Haulotte Star 10, Star 26J TRAINING MANUAL

T

E

C

H

T

E

C

DII

D

H

A

A

NII

N

G

G

C

C

N

OSSTTII

N

O

A

A

L

L

T

R

R

AII

A

T

C LLEEVVEELL IIII

C

NII

N

N

N

G

G

Stt

S

arr

a

1

1

0

0

–

–

Stt

S

arr

a

2

2

6

6

J

J

HHooww ttoo uussee tthhiiss ddooccuummeenntt??

YYoouu hhaavvee bbeettwweeeenn tthhee hhaannddss tthhee ssuummmmaarryy ggiivveenn dduurriinngg tthhee tteecchhnniiccaall ttrraaiinniinngg HHAAUULLOOTTTTEE .

wwiillll eennaabbllee yyoouu ttoo ffiinndd iinnffoorrmmaattiioonn nneecceessssaarryy ffoorr tthhee mmaaiinntteennaannccee aanndd tthhee rreeppaaiirr ooff yyoouurr

mmaacchhiinnee HHAAUULLOOTTTTEE ..

TThhaannkkss ttoo tthhee gguuiiddee bbeellooww yyoouu wwiillll rreeaacchh tthhee rreeqquuiirreedd cchhaapptteerr qquuiicckkllyy..

CChhaapptteerr 11:: MMaaiinn ffeeaattuurreess aanndd ffuunnccttiioonnss

IItt iiss aabboouutt aa rreeccaallll ooff tthhee iinnffoorrmmaattiioonn ccoonnttaaiinneedd iinn tthhee mmaannuuaall uusseerr ddeelliivveerreedd wwiitthh tthhee mmaacchhiinnee:

ccoommppoonneennttss,, oovveerraallll ddiimmeennssiioonnss,, wwoorrkkiinngg zzoonneess ,, ccoommmmaannddss,, eettcc……

CChhaapptteerr 22:: SSttuuddyy ooff tthhee wwiirriinngg ddiiaaggrraamm

YYoouu wwiillll ffiinndd tthheerree tthhee eelleemmeennttss ffoolllloowwiinngg::

-- AA ssuummmmaarryy ooff tthhee ssttaannddaarrddiizzeedd ssyymmbboollss uusseedd bbyy HHAAUULLOOTTTTEE GGrroouupp

-- TThhee ccoommpplleettee wwiirriinngg ddiiaaggrraamm ooff tthhee ssttuuddiieedd mmooddeell

-- TThhee nnoonn eexxhhaauussttiivvee lliisstt ooff tthhee eelleeccttrriicc lloooommss aanndd eelleeccttrroonniicc bbooaarrddss

-- LLooccaalliizzaattiioonn ooff tthhee pprriinncciippaall ssaaffeettyy uunniittss ((ttiilltt ,, lliimmiitt sswwiittcchheess,, sseennssoorrss,, ttrraannssdduucceerrss……))

-- LLooggiiccaall eeqquuaattiioonnss ooff ooppeerraattiioonn:: bbyy ffuunnccttiioonn,, ttoo ddiiaaggnnoossee tthhee mmaaiinn ddyyssffuunnccttiioonnss

CChhaapptteerr 33:: SSttuuddyy ooff tthhee hhyyddrraauulliicc ddiiaaggrraamm

YYoouu wwiillll ffiinndd tthheerree tthhee eelleemmeennttss ffoolllloowwiinngg::

-- aa ssuummmmaarryy ooff tthhee ssttaannddaarrddiizzeedd ssyymmbboollss uusseedd bbyy HHAAUULLOOTTTTEE GGrroouupp

-- tthhee ccoommpplleettee hhyyddrraauulliicc ddiiaaggrraamm ooff tthhee ssttuuddiieedd mmooddeell

-- tthhee nnoonn eexxhhaauussttiivvee lliisstt ooff tthhee hhoosseess ttrraacckk

-- aa llooccaalliizzaattiioonn ooff tthhee pprriinncciippaall hhyyddrraauulliiccss mmaanniiffoolldd ((pprrooppoorrttiioonnaall bblloocckk ,, oonn//ooffff mmoovveemmeennttss

bblloocckk,,……))

-- LLooggiiccaall eeqquuaattiioonnss ooff ooppeerraattiioonn:: bbyy ffuunnccttiioonn,, ttoo ddiiaaggnnoossee tthhee mmaaiinn ddyyssffuunnccttiioonnss

CChhaapptteerr 44:: AAddjjuussttmmeennttss

TThhiiss iiss tthhee aaddjjuussttmmeennttss aanndd ccaalliibbrraattiioonnss,, hhyyddrraauulliiccss aanndd eelleeccttrriicc,, nneecceessssaarryy ttoo tthhee ggoooodd mmaaiinntteennaannccee

ooff tthhee mmaatteerriiaall.. YYoouu wwiillll ffiinndd aass wweellll tthhee mmeetthhooddss ooff aaddjjuussttmmeenntt wwiitthh ttaabbllee vvaalluueess..

CChhaapptteerr 55:: GGuuiiddee ooff bbrreeaakkddoowwnn

QQuuiicckk ssuummmmaarryy ooff tthhee sstteepp ttoo bbee ffoolllloowweedd ffoorr ppoossssiibbllee ssoouurrcceess ooff bbrreeaakkddoowwnn..

IInn ccaassee ooff aannyy ddeeffeecctt oorr aannyy ddyyssffuunnccttiioonn yyoouu wwiillll bbee aabbllee ttoo iiddeennttiiffyy tthhee eelleemmeennttss iinn qquueessttiioonn,,

wwhhaatteevveerr tthheeyy aarree eelleeccttrriicc oorr hhyyddrraauulliicc..

CChhaapptteerr 66:: SSuummmmaarryy ooff tthhee vveerrssiioonnss

TThhiiss mmaannuuaall ttrreeaattss ooff tthhee llaatteesstt vveerrssiioonn ,, hhoowweevveerr tthhiiss ssuummmmaarryy ttaabbllee eennaabblleess yyoouu ttoo ffiinndd tthhee ffoorrmmeerr

vveerrssiioonnss ooff tthhee mmaatteerriiaall ((eelleeccttrriicc aanndd hhyyddrraauulliiccss))..

CChhaapptteerr 77:: SSppeecciiaall ffuunnccttiioonnss

TThhiiss cchhaapptteerr ggaatthheerrss aallll tthhee ffuunnccttiioonnss aanndd aaddjjuussttmmeenntt ssppeecciiffiicc ttoo ccaarrrryy oouutt oonn tthhee mmaacchhiinnee.. TThheerree

ddooeess nnoott eexxiisstt ffoorr aallll tthhee mmaatteerriiaallss aanndd ddeeppeennddss oonn tthhee ssttuuddiieedd mmooddeell..

IItt mmuusstt bbee tthhee ssuubbjjeecctt ooff aa ssppeecciiaall aatttteennttiioonn ooff yyoouurr sshhaarree bbeeccaauussee aann iinntteerrvveennttiioonn bbaaddllyy ccaarrrriieedd oouutt

ccaann ddeetteerriioorraattee tthhee ggoooodd ppeerrffoorrmmaannccee ooff tthhee mmaacchhiinnee aanndd tthhuuss ccoonnsseeqquueennttllyy tthhee ssaaffeettyy ooff tthhee uusseerrss..

OOnnllyy aa tteecchhnniicciiaann HHAAUULLOOTTTTEE oorr aapppprroovveedd bbyy HHAAUULLOOTTTTEE SSeerrvviicceess iiss aabbllee ttoo ccaarrrryy oouutt tthhiiss kkiinndd ooff

iinntteerrvveennttiioonn..

OOnn tthhiiss cchhaapptteerr,, ssoommee ssppeecciiaall aaddjjuussttmmeenntt ((sseennssoorrss)) aarree aallssoo eexxppllaaiinneedd pprriioorr ttoo ccaalliibbrraattiioonn ((ddeeppeennddss

oonn tthhee mmooddeell))

MMAAIINNTTEENNAANNCCEE AANNDD RREEPPÄÄIIRR OOPPEERRAATTIIOONNSS OONN YYOOUURR HHAAUULLOOTTTTEE MMAACCHHIINNEE

MMUUSSTT BBEE DDOONNEE OONNLLYY BBYY TTRRAAIINNEEDD ,,EEXXPPEERRIIEENNCCEEDD AANNDD AAUUTTHHOORRIIZZEEDD TTEECCHHNNIICCIIAANNSS

. IItt

:

2/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

SUMMARY

1. MAIN FEATURES AND FUNCTIONS....................................................................................................................5

1.1. C

1.2. COMMANDS S

2. STUDY OF THE WIRING SCHEMATICS ........................................................................................................... 14

2.1. S

2.2. M

2.3. T

2.4.

2.5. L

2.6.

2.7. L

2.8. O

2.9. L

2.10.

2.11.

HARACTERISTICS

1.1.1.

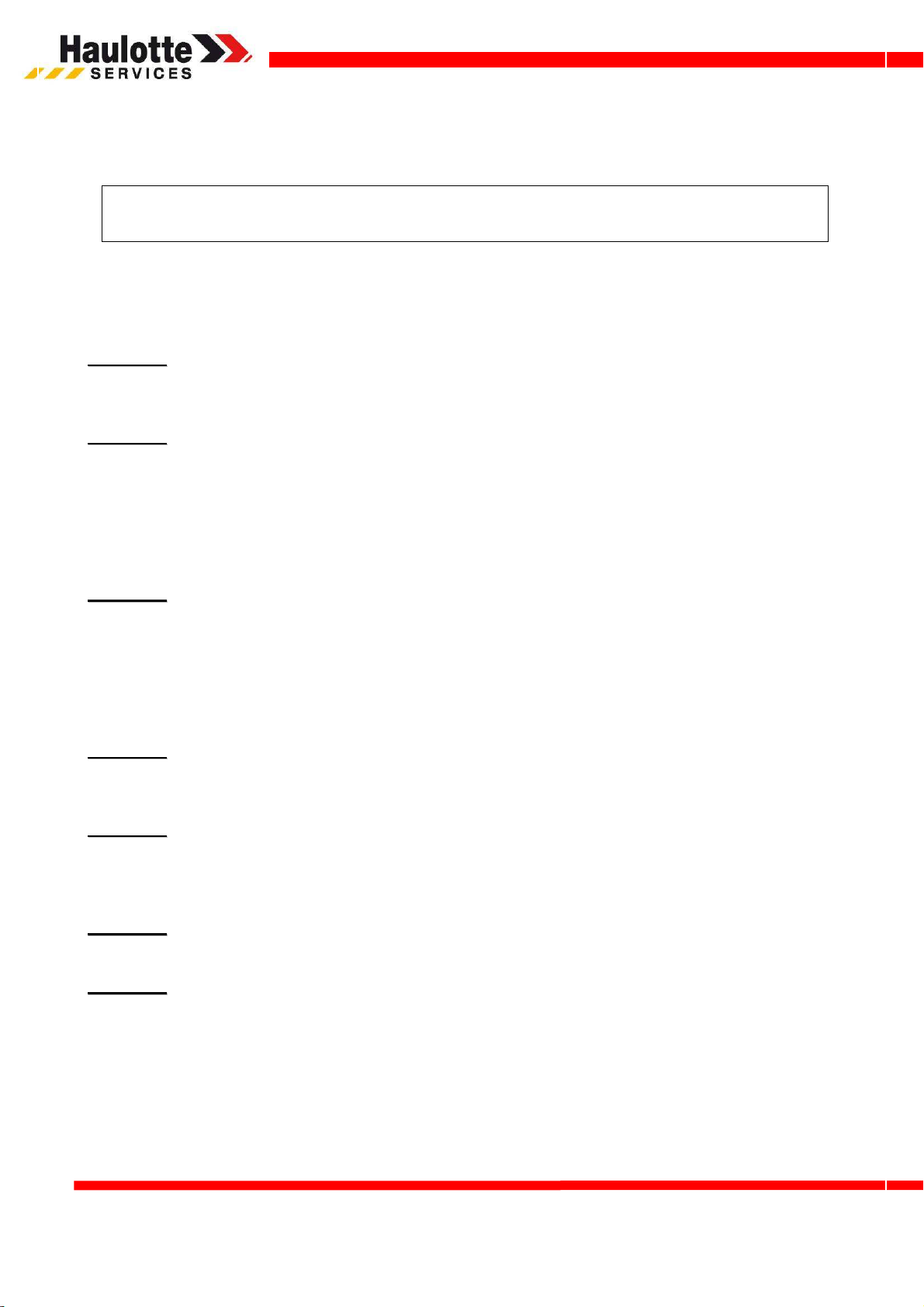

Main components.......................................................................................................................................... 5

1.1.2.

