Haulotte Group H12SXL, COMPACT 2668RT, COMPACT 12DX, COMPACT 3368RT, H15SX Operator's Manual

...

Operator's manual

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL -

COMPACT 10/12 DX - COMPACT 2668/3368 RT

4000014860 E10.16 USA / GB

Operator's manual

ENGINE-POWERED SCISSOR LIFTS

H12SX (HS 3388RT) - H12SXL (HS 3388RTXL) H15SX (HS 4388RT) - H15SXL (HS 4388RTXL) H18SX (HS 5388RT) - H18SXL (HS 5388RTXL) -

COMPACT 10DX (COMPACT 2668RT)

COMPACT 12DX (COMPACT 3368RT)

4000003660

X

USA

2 4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

3

CONTENTS

Operator's manual

CONTENTS

1 - Operator's manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

2 - After Sales Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

3 - Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

4 - HAULOTTE Services® contact details . . . . . . . . . . . . . . .

9

A

SAFETY PRECAUTIONS

1 - Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

1.1 - Operator's manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2 - Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 - Decal colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 - Pre-operation instructions. . . . . . . . . . . . . . . . . . . . . . . .

13

2.1 - General instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2 - Specific instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 - Operation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . .

15

3.1 - Prohibitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 - Potential risks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.1 - Risk of command system disturbance . . . . . . . . . . . . . . . . . . . . 16

3.2.2 - Risk of falling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.3 - Risk of electrocution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.4 - Risk of uncontrolled movement and overturning . . . . . . . . . . . . 18

3.2.5 - Risk of burns and explosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.6 - Risk of crushing and collision . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

B

INTERVENOR'S RESPONSIBILITY

1 - Owner's (or hirer's) responsibility. . . . . . . . . . . . . . . . . .

23

2 - Employer's responsibility . . . . . . . . . . . . . . . . . . . . . . . .

23

3 - Trainer's responsibility . . . . . . . . . . . . . . . . . . . . . . . . . .

23

4 - Operator's responsibility . . . . . . . . . . . . . . . . . . . . . . . . .

23

5 - Inspection and maintenance . . . . . . . . . . . . . . . . . . . . . .

24

4

Operator's manual

C

MACHINE LAYOUT

1 - Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25

2 - Main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26

3 - Safety devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28

3.1 - Sliding (or swinging) intermediate guardrail . . . . . . . . . . . . . . . . . . . . . . . 28

3.2 - Anchorage point (Please see machine configuration) . . . . . . . . . . . . . 29

3.3 - Maintenance support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.4 - Folding guardrails - Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4 - Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31

4.1 - Classification plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1.1 - Red decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1.2 - Orange decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.1.3 - Yellow decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.1.4 - Other decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.1.5 - Green decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.1.6 - Blue decals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.2 - Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5 - Control boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

60

5.1 - Ground control box - Emergency control box. . . . . . . . . . . . . . . . . . . . . 60

5.2 - Platform control box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

D

OPERATING PRINCIPLE

1 - Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

69

2 - Safety devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

70

2.1 - Activation of controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

2.2 - Plateform lifting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

2.3 - Drive speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

2.4 - Anti-crush system when lowering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

2.5 - On-board electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

2.6 - Thermostat location / limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

2.7 - Detection of internal fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

2.8 - Automatic engine cut-out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

2.9 - Load limiting in the platform (if fitted) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

2.10 - Chassis tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

2.11 - Drive buzzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5

CONTENTS

Operator's manual

E

DRIVING

1 - Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

73

2 - Checks before use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

74

2.1 - Visual inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

2.1.1 - General mechanical functions . . . . . . . . . . . . . . . . . . . . . . . . . . 74

2.1.2 - Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

2.2 - Functional tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

2.2.1 - Safety features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

2.2.2 - Ground box controls (emergency station). . . . . . . . . . . . . . . . . . 77

2.2.3 - Platform box controls (driving station) . . . . . . . . . . . . . . . . . . . . 78

2.3 - Periodical checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

2.4 - Repairs and adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

2.5 - Inspection / Testing requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

3 - Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

80

3.1 - Test procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

3.1.1 - E-stop button operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

3.1.2 - Tilt sensor switch operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.1.3 - Visual and sound alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.1.4 - Weighing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

3.2 - Operation from ground position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.2.1 - Machine start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.2.2 - Machine shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.2.3 - Movement control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.2.4 - Other controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3.3 - Operations from the platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3.3.1 - Machine shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3.3.2 - Movement control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3.3.3 - Other controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

F

SPECIAL PROCEDURE

1 - Emergency lowering. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

89

1.1 - Principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

1.2 - Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

1.3 - Extraordinary procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

2 - Lowering for repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

91

2.1 - Principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

2.2 - Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3 - Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

93

3.1 - Disengaging the drive hubs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

3.2 - Brake release. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

3.3 - Re-engaging the drive hubs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

4 - Loading and unloading . . . . . . . . . . . . . . . . . . . . . . . . . .

96

4.1 - Principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

4.1.1 - Lifting operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

4.1.2 - Lifting operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

4.2 - Putting in transport position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

4.3 - Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

4.4 - Warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5 - Detection of internal fault. . . . . . . . . . . . . . . . . . . . . . . .

108

5.1 - Principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

5.2 - Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6 - On-board generator . . . . . . . . . . . . . . . . . . . . . . . . . . . .

109

6.1 - Principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

6.2 - Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

6

Operator's manual

G

TECHNICAL SPECIFICATIONS

1 - Main characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . .

