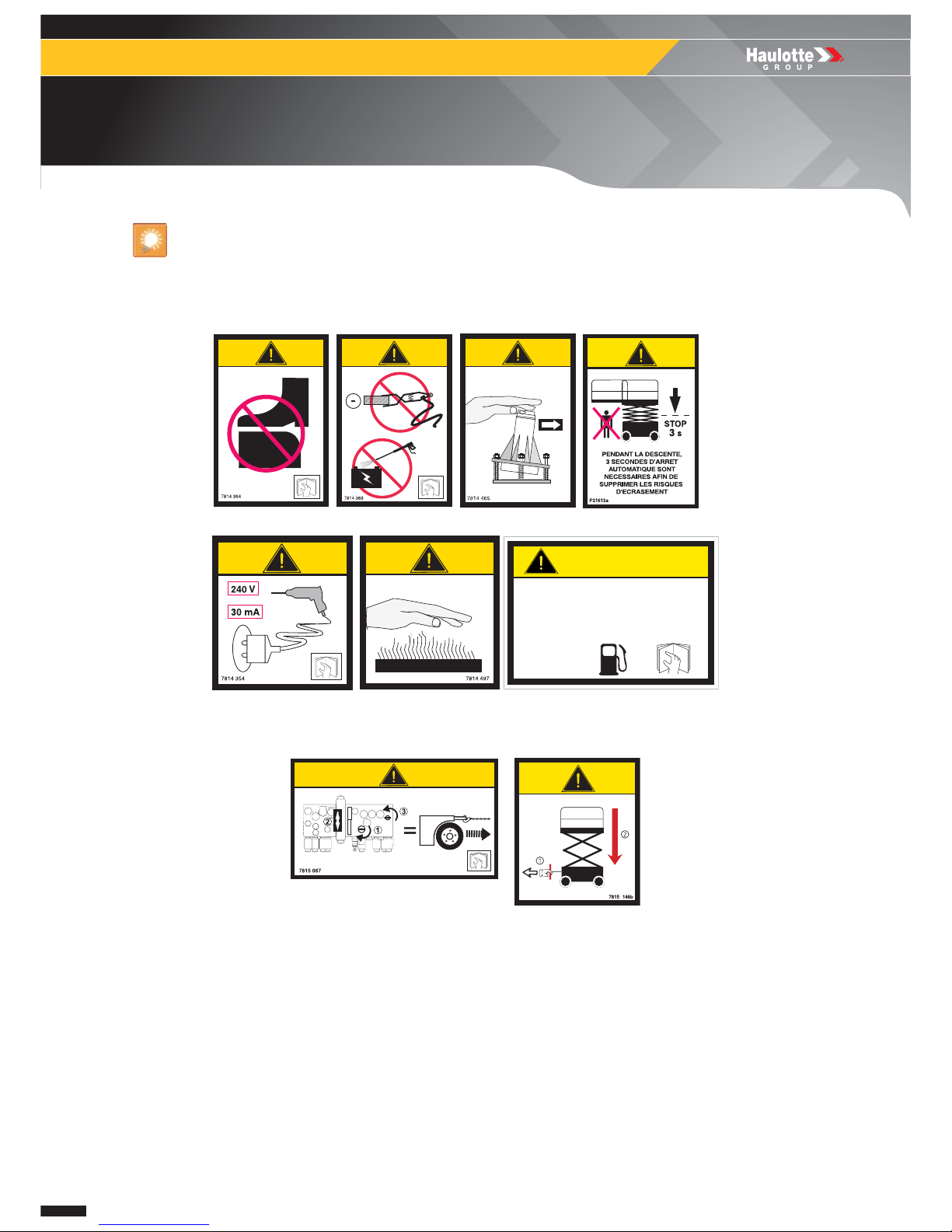

3.1.3 - Yellow labels

Common labels

Specific COMPACT 10DX (COMPACT 2668RT) and COMPACT 12DX (COMPACT 3368RT) labels

The yellow labels indicate a risk of material damage and/or minor injury.