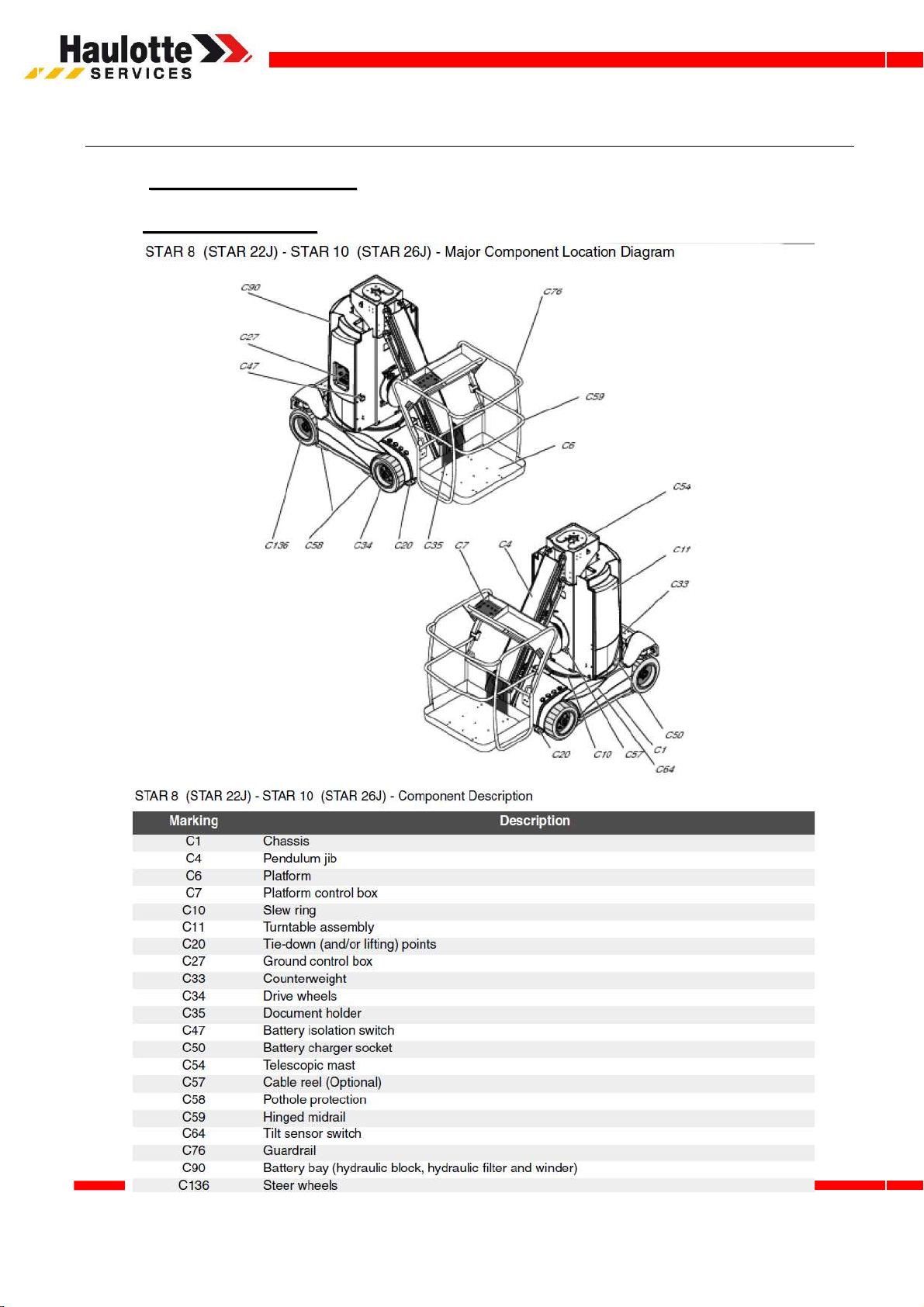

Overall dimensions – Star10 ........................................................................................................................ 7

1.1.3.

working zone Star 8...................................................................................................................................... 8

1.1.4.

working zone Star10..................................................................................................................................... 9

1.1.5.

main characteristics ................................................................................................................................... 10

1.2.1.

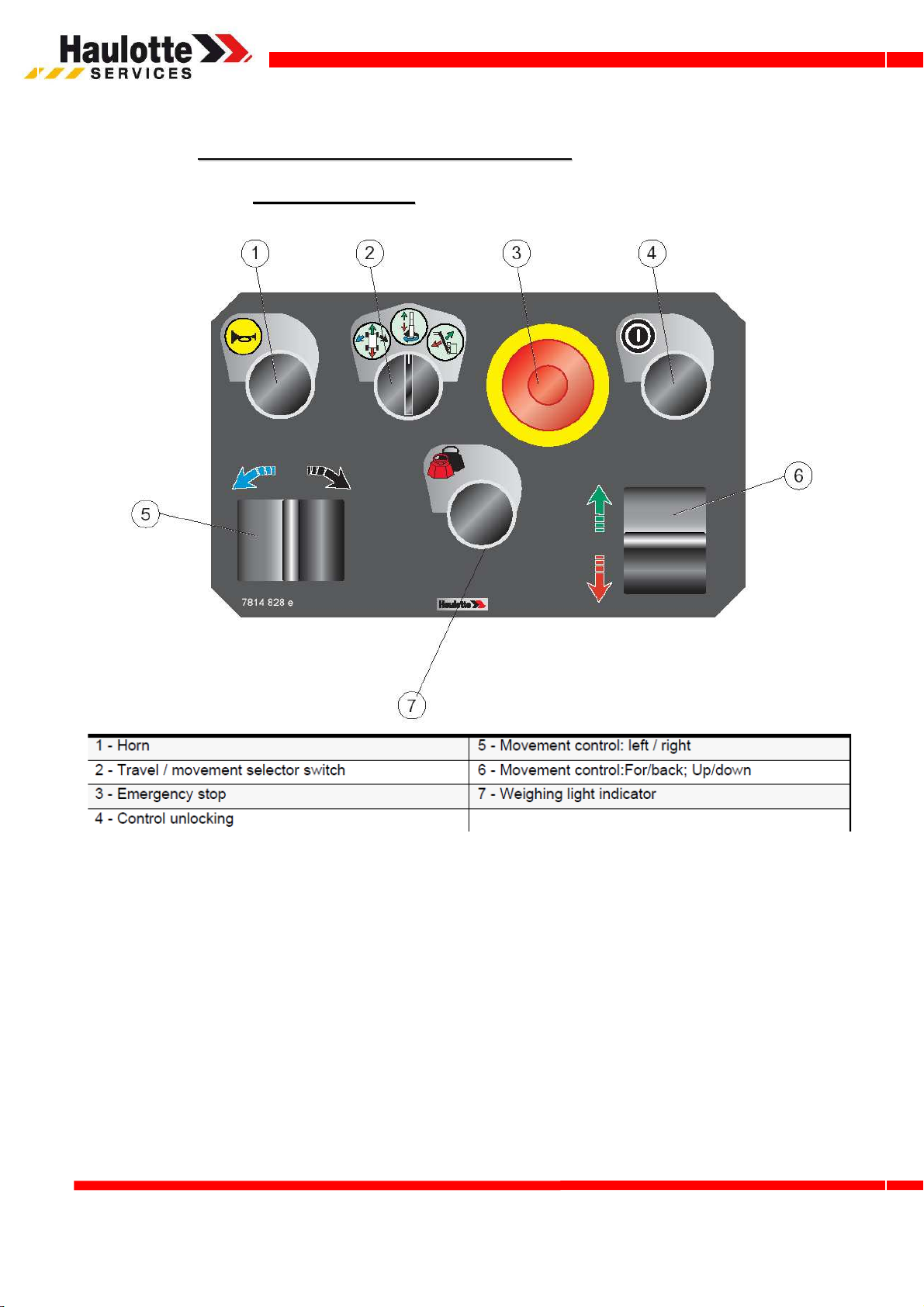

Upper controls............................................................................................................................................ 12

1.2.2.

Lower controls............................................................................................................................................ 13

YMBOLS USED

ETHODOLOGY OF CONTROL

2.2.1.

electric continuity control........................................................................................................................... 19

2.2.2.

Control of an on/off valve........................................................................................................................... 20

2.2.3.

Control of components ...............................................................................................................................21

HE WIRING DIAGRAM

LOOMS

(155P258150).......................................................................................................................................... 24

2.4.1.

The weighing board (bpe)........................................................................................................................... 28

2.4.2.

Cables on bpe board...................................................................................................................................29

OCALIZATION OF THE MAIN SAFETY COMPONENTS

PRINTED CIRCUIT LOWER PANEL

IST COMPONENTS

2.7.1.

Fuses........................................................................................................................................................... 33

2.7.2.

inputs.......................................................................................................................................................... 33

2.7.3.

Outputs ....................................................................................................................................................... 34

2.7.4.

Others......................................................................................................................................................... 35

PTIONS

USA...................................................................................................................................................... 35

OGICAL EQUATIONS OF OPERATION

2.9.1.

Powering .................................................................................................................................................... 36

2.9.2.

Steering....................................................................................................................................................... 36

2.9.3.

Drive........................................................................................................................................................... 36

2.9.4.

mast lifting.................................................................................................................................................. 37

2.9.5.

Jib lifting.....................................................................................................................................................37

2.9.6.

Turret slewing.............................................................................................................................................38

ALARMS

BATTERIES CHARGE

CODES..................................................................................................................................................39

................................................................................................................................................. 5

TAR

(UP AND DOWN) ............................................................................................................. 12

.................................................................................................................................................... 14

............................................................................................................................... 19

(E621E)........................................................................................................................... 23

........................................................................................................................... 31

............................................................................................................................................... 33

INDICATOR.......................................................................................................................42

............................................................................................30

.................................................................................................................... 36

3. STUDY OF THE HYDRAULIC SCHEMATICS...................................................................................................43

3.1. S

3.2. H

3.3. D

3.4.

4. ADJUSTMENTS........................................................................................................................................................ 51

4.1.

4.2. S

4.3. S

YMBOLS USED

YDRAULIC DIAGRAM STAR10

ETAILS OF HYDRAULIC BLOCK

HYDRAULIC LOGICAL EQUATIONS

DESCRIPTION CALIBRATOR

TEERING

•

adjustment...........................................................................................................................................................56

YSTEM OF LOAD CONTROL

4.3.1.

Operation....................................................................................................................................................58

principle of the load control.........................................................................................................................................58

4.3.2.

The angle sensor A1 ................................................................................................................................... 58

4.3.3.

Electric stop................................................................................................................................................ 58

4.3.4.

State of the outputs of the relays................................................................................................................. 58

4.3.5.

Management of the overlap of nominal load..............................................................................................59

4.3.6.

connection of the calibrator tool ................................................................................................................59

4.3.7.

Procedure of overload calibration .............................................................................................................60

4.3.8.

alarms codes on weighing board bpe......................................................................................................... 61

4.3.9.

values of the sensors...................................................................................................................................61

.................................................................................................................................................... 43

(P23343NG)....................................................................................................... 47

........................................................................................................................... 48

........................................................................................................................ 49

...................................................................................................................................51

.............................................................................................................................................................55

................................................................................................................................. 58

4.4. P

4.5. ZAPI P

4.6.

5. BREAKDOWN SERVICE GUIDE..........................................................................................................................74

5.1. NO START.......................................................................................................................................................... 74

5.2. N

5.3. N

5.4. N

5.5. N

5.6. N

5.7. N

5.8. N

5.9. N

5.10. N

5.11. N

5.12.

5.13. N

6. SUMMARY OF THE STAR VERSIONS ...............................................................................................................77

7. SENSORS MOUNTING INSTRUCTIONS ............................................................................................................ 78

7.1. ANGLE SENSOR............................................................................................................................................... 78

7.2. PRESSURE SENSOR.........................................................................................................................................78

7.3.

7.4.

ARAMETER SETTINGS

ARAMETER

PRESS

URES......................................................................................................................................................... 71

4.6.1.

Table of the pressures.................................................................................................................................73

O MOVEMENT (BOTH CONTROLS

O MOVEMENT FROM UP

O MOVEMENT FROM

O JIB FROM UP

O JIB FROM LOWER CONTROLS

O MAST FROM UPPER CONTROLS

O MAST FROM LOWER CONTROLS

O TURRET ROTATION FROM UPPER CONTROLS

O TURRET ROTATION FROM LOWER CONTROLS

O DRIVE

MICROSPEED ONLY

O STEERING

BRAKE RELEASE FUNCTION

VARIATOR TRIPLAT IMPEDANCE CHECK

.............................................................................................................................................................76

....................................................................................................................................................... 76

......................................................................................................................................... 62

............................................................................................................................................... 63

PER

CONTROLS

LOWER

PER

CONTROLS

............................................................................................................................................... 76

..................................................................................................................................79

).......................................................................................................................74

.............................................................................................................74

CONTROLS

........................................................................................................................... 74

........................................................................................................................... 75

........................................................................................................................ 75

.......................................................................................................... 74

...................................................................................................................... 75

................................................................................................... 75

.................................................................................................. 76

...............................................................................................................81

4/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

11.. MMAAIINN FFEEAATTUURREESS AANNDD FFUUNNCCTTIIOONNSS

11..11..