111

1.1 - Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

1.2 - Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

2 - Overall dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

120

3 - Working area / Range of motion . . . . . . . . . . . . . . . . . .

123

3.1 - Machine COMPACT 10DX (COMPACT 2668RT) . . . . . . . . . . . . . 123

3.2 - Machine COMPACT 12DX (COMPACT 3368RT) . . . . . . . . . . . . . 124

3.3 - Machine H12SX (HS3388RT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

3.4 - Machine H15SX (HS4388RT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

3.5 - Machine H18SX (HS5388RT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

3.6 - Machine H12SXL (HS3388RTXL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

3.7 - Machine H15SXL (HS4388RTL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

3.8 - Machine H18SXL (HS5388RTXL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

4 - AS - CE standard specificities . . . . . . . . . . . . . . . . . . .

131

4.1 - Overload test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

4.2 - Functional test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

4.3 - Stability test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

5 - Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . .

137

H

INTERVENTION REGISTER

1 - Intervention register. . . . . . . . . . . . . . . . . . . . . . . . . . . .

139

7

4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

You have just purchased a HAULOTTE® product

and we would like to thank you for your business.

1 - Operator's manual

As stated on the delivery slip, this manual is one of the documents in the on-board document holder

provided upon delivery of your HAULOTTE® machine.

The operator manual is a translation of the original instructions.

Safe operation of this product can only be assured if you follow the operating instructions contained in

this manual are followed.

We would particularly like to draw your attention to 2 essential points :

• Compliance with safety instruction (machine, use, environment)

• Use of the equipment within the performance limits.

2 - After Sales Service

Our HAULOTTE Services® After Sales Service is at your disposal throughout your machine's service

life to ensure the optimum use of your HAULOTTE product.

• When contacting our After Sales Service, ensure that you provide the machine model and serial

number.

• When ordering any consumables or spare parts, please use this manual and the Haulotte Essential

catalogue to receive your genuine HAULOTTE spare parts, your only guarantee of parts

interchangeability and correct machine operation..

• If there is an equipment malfunction involving a HAULOTTE® product, then contact HAULOTTE

Services® immediately even if the malfunction does not involve material and/or bodily damage..

• HAULOTTE® must be informed in the event of an incident that either involves one of these products

or has caused bodily injury or significant deterioration of property (personal property or the product);

contact HAULOTTE Services® immediately (See : HAULOTTE Services® contact details)

With regard to the designation of our equipment, we stress that this is purely for commercial purposes and

not to be confused with the technical specifications. Only the specifications in this manual should be used

to study the suitability of the equipment for the intended use.

8 4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

3 - Compliance

We would like to remind you that HAULOTTE® complies with the provisions of any applicable

directives applicable to this type of machine.

HAULOTTE advises you that NO modifications carried out without the written permission

of HAULOTTE® will void the HAULOTTE warranty.

HAULOTTE® cannot be held liable for any changes to the technical characteristics/specifications

contained in this manual.

HAULOTTE® reserves the right to alter technical specifications and to make improvements or

modifications to the machine without modifying this manual.

Certain options can modify the machine's operating characteristics and its associated safety. If your

machine was originally delivered with options fitted, replacing a safety component associated with a

particular options not require any particular precautions other than those associated with the installation

itself (static test).

Otherwise, it is essential to follow the manufacturer's recommendations as stated below :

• Installation by authorised HAULOTTE® personnel only.

• Update the manufacturer's identification plate.

• Have stability tests carried out by a certified agency/competent person.

• Ensure decal compliance.

9

4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

4 - HAULOTTE Services® contact details

HAULOTTE Services® contact details

HAULOTTE FRANCE

PARC DES LUMIERES

601 RUE NICEPHORE NIEPCE

69800 SAINT-PRIEST

TECHNICAL Department:

+33 (0)820 200 089

SPARE PARTS : +33 (0)820 205 344

FAX : +33 (0)4 72 88 01 43

E

-mail : haulottefrance@haulotte.com

www.haulotte.fr

HAULOTTE ITALIA

VIA LOMBARDIA 15

20098 SAN GIULIANO MILANESE

(MI)

TEL: +39 02 98 97 01

FAX: +39 02 9897 01 25

E-mail : haulotteitalia@haulotte.com

www.haulotte.it

HAULOTTE HUBARBEITSBÜHNEN GmbH

Ehrenkirchener Strasse 2

D-79427 ESCHBACH

TEL : +49 (0) 7634 50 67 - 0

FAX : +49 (0) 7634 50 67 - 119

E.mail : haulotte@de.haulotte.com

www.haulotte.de

HAULOTTE VOSTOK

35, SVOBODY STREET

Bldg. 19

125362 MOSCOW

RUSSIA

TEL/FAX : +7 495 221 53 02 / 03

E.mail : info@haulottevostok.ru

www.haulotte-international.com

HAULOTTE DO BRASIL

AV. Tucunaré, 790

CEP: 06460-020 – TAMBORE

BARUERI – SAO PAULO – BRASIL

TEL : +55 11 4196 4300

FAX : +55 11 4196 4316

E.mail

:

haulotte@haulotte.com.br

www.haulotte

.com.br

HAULOTTE IBERICA

C/ARGENTINA N° 13 - P.I. LA GARENA

28806 ALCALA DE HENARES

MADRID

TEL : +34 902 886 455

TEL SAT : +34 902 886 444

FAX : +34 911 341 844

E.mail : iberica@haulotte.com

www.haulotte.es

HAULOTTE POLSKA Sp. Z.o.o.

