Haulotte STAR 6, STAR 13, STAR 10NG, STAR 8NG, STAR 26J Operator's Manual

...

Operator manual

T

ELESCOPIC

MASTS

24203 3207 0 E 07 07 EN

Operator manual

TELESCOPIC MASTS

STAR 6 (STAR 13) - STAR 8NG

(STAR 22J) - STAR 9 - STAR 10NG

(STAR 26J) - STAR 11 - STAR 12

EN

2 24203 3207 0 E 07 07 EN

Telescopic masts

3

CONTENTS

Operator manual

CONTENTS

1 - Operator manual. . . . . . . . . . . . . . . . . . . . . . . . .

7

2 - After Sales Service . . . . . . . . . . . . . . . . . . . . . . .

7

3 - Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

A

SAFETY PRECAUTIONS

1 - Recommendations . . . . . . . . . . . . . . . . . . . . . . .

9

1.1 - Operator manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 - Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3 - Label colours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 - Pre-operation instructions. . . . . . . . . . . . . . . .

11

2.1 - General instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 - Specific instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 - Operation instructions . . . . . . . . . . . . . . . . . . .

12

3.1 - Prohibitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 - Potential risks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.1 - Risk of command system disturbance . . . . . . . . . . . . . . . . . . . . 13

3.2.2 - Risk of falling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.3 - Risk of electrocution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.4 - Risk of jerks and overturning . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.5 - Risk of burns and explosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.6 - Risk of crushing and collision . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

B

INTERVENOR'S RESPONSIBILITY

1 - Owner's (or hirer's) responsibility . . . . . . . . .

19

2 - Employer's responsibility . . . . . . . . . . . . . . . .

19

3 - Trainer's responsibility . . . . . . . . . . . . . . . . . .

19

4 - Operator's responsibility . . . . . . . . . . . . . . . . .

20

5 - Inspection and maintenance . . . . . . . . . . . . . .

21

C

MACHINE LAYOUT

1 - Identification . . . . . . . . . . . . . . . . . . . . . . . . . . .

23

2 - Main components . . . . . . . . . . . . . . . . . . . . . . .

25

2.1 - Electrical version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3 - Safety devices. . . . . . . . . . . . . . . . . . . . . . . . . .

30

3.1 - Sliding mid-rail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.2 - Anchorage point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4 - Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31

4.1 - Classification plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1.1 - Red labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1.2 - Orange labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.1.3 - Yellow labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.1.4 - Other labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4

Operator manual

4.1.5 - Green labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.2 - Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5 - Consoles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

49

5.1 - Lower console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.2 - Upper console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

D

OPERATING PRINCIPLE

1 - Description . . . . . . . . . . . . . . . . . . . . . . . . . . . .

57

2 - Safety devices. . . . . . . . . . . . . . . . . . . . . . . . . .

57

2.1 - Activation of controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2.2 - Driving speed (minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2.3 - Electronic speed controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

2.4 - Multi-function LEDBattery charge status controllerEngine hour meter58

2.5 - Automatic engine cut-out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

2.6 - Load in the platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

2.7 - Machine tilt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2.8 - Machine braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2.9 - Wheel motor brake release. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2.10 - Anti-pothole safety system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2.11 - On-board charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

E

DRIVING

1 - Recommendations . . . . . . . . . . . . . . . . . . . . . .

61

2 - Checks before use . . . . . . . . . . . . . . . . . . . . . .

61

2.1 - Visual inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

2.1.1 - General mechanical functions . . . . . . . . . . . . . . . . . . . . . . . . . . 61

2.1.2 - Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

2.2 - Functional tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

2.2.1 - Safety features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

2.2.2 - Lower console controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2.2.3 - Upper console controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

2.3 - Regular checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.4 - Repairs and adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.5 - Checks when the machine is put back in service . . . . . . . . . . . . . . . . . 65

3 - Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

66

3.1 - Test procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3.1.1 - Emergency stop push button function . . . . . . . . . . . . . . . . . . . . 66

3.1.2 - Tilt control box function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.1.3 - Visual and audio alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.1.4 - Weighing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

3.2 - Ground operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

3.2.1 - Machine start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

3.2.2 - Machine shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

3.2.3 - Movement control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

3.2.4 - Other controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.3 - Operations from the platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.3.1 - Machine start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.3.2 - Machine shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.3.3 - Movement control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.3.4 - Other controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5

CONTENTS

Operator manual

F

SPECIAL PROCEDURE

1 - Emergency lowering . . . . . . . . . . . . . . . . . . . .

75

1.1 - Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

1.2 - Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

2 - Lowering for repairs. . . . . . . . . . . . . . . . . . . . .

77

2.1 - Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

2.2 - Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3 - Towing service . . . . . . . . . . . . . . . . . . . . . . . . .

79

3.1 - Releasing of the brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4 - Loading and unloading . . . . . . . . . . . . . . . . . .

80

4.1 - Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.1.1 - Loading by ramp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.1.2 - Loading by power lift truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4.1.3 - Unloading by power lift truck . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4.1.4 - Loading by lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4.1.5 - Unloading by lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4.2 - Putting in transport position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4.3 - Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

4.4 - Warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5 - Detection of internal fault . . . . . . . . . . . . . . . .

84

5.1 - Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

5.2 - Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

G

TECHNICAL CHARACTERISTICS

1 - Main characteristics . . . . . . . . . . . . . . . . . . . . .

85

2 - Overall dimensions . . . . . . . . . . . . . . . . . . . . .

89

3 - Working area. . . . . . . . . . . . . . . . . . . . . . . . . . .

92

3.1 - Machine STAR 6 (STAR 13). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3.2 - Machine STAR 8 (STAR 22J) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

3.3 - Machine STAR 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

3.4 - Machine STAR 10 (STAR 26J) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

3.5 - Machine STAR 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

3.6 - Machine STAR 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

4 - ANSI standard specificities . . . . . . . . . . . . . .

98

4.1 - Overload test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

4.2 - Operational test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

4.3 - Stability test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

H

INTERVENTION LOG

1 - Intervention log. . . . . . . . . . . . . . . . . . . . . . . .

103

6

Operator manual

724203 3207 0 E 07 07 EN

Telescopic masts

You have just bought a HAULOTTE® telescopic

handler and we would like to thank you for your

trust.

1 - Operator manual

AS indicated on the delivery slip, this manual is one of the documents in the on-board case supplied

upon delivery of your telescopic handler.

In order to guarantee you full satisfaction, you must scrupulously follow the operating instructions

contained in this manual.

We would like to draw your attention in particular to 2 essential points :

• Compliance with the safety precautions (machine, operation, environment)

• Use within the equipment performance limits.