11..11..11.. M

M

CCHHAARRAACCTTEERRIISSTTIICCS

AAIINN CCOOMMPPOONNEENNTTSS

S

5/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

6/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

11..11..22.. O

O

VVEERRAALLLL DDIIMMEENNSSIIOONNSS

–

S

R

TTAAR

–

S

1100

7/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

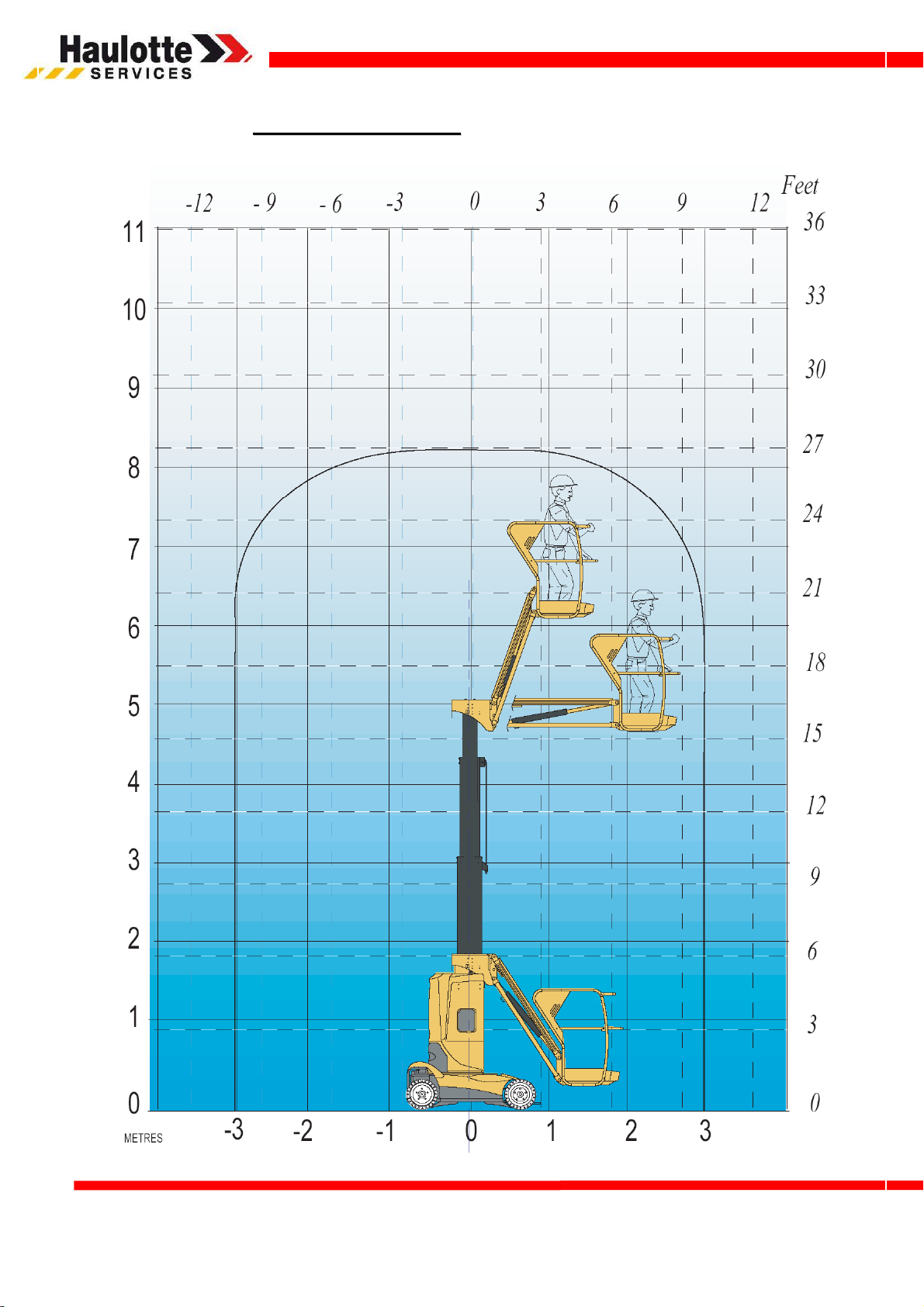

11..11..33..

WWOORRKKIINNGG ZZOONNEE

S

S

TTAARR

88

8/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

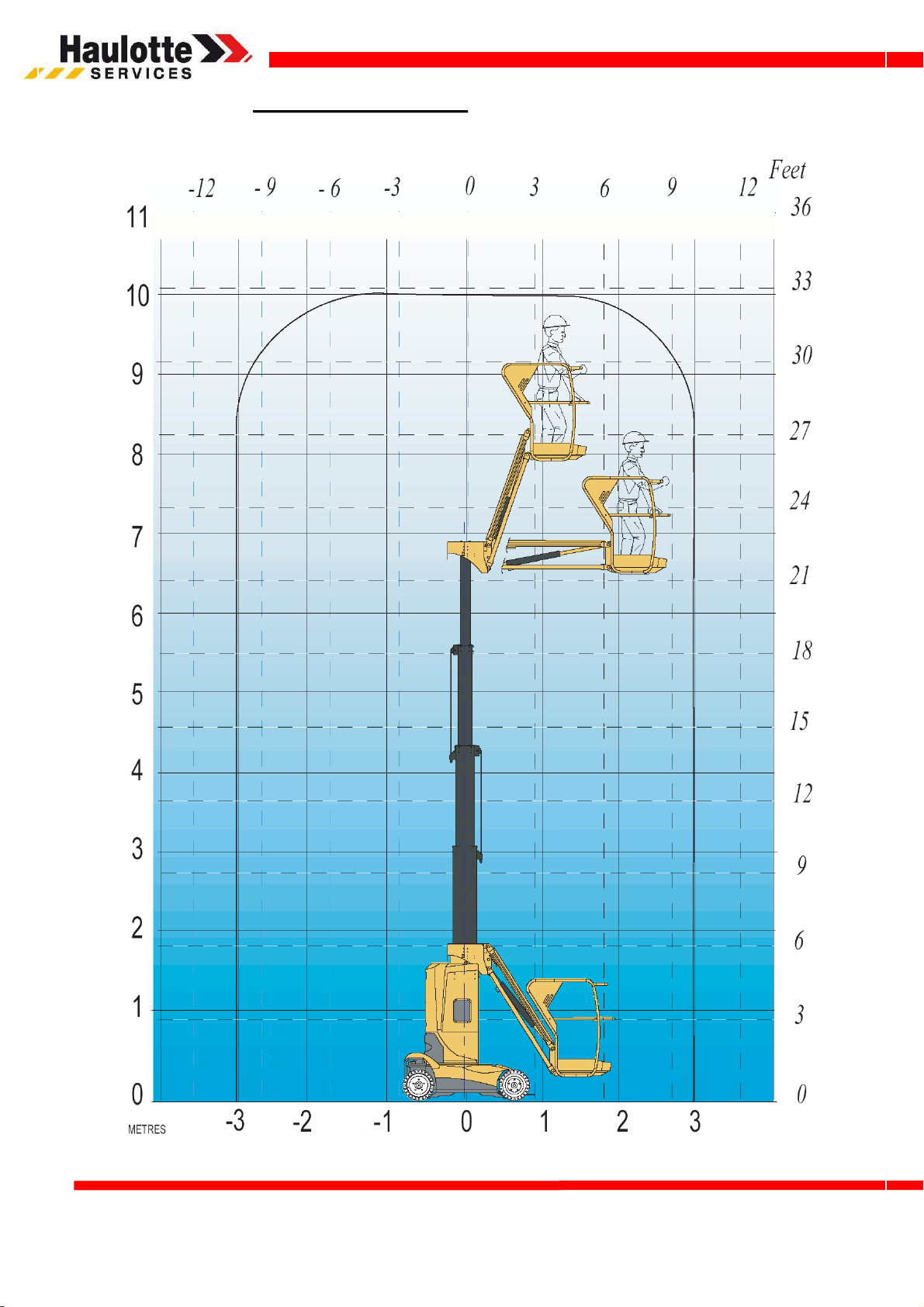

11..11..44..

WWOORRKKIINNGG ZZOONNEE

S

R

S

TTAAR

1100

9/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

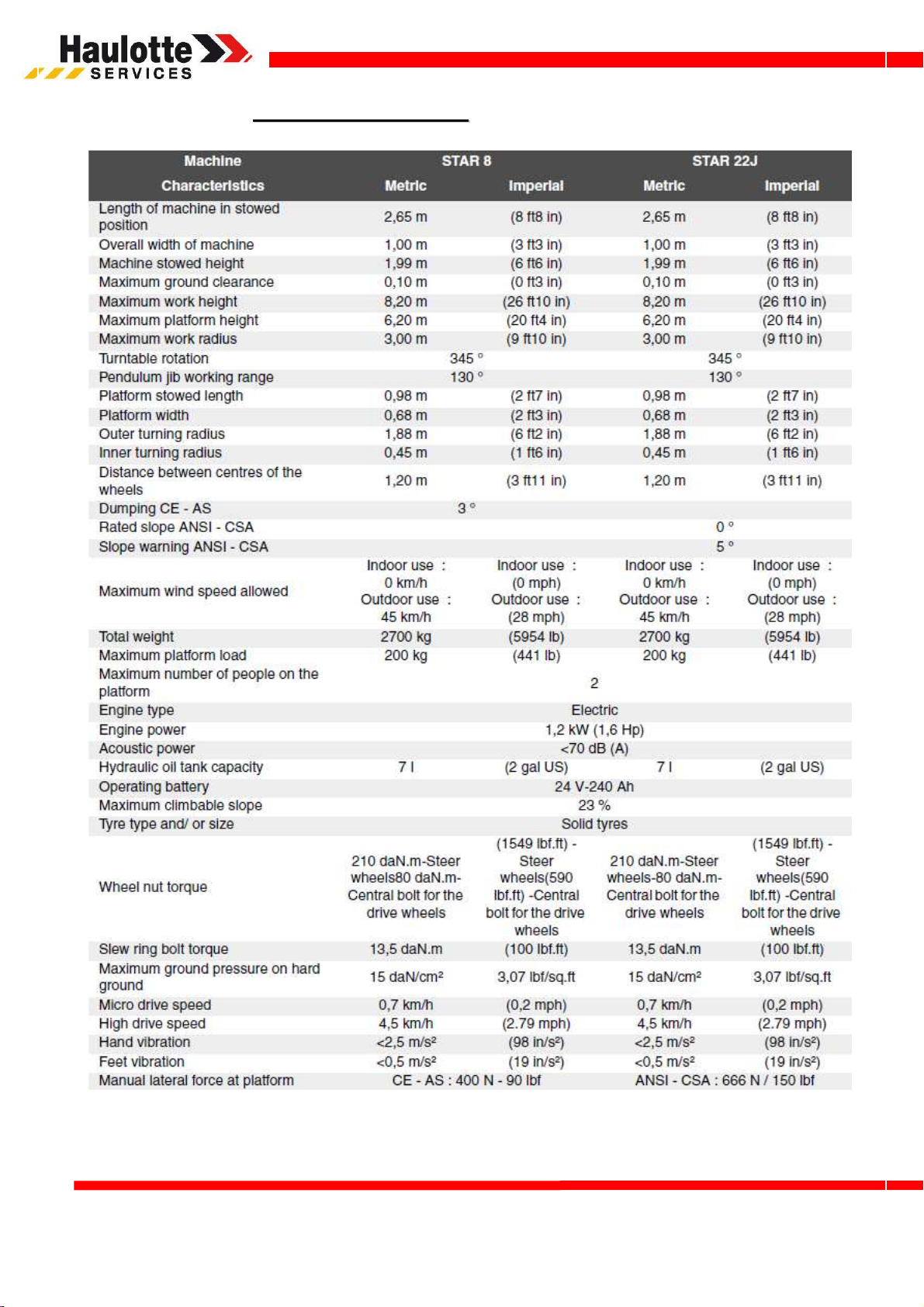

11..11..55..