UL. GRANICZNA 22

05-090 RASZYN - JANKI-

TEL : +48 22 720 08 80

FAX : +48 22 720 35 06

E-mail :

haulottepolska@haulotte.com

www.haulotte.pl

HAULOTTE MÉXICO, Sa de Cv

Calle 9 Este, Lote 18, Civac, Jiutepec,

Morelos

CP 62500 Cuernavaca

México

TEL : +52 77 7321 7923

FAX : +52 77 7516 8234

E-mail : haulotte.mexico@haulotte.com

www.haulotte-international.com

HAULOTTE PORTUGAL

ESTRADA NACIONAL NUM. 10

KM. 140 - LETRA K

2695 - 066 BOBADELA LRS

TEL : + 351 21 995 98 10

FAX : + 351 21 995 98 19

E.mail : haulotteportugal@haulotte.com

www.haulotte.es

HAULOTTE SINGAPORE Pte Ltd.

No.26 CHANGI NORTH WAY,

SINGAPORE 498812

Parts and service Hotline:

+65 6546 6150

FAX : +65 6536 3969

E-mail: haulotteasia@haulotte.com

www.haulotte.sg

HAULOTTE MIDDLE EAST FZE

PO BOX 293881

Dubaï Airport Free Zone

DUBAÏ

United Arab Emirates

TEL : +971 (0)4 299 77 35

FAX : +971 (0) 4 299 60 28

E-mail : haulottemiddle-

east@haulotte.com

www.haulotte-international.com

HAULOTTE SCANDINAVIA AB

Taljegårdsgatan 12

431 53 Mölndal

SWEDEN

TEL : +46 31 744 32 90

FAX : +46 31 744 32 99

E-mail : info@se.haulotte.com

spares@se.haulotte.com

www.haulotte.se

HAULOTTE TRADING (SHANGHAI)

Co. Ltd.

#7 WORKSHOP

No 191 HUA JIN ROAD

MIN HANG DISTRICT

SHANGHAI 201108 CHINA

TEL : +86 21 6442 6610

FAX : +86 21 6442 6619

E-mail :

haulotteshanghai@haulotte.com

www.haulotte.cn

HAULOTTE ARGENTINA

Ruta Panamericana Km. 34,300

(Ramal A Escobar)

1615 Gran Bourg

(Provincia de Buenos Aires)

Argentina

TEL.: +54 33 27 445991

FAX. +54 33 27 452191

E-mail : haulotteargentina@haulotte.com

www.haulotte-international.com

HAULOTTE UK Ltd

STAFFORD PARK 6

TELFORD - SHROPSHIRE TF3 3AT

TEL : +44 (0)1952 292753

FAX : + 44 (0)1952 292758

E.mail : salesuk@haulotte.com

www.haulotte.co.uk

HAULOTTE GROUP / BILJAX

125 TAYLOR PARKWAY

ARCHBOLD, OH 43502 – USA

TEL : +1 419 445 8915

FAX :+1 419 445 0367

Toll free : +1 800 537 0540

E.mail : sales@us.haulotte.com

www.haulotte-usa.com

HAULOTTE GROUP

1301 E PATRICK STREET

FREDERICK, MD 21701 – USA

TEL : +1 301 663 0852

FAX :+1 301 663 0572

Toll free : +1 800 537 0540

E.mail : sales@us.haulotte.com

www.haulotte

HAULOTTE CHILE

El Arroyo 840

Lampa (9380000)

Santiago (RM)

TEL : + 562 2 3727630

E.mail : haulotte-chile@haulotte.com

www.haulotte-chile.com

-usa.com

HAULOTTE NETHERLANDS BV

Koopvaardijweg 26

4906 CV OOSTERHOUT - Nederland

TEL : +31 (0) 162 670 707

FAX : +31 (0) 162 670 710

E.mail :

info@haulotte.nl

HAULOTTE AUSTRALIA PTY Ltd

46 GREENS ROAD

DANDENONG – VIC – 3175

TEL : 1 300 207 683

FAX : +61 (0)3 9792 1011

E.mail :

sales@haulotte.com.au

HAULOTTE INDIA

Unit No. 1205, 12th foor,Bhumiraj Costarica,

Plot No. 1&2, Sector 18,

Palm Beach Road,

Sanpada, Navi Mumbai- 400 705

Maharashtra, INDIA

Tel. : +91 22 66739531 to 35

E-mail : sray@haulotte.com

www.haulotte.in

10 4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

Notes

A

B

C

D

E

F

G

H

I

11

4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

A

- Safety precautions

Safety precautions

1 - Recommendations

1.1 - OPERATOR'S MANUAL

This operators manual is specific to the HAULOTTE® products listed on the cover page of this

manual..

1.2 - SYMBOLS USED

Symbols are used to alert the operator to safety precautions or to highlight practical

information.

Legend

The operator manual does not replace the basic training required for all worksite equipment operators.

HAULOTTE® has compiled this manual to assist in safe and efficient operation of the products covered

by the manual.

This manual must be kept on the machine (or in the cab in its storage case. The manual must be available

to all operators and must be kept in good condition. Additional copies can be ordered from HAULOTTE

Services®.