2 - After Sales Service

Our HAULOTTE Services® After Sales Service is completely at your disposal during and beyond the

warranty period to provide the service you require.

• Contact our After Sales Service, specifying the exact machine type and its serial number.

• When ordering any consumables or spare parts, please use this manual and the Haulotte Essential

catalogue to receive original spare parts, the only guarantee of interchangeability and perfect

operation.

• In the event of malfunctions or incidents involving a HAULOTTE® machine, contact HAULOTTE

Services® immediately even if no material or bodily damage is observed and we will intervene as

soon as possible.

8 24203 3207 0 E 07 07 EN

Telescopic masts

3 - Conformity

We remind you that HAULOTTE® machines comply with the provisions of the directives currently

applicable to this type of machine.

Any modification without having obtained written authorization from HAULOTTE®, renders this

conformity null..

HAULOTTE® cannot be held liable for the technical specifications contained in this manual.

HAULOTTE® reserves the right to make improvements or modifications to the machine without

modifying this manual.

A

B

C

D

E

F

G

H

I

924203 3207 0 E 07 07 EN

Telescopic masts

A

- Safety precautions

Safety precautions

1 - Recommendations

1.1 - OPERATOR MANUAL

The operator manual is intended for HAULOTTE® machine operators.

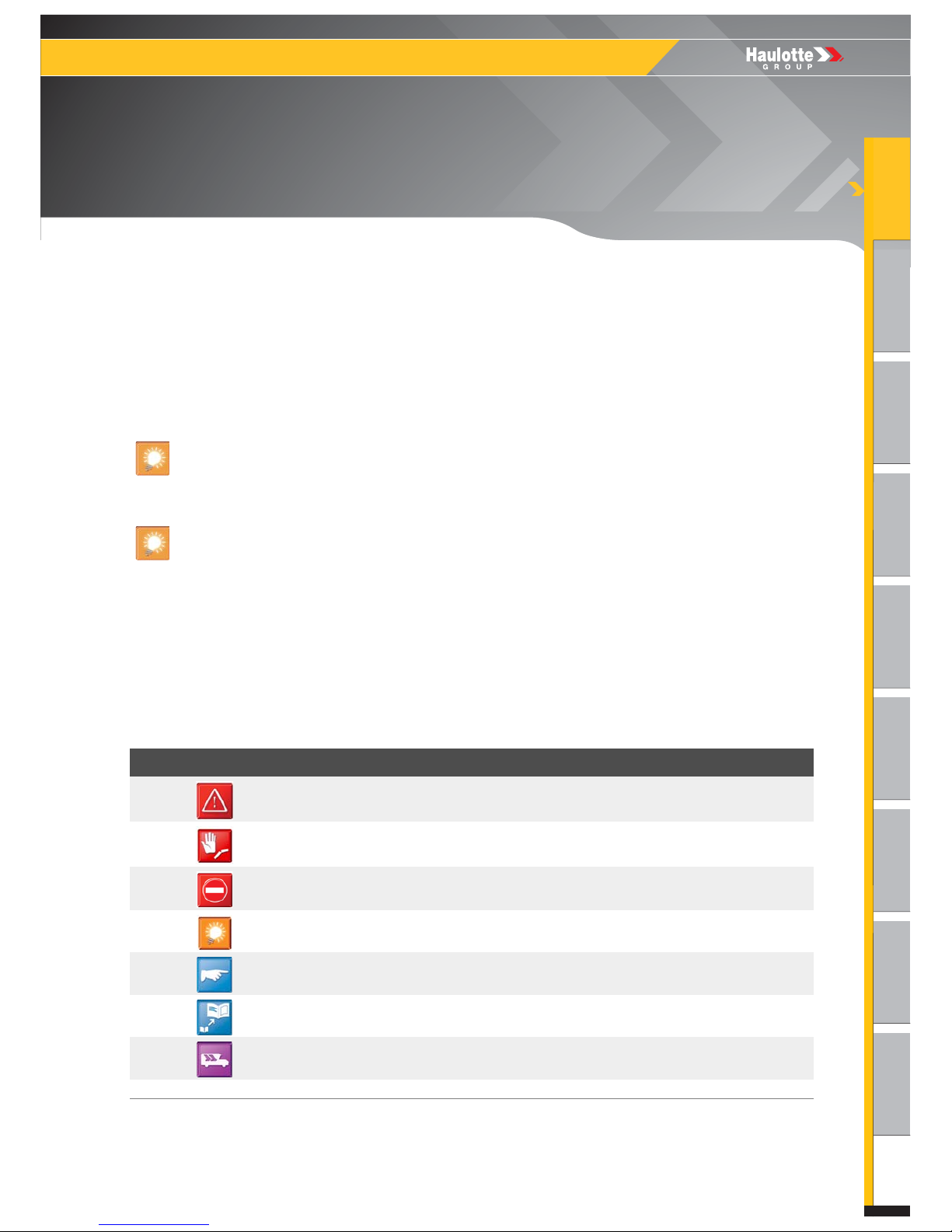

1.2 - SYMBOLS USED

Symbols are used to alert the operator of the safety precautions or to highlight practical

information.

Symbol meanings

The operator manual does not replace the basic training required for all worksite equipment operators.

This manual contains the operator instructions provided by HAULOTTE® for using the machines

efficiently and safely.

The operator manual must be kept in the cab in its storage case. This manual must be made available to

each operator and kept in good condition.

Additional copies can be ordered from HAULOTTE Services®.

Symbol Meaning

Danger : Risk of injury or death (work safety)

Caution : Risk of material damage (work quality)

Prohibition relating to work safety and quality

Reminder : No identified risk but a reminder of common sense, good

practice or pre-action prerequisites

Cross-reference to another part of the manual (see section or sheet)

Cross-reference to another manual (see manual)

Cross-reference to repairs (contact HAULOTTE Services®)