STAR 8

MMAAIINN CCHHAARRAACCTTEERRIISSTTIICCS

S

10/92

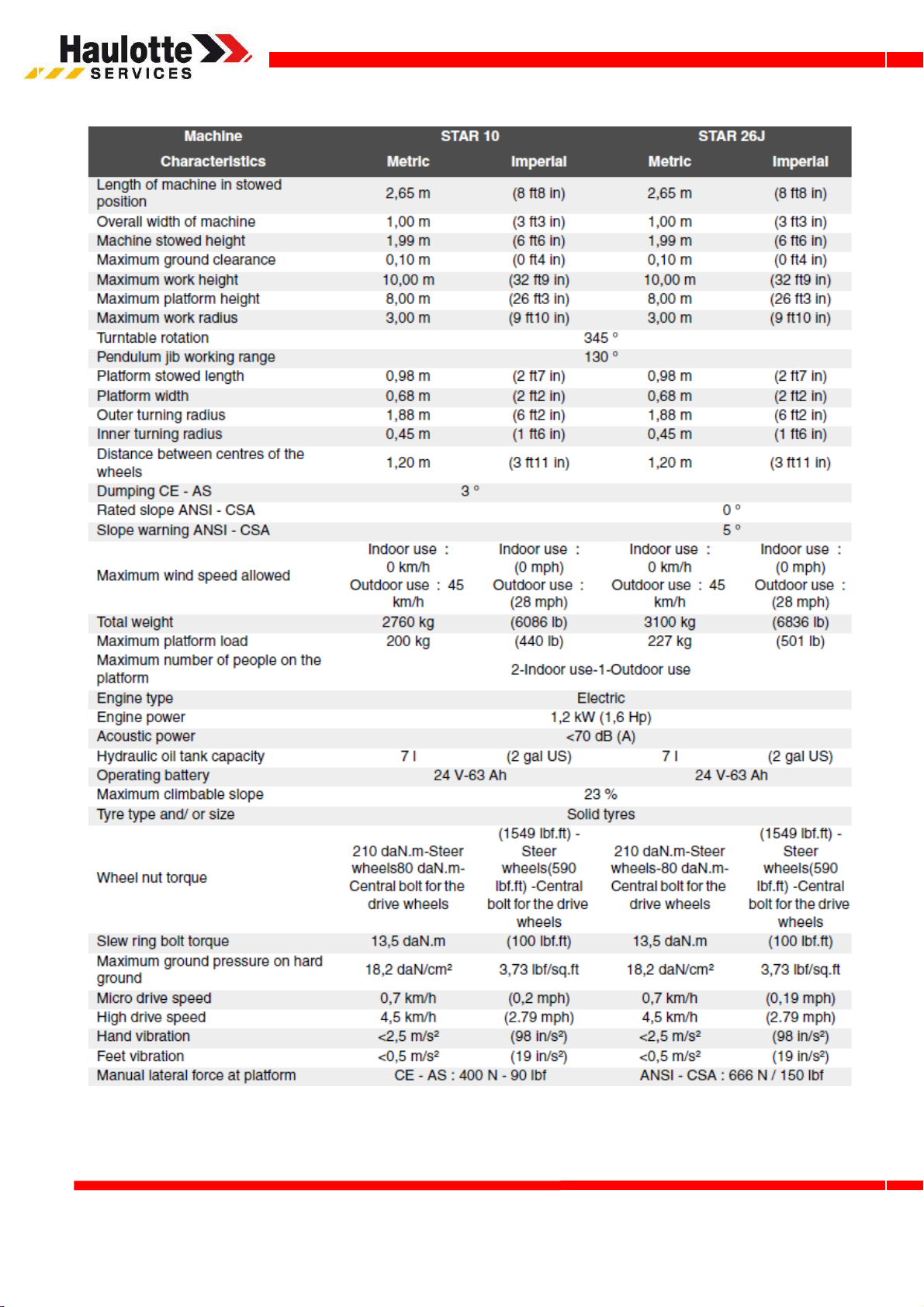

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

STAR 10

11/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

11..22..

11..22..11..

CCOOMMMMAANNDDSS SSTTAARR ((UUPP AANNDD DDOOWWNN))

U

PPPPEERR CCOONNTTRROOLLS

U

S

12/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

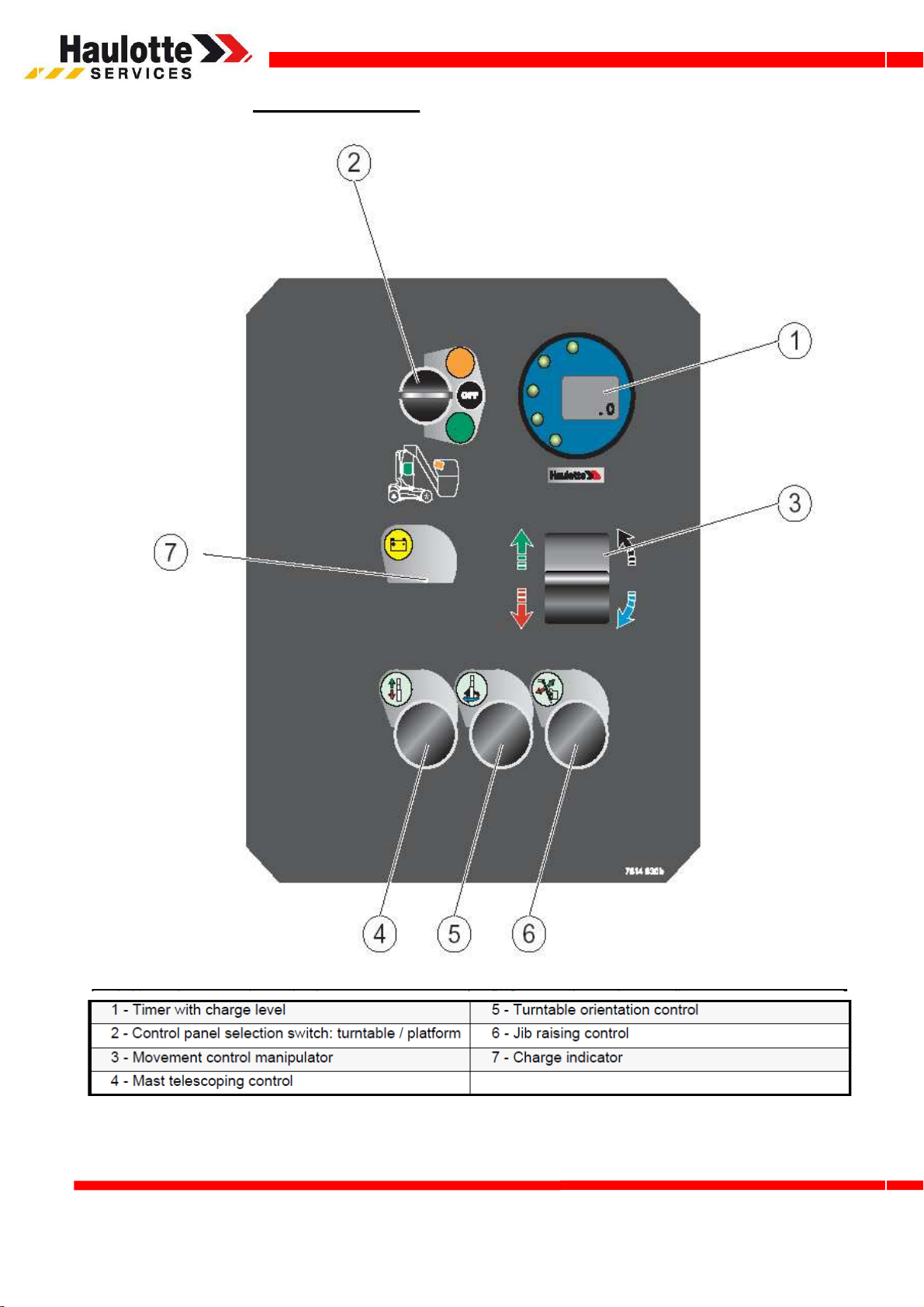

11..22..22..