Symbol Description

Danger : Risk of injury or death

Caution : Risk of material damage

Prohibition relating to work safety and quality

Reminder : No identified risk, but a reminder of the need for common sense,

good practice or pre-action prerequisites

Cross-reference to another part of the manual (see section or sheet)

Cross-reference to another manual (see manual)

Cross-reference to repairs (contact HAULOTTE Services®)

N.B. : Additional technical information

12 4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

A

- Safety precautions

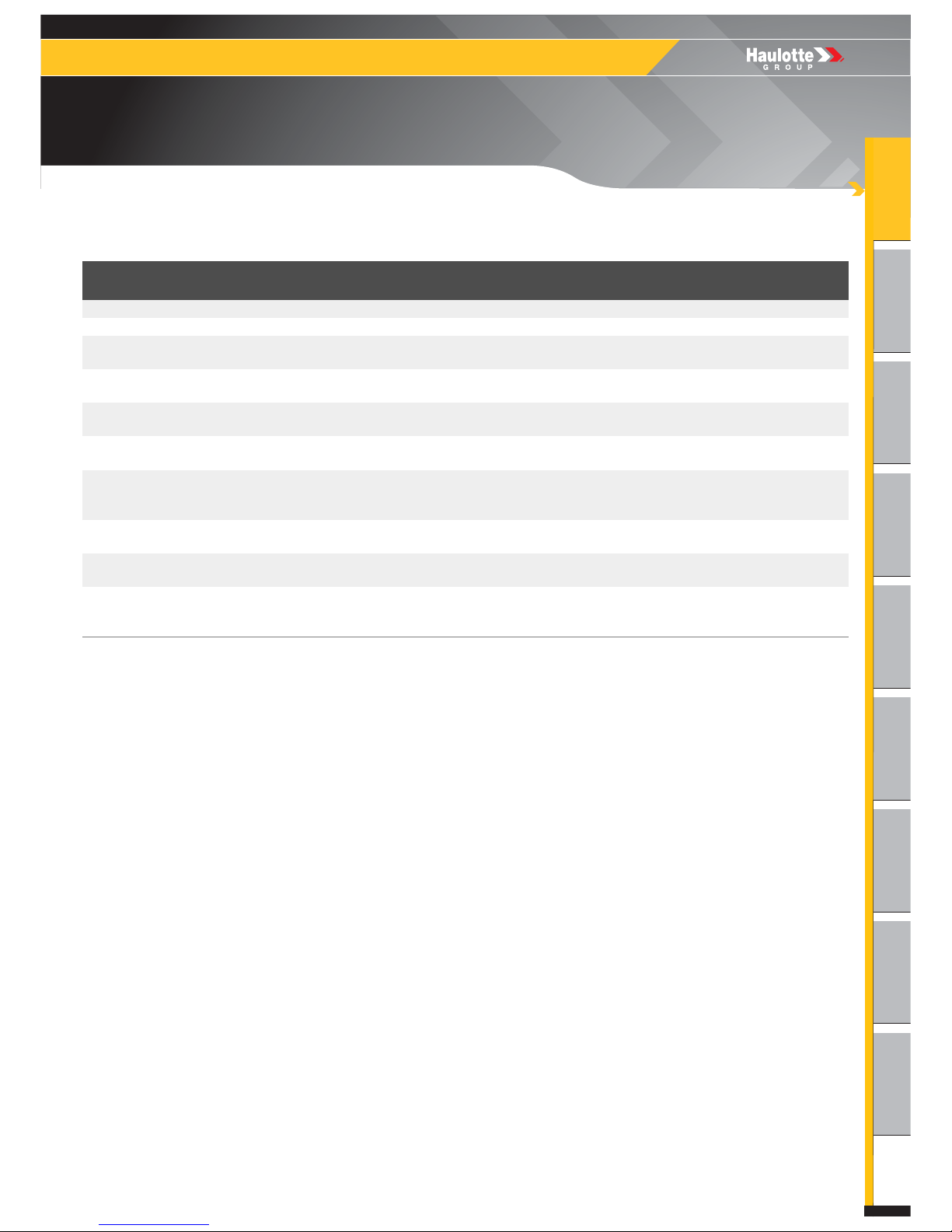

1.3 - DECAL COLORS

The potential dangers and any specific regulations are indicated around the product by decals

and identification plates.

Familiarize yourself with the decals and their respective color codes.

Decal color code

Decal color code-For Russia and the Ukraine only

The decals must be kept in good condition. Additional decals can be ordered from HAULOTTE Services®.

Decals Color Description

Red Potentially fatal danger

Orange Risk of serious injury

Yellow Risk of material damage and/or minor injury

Other Additional technical information

Green Maintenance operation or information

Decals Color Description

Red Prohibitions - Danger

Yellow Warning : Risk of material damage and/or minor injury

Blue Precaution

Blue Information

Other Additional technical information

A

B

C

D

E

F

G

H

I

13

4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

A

- Safety precautions

2 - Pre-operation instructions

2.1 - GENERAL INSTRUCTIONS

• On soft, unstable or cluttered ground.

• With wind blowing faster than the permissible limit. Check the maximum allowable value in the

technical characteristics / specifications ( Section G 1-Main characteristics). Consult the

Beaufort scale ( Section A 3.2.4-Risk of uncontrolled movement and overturning).

• Close to power lines. Respect the safety distance ( Section A 3.2.3-Risk of electrocution).

• At ambient temperatures higher than 45 °C(113 °F) and lower than -15 °C(5 °F) .

Consult HAULOTTE® if it is necessary to work outside this range.

• In an explosive atmosphere.

• During storms (risk of lightning).

• In the presence of strong electromagnetic fields.

N.B.-:-You are advised to use the machine under "NORMAL" climatic conditions.. If you need to use

the machine in climatic conditions likely to cause deterioration (extreme : humidity, temperatures,

salinity, corrosiveness, atmospheric pressure), contact HAULOTTE Services®. Reduce intervals

between servicing.

N.B.-:-Whilst the machine is not in use, care must be taken to ensure that if the machine is not locked

in a secure location, that the unit key switch is removed to prevent unauthorised use of the machine.