N.B. : Additional technical information

10 24203 3207 0 E 07 07 EN

Telescopic masts

A

- Safety precautions

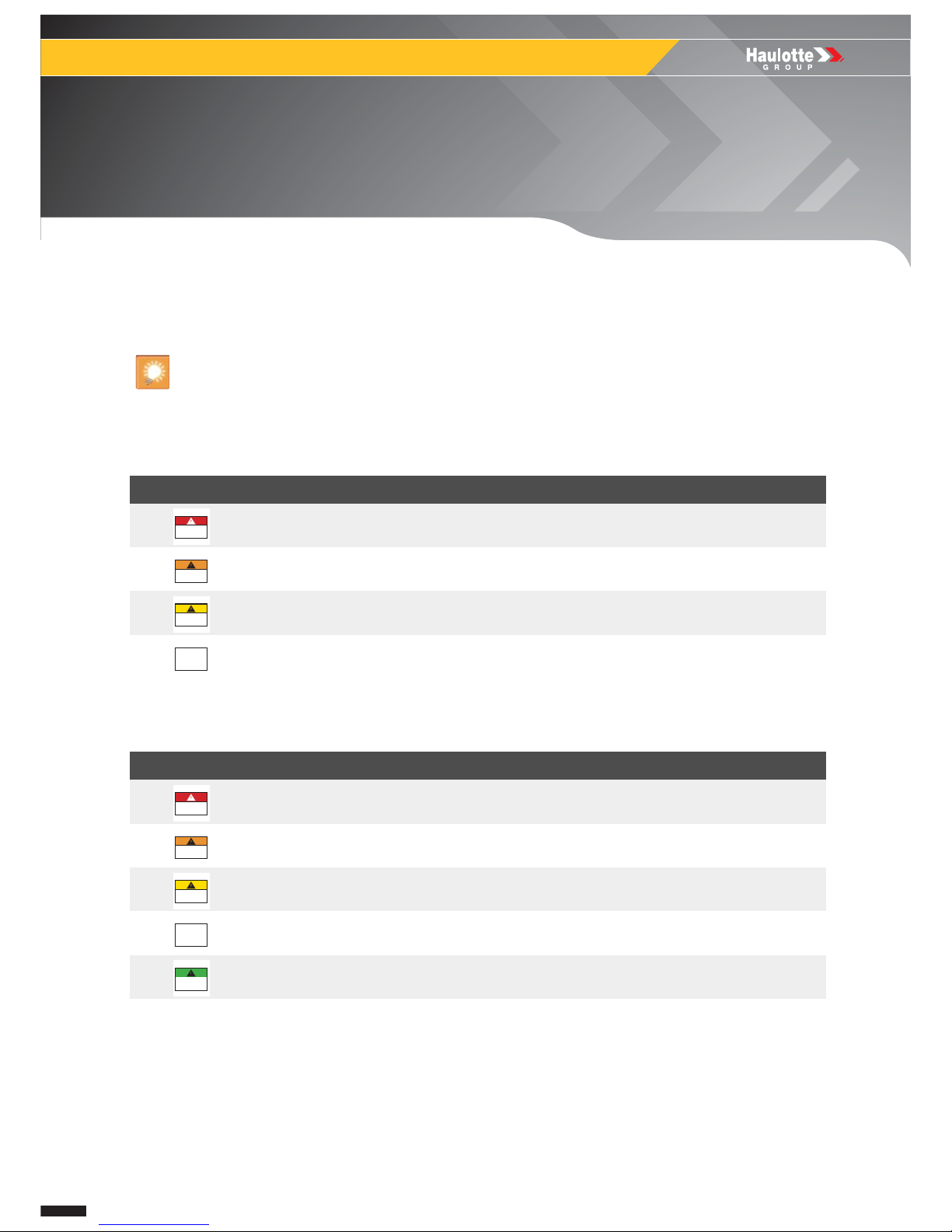

1.3 - LABEL COLOURS

The potential dangers and specific regulations are indicated on the machine by labels and

identification plates.

Familiarize yourself with the labels and their respective color codes.

Label color code-CE - AS

Label color code-ANSI - CSA

The labels must be kept in good condition. Additional labels can be obtained from HAULOTTE Services®.

Labels Color Meaning

Red Potentially fatal danger

Orange Risk of serious injury

Yell ow Risk of material damage and/or minor injury

Other Additional technical information

Labels Color Meaning

Red Potentially fatal danger

Orange Risk of serious injury

Yell ow Risk of material damage and/or minor injury

Other Additional technical information

Green CSA maintenance operation or information

A

B

C

D

E

F

G

H

I

1124203 3207 0 E 07 07 EN

Telescopic masts

A

- Safety precautions

2 - Pre-operation instructions

2.1 - GENERAL INSTRUCTIONS

• On a soft, unstable or cluttered ground.

• With wind blowing faster than the permissible limit. Check the maximum value in the technical

characteristics ( Section G 1- Main characteristics). Consult the Beaufort scale

( Section A 3.2.3- Risk of jerks and overturning).

• Close to power lines. Respect the safety distance ( Section A 3.2.1- Risk of electrocution).

• At temperatures higher than 45 °C (113 °F) and lower than -15 °C (5 °F). Consult HAULOTTE® if it is

necessary to work outside this range.

• In explosive atmosphere.

• During storms (risk of lightning).

• In the presence of strong electromagnetic field (radar ...).

2.2 - SPECIFIC INSTRUCTIONS

• If the load in the platform exceeds the maximum load authorized. Check the maximum value in the

technical characteristics ( Section G 1- Main characteristics).

• If the ground has more slope than the permissible limit.. Check the maximum value in the technical

characteristics ( Section G 1- Main characteristics).

• At night if not equipped with the optional light.

• If the number of persons is more than the number permissible. Check the maximum value in the

technical characteristics ( Section G 1- Main characteristics)

• If the side force in the platform is more than the permissible force. Check the maximum value in the

technical characteristics ( Section G 1- Main characteristics)

Never operate the machine in the following situations :

Never operate the machine in the following situations :

12 24203 3207 0 E 07 07 EN

Telescopic masts

A

- Safety precautions

3 - Operation instructions

3.1 - PROHIBITIONS

The operation of the machine is recommended on flat, developed ground (tarmac, concrete, etc.).

• Never use a defective machine (hydraulic leakage, worn out tyres, malfunction).

• Never operate the machine controls with sudden actions.

• Never place the machine against a structure to maintain this structure.

• Never use the machine to tow or drag.

• Never expose the batteries or electrical components to water (pressure cleaner, rain).

• Never neutralize the securities.

• Do not hit a fixed or mobile obstacle. The contact can cause premature deterioration of the structure and

lead to the rupture of certain safety elements.

• Do not climb on the hoods.

• Never use the machine alone. It must be operated by pairs of operators.

• Never use the machine with a cluttered platform.

• Never increase the surface in the platform by using floor extensions or accessories not authorized

by HAULOTTE®.

• Never leave the hydraulic cylinders entirely extended or retracted before switching the machine off, or

during an extended stop period.

• Never use the machine with material or objects suspended on the guard-rail.

• Never use the machine with the elements that can increase the load of the wind (board).

• Never increase the height of work by using attachments (ladder).

• Never use the guardrail as the means of access to climb up or down the platform. Steps have been

provided to this effect on the platform.

• Never climb on the guardrail.

• Never use the machine without installing the sliding midrail or without closing the safety gate.

• Never use the machine as crane, goods lift or elevator.

• Never use the machine for any other purpose than to transport people, their tools and material to the

desired place.

• Never drive fast in narrow or badly cleared areas. Keep speed under control on bends.

• Never tow the machine (it must be transported on a trailer).