L

OOWWEERR CCOONNTTRROOLLS

L

S

13/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

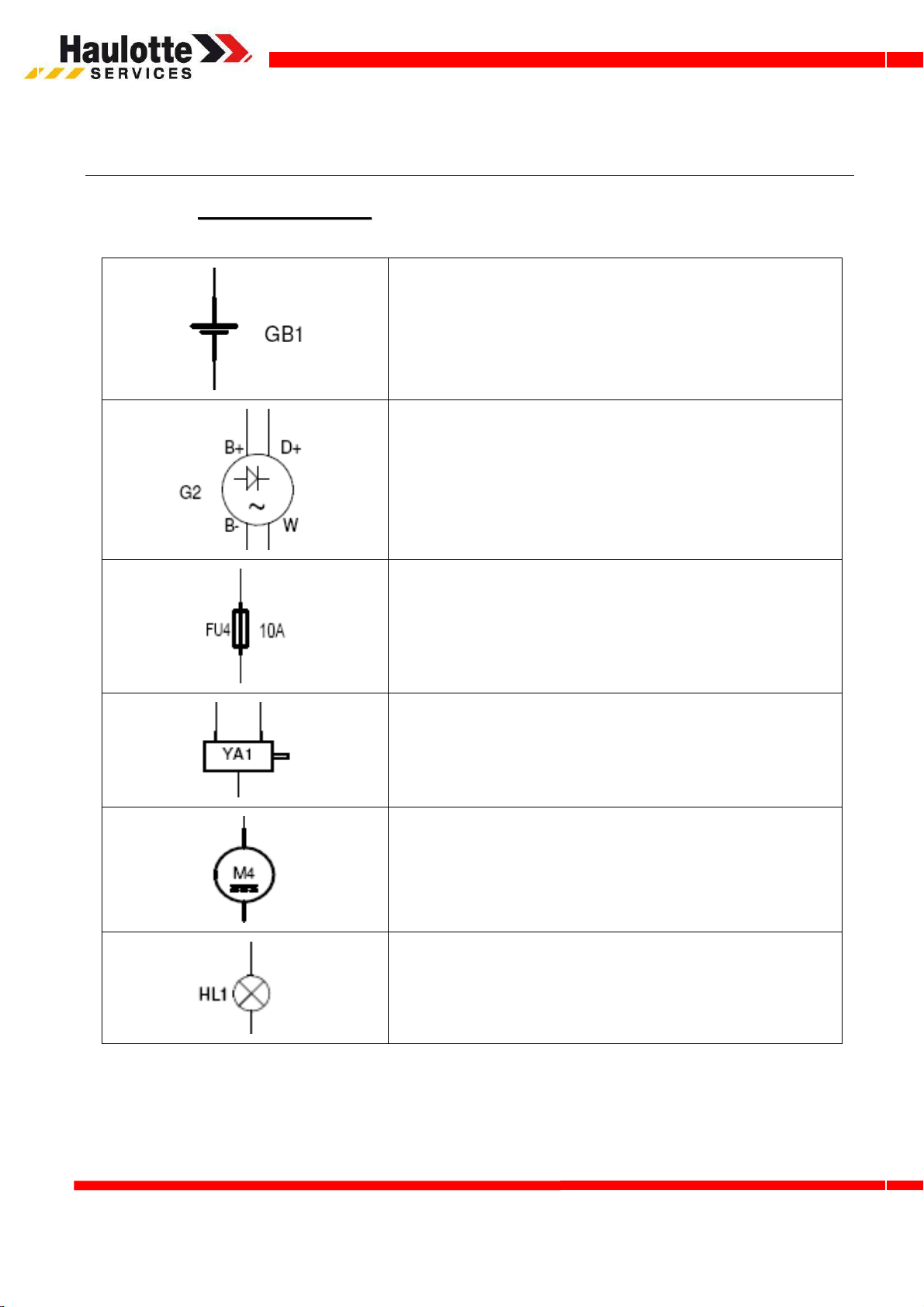

22.. SSTTUUDDYY OOFF TTHHEE WWIIRRIINNGG SSCCHHEEMMAATTIICCSS

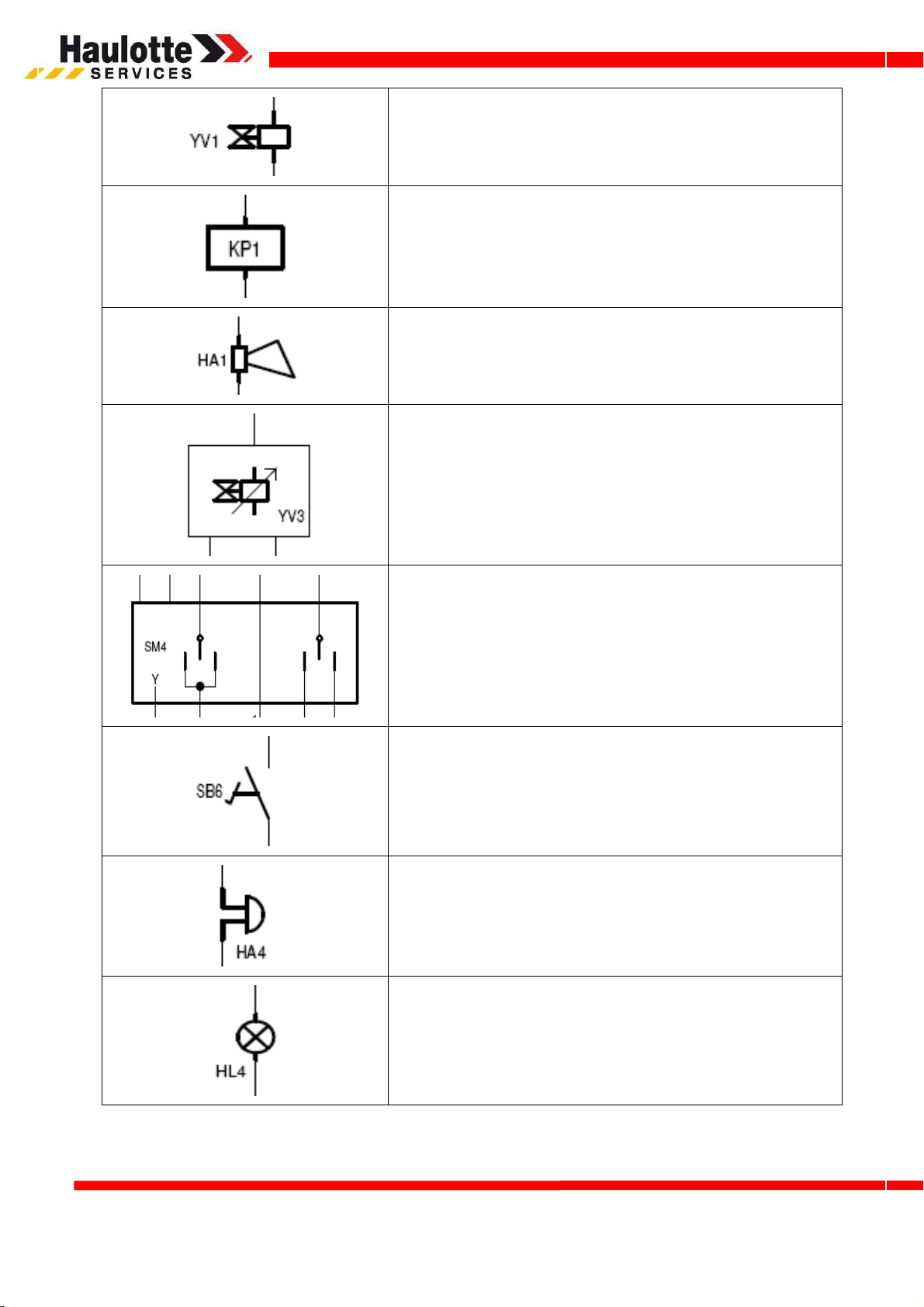

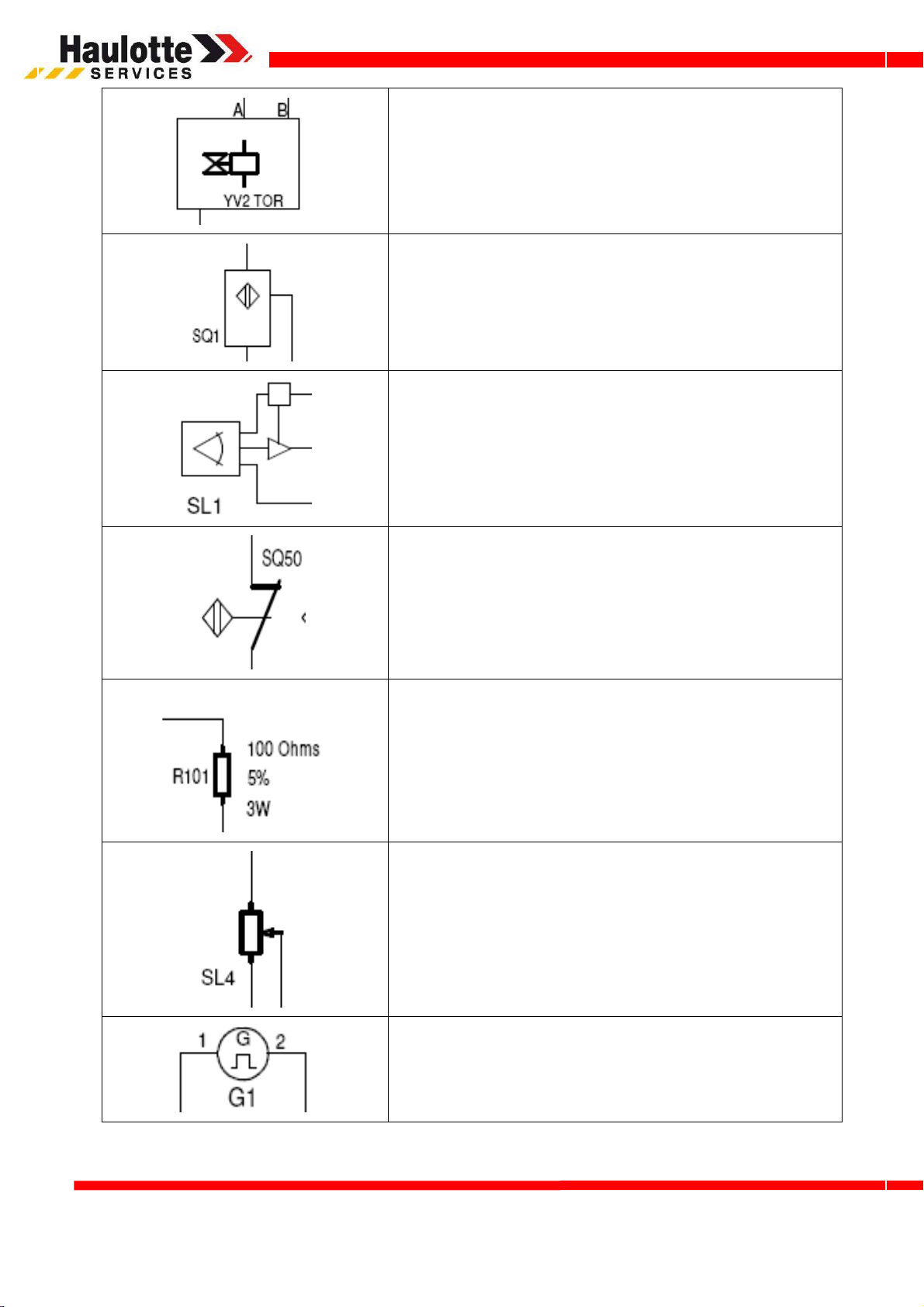

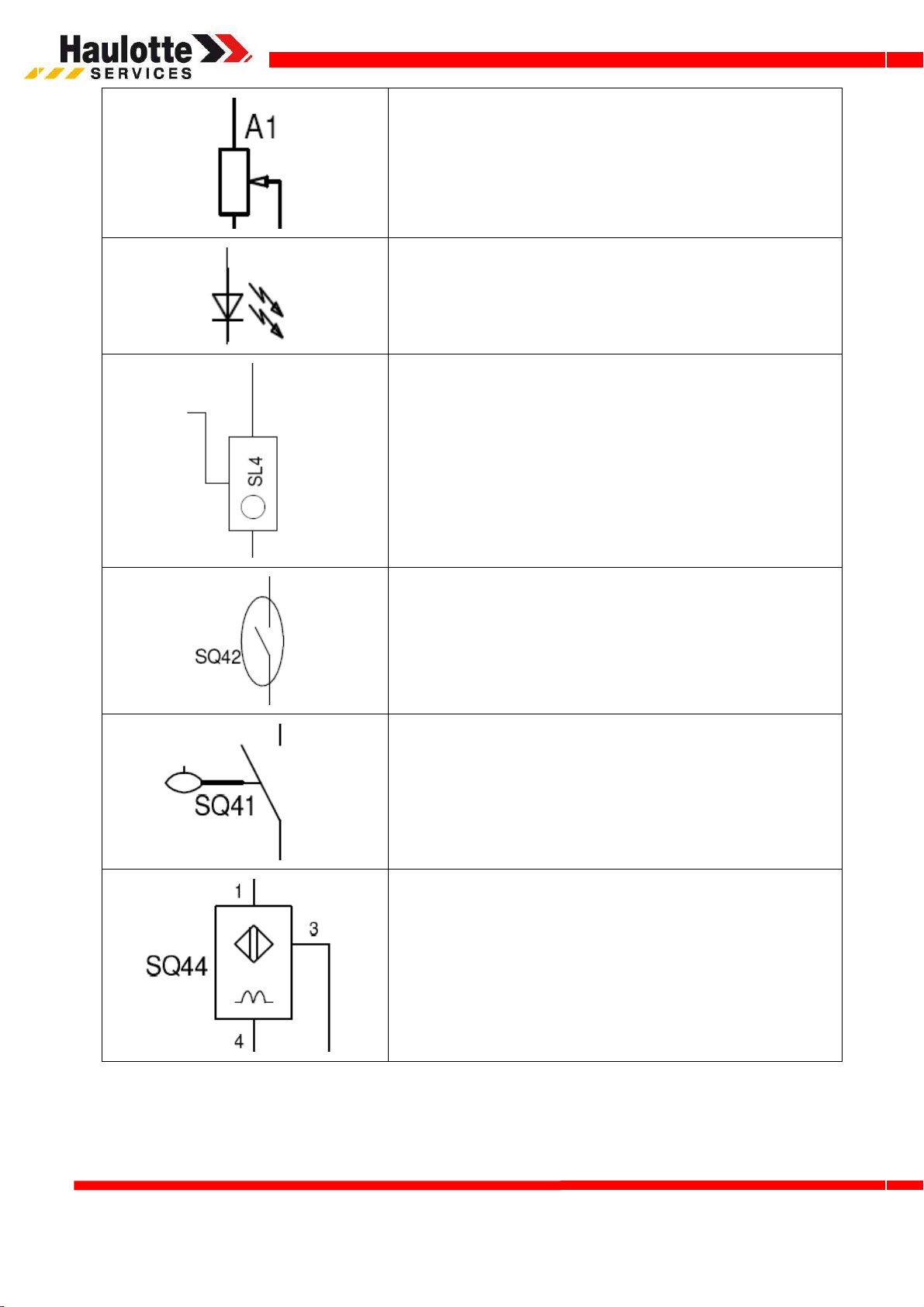

22..11..

SSYYMMBBOOLLSS UUSSEEDD

Battery with one element

Alternator

Fuse (Here 10 amps)