• The employer has the obligation to issue a driving permit to the operator.

• The employer is obliged to inform the operator of the local regulations.

Do not operate the product in the following situations :

14 4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

A

- Safety precautions

2.2 - SPECIFIC INSTRUCTIONS

• If the load in the platform exceeds the maximum load authorized. Check the maximum allowable value

in the technical characteristics / specifications ( Section G 1-Main characteristics).

• If the ground slope is greater than the permissible limit. Check the maximum allowable value in the

technical characteristics / specifications ( Section G 1-Main characteristics).

• In a non-ventilated area as the exhaust gases are toxic.

• At night unless the machine is equipped with the optional light.

• If the number of persons exceeds the permissible limit. Check the maximum allowable value in the

technical characteristics / specifications ( Section G 1-Main characteristics).

• If the side force is greater than the permissible force. Check the maximum allowable value in the

technical characteristics / specifications ( Section G 1-Main characteristics).

Do not operate the product in the following situations :

A

B

C

D

E

F

G

H

I

15

4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

A

- Safety precautions

3 - Operation instructions

3.1 - PROHIBITIONS

It is preferable to operate the machine on flat, consolidated ground (tarmac, concrete, etc.).

• Never use a faulty machine (hydraulic leaks, worn tires/tyres, malfunction).

• Never operate the machine controls suddenly.

• Never place the machine against a structure to hold that structure in place.

• Never use the machine to tow other machines or to drag materials.

• Never expose the batteries or electrical components to water (pressure cleaner, rain).

• Never disable the safety devices.

• Do not make contact with a fixed or mobile obstacle. The contact can cause premature deterioration of

the structure and lead to the corruption of certain safety elements.

• Do not climb onto the covers.

• Never use the machine with only an operator in the platform. A second person competent in the operation

of emergency retrieval, should be present on the ground in case of an emergency.

• Never use the machine when the platform is cluttered.

• Never increase the surface area of the platform by using floor extensions or accessories not authorized

by HAULOTTE®.

• Never leave the hydraulic cylinders fully extended or retracted before switching off the machine, or when

stationary for an extended period of time.

• Never use the machine with material or objects suspended from the guard-rail.

• Never use the machine with elements that can increase the wind force (panels).

• Never increase the working height by using attachments (ladder).

• Never use the guardrail as a means of access for climbing in or out of the platform. The basket can be

easily accessed in its low position. For machines fitted with : Steps have been provided for this purpose

where required.

• Never climb on the guardrail.

• Do not use the machine if the guard rails are not correctly installed and locked.

• Never use the machine without fitting the sliding (or rotating) middle rail, closing the safety gate or the

swing gates beforehand.

• Never use the machine as a crane, material lift or elevator.

• Never use the machine for any other purpose than to transport people, their tools and material to the

desired place.

• Never drive fast in narrow or cluttered areas. Keep speed under control in bends.

• Never tow the machine over extended distances (it must be transported on a trailer).

16 4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

A

- Safety precautions

3.2 - POTENTIAL RISKS

3.2.1 - Risk of command system disturbance

Risk of disrupted movement. Maintain clearance from high voltage lines or magnetic fields.

3.2.2 - Risk of falling

When in the platform, respect the following instructions :

• Carry individual protection equipment adapted to the work conditions and local

rules.

• Avoid contact with fixed or mobile obstacles (other machines).

• Ensure that the adjustable midrail is closed (low position and against the guardrails).

• Ensure that the gate is closed and locked (For machines fitted with).

• Hold on securely to the guardrails during elevation and driving.

• Do not sit, stand, or climb on the platform guard rails.

• Ensure that guard rails are correctly installed and locked.

• Always keep your feet firmly on the floor of the platform.

• Remove any trace of oil or grease from the steps, floor, handrail and the guardrails.

• Keep the floor of the platform free of debris.

• Do not leave the platform until it is fully in its stowed position.

• Do not climb on to the platform if the machine is not in the stowed position.

To climb up or climb down from the platform :

• The machine must be completely stowed.

• Face the machine to access the entry opening to the platform

• Keep 3 support points between the steps and the guardrail

A

B

C

D

E

F

G

H

I

17

4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

A

- Safety precautions

3.2.3 - Risk of electrocution

The machine is not electrically insulated and does not offer any insulation

protection.

The risks of electrocution are high in the following situations :

• Close to live power lines, consider the movement of the machine and the sway of the electric power

lines particularly in windy conditions.

• In the event that you were to make accidental contact with a high voltage line, wait for the power to

the line to be switched off before operating the machine.

• During storms.

Never use the machine as a welding earth.

Maintain a minimum safe distance with regard to power lines and electrical devices.

Respect the local rules and the minimum safety distance from power lines.

Minimum safe approach distances

N.B.-:-This table is applicable, except when the local regulations are more strict.

Electric voltage Minimum safety distance

Mètre Feet

0 - 300 V Avoid contact

300 V - 50 kV 3 10

50 - 200 kV 5 15

200 - 350 kV 6 20

350 - 500 kV 8 25

500 - 750 kV 11 35

750 - 1000 kV 14 45

18 4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

A

- Safety precautions

3.2.4 - Risk of uncontrolled movement and overturning

When in the platform, respect the following instructions :

• Before operating the machine on any indoor or outdoor surface (premises, bridge,

truck, etc.), check that the surface is capable of supporting the combined machine

weight and platform capacity. Check the maximum allowable value in the technical characteristics /

specifications ( Section G 1-Main characteristics).