A

B

C

D

E

F

G

H

I

1324203 3207 0 E 07 07 EN

Telescopic masts

A

- Safety precautions

• The LPG bottle must be firmly attached in the correct position.

• Check the bottle and its connections regularly (every 250h) to detect any leaks. Never use matches.

Always use a specially-designed leak detector product.

• The outside of the LPG bottle must always be kept free of rust by regularly applying specific paint

protection.

3.2 - POTENTIAL RISKS

3.2.1 - Risk of command system disturbance

Risk of disrupted movement close to high voltage lines or magnetic fields.

3.2.2 - Risk of falling

On board the machine, respect the following instructions :

• Carry individual protection equipment adapted to the work conditions and local

rules. Wearing of an approved helmet is strongly recommended.

• The occupants of the platform must wear a buckle or a safety harness ( 1 per person).

• Avoid hitting fixed or mobile obstacles (other machines).

• Ensure that the adjustable midrail is closed (low position and against the guardrails).

• During raising and driving, hold on tightly to the guardrails.

• Do not sit, stand, or climb on the guard rails of the platform.

• Constantly keep the feet firmly on the floor of the platform.

• Remove any trace of oil or grease on the steps, floor, handrail and the guardrails.

• Keep the floor of the platform free of debris.

• Do not leave the platform if the machine is not in stowed position.

To climb up or climb down from the platform : :

• The machine must be completely stowed.

• Face the machine to use the access hatch

• Keep 3 support points between the steps and the guardrail

14 24203 3207 0 E 07 07 EN

Telescopic masts

A

- Safety precautions

3.2.3 - Risk of electrocution

This machine is not isolated and does not offer any protection.

The risks of electrocution are high in the following situations :

• Close to live power lines, consider the movement of the machine and the swaying of the electric power

lines.

• In case of hitting a high voltage line, wait for the power cut of the high voltage line before using the

machine (clearance, distancing of the machine).

• During storms.

Never use the machine as a solder mass.

Maintain a minimum safe distance with regard to lines and electrical devices.

Respect the local rules and the minimum safety distance.

Minimum safety distance

N.B.-:-THIS TABLE IS APPLICABLE, EXCEPT WHEN THE LOCAL REGULATIONS ARE MORE STRICT.

Electric voltage Minimum safety distance

Mètre Feet

0 - 300 V Avoid contact

300 V - 50 V 3 10

50 - 200 V 5 15

200 - 350 V 6 20

350 - 500 V 8 25

500 - 750 V 11 35

750 - 1000 V 14 45

A

B

C

D

E

F

G

H

I

1524203 3207 0 E 07 07 EN

Telescopic masts

A

- Safety precautions

3.2.4 - Risk of jerks and overturning

On board the machine, respect the following instructions :

• Before engaging the machine on any internal or external surface (premises, bridge,

truck, etc.), check that the ground is capable of supporting the load. Check the

maximum value in the technical characteristics ( Section G 1- Main characteristics).

• During movement reversal from the upper or lower console, the joysticks or switches must be stopped

in the neutral position.

• According to the overall dimensions, place the loads in the centre of the platform or distribute them in

a uniform manner.

• On platforms, footpaths, etc. remain vigilant of the reversal of driving direction. Check the driving

direction with the help of the red or green arrow on the chassis and on the upper console.

• Make sure that the chassis is never closer than 1 m (3 ft 3 in) m to holes, bumps, steep slopes,

obstructions, debris and ground covering which may hide holes and other dangers.

N.B.-:-T

HE BEAUFORT SCALE MEASURES THE WIND FORCE WITH A GRADUATION SYSTEM. A WIND SPEED

RANGE

AT 10 M (32 FT 9 IN) ABOVE FLAT, CLEAR LAND IS ASSOCIATED WITH EACH DEGREE.

• Do not drive the machine on slopes or tilts beyond limits. Check the maximum value in the technical

characteristics( Section G 1- Main characteristics).

• Do not descend slopes at high speed.

• Do not raise the platform or drive with the platform raised on slopes or when the machine is tilted.

• Do not drive in reverse (direction opposite to the field of vision).

• Never use the machine in winds exceeding the authorized limit.

• Do not increase the surface area exposed to the wind. The greater the surface area exposed, the more

unstable the machine becomes.

16 24203 3207 0 E 07 07 EN

Telescopic masts

A

- Safety precautions

Beaufort scale

Force

Meteorological

description

Observed effects m/s km/h mph

0 Calm Smoke rises vertically. 0 - 0,2 0 - 1 0 - 0,62

1 Very light breeze

Smoke indicates the wind

direction.

0,3 - 1,5 1 - 5 0,62 - 3,11

2 Light breeze

Wind felt on the face. Leaves

rustle. Weathervanes turn.

1,6 - 3,3 6 - 11 3,72 - 6,84

3 Slight breeze

Leaves and small branches in

constant movement.. Flags

move slightly.

3,4 - 5,4 12 - 19 7,46 - 11,8

4 Nice breeze

Dust and loose papers fly. Small

branches bend.

5,5 - 7,9 20 - 28

12,43 -

17,4

5 Nice breeze

Small trees sway. Crested

wavelets form on inland waters.

8,0 - 10,7 29 - 38

18,02 -

23,6

6 Cool wind

Large branches shake. Power

lines and chimneys 'sing'. It is

difficult to use an umbrella.

10,8 - 13,8 39 - 49

24,23 -

30,45

7 Strong cool wind

All trees shake. Walking against

the wind becomes difficult.

13,9 - 17,1 50 - 61 31 - 37,9

8 Squall

Some branches break.

Generally we cannot walk

against the wind.

17,2 - 20,7 62 - 74

38,53 -

45,98

9 Strong squall

The wind causes slight damage

to buildings. Tiles and chimney

stacks are blown off.

20,8 - 14,4 75 - 88

46,60 -

54,68

A

B

C

D

E

F

G

H

I

1724203 3207 0 E 07 07 EN

Telescopic masts

A

- Safety precautions

3.2.5 - Risk of burns and explosion

N.B.-:-ACID IS NEUTRALISED WITH SODIUM BICARBONATE AND WATER.

3.2.6 - Risk of crushing and collision

On board the machine, respect the following instructions :

• During operation, keep all the parts of the body inside the platform.

• Adapt the movement speed according to the ground conditions (traffic, slope, etc.).

• Respect stopping distances :

• 3 m (9 ft 10 in) at fast speed.

• 1 m (3 ft 3 in) at slow speed.

• To position the machine close to obstacles, use the lifting controls (arm, boom, etc.) instead of the

drive controls.

• Make sure there are no obstacles (structure) in the work area.

• When moving, position the platform so as to have the best possible visibility.

• Always have someone to guide manoeuvres in case of low visibility.

• All personnel on the machine or on the ground must wear a safety helmet.