J3 J4 J6 J9

J12

a

J10

DIESEL LOW SULFUR OR ULTRA-LOW SULFUR /

DIESEL À FAIBLE OU TRÈS FAIBLE TENEUR EN SOUFRE /

GASÓLEO BAJO EN AZUFRE O ULTRA-BAJO EN AZUFRE /

DIESEL A BASSO TENORE DI ZOLFO O A BASSISSIMO TENORE DI ZOLFO /

DIESELKRATSTOFF MIT NIEDRIGEM ODER EXTREM NIEDRIGEM SCHWEFELGEHALT

EU (EN 590)

US (ASTM D975-91 class 2D)

WARNING

307P232480 a

J32

J5 J16

A

B

C

D

E

F

G

H

I

27

4000014930 e10 12 EN

Engine-powered scissor lifts

B

- Recommendations

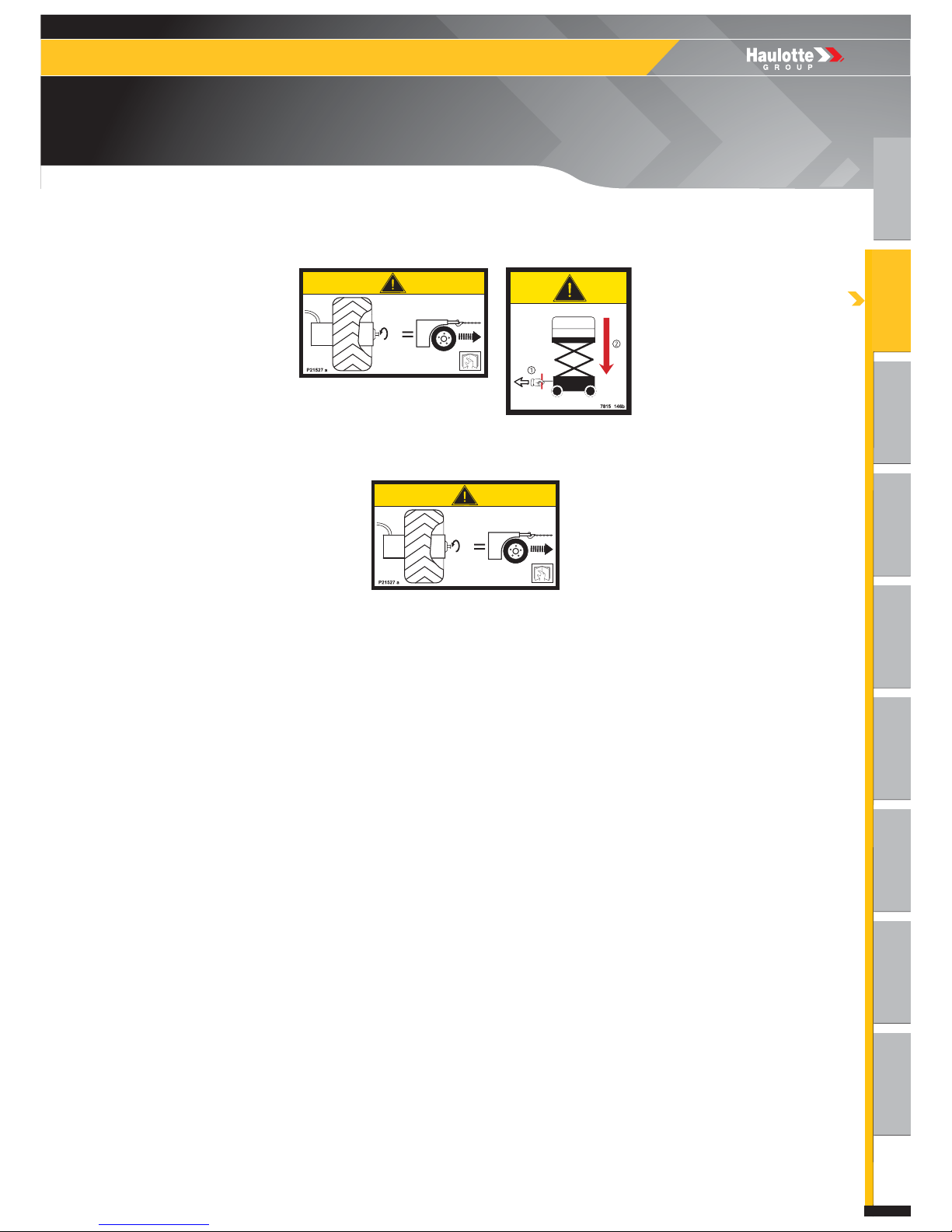

Specific H12SX (HS3388RT) , H15SX (HS4388RT) , H12SXL (H3388RTXL) and H15SXL (HS4388RTXL)