• Remain vigilant of driving direction reversal at the platform. Check the driving direction with the help

of the red or green arrow on the chassis relative to the red and green arrows on the platform control

box.

• Always ensure that the chassis is never driven any closer than 1 m(3 ft3 in) to holes, bumps, slopes,

obstructions, debris and ground coverings that may hide holes and other dangers.

• During motion direction reversal from the platform or ground control box, the joysticks or switches

must be in neutral position before reversing the direction of motion.

• Taking note of the overall load dimensions and weight, place the loads in the centre of the platform or

distribute them it a uniform manner.

• If the tilt alarm sounds when the platform is raised, lower platform completely, then reposition machine

onto level ground before raising platform.

• Do not drive the machine on slopes or tilts beyond the design limits. Check the maximum allowable value

in the technical characteristics / specifications( Section G 1-Main characteristics).

• Do not travel down slopes in high speed.

• Do not use the machine (elevation and travel) on an incline greater than that permitted by the slope

sensor.

• Do not drive in reverse (direction opposite the field of vision).

• Never use the machine in winds exceeding the permissible limit.

• Do not increase the surface area exposed to wind. The greater the surface area exposed, the more

unstable the machine becomes.

For COMPACT 10DX (COMPACT 2668RT) - COMPACT 12DX (COMPACT 3368RT) :

• Make sure manual brake system is closed (tap is completely screwed in).

• Do not operate machine if brakes are released.

• Section F 2.1Manual brake release

A

B

C

D

E

F

G

H

I

19

4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

A

- Safety precautions

N.B.-:-The Beaufort scale measures the wind fo rce with a graduation system. A wind speed range at 10

m(32 ft9 in) above flat, clear land is associated with each degree.

Beaufort scale

Force

Meteorological

description

Observed effects m/s km/h mph

0 Calm Smoke rises vertically. 0 - 0,2 0 - 1 0 - 0,62

1 Very light breeze Smoke indicates the wind direction. 0,3 - 1,5 1 - 5 0,62 - 3,11

2 Light breeze

Wind felt on the face. Leaves rustle.

Weather vanes turn.

1,6 - 3,3 6 - 11 3,72 - 6,84

3 Slight breeze

Leaves and small twigs in constant

motion. Flags move slightly.

3,4 - 5,4 12 - 19 7,46 - 11,8

4 Nice breeze

Raised dust and loose papers. Small

branches are moved.

5,5 - 7,9 20 - 28 12,43 - 17,4

5 Nice breeze

Small trees in leaf to sway. Crested

wavelets form on inland waterways.

8,0 - 10,7 29 - 38 18,02 - 23,6

6 Cool wind

Large branches in motion. Power lines

and chimneys 'sing'. Umbrellas used

with difficulty.

10,8 - 13,8 39 - 49 24,23 - 30,45

7 Strong cool wind

Whole trees in motion. Inconvenience

felt when walking against wind.

13,9 - 17,1 50 - 61 31 - 37,9

8 Squall

Some branches break. Generally we

cannot walk against the wind.

17,2 - 20,7 62 - 74 38,53 - 45,98

9 Strong squall

The wind causes slight damage to

buildings. Tiles and chimney stacks are

blown off.

20,8 - 24,4 75 - 88 46,60 - 54,68

20 4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

A

- Safety precautions

3.2.5 - Risk of burns and explosion

N.B.-:-Acid is neutralized with sodium bicarbonate and water.

For any intervention on the power sources, wear glasses and protective clothes (acid spray).

• Do not work in an explosive or flammable atmosphere (spark, flame, etc.).

• Do not touch the hot parts of the hydraulic power source (engine, filters, etc.).

• Do not bridge the battery terminals with metallic objects.

• Do not service the battery in proximity of spark, open flame, lit cigarettes.

• Do not fill up the fuel tank, when the engine is running and/or near a flame.

A

B

C

D

E

F

G

H

I

21

4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

A

- Safety precautions

3.2.6 - Risk of crushing and collision

When in the platform, respect the following instructions :

• During operation, keep all the parts of the body inside the platform.

• Keep hands and limbs well away from the scissor arms.

• Adjust the movement speed to the ground conditions (traffic, slope, etc.).

• Respect stopping distances after the controls are released :

• 3 m(9 ft10 in) at high speed.

• 1 m(3 ft3 in) at low speed.

• Ensure there are no obstacles (structure) in the work area.

• Always obtain assistance from a guide on the ground when manoeuvring.

• All the personnel in the platform or on the within the vicinity of the machine must wear Personal

Protection Equipment (safety helmet, etc.).

• When moving the machine, ensure that the machine operating areas is free of persons and obstacles.

Do not operate other machines (crane, aerial work platform, etc.) in the work area.

Take account of the distance, reduced visibility and blind spots during use of the machine.

22 4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

A

- Safety precautions

Notes

A

B

C

D

E

F

G

H

I

23

4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

B

- Intervenor's responsibility

Intervenor's responsibility

1 - Owner's (or hirer's) responsibility

The owner (or hirer) has the obligation to inform operators of the instructions contained in the Operator

Manual.

The owner (or hirer) has the obligation to renew all manuals or decals that are either missing or in bad

condition. Additional copies can be ordered from HAULOTTE Services®.

The owner (or hirer) is responsible for applying the local regulations regarding operation of the

machine.

2 - Employer's responsibility

The employer has the obligation to issue a driving permit to the operator.

N.B.-:-In accordance with the regulation of the country where the machine is operating, the user must

be authorized by the doctor of Labour Ministry to operate the mach ine.

3 - Trainer's responsibility

The trainer must be qualified to provide training to operators in accordance with applicable local

regulations. The training must be given in an obstacle-free area until the trainee is considered

competent as defined by the training program undertaken.