• When raising or lowering the machine, and during drive, the operator must check that the area above,

below and on each side of the machine, is clear.

• When moving the machine, ensure that there are no people or obstacles in the way..

For any intervention on the power sources, wear glasses and protective clothes (acid

spray).

• Do not work in an explosive or inflammable ambience (spark, flame, etc.).

• Do not touch the hot parts of the motorization system (engine, filters, etc.).

• Do not use a tool to make contact between the battery terminals.

• Do not manipulate the battery close to a spark, flame, glowing tobacco (emission of gas).

Do not operate other machines (crane, platform, etc.) in the work area.

Take into account the distance, reduced visibility and dead angles during the driving and/or use of the

machine.

18 24203 3207 0 E 07 07 EN

Telescopic masts

A

- Safety precautions

A

B

C

D

E

F

G

H

I

1924203 3207 0 E 07 07 EN

Telescopic masts

B

- Intervenor's responsibility

Intervenor's responsibility

1 - Owner's (or hirer's) responsibility

The owner (or hirer) has the obligation to inform operators of the operator manual instructions.

The owner (or hirer) has the obligation to renew all manuals or labels that are either missing or in bad

condition. Additional copies can be ordered from HAULOTTE Services®.

The owner (or hirer) is responsible for applying the local regulations regarding operation.

2 - Employer's responsibility

The employer is obliged to issue a driving permit to the operator.

The employer is obliged to inform the operator of the local regulations.

3 - Trainer's responsibility

The trainer must be qualified to provide training to operators. The training must be given in an obstaclefree area until the trainee is able to drive and operate the machine safely.

Forbid machine operation to anyone :

• Under the influence of drugs, alcohol, etc..

• subject to fits, loss of motricity, dizziness, etc..

20 24203 3207 0 E 07 07 EN

Telescopic masts

B

- Intervenor's responsibility

4 - Operator's responsibility

The operator must read and understand this manual and the labels affixed on the machine.

The operator must inform the owner (or hirer) if the manual or any labels are missing or in bad condition,

and of any malfunction of the machine.

The operator may only operate the machine for the purpose intended by the manufacturer.

All operators must be familiar with the emergency controls and how to operate the machine in an

emergency.

The operator must stop using the machine in the event of malfunction or safety problems on the

machine or in the work area.

Only authorized and qualified operators may operate HAULOTTE® machines.

A

B

C

D

E

F

G

H

I

2124203 3207 0 E 07 07 EN

Telescopic masts

B

- Intervenor's responsibility

5 - Inspection and maintenance

The inspection and maintenance table identifies the role and the responsibilities of each party in regular

machine maintenance.

Inspections and maintenance

If the machine is operated in a hostile environment or intensively, increase the frequency of maintenance.

Type of

intervention

Frequency

Person-in-

charge

Intervenor

Reference

document

Pre-delivery

inspection

Before each delivery

of sold, hired or

resold equipment

Owner (or hirer)

Qualified HAULOTT

E Services®

technician

Operator manual

Pre-operation

inspection

Before operation or

when the operator

changes

Operator Operator Operator manual

Regular preventive

maintenance

At the specified

intervals (250h or 1

year)

Owner (or hirer)

On-site technician

or

qualified HAULOTT

E Services®

technician

Maintenance book

Regular visit

2 times a year or at

the latest 6 months

after the last regular

visit, and according

to the local

regulations

Owner (or hirer)