labels

Specific H18SX (HS5388RT) and H18SXL (HS5388RTXL) labels

J5 J16

J5

28 4000014930 e10 12 EN

Engine-powered scissor lifts

B

- Recommendations

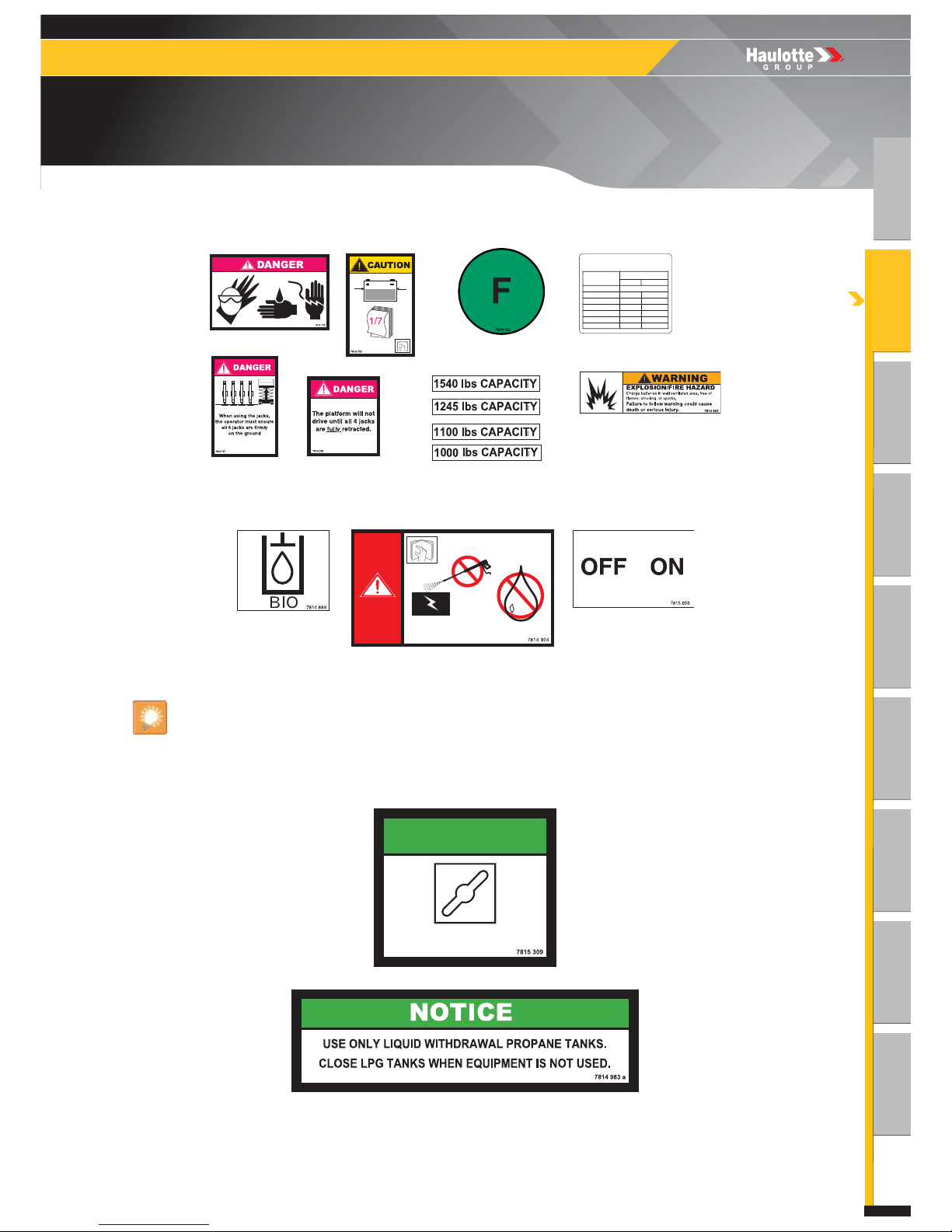

3.1.4 - Other labels

Common labels

Specific labels AS

The other labels provide additional technical information.

A5

A16

A4

A8

A7

A15

A9

A10

A89

A24

4WD

A10

307P226580a

A80

4000012860

L

WA

dB

101

A10

A90

R14

R17

J10

R23 R24

A28

RESCUE OPERATIONS IF

SAFETY DEVICE PREVENT

NORMAL MOVEMENT

. Turn the key-operated selector

to turntable position

. Be carreful that the emergency

stop button is released

. Activate and hold the overriding-system

switch and activate the switch

corresponding to the movement required

in the same time

4000013250 a

RESCUE OPERATIONS

IF NORMAL MOVEMENT

ARE AVAILABLE

. Turn the key-operated selector

to turntable position

. Be carreful that the emergency

stop button is released

. Activate and hold the enable switch and

activate the switch corresponding to

the movement required in the same time

R54

A

B

C

D

E

F

G

H

I

29

4000014930 e10 12 EN

Engine-powered scissor lifts

B

- Recommendations

Specific labels ANSI : Diesel version

Specific labels, optional

3.1.5 - Green labels

Common labels

3.1.6 - Blue labels

N.B.-:-The blue labels indicate information or a precaution to be taken in case of danger.

Green labels indicate maintenance, operations or information ( CSA standard).

R21

R23

R24

J13 A22

A25

O3

A27

Minimum safe approach distance

(M.S.A.D) to energized (exposed or

insulated) power lines

Voltage Range

(Phase to phase)

Minimum safe approach distance

0 to 300 V

Over 300 V to 50 kV

Over 50 kV to 200 kV

Over 200 kV to 350 kV

Over 350 kV to 500 kV

Over 500 kV to 750 kV

Over 750 kV to 1000 kV

AVOID CONTACT

10

15

20

25

35

45

3.05

4.60

6.10

7.62

10.67

13.72

3078147890 c

(Feet) (Meters)

A8 R18 - HSX(L) A31 - HSX(L)