4 - Operator's responsibility

The operator must read and understand the contents of this manual and the decals affixed on the

machine.

The operator must inform the owner (or hirer) if the manual or any decals are missing or in poor

condition, and of any malfunction of the machine.

The operator may only operate the machine for the purpose intended by the manufacturer.

All operators must become familiar with and fully understand the emergency controls and how to

operate the machine in an emergency as a component of their formal operator training.

The operator has the obligation stop using the machine in the event of malfunction or safety problems

on the machine or in the work area and report the problem to his/her supervisor.

Forbid anyone from operating the machine who is :

• Under the influence of drugs, alcohol, etc..

• Subject to fits, loss of motor skills, dizziness, etc..

Only authorized and qualified operators may operate HAULOTTE® machines.

24 4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

B

- Intervenor's responsibility

5 - Inspection and maintenance

The inspection and maintenance table below, identifies the role and the responsibilities of each party

in periodical machine maintenance..

Inspections and maintenance

If the machine is operated in a hostile environment or intensively, increase the frequency of maintenance.

Type of intervention Frequency Person-in-charge Intervenor Reference document

Pre-delivery inspection

Before each delivery of

sold, hired or resold

equipment

Owner (or hirer)

Qualified HAULOTTE

Services® technician

Operator's manual

Pre-operation inspection

Before operation or when

the operator changes

Operator Operator Operator's manual

Periodical preventive

maintenance

At the specified intervals

(250 hours or 1 year)

Owner (or hirer)

On-site technician or

qualified HAULOTTE

Services® technician

Maintenance book

Periodical visit

2 times a year or at the

latest 6 months after the

last periodic visit, and

according to the local

regulations

Owner (or hirer)

Organization or

technician approved by

the employer or by the

intermediary of

HAULOTTE Services® in

accordance with the

HAULOTTE Services®

contract

Maintenance book

A

B

C

D

E

F

G

H

I

25

4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

C

- Machine layout

Machine layout

1 - Identification

The manufacturers identification plate fixed on the chassis bears all pertinent information to identify the

machine (Please see machine configuration).

For any request for information, intervention or spare parts, specify the type and serial number of the

machine.

26 4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

C

- Machine layout

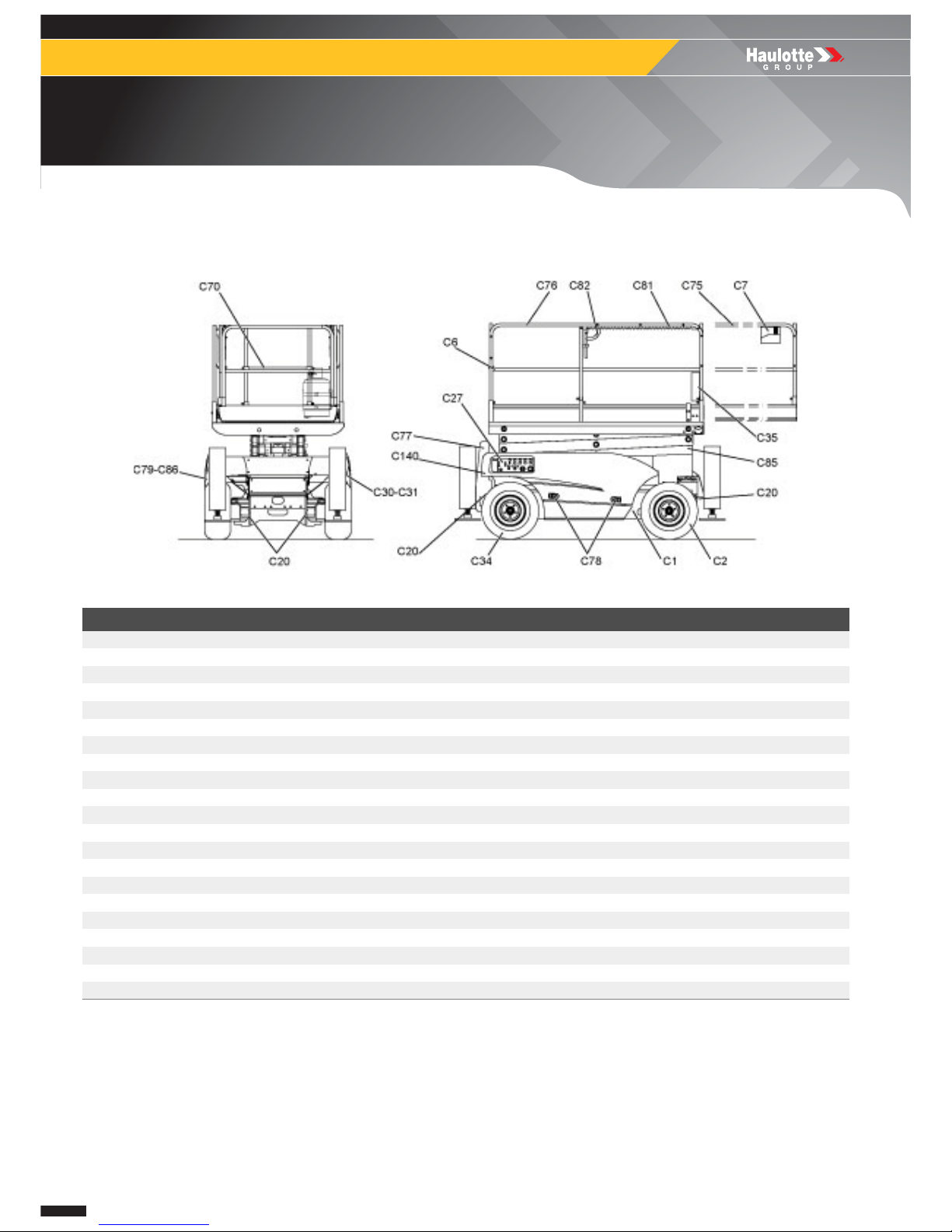

2 - Main components

COMPACT 10DX (COMPACT 2668RT) - COMPACT 12DX (COMPACT 3368RT) - Major Component

Location Diagram

COMPACT 10DX (COMPACT 2668RT) - COMPACT 12DX (COMPACT 3368RT) - Description of the components