Organization or

technician approved

by the employer or

by the intermediary

of HAULOTTE

Services® in

accordance with

the HAULOTTE

Services® contract

Maintenance book

22 24203 3207 0 E 07 07 EN

Telescopic masts

B

- Intervenor's responsibility

A

B

C

D

E

F

G

H

I

2324203 3207 0 E 07 07 EN

C

- Machine layout

Telescopic masts

Machine layout

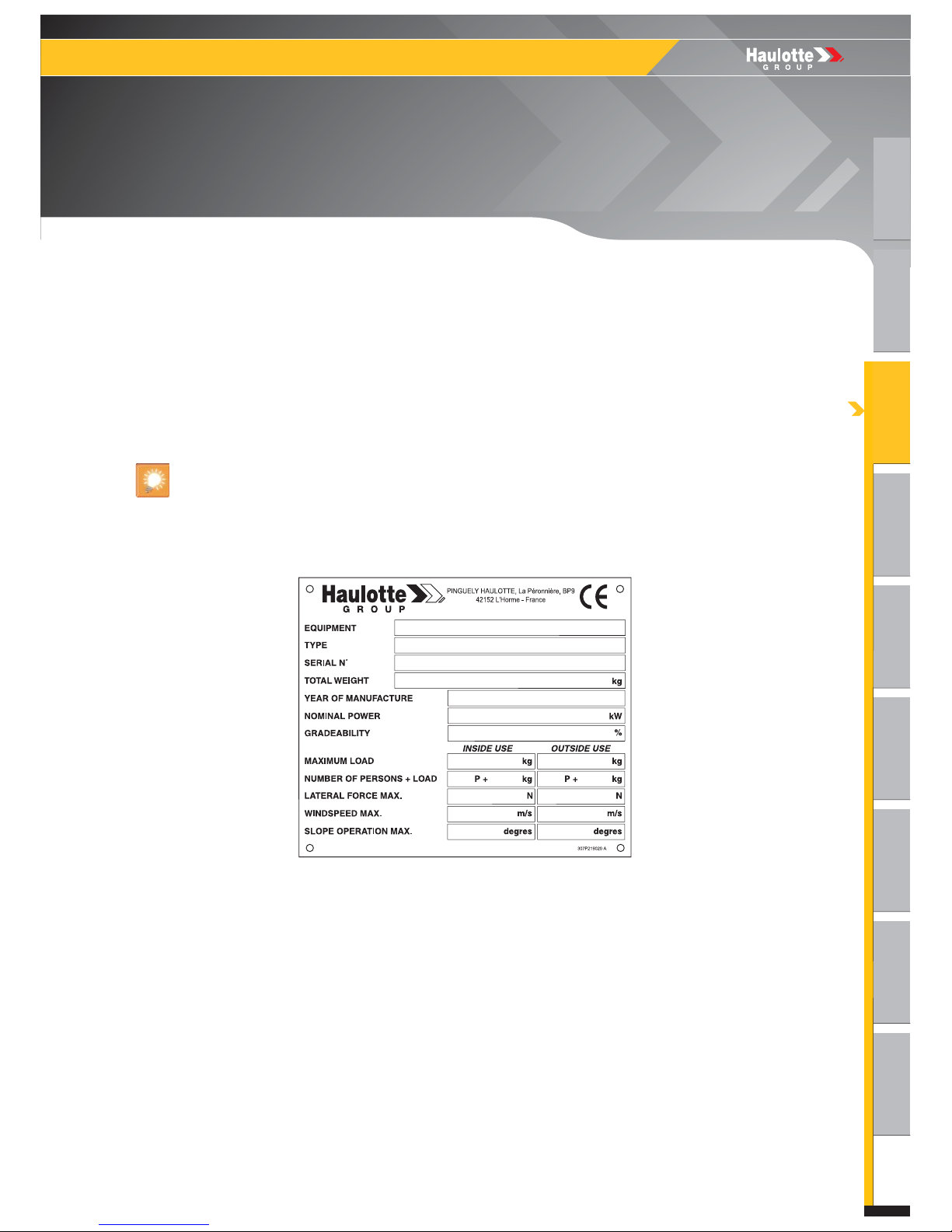

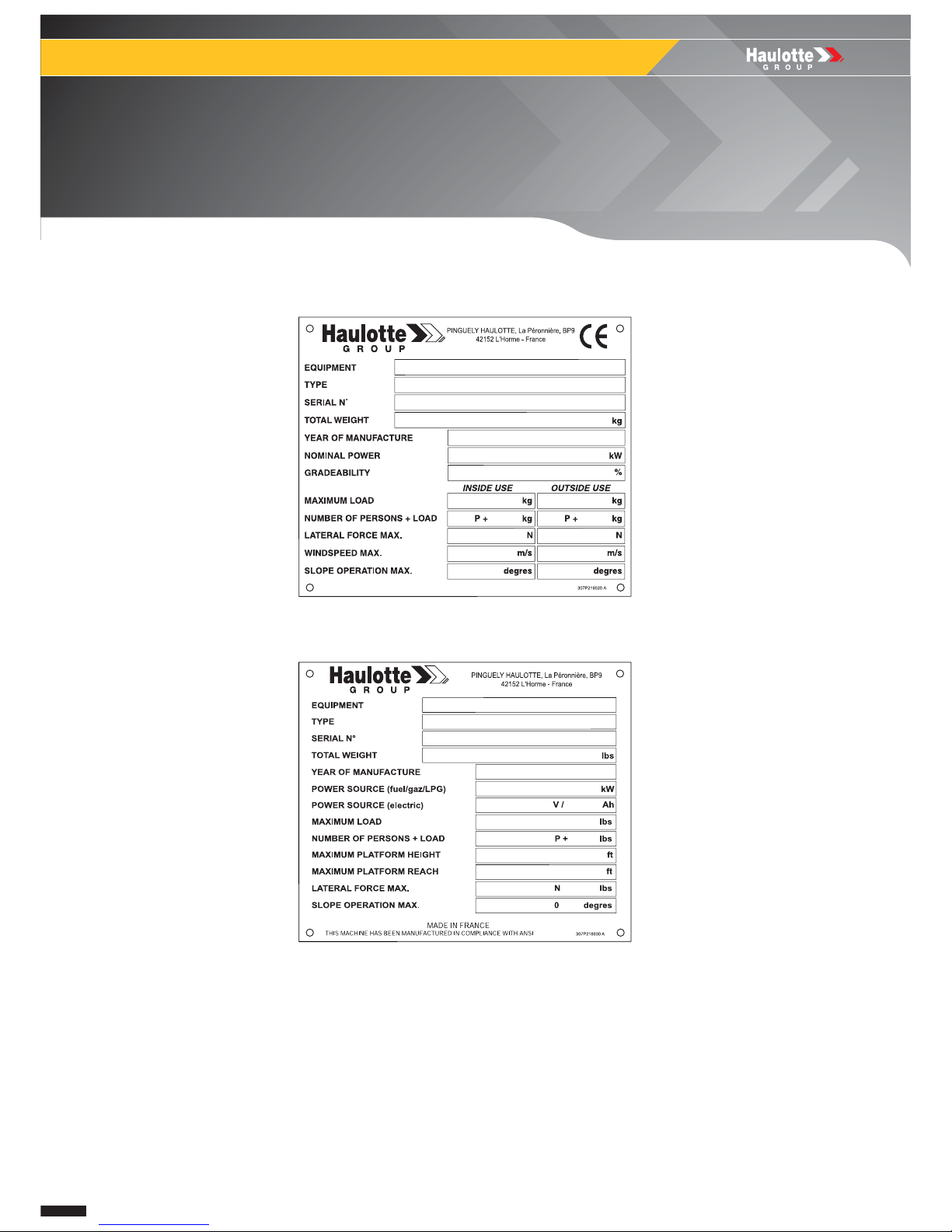

1 - Identification

The identification plate fixed to the rear right side of the chassis bears all the indications allowing

machine identification.

The constructor's plate at the rear of the mast bears all the indications allowing machine identification..

Identification plate-CE

For any request for information, intervention or spare parts, specify the type and serial number of the

machine.