Coil winding roll

Electric motor

light

14/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

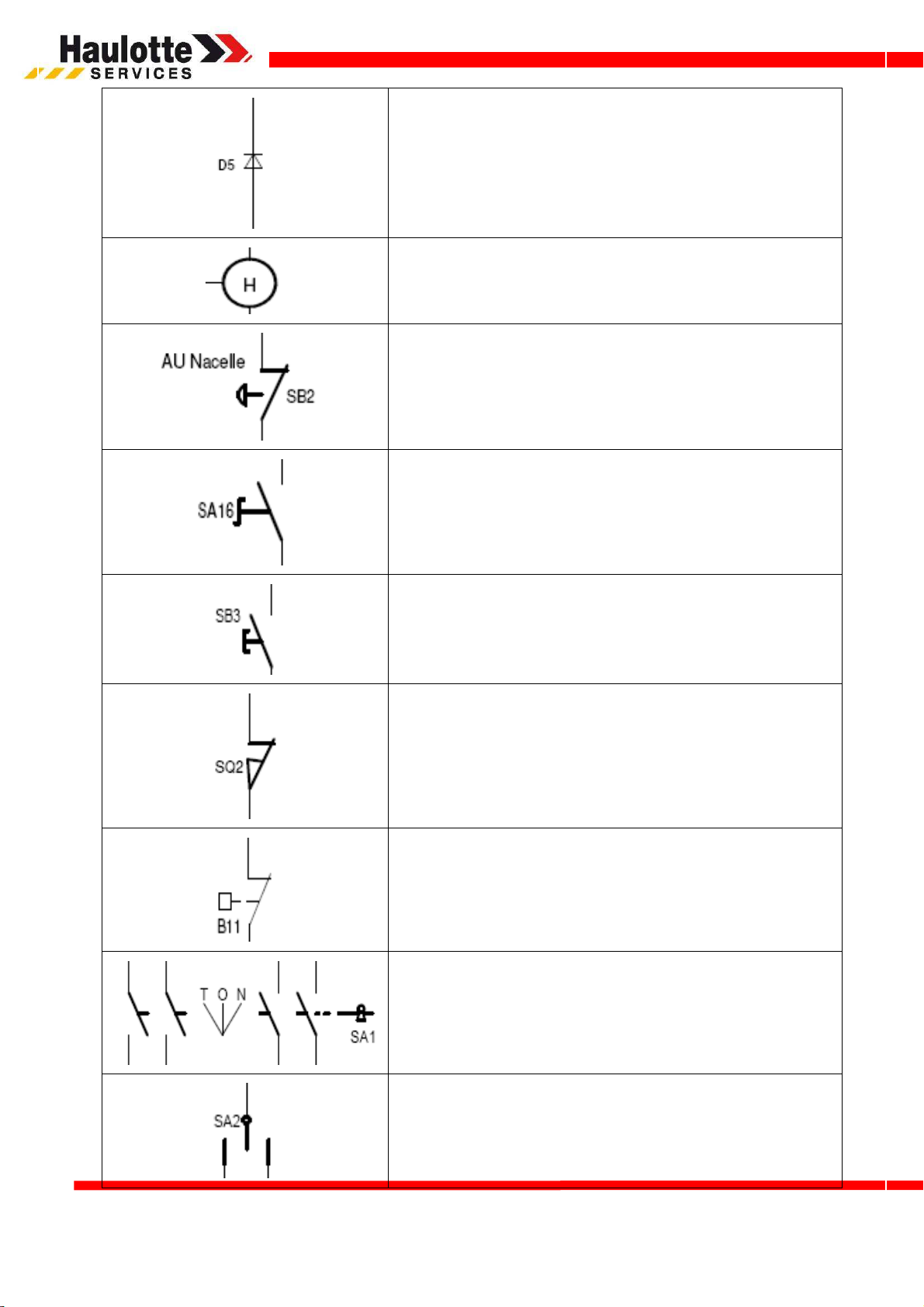

Diode

Hourmeter

Standard push-button of safety “mushroom-headed

button”

Rotary knob

Push-button

Limit switch

Pressure switch

Key selector with 3 positions (T turret, O neutral, N

platform)

Toggle switch with 2 positions

15/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

Electrovalve

relay

horn

Proportional electrovalve

Controller/joysticks

Pedals “dead man” or “foot dead man” switch

buzzer

“light”

16/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

Electrovalve “ON/OFF » ( bang-bang)

Tilt sensor ( ramp detection)

Angle sensor (reach limitation)

Contact « mercury » (angle detection)

Resistor (here value 100 ohms, 3 Watts, tolerance of 5%)

Sensor length (reach limitation)

Pressure sensor (weighing)

17/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

Angle sensor (weighing)

Standard light “Led”

Strain gauge

Interruptor Lame Switch (ILS) detection of the magnets

on the telescopic boom/arm extension

Level detector (diesel tank)

Proximity detector with impulses (detection teeth slew

ring)

18/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

22..22.. MMEETTHHOODDOOLLOOGGYY OOFF CCOONNTTRROOLL

Note: during an intervention on a component or a loom, it is important to remember to switch

OFF the power supply of the machine in order to avoid any risk.

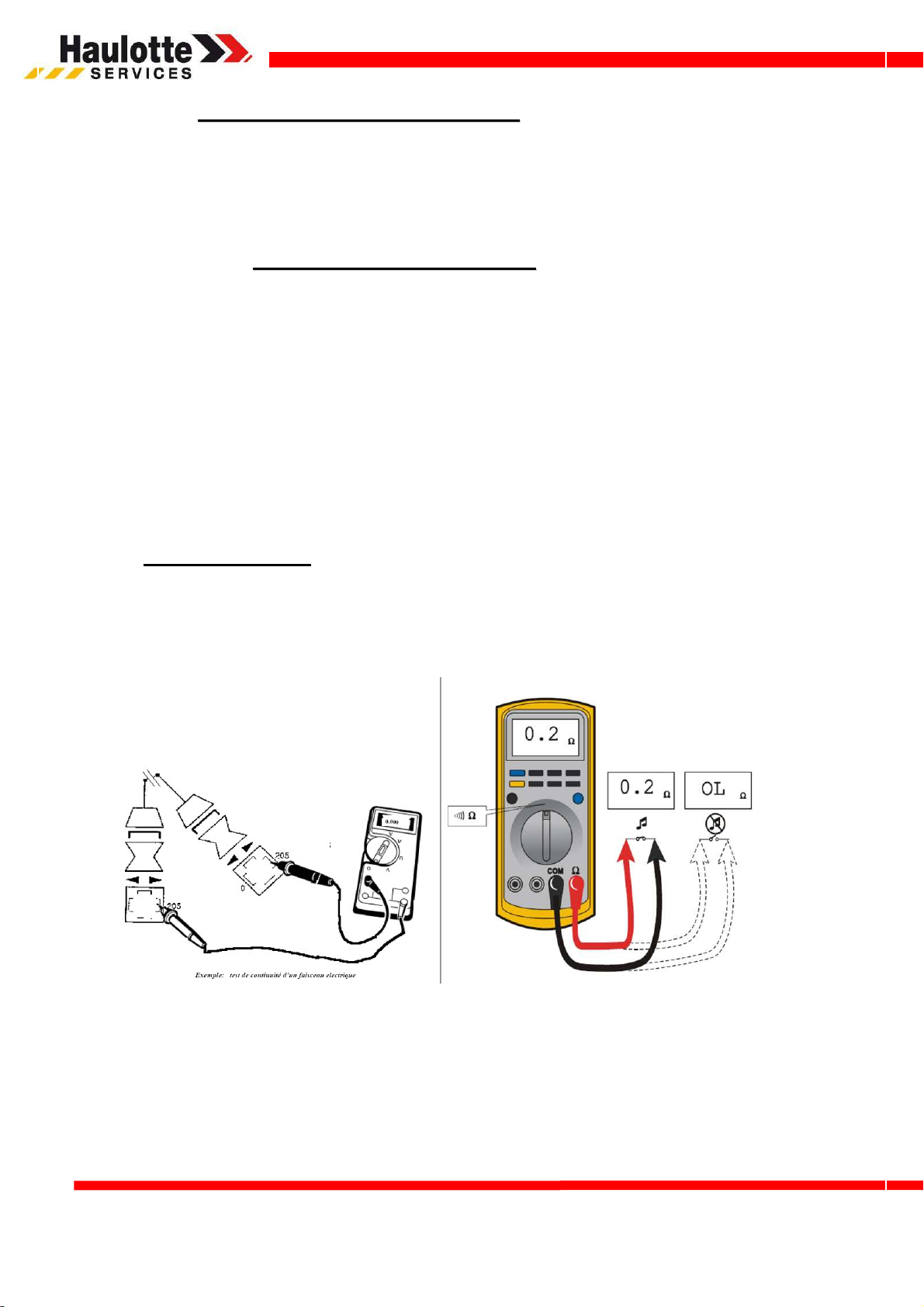

22..22..11..

The continuity check of a loom or an electric component determines the resistor of this

device, in order to detect a possible interruption of continuity (open circuit, short-circuit…).

This control is carried out with a multimeter commutated in position Ohmmeter (Ω).

First of all, it is necessary to determine the terminals of the component or the cable to control

and insulate them.

Then, connect the multimeter in order to record the value.

It must indicate a value of resistor close to 0 Ω if continuity is good.

In the contrary case (resistor which tends towards the infinite one : ∞), continuity presents a

defect.

Control of insulation

EELLEECCTTRRIICC CCOONNTTIINNUUIITTYY CCOONNTTRROOL

L

At the contrary of continuity, insulation represents a non electric connection between the

ground and the component

The test of insulation consists in obtaining the opposite result of that described for continuity,

i.e. a value of the Ohmmeter which must tend towards the infinite one :

∞

19/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

C

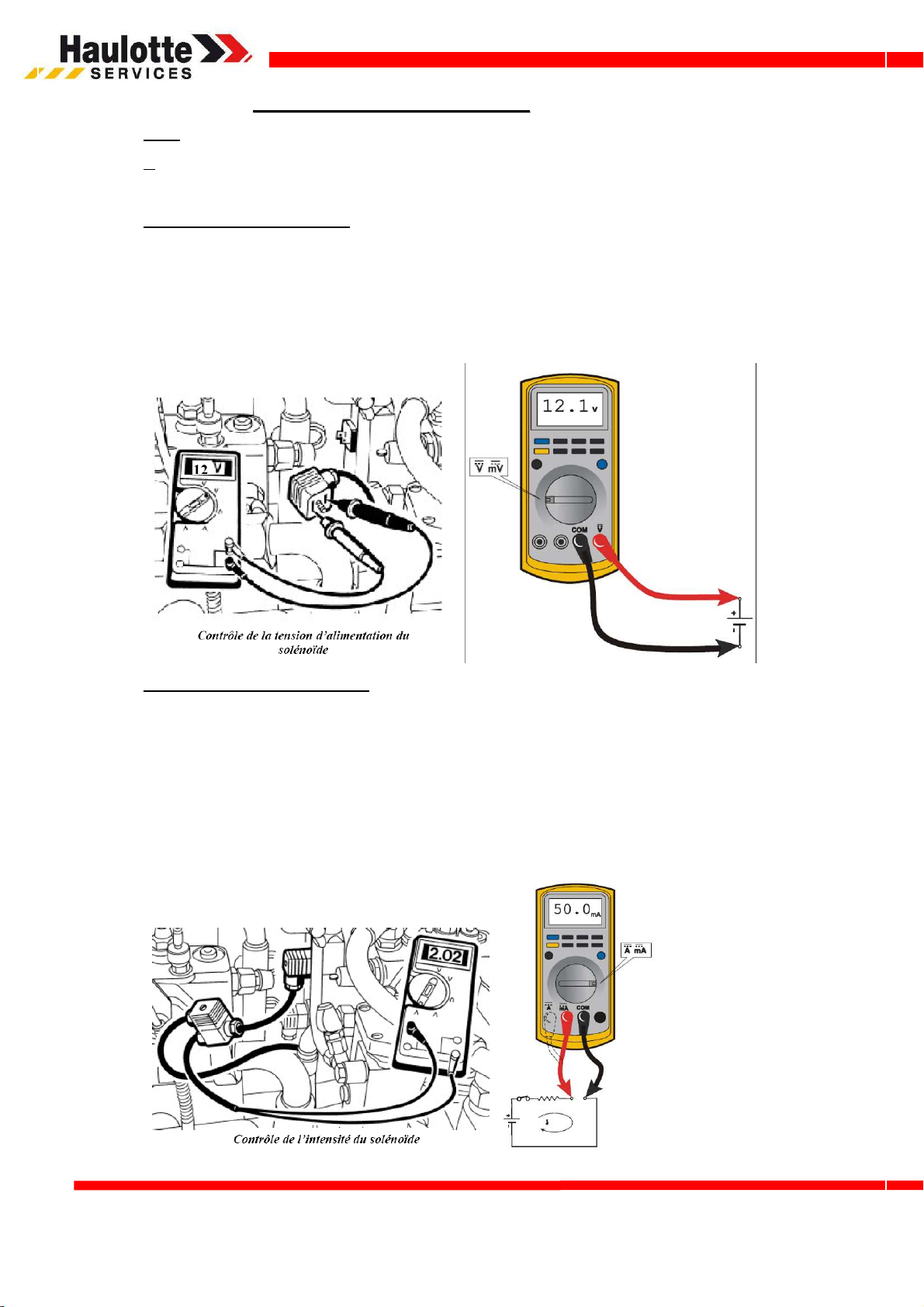

22..22..22..

Note: These tests are to be carried out when power is ON .

Also control the state of the terminals or any another connectors (oxidation…)

Control supply of the coil

disconnect the plug socket of supply of the valve in order to connect in derivation the

multimeter on the terminals of the connector (see below).

select the position to voltmeter (V), then activate the command to the valve which must be

tested.

The voltage indicated by the voltmeter must be close to the tension of battery

OONNTTRROOLL OOFF AANN OON

C

N

/

OOFFFF VVAALLVVE

/

E

Control intensity of the coil

disconnect the plug socket of supply of the valve in order to connect in series the multimeter

on the terminals of the connector (example below).

select the position Ammeter (A), then activate the command to the valve which must be

tested.

The intensity indicated by the voltmeter must be of approximately 2A (to be checked

according to the data manufacturer)

20/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

Control resistance of the coil

disconnect the plug socket of supply of the valve in order to connect the multimeter on the

terminals of the connector industry.

select the position Ohmmeter (Ω), then compare the value measured with that of the data

manufacturer.