Marking Description

C1 Chassis

C2 Front driven steering axle

C6 Platform

C7 Platform control box

C20 Anchorage point

C27 Ground control box

C30 Hydraulic oil tank

C31 Fuel tank

C31 Drive wheels

C35 Document holder

C70 Platform access bar

C75 Extension

C76 Guardrail

C77 Platform access ladder

C78 Hood locking catch

C79 Engine bay

C81 Sliding guardrail

C82 Deck extension handle

C83 Stabiliser

C85 Scissors

C86 Internal combustion engine

28 4000014860 E10.16 USA / GB

H12/15/18 SX/SXL - HS 3388/4388/5388 RT/RTXL - COMPACT 10/12 DX - COMPACT 2668/3368 RT

C

- Machine layout

3 - Safety devices

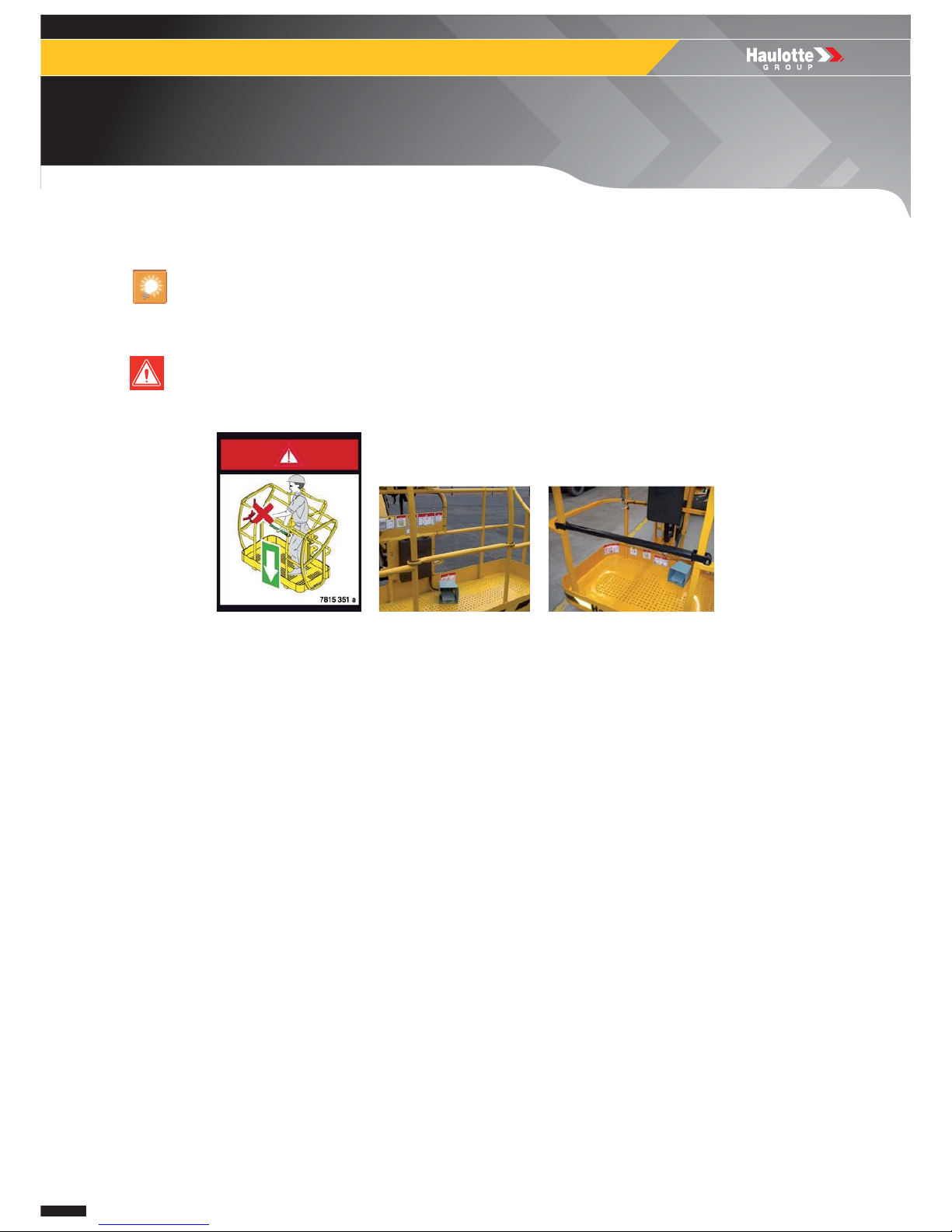

3.1 - SLIDING (OR SWINGING) INTERMEDIATE GUARDRAIL

The platform is comprised of guardrails and a sliding mid-rail facilitating platform access.

The illustrations in this paragraph do not necessarily correspond to the range of products designated in

the manual.

Do not restrain the sliding midrail to the guard rail.

Loading...

Loading...