A3

24 24203 3207 0 E 07 07 EN

Telescopic masts

C

- Machine layout

Identification plate-AS

Identification plate-ANSI - CSA

A3

A3

A

B

C

D

E

F

G

H

I

2524203 3207 0 E 07 07 EN

C

- Machine layout

Telescopic masts

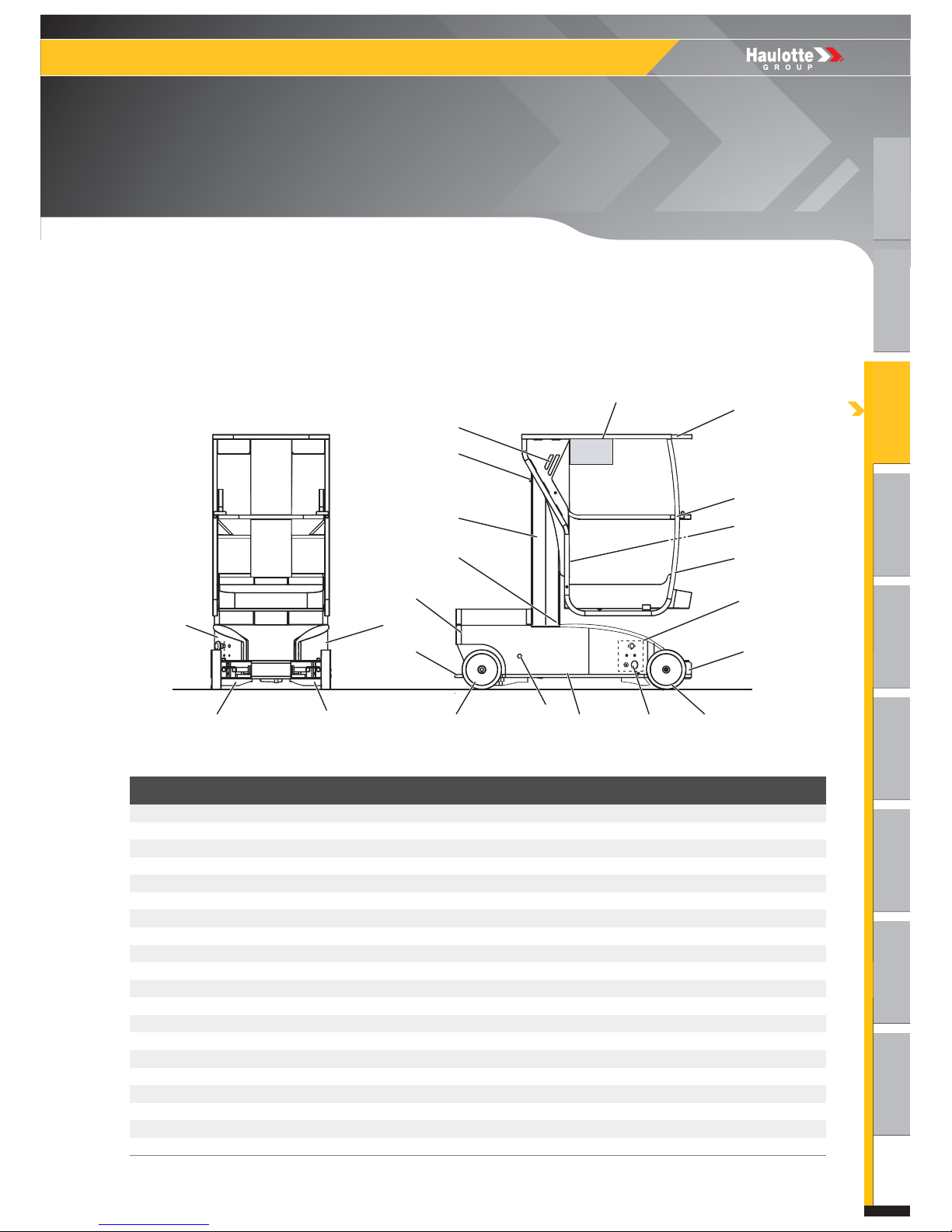

2 - Main components

2.1 - ELECTRICAL VERSION

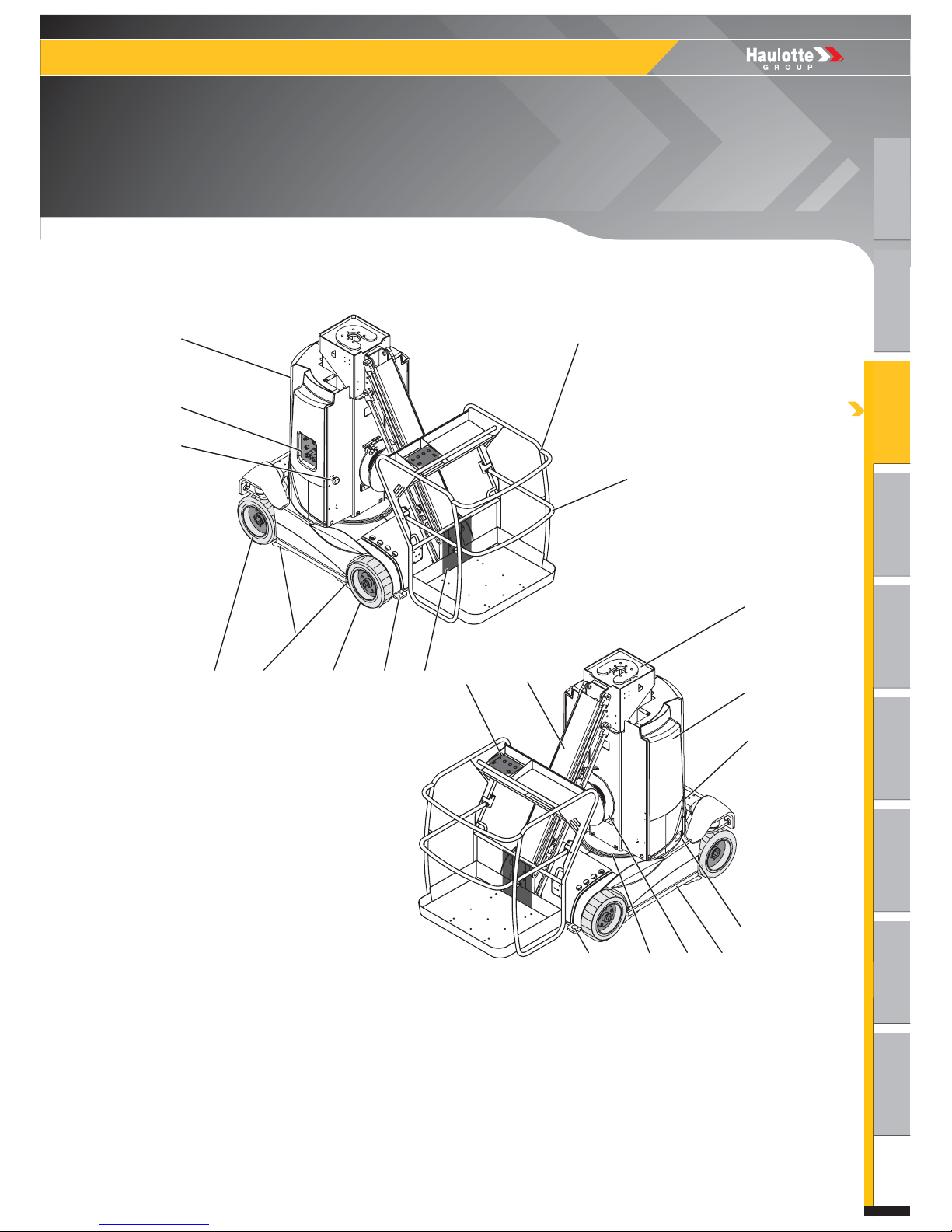

View of the components STAR 6 (STAR 13)