In the event of nonconformity of the coil, carry out its replacement

C

22..22..33..

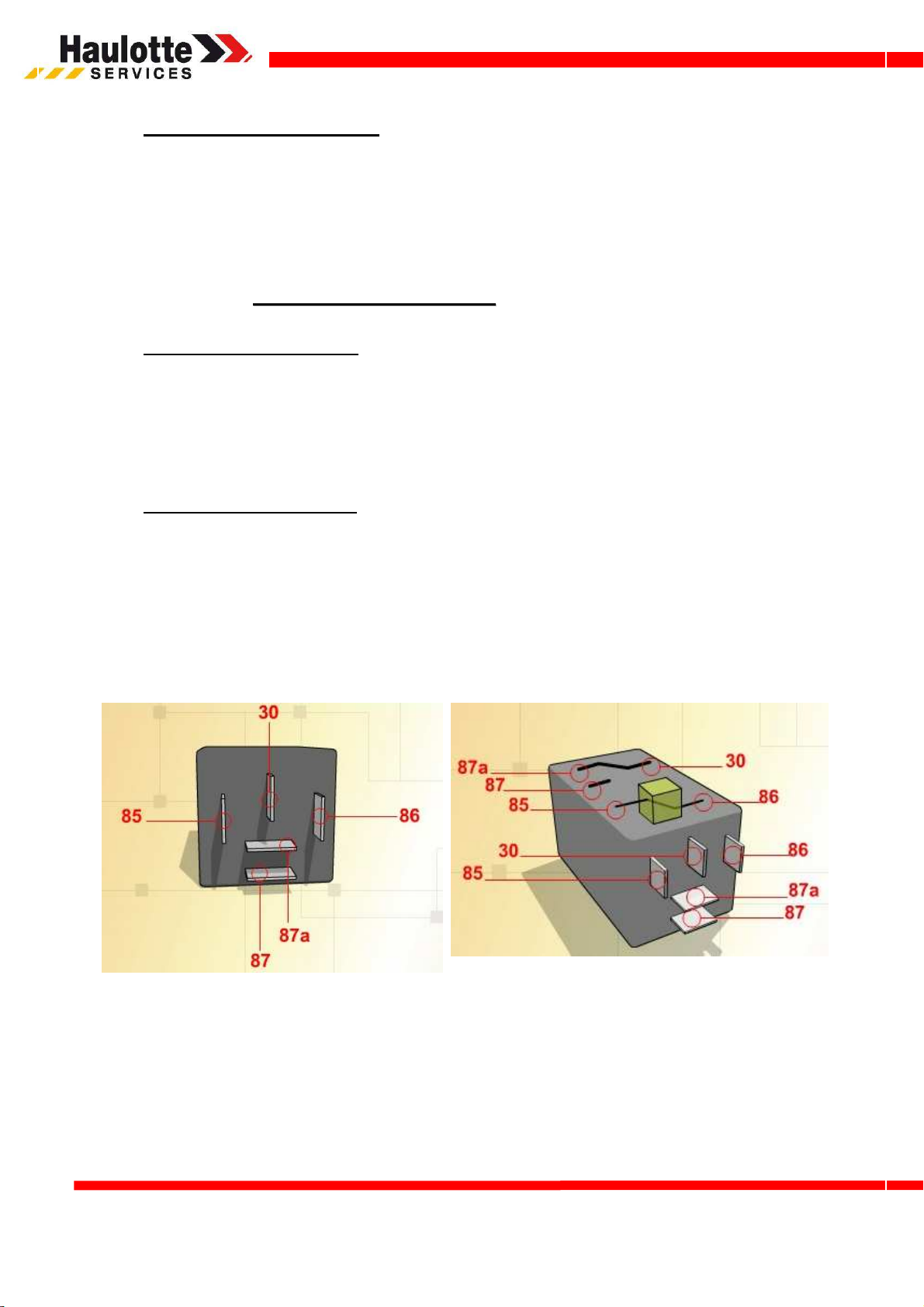

• Control of an electric relay

Disconnect the relay, then locate its various terminals.

Control the resistor of the solenoid terminals 85 and 86 (see manufacturer data’s) using

a multimeter in Ohmmeter position.

If the resistor is null, change the relay.

If this test is OK, check continuity between terminals 30 and 87a and insulation between

terminals 30 and 87

In the event of dysfunction, replace the relay.

• supply control of the relay

locate the relay without disconnecting it and locating it its various terminals.

control the continuity of terminal 86 with the ground

.(In the event of defect of continuity, check the concerned loom)

connect the multimeter in position Voltmeter (V) between terminal 30 and the ground and thus

control the power supply of the component (It must be close to the battery voltage Vbat)

select the function of this relay and check the output voltage between terminal 87 and ground.

In the event of dysfunction, replace the relay.

OONNTTRROOLL OOFF CCOOMMPPOONNEENNTTS

C

S

21/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

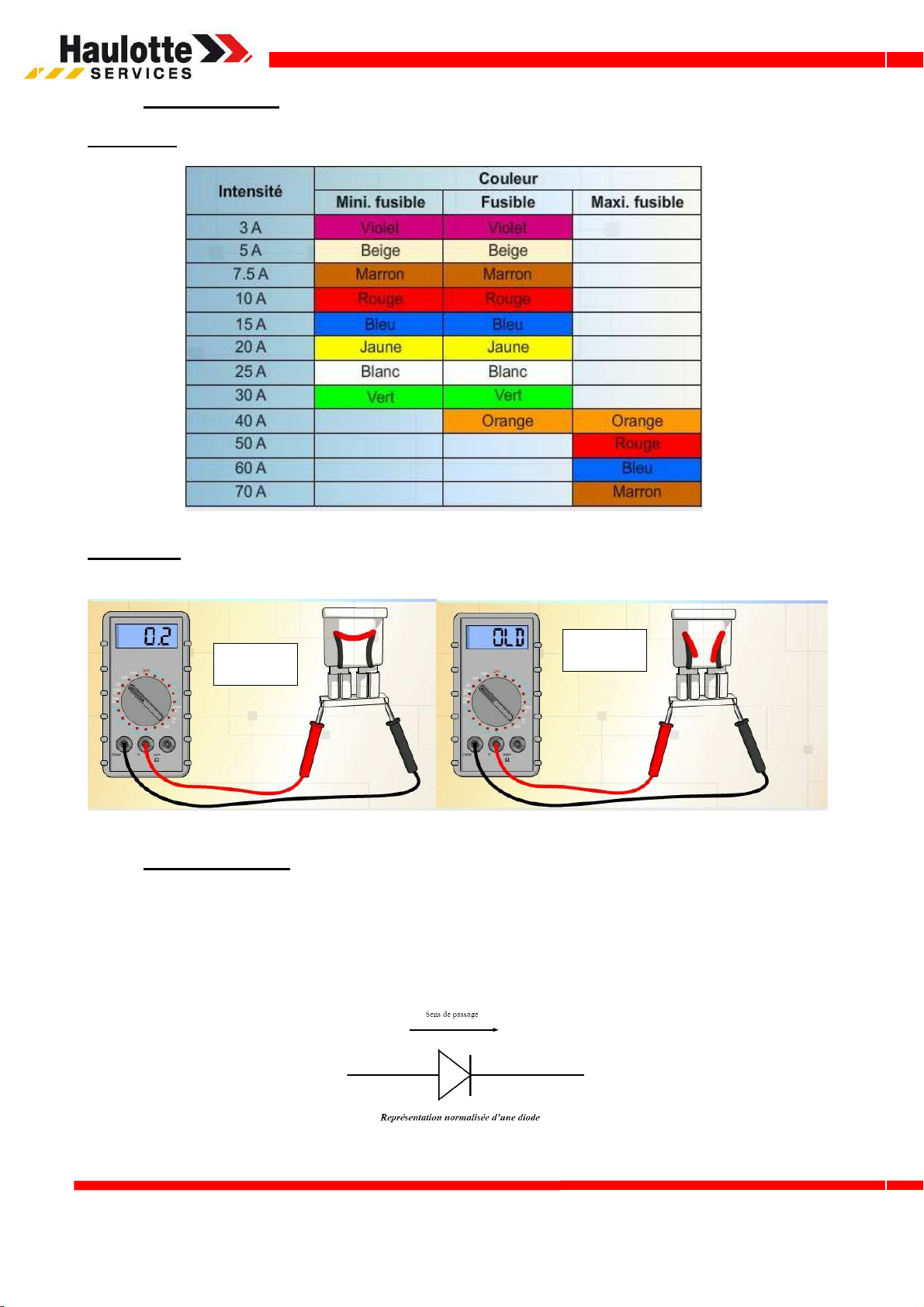

• Control of a fuse

Color code

Fuse check

Multimeter in Ω position, it must indicate a value near 0

OK

NOK

• Control of a diode

locate the diode and disconnect it from the loom.

Control must be done with a multimeter in “diode” position .

connect the multimeter on each terminal of the diode, in one direction then on the other.

In a direction, the diode should have no continuity,

in the other it must be beep

If the diode is beeping in both ways, replace it.

22/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

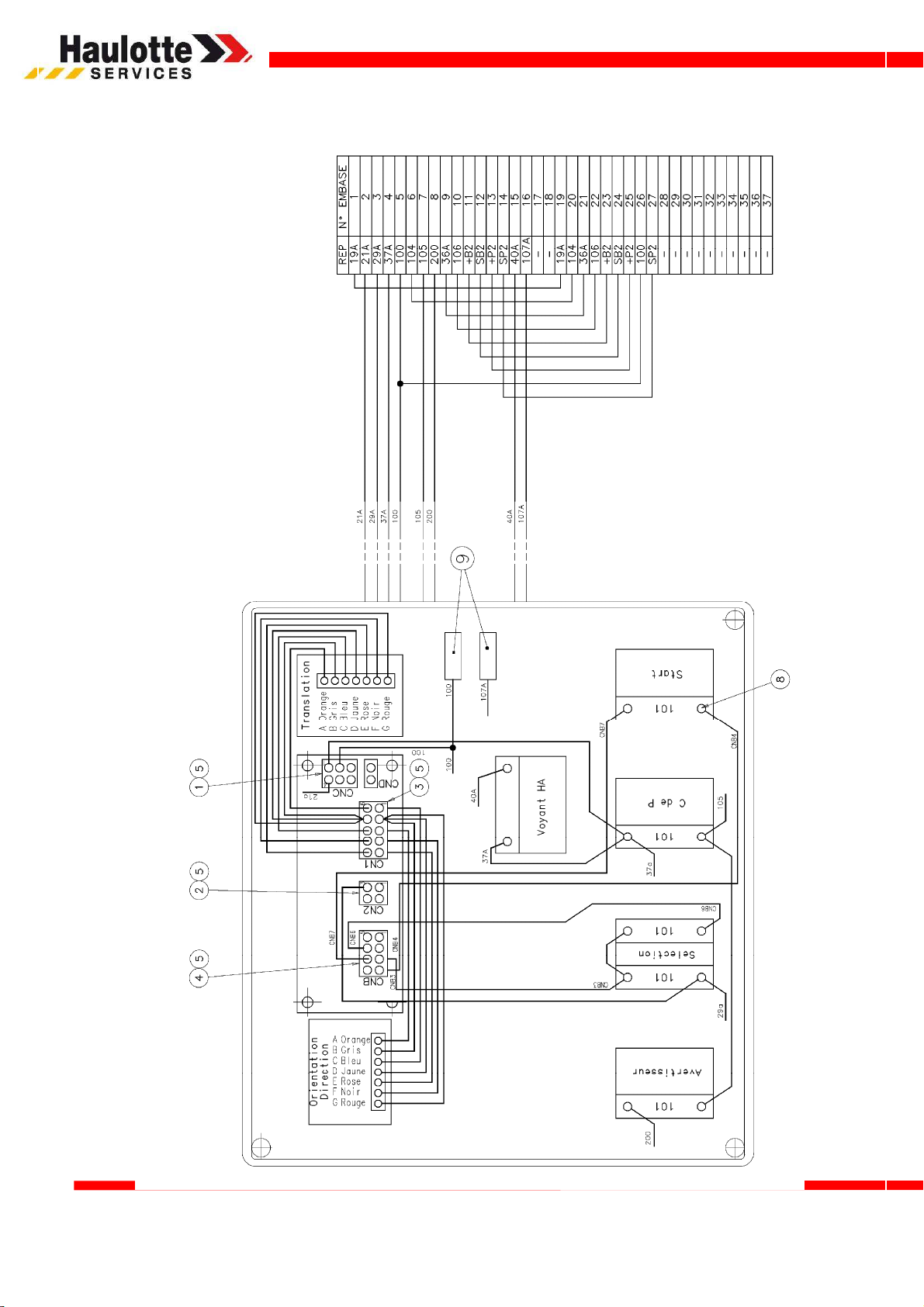

22..33..