V2

UNDER THE HOOD

V1

30 4000014930 e10 12 EN

Engine-powered scissor lifts

B

- Recommendations

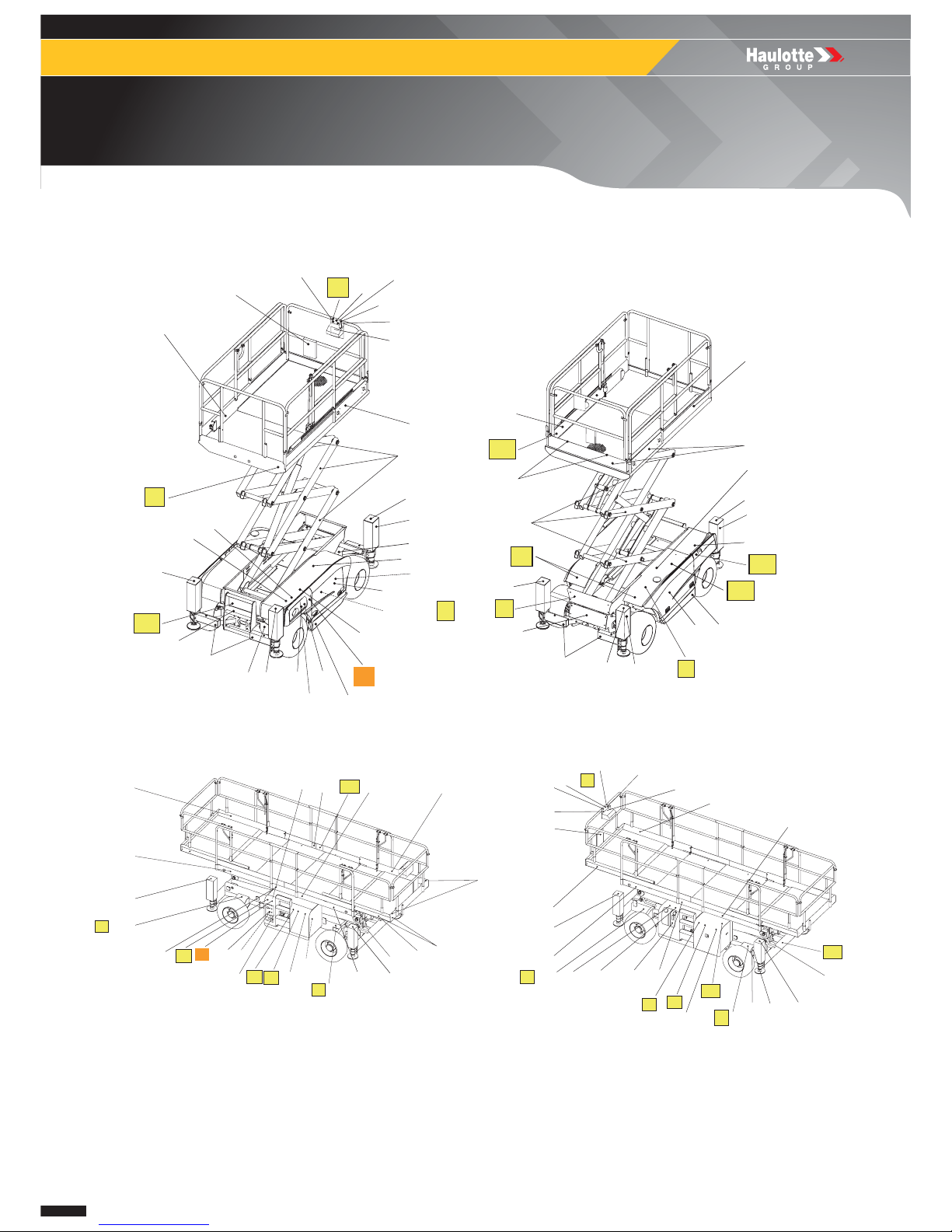

3.2 - IDENTIFICATION

Location of the Compact DX labels - Standards CE and AS

Location of HSX and HSXL labels - Standards CE and AS

A16

A5

R4

R13

R13

R7

A5

J3

R2

O1

R13

J16

R9

R10

R13

R5

R2

A7

J9 R8

R17

A1

A5

R4

R13

R6

A4

J6

A8 - A9 - J5

A3 - A10

R1

R23 - R24

J4

A2

A24

R13

J10

A15

J12

A24

A4

R14

A80

A80

- A28

A87

R9 -

J32

R9

R10

R10

R7 - R9

R10

R3

R5

R1

A28

R3

R54

A89

A90

J4

A89

A90

R1 - J9

A1

R2

A4 - A5

R10 - R13A3

A30

J16

A10

J12

J3

R3A9A8R14

J4

J5 - R9

J5 - R9

R10 - R13

A4

A16

R7

R23

R17

R26

R24

A7

R2

A4

R10 - R13

J5 - R9

R10 - R13

R3 J6 O1 A2 R6

J4 J3 R7

R18

A4

A15

R5 - A28J10A31 R1

A16

A30

A80

A80

J5 - R9

A5

A87

Loading...

Loading...