Description of the components

Marking Description

C1 Dolly

C6 Platform

C7 Upper console

C20 Tie-down and lift lug

C27 Lower console

C34 Drive wheel

C35 Document carrier

C34 Drive wheel

C44 Slack chain contactor

C45 Mast raised/mast lowered contactor

C50 Battery charger socket

C52 Emergency lowering

C53 Connection console/chassis

C54 Telescopic mast

C55 Platform console connection

C56 Battery bay

C58 Anti-tipping over device

C59 Hinged midrail

C76 Guardrail

C136 Steering wheels

C54

C53

C20 C20

C45

C55

C7

C56C56

C35

C6

C59

C76

C27

C136C50C1

C44

C34C58 C58 C52

26 24203 3207 0 E 07 07 EN

Telescopic masts

C

- Machine layout

View of the components STAR 9

Description of the components

Marking Description

C1 Dolly

C6 Platform

C7 Upper console

C10 Rotation crown gear

C11 Tu r n ta b l e

C20 Tie-down and lift lug

C27 Lower console

C34 Drive wheel

C35 Document carrier

C50 Battery charger socket

C54 Telescopic mast

C56 Battery bay

C59 Hinged midrail

C63 Mast stop

C66 Hydraulic ladder

C75 Extension

C76 Guardrail

C109 Hydraulic unit

C136 Steering wheels

C76 C7 C54

C63

C109

C56

C50

C27

C20

C136

C1

C34C20

C11

C66

C6

C75

C59

C10

C35

A

B

C

D

E

F

G

H

I

2724203 3207 0 E 07 07 EN

C

- Machine layout

Telescopic masts

View of the components STAR 8 (STAR 22J) - STAR

10 (STAR 26J)

C90

C47

C27

C136 C58 C34 C20 C35

C59

C76

C4

C11

C54

C33

C10 C57 C1

C50

C20

C7

28 24203 3207 0 E 07 07 EN

Telescopic masts

C

- Machine layout

Description of the components

Marking Description

C1 Dolly

C4 Jib

C6 Platform

C7 Upper console

C10 Rotation crown gear

C11 Tu r n ta b l e

C20 Tie-down and lift lug

C27 Lower console

C33 Counterweight

C34 Drive wheel

C35 Document carrier

C47 Battery cut-off

C50 Battery charger socket

C54 Telescopic mast

C57 Winder

C58 Anti-tipping over device

C59 Hinged midrail

C76 Guardrail

C90 Battery bay (hydraulic block and filter)

C136 Steering wheels

A

B

C

D

E

F

G

H

I

2924203 3207 0 E 07 07 EN

C

- Machine layout

Telescopic masts

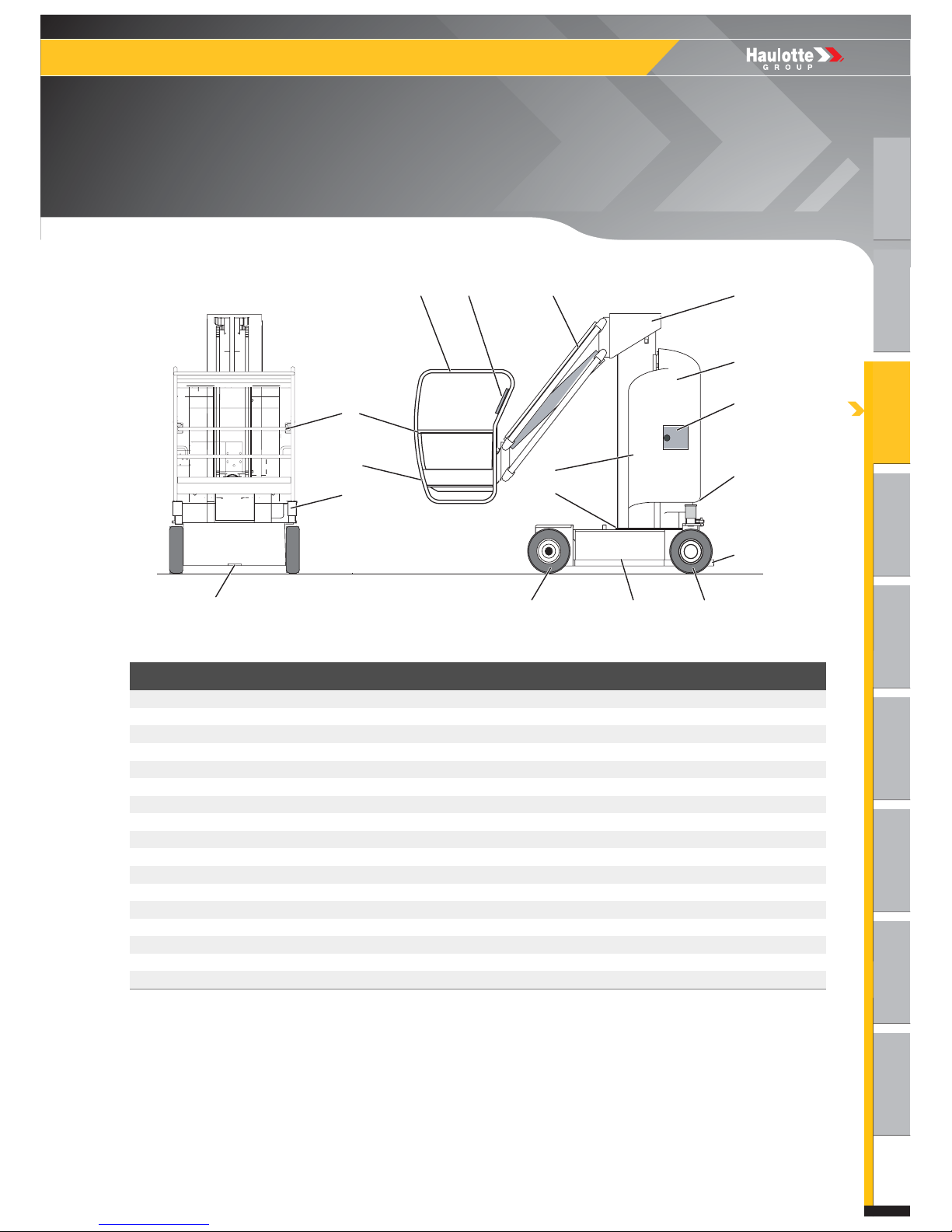

View of the components STAR 11 - STAR 12

Description of the components

Marking Description

C1 Dolly

C4 Jib

C6 Platform

C7 Upper console

C10 Rotation crown gear

C11 Tu r n ta b l e

C20 Tie-down and lift lug

C27 Lower console

C33 Counterweight

C34 Drive wheel

C35 Document carrier

C50 Battery charger socket

C54 Telescopic mast

C59 Hinged midrail

C76 Guardrail

C90 Battery bay (hydraulic block and filter)

C136 Steering wheels

C54 C4 C7 C76

C59

C50

C6

C90

C27

C33

C20

C136 C1

C10

C11

C34

C20

30 24203 3207 0 E 07 07 EN

Telescopic masts

C

- Machine layout

3 - Safety devices

3.1 - SLIDING MID-RAIL

3.2 - ANCHORAGE POINT

The platform is composed of guardrails and a sliding

midrail facilitating access to the platform.

Do not attach the sliding midrail to the guard rail.

The machine is equipped with approved anchorage

points accepting a single harness per anchorage point.

The anchorage points are identified by the presence of

the Anchorage point label.

If the local regulation imposes the wearing of a harness,

use the approved anchorage points.

Loading...

Loading...