See at the end of this manual

TTHHEE WWIIRRIINNGG DDIIAAGGRRAAMM ((EE662211EE))

23/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

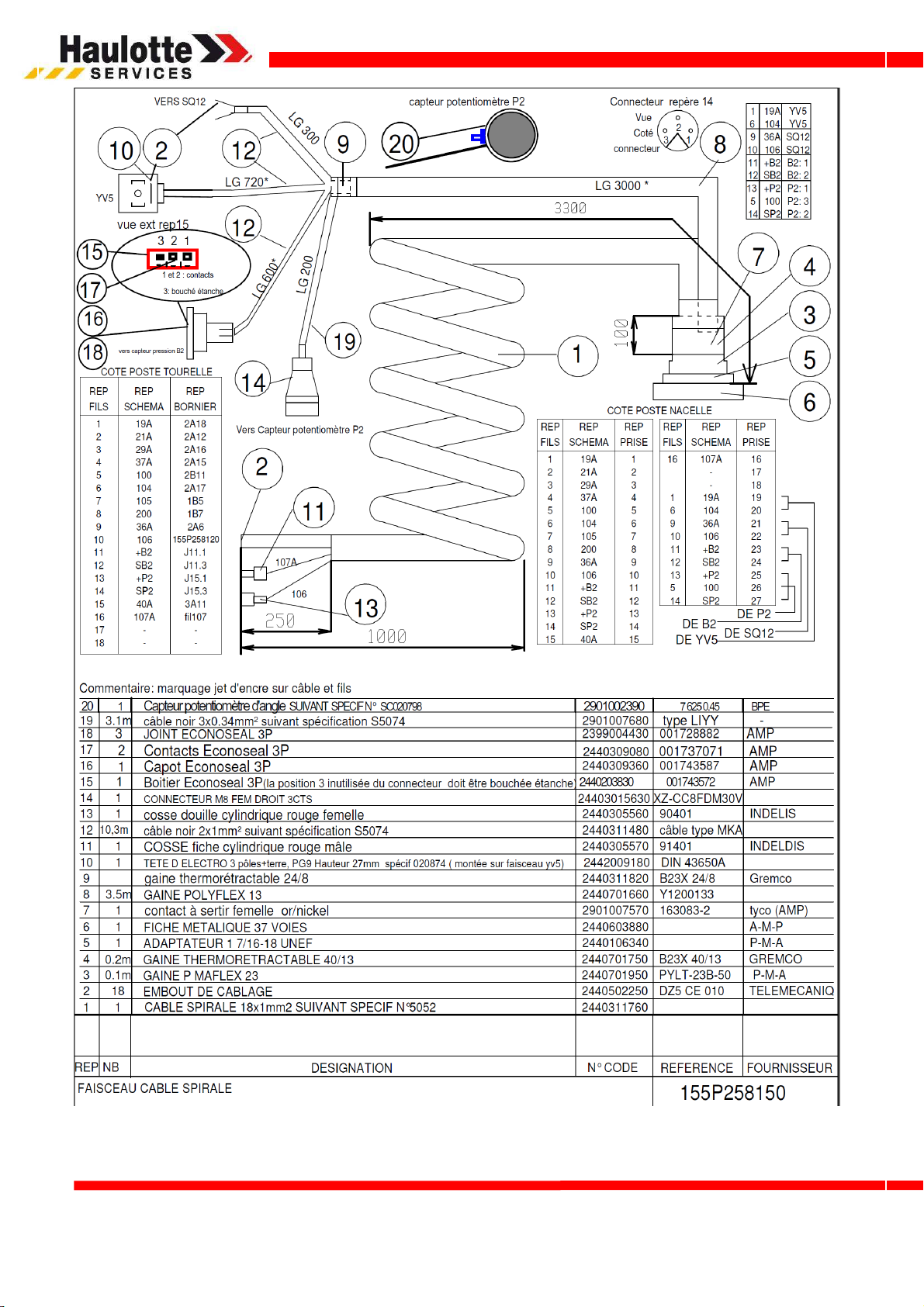

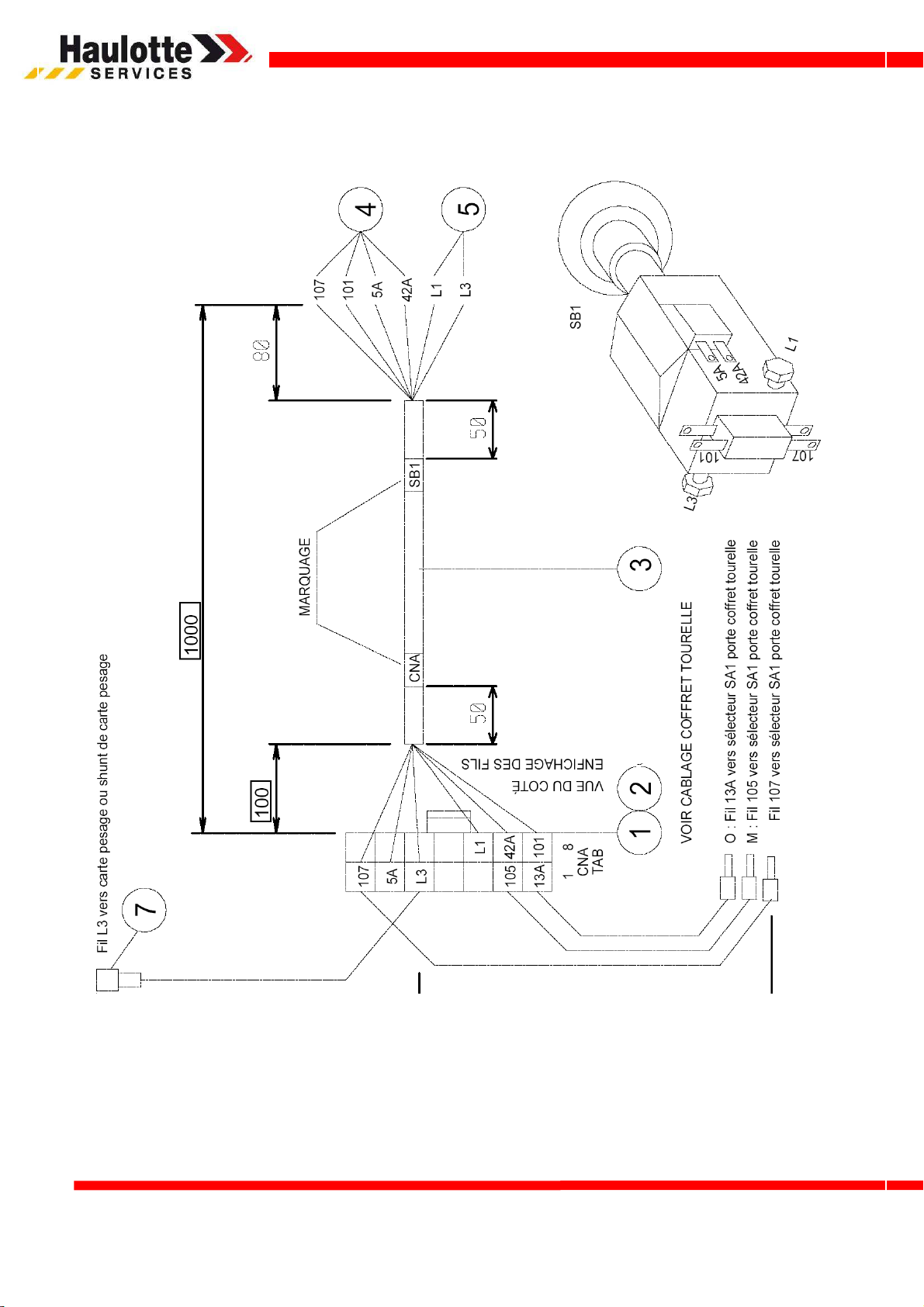

22..44..

Old version

LLOOOOMMSS ((115555PP225588115500))

24/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

25/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

Turntable box (P20593)

See at the end of this manual

Battery main switch SB1 (155P258130)

26/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

upper box (155P258800)

27/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

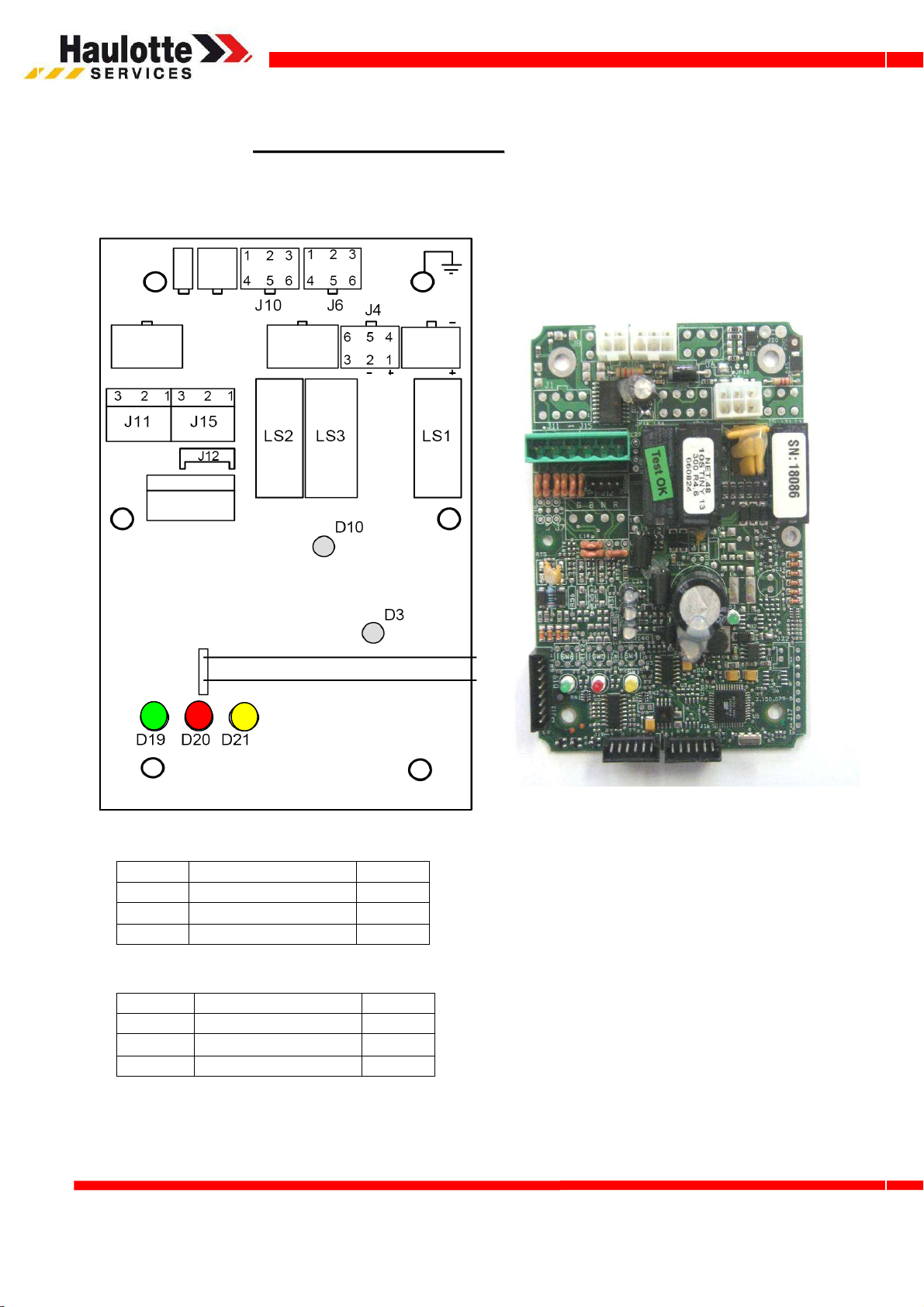

Connector J11 (pressure sensor)

Connector J15 (angle sensor)

22..44..11..

T

HHEE WWEEIIGGHHIINNGG BBOOAARRDD

T

(

(

E

BBPPE

))

terminal Description Notes

1 Positive Red

2 - 3 Signal 4-20mA white

Terminal Description Notes

1 Positive red

2 Négative black

3 Signal white

28/92

TRAINING MANUAL DIAGNOSTIC Level 2 STAR 8/10P

2420339160 E03-11

Supply on BPE board :

Connector J4 :

J4.1 : + ALIM

J4.2 : - ALIM

J4.3 : input VAR 38

J4.4 :

J4.5 : input VAR 26

J4.6 :

Loading...

Loading...